Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Ti6Al4V Samples

2.2. Surface Modification Technologies

- Etched in 0.017 mol/dm3 of hydrofluoric acid (HF) for 120 s at room temperature.

- Blasted with Al2O3 particles (70–100 μm) with 4 bar blasting pressure. The blasting was performed with a Renfert Basic Quattro IS.

- Blasted with Al2O3 particles and etched in 0.017 mol/dm3 of hydrofluoric acid (HF) for 120 s at room temperature.

- Blasted with ZrO2 particles (50–130 μm) with 4 bar blasting pressure.

- Blasted with ZrO2 and etched in 0.017 mol/dm3 of hydrofluoric acid (HF) for 120 s at room temperature.

2.3. Surface Roughness and Topography

3. Results and Discussion

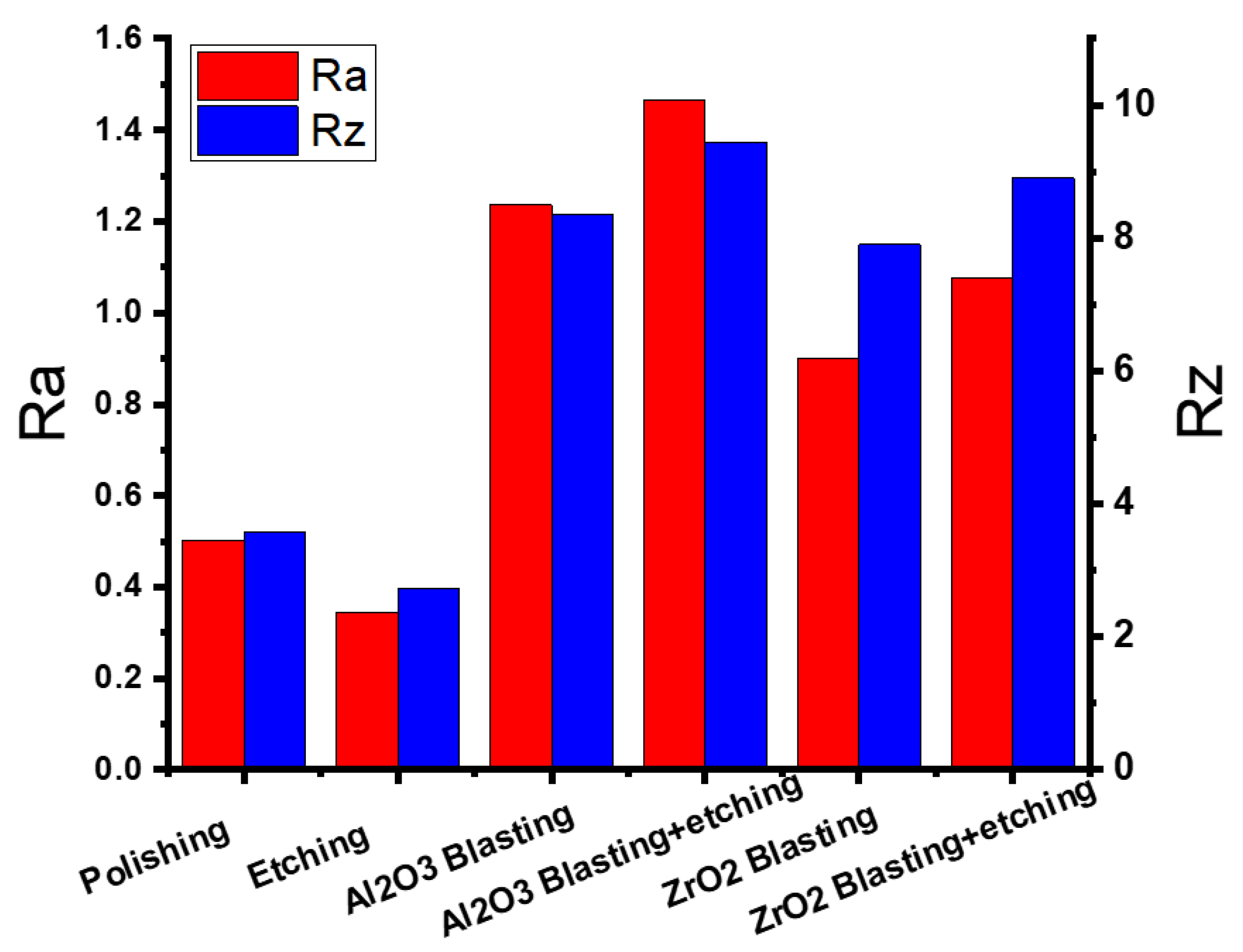

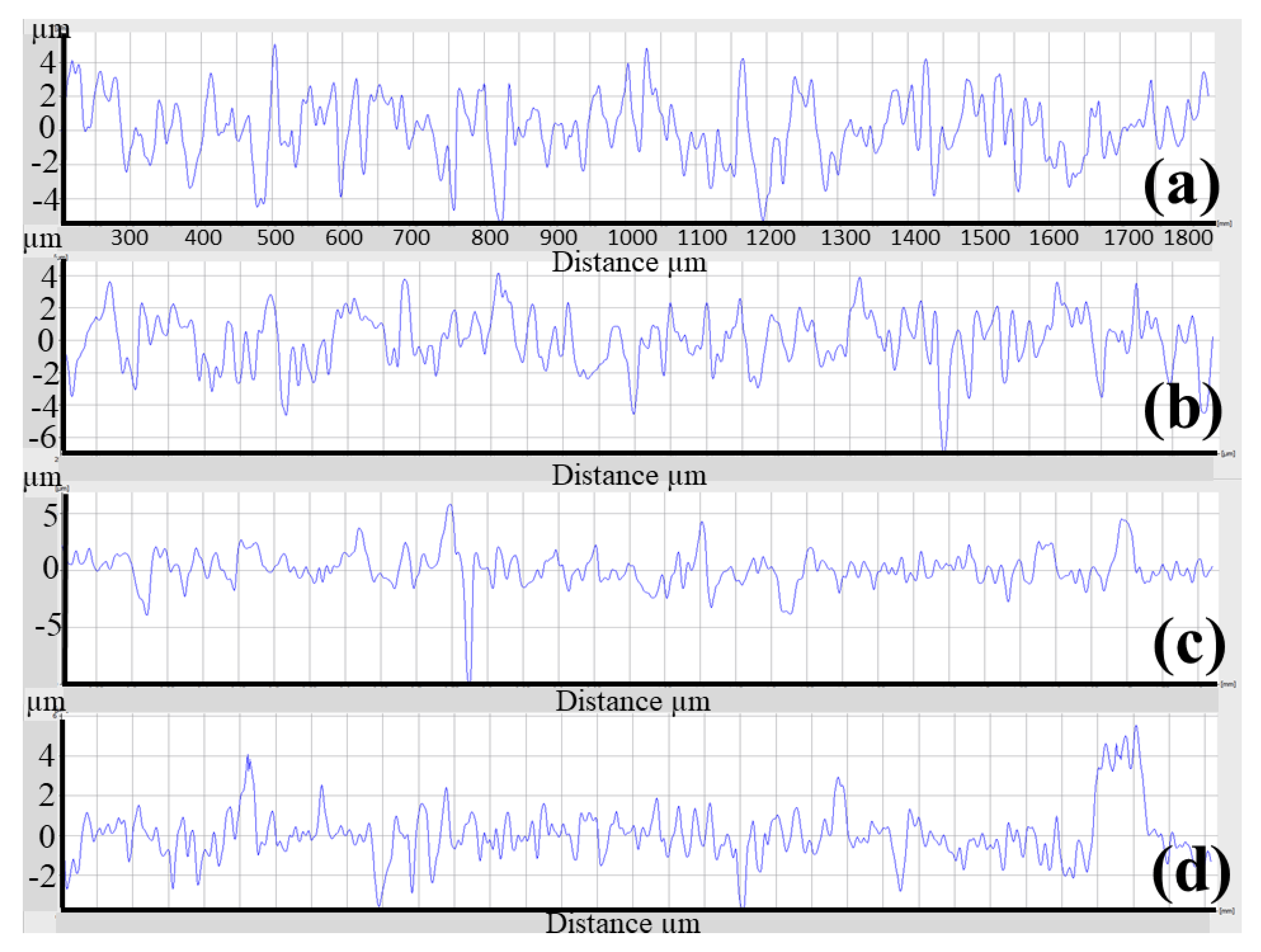

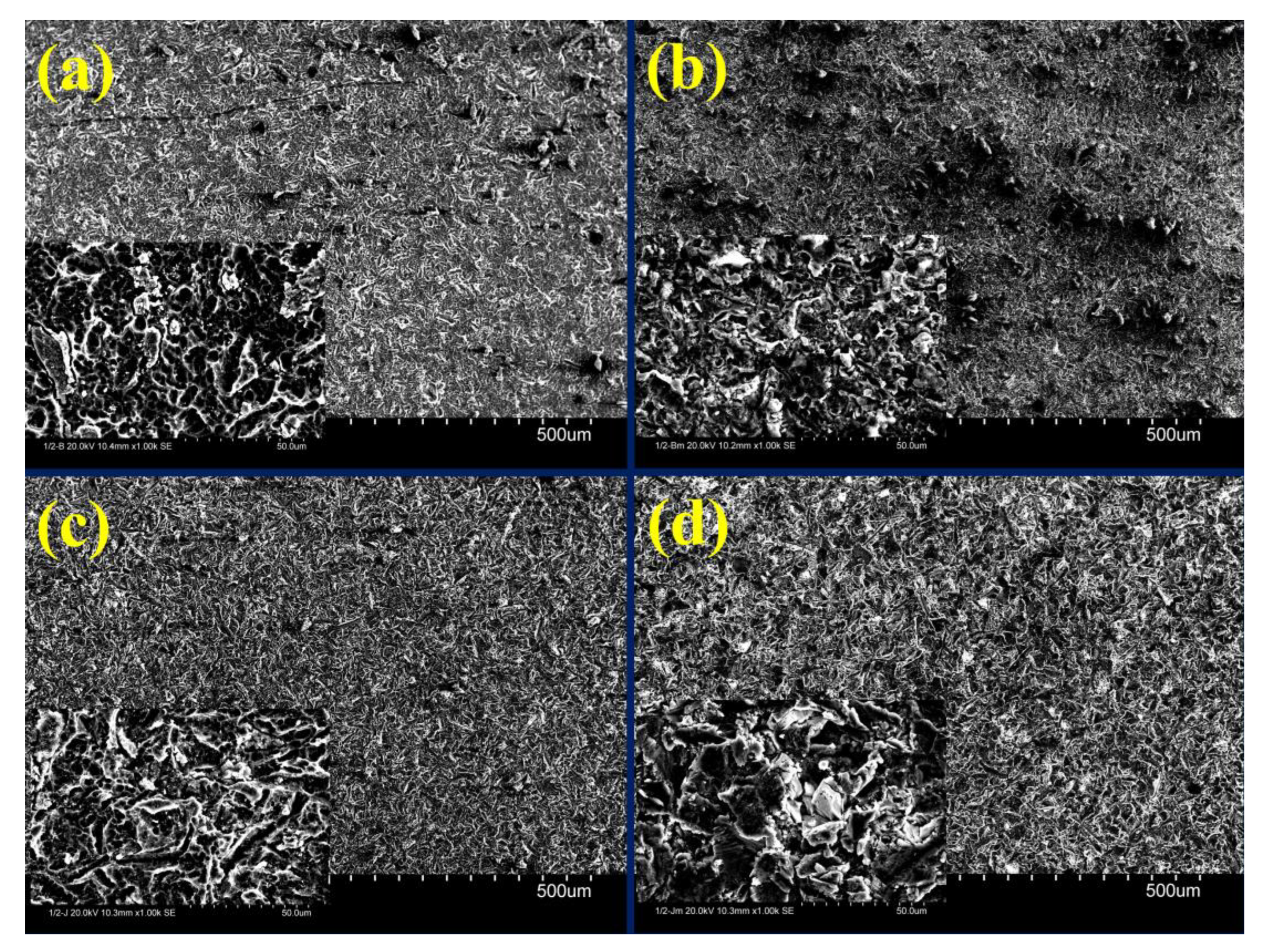

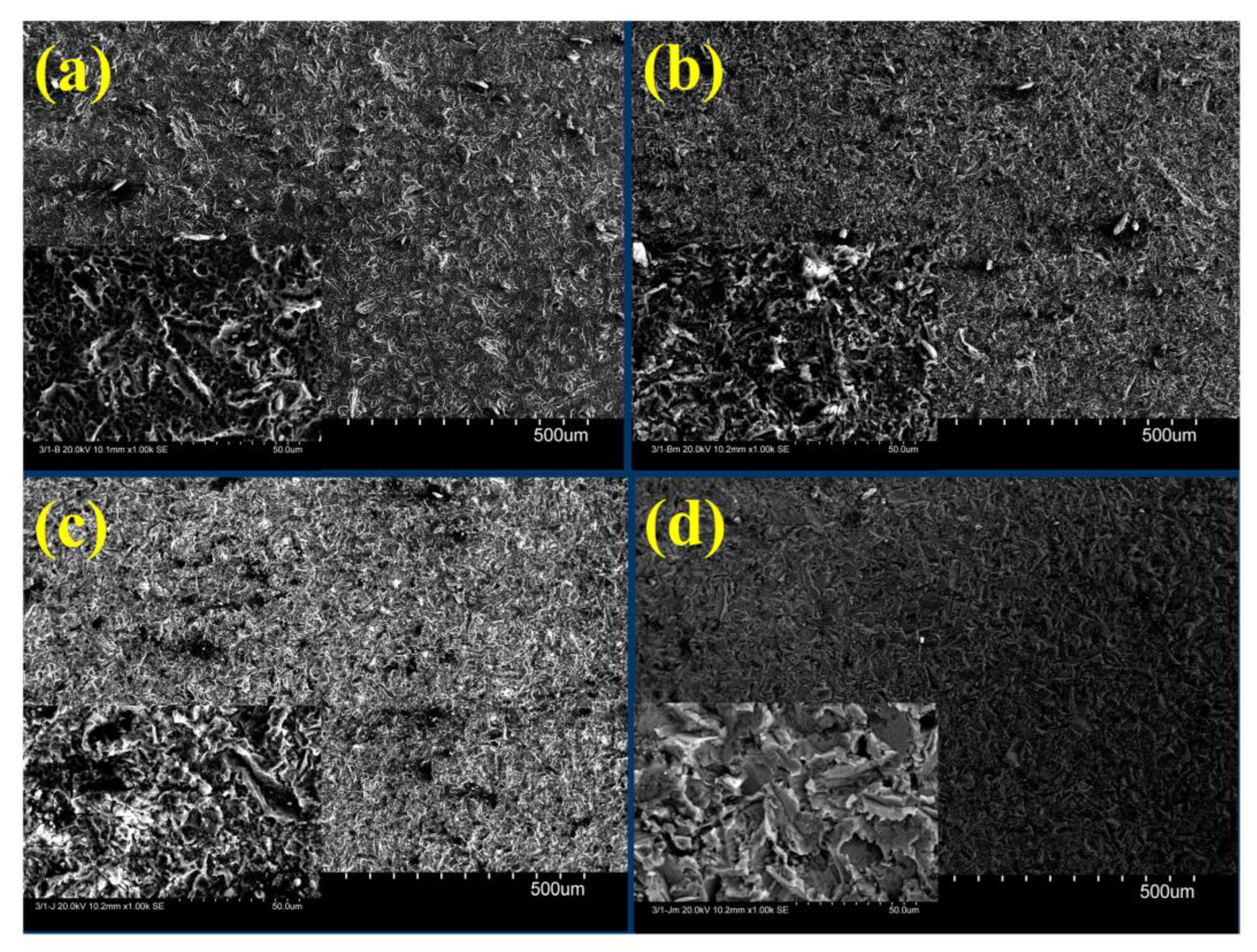

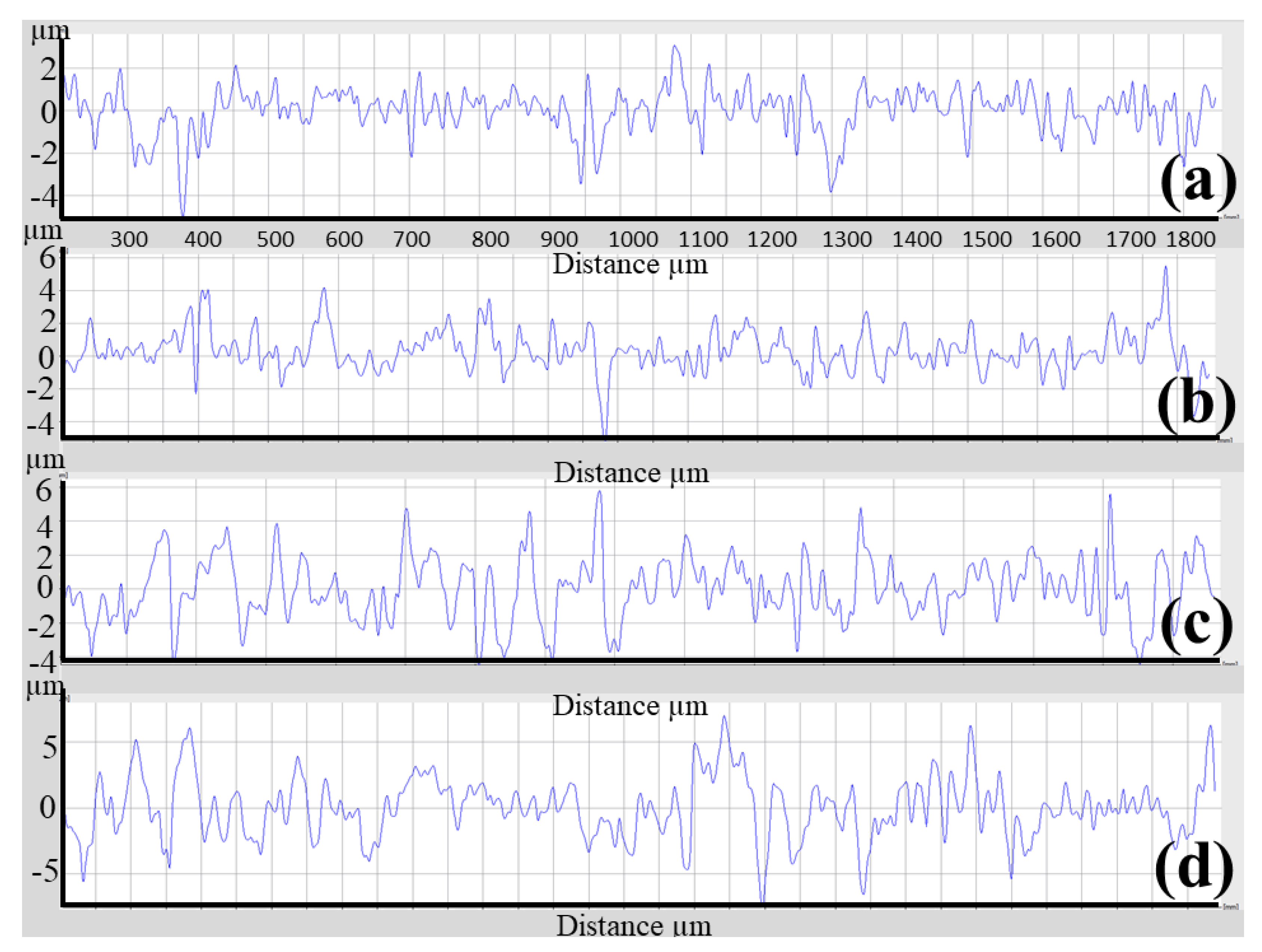

3.1. Casting

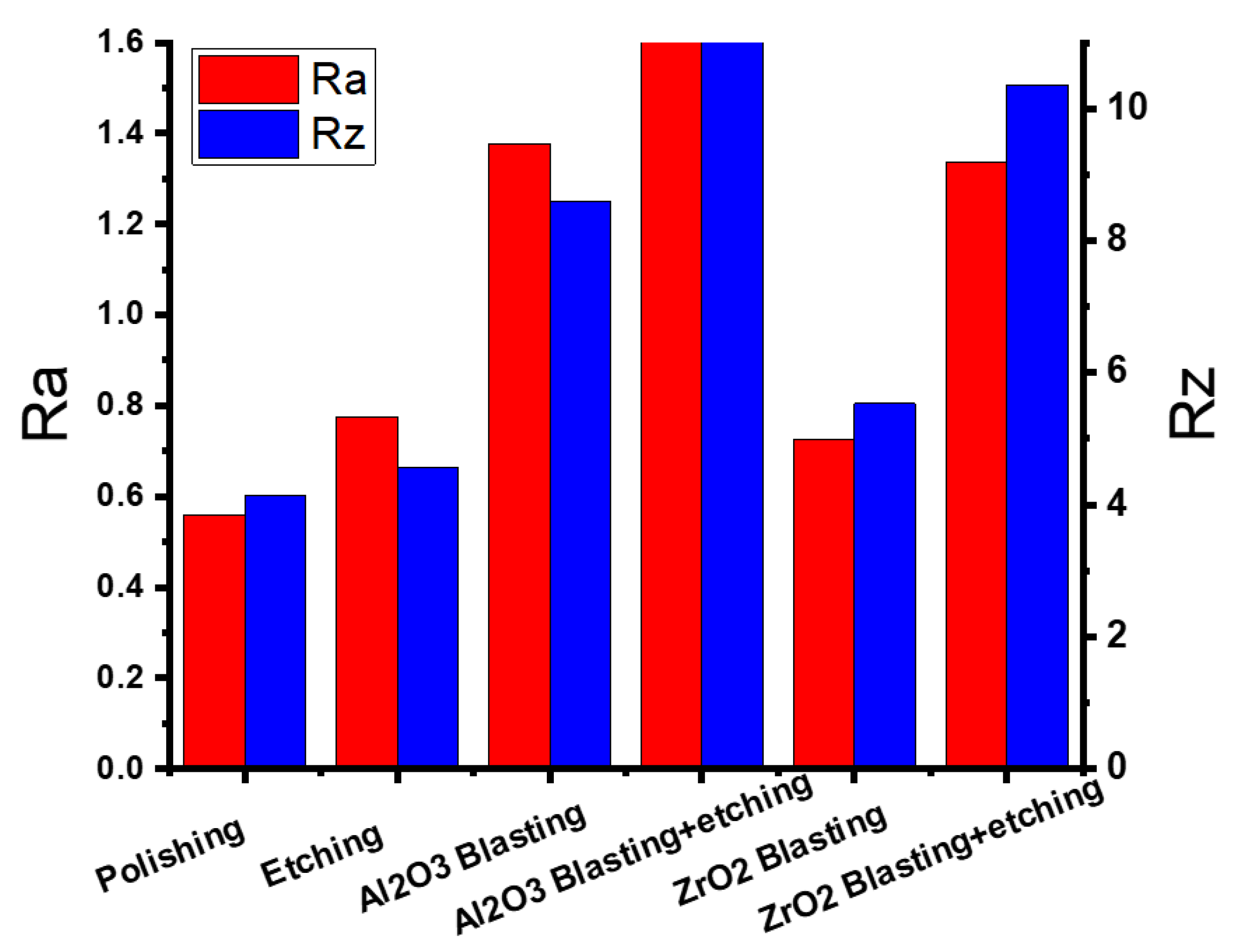

3.2. Wrought

3.3. 3D Printing

4. Conclusions

- Significant differences were found in the surface roughness of specimens produced by 3D printing compared to those produced by casting and wrought after surface modifications were performed. This can be attributed to the difference in the surface properties of the manufactured samples, which leads to different inclusion of ejected particles on the surface of the samples.

- The highest outcomes were collected for Ti6Al4V alloys fabricated using SLM and blasting with Al2O3, followed by HF etching (Ra = 2.043, Rz = 11.742 µm), or with Ti6Al4V fabricated using wrought and blasting with ZrO2, followed by HF etching (Ra = 1.631, Rz = 10.953 µm).

- The surface roughness of the SLM-fabricated samples and blasting with Al2O3 or ZrO2 was considerably influenced by HF etching. In the case of the specimens with Al2O3 blasting + HF etching, the surface roughness increased from (Ra = 1.337, Rz = 8.594 µm) to (Ra = 2.043, Rz = 11.742 µm). For the specimens of ZrO2 blasting + HF etching, the surface roughness increased from (Ra = 0.726, Rz = 5.533 µm) to (Ra = 1.336, Rz = 10.353 µm).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaber, H.; Kovacs, T. Selective laser melting of Ti alloys and hydroxyapatite for tissue engineering: Progress and challenges. Mater. Res. Express 2019, 6, 082003. [Google Scholar] [CrossRef]

- Jemat, A.; Ghazali, M.J.; Razali, M.; Otsuka, Y. Surface Modifications and Their Effects on Titanium Dental Implants. BioMed Res. Int. 2015, 2015, 791725. [Google Scholar] [CrossRef] [PubMed]

- Monetta, T.; Bellucci, F. The effect of sand-blasting and hydrofluoric acid etching on Ti CP2 and Ti CP4 surface topography. Open J. Regen. Med. 2012, 1, 41–50. [Google Scholar] [CrossRef]

- Li, J.; Zhou, P.; Attarilar, S.; Shi, H. Innovative Surface Modification Procedures to Achieve Micro/Nano-Graded Ti-Based Biomedical Alloys and Implants. Coatings 2021, 11, 647. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef]

- Souza, J.G.S.; Bertolini, M.; Costa, R.C.; Lima, C.V.; Barão, V.A.R. Proteomic profile of the saliva and plasma protein layer adsorbed on Ti–Zr alloy: The effect of sandblasted and acid-etched surface treatment. Biofouling 2020, 36, 428–441. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Sin, W.J.; Nai, M.L.S.; Wei, J. Effects of Processing Parameters on Surface Roughness of Additive Manufactured Ti-6Al-4V via Electron Beam Melting. Materials 2017, 10, 1121. [Google Scholar] [CrossRef] [PubMed]

- Szymczyk-Ziółkowska, P.; Hoppe, V.; Rusińska, M.; Gąsiorek, J.; Ziółkowski, G.; Dydak, K.; Czajkowska, J.; Junka, A. The Impact of EBM-Manufactured Ti6Al4V ELI Alloy Surface Modifications on Cytotoxicity toward Eukaryotic Cells and Microbial Biofilm Formation. Materials 2020, 13, 2822. [Google Scholar] [CrossRef] [PubMed]

- Jaber, H.; Kónya, J.; Kovács, T.A. Selective Laser Melting of Ti6Al4V-2%Hydroxyapatite Composites: Manufacturing Behavior and Microstructure Evolution. Metals 2021, 11, 1295. [Google Scholar] [CrossRef]

- Jaber, H.; Kónya, J.; Kulcsár, K.; Kovács, T. Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting. Materials 2022, 15, 1978. [Google Scholar] [CrossRef] [PubMed]

- Jaber, H.; Kovacs, T.; János, K. Investigating the impact of a selective laser melting process on Ti6Al4V alloy hybrid powders with spherical and irregular shapes. Adv. Mater. Process. Technol. 2020, 8, 715–731. [Google Scholar] [CrossRef]

- ASTM Standard B348/B348M; Standard Specification for Titanium and Titanium Alloy Bars and Billets. ASTM International: West Conshohocken, PA, USA, 2019; pp. 1–5. [CrossRef]

- Ferraris, S.; Spriano, S.; Pan, G.; Venturello, A.; Bianchi, C.L.; Chiesa, R.; Faga, M.G.; Maina, G.; Verné, E. Surface modification of Ti–6Al–4V alloy for biomineralization and specific biological response: Part I, inorganic modification. J. Mater. Sci. Mater. Med. 2011, 22, 533–545. [Google Scholar] [CrossRef] [PubMed]

- Da Rocha, S.S.; Adabo, G.L.; Henriques, G.E.P.; Nóbilo, M.A.D.A. Vickers hardness of cast commercially pure titanium and Ti-6Al-4V alloy submitted to heat treatments. Braz. Dent. J. 2006, 17, 126–129. [Google Scholar] [CrossRef] [PubMed]

- Shunmugavel, M.; Polishetty, A.; Goldberg, M.; Singh, R.; Littlefair, G. A comparative study of mechanical properties and machinability of wrought and additive manufactured (selective laser melting) titanium alloy—Ti-6Al-4V. Rapid Prototyp. J. 2017, 23, 1051–1056. [Google Scholar] [CrossRef]

- Reshadi, F.; Khorasani, S.; Faraji, G. Surface characterization of nanostructured commercially pure titanium modified by sandblasting and acid-etching for implant applications. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 234, 414–423. [Google Scholar] [CrossRef]

- Demirci, S.; Dikici, T.; Güllüoğlu, A.N. Micro/Nanoscale Surface Modification of Ti6Al4V Alloy for Implant Applications. J. Mater. Eng. Perform. 2021, 31, 1503–1511. [Google Scholar] [CrossRef]

- Souza, J.C.M.; Sordi, M.B.; Kanazawa, M.; Ravindran, S.; Henriques, B.; Silva, F.S.; Aparicio, C.; Cooper, L.F. Nano-scale modification of titanium implant surfaces to enhance osseointegration. Acta Biomater. 2019, 94, 112–131. [Google Scholar] [CrossRef] [PubMed]

| (Mass%) | Al | V | Fe | O | N | C | H | Ti | |

|---|---|---|---|---|---|---|---|---|---|

| Ti6Al4V powder | 6.11 | 4.02 | 0.17 | 0.090 | 0.023 | 0.01 | 0.003 | Bal | |

| ASTM B348 Gr.23 [12] | Max | 6.75 | 4.50 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | Bal |

| Min | 5.50 | 3.50 | - | - | - | - | - | - | |

| Production Technology | Surface Treatment | Surface Roughness, Ra (μm) | Roughness Height, Rz (μm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Specimen Number | Average | Specimen Number | Average | ||||||

| 1 | 2 | 3 | 1 | 2 | 3 | ||||

| Casting | Polishing | 0.479 | 0.531 | 0.499 | 0.503 | 3.397 | 3.506 | 3.816 | 3.573 |

| Casting | Etching | 0.312 | 0.353 | 0.367 | 0.344 | 2.317 | 2.889 | 2.964 | 2.723 |

| Casting | Al2O3 Blasting | 1.208 | 1.140 | 1.360 | 1.236 | 9.329 | 7.482 | 8.265 | 8.359 |

| Casting | Al2O3 Blasting + etching | 1.423 | 1.468 | 1.508 | 1.466 | 11.703 | 8.000 | 8.580 | 9.428 |

| Casting | ZrO2 Blasting | 0.734 | 1.049 | 0.916 | 0.900 | 7.499 | 9.777 | 6.417 | 7.898 |

| Casting | ZrO2 Blasting + etching | 0.804 | 1.307 | 1.061 | 1.075 | 8.198 | 9.843 | 8.670 | 8.904 |

| Wrought | Polishing | 0.360 | 0.475 | 0.555 | 0.463 | 2.497 | 3.083 | 3.679 | 3.086 |

| Wrought | Etching | 0.332 | 0.499 | 0.556 | 0.462 | 2.416 | 3.310 | 3.610 | 3.112 |

| Wrought | Al2O3 Blasting | 0.493 | 0.634 | 0.823 | 0.650 | 3.515 | 4.415 | 6.222 | 4.171 |

| Wrought | Al2O3 Blasting + etching | 0.729 | 0.877 | 1.215 | 0.940 | 6.144 | 5.982 | 10.953 | 7.693 |

| Wrought | ZrO2 Blasting | 1.329 | 1.460 | 1.415 | 1.401 | 9.017 | 7.951 | 8.965 | 8.644 |

| Wrought | ZrO2 Blasting + etching | 1.519 | 1.636 | 1.738 | 1.631 | 10.001 | 10.462 | 12.397 | 10.953 |

| 3D printing | Polishing | 0.474 | 0.701 | 0.502 | 0.559 | 4.079 | 4.915 | 3.4516 | 4.149 |

| 3D printing | Etching | 0.755 | 0.995 | 0.579 | 0.776 | 4.787 | 5.974 | 2.923 | 4.561 |

| 3D printing | Al2O3 Blasting | 1.328 | 1.239 | 1.444 | 1.377 | 9.091 | 7.507 | 9.183 | 8.594 |

| 3D printing | Al2O3 Blasting + etching | 2.623 | 1.763 | 1.743 | 2.043 | 12.625 | 11.252 | 11.349 | 11.742 |

| 3D printing | ZrO2 Blasting | 0.715 | 0.677 | 0.786 | 0.726 | 6.103 | 5.024 | 5.473 | 5.533 |

| 3D printing | ZrO2 Blasting + etching | 1.549 | 1.557 | 0.903 | 1.336 | 11.618 | 12.693 | 6.748 | 10.353 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kónya, J.; Hargitai, H.; Jaber, H.; Pinke, P.; Kovács, T.A. Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought. Materials 2023, 16, 3989. https://doi.org/10.3390/ma16113989

Kónya J, Hargitai H, Jaber H, Pinke P, Kovács TA. Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought. Materials. 2023; 16(11):3989. https://doi.org/10.3390/ma16113989

Chicago/Turabian StyleKónya, János, Hajnalka Hargitai, Hassanen Jaber, Péter Pinke, and Tünde Anna Kovács. 2023. "Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought" Materials 16, no. 11: 3989. https://doi.org/10.3390/ma16113989

APA StyleKónya, J., Hargitai, H., Jaber, H., Pinke, P., & Kovács, T. A. (2023). Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought. Materials, 16(11), 3989. https://doi.org/10.3390/ma16113989