A Semi-Empirical Damage Model of Helankou Rocks Based on Acoustic Emission

Abstract

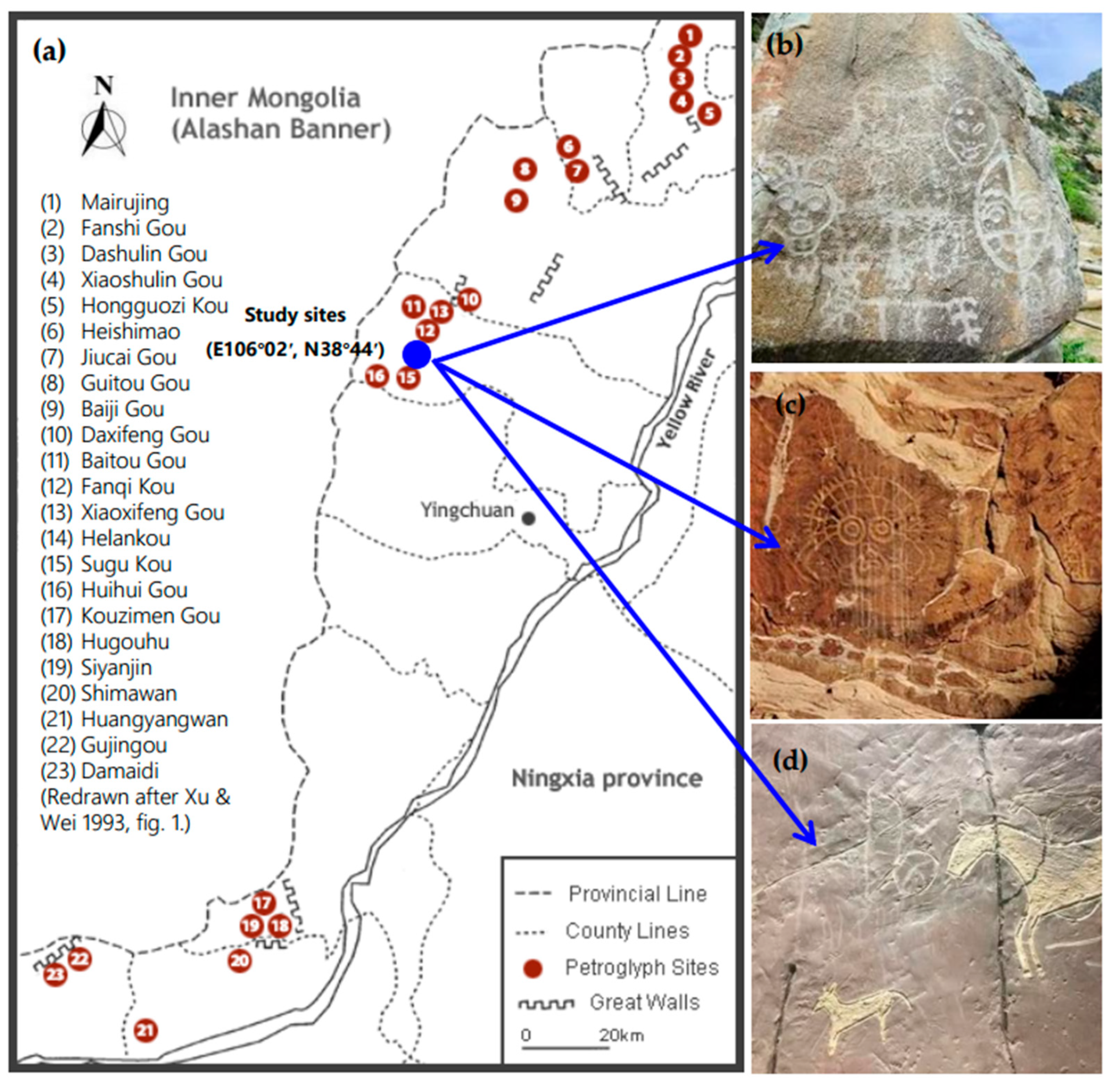

:1. Introduction

2. Laboratory Program

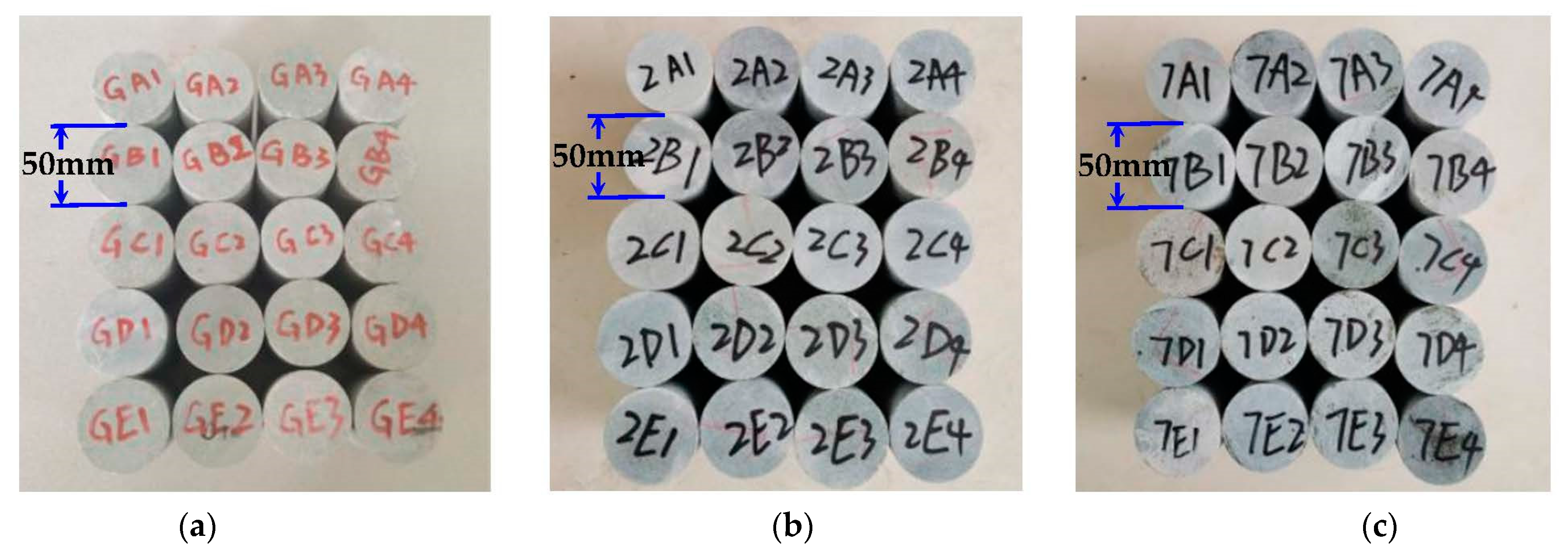

2.1. Specimens Preparation

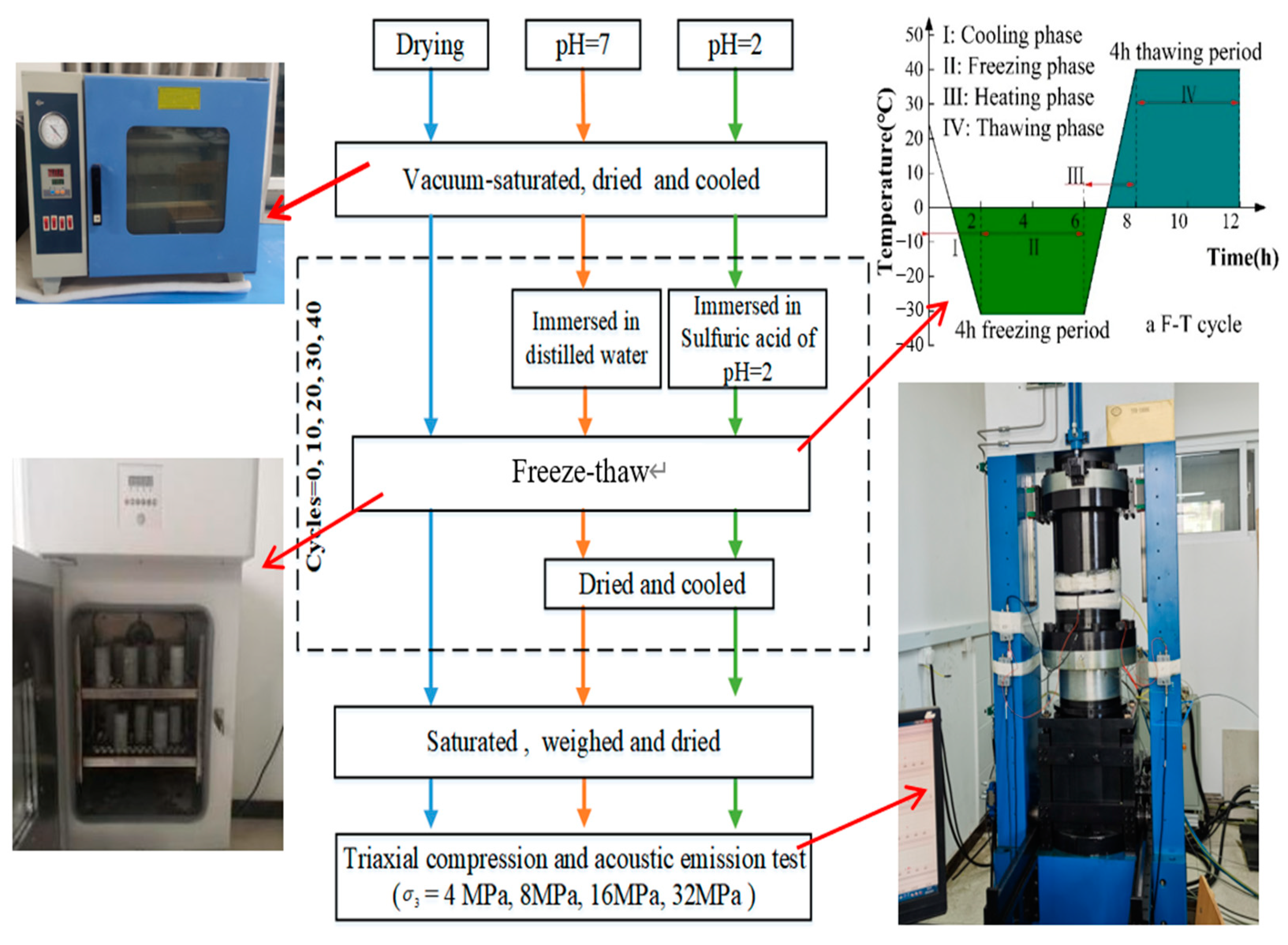

2.2. Test Equipment and Scheme

- Each rock specimen was saturated by vacuum evacuation for at least 12 h. Subsequently, the saturated specimens were weighed and placed in an oven at 105 °C for a minimum of 12 h, and then cooled down to the room temperature.

- Rock samples group with pH = 2 and pH = 7 was placed in concentrated sulfuric acid at pH = 2 and distilled water for at least 12 h, respectively.

- All specimens were subjected to cycles of high-low temperatures, which varied between −31 °C for 2 to 4 h, and then it increased to 40 °C for 2 to 4 h, as shown in the upper right inset of Figure 3. Notably, 0, 10, 20, 30, and 40 freeze-thaw (F-T) cycles were applied in this study.

- After F-T cycling, the rock samples of pH = 2 and pH = 7 groups were dried for 12 h and cooled down. The two groups of rock samples were soaked and dried before and after each cycle.

- Each specimen was subjected to triaxial compression testing under 4 MPa, 8 MPa, 16 MPa, and 32 MPa cell pressures, and the acoustic emission (AE) non-destructive testing.

3. Results and Discussion

3.1. Analysis of Elastic Modulus Variation

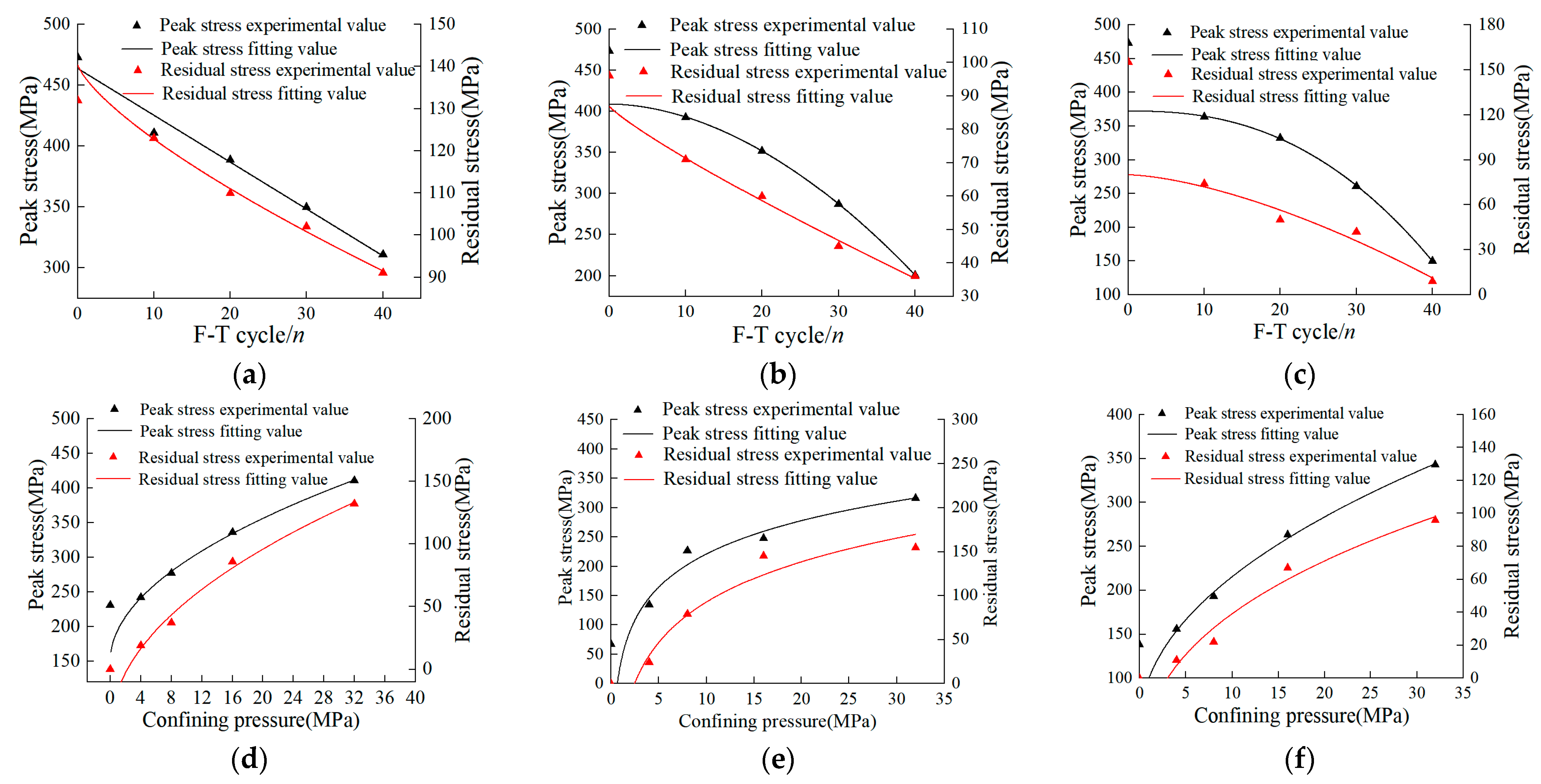

3.2. Analysis of Residual Stress and Peak Stress Variations

3.2.1. Effects of D-W and F-T Conditions

3.2.2. Effect of Cell Pressure

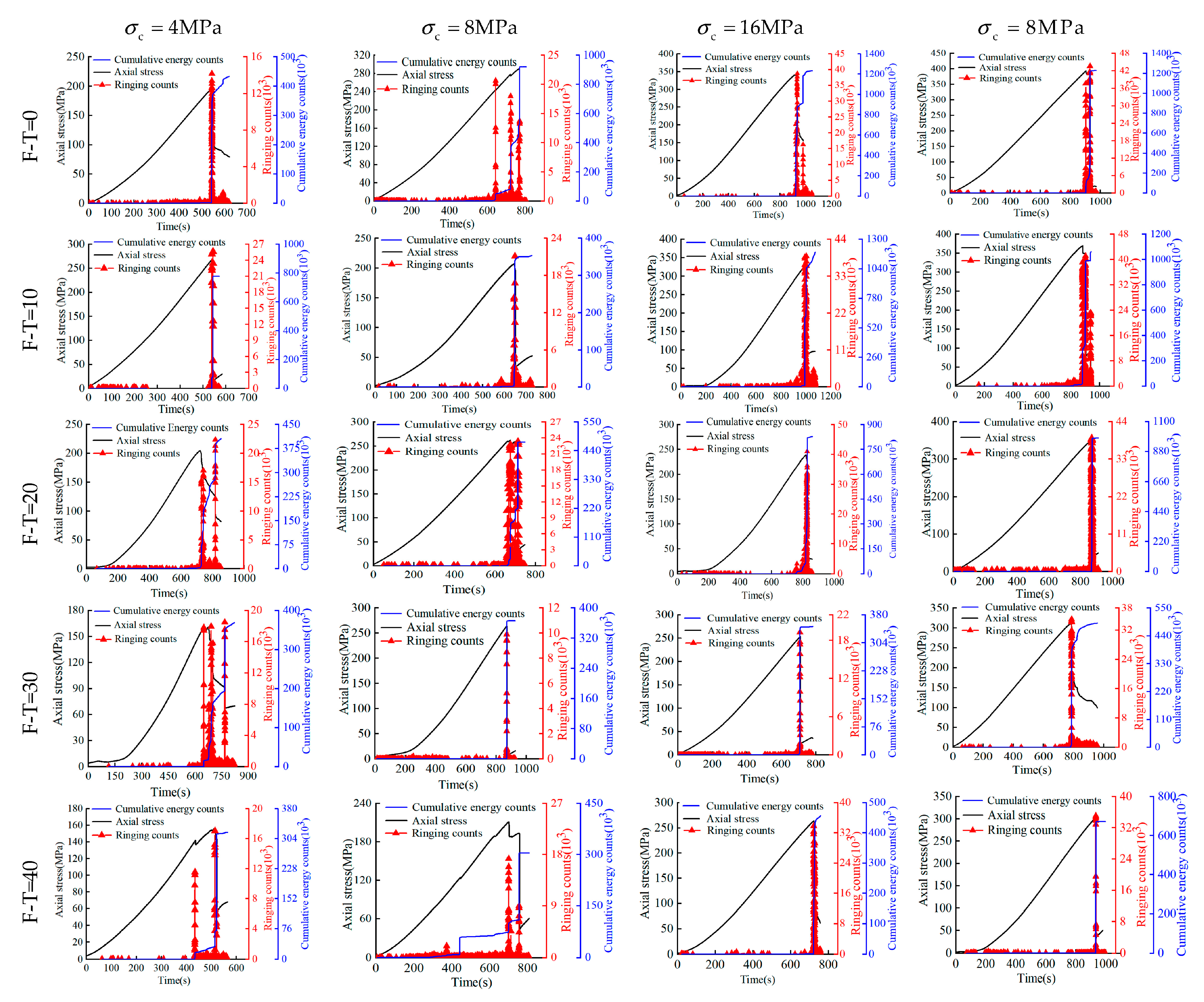

3.3. Chemically Induced Variations of AE Parameters

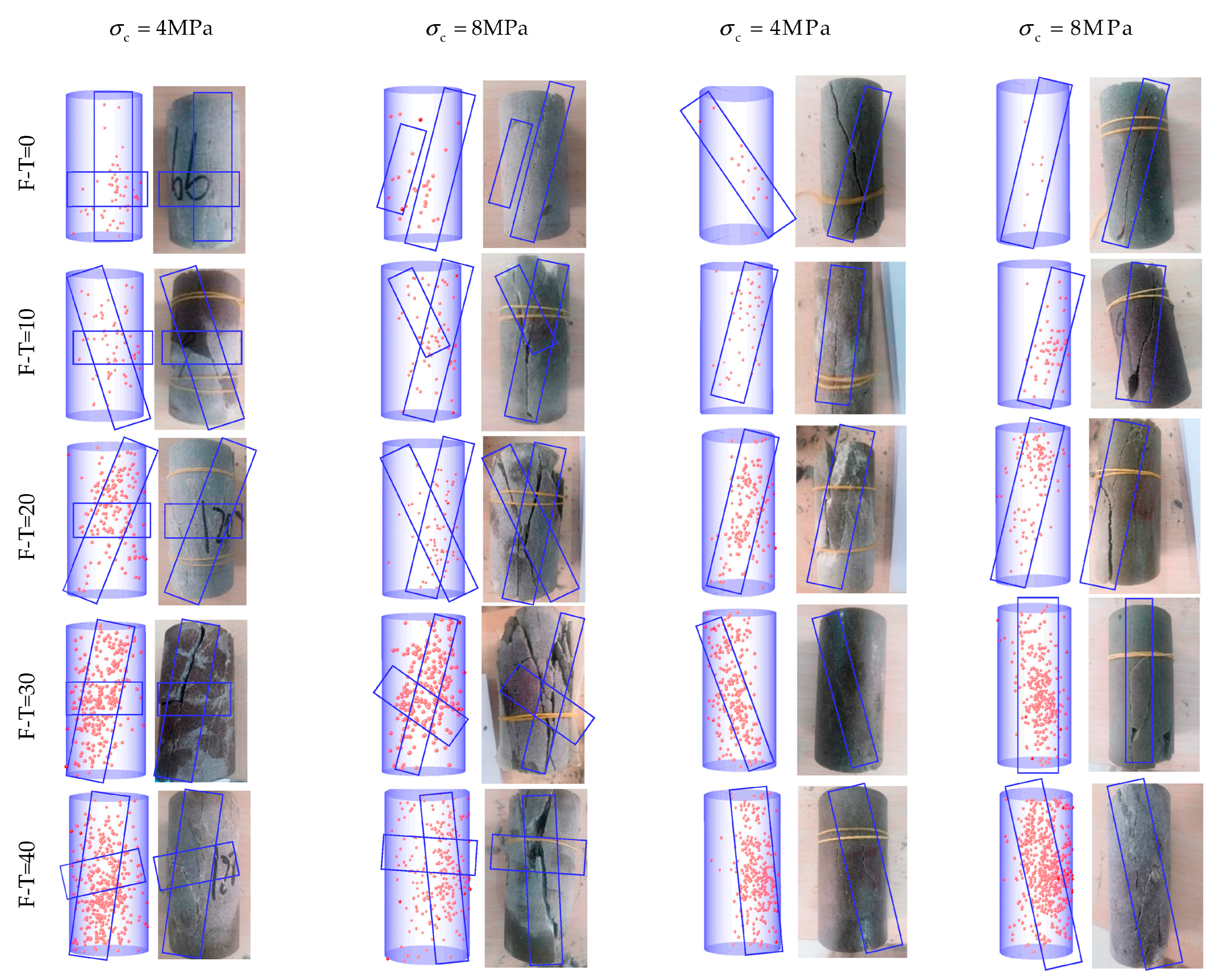

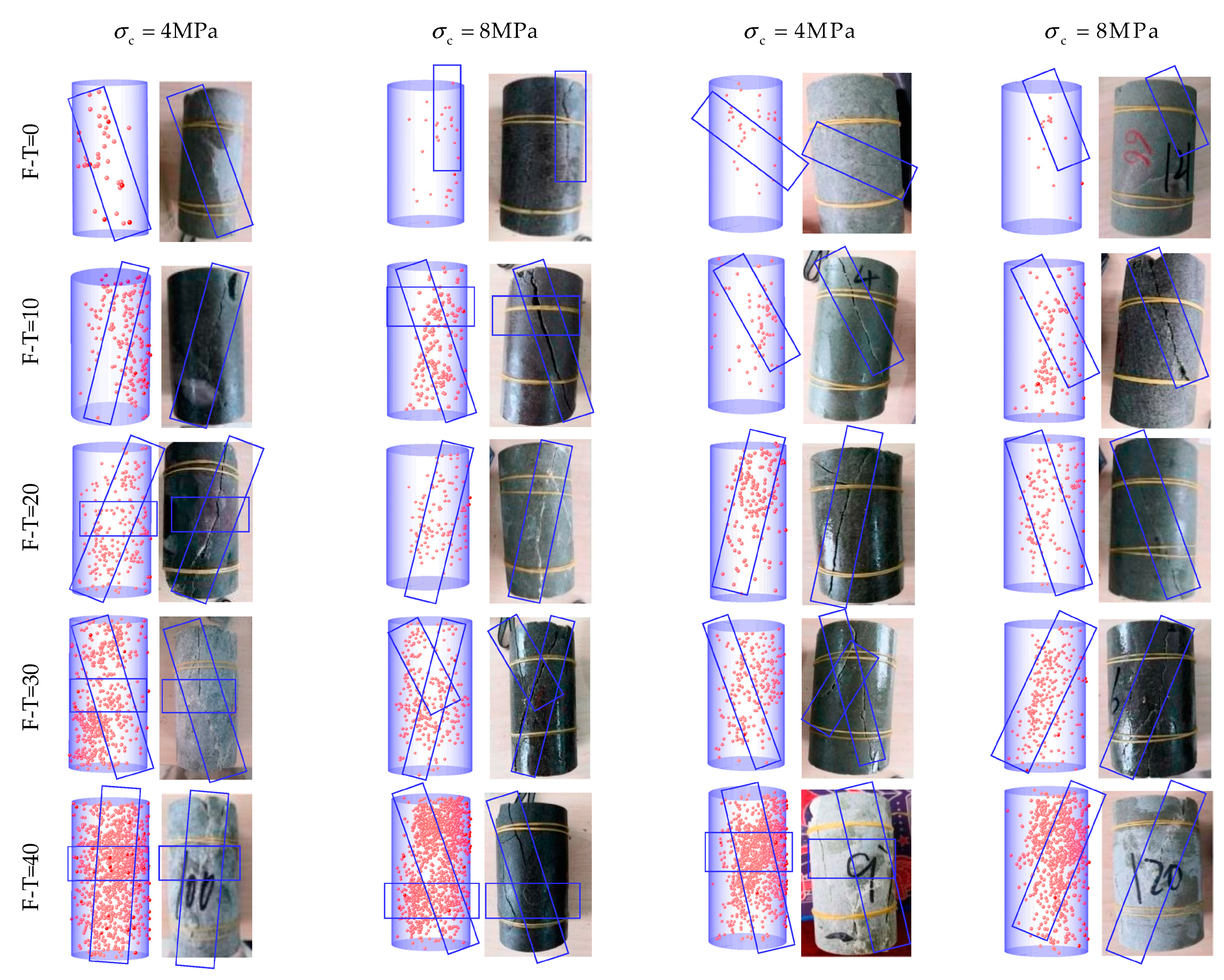

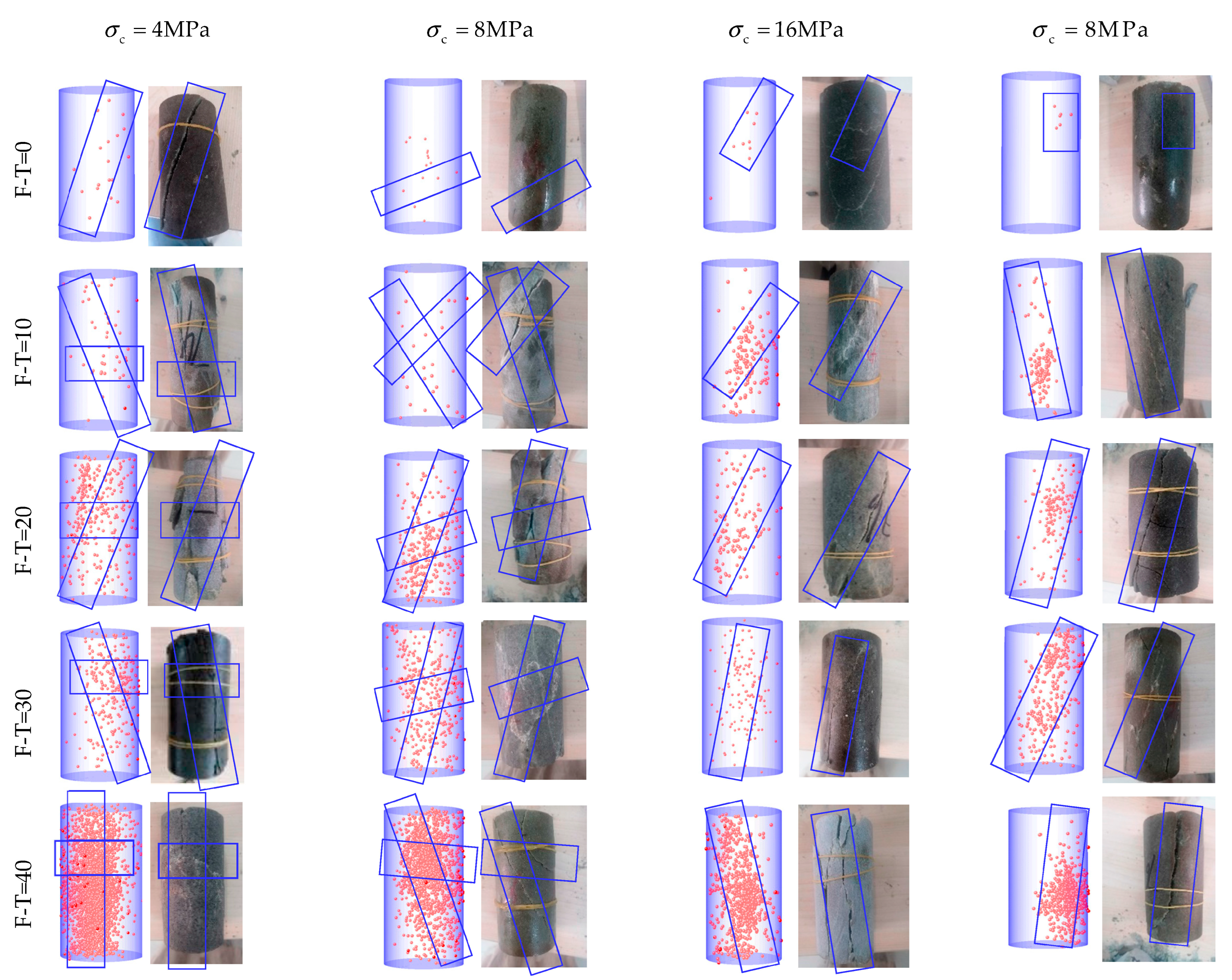

3.4. The Characteristics of AE Positioning

4. Damage Model

4.1. Cross-Scale Definition of Damage Variables

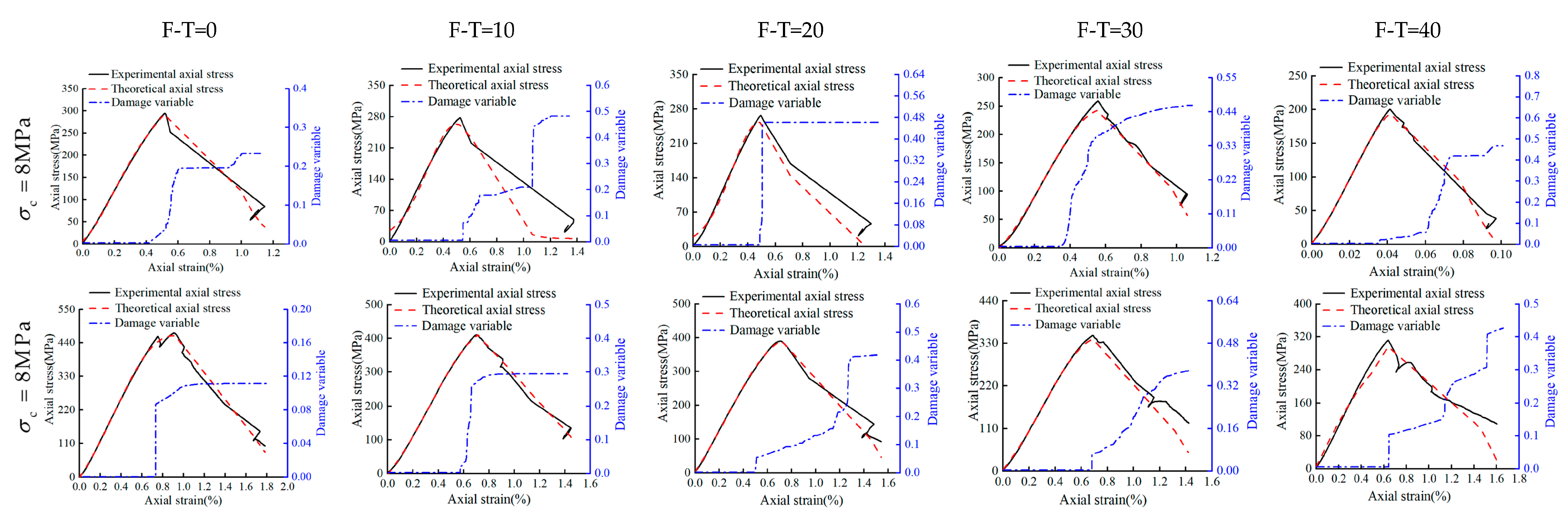

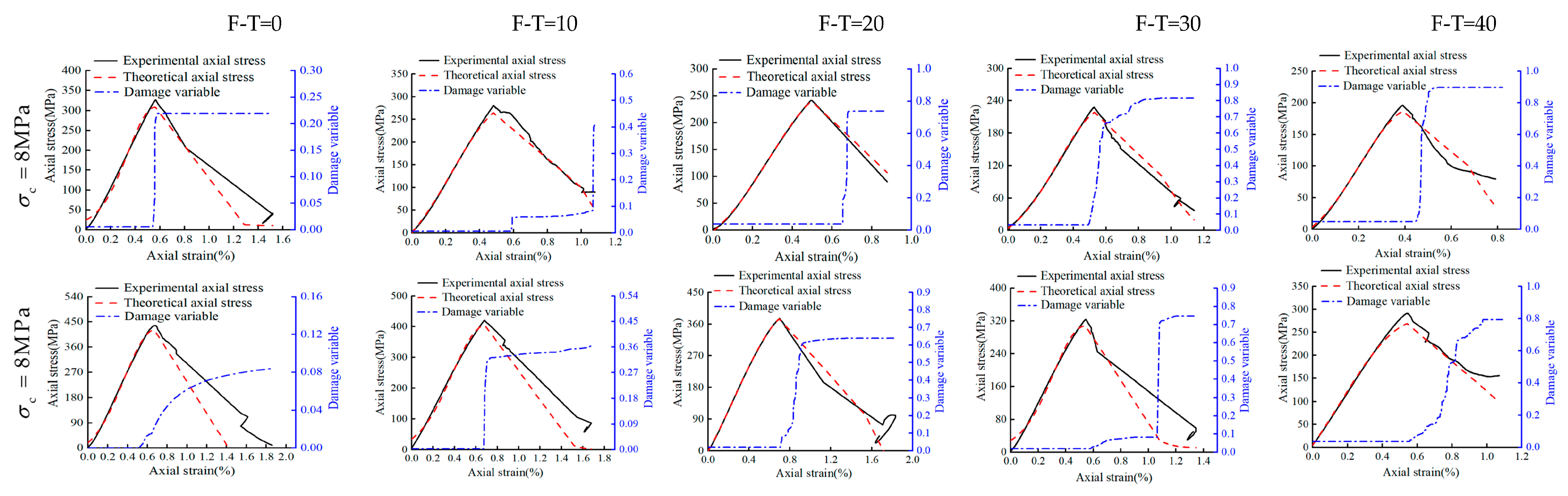

4.2. Model Verification

5. Scope and Limitations of This Study

6. Conclusions

- ➢

- The elastic modulus could then be correlated with a multivariate function, residual stress, and peak stress using a non-linear function decreasing with environmental deterioration (more F-T cycles) and increasing with the cell pressure. For instance, after 0 to 40 freeze-thaw cycles, the residual stress and peak stress in the pH = 2 group decreased by 146 MPa and 212 MPa, respectively. As the cell pressure increases from 4 to 32 MPa, the residual stress and peak stress in the drying group increased by 113 MPa and 169 MPa.

- ➢

- The environmental effects on rock samples could be imitated in the laboratory, whereby freeze-thaw and dry-wet cycling could be done to simulate extreme weathers, while acidic, neutral, and basic environments could be modeled by varying the pH values of rock samples. For instance, cracking could be induced by F-T and D-W cycling, progressed, and propagated by the acidic environment, and controlled further through varying cell pressures.

- ➢

- In this study, both acoustic energy and cumulative energy (CE) could capture the process of rock damage in the form of initiation and progression of cracks leading to the development of full failure. For instance, AE and CE ringing counts increased substantially at the onset of rock damage and dropped subsequently to indicate a marked strength reduction in rocks (i.e., development of rock failure).

- ➢

- A new damage model has been proposed based on both elastic modulus and AE ringing counts that could capture the combined impacts of weathering and other mechanical agents damaging the rocks. The established model could successfully capture the damage evolution and mechanism of Helankou rocks under extreme climatic environmental conditions and high cell pressures. For a prompt and preliminary assessment, the rocks strength may be quantified through the proposed model that could provide basis for both risk assessment of rock paintings and technical support for preserving the rock relics in Helan Mountains region.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Men, X. On Declaration of Yinshan and Helanshan Rock Arts as World Cultural Heritage. Chin. Three Gorg. Trib. 2011, 2, 90–93+149. [Google Scholar]

- Lv, R. Weathering Characteristics and Mechanism Study on the Carrier of Rock Paintings in Helankou. Master’s Thesis, Lanzhou University, Lanzhou, China, 2020. [Google Scholar]

- Li, F.; Xiao, Y.; Wang, Z.; Tan, H. Analysis and Controlling Measure on Variation of Precipitation pH in Yinchuan from 2001 to 2007. J. Agric. Sci. 2009, 30, 41–43. [Google Scholar]

- Inner Mongolia & Ningxia Rock Art Sites. Available online: https://www.bradshawfoundation.com/china/ningxia/page2.php (accessed on 17 September 2014).

- Akulov, N.I.; Kashik, S.A.; Mazilov, V.N.; Fileva, T.S. Weathering crusts of the southern coast of Lake Baikal. Russ. Geol. Geophys. 1996, 37, 82–87. [Google Scholar]

- Khanlari, G.; Sahamieh, R.; Abdilor, Y. The Effect of Freeze–Thaw Cycles on Physical and Mechanical Properties of Upper Red Formation Sandstones, Central Part of Iran. Arab. J. Geo Sci. 2015, 8, 5991–6001. [Google Scholar] [CrossRef]

- Jia, H.; Ding, S.; Zi, F.; Dong, Y.; Shen, Y. Evolution in sandstone pore structures with freeze-thaw cycling and interpretation of damage mechanisms in saturated porous rocks. Catena 2020, 195, 104915. [Google Scholar] [CrossRef]

- Gratchev, I.; Pathiranagei, S.V.; Kim, D.H. Strength properties of fresh and weathered rocks subjected to wetting–drying cycles. Geomech. Geophys. Geo-Energ. Geo-Resour. 2019, 5, 211–221. [Google Scholar] [CrossRef]

- Zhang, H.; Meng, X.; Yang, G. A Study on Mechanical Properties and Damage Model of Rock Subjected to Freeze-Thaw Cycles and Confining Pressure. Cold Reg. Sci. Tech. 2020, 174, 103056. [Google Scholar] [CrossRef]

- Mousavi, S.Z.S.; Tavakoli, H.; Moarefvand, P.; Rezaei, M. Assessing the effect of freezing-thawing cycles on the results of the triaxial compressive strength test for calc-schist rock. Int. J. Rock Mech. Min. 2019, 123, 104090. [Google Scholar] [CrossRef]

- Liao, R.; Chen, W.; Wang, N.; Liu, W. Forecast of Heritage Deterioration Based on Freeze-Thaw Sensitivity of Sandstone. J. Central South Univ. (Sci. Tech.) 2019, 50, 3084–3096. [Google Scholar]

- Zhou, H.; Liu, Z.; Shen, W.; Feng, T.; Zhang, G. Mechanical property and thermal degradation mechanism of granite in thermal-mechanical coupled triaxial compression. Int. J. Rock Mech. Min. 2022, 160, 1365–1609. [Google Scholar] [CrossRef]

- Raynaud, S.; Fabre, D.; Mazerolle, F.; Geraud, Y.; Latière, H.J. Analysis of the Internal Structure of Rocks and Characterization of Mechanical Deformation by a Non-Destructive Method: X-ray Tomodensitometry. Tectonophysics 1989, 159, 149–159. [Google Scholar] [CrossRef]

- Hidajat, I.; Mohanty, K.K.; Flaum, M.; Hirasaki, G. Study of Vuggy Carbonates Using X-ray CT Scanner and NMR. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September 2002. [Google Scholar]

- Cox, S.J.D.; Meredith, P.G. Microcrack Formation and Material Softening in Rock Measured by Monitoring Acoustic Emissions. Int. J. Rock Mech. Min. Sci. 1993, 30, 11–24. [Google Scholar] [CrossRef]

- Stanchits, S.; Burghardt, J.; Surdi, A. Hydraulic Fracturing of Heterogeneous Rock Monitored by Acoustic Emission. Rock Mech. Rock Eng. 2015, 48, 2513–2527. [Google Scholar] [CrossRef]

- Olorunlambe, K.; Eckold, D.; Shepherd, D.E.T.; Dearn, K.D. Bio-Tribo-Acoustic Emissions: Condition Monitoring of a Simulated Joint Articulation. Biotribology 2022, 32, 100217. [Google Scholar] [CrossRef]

- Wright, B.J.; Grigg, S.; Bergsaker, A.S.; Brattgjerd, J.E.; Steen, H.; Pullin, R. Real time monitoring of screw insertion using acoustic emission can predict screw stripping in human cancellous bone. Clin. Bio. Mech. 2020, 76, 105026. [Google Scholar] [CrossRef] [PubMed]

- Dornfeld, D.A.; Kannatey-Asibu, E. Acoustic emission during orthogonal metal cutting. Int. J. Mech. Sci. 1980, 22, 285–296. [Google Scholar] [CrossRef]

- Shridharani, J.K.; Ortiz-Paparoni, M.A.; Eynde, J.; Bass, C.R. Acoustic Emissions in Vertebral Cortical Shell Failure. J. Bio. Mech. 2021, 117, 110227. [Google Scholar] [CrossRef]

- Mohamed, S.; Nadege, R.; Aron, G. Analysis of Bond Behaviour of Textile-Reinforced Cement (TRC) Applied to Masonry Using Distributed Fibre Optic Sensors and Acoustic Emission. Compos. Part B-Eng. 2022, 247, 110327. [Google Scholar]

- Hampton, J.; Gutierrez, M.; Matzar, L. Microcrack Damage Observations near Coalesced Fractures Using Acoustic Emission. Rock Mech. Rock Eng. 2019, 52, 3597–3608. [Google Scholar] [CrossRef]

- Shiotani, T.; Ohtsu, M.; Ikeda, K. Detection and Evaluation of AE Waves Due to Rock Deformation. Constr. Build. Mater. 2001, 15, 235–246. [Google Scholar] [CrossRef]

- Pirskawetz, S.M.; Schmidt, S. Detection of wire breaks in prestressed concrete bridges by Acoustic Emission analysis. Dev. Built Environ. 2023, 14, 100151. [Google Scholar] [CrossRef]

- Liu, H.; Han, S.; Yang, G.; Zhang, Y.; Yu, J.; Feng, Z. Experimental study on mesostructural damage evolution of sandstone subjected to freeze-thaw cycling under uniaxial compression. Res. Cold. Arid Reg. 2022, 14, 317–328. [Google Scholar] [CrossRef]

- Tang, J.; Chen, X.; Dai, F. Experimental Study on the Crack Propagation and Acoustic Emission Characteristics of Notched Rock Beams under Post-Peak Cyclic Loading. Eng. Fract. Mech. 2020, 226, 106890. [Google Scholar] [CrossRef]

- Yang, S.; Tian, W.; Liu, X.; Huang, Y.; Yang, J. An Experimental Study on Failure Mechanical Behavior and Cracking Mechanism of Rectangular Solid Sandstone Containing Two Non-Coplanar Fissures under Conventional Triaxial Compression. Theor. Appl. Fract. Mech. 2021, 114, 102975. [Google Scholar] [CrossRef]

- Fang, W.; Jiang, N.; Luo, X. Establishment of Damage Statistical Constitutive Model of Loaded Rock and Method for Determining Its Parameters under Freeze-Thaw Condition. Cold Reg. Sci. Technol. 2019, 160, 31–38. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, G. Research on Damage Model of Rock Under Coupling Action of Freeze-Thaw and Load. Chin. J. Rock Mech. Eng. 2010, 29, 471–476. [Google Scholar]

- Liu, B.; Huang, J.; Wang, Z.; Liu, L. Study on Damage Evolution and Acoustic Emission Character of Coal-Rock under Uniaxial Compression. Chin. J. Rock Mech. Eng. 2009, 28, 3234–3238. [Google Scholar]

- Liu, H.; Lin, J.; Yang, G.; Yun, Y.; Zhang, H.; Liang, B.; Zhang, Y. Acoustic Emission Test on Tensile Damage Characteristics of Sandstone under Freeze-Thaw Cycle. J. Min. Saf. Eng. 2021, 38, 830–839. [Google Scholar]

- Yang, Y.; Zhao, Y.; Ma, H.; Chen, W.; Feng, H.; Jin, M.; Lin, Q.; Ma, W. The Mechanical Characteristics and Damage Model of Helan Mountain Rock based on Acoustic Emission. J. Wuhan Univ. Technol. (Mater. Sci.) 2021, 36, 845–864. [Google Scholar] [CrossRef]

- Jiang, W.; Lai, Y.; Yu, F.; Ma, Q.; Jiang, H. Mechanical properties investigation and damage constitutive models of red sandstone subjected to freeze-thaw cycles. Cold Reg. Sci. Technol. 2023, 207, 103776. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, S.; Zhao, J.; Shi, L.; Zhou, S. A temperature-dependent elastoplastic damage model for frozen sandstone. Cold Reg. Sci. Technol. 2023, 208, 103792. [Google Scholar] [CrossRef]

- Ministry of Electric Power Industry of The People’s Republic of China. Standard for Test Methods of Engineering Rock Mass; China Planning Press: Beijing, China, 2013.

- Cui, K.; Gu, X.; Wu, G.; Li, H.; Du, Z. Dry-wet damage characteristics and mechanism of metamorphic sandstone carrying Helan mouth’s rock paintings under different conditions. Chin. J. Rock Mech. Eng. 2021, 40, 1236–1247. [Google Scholar]

- Sitzia, F.; Lisci, C.; Mirao, J. The interaction between rainwater and polished building stones for flooring and cladding Implications in architecture. J. Build. Eng. 2022, 52, 104495. [Google Scholar] [CrossRef]

- Kachanov, L.M. Time Rupture Process under Creep Condition. Int. J. Fract. 1999, 97, 11–18. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.; Guo, M.; Li, B. Study of Rock Damage Characteristics Based on Acoustic Emission Tests under Triaxial Compression. Chin. J. Rock Mech. Eng. 2014, 33, 98–104. [Google Scholar]

| Grouping | Drying Group | pH = 2 Group | pH = 7 Group |

|---|---|---|---|

| /GPa | 49.94 | 55.87 | 57.45 |

| −0.16 | −0.51 | −0.35 | |

| 0.53 | 0.42 | 0.36 | |

| R2 | 0.96 | 0.95 | 0.96 |

| /MPa | 140.71 | 79.88 | 87.02 |

| −3.36 | −0.23 | −2.15 | |

| 0.73 | 1.55 | 0.86 | |

| R2 | 0.995 | 0.959 | 0.993 |

| /MPa | 424.24 | 372.06 | 408.75 |

| −0.31 | −0.02 | −0.21 | |

| 1.60 | 2.44 | 1.87 | |

| R2 | 0.997 | 0.999 | 0.999 |

| /MPa | −51.88 | −49,644.81 | 69.83 |

| 35.10 | 49,585.18 | 46.32 | |

| 0.48 | 0.13 × 10−2 | 0.371 | |

| R2 | 0.990 | 0.936 | 0.971 |

| /MPa | 149.07 | −38,785.26 | 41.48 |

| 45.66 | 38,818.54 | 58.17 | |

| 0.51 | 0.21 × 10−2 | 0.476 | |

| R2 | 0.999 | 0.949 | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Lin, Q.; Ma, H.; Israr, J.; Liu, W.; Zhao, Y.; Ma, W.; Zhang, G.; Li, H. A Semi-Empirical Damage Model of Helankou Rocks Based on Acoustic Emission. Materials 2023, 16, 4001. https://doi.org/10.3390/ma16114001

Yang Y, Lin Q, Ma H, Israr J, Liu W, Zhao Y, Ma W, Zhang G, Li H. A Semi-Empirical Damage Model of Helankou Rocks Based on Acoustic Emission. Materials. 2023; 16(11):4001. https://doi.org/10.3390/ma16114001

Chicago/Turabian StyleYang, Youzhen, Qingqing Lin, Hailong Ma, Jahanzaib Israr, Wei Liu, Yishen Zhao, Wenguo Ma, Gang Zhang, and Hongbo Li. 2023. "A Semi-Empirical Damage Model of Helankou Rocks Based on Acoustic Emission" Materials 16, no. 11: 4001. https://doi.org/10.3390/ma16114001

APA StyleYang, Y., Lin, Q., Ma, H., Israr, J., Liu, W., Zhao, Y., Ma, W., Zhang, G., & Li, H. (2023). A Semi-Empirical Damage Model of Helankou Rocks Based on Acoustic Emission. Materials, 16(11), 4001. https://doi.org/10.3390/ma16114001