Friction Stir Welding of Dissimilar Al 6061-T6 to AISI 316 Stainless Steel: Microstructure and Mechanical Properties

Abstract

:1. Introduction

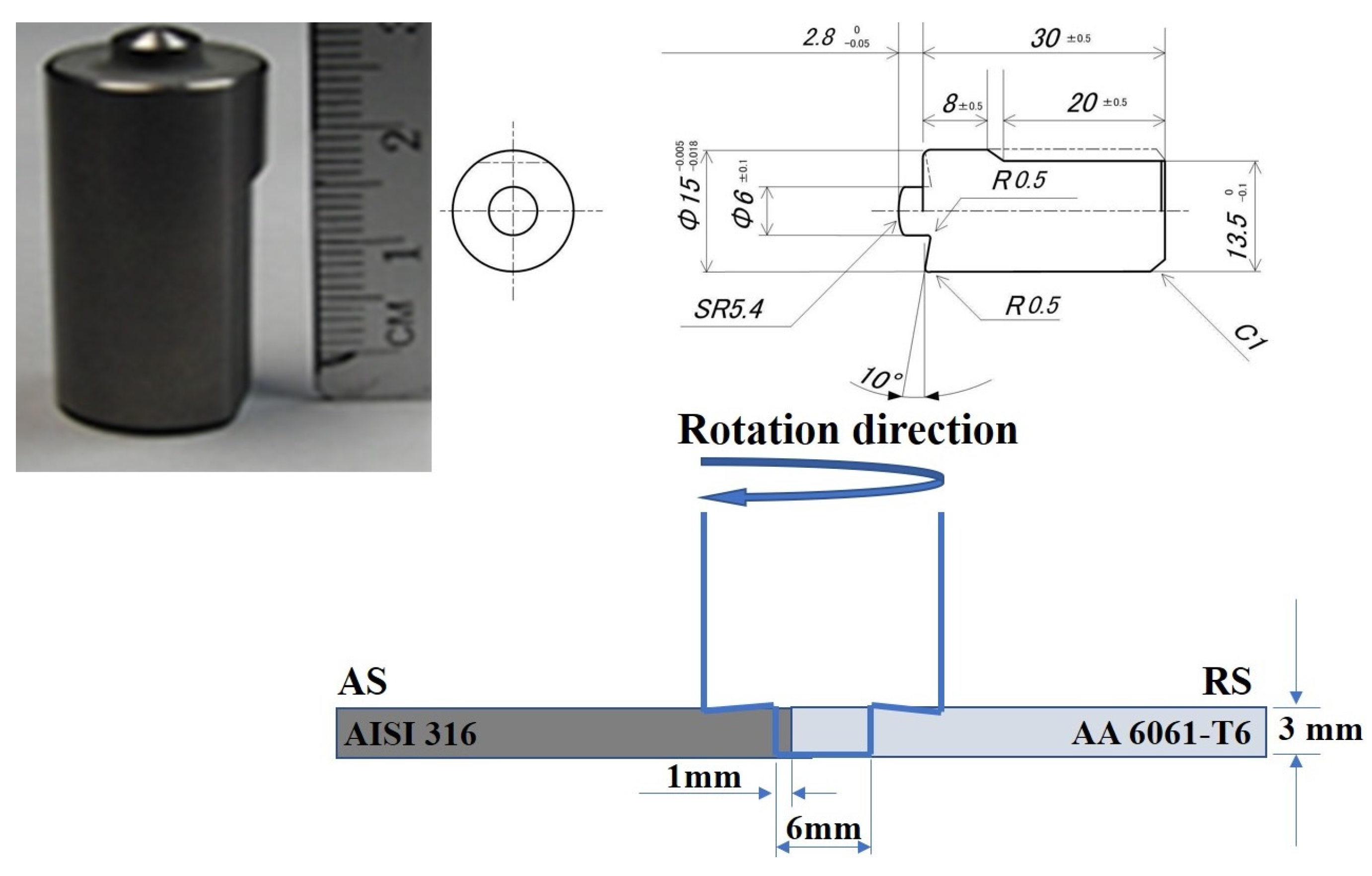

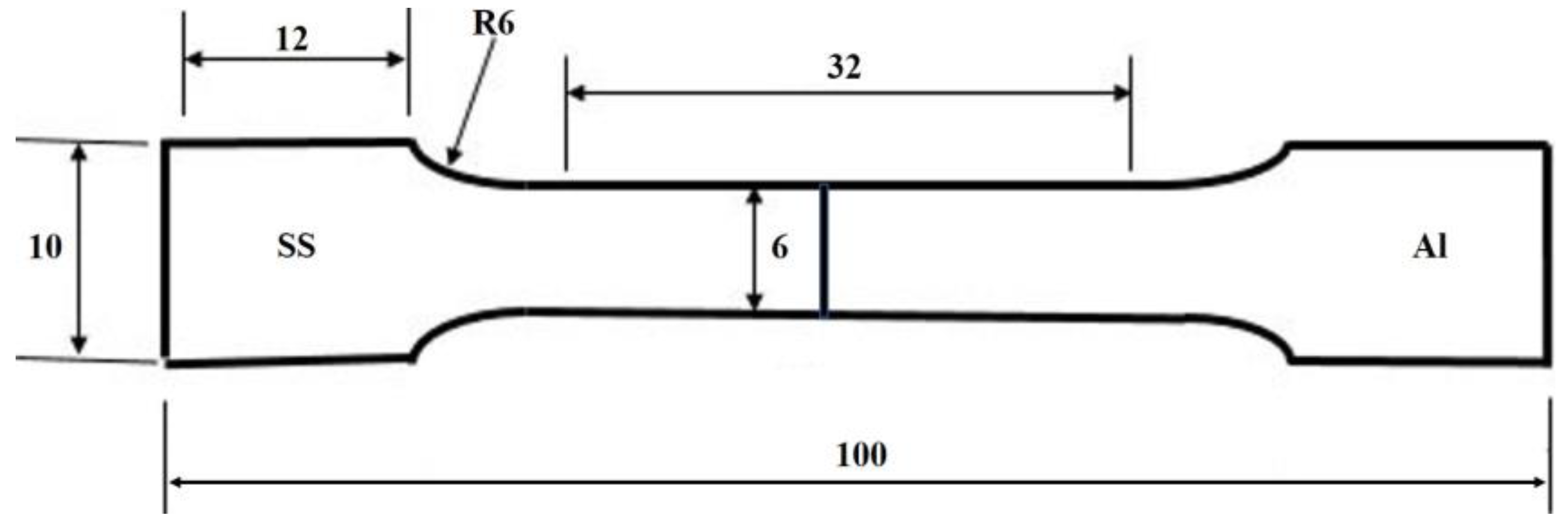

2. Experimental Procedures

3. Results and Discussion

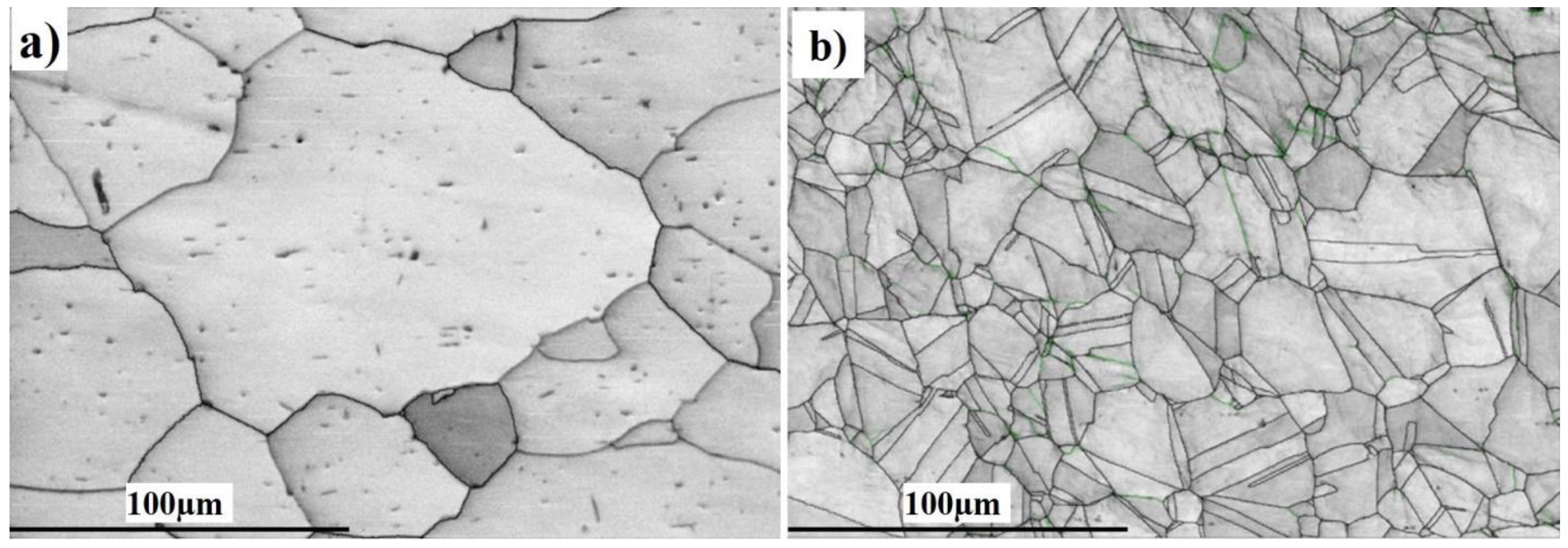

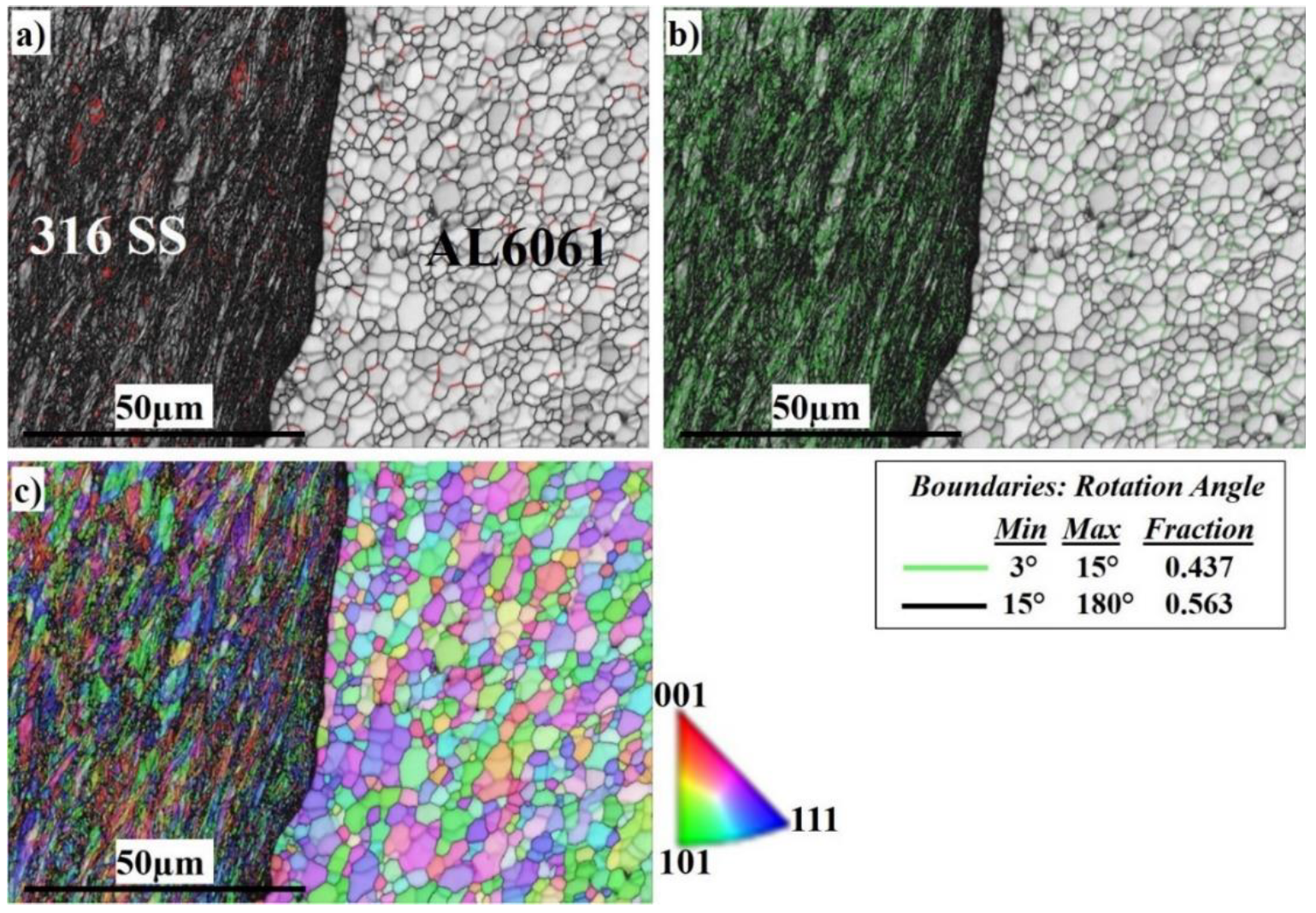

3.1. Characteristics of the Base Metals

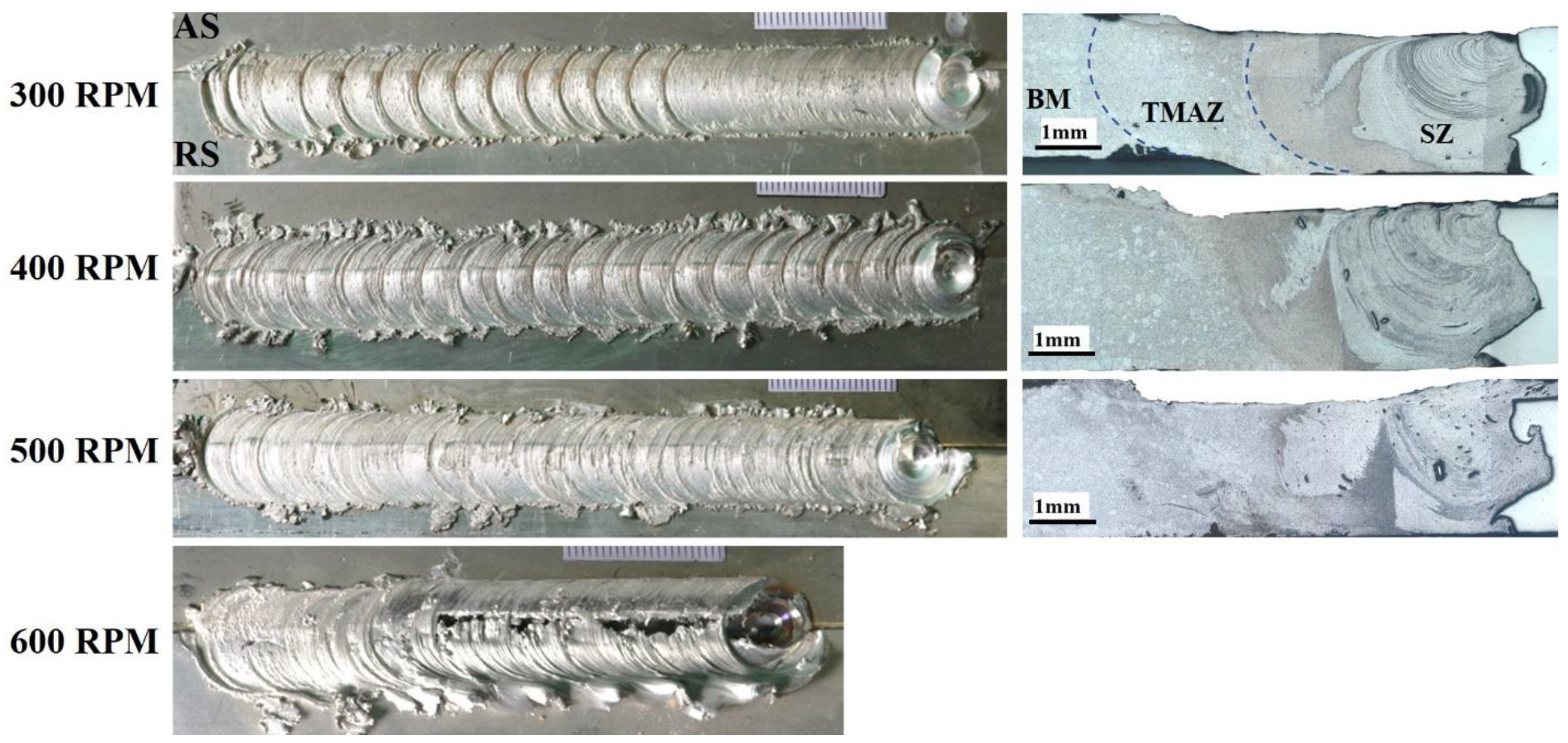

3.2. Surface Appearance and Macrostructure

3.3. X-ray Diffraction Analysis

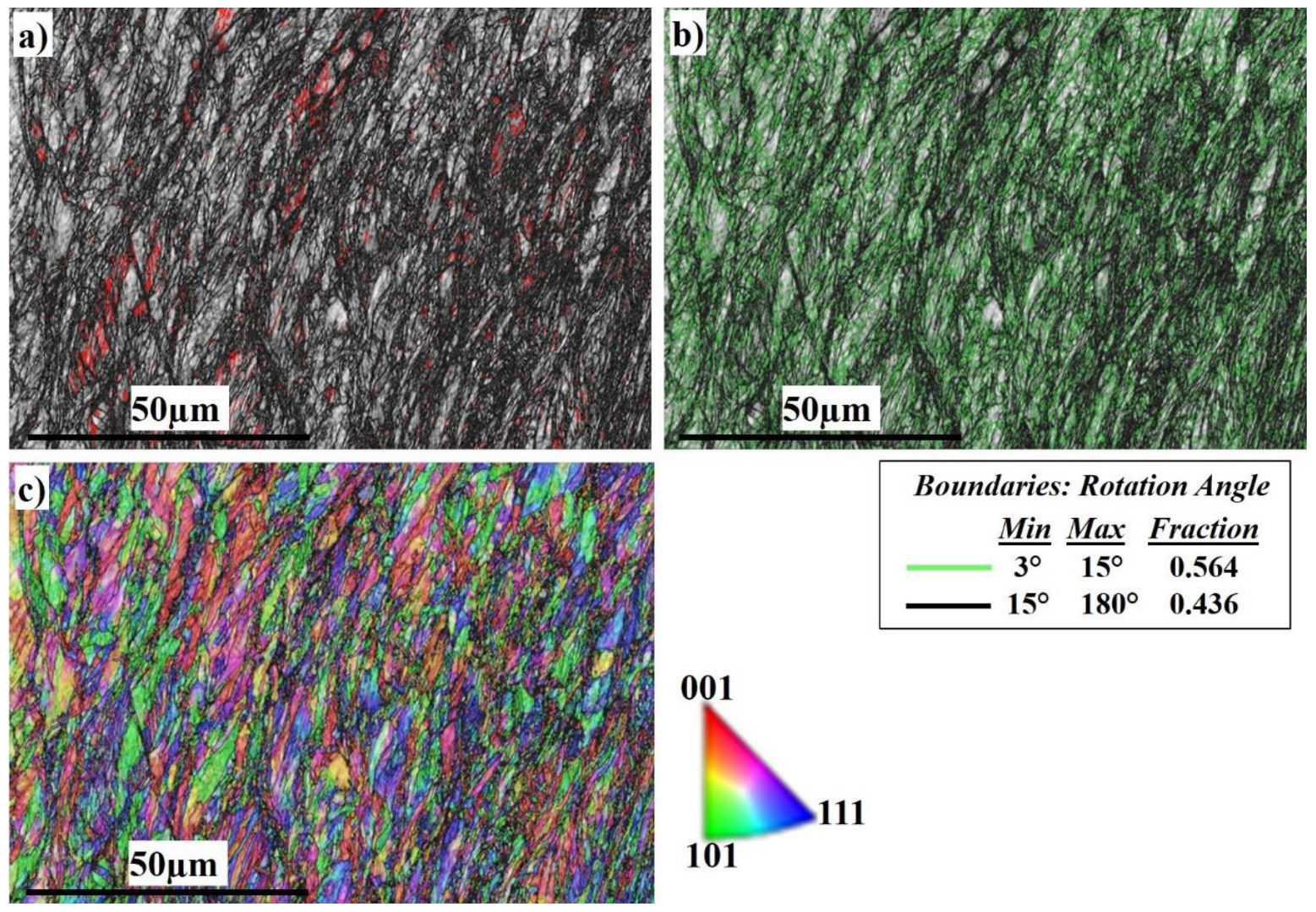

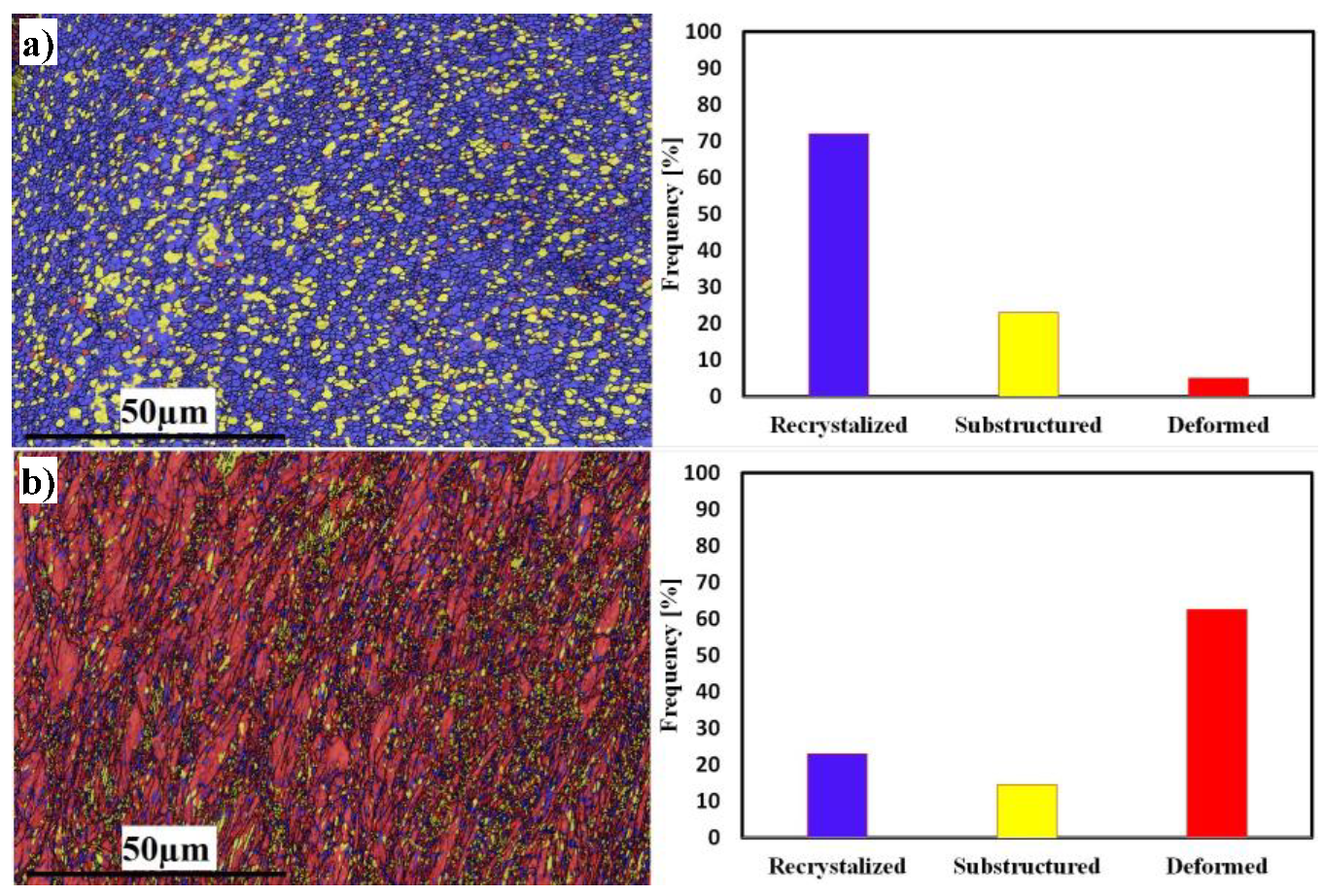

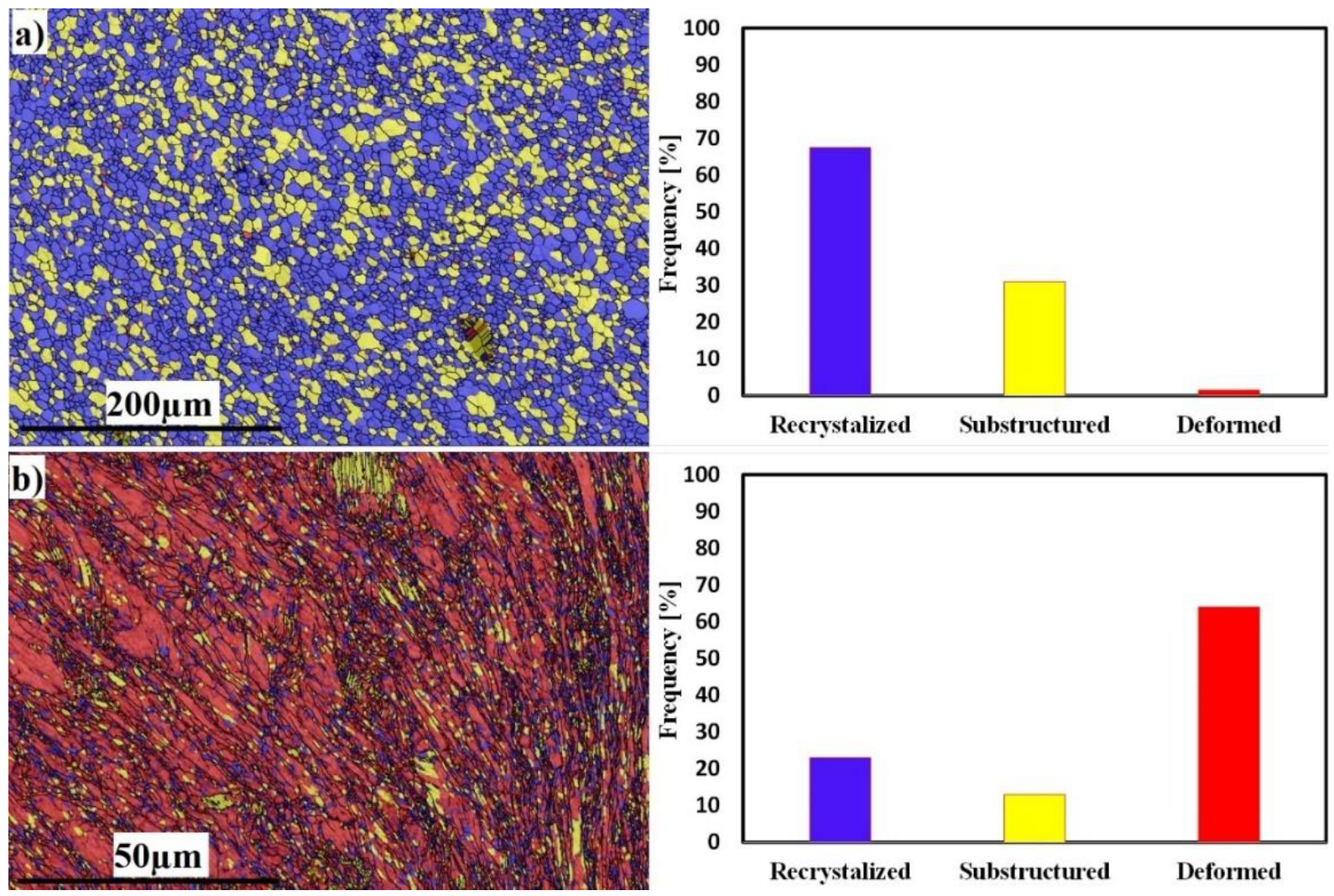

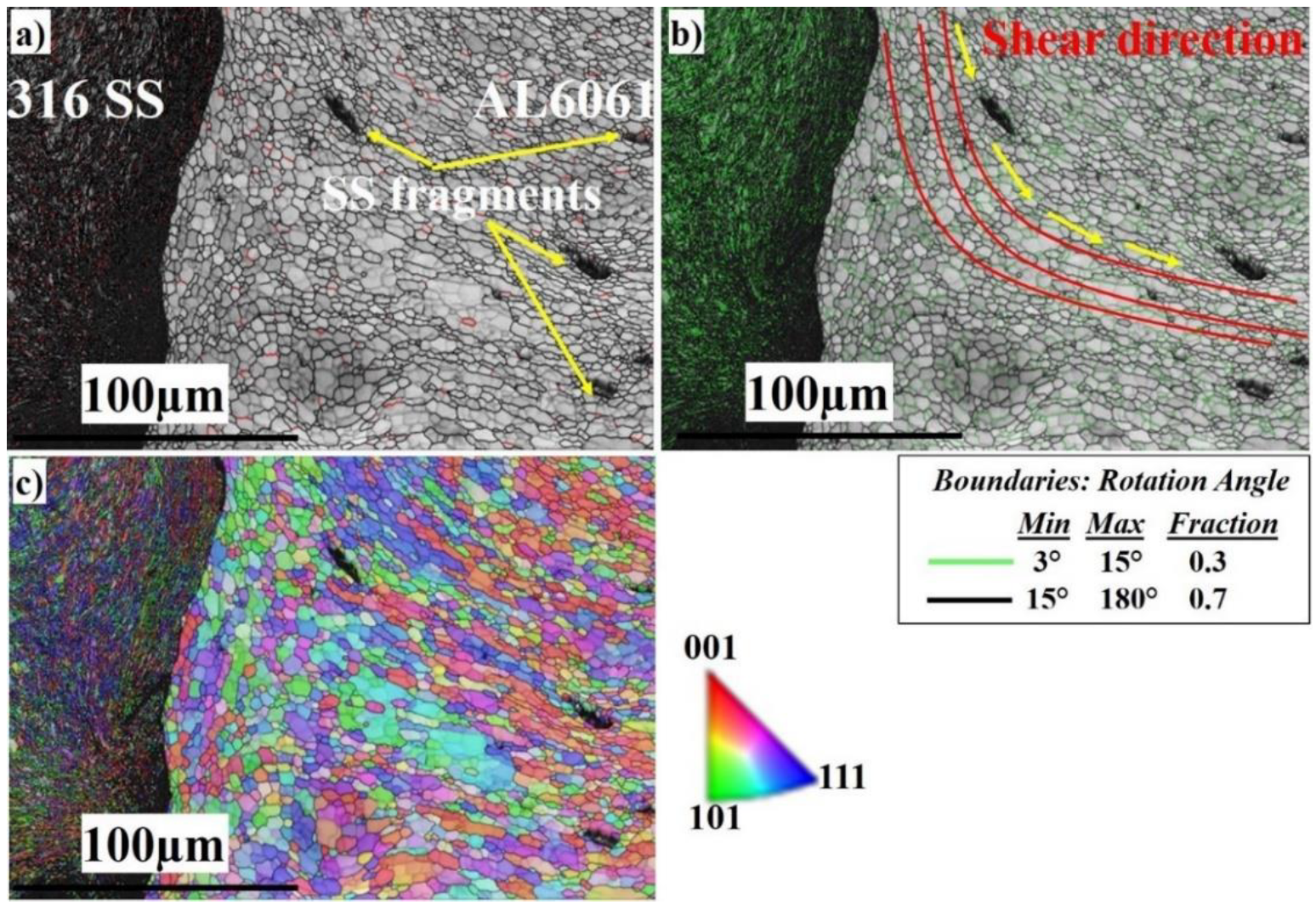

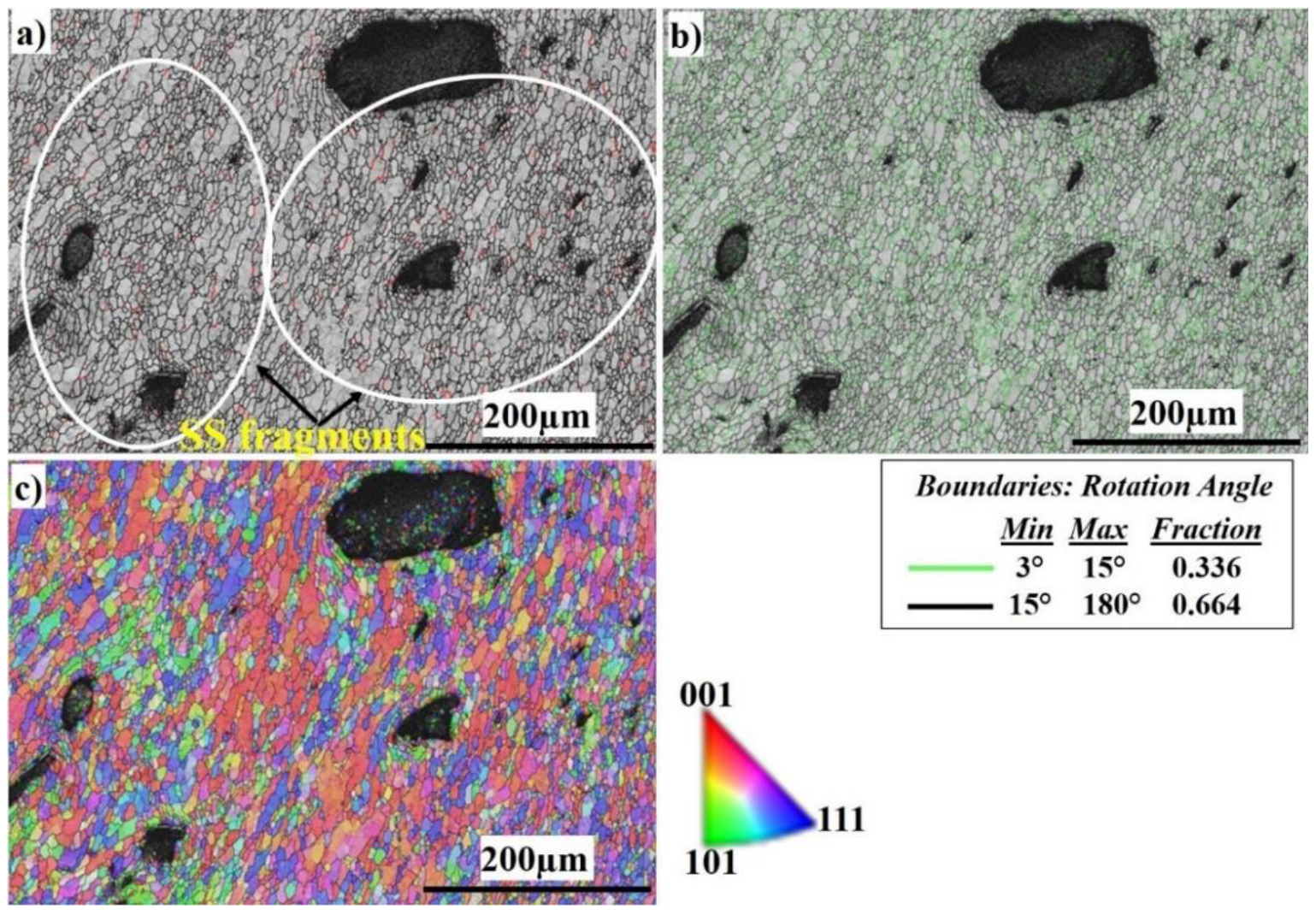

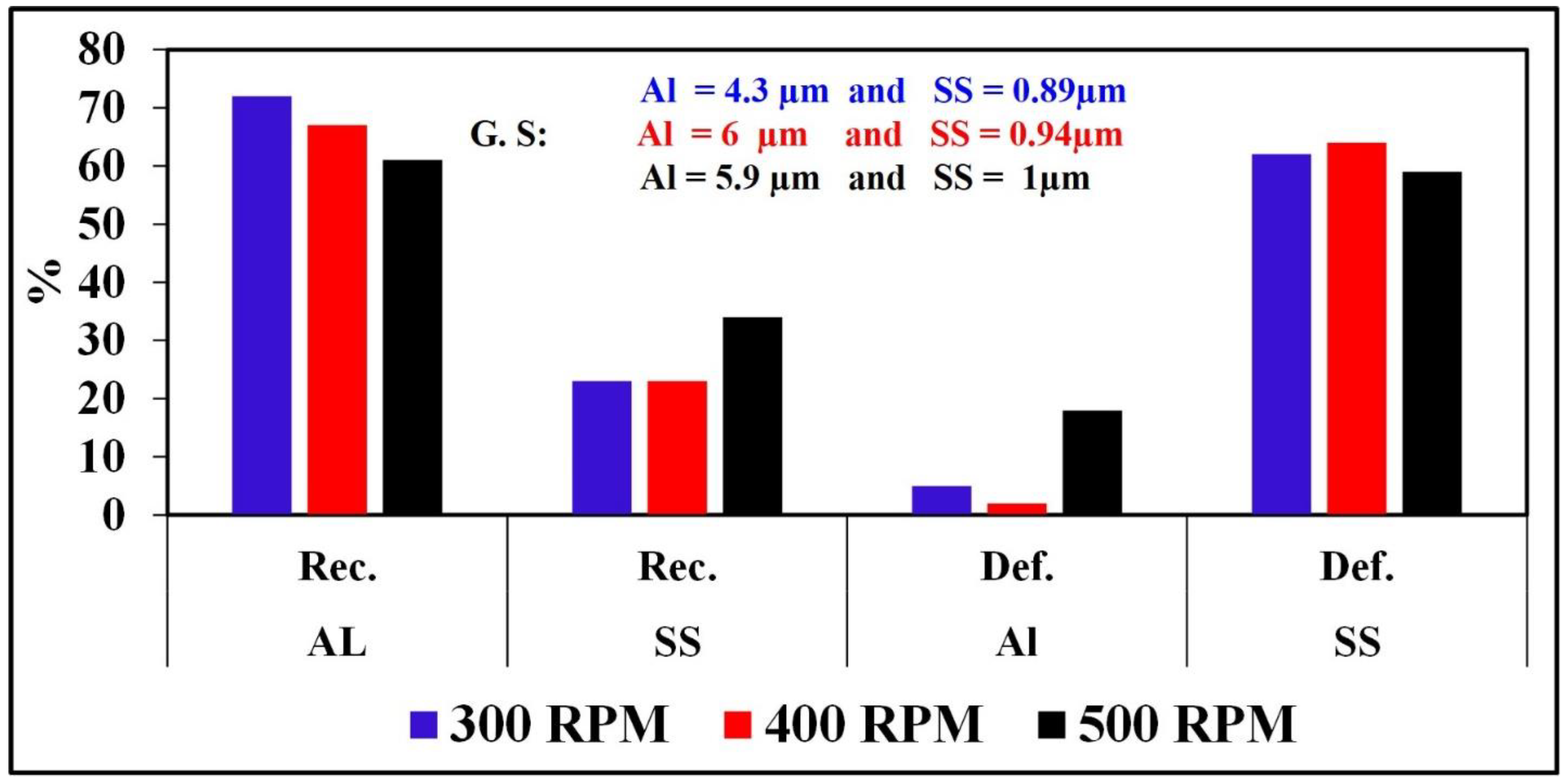

3.4. Microstructural Characteristics of the Welded Dissimilar Joints

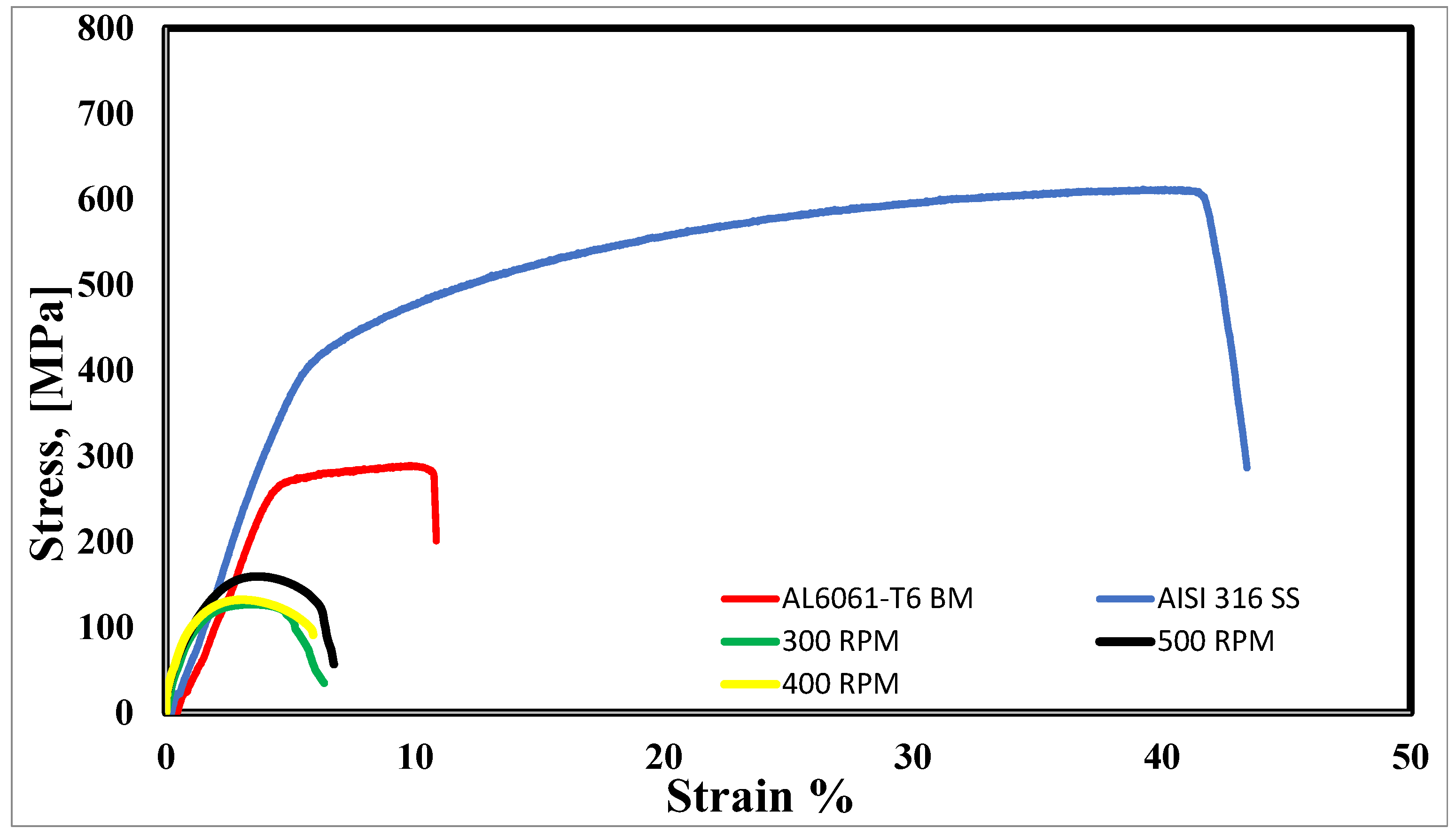

3.5. Tensile Properties and Micro-Indentation Hardness of Dissimilar Metal Joints

4. Conclusions

- Successful butt joints were obtained between stainless steel AISI316 and the aluminum alloy AA6061-T6.

- At the interface of the Al and SS, many kinds of IMCs were found, including FeAl6, FeAl3, Ni3Al, Al11Cr2, and FeCr.

- Dissimilar welded butt joints show very fine recrystallized grains for Al 606 and very fine deformed grains of the AISI 316 SZ with HAGBs and LAGBs, respectively.

- The highest obtained UTS of 160 MPa was found for the joint at 500 RPM and 20 cm/min traverse speed, which is 56% of that of the Al BM. In addition, all tensile specimens were fractured at the aluminum SZ.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ambroziak, A.; Korzeniowski, M.; Kustroń, P.; Winnicki, M.; Sokołowski, P.; Harapińska, E. Friction Welding of Aluminium and Aluminium Alloys with Steel. Adv. Mater. Sci. Eng. 2014, 2014, 981653. [Google Scholar] [CrossRef]

- Ghaffarpour, M.; Aziz, A.; Hejazi, T.-H. Optimization of friction stir welding parameters using multiple response surface methodology. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 571–583. [Google Scholar] [CrossRef]

- Shah, L.H.; Ishak, M. Review of Research Progress on Aluminum–Steel Dissimilar Welding. Mater. Manuf. Process. 2014, 29, 928–933. [Google Scholar] [CrossRef]

- Fahmy, M.H.; Abdel-Aleem, H.A.; Abdel-Elraheem, N.A.; El-Kousy, M.R. Friction Stir Spot Welding of AA2024-T3 with Modified Refill Technique. Key Eng. Mater. 2020, 835, 274–287. [Google Scholar] [CrossRef]

- Fahmy, M.H.; Abdel-Aleem, H.; Elkousy, M.R.; Abdel-Elraheem, N.M. Comparative Study of Spot Welding and Firiction Stir Spot Welding of Al 2024-T3. Key Eng. Mater. 2018, 786, 104–118. [Google Scholar] [CrossRef]

- Riahi, M.; Nazari, H. Analysis of transient temperature and residual thermal stresses in friction stir welding of aluminum alloy 6061-T6 via numerical simulation. Int. J. Adv. Manuf. Technol. 2011, 55, 143–152. [Google Scholar] [CrossRef]

- Kumar, S.S.; Murugan, N.; Ramachandran, K. Effect of tool tilt angle on weld joint properties of friction stir welded AISI 316L stainless steel sheets. Measurement 2020, 150, 107083. [Google Scholar] [CrossRef]

- Bhattacharyya, M.; Gnaupel-Herold, T.; Raja, K.S.; Darsell, J.; Jana, S.; Charit, I. Evaluation of residual stresses in isothermal friction stir welded 304L stainless steel plates. Mater. Sci. Eng. A 2021, 826, 141982. [Google Scholar] [CrossRef]

- Kalil Rahiman, M.; Santhoshkumar, S.; Mathan Kumar, P. Experimental analysis on friction stir welded AA 7075/AA 6061 using Taguchi grey relational analysis. Mater. Today Proc. 2021, 45, 3290–3295. [Google Scholar] [CrossRef]

- Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef]

- Nourani, M.; Milani, A.S.; Yannacopoulos, S. On experimental optimization of friction stir welding of aluminum 6061: Understanding processing-microstructure-property relations. Int. J. Adv. Manuf. Technol. 2015, 79, 1425–1441. [Google Scholar] [CrossRef]

- Victor Christy, J.; Ismail Mourad, A.; Sherif, M.M.; Shivamurthy, B. Review of recent trends in friction stir welding process of aluminum alloys and aluminum metal matrix composites. Trans. Nonferrous Met. Soc. China 2021, 31, 3281–3309. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Tozaki, Y.; Nakashimac, Y. Fatigue behaviour of dissimilar friction stir spot weld between A6061 and SPCC welded by a scrolled groove shoulder tool. Procedia Eng. 2010, 2, 193–201. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, C.; Liu, G. Study on the joining of titanium and aluminum dissimilar alloys by friction stir welding. Open Mater. Sci. J. 2011, 5, 256–261. [Google Scholar] [CrossRef]

- Kasai, H.; Morisada, Y.; Fujii, H. Dissimilar FSW of immiscible materials: Steel/magnesium. Mater. Sci. Eng. A 2015, 624, 250–255. [Google Scholar] [CrossRef]

- Pourahmad, P.; Abbasi, M. Materials flow and phase transformation in friction stir welding of Al 6013/Mg. Trans. Nonferrous Met. Soc. China 2013, 23, 1253–1261. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.; Ni, D.; Ma, Z. Enhanced mechanical properties of friction stir welded dissimilar Al–Cu joint by intermetallic compounds. Mater. Sci. Eng. A 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Sajan, S.G.; Meshram, M.; Pankaj, P.S.; Dey, S.R. Friction Stir Welding of Aluminum 6082 with Mild Steel and Its Joint Analyses; Department of Materials Science and Engineering, Indian Institute of Technology Hyderabad: Yeddumailaram, India, 2013. [Google Scholar] [CrossRef]

- Lan, S.; Liu, X.; Ni, J. Microstructural evolution during friction stir welding of dissimilar aluminum alloy to advanced high-strength steel. Int. J. Adv. Manuf. Technol. 2016, 82, 2183–2193. [Google Scholar] [CrossRef]

- Habibnia, M.; Shakeri, M.; Nourouzi, S.; Givi, M.B. Microstructural and mechanical properties of friction stir welded 5050 Al alloy and 304 stainless steel plates. Int. J. Adv. Manuf. Technol. 2015, 76, 819–829. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Mei, S.; Wang, L.; Zeng, X. Parameter optimization and mechanism of laser–arc hybrid welding of dissimilar Al alloy and stainless steel. Int. J. Adv. Manuf. Technol. 2014, 74, 199–208. [Google Scholar] [CrossRef]

- Abdel-Aleem, H.; Katoh, M.; Nishio, K.; Yamaguchi, T.; Tsue, Y. Evaluation by ultrasonic testing and TEM observation of bond interface for ultrasonic bonds of 505/SUS304 and 5052/SPCC. Q. J. Jpn. Weld. Soc. 2005, 23, 194–202. [Google Scholar] [CrossRef]

- Abbasi, M.; Dehghani, M.; Guim, H.; Kim, D. Investigation of Fe-rich fragments in aluminum-steel friction stir welds via simultaneous Transmission Kikuchi Diffraction and EDS. Acta Mater. 2016, 117, 262–269. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.; Queiros, A.; Marques, E.A.S.; Shi, R.; da Silva, L.F.M. Comparative Study between Stainless Steel and Carbon Steel during Dissimilar Friction Stir Welding with Aluminum: Kinetics of Al–Fe Intermetallic Growth. Met. Mater. Int. 2022, 28, 1948–1959. [Google Scholar] [CrossRef]

- Tanaka, T.; Morishige, T.; Hirata, T. Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr. Mater. 2009, 61, 756–759. [Google Scholar] [CrossRef]

- Picot, F.; Gueydan, A.; Martinez, M.; Moisy, F.; Hug, E. A Correlation between the Ultimate Shear Stress and the Thickness Affected by Intermetallic Compounds in Friction Stir Welding of Dissimilar Aluminum Alloy–Stainless Steel Joints. Metals 2018, 8, 179. [Google Scholar] [CrossRef]

- Kundu, S.; Roy, D.; Bhola, R.; Bhattacharjee, D.; Mishra, B.; Chatterjee, S. Microstructure and tensile strength of friction stir welded joints between interstitial free steel and commercially pure aluminium. Mater. Des. 2013, 50, 370–375. [Google Scholar] [CrossRef]

- Elrefaey, A.; Gouda, M.; Takahashi, M.; Ikeuchi, K. Characterization of aluminum/steel lap joint by friction stir welding. J. Materi. Eng. Perform. 2005, 14, 10–17. [Google Scholar] [CrossRef]

- Chen, Y.; Gholinia, A.; Prangnell, P. Interface structure and bonding in abrasion circle friction stir spot welding: A novel approach for rapid welding aluminium alloy to steel automotive sheet. Mater. Chem. Phys. 2012, 134, 459–463. [Google Scholar] [CrossRef]

- Dehghani, M.; Amadeh, A.; Akbari Mousavi, S. Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater. Des. 2013, 49, 433–441. [Google Scholar] [CrossRef]

- Campanella, D.; Spena, P.R.; Buffa, G.; Fratini, L. Dissimilar Al/steel friction stir welding lap joints for automotive applications. AIP Conf. Proc. 2016, 1769, 100005. [Google Scholar] [CrossRef]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Chen, T. Process parameters study on FSW joint of dissimilar metals for aluminum—Steel. J. Mater. Sci. 2009, 44, 2573–2580. [Google Scholar] [CrossRef]

- Tang, J.; Shen, Y. Effects of preheating treatment on temperature distribution and material flow of aluminum alloy and steel friction stir welds. J. Manuf. Process. 2017, 29, 29–40. [Google Scholar] [CrossRef]

- Dehghani, M.; Mousavi, S.A.; Amadeh, A. Effects of welding parameters and tool geometry on properties of 3003-H18 aluminum alloy to mild steel friction stir weld. Trans. Nonferrous Met. Soc. China 2013, 23, 1957–1965. [Google Scholar] [CrossRef]

- Ramachandran, K.; Murugan, N.; Shashi Kumar, S. Influence of tool traverse speed on the characteristics of dissimilar friction stir welded aluminium alloy, AA5052 and HSLA steel joints. Arch. Civ. Mech. Eng. 2015, 15, 822–830. [Google Scholar] [CrossRef]

- Coelho, R.; Kostka, A.; dos Santos, J.; Kaysser-Pyzalla, A. Friction-stir dissimilar welding of aluminium alloy to high strength steels: Mechanical properties and their relation to microstructure. Mater. Sci. Eng. A 2012, 556, 175–183. [Google Scholar] [CrossRef]

- Haghshenas, M.; Abdel-Gwad, A.; Omran, A.; Gökçe, B.; Sahraeinejad, S.; Gerlich, A. Friction stir weld assisted diffusion bonding of 5754 aluminum alloy to coated high strength steels. Mater. Des. 2014, 55, 442–449. [Google Scholar] [CrossRef]

- Wang, T.; Komarasamy, M.; Liu, K.; Mishra, R.S. Friction stir butt welding of strain-hardened aluminum alloy with high strength steel. Mater. Sci. Eng. A 2018, 737, 85–89. [Google Scholar] [CrossRef]

- Liu, X.; Chen, G.; Ni, J.; Feng, Z. Computational Fluid Dynamics Modeling on Steady-State Friction Stir Welding of Aluminum Alloy 6061 to TRIP Steel. J. Manuf. Sci. Eng. 2017, 139, 051004. [Google Scholar] [CrossRef]

- Ghosh, M.; Kar, A.; Kumar, K.; Kailas, S.V. Structural characterisation of reaction zone for friction stir welded aluminium–stainless steel joint. Mater. Technol. 2012, 27, 169–172. [Google Scholar] [CrossRef]

- Murugan, B.; Thirunavukarasu, G.; Kundu, S.; Kailas, S.V. Influence of Tool Traverse Speed on Structure, Mechanical Properties, Fracture Behavior, and Weld Corrosion of Friction Stir Welded Joints of Aluminum and Stainless Steel. Adv. Eng. Mater. 2019, 21, 1800869. [Google Scholar] [CrossRef]

- Fallahi, A.; Shokuhfar, A.; Ostovari Moghaddam, A.; Abdolahzadeh, A. Analysis of SiC nano-powder effects on friction stir welding of dissimilar Al-Mg alloy to A316L stainless steel. J. Manuf. Process. 2017, 30, 418–430. [Google Scholar] [CrossRef]

- Rafiei, R.; Ostovari Moghaddam, A.; Hatami, M.R.; Khodabakhshi, F.; Abdolahzadeh, A.; Shokuhfar, A. Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–Mg alloy and A316L stainless steel. Int. J. Adv. Manuf. Technol. 2017, 90, 2785–2801. [Google Scholar] [CrossRef]

- Martinez Celis, M.; Veselý, J.; Kozlík, J.; Picot, F.; Harcuba, P.; Hug, E. Interface microstructure of friction stir welded aluminum alloy and stainless steel. MRS Adv. 2022, 7, 818–823. [Google Scholar] [CrossRef]

- Fukumoto, S.; Tsubakino, H.; Okita, K.; Aritoshi, M.; Tomita, T. Friction welding process of 5052 aluminium alloy to 304 stainless steel. Mater. Sci. Technol. 1999, 15, 1080–1086. [Google Scholar] [CrossRef]

- Xiong, J.T.; Li, J.L.; Qian, J.W.; Zhang, F.S.; Huang, W.D. High strength lap joint of aluminium and stainless steels fabricated by friction stir welding with cutting pin. Sci. Technol. Weld. Join. 2012, 17, 196–201. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Xiong, J.; Zhang, F. Effect of Tool Pin Insertion Depth on Friction Stir Lap Welding of Aluminum to Stainless Steel. J. Materi. Eng. Perform. 2013, 22, 3005–3013. [Google Scholar] [CrossRef]

- Babu, S.; Panigrahi, S.K.; Ram, G.D.J.; Venkitakrishnan, P.V.; Kumar, R.S. Friction Stir Welding of Austenitic Stainless Steel to an Aluminum-Copper Alloy; Friction Stir Welding and Processing, VIII; Mishra, R.S., Mahoney, M.W., Sato, Y., Hovanski, Y., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Jabraeili, R.; Jafarian, H.R.; Khajeh, R.; Park, N.; Kim, Y.; Heidarzadeh, A.; Eivani, A.R. Effect of FSW process parameters on microstructure and mechanical properties of the dissimilar AA2024 Al alloy and 304 stainless steel joints. Mater. Sci. Eng. A 2021, 814, 140981. [Google Scholar] [CrossRef]

- Goel, P.; Khan, N.Z.; Khan, Z.A.; Ahmari, A.; Gangil, N.; Abidi, M.H.; Siddiquee, A.N. Investigation on material mixing during FSW of AA7475 to AISI304. Mater. Manuf. Process. 2019, 34, 192–200. [Google Scholar] [CrossRef]

- Muhamad, M.R.; Jamaludin, M.F.; Yusof, F.; Mahmoodian, R.; Morisada, Y.; Suga, T.; Fujii, S.H. Effects of Al-Ni powder addition on dissimilar friction stir welding between AA7075-T6 and 304 L. Mat. Sci. Eng. Technol. 2020, 51, 1274. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Xue, P.; Zhang, H.; Ni, D.; Wang, K.; Ma, Z. High-quality dissimilar friction stir welding of Al to steel with no contacting between tool and steel plate. Mater. Charact. 2022, 191, 112128. [Google Scholar] [CrossRef]

- Ogura, T.; Saito, Y.; Nishida, T.; Nishida, H.; Yoshida, T.; Omichi, N.; Fujimoto, M.; Hirose, A. Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminum alloy/stainless steel lap joint. Scr. Mater. 2012, 66, 531–534. [Google Scholar] [CrossRef]

- Hatano, R.; Ogura, T.; Matsuda, T.; Sano, T.; Hirose, A. Relationship between intermetallic compound layer thickness with deviation and interfacial strength for dissimilar joints of aluminum alloy and stainless steel. Mater. Sci. Eng. A 2018, 735, 361–366. [Google Scholar] [CrossRef]

- Harwani, D.M.; Badheka, V.J. Effect of Shoulder Diameter on Friction Stir Welding of Al 6061 to SS 304. In Innovations in Infrastructure; Advances in Intelligent Systems and Computing; Deb, D., Balas, V., Dey, R., Eds.; Springer: Singapore; Volume 757. [CrossRef]

- Uematsu, Y.; Kakiuchi, T.; Ogawa, D.; Hashiba, K. Fatigue crack propagation near the interface between Al and steel in dissimilar Al/steel friction stir welds. Int. J. Fatigue 2020, 138, 105706. [Google Scholar] [CrossRef]

- Kakiuchi, T.; Uematsu, Y.; Suzuki, K. Evaluation of fatigue crack propagation in dissimilar Al/steel friction stir welds. Procedia Struct. Integr. 2016, 2, 1007–1014. [Google Scholar] [CrossRef]

- Uzun, H.; Dalle Donne, C.; Argagnotto, A.; Ghidini, T.; Gambaro, C. Friction stir welding of dissimilar Al 6013-T4 To X5CrNi18-10 stainless steel. Mater. Des. 2005, 26, 41–46. [Google Scholar] [CrossRef]

- Bang, H.; Bang, H.; Jeon, G.; Oh, I.; Ro, C. Gas tungsten arc welding assisted hybrid friction stir welding of dissimilar materials Al6061-T6 aluminum alloy and STS304 stainless steel. Mater. Des. 2012, 37, 48–55. [Google Scholar] [CrossRef]

- Paventhan, R.; Lakshminarayanan, P.; Balasubramanian, V. Prediction and optimization of friction welding parameters for joining aluminium alloy and stainless steel. Trans. Nonferrous Met. Soc. China 2011, 21, 1480–1485. [Google Scholar] [CrossRef]

- Li, Z.; Chen, S.; Meng, L.; Gao, Y.; Yang, Z.; Shi, M.; Chen, X.; Zhang, H.; Zhang, Y. On the Effects of High and Ultra-High Rotational Speeds on the Strength, Corrosion Resistance, and Microstructure during Friction Stir Welding of Al 6061-T6 and 316L SS Alloys. Coatings 2021, 11, 1550. [Google Scholar] [CrossRef]

- Zandsalimi, S.; Heidarzadeh, A.; Saeid, T. Dissimilar friction-stir welding of 430 stainless steel and 6061 aluminum alloy: Microstructure and mechanical properties of the joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1791–1801. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, Y.; Shen, J.; Fu, X.; Mi, S. A new calculation method of viscoplastic heat production generated by plastic flow of friction stir welding process. Mater. Chem. Phys. 2021, 270, 124795. [Google Scholar] [CrossRef]

- Liu, S.; Paidar, M.; Mehrez, S.; Ojo, O.O.; Mahariq, I.; Elbadawy, I. Development of AA6061/316 stainless steel surface composites via friction stir processing: Effect of tool rotational speed. Mater. Charact. 2022, 192, 112215. [Google Scholar] [CrossRef]

- Commin, L.; Dumont, M.; Masse, J.; Barrallier, L. Friction stir welding of AZ31 magnesium alloy rolled sheets: Influence of processing parameters. Acta Mater. 2009, 57, 326–334. [Google Scholar] [CrossRef]

- Ebrahimzadeh, V.; Paidar, M.; Safarkhanian, M.A.; Oladimeji Ojo, O. Orbital friction stir lap welding of AA5456-H321/AA5456-O aluminum alloys under varied parameters. Int. J. Adv. Manuf. Technol. 2018, 96, 1237–1254. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Paidar, M.; Mohanavel, V.; Ojo, O.; Mehrez, S.; Rajkumar, S.; Ravichandran, M. Dieless Friction Stir Extrusion-Brazing (DFSE-B) of AA2024-T3 aluminum alloy to Copper with Zn interlayer. Results Phys. 2021, 24, 104101. [Google Scholar] [CrossRef]

- Tagimalek, H.; Maraki, M.R.; Mahmoodi, M.; Moghaddam, H.K.; Farzad-Rik, S. Prediction of mechanical properties and hardness of friction stir welding of Al 5083/pure Cu using ANN, ICA and PSO model. SN Appl. Sci. 2022, 4, 102. [Google Scholar] [CrossRef]

- Siddiquee, A.N.; Pandey, S.; Khan, N.Z. Friction Stir Welding of Austenitic Stainless Steel: A Study on Microstructure and Effect of Parameters on Tensile Strength. Mater. Today Proc. 2015, 2, 1388–1397. [Google Scholar] [CrossRef]

- Meran, C.; Kovan, V.; Alptekin, A. Friction stir welding of AISI 304 austenitic stainless steel. Mater. Werkst. Entwickl. Fert. Prüfung Eig. Anwend. Tech. Werkst. 2007, 38, 829–835. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Ni | Cr | Mo | Fe | Al | Mg | Cu | Zn | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 316SS | 0.04 | 0.89 | 1.8 | 0.03 | 0.02 | 12 | 17 | 2.7 | Bal. | - | - | - | - | - |

| AL 6061-T6 | - | 0.61 | - | - | - | - | 0.3 | 0.17 | 98.2 | 0.58 | 0.28 | 0.01 | 0.012 |

| Material | YS (MPa) | UTS (MPa) | A50 (%) |

|---|---|---|---|

| AISI 316 | 225 | 650 | 40 |

| AL 6061-T6 | 250 | 290 | 14 |

| Sample No. | RPM | Travel Speed cm/min | Tilt Angle | AS | RS | Tool Offset |

|---|---|---|---|---|---|---|

| 1 | 300 | 30 | 3° | AISI 316 | AL6061 | 2 mm to Al side |

| 2 | 400 | 20 | 3° | AISI 316 | AL6061 | 2 mm to Al side |

| 3 | 500 | 20 | 3° | AISI 316 | AL6061 | 2 mm to Al side |

| 4 | 600 | 20 | 3° | AISI 316 | AL6061 | 2 mm to Al side |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Newishy, M.; Jaskari, M.; Järvenpää, A.; Fujii, H.; Abdel-Aleem, H.A. Friction Stir Welding of Dissimilar Al 6061-T6 to AISI 316 Stainless Steel: Microstructure and Mechanical Properties. Materials 2023, 16, 4085. https://doi.org/10.3390/ma16114085

Newishy M, Jaskari M, Järvenpää A, Fujii H, Abdel-Aleem HA. Friction Stir Welding of Dissimilar Al 6061-T6 to AISI 316 Stainless Steel: Microstructure and Mechanical Properties. Materials. 2023; 16(11):4085. https://doi.org/10.3390/ma16114085

Chicago/Turabian StyleNewishy, Mohamed, Matias Jaskari, Antti Järvenpää, Hidetoshi Fujii, and Hamed Ahmed Abdel-Aleem. 2023. "Friction Stir Welding of Dissimilar Al 6061-T6 to AISI 316 Stainless Steel: Microstructure and Mechanical Properties" Materials 16, no. 11: 4085. https://doi.org/10.3390/ma16114085

APA StyleNewishy, M., Jaskari, M., Järvenpää, A., Fujii, H., & Abdel-Aleem, H. A. (2023). Friction Stir Welding of Dissimilar Al 6061-T6 to AISI 316 Stainless Steel: Microstructure and Mechanical Properties. Materials, 16(11), 4085. https://doi.org/10.3390/ma16114085