The Use of Aluminosilicate Ash Microspheres from Waste Ash and Slag Mixtures in Gypsum-Lime Compositions

Abstract

1. Introduction

- -

- fly ash (dry removal, sedimentation of ash particles in cyclones and electro-filters, accumulation in silos)

- -

- fuel slags (melt precipitation at complete melting of part of the fuel in the lower part of the boiler furnace)

- -

- ash and slag mixture (wet removal, directed to the ash dump in the form of pulp).

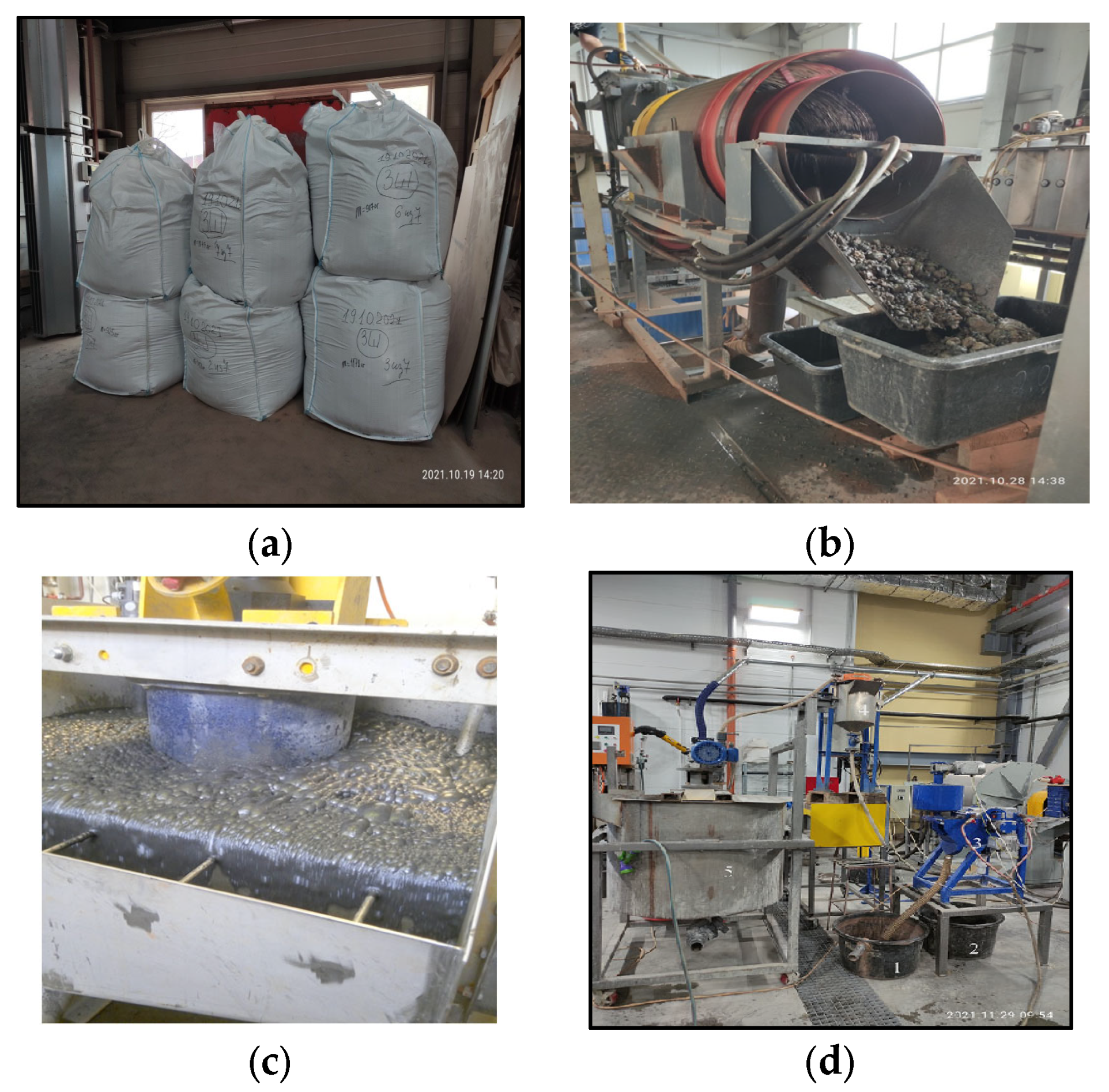

2. Materials and Methods

3. Research Results

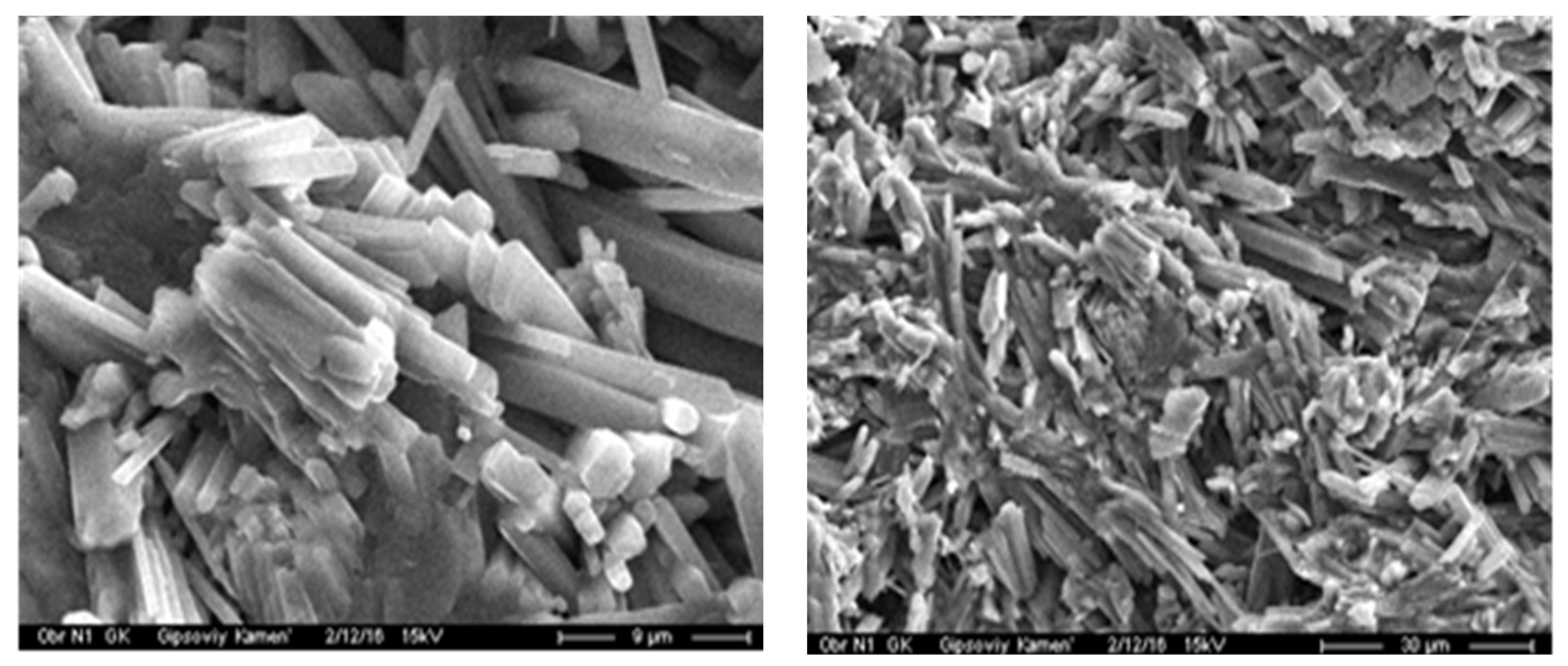

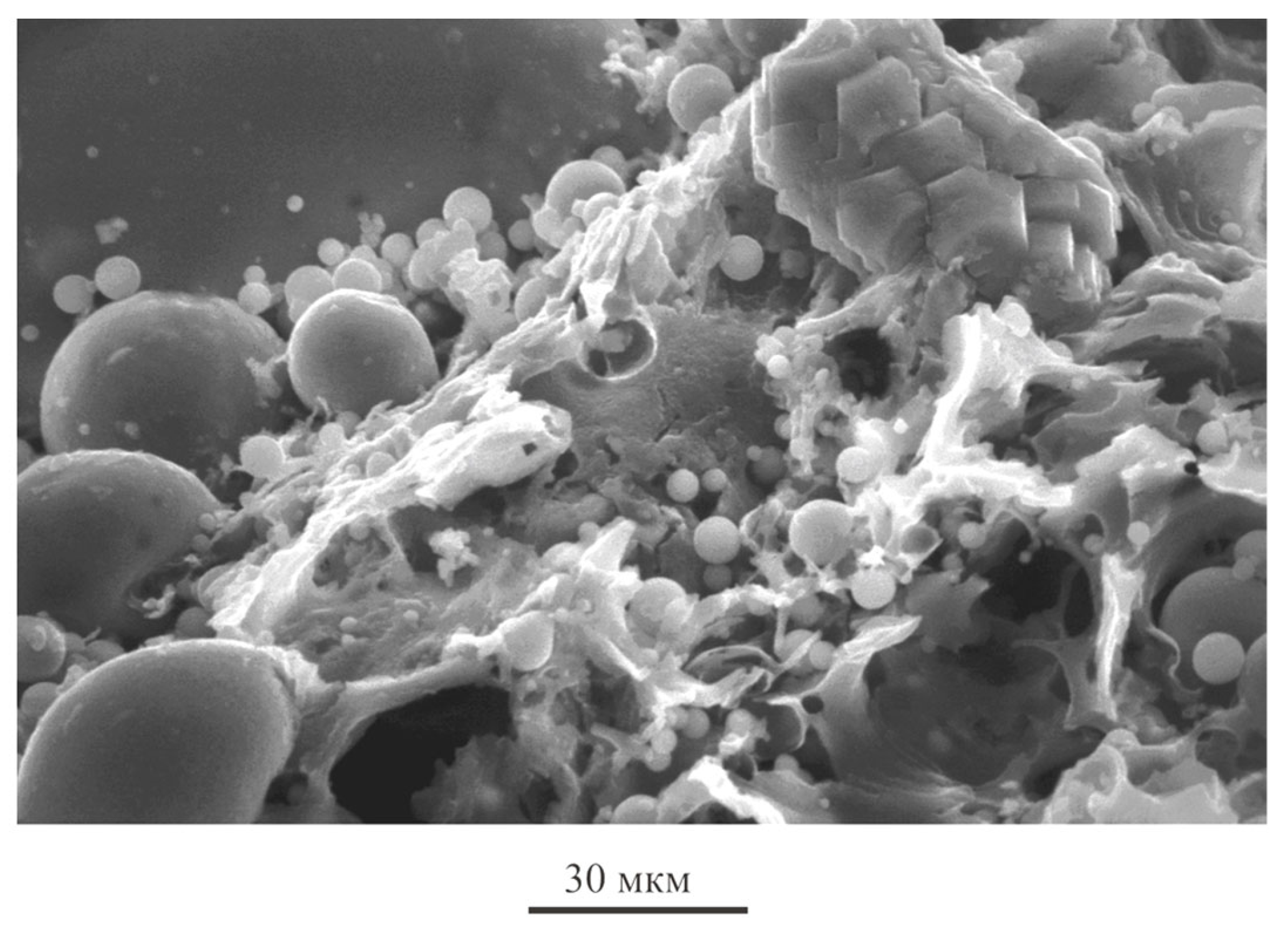

3.1. The Mineral Composition of the Composition

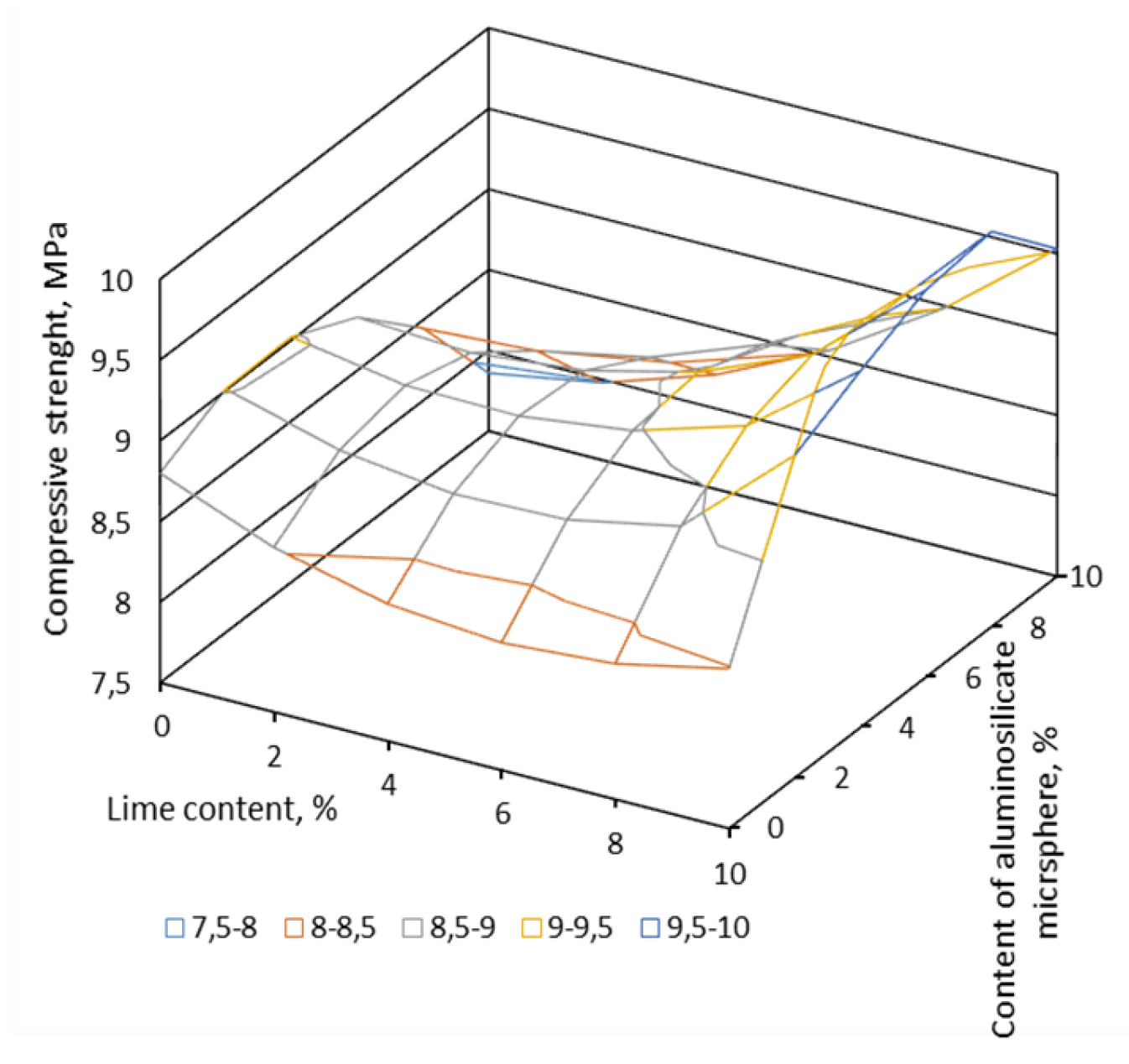

3.2. Optimization of the Prescription Composition of the Compositions

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, M.; Siddique, R.; Singh, J. Coal Fly Ash. In Sustainable Concrete Made with Ashes and Dust from Different Sources; Woodhead Publishing: Sawston, UK, 2022. [Google Scholar] [CrossRef]

- Nayak, D.; Abhilash, P.P.; Singh, R.; Kumar, R.; Kumar, V. Fly Ash for Sustainable Construction: A review of fly ash concrete and its beneficial use case studies. Civ. Eng. Archit. 2022, 10, 2686–2705. [Google Scholar] [CrossRef]

- Win, T.T.; Wattanapornprom, R.; Prasittisopin, L.; Pansuk, W.; Pheinsusom, P. Investigation of Fineness and Calcium-Oxide Content in Fly Ash from ASEAN Region on Properties and Durability of Cement-Fly Ash System. Eng. J. 2022, 26, 77–90. [Google Scholar] [CrossRef]

- Naqvi, S.; Ramkumar, J.; Kar, K. Functionalization of Fly Ash. In Handbook of Fly Ash; Butterworth-Heinemann: Oxford, UK, 2021. [Google Scholar]

- Steshenko, A.; Kudyakov, A. Cement based foam concrete with aluminosilicate microspheres for monolithic construction. Mag. Civ. Eng. 2018, 8, 86–96. [Google Scholar] [CrossRef]

- Suhas, H.B. Study on Fiber Reinforced Foamed Concrete with Ggbs and Flyash. J. Struct. Eng. 2020, 13, 15–36. [Google Scholar]

- Amran, M.; Onaizi, A.M.; Qader, D.N.; Murali, G. Innovative Use of Fly Ash-Finely Powdered Glass Cullet as a Nano Additives for a Sustainable Concrete: Strength and Microstructure and Cost Analysis. Case Stud. Constr. Mater. 2022, 17, e01688. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.; Sulman, M.; Novichenkova, T.; Petropavlovskii, K. Corrosion Resistant Fine-Grained Ash Concrete for Repairs of Constructions in the Linen Production. J. Phys. Conf. Ser. 2021, 1926, 012045. [Google Scholar] [CrossRef]

- Kosivtsov, Y.; Chalov, K.; Sulman, M.; Lugovoy, Y.; Novichenkova, T.; Petropavlovskaya, V.; Gadzhiev, S.; Popel, O. Use of Ash and Slag Waste from Thermal Power Plants as an Active Component of Building Materials. Chem. Eng. Trans. 2021, 88, 337–342. [Google Scholar] [CrossRef]

- Chinnu, S.N.; Minnu, S.N.; Bahurudeen, A.; Rajendran, S. Influence of Palm Oil Fuel Ash in Concrete and a Systematic Comparison with Widely Accepted Fly Ash and Slag: A Step Towards Sustainable Reuse of Agro-Waste Ashes. Clean. Mater. 2022, 5, 100122. [Google Scholar] [CrossRef]

- Sharbaf, M.; Najimi, M.; Ghafoori, N. A Comparative Study of Natural Pozzolan and Fly Ash: Investigation on Abrasion Resistance and Transport Properties of Self-Consolidating Concrete. Constr. Build. Mater. 2022, 346, 128330. [Google Scholar] [CrossRef]

- AzariJafari, H.; Taheri Amiri, M.J.; Ashrafian, A.; Rasekh, H. Ternary Blended Cement: An Eco-Friendly Alternative to Improve Resistivity of High-Performance Self-Consolidating Concrete Against Elevated Temperature. J. Clean. Prod. 2019, 223, 575–586. [Google Scholar] [CrossRef]

- Salih, M.A.; Ahmed, S.K.; Alsafi, S.; Al Bakri Abullah, M.M. Strength and Durability of Sustainable Self-Consolidating Concrete with High Levels of Supplementary Cementitious Materials. Materials 2022, 15, 7991. [Google Scholar] [CrossRef]

- Zommer, T.V.; Tkach, E.V.; Chernyshev, S.N.; Zommer, V.L. Disposal of Fly Ash in the Production of Ash-Concrete Within the Coal-Watercoal Cluster. E3S Web Conf. 2021, 263, 01007. [Google Scholar] [CrossRef]

- Song, H.; Yu, J.; Oh, J.E.; Suh, J.I. Production of Lightweight Cementless Binders Using Supplementary Cementitious Materials to Replace Autoclaved Aerated Concrete Blocks. J. Clean. Prod. 2022, 384, 135397. [Google Scholar] [CrossRef]

- Lin, W.-T. Development of Cementless Binder for Low Thermal Conductivity Materials: Reactive Ultra-fine Fly Ash Mixed With Co-Fired Fly Ash. Case Stud. Constr. Mater. 2022, 16, e00899. [Google Scholar] [CrossRef]

- Shah, I.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement Substitution with Secondary Materials Can Reduce Annual Global CO2 Emissions by up to 1.3 Gigatons. Springer Nature. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef]

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving Net Zero Greenhouse Gas Emissions in the Cement Industry Via Value Chain Mitigation Strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- Agbede, O.T.; Taiwo, A.M.; Adeofun, C.O.; Adetunji, M.T. Assessing the Pollution Effect of Cement Dust Emission on the Soil Quality Around Ewekoro Cement Factory, Southwestern Nigeria. Environ. Forensics 2022, 1–11. [Google Scholar] [CrossRef]

- Zvereva, E.R.; Zueva, O.S.; Gilfanov, K.K.; Tutubalina, V.P. Enrichment of Ash and Slag Waste Generated by Burning of Fuels with Additives. IOP Conf. Ser. Earth Environ. Sci. 2019, 337, 012060. [Google Scholar] [CrossRef]

- Hakimi, M.; Kiani, P.; Alikhani, M.; Feizi, N. Reducing Environmental Pollution of Fuel Fly Ash by Extraction and Removal Vanadium Pentoxide. Solid Fuel Chem. 2020, 54, 337–342. [Google Scholar] [CrossRef]

- Pervyshin, G.N.; Yakovlev, G.; Gordina, A.; Keriene, J. Water-resistant Gypsum Compositions with Man-made Modifiers. Procedia Eng. 2017, 172, 867–874. [Google Scholar] [CrossRef]

- Drebezgova, M.Y.; Chernysheva, N.V.; Klimenko, V.A.; Olisov, A.V. Architectural Design of Residential Modules Using Additive Technologies. IOP Conf. Ser. Mater. Sci. Eng. 2019, 698, 033007. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Development of Alternative Cementitious Binders for 3D Printing Applications: A Critical Review of Progress, Advantages and Challenges. Compos. Part B Eng. 2022, 252, 110492. [Google Scholar] [CrossRef]

- Potapova, E.; Guseva, T.; Shchelchkov, K.; Fischer, H.B. Mortar for 3D Printing Based on Gypsum Binders. Mater. Sci. Forum 2021, 1037, 26–31. [Google Scholar] [CrossRef]

- Jia, R.; Qiang, W.; Feng, P. A Comprehensive Overview of Fibre-Reinforced Gypsum-Based Composites (FRGCs) in the Construction Field. Compos. Part B Eng. 2021, 205, 108540. [Google Scholar] [CrossRef]

- Chumachenko, N.G.; Dergunov, S.A.; Orekhov, S.A. Energy Efficient Compositions of Dry Concrete Mixes Based on Gypsum-Bearing Systems. Procedia Eng. 2017, 150, 1591–1599. [Google Scholar] [CrossRef]

- Izryadnova, O.; Yakovlev, G.; Nurieva, L.; Sychugov, S. Role of Polyfunctional Admixture Based on Silica Fume and Carbon Nanotubes in Forming the Structure of Gypsum Cement Composition. Procedia Eng. 2015, 108, 380–386. [Google Scholar] [CrossRef]

- Pisarenko, Z.V.; Ivanov, L.A.; Wang, Q. Nanotechnology in Construction: State of the Art and Future Trends. Nanotechnologies Constr. 2022, 12, 223–231. [Google Scholar] [CrossRef]

- Zhukov, A.D.; Bessonov, I.V.; Bobrova, E.Y.; Gorbunova, E.A.; Demissie, B.A. Materials based on modified gypsum for facade systems. Nanotechnologies Constr. 2021, 13, 144–149. [Google Scholar] [CrossRef]

- Lesovik, V.; Drebezgova, M.; Fediuk, R. Fast-Curing Composites Based on Multicomponent Gypsum Binders. J. Mater. Civ. Eng. 2020, 32, 04020234. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales Conde, M.J.; Pérez-Gálvez, F.; Rubio de Hita, P. Influence of Polycarbonate Waste on Gypsum Composites: Mechanical and Environmental Study. J. Clean. Prod. 2019, 218, 21–37. [Google Scholar] [CrossRef]

- Erbs, A.; Nagalli, A.; Mymrin, V.; Passig, F.H. Properties of Recycled Gypsum from Gypsum Plasterboards and Commercial Gypsum Throughout Recycling Cycles. J. Clean. Prod. 2018, 183, 1314–1322. [Google Scholar] [CrossRef]

- Petropavlovskii, K.; Novichenkova, T.; Petropavlovskaya, V.; Sulman, M.; Fediuk, R.; Amran, M. Faience Waste for the Production of Wall Products. Materials 2021, 14, 6677. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.; Zavadko, M.; Novichenkova, T.; Sulman, M.; Buryanov, A. Effective Building Mixtures Based on Hemihydrate Plaster and Highly Dispersed Mineral Fillers. J. Phys. Conf. Ser. 2021, 1926, 012056. [Google Scholar] [CrossRef]

- Aleksandrova, O.V.; Quang, N.D.V.; Bulgakov, B.I.; Fedosov, S.V.; Lukyanova, N.A.; Petropavlovskaya, V.B. The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete. Materials 2022, 15, 8851. [Google Scholar] [CrossRef]

- Bulgakov, B.I.; Nguyen, V.Q.D.; Aleksandrova, A.V.; Larsen, O.A.; Galtseva, N.A. High-Performance Concrete Produced with Locally Available Materials. Mag. Civ. Eng. 2023, 117, 11702. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.; Sulman, M.; Kosivtsov, Y.; Zavadko, M.; Petropavlovskii, K. Gypsum Composition with a Complex Based on Industrial Waste. Chem. Eng. Trans. 2021, 88, 1009–1014. [Google Scholar] [CrossRef]

- Jamee, M.A.; Al-Asadi, L.; Hacheem, Z.; Al-Ridha, A.S.D. Effect of Chopped Carbon Fibre (CCF) on Enhancing the Compressive Strength and Density of Gypsum Plaster. Mater. Today Proc. 2022, 62, 4539–4544. [Google Scholar] [CrossRef]

- Bostanci, S.C. Coal Ash Use as a Cement Replacement in Concrete Production. IOP Conf. Ser. Mater. Sci. Eng. 2020, 800, 012010. [Google Scholar] [CrossRef]

- Kuntikana, G.; Singh, D.N. Contemporary Issues Related to Utilization of Industrial Byproducts. Adv. Civ. Eng. Mater. 2017, 6, 20160050. [Google Scholar] [CrossRef]

- Hilal, N.N.; Rajab, N.A.; Faraj, R.H. Fresh Behavior and Hardened Properties of Self-Compacting Concrete Containing Coal Ash and Fly Ash as Partial Replacement of Cement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 978, 012005. [Google Scholar] [CrossRef]

- Klimenko, V.G. Influence of Modifying Composition of Gypsum Binders on the Structure of Composite Materials. J. Phys. Conf. Ser. 2018, 1118, 012019. [Google Scholar] [CrossRef]

- GOST 9179-2018; Lime for Building Purposes. Specifications. RussianGost: Moscow, Russia, 2018.

- GOST 23789-2018; Gypsum Binders. Test Methods. RussianGost: Moscow, Russia, 2018.

- GOST R 58766-2019; Building Solutions. General Specifications. RussianGost: Moscow, Russia, 2019.

- GOST 31358-2019; Floor Screeds: Specifications. RussianGost: Moscow, Russia, 2019.

- GOST 31376-2008; Dry Building Mixtures Based on Gypsum Binder: Test Methods. RussianGost: Moscow, Russia, 2008.

| SiO2 | MgO | CaO | Fe2O3 | K2O | Al2O3 | MnO | TiO2 | P2O5 | SiO3 | C | Na2O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 57.38 | 1.68 | 4.42 | 4.83 | 2.21 | 24.9 | 0.11 | 0.95 | 0.42 | 0.11 | 3.36 | 0.63 |

| N° | Gypsum | Anhydrite | Calcite | Dolomite | Ettringite | Quartz | Nacrite |

|---|---|---|---|---|---|---|---|

| 1 | 72.1 | 0.5 | 15.9 | 4.7 | 5.3 | 1.5 | - |

| 2 | 64.5 | 0.8 | 12.9 | 3.6 | 13.4 | 2.6 | 2.2 |

| Spectrum | O | Mg | Al | Si | S | K | Ca | Fe | Result |

|---|---|---|---|---|---|---|---|---|---|

| in weight % | |||||||||

| Spectrum 1 | 59.26 | 2.67 | 8.39 | 19.78 | 1.61 | 1.88 | 4.01 | 2.40 | 100.00 |

| Spectrum 2 | 62.67 | 0.19 | 0.66 | 15.90 | 20.58 | 100.00 | |||

| Spectrum 3 | 57.81 | 0.32 | 0.26 | 1.02 | 16.81 | 23.77 | 100.00 | ||

| Max | 62.67 | 2.67 | 8.39 | 19.78 | 16.81 | 1.88 | 23.77 | 2.40 | |

| Min | 57.81 | 0.32 | 0.19 | 0.66 | 1.61 | 1.88 | 4.01 | 2.40 | |

| in atomic % | |||||||||

| Spectrum 1 | 73.05 | 2.16 | 6.13 | 13.89 | 0.99 | 0.95 | 1.97 | 0.85 | |

| Spectrum 2 | 79.02 | 0.15 | 0.47 | 10.00 | 10.36 | ||||

| Spectrum 3 | 75.43 | 0.28 | 0.20 | 0.76 | 10.95 | 12.38 | |||

| Max | 79.02 | 2.16 | 6.13 | 13.89 | 10.95 | 0.95 | 12.38 | 0.85 | |

| Min | 73.05 | 0.28 | 0.15 | 0.47 | 0.99 | 0.95 | 1.97 | 0.85 | |

| Components, Mass. % | Composition 1 | Composition 2 |

|---|---|---|

| Gypsum binder G-4 grade | 85.48 | - |

| Gypsum binder G-5 grade | - | 85.48 |

| Lime slaked | 7.8 | 7.8 |

| Aluminosilicate microsphere | 6.3 | 6.3 |

| Hyperplasticizer | 0.13 | 0.13 |

| Powder defoamer | 0.13 | 0.13 |

| Wine acid | 0.05 | 0.05 |

| Water retention additive | 0.05 | 0.05 |

| Shrinkage compensator | 0.06 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petropavlovskaya, V.; Zavadko, M.; Novichenkova, T.; Petropavlovskii, K.; Sulman, M. The Use of Aluminosilicate Ash Microspheres from Waste Ash and Slag Mixtures in Gypsum-Lime Compositions. Materials 2023, 16, 4213. https://doi.org/10.3390/ma16124213

Petropavlovskaya V, Zavadko M, Novichenkova T, Petropavlovskii K, Sulman M. The Use of Aluminosilicate Ash Microspheres from Waste Ash and Slag Mixtures in Gypsum-Lime Compositions. Materials. 2023; 16(12):4213. https://doi.org/10.3390/ma16124213

Chicago/Turabian StylePetropavlovskaya, Victoria, Maria Zavadko, Tatiana Novichenkova, Kirill Petropavlovskii, and Mikhail Sulman. 2023. "The Use of Aluminosilicate Ash Microspheres from Waste Ash and Slag Mixtures in Gypsum-Lime Compositions" Materials 16, no. 12: 4213. https://doi.org/10.3390/ma16124213

APA StylePetropavlovskaya, V., Zavadko, M., Novichenkova, T., Petropavlovskii, K., & Sulman, M. (2023). The Use of Aluminosilicate Ash Microspheres from Waste Ash and Slag Mixtures in Gypsum-Lime Compositions. Materials, 16(12), 4213. https://doi.org/10.3390/ma16124213