Development of Pore Pressure in Cementitious Materials under Low Thermal Effects: Evidence from Optimization of Pore Structure by Incorporation of Fly Ash

Abstract

1. Introduction

2. Materials and Experimental Procedures

2.1. Materials and Matching Ratio

2.1.1. Materials

2.1.2. Matching Ratio

2.2. Design of Pore Pressure Measurement Test

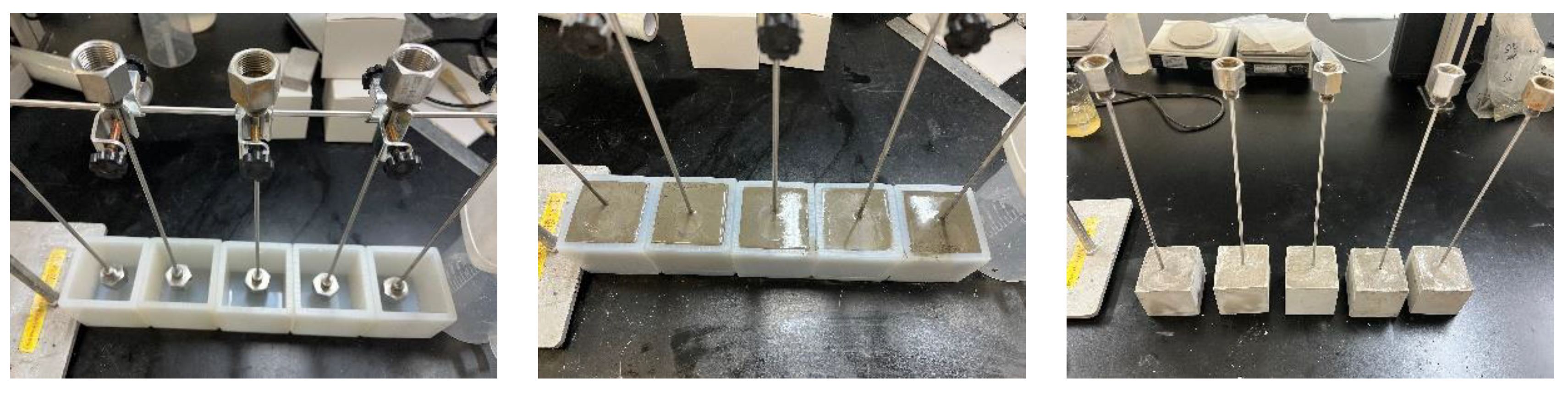

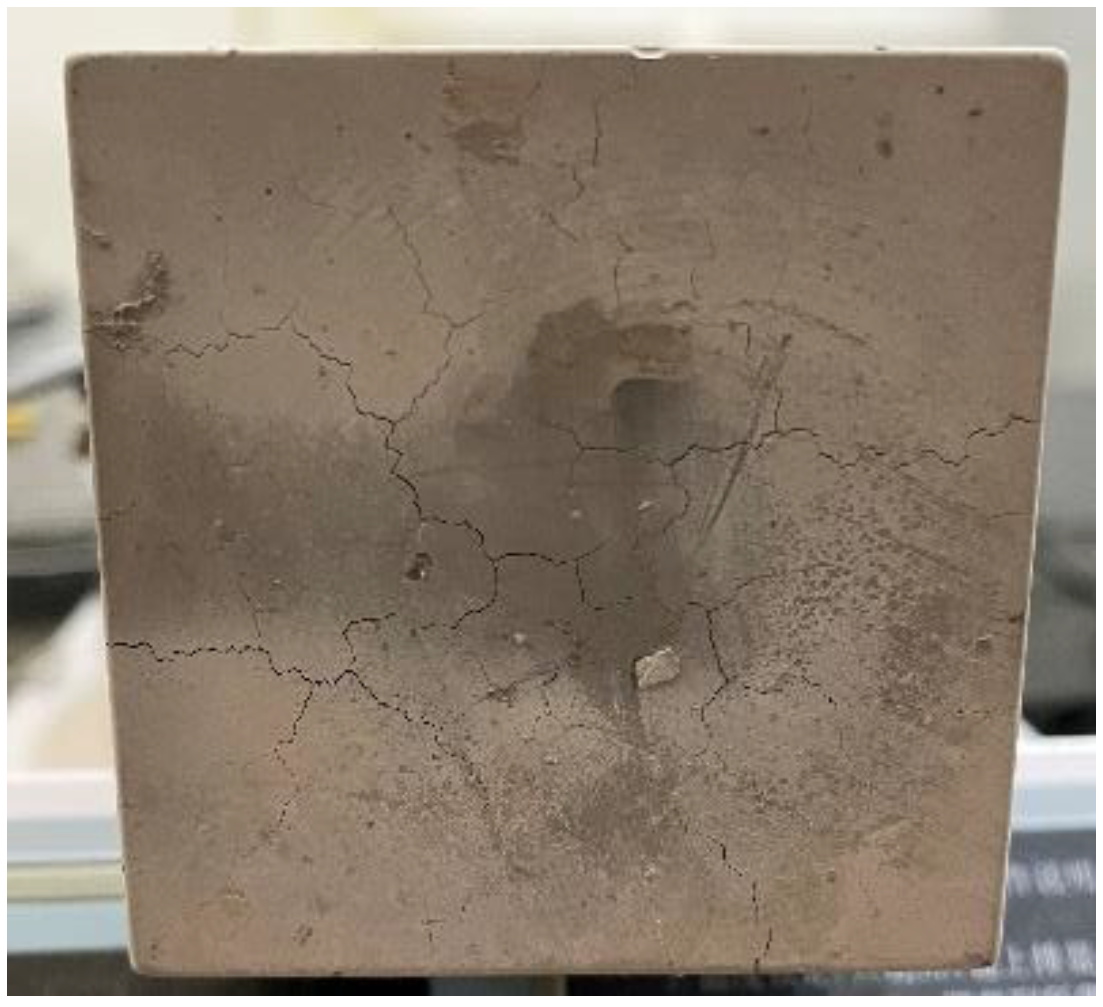

2.2.1. The Preparation Process of Cement Paste Test Block

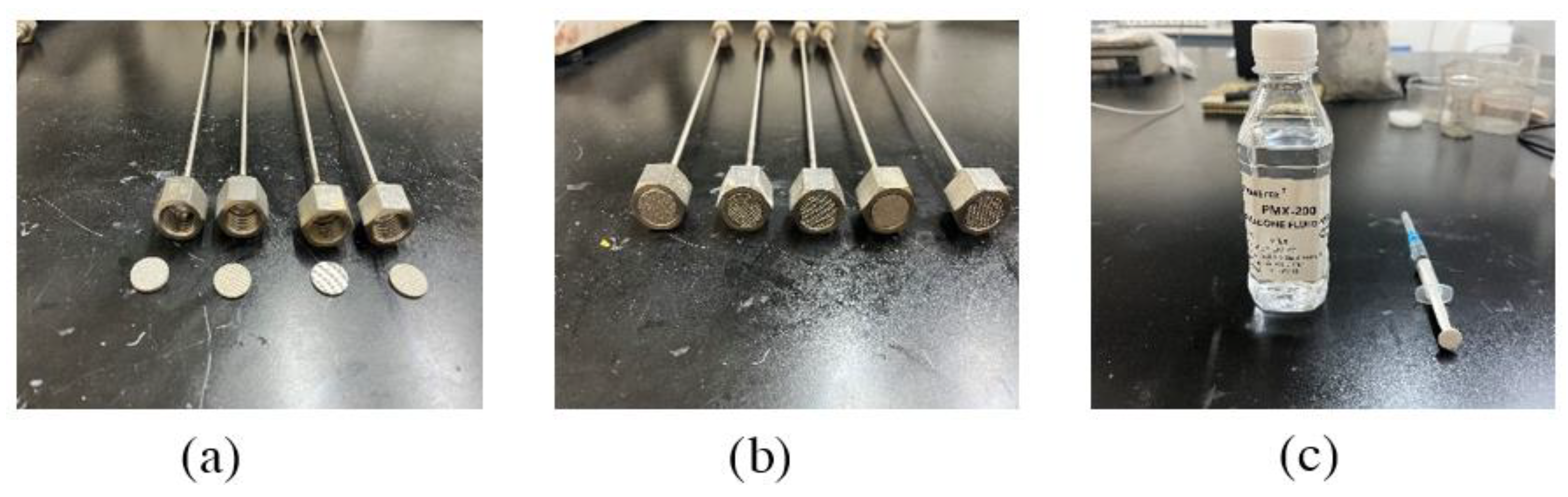

2.2.2. Test Device and Method

2.2.3. Connection and Installation of Cement Paste Specimen and Test Device

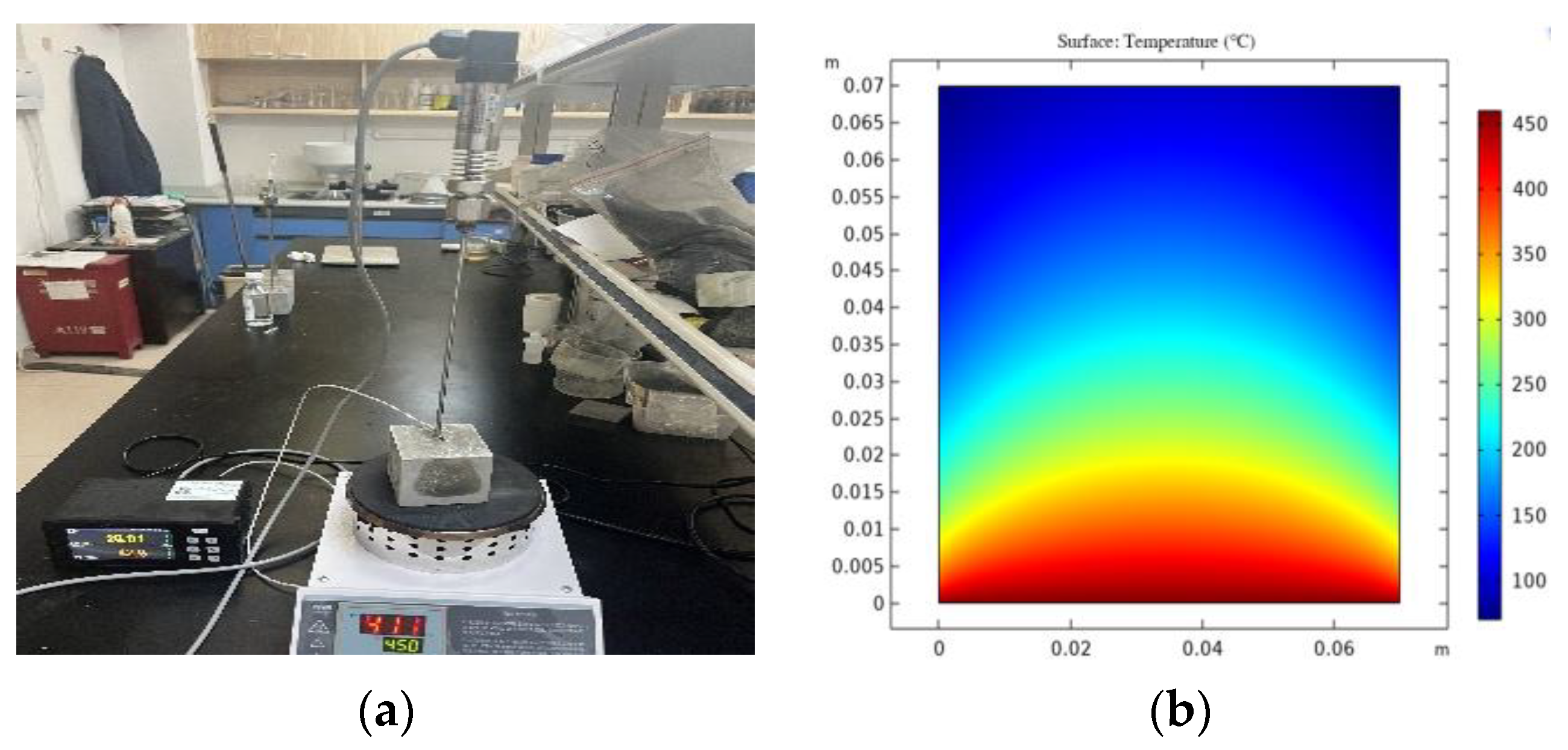

2.2.4. Test Process

2.3. Mercury Compression Test of Cement Paste Specimens

2.3.1. Preparation of Mercury-Pressed Specimens

2.3.2. Mercury-Pressing Experimental Apparatus

3. Phase-Field Simulation of Pore Pressure Inside the Cement Paste

3.1. Model Building

3.1.1. Assumption of Ideal Conditions

- (a)

- The cement paste is considered a continuous isotropic homogeneous porous medium.

- (b)

- It is assumed that only water vapor generates pressure in the internal pores of the cement paste, neglecting the effect of internal air (since the air content is relatively small) and considering water vapor as an ideal gas.

- (c)

- The cement paste is assumed to be saturated and fully hydrated at room temperature (i.e., the internal hydrates are considered to no longer undergo hydration reactions).

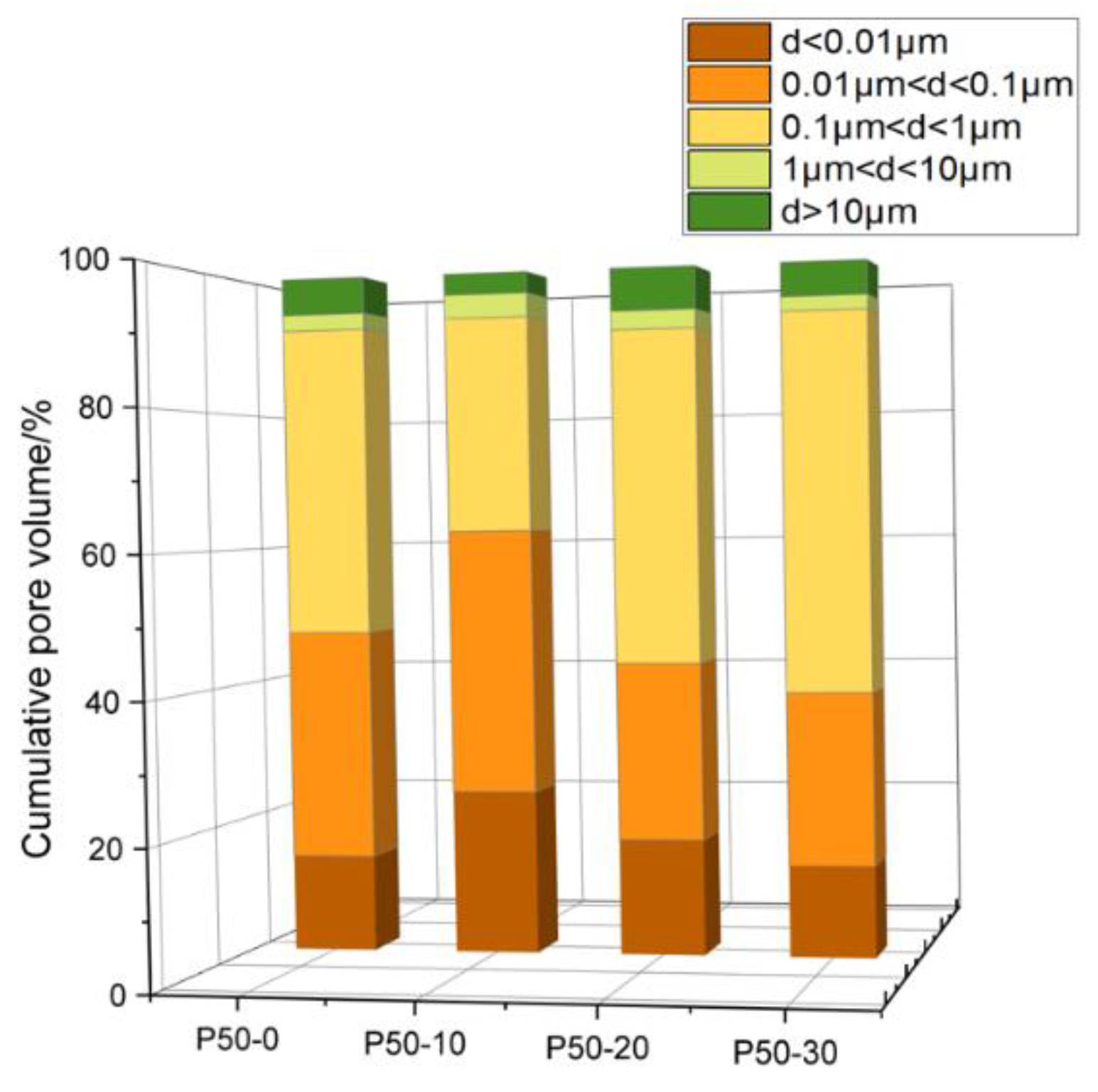

3.1.2. Pore Size Selection

3.1.3. Parameter Selection

4. Test Results and Analysis

4.1. Test Results and Analysis of Cement Paste Pore Pressure under High Temperature

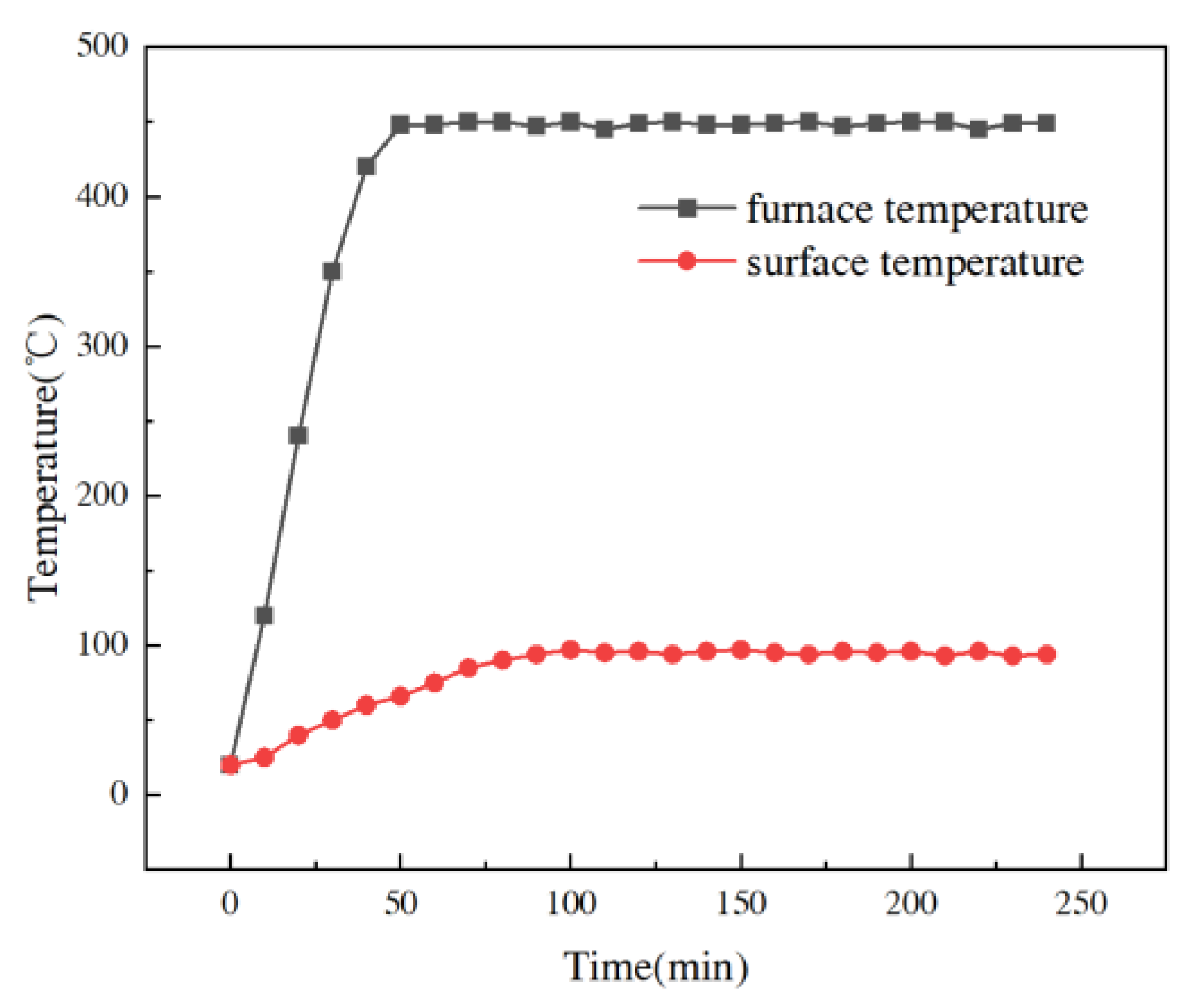

4.1.1. Temperature–Time Curve

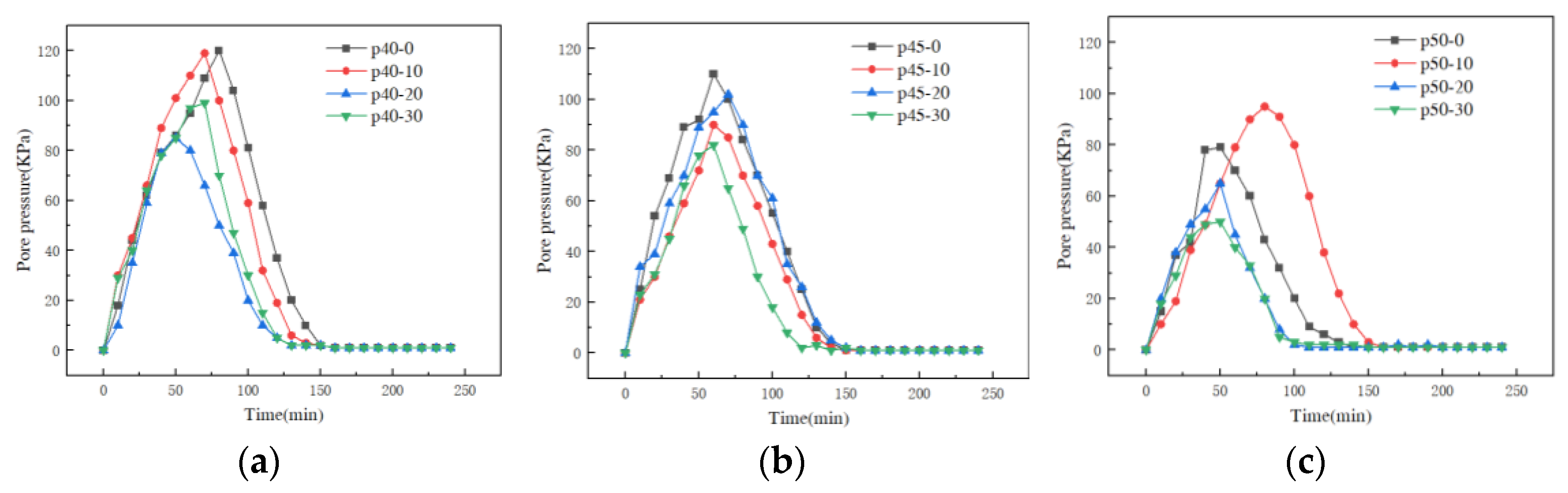

4.1.2. Pressure–Time Curve

4.2. Effective Pore Pressure of Cement Paste Specimens with Measured Analysis

4.2.1. Effective Pore Pressure of Cement-Based Materials

4.2.2. Numerical Calculation Results of the Average Effective Pore Pressure

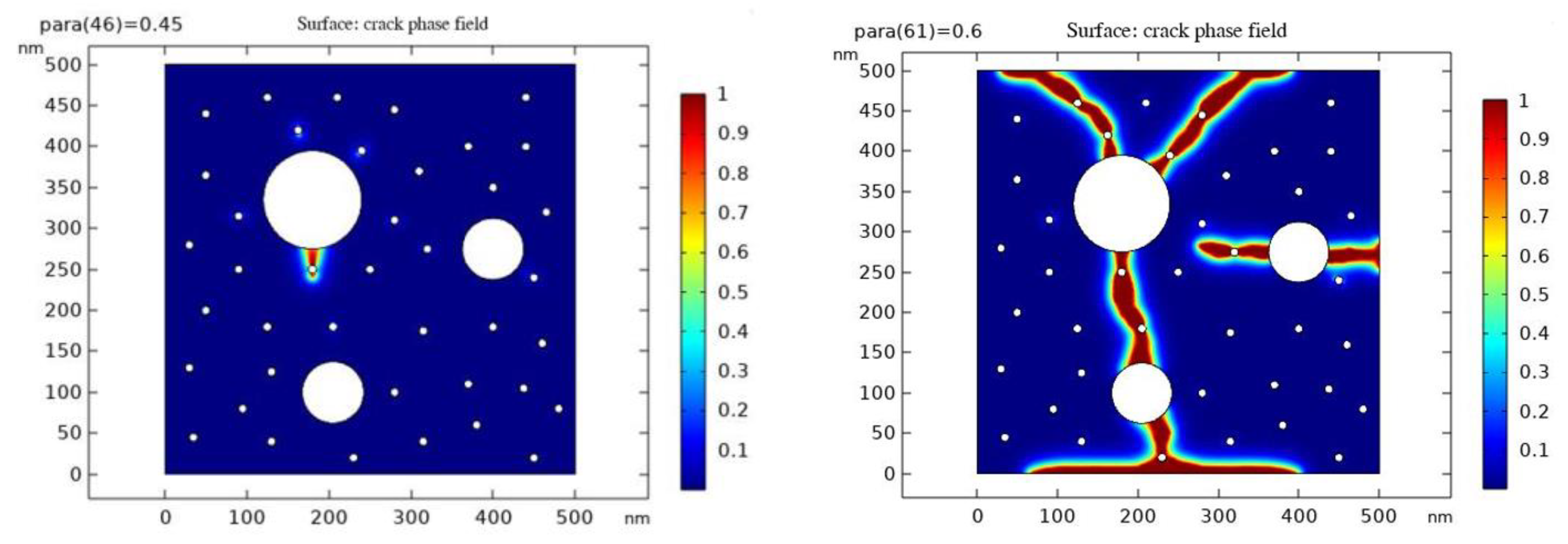

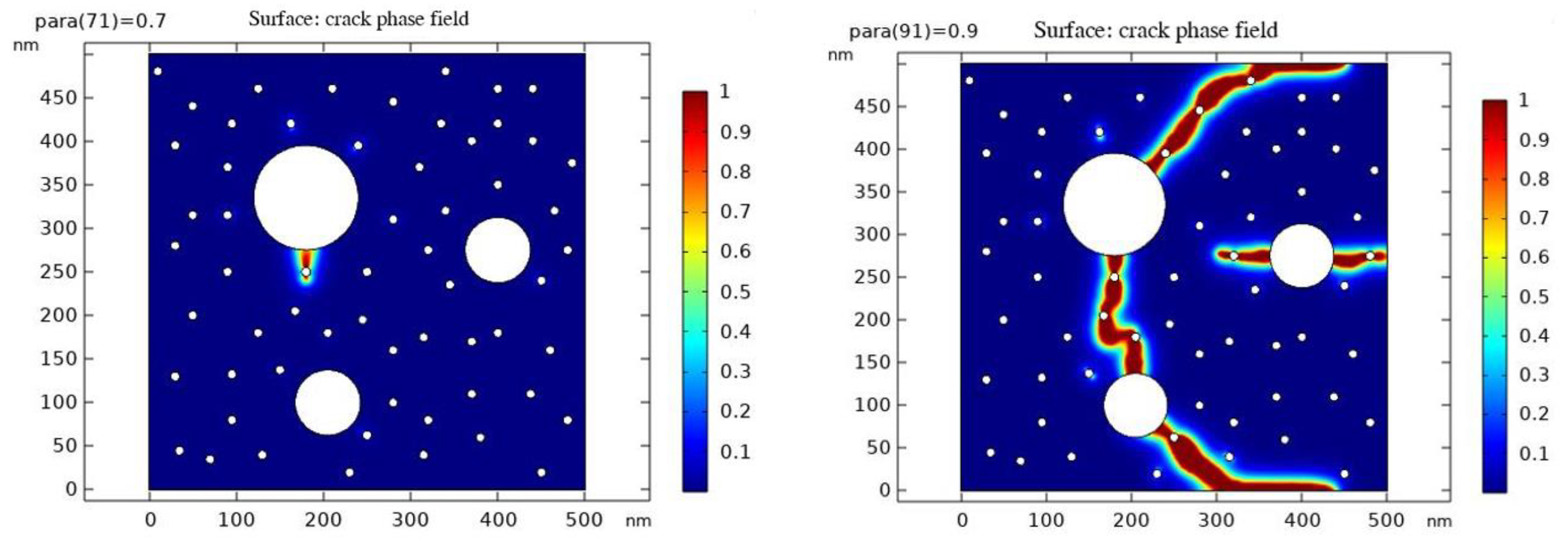

4.3. Simulation of Microscopic Crack Development by Phase-Field Method

- (1)

- Crack sprouting and development in group P50-0

- (2)

- P50-10 group crack sprouting and development

5. Conclusions

- (1)

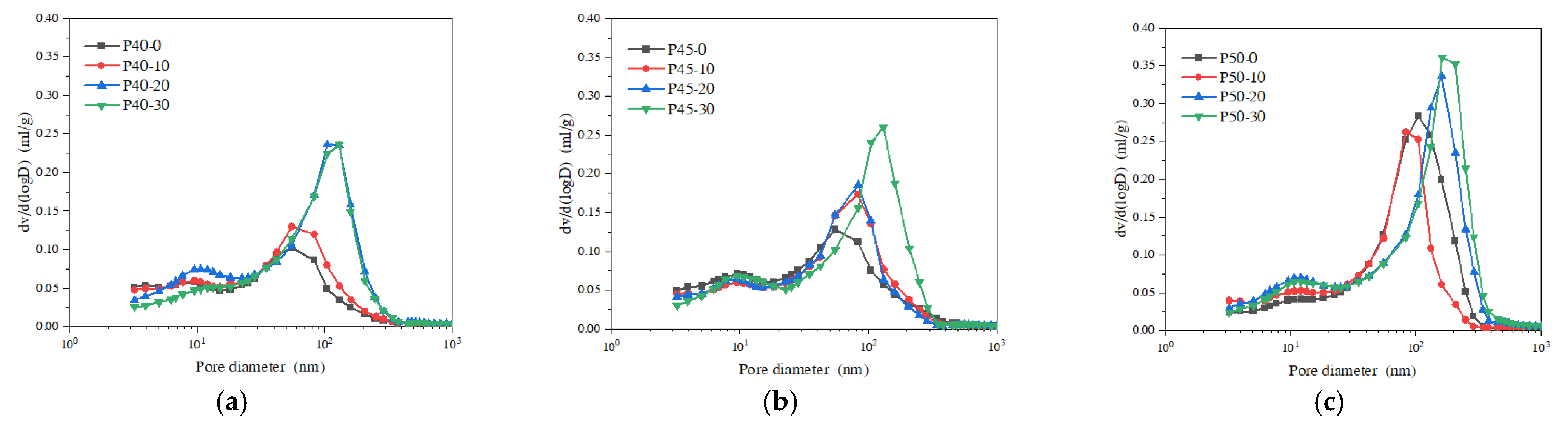

- As the water–binder ratio increases, the pore size where the differential pore distribution peak of the specimen is located gradually becomes larger, and the pore pressure test peak gradually decreases. This is because when the water-ash increases, the crystallization nucleation and crystal growth of hydration products are weakened, slowing down the degree of hydration reaction in the early stage of the net slurry, and the compactness of the specimen decreases, and the pore pressure required to produce cracks in the micro-pore structure becomes smaller.

- (2)

- The physical action of the fly ash and volcanic ash reaction has important effects on the pore structure of cement paste. In the early stage of hydration, the incorporation of fly ash can reduce the water requirement of cement paste and improve the hydration of cement. When the fly ash admixture is 30%, the specimen appears relatively large with respect to porosity, and with an increase in fly ash admixture, its volcanic ash effect leads to a large number of connected capillaries, which increases the porosity of the specimen and therefore leads to a decrease in pore pressure.

- (3)

- The larger the characteristic pore size of the net slurry, the smaller its average effective pore pressure; the theoretically calculated pore pressure value and the pore pressure value obtained from the test have the same variation trend.

- (4)

- The results of simulating crack development by the phase field method show that when 10% fly ash is added, there is a significant delay in the sprouting and development of cracks. The results in the pore pressure test are verified: when 10% fly ash is added to the P50-0 group, its porosity decreases from 29.6% to 26.5%, the pore size where the differential pore distribution peak is located becomes smaller, the compactness of the specimen rises, and the micro-pore structure requires greater pore pressure to produce micro-cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhong, R.; Wille, K. Influence of Matrix and Pore System Characteristics on the Durability of Pervious Concrete. Constr. Build. Mater. 2018, 162, 132–141. [Google Scholar] [CrossRef]

- Adediran, A.; Yliniemi, J.; Carvelli, V.; Adesanya, E.; Illikainen, M. Durability of Alkali-Activated Fe-Rich Fayalite Slag-Based Mortars Subjected to Different Environmental Conditions. Cem. Concr. Res. 2022, 162, 106984. [Google Scholar] [CrossRef]

- Shpak, A.; Gong, F.; Jacobsen, S. Frost Durability of High-Volume Fly Ash Concrete: Relation Liquid Transport-Damage. Cem. Concr. Res. 2023, 163, 107017. [Google Scholar] [CrossRef]

- Shen, D.; Jiang, J.; Wang, W.; Shen, J.; Jiang, G. Tensile Creep and Cracking Resistance of Concrete with Different Water-To-Cement Ratios at Early Age. Constr. Build. Mater. 2017, 146, 410–418. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallization in Pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Powers, T.C. A Working Hypothesis for Further Studies of Frost Resistance of Concrete. J. Am. Concr. 1945, 16, 245–272. [Google Scholar]

- Chen, D.; Deng, Y.; Shen, J.; Sun, G.; Shi, J. Study On Damage Rules On Concrete Under Corrosion of Freeze-Thaw and Saline Solution. Constr. Build. Mater. 2021, 304, 124617. [Google Scholar] [CrossRef]

- Felicetti, R.; Monte, F.L.; Pimienta, P. A New Test Method to Study the Influence of Pore Pressure On Fracture Behaviour of Concrete During Heating. Cem. Concr. Res. 2017, 94, 13–23. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.; Fen-chong, T.; Dangla, P. Pore Structure Characterization of Cement Pastes Blended with High-Volume Fly-Ash. Cem. Concr. Res. 2012, 42, 194–204. [Google Scholar] [CrossRef]

- Zeng, Q.; Fen-Chong, T.; Li, K. Freezing Behavior of Cement Pastes Saturated with Nacl Solution. Constr. Build. Mater. 2014, 59, 99–110. [Google Scholar] [CrossRef]

- Feng, W.C.; Bin, J.D.; Qiang, Y.Z.; Liu, L. Analysis of High-Permeable Concrete Pavement Heat Transfer Mechanism. Adv. Mat. Res. 2010, 168–170, 859–863. [Google Scholar]

- Mindeguia, J.; Pimienta, P.; Noumowé, A.; Kanema, M. Temperature, Pore Pressure and Mass Variation of Concrete Subjected to High Temperature—Experimental and Numerical Discussion On Spalling Risk. Cem. Concr. Res. 2010, 40, 477–487. [Google Scholar] [CrossRef]

- Phan, L.T. Pore Pressure and Explosive Spalling in Concrete. Mater. Struct. 2008, 41, 1623–1632. [Google Scholar] [CrossRef]

- Ju, Y.; Yang, Y.; Peng, R.; Mao, L. Effects of Pore Structures on Static Mechanical Properties of Sandstone. J. Geotech. Geoenviron. 2013, 139, 1745–1755. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, A.; Amin, M.N.; Ahmad, W.; Nazar, S.; Arab, A.M.A. Comparative Study of Experimental and Modeling of Fly Ash-Based Concrete. Materials 2022, 15, 3762. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N.; Saleem, M.U.; Qureshi, H.J.; Al-Faiad, M.A.; Qadir, M.G. Effect of Fineness of Basaltic Volcanic Ash On Pozzolanic Reactivity, Asr Expansion and Drying Shrinkage of Blended Cement Mortars. Materials 2019, 12, 2603. [Google Scholar] [CrossRef]

- Wang, H.; Hellmich, C.; Yuan, Y.; Mang, H.; Pichler, B. May Reversible Water Uptake/Release by Hydrates Explain the Thermal Expansion of Cement Paste?—Arguments From an Inverse Multiscale Analysis. Cem. Concr. Res. 2018, 113, 13–26. [Google Scholar] [CrossRef]

- Du, H.; Zhang, M. Experimental investigation of thermal pore pressure in reinforced C80 high performance concrete slabs at elevated temperatures. Constr. Build. Mater. 2020, 260, 120451. [Google Scholar] [CrossRef]

- Li, Y.; Yang, E.; Zhou, A.; Liu, T. Pore Pressure Build-Up and Explosive Spalling in Concrete at Elevated Temperature: A Review. Constr. Build. Mater. 2021, 284, 122818. [Google Scholar] [CrossRef]

- Toropovs, N.; Lo Monte, F.; Wyrzykowski, M.; Weber, B.; Sahmenko, G.; Vontobel, P.; Felicetti, R.; Lura, P. Real-Time Measurements of Temperature, Pressure and Moisture Profiles in High-Performance Concrete Exposed to High Temperatures During Neutron Radiography Imaging. Cem. Concr. Res. 2015, 68, 166–173. [Google Scholar] [CrossRef]

- Badmann, R.; Stockhausen, N.; Setzer, M.J. The Statistical Thickness and the Chemical Potential of Adsorbed Water Films. J. Colloid Interf. Sci. 1981, 82, 534–542. [Google Scholar] [CrossRef]

- Pichler, B.; Dormieux, L. Cracking Risk of Partially Saturated Porous Media—Part I: Microporoelasticity Model. Int. J. Numer. Anal. Met. 2010, 34, 135–157. [Google Scholar] [CrossRef]

- Dormieux, L.; Kondo, D.; Ulm, F.J. Microporomechanics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Iwama, K.; Higuchi, K.; Maekawa, K. Thermo-Mechanistic Multi-Scale Modeling of Structural Concrete at High Temperature. J. Adv. Concr. Technol. 2020, 18, 272–293. [Google Scholar] [CrossRef]

- Huang, Q.; Jiang, Z.; Gu, X.; Zhang, W.; Guo, B. Numerical Simulation of Moisture Transport in Concrete Based On a Pore Size Distribution Model. Cem. Concr. Res. 2015, 67, 31–43. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Lura, P. Moisture Dependence of Thermal Expansion in Cement-Based Materials at Early Ages. Cem. Concr. Res. 2013, 53, 25–35. [Google Scholar] [CrossRef]

- Miehe, C.; Welschinger, F.; Hofacker, M. Thermodynamicallyconsistentphase-Fieldmodelsoffracture: Variationalprinciples and Multi-Fieldfeimplementations. Int. J. Numer. Methods Eng. 2010, 83, 39. [Google Scholar]

- Borden, M.J.; Verhoosel, C.V.; Scott, M.A.; Hughes, T.J.R.; Landis, C.M. A Phase-Field Description of Dynamic Brittle Fracture. Comput. Meth. Appl. Mech. Eng. 2012, 217–220, 77–95. [Google Scholar] [CrossRef]

| Composition | Cement (%) | Fly Ash (%) |

|---|---|---|

| CaO | 66.41 | 7.88 |

| SiO2 | 20.99 | 52.50 |

| Fe2O3 | 3.44 | 3.42 |

| SO3 | 2.40 | 1.47 |

| Al2O3 | 4.43 | 27.43 |

| K2O | 0.71 | 1.15 |

| MgO | 0.87 | 1.05 |

| P2O5 | 0.12 | 0.47 |

| Others | 0.62 | 4.63 |

| W/B | Sample | Cement (kg/m3) | Fly Ash (kg/m3) | Water (kg/m3) | Fly Ash Content (%) |

|---|---|---|---|---|---|

| 0.4 | P40-0 | 1368 | 0 | 547 | 0 |

| P40-10 | 1204 | 134 | 535 | 10 | |

| P40-20 | 1052 | 263 | 526 | 20 | |

| P40-30 | 900 | 385 | 514 | 30 | |

| 0.45 | P45-0 | 1231 | 0 | 578 | 0 |

| P45-10 | 1130 | 113 | 565 | 10 | |

| P45-20 | 986 | 247 | 555 | 20 | |

| P45-30 | 843 | 361 | 542 | 30 | |

| 0.5 | P50-0 | 1218 | 0 | 609 | 0 |

| P50-10 | 1078 | 120 | 599 | 10 | |

| P50-20 | 941 | 235 | 588 | 20 | |

| P50-30 | 805 | 345 | 575 | 30 |

| Parameters | Value (P50-0) | Value (P50-10) |

|---|---|---|

| Density | 1.2 g/cm3 | 1.1 g/cm3 |

| Conductivity of Heat | 0.65 W/m·K | 0.69 W/m·K |

| Specific Heat Capacity | 1.88 kJ/(kg·K) | 2.02 kJ/(kg·K) |

| Modulus of Elasticity | 17.4 GPa | 18.5 GPa |

| Sample | Porosity | Peak Pore Pressure (kPa) | Peak Corresponding Time (min) |

|---|---|---|---|

| P40-0 | 21.1088 | 121 | 80 |

| P40-10 | 23.2357 | 119 | 71 |

| P40-20 | 28.4297 | 85 | 50 |

| P40-30 | 26.5230 | 99 | 69 |

| P45-0 | 24.4409 | 110 | 61 |

| P45-10 | 26.9927 | 90 | 58 |

| P45-20 | 25.1176 | 102 | 70 |

| P45-30 | 28.7912 | 82 | 60 |

| P50-0 | 29.6131 | 79 | 50 |

| P50-10 | 26.5323 | 95 | 80 |

| P50-20 | 30.8705 | 65 | 54 |

| P50-30 | 31.9042 | 50 | 50 |

| Sample | Characteristic Pore Diameter (nm) | RH=0.90 (MPa) | RH=0.95 (MPa) | RH=0.98 (MPa) |

|---|---|---|---|---|

| P40-0 | 27.61 | 8.533 | 5.486 | 2.613 |

| P40-10 | 27.59 | 8.534 | 5.486 | 2.613 |

| P40-20 | 52.52 | 6.080 | 4.270 | 2.334 |

| P40-30 | 65.46 | 5.336 | 3.843 | 2.196 |

| P45-0 | 27.61 | 8.533 | 5.486 | 2.613 |

| P45-10 | 41.45 | 6.942 | 4.731 | 2.460 |

| P45-20 | 41.65 | 6.924 | 4.722 | 2.458 |

| P45-30 | 65.55 | 5.332 | 3.840 | 2.19512 |

| P50-0 | 52.55 | 6.078 | 4.268 | 2.334 |

| P50-10 | 41.55 | 6.933 | 4.726 | 2.459 |

| P50-20 | 80.45 | 4.696 | 3.455 | 2.052 |

| P50-30 | 81.15 | 4.670 | 3.439 | 2.046 |

| Sample | Crack Initiation Pore Pressure (kPa) | Crack through Hole Pressure (kPa) | Peak Pore Pressure Time (min) |

|---|---|---|---|

| P50-0 | 45 | 60 | 50 |

| P50-10 | 70 | 90 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, W.; Zhang, D.; Zheng, X.; Li, W. Development of Pore Pressure in Cementitious Materials under Low Thermal Effects: Evidence from Optimization of Pore Structure by Incorporation of Fly Ash. Materials 2023, 16, 4214. https://doi.org/10.3390/ma16124214

Jiang W, Zhang D, Zheng X, Li W. Development of Pore Pressure in Cementitious Materials under Low Thermal Effects: Evidence from Optimization of Pore Structure by Incorporation of Fly Ash. Materials. 2023; 16(12):4214. https://doi.org/10.3390/ma16124214

Chicago/Turabian StyleJiang, Wei, Dandan Zhang, Xinyue Zheng, and Wenqian Li. 2023. "Development of Pore Pressure in Cementitious Materials under Low Thermal Effects: Evidence from Optimization of Pore Structure by Incorporation of Fly Ash" Materials 16, no. 12: 4214. https://doi.org/10.3390/ma16124214

APA StyleJiang, W., Zhang, D., Zheng, X., & Li, W. (2023). Development of Pore Pressure in Cementitious Materials under Low Thermal Effects: Evidence from Optimization of Pore Structure by Incorporation of Fly Ash. Materials, 16(12), 4214. https://doi.org/10.3390/ma16124214