Experimental Study on the Shear Strength and Failure Mechanism of Cemented Soil–Concrete Interface

Abstract

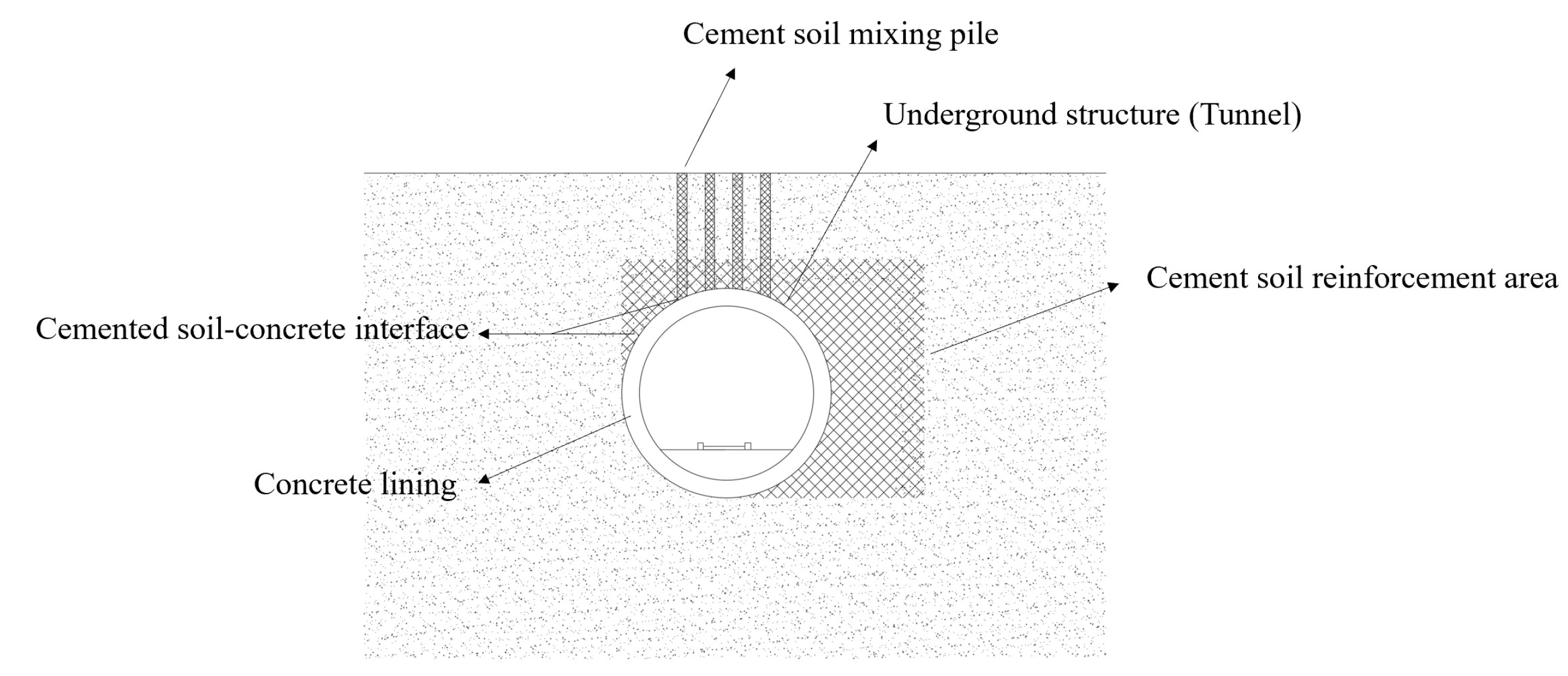

:1. Introduction

2. Materials and Methods

2.1. Materials

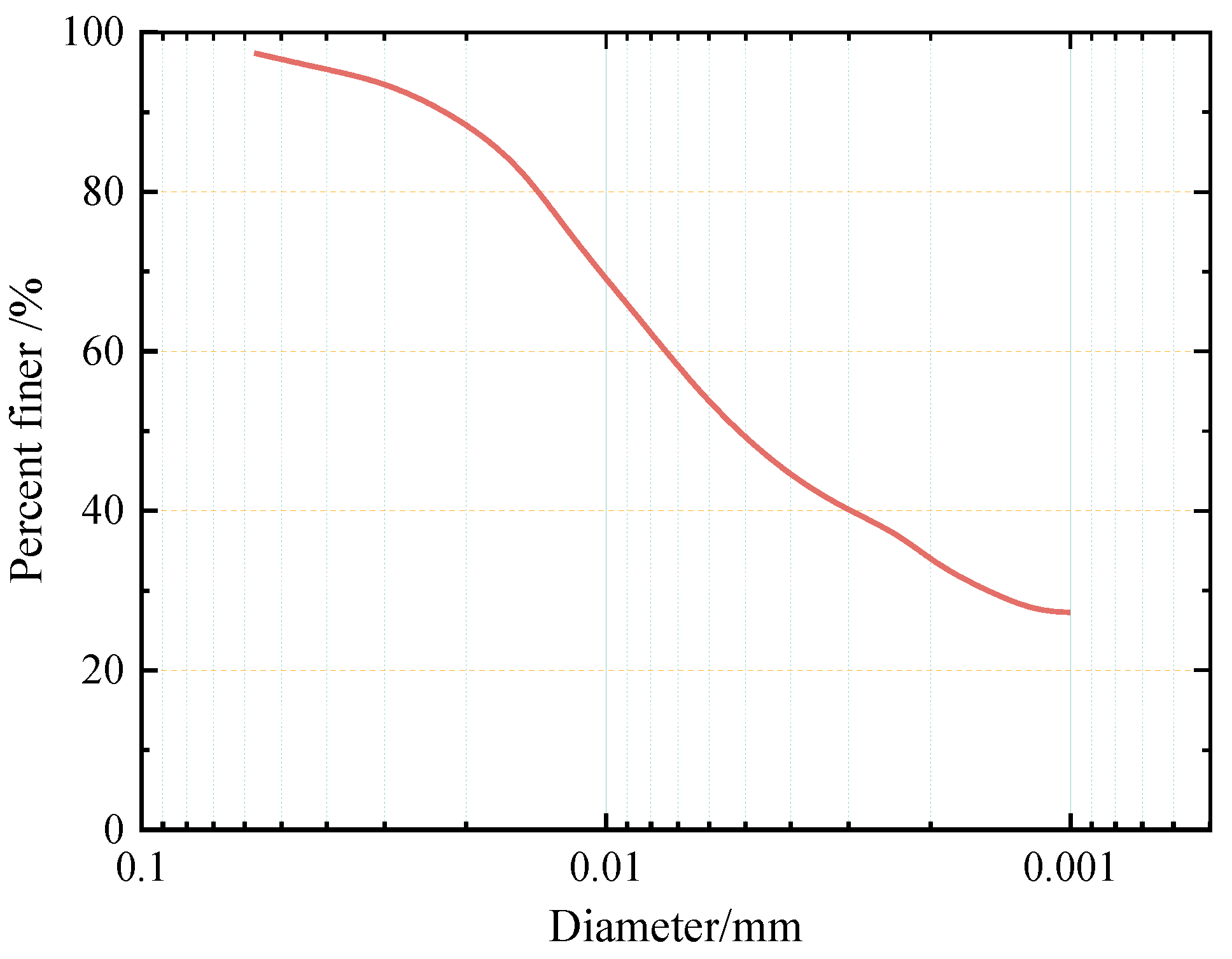

2.1.1. Soil In Situ

2.1.2. Cemented Soil

2.1.3. Concrete Slab

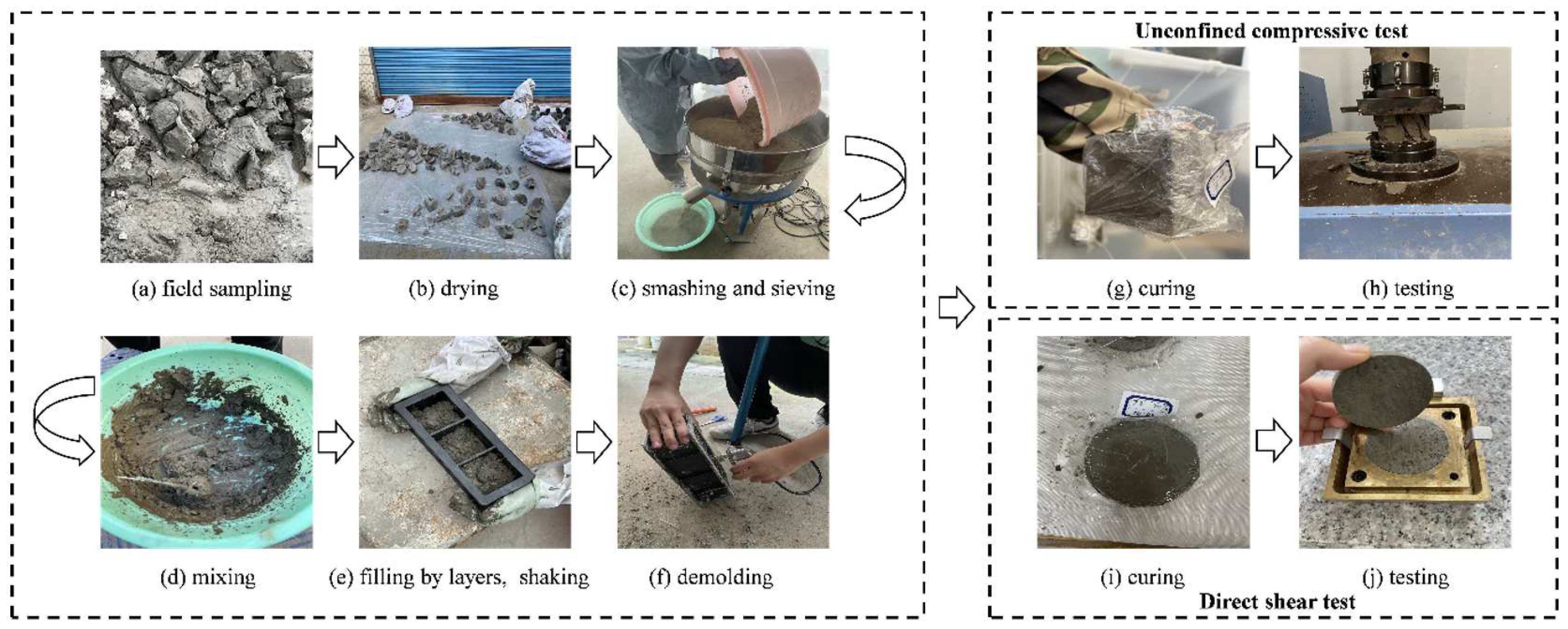

2.2. Experimental Program and Sample Preparation

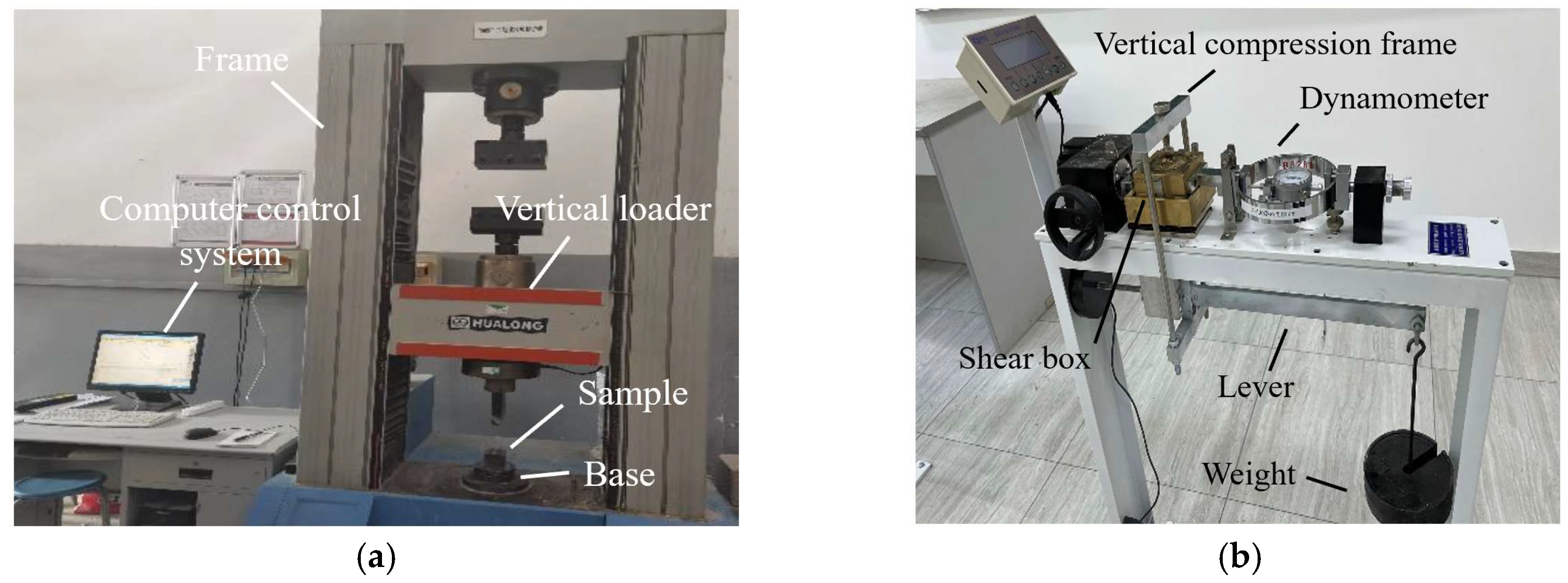

2.2.1. Large-Scale Shear Tests of Cemented Soil–Concrete Interface

- (1)

- Experimental apparatus and program

- (2)

- Preparation of cemented soil–concrete interface sample

- (3)

- Specimen quality control

2.2.2. Unconfined Compression Test and Direct Shear Test of Cemented Soil

3. Results and Discussion

3.1. Shear Strength of Cemented Soil–Concrete Interface

3.2. Unconfined Compressive Strength and Shear Strength of Cemented Soil

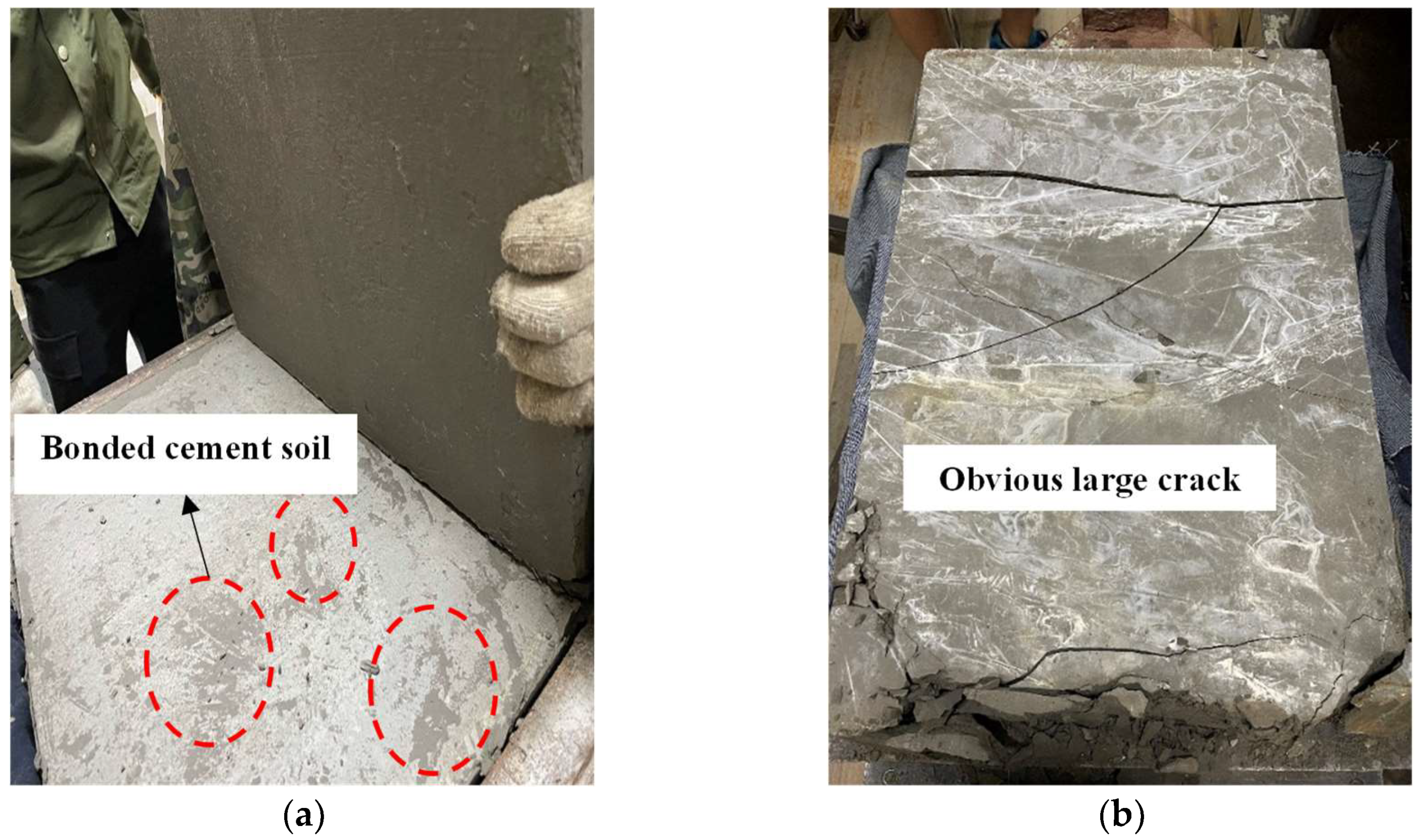

3.3. Failure Mechanism of Cemented Soil–Concrete Interface

4. Conclusions

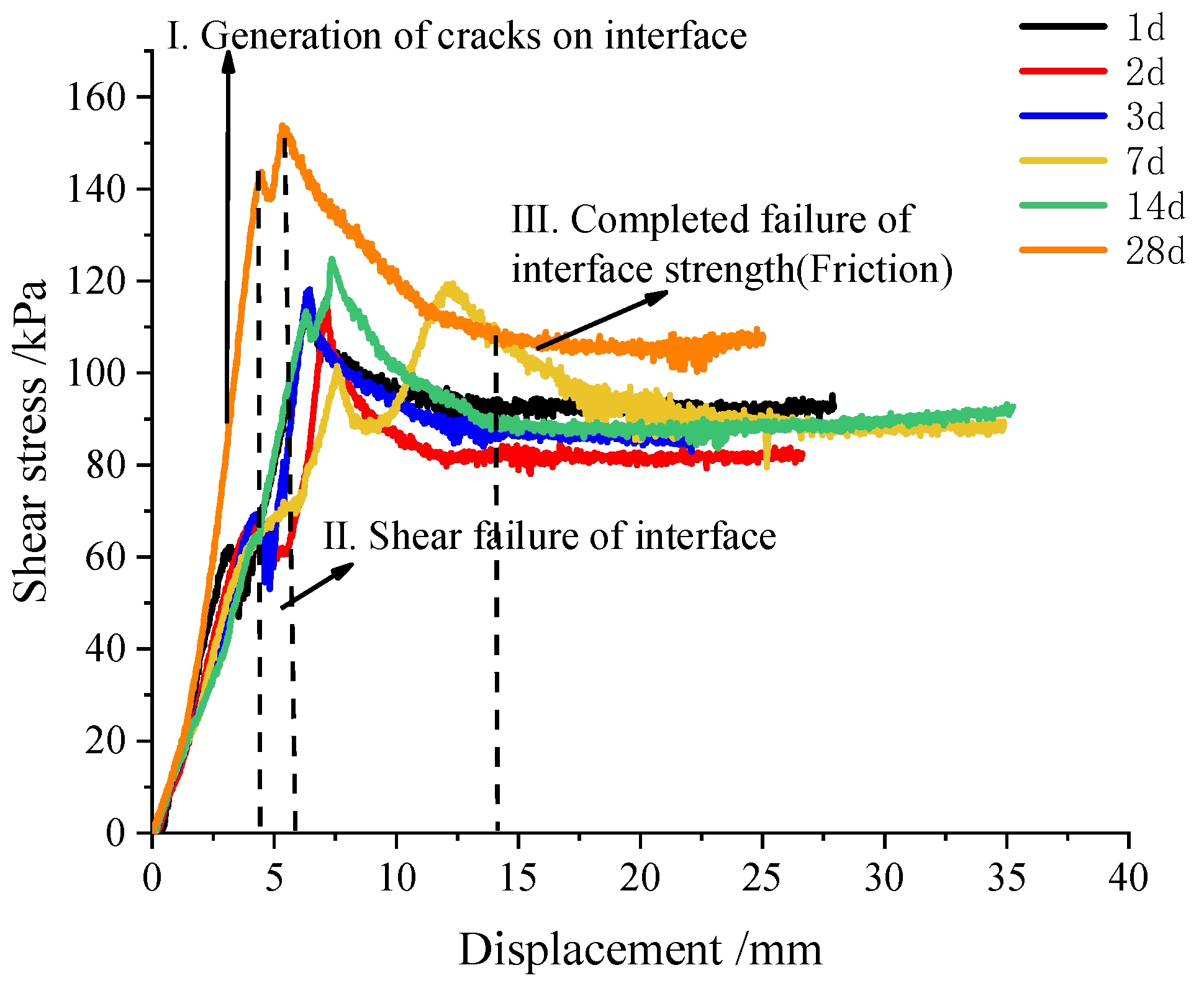

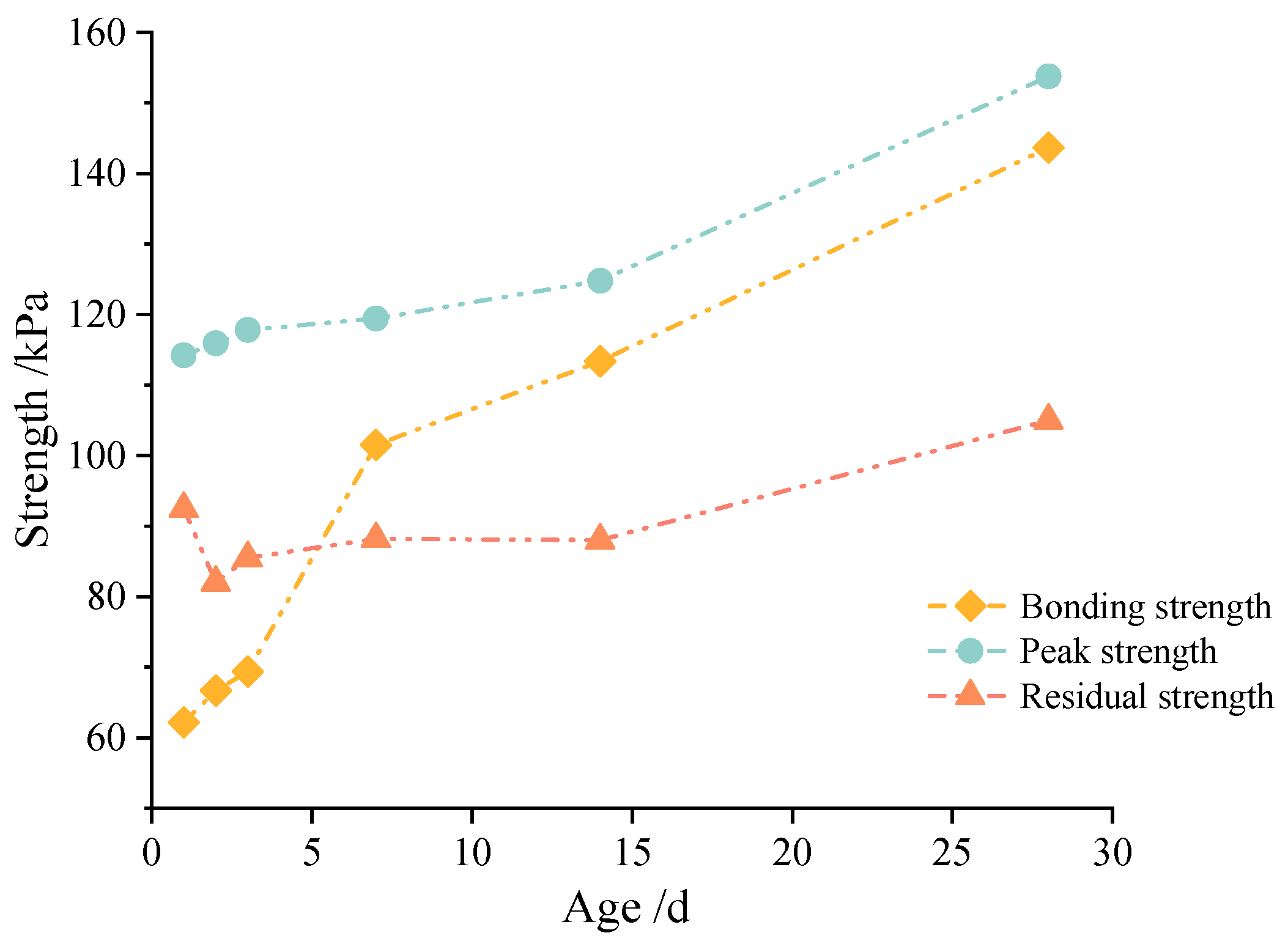

- Three stages of the failure process of the cemented soil–concrete interface can be observed: (1) the generation of cracks at the interface; (2) the interface is destroyed and shear failure occurs; (3) the interface completely fails, and the residual strength mainly consists of friction. The bonding strength, peak (shear) strength and residual shear strength of the cemented soil–concrete interface are correspondingly proposed and analyzed.

- The shear strength of the interface increases with the age, cement mixing ratio and normal stress, and decreases with an increase in the water–cement ratio. Additionally, the interface shear strength grows rapidly at 14 d to 28 d. Hence, the cemented soil used in some practical projects needs to be cured for a sufficient amount of time, such that the strength of the cemented soil–concrete interface can be improved sufficiently.

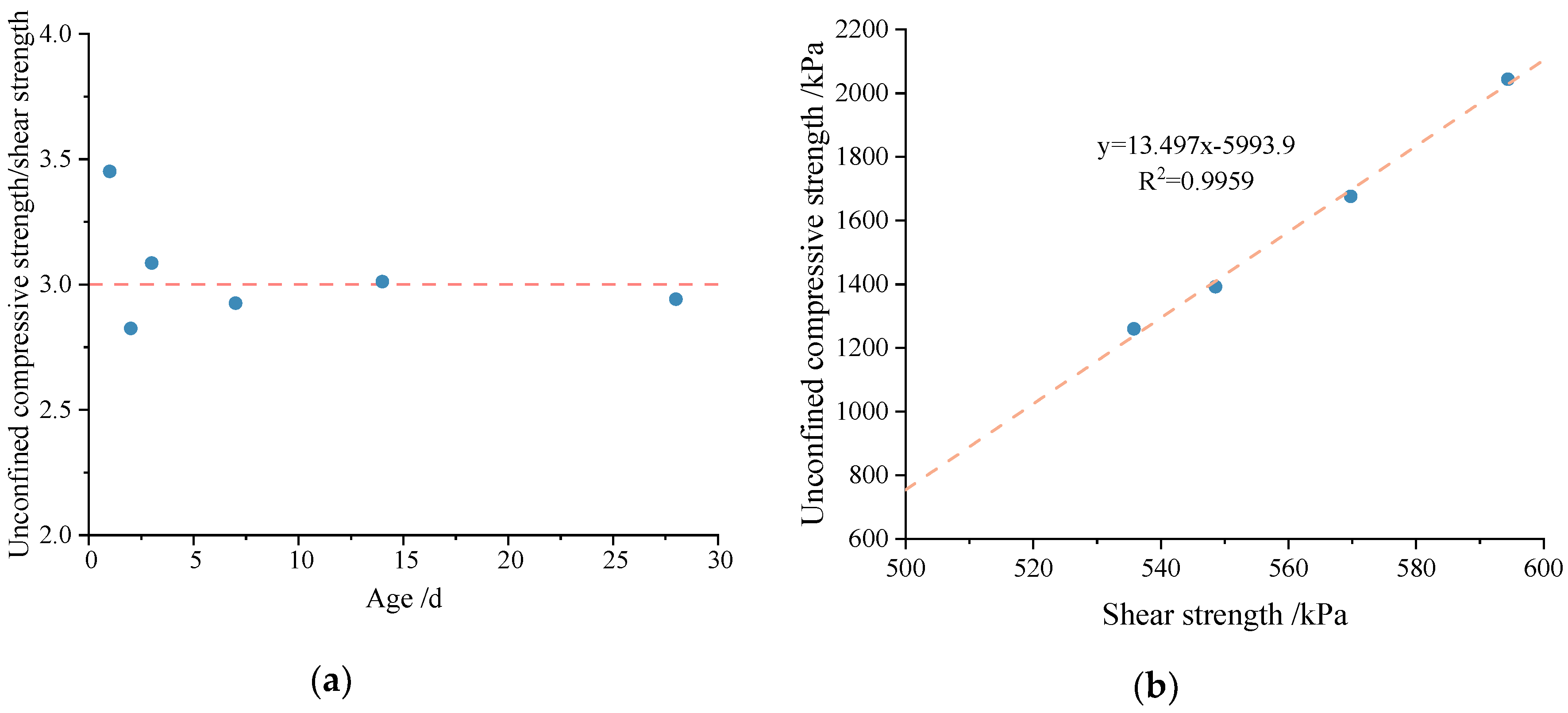

- The results of the unconfined compressive test and direct shear test on the cemented soil indicate that the unconfined compressive strength and shear strength are positively correlated. Additionally, both of them increase with age and the cement mixing ratio and decrease with an increase in the water–cement ratio. There is a positive correlation between interface shear strength and the unconfined compressive strength or shear strength of cemented soil. However, the trends of the interface bonding strength and unconfined compressive strength or shear strength of cemented soil are much closer than those of the interface peak strength and unconfined compressive strength or shear strength, and the interface residual strength and unconfined compressive strength or shear strength. This is considered to be related to the cementation of cement hydration products and probably the particle arrangement of the interface and its friction. Additionally, interface strength is always smaller than the unconfined compressive strength or shear strength of the cemented soil itself.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, H.; Zhou, G.; Du, Z. Experimental study of the soil-underground structure interfacial layer effect. J. China Univ. Min. Technol. 2011, 40, 846–851. [Google Scholar]

- He, Y.X.; Wu, H.B. Ground-Liner Interaction Analysis in Underground Opening. In Proceedings of the International Conference on Civil Engineering and Building Materials (CEBM), Kunming, China, 29–31 July 2011. [Google Scholar]

- Veerla, V.K.; Srinivas, K.A. Study on soil interface interaction; proceedings of the International Conference on Advances in Materials Science (ICAMS). Mater. Today Proc. 2022, 51, 2561–2568. [Google Scholar] [CrossRef]

- Isaev, O.N.; Sharafutdinov, R.F. Soil Shear Strength at the Structure Interface. Soil. Mech. Found. Eng. 2020, 57, 139–146. [Google Scholar] [CrossRef]

- Gong, H.; Zhao, C.F.; Tao, G.X.; Zhao, C. Research on effect of stress history on shear behavior of interface between clay and concrete. Chin. J. Rock. Mech. Eng. 2011, 30, 1712–1719. [Google Scholar]

- Liu, J.Q. Experimental Study on the Shear Performance of Silty Clay-CONCRETE interface under Freeze-Thaw Cycles. Master’s Thesis, Jilin University, Jilin, China, 2022. [Google Scholar]

- Namdar, A. A numerical investigation on soil-concrete foundation interaction. Procedia Struct. Integr. 2016, 2, 2803–2809. [Google Scholar] [CrossRef] [Green Version]

- Bergado, D.T.; Long, P.V.; Jamsawang, P.; Lampun, C.N.; Balasubramaniam, A.S. On Prefabricated Vertical Drain (PVD) and Deep Cement Mixing (DCM)/Stiffened DCM (SDCM) Techniques for Soft Ground Improvement. Geotech. Eng. 2018, 49, 164–181. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.Q.; Zhang, Y.F.; Zhou, D.W.; Wang, W.J.; Ke, Z.B.; Halder, S. Fly ash foundation reinforced by cement-soil mixing piles. DYNA-Ing. E Ind. 2020, 95, 198–204. [Google Scholar]

- Dong, P.; Chen, Z.; Qin, R. Use of concrete-cored DCM pile in soft ground. Chin. J. Geotech. Eng. 2002, 24, 204–207. [Google Scholar]

- Zhou, J.J.; Gong, X.N.; Wang, K.H.; Zhang, R.H.; Yan, J.J. Testing and modeling the behavior of pre-bored grouting planted piles under compression and tension. Acta Geotech. 2017, 12, 1061–1075. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Oliveira, P.J.V.; Lemos, L.J.L. Strength assessment of chemically stabilised soft soils. Proc. Inst. Civ. Eng.-Geotech. Eng. 2019, 172, 218–227. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Assessment of strength development in cement-admixed high water content clays with Abrams’ law as a basis. Geotechnique 2003, 53, 439–444. [Google Scholar] [CrossRef]

- Tanchaisawat, T.; Suriyavanagul, P.; Jamsawang, P. Stiffened deep cement mixing (SDCM) pile: Laboratory investigation. In Proceedings of the International Conference on Concrete Construction, London, UK, 9–10 September 2008. [Google Scholar]

- Wu, M.; Zhao, X.; Dou, Y.M.; Wang, E.Y. Experimental study on stiffened DCM pile in laboratory. Ind. Constr. 2004, 11, 45–48. [Google Scholar]

- Peng, T.; Li, L.Y.; Zhang, D.W. Experimental research on interfacial performance between cement treated soil and concrete. Mod. Transp. Technol. 2017, 14, 19–23. [Google Scholar]

- Jamsawang, P.; Bergado, D.T.; Voottipruex, P. Field behaviour of stiffened deep cement mixing piles. Proc. Inst. Civ. Eng.-Ground Improv. 2011, 164, 33–49. [Google Scholar] [CrossRef]

- Li, Y.H.; Sun, L.Q.; Li, X.; Huang, M.S. Experimental study on the shear mechanical properties of the cemented soil-concrete interface. Eur. J. Environ. Civil. Eng. 2022, 26, 4725–4739. [Google Scholar] [CrossRef]

- Yu, J.L.; Xu, J.C.; Zhou, J.J.; Gong, X.N. Experimental study on frictional capacity of concrete-cemented soil interface of concrete-cored cemented soil column. Chin. Civ. Eng. J. 2022, 55, 93–104, 117. [Google Scholar]

- Zhou, J.J.; Yu, J.L.; Gong, X.N.; Naggar, M.H.; Zhang, R.H. The effect of cemented soil strength on the frictional capacity of precast concrete pile-cemented soil interface. Acta Geotech. 2020, 15, 3271–3282. [Google Scholar] [CrossRef]

- Zhou, J.J.; Gong, X.N.; Zhang, R.H. Model tests comparing the behavior of pre-bored grouted planted piles and a wished-in-place concrete pile in dense sand. Soils Found. 2019, 59, 84–96. [Google Scholar] [CrossRef]

- DGJ32/TJ 151–2013; Technical Specification for Strength Composite Piles. Department of Housing and Urban-Rural Development of Jiangsu Province: Nanjing, China; Jiangsu Science Press: Nanjing, China, 2013.

- GB/T 50783–2012; Technical Code for Composite Foundation. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Planning Press: Beijing, China, 2012.

- JGJ/T 330-2014; Technical Specification for Pile Foundation of Pipe Pile Embedded in Cement Soil. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Architecture and Building Press: Beijing, China, 2014.

- Yi, K.J. Analysis on Engineering Property of Soft Soils in Shanghai and Ningbo Area. Zhejiang Constr. 2012, 29, 30–32. [Google Scholar]

- JCJ/T 233-2011; Specification for Mix Proportion Design of Cement Soil. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Architecture and Building Press: Beijing, China, 2011.

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Architecture and Building Press: Beijing, China, 2011.

- GB/T 41054-2021; Technical Specification for High Performance Concrete. State Administration for Market Regulation, Standardization Administration: Beijing, China, 2021.

- GB/T 50266-2013; Standard for Test Methods of Engineering Rock Mass. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Planning Press: Beijing, China, 2013.

- DG/TJ 08-61-2010; Technical Code for Excavation Engineering. Shanghai Urban-Rural Construction and Municipal Transportation Commission: Shanghai, China, 2010.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, State Administration for Market Regulation: Beijing, China; China Planning Press: Beijing, China, 2019.

| Water Content ω/% | Density ρ/g cm−3 | Void Ratio e | Liquidity Index IL | Plasticity Index IP | Liquid Limit ωL/% | Plastic Limit ωP/% | Shear Strength * | |

|---|---|---|---|---|---|---|---|---|

| Cohesion c/kPa | Friction Angle φ/° | |||||||

| 49.3 | 1.73 | 1.36 | 1.35 | 19.0 | 42.7 | 23.7 | 11.90 | 8.00 |

| Dry Density/g·cm−3 | Fineness/% | Initial Setting Time/min | Final Setting Time/min | Compressive Strength (28 d)/MPa | Flexural Strength (28 d)/MPa |

|---|---|---|---|---|---|

| 3.1 | 1.1 | 130 | 210 | 43.5 | 7.8 |

| Water–Cement Ratio | Cement/kg | Ground Sand/kg | Sand/kg | Stone/kg | Water Reducing Agent/kg |

|---|---|---|---|---|---|

| 0.3 | 301 | 129 | 697 | 1250 | 14 |

| Specification | Cement Mixing Ratio/% | Water–Cement Ratio |

|---|---|---|

| Specification for mixed proportion design of cement soil (JCJ/T 233-2011) [26] | 3~25 | 0.45~2.0 |

| Technical code for composite foundation (GBT50783-2012) [23] | 10~20 | - |

| Technical specification for pile foundation of pipe pile embedded in cemented soil (JGJ/T 330-2014) [24] | ≥20 | 0.8~1.5 |

| Technical specification for strength composite piles (DGJ32/TJ 151-2013) [22] | 15~25 | 0.8~1.2 |

| Technical code for excavation engineering (DG/TJ 08-61-2010) [30] | Biaxial cement mixing pile: 13~15 Triaxial cement mixing pile: 20~22 | 0.5–0.6 |

| Age/d | Cement Mixing Ratio/% | Water–Cement Ratio | Normal Stress/kPa |

|---|---|---|---|

| 1 | 15 | 0.5 | 150 |

| 2 | 15 | 0.5 | 150 |

| 3 | 15 | 0.5 | 150 |

| 7 | 15 | 0.5 | 150 |

| 14 | 15 | 0.5 | 150 |

| 28 | 15 | 0.5 | 150 |

| 28 | 13 | 0.5 | 150 |

| 28 | 18 | 0.5 | 150 |

| 28 | 15 | 0.8 | 150 |

| 28 | 15 | 0.5 | 50 |

| 28 | 15 | 0.5 | 250 |

| Experiments | Age/d | Cement Ratio/% | Water–Cement Ratio | Normal Stress/kPa |

|---|---|---|---|---|

| Unconfined compression test | 1, 2, 3, 7, 14, 28 | 15 | 0.5 | - |

| 28 | 13 | 0.5 | - | |

| 28 | 18 | 0.5 | - | |

| 28 | 15 | 0.8 | - | |

| 28 | 15 | 1.0 | - | |

| Direct shear test | 1, 2, 3, 7, 14, 28 | 15 | 0.5 | 50, 150, 250 |

| 28 | 13 | 0.5 | 50, 150, 250 | |

| 28 | 18 | 0.5 | 50, 150, 250 | |

| 28 | 15 | 0.8 | 50, 150, 250 | |

| 28 | 15 | 1.0 | 50, 150, 250 |

| Age/d | Cement Mixing Ratio/% | Water Cement Ratio | Normal Stress/kPa | Bonding Strength/kPa | Shear (Peak) Strength/kPa | Residual Strength/kPa |

|---|---|---|---|---|---|---|

| 1 | 15 | 0.5 | 150 | 62.158 | 114.216 | 92.5 |

| 2 | 15 | 0.5 | 150 | 66.667 | 115.908 | 82.0 |

| 3 | 15 | 0.5 | 150 | 69.382 | 117.828 | 85.5 |

| 7 | 15 | 0.5 | 150 | 101.522 | 119.449 | 88.2 |

| 14 | 15 | 0.5 | 150 | 113.359 | 124.793 | 88.0 |

| 28 | 15 | 0.5 | 150 | 143.665 | 153.786 | 105 |

| 28 | 13 | 0.5 | 150 | 75.193 | 140.292 | 90.5 |

| 28 | 18 | 0.5 | 150 | 81.703 | 163.978 | 118.8 |

| 28 | 15 | 0.8 | 150 | 110.090 | 135.825 | 101.0 |

| 28 | 15 | 0.5 | 50 | 23.450 | 62.296 | 39.6 |

| 28 | 15 | 0.5 | 250 | 203.693 | 238.815 | 198.5 |

| Age/d | Cement Mixing Ratio/% | Water-Cement Ratio | Normal Stress/kPa | Unconfined Compressive Strength/kPa | Shear Strength/kPa | Cohesion c/kPa | Friction Angle φ/° |

|---|---|---|---|---|---|---|---|

| 1 | 15 | 0.5 | 150 | 586.18 | 169.83 | 65.93 | 34.68 |

| 2 | 15 | 0.5 | 150 | 676.28 | 239.43 | 135.57 | 34.56 |

| 3 | 15 | 0.5 | 150 | 883.35 | 286.29 | 173.70 | 35.90 |

| 7 | 15 | 0.5 | 150 | 1076.31 | 367.92 | 257.19 | 38.16 |

| 14 | 15 | 0.5 | 150 | 1489.29 | 494.49 | 366.04 | 44.63 |

| 28 | 15 | 0.5 | 150 | 1675.95 | 569.75 | 408.03 | 45.59 |

| 28 | 13 | 0.5 | 150 | 1392.14 | 548.56 | 363.63 | 46.83 |

| 28 | 18 | 0.5 | 150 | 2043.90 | 594.37 | 450.47 | 43.67 |

| 28 | 15 | 0.8 | 150 | 1259.98 | 535.78 | 362.80 | 49.05 |

| 28 | 15 | 1.0 | 150 | 938.08 | 501.68 | 341.88 | 50.04 |

| 28 | 15 | 0.5 | 50 | 1675.95 | 454.76 | 408.03 | 45.59 |

| 28 | 15 | 0.5 | 250 | 1675.95 | 658.91 | 408.03 | 45.59 |

| Age/d | Cemented Soil–Concrete Interface | Cemented Soil | |||

|---|---|---|---|---|---|

| Interface Shear (Peak) Strength/kPa | Bonding Strength/kPa | Residual Strength/kPa | Shear Strength/kPa | Unconfined Compressive Strength/kPa | |

| 1 | 114.216 | 62.158 | 92.5 | 169.83 | 586.18 |

| 2 | 115.908 | 66.667 | 82.0 | 239.43 | 676.28 |

| 3 | 117.828 | 69.382 | 85.5 | 286.29 | 883.35 |

| 7 | 119.449 | 101.522 | 88.2 | 367.92 | 1076.31 |

| 14 | 124.793 | 113.359 | 88.0 | 494.49 | 1489.29 |

| 28 | 153.786 | 143.665 | 105.0 | 569.75 | 1675.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Ban, C.; Zhou, H.; Ren, J.; Liu, Z. Experimental Study on the Shear Strength and Failure Mechanism of Cemented Soil–Concrete Interface. Materials 2023, 16, 4222. https://doi.org/10.3390/ma16124222

Zhou J, Ban C, Zhou H, Ren J, Liu Z. Experimental Study on the Shear Strength and Failure Mechanism of Cemented Soil–Concrete Interface. Materials. 2023; 16(12):4222. https://doi.org/10.3390/ma16124222

Chicago/Turabian StyleZhou, Jie, Chao Ban, Huade Zhou, Junjie Ren, and Zhong Liu. 2023. "Experimental Study on the Shear Strength and Failure Mechanism of Cemented Soil–Concrete Interface" Materials 16, no. 12: 4222. https://doi.org/10.3390/ma16124222

APA StyleZhou, J., Ban, C., Zhou, H., Ren, J., & Liu, Z. (2023). Experimental Study on the Shear Strength and Failure Mechanism of Cemented Soil–Concrete Interface. Materials, 16(12), 4222. https://doi.org/10.3390/ma16124222