High-Temperature Liquid–Liquid Phase Transition in Glass-Forming Liquid Pd43Ni20Cu27P10

Abstract

1. Introduction

2. Experimental and Simulation Details

3. Results and Discussion

3.1. Experimental Results

3.2. AIMD Simulations

3.2.1. Thermophysical Properties

3.2.2. Atomic Structures

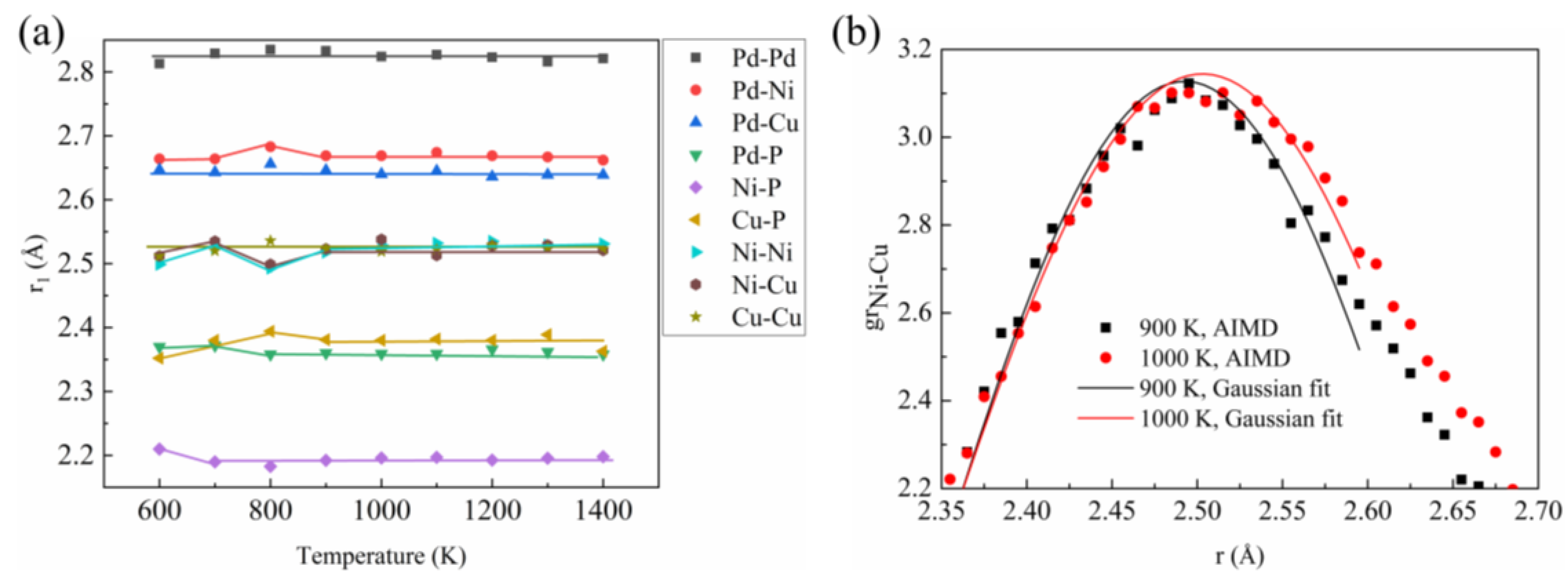

Pair Distribution Function

Voronoi Polyhedra

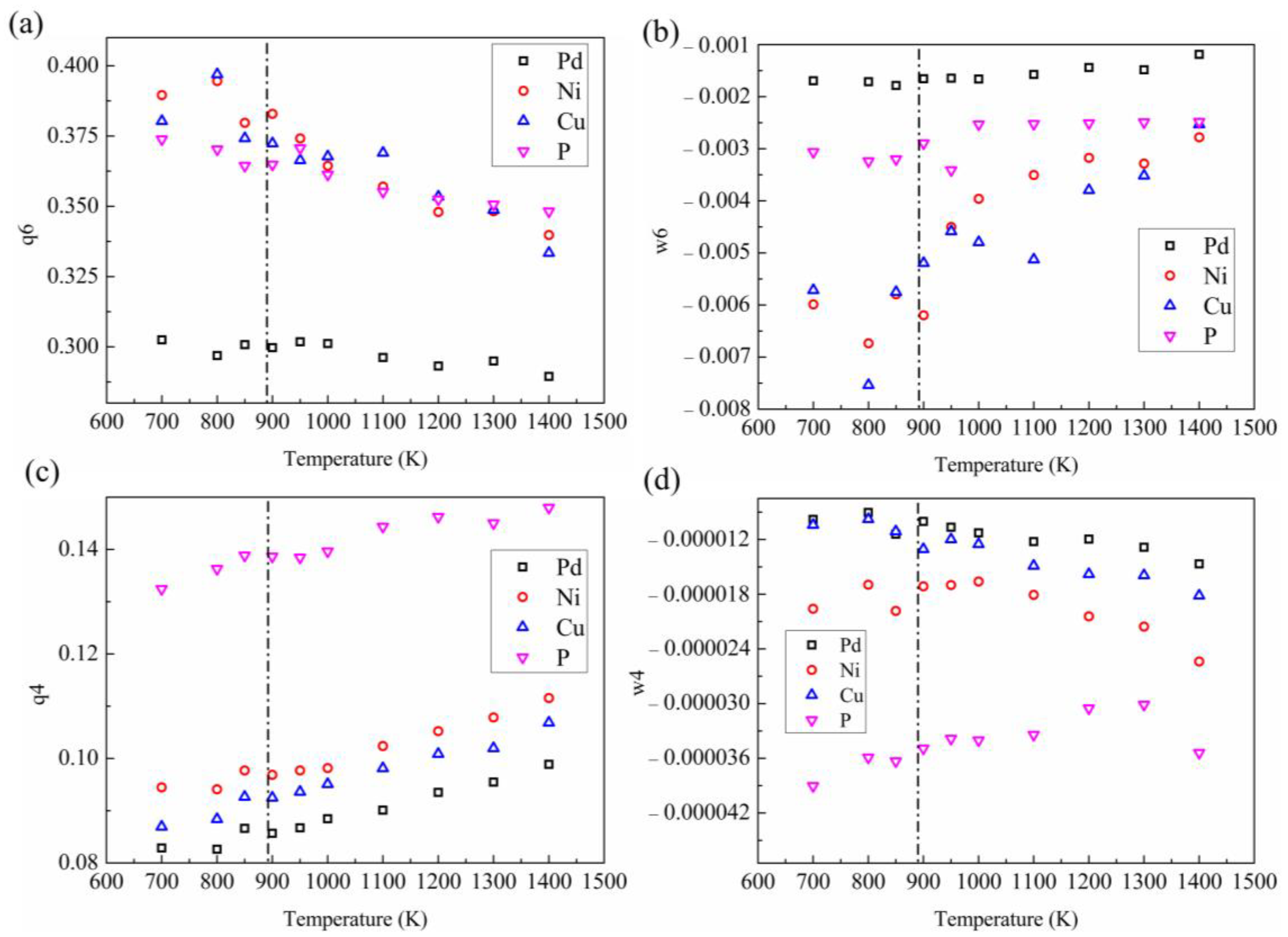

Bond Order Orientation

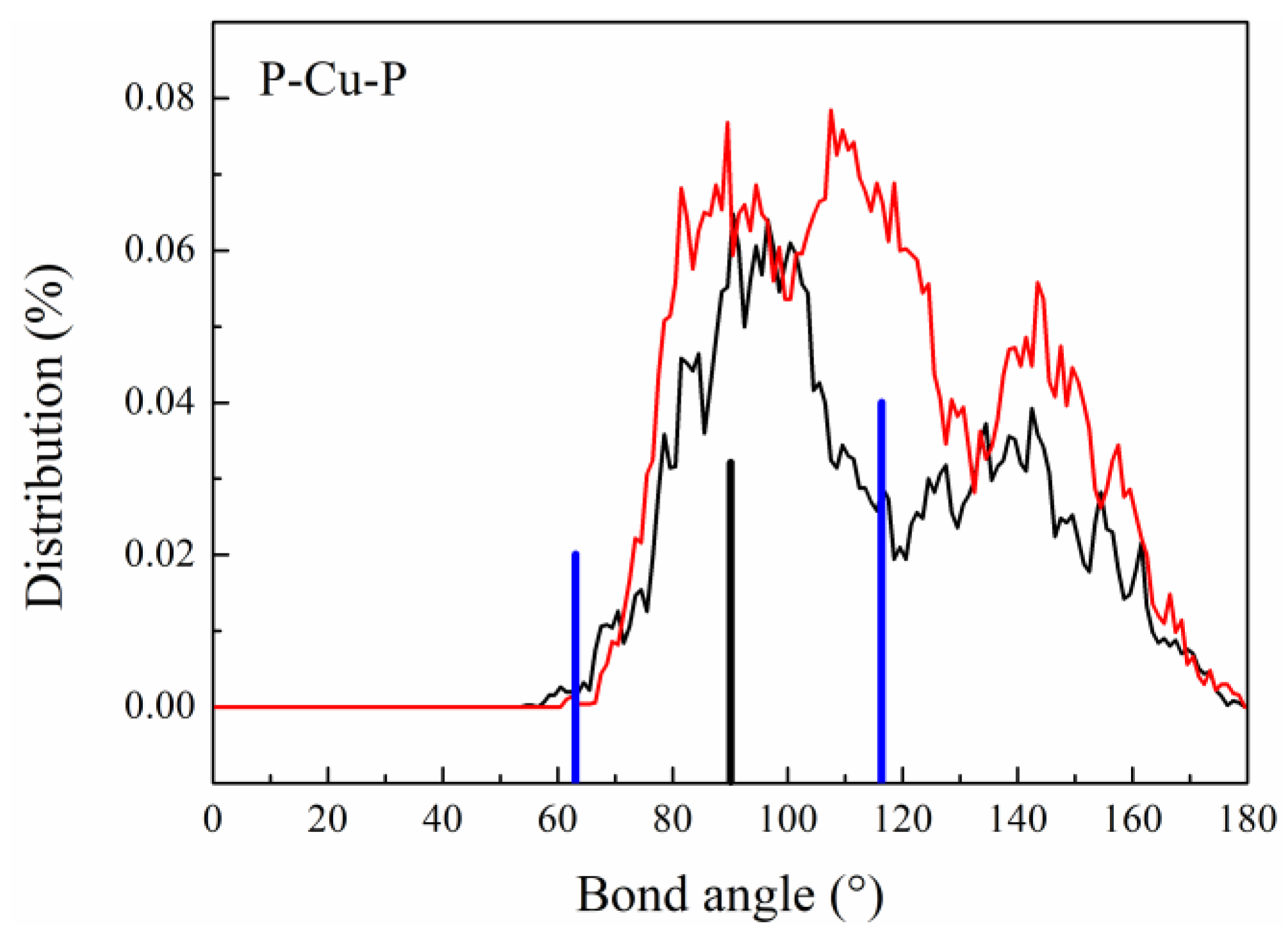

Bond Angle Distribution

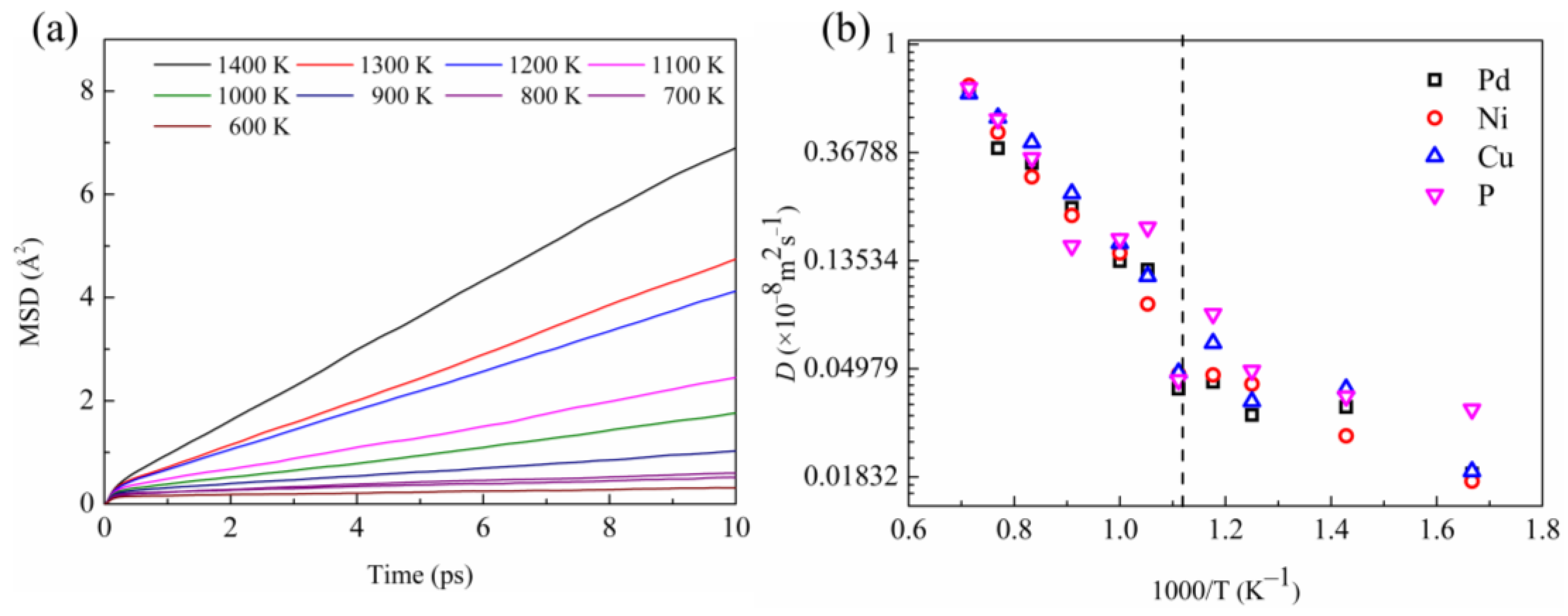

3.2.3. Atomic Dynamics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sastry, S.; Austen Angell, C. Liquid–liquid phase transition in supercooled silicon. Nat. Mater. 2003, 2, 739–743. [Google Scholar] [CrossRef] [PubMed]

- Jakse, N.; Pasturel, A. Liquid-liquid phase transformation in silicon: Evidence from first-principles molecular dynamics simulations. Phys. Rev. Lett. 2007, 99, 205702. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, P.; Widom, M. Liquid-liquid transition in supercooled silicon determined by first-principles simulation. Phys. Rev. Lett. 2009, 102, 075701. [Google Scholar] [CrossRef] [PubMed]

- Vasisht, V.V.; Saw, S.; Sastry, S. Liquid–liquid critical point in supercooled silicon. Nat. Phys. 2011, 7, 549–553. [Google Scholar] [CrossRef]

- Katayama, Y.; Mizutani, T.; Utsumi, W.; Shimomura, O.; Yamakata, M.; Funakoshi, K.-I. A first-order liquid–liquid phase transition in phosphorus. Nature 2000, 403, 170–173. [Google Scholar] [CrossRef]

- Katayama, Y.; Inamura, Y.; Mizutani, T.; Yamakata, M.; Utsumi, W.; Shimomura, O. Macroscopic separation of dense fluid phase and liquid phase of phosphorus. Science 2004, 306, 848–851. [Google Scholar] [CrossRef]

- Cadien, A.; Hu, Q.Y.; Meng, Y.; Cheng, Y.Q.; Chen, M.W.; Shu, J.F.; Mao, H.K.; Sheng, H.W. First-order liquid-liquid phase transition in cerium. Phys. Rev. Lett. 2013, 110, 125503. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Z.; Chen, J.; Chen, S.; Yang, W.; Ren, Y.; Zuo, X.; Zeng, J.; Wu, Q.; Sheng, H. Folded network and structural transition in molten tin. Nat. Commun. 2022, 13, 1–10. [Google Scholar] [CrossRef]

- Poole, P.H.; Sciortino, F.; Essmann, U.; Stanley, H.E. Phase behaviour of metastable water. Nature 1992, 360, 324–328. [Google Scholar] [CrossRef]

- Mishima, O.; Stanley, H.E. The relationship between liquid, supercooled and glassy water. Nature 1998, 396, 329–335. [Google Scholar] [CrossRef]

- Mallamace, F.; Broccio, M.; Corsaro, C.; Faraone, A.; Majolino, D.; Venuti, V.; Liu, L.; Mou, C.-Y.; Chen, S.-H. Evidence of the existence of the low-density liquid phase in supercooled, confined water. Proc. Natl. Acad. Sci. USA 2007, 104, 424–428. [Google Scholar] [CrossRef]

- Saika-Voivod, I.; Poole, P.H.; Sciortino, F. Fragile-to-strong transition and polyamorphism in the energy landscape of liquid silica. Nature 2001, 412, 514–517. [Google Scholar] [CrossRef]

- Yu, Q.; Wang, X.D.; Su, Y.; Cao, Q.P.; Ren, Y.; Zhang, D.X.; Jiang, J.Z. Liquid-to-liquid crossover in the GaIn eutectic alloy. Phys. Rev. B 2017, 95, 224203. [Google Scholar] [CrossRef]

- Aasland, S.; McMillan, P.F. Density-driven liquid–liquid phase separation in the system AI2O3–Y2O3. Nature 1994, 369, 633–636. [Google Scholar] [CrossRef]

- Greaves, G.N.; Wilding, M.C.; Fearn, S.; Langstaff, D.; Kargl, F.; Cox, S.; Van, Q.V.; Majérus, O.; Benmore, C.J.; Weber, R.; et al. Detection of first-order liquid/liquid phase transitions in yttrium oxide-aluminum oxide melts. Science 2008, 322, 566–570. [Google Scholar] [CrossRef] [PubMed]

- Lan, S.; Ren, Y.; Wei, X.Y.; Wang, B.; Gilbert, E.P.; Shibayama, T.; Watanabe, S.; Ohnuma, M.; Wang, X.L. Hidden amorphous phase and reentrant supercooled liquid in Pd-Ni-P metallic glasses. Nat. Commun. 2017, 8, 14679. [Google Scholar] [CrossRef]

- Ge, J.; He, H.; Zhou, J.; Lu, C.; Dong, W.; Liu, S.; Lan, S.; Wu, Z.; Wang, A.; Wang, L.; et al. In-situ scattering study of a liquid-liquid phase transition in Fe-B-Nb-Y supercooled liquids and its correlation with glass-forming ability. J. Alloys Compd. 2019, 787, 831–839. [Google Scholar] [CrossRef]

- Dong, W.; Wu, Z.; Ge, J.; Liu, S.; Lan, S.; Gilbert, E.P.; Ren, Y.; Ma, D.; Wang, X.-L. In situneutron scattering studies of a liquid–liquid phase transition in the supercooled liquid of a Zr–Cu–Al–Ag glass-forming alloy. Appl. Phys. Lett. 2021, 118, 191901. [Google Scholar] [CrossRef]

- Hao-Ran, J.; Jochi, T.; Nico, N.; Jenifer, B.; Bastian, A.; Maximilian, F.; Ann-Christin, D.; Soham, B.; Isabella, G.; Ai-Han, F.; et al. On the devitrification of Cu–Zr–Al alloys: Solving the apparent contradiction between polymorphic liquid-liquid transition and phase separation. Acta Mater. 2022, 226, 117668. [Google Scholar] [CrossRef]

- Shen, J.; Lu, Z.; Wang, J.Q.; Lan, S.; Zhang, F.; Hirata, A.; Chen, M.W.; Wang, X.L.; Wen, P.; Sun, Y.H.; et al. Metallic glacial glass formation by a first-Order liquid-liquid transition. J. Phys. Chem. Lett. 2020, 11, 6718–6723. [Google Scholar] [CrossRef]

- Ge, X.; Hu, Q.; Yang, F.; Xu, J.; Han, Y.; Lai, P.; Qin, J.; Li, J. Anomalous structure transition in undercooled melt regulates polymorphic selection in barium titanate crystallization. Commun. Chem. 2021, 4, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.Z.; Saksl, K.; Nishiyama, N.; Inoue, A. Crystallization in Pd40Ni40P20 glass. J. Appl. Phys. 2002, 92, 3651–3656. [Google Scholar] [CrossRef]

- Yu, P.F.; Xia, M.; Cao, S.C.; Zeng, L.; Lu, W.Q.; Li, J.G. Liquid structure transition upon cooling of liquid Pd40Ni40P20. Appl. Phys. Lett. 2021, 118, 231902. [Google Scholar] [CrossRef]

- Li, X.; Shi, Z.; Zhang, T. Effect of similar element substitution on Fe-B-Si-Mo bulk metallic glasses studied by experiment and ab initio molecular dynamics simulation. J. Alloys Compd. 2019, 784, 1139–1144. [Google Scholar] [CrossRef]

- Shangke, J.; Yuhang, J.; Shunwei, C.; Xiujun, H. Enhancing glass forming ability and magnetic properties of Co–Fe–Si–B metallic glasses by similar element substitution: Experimental and theoretical investigations. Comput. Mater. Sci. 2022, 213, 111639. [Google Scholar] [CrossRef]

- Qin, J.; Gu, T.; Pan, S.; Bian, X.; Zhang, T. Investigation on structure and dynamic property of liquid Pd-Cu-Ni-P alloys using ab initio molecular dynamics simulation. Sci. China Technol. Sci. 2012, 56, 376–386. [Google Scholar] [CrossRef]

- Schroers, J.; Johnson, W.L.; Busch, R. Crystallization kinetics of the bulk-glass-forming Pd43Ni10Cu27P20 melt. Appl. Phys. Lett. 2000, 77, 1158–1160. [Google Scholar] [CrossRef]

- Schroers, J.; Löffler, J.F.; Pekarskaya, E.; Busch, R.; Johnson, W.L. Crystallization of bulk glass forming Pd-based melts. J. Metastable Nanocrystalline Mater. 2001, 10, 79–84. [Google Scholar] [CrossRef]

- Ali Khan, S.; Wang, X.-D.; Saeed Ahmad, A.; Cao, Q.-P.; Zhang, D.-X.; Fang, Y.-Z.; Wang, H.; Jiang, J.-Z. Temperature- and pressure-induced polyamorphic transitions in AuCuSi alloy. J. Phys. Chem. C 2019, 123, 20342–20350. [Google Scholar] [CrossRef]

- Tournier, R.F. First-order transitions in glasses and melts induced by solid superclusters nucleated and melted by homogeneous nucleation instead of surface melting. Chem. Phys. 2019, 524, 40–54. [Google Scholar] [CrossRef]

- Chu, W.; Shang, J.; Yin, K.; Ren, N.; Hu, L.; Zhao, Y.; Dong, B. Generality of abnormal viscosity drop on cooling of CuZr alloy melts and its structural origin. Acta Mater. 2020, 196, 690–703. [Google Scholar] [CrossRef]

- Du, Q.; Liu, X.; Fan, H.; Zeng, Q.; Wu, Y.; Wang, H.; Chatterjee, D.; Ren, Y.; Ke, Y.; Voyles, P.M.; et al. Reentrant glass transition leading to ultrastable metallic glass. Mater. Today 2019, 34, 66–77. [Google Scholar] [CrossRef]

- Chen, E.-Y.; Peng, S.-X.; Peng, L.; Di Michiel, M.; Vaughan, G.B.; Yu, Y.; Yu, H.-B.; Ruta, B.; Wei, S.; Liu, L. Glass-forming ability correlated with the liquid-liquid transition in Pd42.5Ni42.5P15 alloy. Scr. Mater. 2021, 193, 117–121. [Google Scholar] [CrossRef]

- Gomidželović, L.l.y.c.; Pouraliakbar, H.; Khalaj, G.; Kostov, A. Thermodynamic analysis of ternary Al-Cu-Ni system. J. Chem. Technol. Metall. 2014, 49, 402–408. [Google Scholar]

- Tournier, R.F.; Ojovan, M.I. Prediction of second melting temperatures already observed in pure elements by molecular dynamics simulations. Materials 2021, 21, 6509. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Beygi, R.; Fallah, V.; Monazzah, A.H.; Jandaghi, M.R.; Khalaj, G.; da Silva, L.F.; Pavese, M. Processing of Al-Cu-Mg alloy by FSSP: Parametric analysis and the effect of cooling environment on microstructure evolution. Mater. Lett. 2022, 308, 131157. [Google Scholar] [CrossRef]

- Su, Y.; Wang, X.; An, P.; Zhang, J.; Hu, T.; Ren, Y.; Tao, Q.; Cao, Q.; Zhang, D.; Jiang, J.-Z. Temperature-dependent structural evolution in Au44Ga56 liquid eutectic alloy. J. Phys. Chem. C 2019, 123, 25209–25219. [Google Scholar] [CrossRef]

- Cheng, Q.; Sun, Y.; Orava, J.; Bai, H.; Wang, W. Kinetically facilitated liquid-liquid transition in a metallic liquid. Acta Mater. 2022, 230, 117834. [Google Scholar] [CrossRef]

- Kresse, G.; Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 1993, 47, 558–561. [Google Scholar] [CrossRef]

- Blöchl, N. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef]

- Pelletier, J.M.; Van de Moortèle, B.; Lu, I.R. Viscoelasticity and viscosity of Pd–Ni–Cu–P bulk metallic glasses. Mater. Sci. Eng. A 2002, 336, 190–195. [Google Scholar] [CrossRef]

- Haruyama, O. Thermodynamic approach to free volume kinetics during isothermal relaxation in bulk Pd–Cu–Ni–P20 glasses. Intermetallics 2007, 15, 659–662. [Google Scholar] [CrossRef]

- Hafner, J. Triplet correlation functions in metallic glasses. J. Physics. F Metal. Phys. 1982, 12, L205. [Google Scholar] [CrossRef]

- Tanaka, H. Bond orientational ordering in a metastable supercooled liquid: A shadow of crystallization and liquid–liquid transition. J. Stat. Mech. Theory Exp. 2010, 2010, P12001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Yu, P.; Miao, X.; Peng, C.; Fu, L.; Si, C.; Lu, Q.; Chen, S.; Han, X. High-Temperature Liquid–Liquid Phase Transition in Glass-Forming Liquid Pd43Ni20Cu27P10. Materials 2023, 16, 4353. https://doi.org/10.3390/ma16124353

Zhou H, Yu P, Miao X, Peng C, Fu L, Si C, Lu Q, Chen S, Han X. High-Temperature Liquid–Liquid Phase Transition in Glass-Forming Liquid Pd43Ni20Cu27P10. Materials. 2023; 16(12):4353. https://doi.org/10.3390/ma16124353

Chicago/Turabian StyleZhou, Huanyi, Pengfei Yu, Xiaoyu Miao, Cunjin Peng, Lulu Fu, Conghui Si, Qifang Lu, Shunwei Chen, and Xiujun Han. 2023. "High-Temperature Liquid–Liquid Phase Transition in Glass-Forming Liquid Pd43Ni20Cu27P10" Materials 16, no. 12: 4353. https://doi.org/10.3390/ma16124353

APA StyleZhou, H., Yu, P., Miao, X., Peng, C., Fu, L., Si, C., Lu, Q., Chen, S., & Han, X. (2023). High-Temperature Liquid–Liquid Phase Transition in Glass-Forming Liquid Pd43Ni20Cu27P10. Materials, 16(12), 4353. https://doi.org/10.3390/ma16124353