Structural Changes and Very-Low-Frequency Nonlinear Dielectric Response of XLPE Cable Insulation under Thermal Aging

Abstract

:1. Introduction

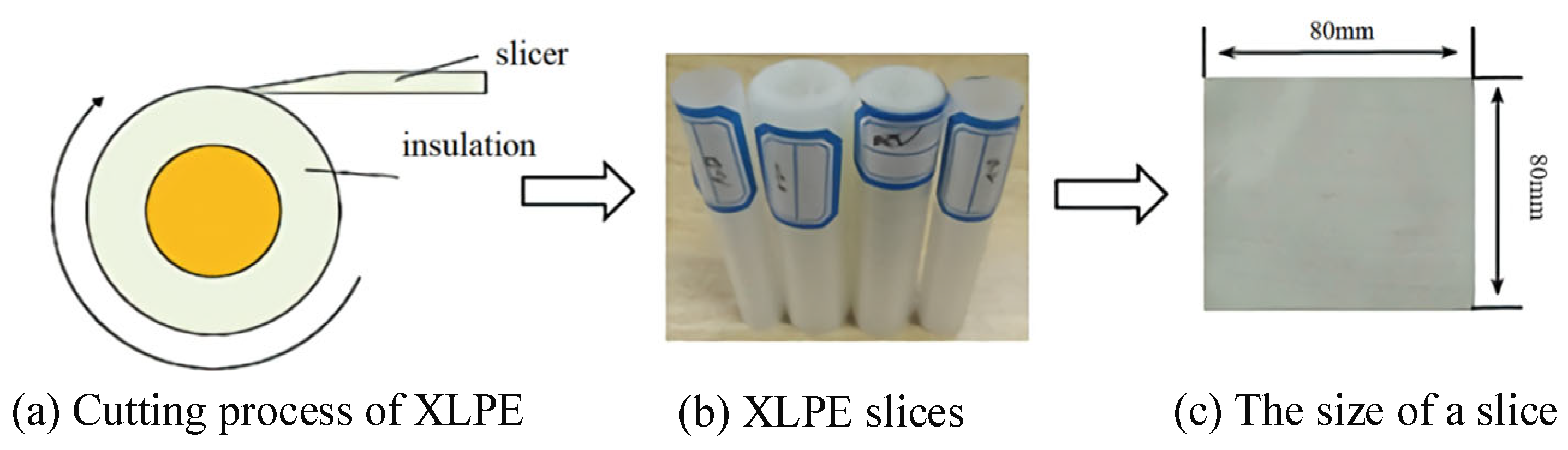

2. Samples and Experiments

2.1. Samples Preparation and Thermal Aging Experiment

2.2. FTIR and DSC

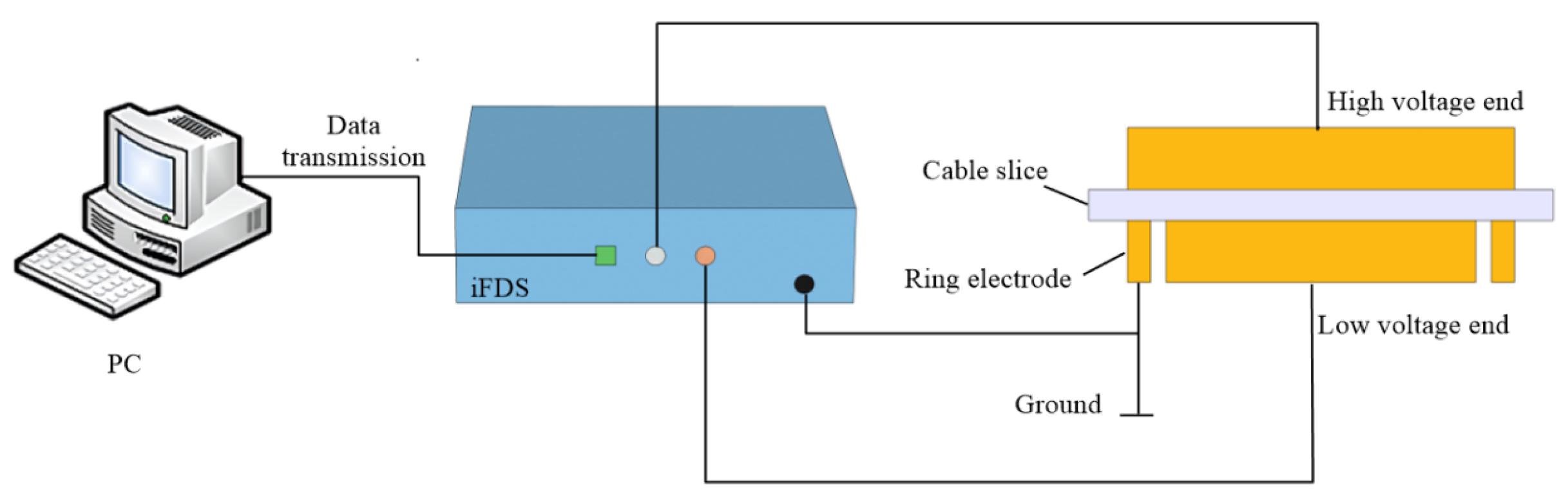

2.3. VLF Dielectric Spectroscopy

3. Results and Discussions

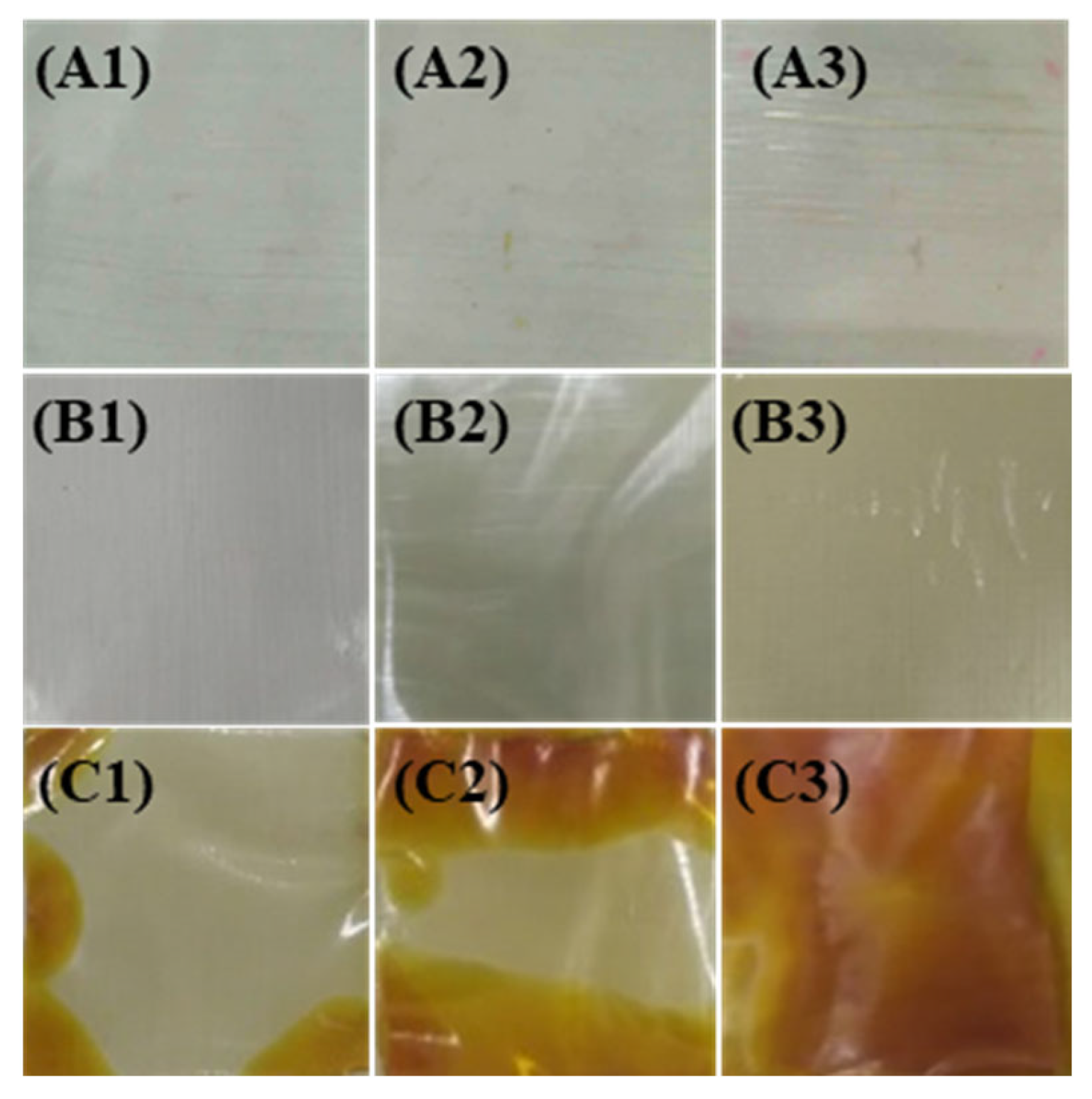

3.1. Color Change of Samples

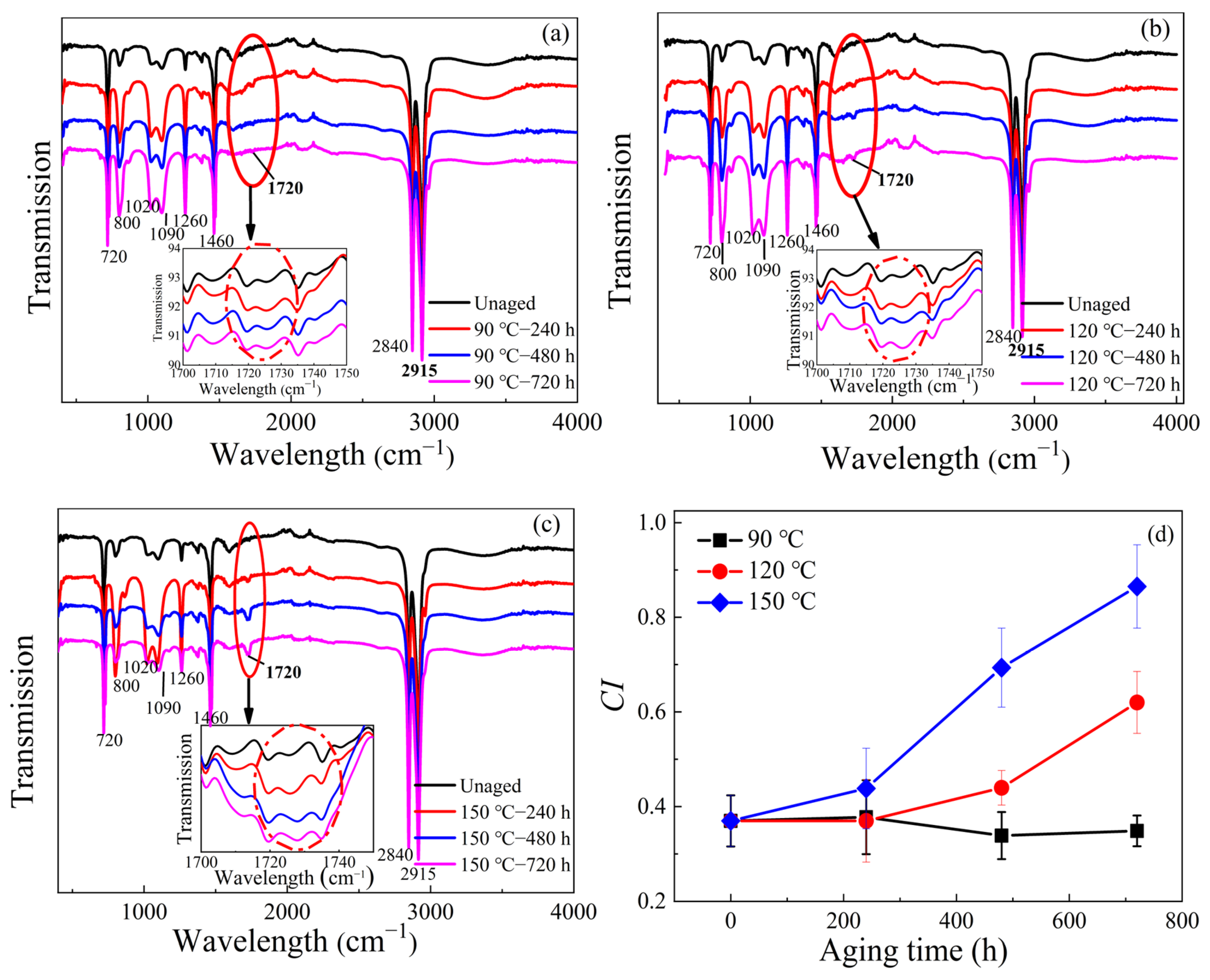

3.2. FTIR Spectroscopy Analysis

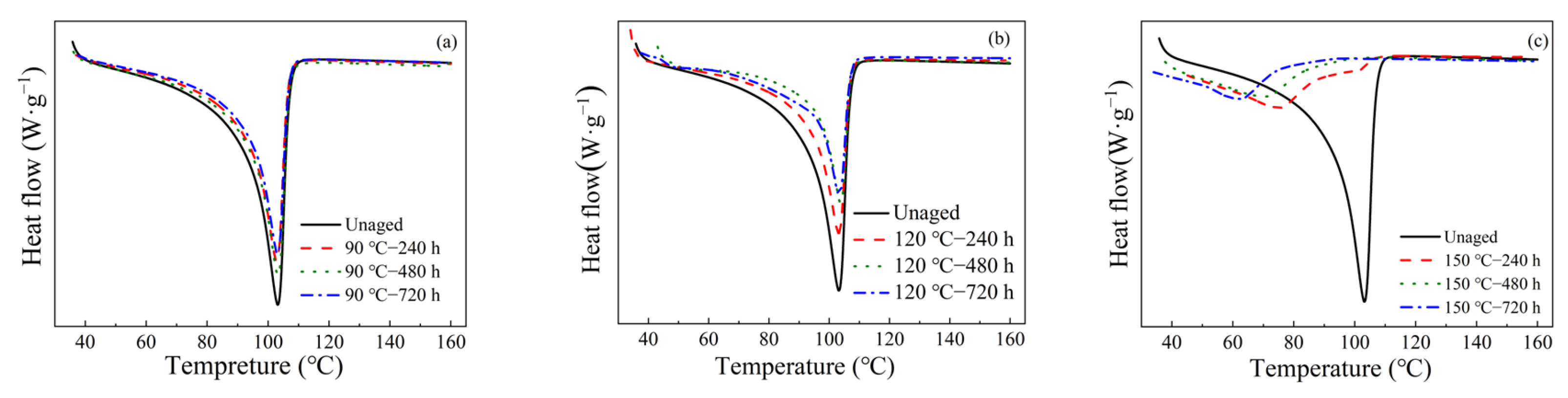

3.3. DSC Results

3.4. VLF Dielectric Spectroscopy

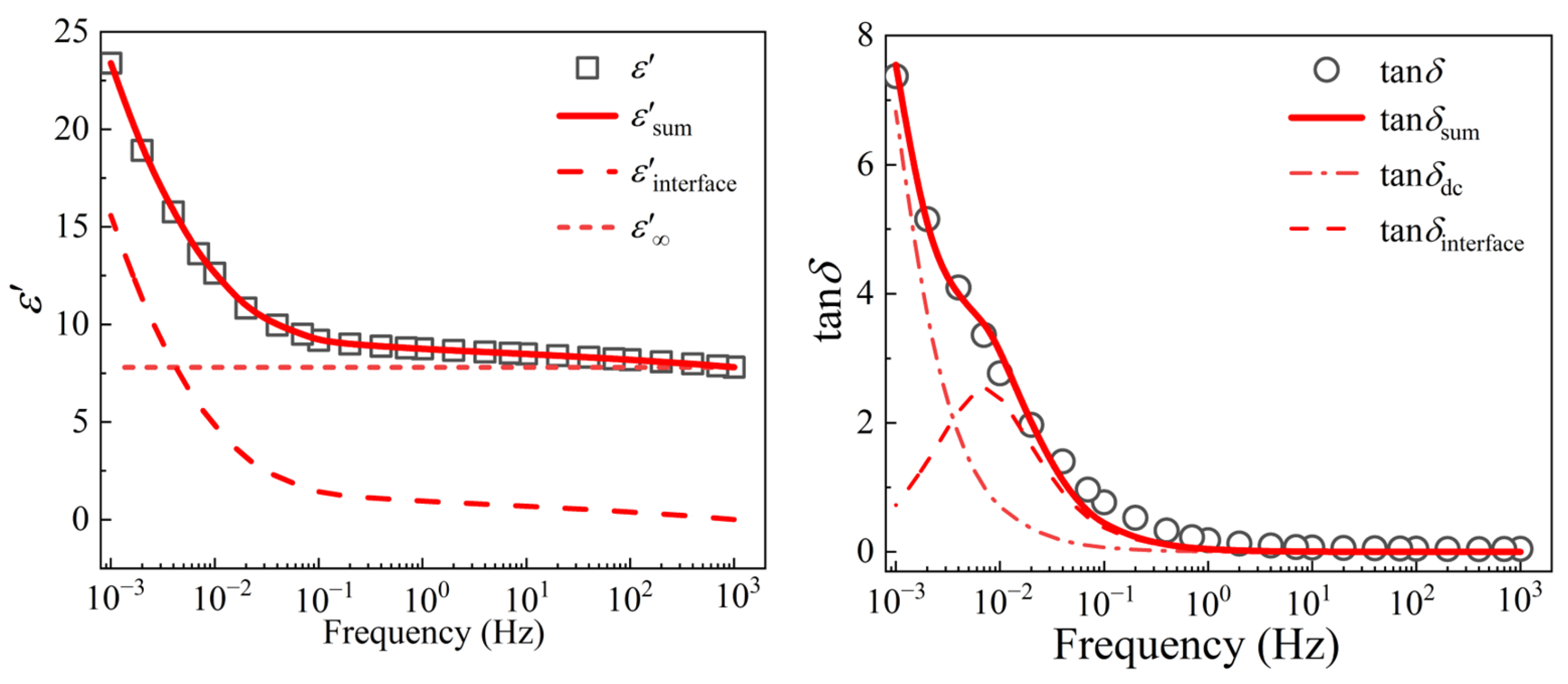

3.5. VLF Dielectric Spectroscopy of XLPE Samples

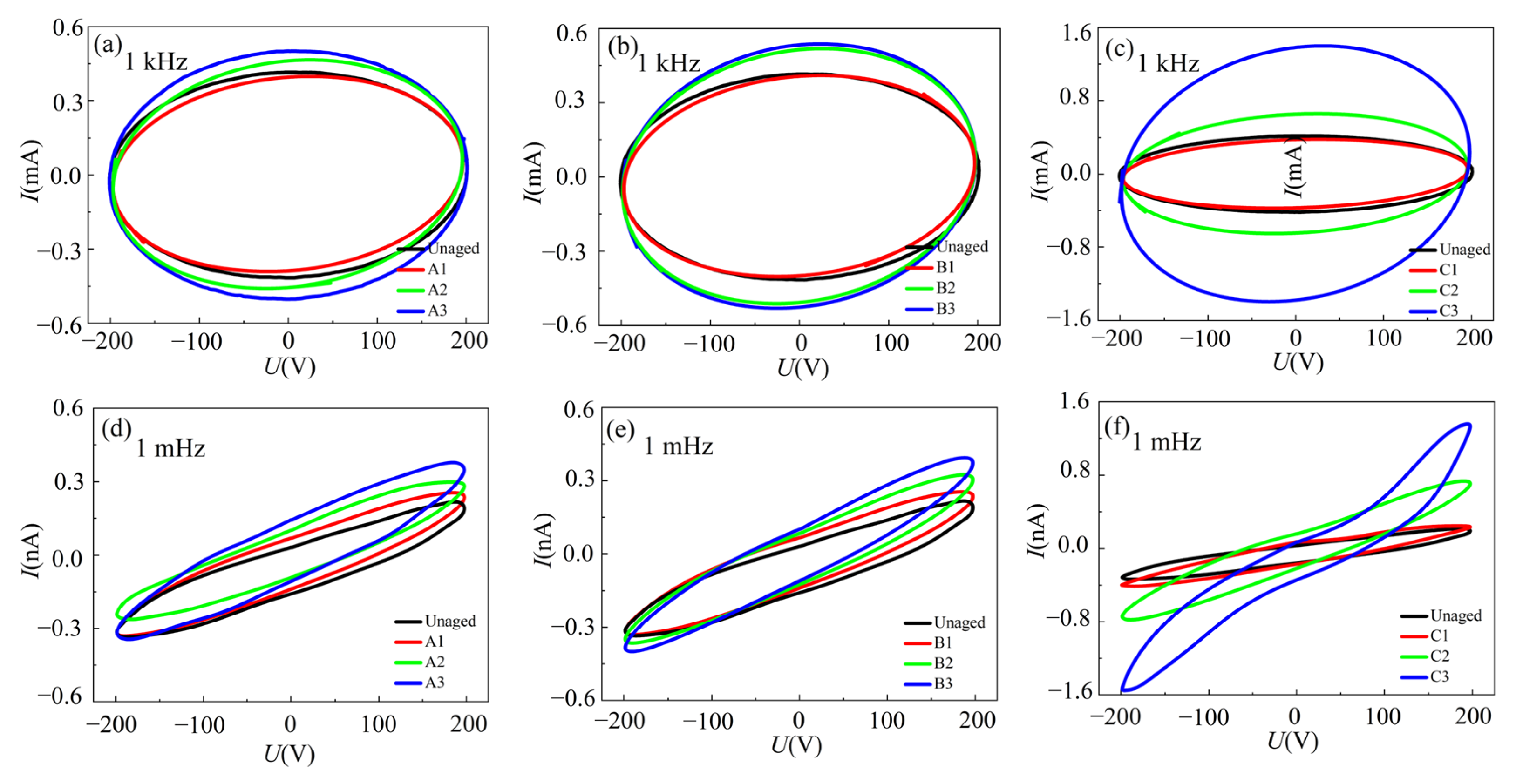

3.6. Nonlinear U–I Hysteresis Curves

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C.; Wang, M.; Zhang, M.; Li, X.; Wang, H.; Xing, Z.; Ye, L.-F.; Wu, G. Supercritical CO2 foaming of radiation cross-linked isotactic polypropylene in the presence of TAIC. Molecules 2016, 21, 1660. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, C.; Zhao, X.; Ren, L.; Yu, L.; Jin, Y.; Tan, W.; Zheng, W.; Li, H.; Yang, L.; Liao, R. Enhanced dielectric and energy storage properties of P(VDF-HFP) through elevating β-phase formation under unipolar nanosecond electric pulses. Appl. Phys. Lett. 2023, 122, 023903. [Google Scholar] [CrossRef]

- Ren, L.; Li, H.; Xie, Z.; Ai, D.; Zhou, Y.; Liu, Y.; Zhang, S.; Yang, L.; Zhao, X.; Peng, Z.; et al. High-temperature high-energy-density dielectric polymer nanocomposites utilizing inorganic core–shell nanostructured nanofillers. Adv. Energy Mater. 2021, 11, 2101297. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Y.; Fu, C.; Meng, S.; Peng, C.; Li, Z.; Du, B. Effects of pre-crosslinking on space charge and breakdown characteristics of XLPE cable insulation. Energies 2022, 15, 2360. [Google Scholar] [CrossRef]

- Teyssedre, G.; Laurent, C. Advances in high-field insulating polymeric materials over the past 50 years. IEEE Electr. Insul. Mag. 2013, 29, 26–36. [Google Scholar] [CrossRef]

- Andrews, T.; Hampton, R.N.; Smedberg, A.; Wald, D.; Waschk, V.; Weissenberg, W. The role of degassing in XLPE power cable manufacture. IEEE Electr. Insul. Mag. 2006, 22, 5–16. [Google Scholar] [CrossRef]

- Suo, C.; Qin, Y.; Li, Z. Effect of thermal ageing on DC conductivity of NANO-CB/XLPE insulating composites. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018; pp. 1–4. [Google Scholar]

- Gulmine, J.V.; Akcelrud, L. Correlations between structure and accelerated artificial ageing of XLPE. Eur. Polym. J. 2006, 42, 553–562. [Google Scholar] [CrossRef]

- Kemari, Y.; Mekhaldi, A.; Teyssèdre, G.; Teguar, M. Correlations between structural changes and dielectric behavior of thermally aged XLPE. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1859–1866. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Ma, Y.; Yan, Q.; Ouyang, B. The role of thermo-oxidative ageing at different temperatures on the crystal structure of crosslinked polyethylene. J. Mater. Sci. Mater. Electron. 2018, 29, 3696–3703. [Google Scholar] [CrossRef]

- Ouyang, B.; Li, H.; Zhang, X.; Wang, S.; Li, J. The role of micro-structure changes on space charge distribution of XLPE during thermo-oxidative ageing. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3849–3859. [Google Scholar] [CrossRef]

- Dai, X.; Hao, J.; Jian, Z.; Gao, Z.; Cheng, J.; Zheng, X. Ageing state identification and analysis of AC 500 kV XLPE submarine cable based on high-voltage frequency dielectric response. IET Sci. Meas. Technol. 2020, 14, 977–984. [Google Scholar] [CrossRef]

- Farahani, M.; Borsi, H.; Gockenbach, E. Dielectric response studies on insulating system of high voltage rotating machines. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 383–393. [Google Scholar] [CrossRef]

- Perkel, J.; Del Valle, Y.; Hampton, R.N.; Hernandez-mejia, J.C.; Densley, J. Interpretation of dielectric loss data on service aged polyethylene based power cable systems using VLF test methods. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1699–1711. [Google Scholar] [CrossRef]

- Hernandez-Mejia, J.C.; Perkel, J.; Harley, R.; Hampton, N.; Hartlein, R. Correlation between tan δ diagnostic measurements and breakdown performance at VLF for MV XLPE cables. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 162–170. [Google Scholar] [CrossRef]

- Morsalin, S.; Phung, B.T. Dielectric response measurement on service-aged XLPE cables: From very low frequency to power frequency. IEEE Electr. Insul. Mag. 2020, 36, 19–31. [Google Scholar] [CrossRef]

- Cheng, X.; Ye, G.; Sun, H.; Li, T.; Sun, C. Analysis of low-frequency dielectric loss of XLPE cable insulation based on extended Debye model. AIP Adv. 2021, 11, 085103. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.; Gao, J.; Zheng, H.; Li, Y. Accelerating frequency domain dielectric spectroscopy measurements on insulation of transformers through system identification. IET Sci. Meas. Technol. 2018, 12, 247–254. [Google Scholar] [CrossRef]

- IEC. Part 1: General guidelines for ageing procedures and evaluation of test result. In Guide for the Determination of Thermal Endurance Properties of Electrical Insulating Materials, 4th ed.; IEC: Geneva, Switzerland, 1991. [Google Scholar]

- Huang, B.; Wang, W.; Li, S.; Li, X.; Nie, Y.; Deng, Y.; Jiang, Q. Study on insulation performance of thermal ageing XLPE cables by direct current integrated charge technique. In Proceedings of the 2021 International Conference on Electrical Materials and Power Equipment (ICEMPE), Chongqing, China, 11 April 2021; pp. 1–4. [Google Scholar]

- Lv, H.; Yang, K.; Xiao, X.; Kuang, G.; Yu, S.; Kang, H.; Jin, H. Research on thermal endurance properties of XLPE aged in different media. IOP Conf. Ser. Earth Environ. Sci. 2020, 440, 022067. [Google Scholar] [CrossRef]

- Li, K.; Zhou, K.; Zhang, H.; Jin, H.; Li, X. Understanding the crystalline region damage mechanism of XLPE in water tree propagation by erosion method. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 2074–2082. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Adam, T.Z. Evaluation of thermally aged nuclear power plant power cables based on electrical condition monitoring and regression analysis. In Proceedings of the 2019 International IEEE Conference and Workshop in Óbuda on Electrical and Power Engineering (CANDO-EPE), Budapest, Hungary, 20–21 November 2019; pp. 203–206. [Google Scholar]

- Yang, L.; Chen, J.; Wang, S.; Gao, J. Dielectric response measurement of oil-paper insulation based on system identification and its time-frequency-domain conversion method. IEEE Trans. Dielect. Electr. Insul. 2018, 25, 1688–1698. [Google Scholar] [CrossRef]

- Kemari, Y.; Mekhaldi, A.; Teguar, M. Experimental investigation and signal processing techniques for degradation assessment of XLPE and PVC/B materials under thermal ageing. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2559–2569. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Tian, J.; Meng, S.; Zhou, Y. Thermal ageing properties of 500 kV AC and DC XLPE cable insulation materials. Polymers 2022, 14, 5400. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sun, M.; Zhao, K.; Wang, X.; Xu, Q.; Wang, W.; Li, C. High-voltage FDS of thermally aged XLPE cable and its correlation with physicochemical properties. Polymers 2022, 14, 3519. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Gao, J.; Wang, S.; Wu, K.; Li, J. Ageing assessment of XLPE cable insulation by residual antioxidant content. IEEE Trans. Dielect. Electr. Insul. 2020, 27, 1795–1802. [Google Scholar] [CrossRef]

- Nobrega, A.M.; Martinez, M.L.B.; de Queiroz, A.A.A. Investigation and analysis of electrical ageing of XLPE insulation for medium voltage covered conductors manufactured in Brazil. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 628–640. [Google Scholar] [CrossRef]

- Li, W.; Zheng, W.; Ren, L.; Li, H.; Zhao, X.; Wang, C.; Li, J. A comparative study on the insulation ageing of 10 kV XLPE cable via accelerated electrical test and accelerated water tree test. J. Electr. Eng. Technol. 2022, 17, 475–484. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Yu, L.; Li, Y.; Gao, L. Effect of thermal stress on the space charge distribution of 160 kV HVDC cable insulation material. IEEE Trans. Dielect. Electr. Insul. 2017, 24, 1355–1364. [Google Scholar] [CrossRef]

- Zheng, W.; Ren, L.; Zhao, X.; Li, H.; Xie, Z.; Li, Y.; Wang, C.; Yu, L.; Yang, L.; Liao, R. Tuning interfacial relaxations in P(VDF-HFP) with Al2O3@ZrO2 core-shell nanofillers for enhanced dielectric and energy storage performance. Compos. Sci. Technol. 2022, 222, 109379. [Google Scholar] [CrossRef]

- Meng, H.; Wu, X.; Zhang, K.; Liu, H.; Mao, H.; Gao, F.; Gao, Y.; Li, L.; Su, G.; Zhang, H.; et al. Ageing evaluation of 10 kV overhead cables based on frequency domain spectroscopy. In Proceedings of the 2020 IEEE 1st China International Youth Conference on Electrical Engineering (CIYCEE), Wuhan, China, 1–4 November 2020; pp. 1–5. [Google Scholar]

- Liu, J.; Xu, Y.; Wei, X.; Li, X. Research of Dielectric spectroscopy on insulation ageing assessment of XLPE cables. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 140–143. [Google Scholar]

- Moynihan, C.T.; Bressel, R.D.; Angell, C.A. Conductivity and dielectric relaxation in concentrated aqueous lithium chloride solutions. J. Chem. Phys. 1971, 55, 4414–4424. [Google Scholar] [CrossRef]

- Hvidsten, S.; Ildstad, E.; Faremo, H. Mechanisms causing nonlinear dielectric response of water treed XLPE cables. In Proceedings of the 1998 IEEE 6th International Conference on Conduction and Breakdown in Solid Dielectrics (Cat. No.98CH36132), Vasteras, Sweden, 22–25 June 1998; pp. 73–78. [Google Scholar]

- Deng, Y.; Yang, L.; Guo, X.; Nie, W.; Liao, R.; Li, W.; Qin, Z. Nonlinear dielectric response characteristics of damp oil-paper insulation and application of H-W model in time-frequency conversion. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 2078–2086. [Google Scholar] [CrossRef]

| Sample Number | Aging Temperature (°C) | Aging Time (h) |

|---|---|---|

| Unaged | / | / |

| A1 | 90 | 240 |

| A2 | 90 | 480 |

| A3 | 90 | 720 |

| B1 | 120 | 240 |

| B2 | 120 | 480 |

| B3 | 120 | 720 |

| C1 | 150 | 240 |

| C2 | 150 | 480 |

| C3 | 150 | 720 |

| Samples | Tm (°C) | Tc (°C) | ∆Tm (°C) | ∆Hm (J·g−1) | Xc |

|---|---|---|---|---|---|

| Unaged | 103.17 | 90.51 | 10.76 | 108.90 | 0.379 |

| A1 | 103.27 | 91.02 | 10.37 | 103.00 | 0.359 |

| A2 | 103.31 | 90.9 | 10.51 | 101.10 | 0.352 |

| A3 | 103.15 | 91.1 | 10.11 | 102.47 | 0.357 |

| B1 | 103.76 | 91.3 | 10.55 | 97.95 | 0.341 |

| B2 | 103.77 | 92.28 | 8.14 | 76.75 | 0.267 |

| B3 | 103.33 | 91.53 | 9.19 | 71.27 | 0.248 |

| C1 | 75.39 | 57.3 | 45.31 | 57.96 | 0.202 |

| C2 | 68.70 | 49.71 | 30.16 | 51.45 | 0.179 |

| C3 | 62.23 | 43.7 | 27.56 | 42.60 | 0.148 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Zhao, X.; Qiao, J.; Xiao, Y.; Zhang, J.; Li, Y.; Cao, H.; Yang, L.; Liao, R. Structural Changes and Very-Low-Frequency Nonlinear Dielectric Response of XLPE Cable Insulation under Thermal Aging. Materials 2023, 16, 4388. https://doi.org/10.3390/ma16124388

Wang C, Zhao X, Qiao J, Xiao Y, Zhang J, Li Y, Cao H, Yang L, Liao R. Structural Changes and Very-Low-Frequency Nonlinear Dielectric Response of XLPE Cable Insulation under Thermal Aging. Materials. 2023; 16(12):4388. https://doi.org/10.3390/ma16124388

Chicago/Turabian StyleWang, Can, Xuetong Zhao, Jingqi Qiao, Yongjian Xiao, Jie Zhang, Yuchen Li, Hanzhong Cao, Lijun Yang, and Ruijin Liao. 2023. "Structural Changes and Very-Low-Frequency Nonlinear Dielectric Response of XLPE Cable Insulation under Thermal Aging" Materials 16, no. 12: 4388. https://doi.org/10.3390/ma16124388