Investigation of Water Absorption Behavior of Recycled Aggregates and its Effect on Concrete Strength

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportion and Sample Preparation

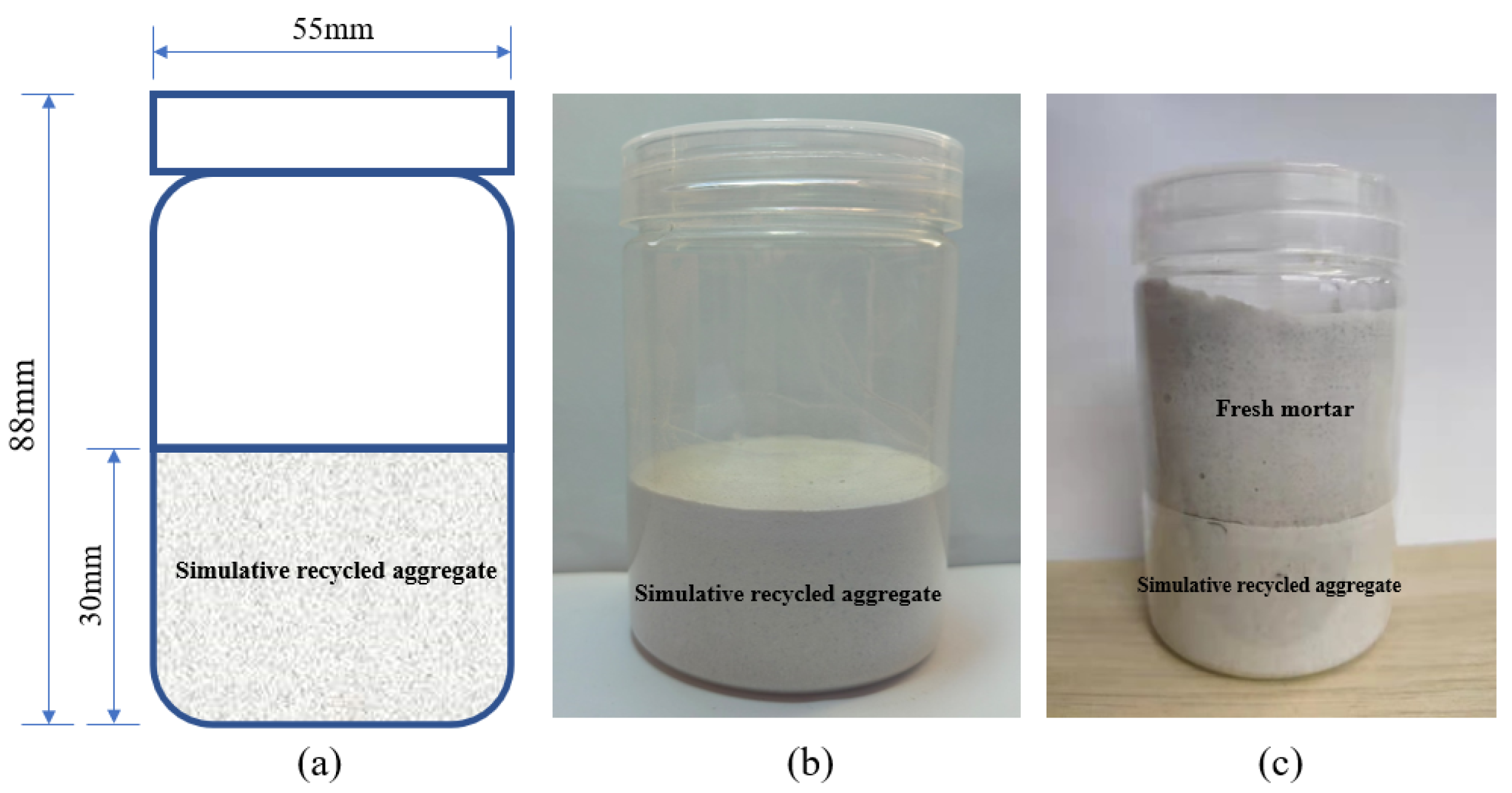

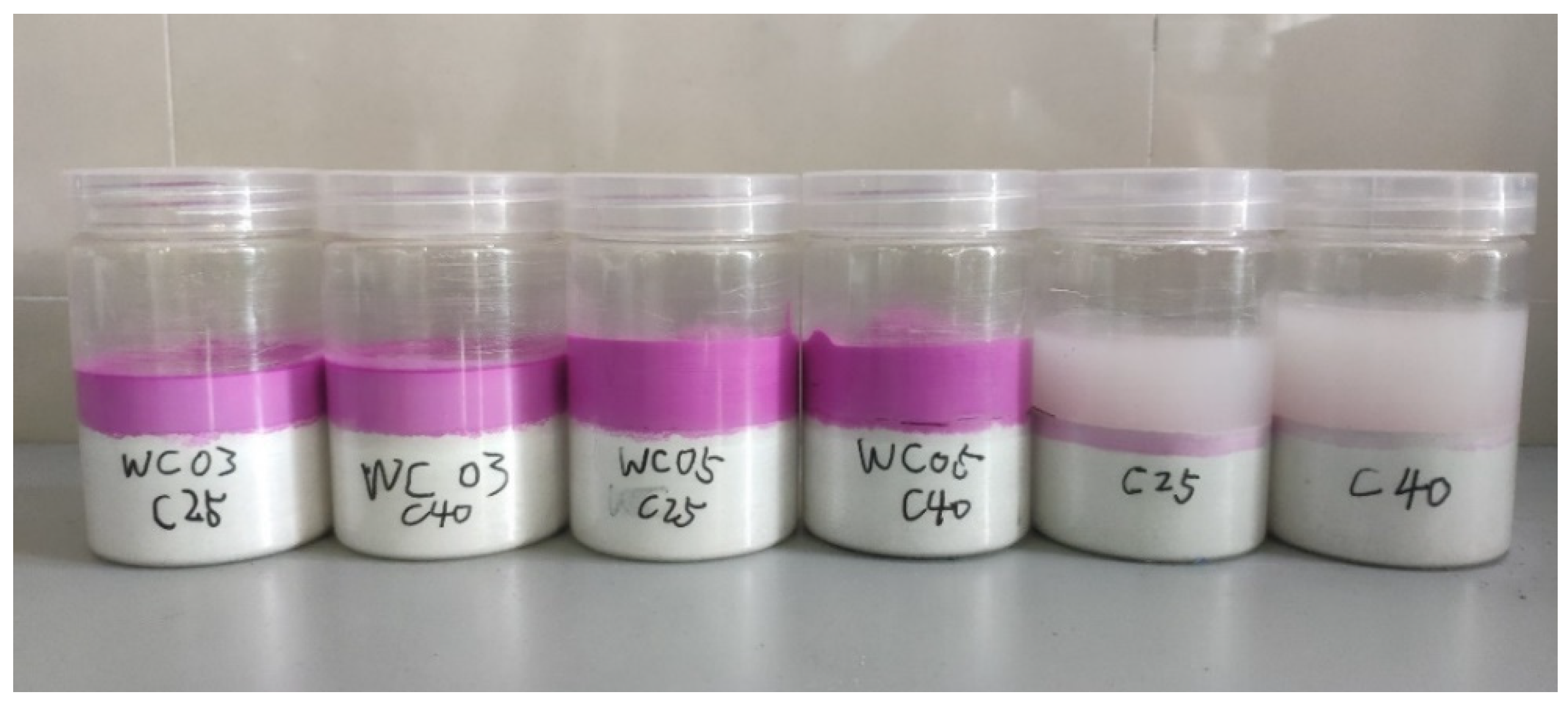

2.2.1. Specimen Preparation for 1D Frequency Coding Sequence Test

2.2.2. Specimen Preparation for CPMG Pulse Sequence Test

2.2.3. Mix Proportions of Concrete

2.3. Methods

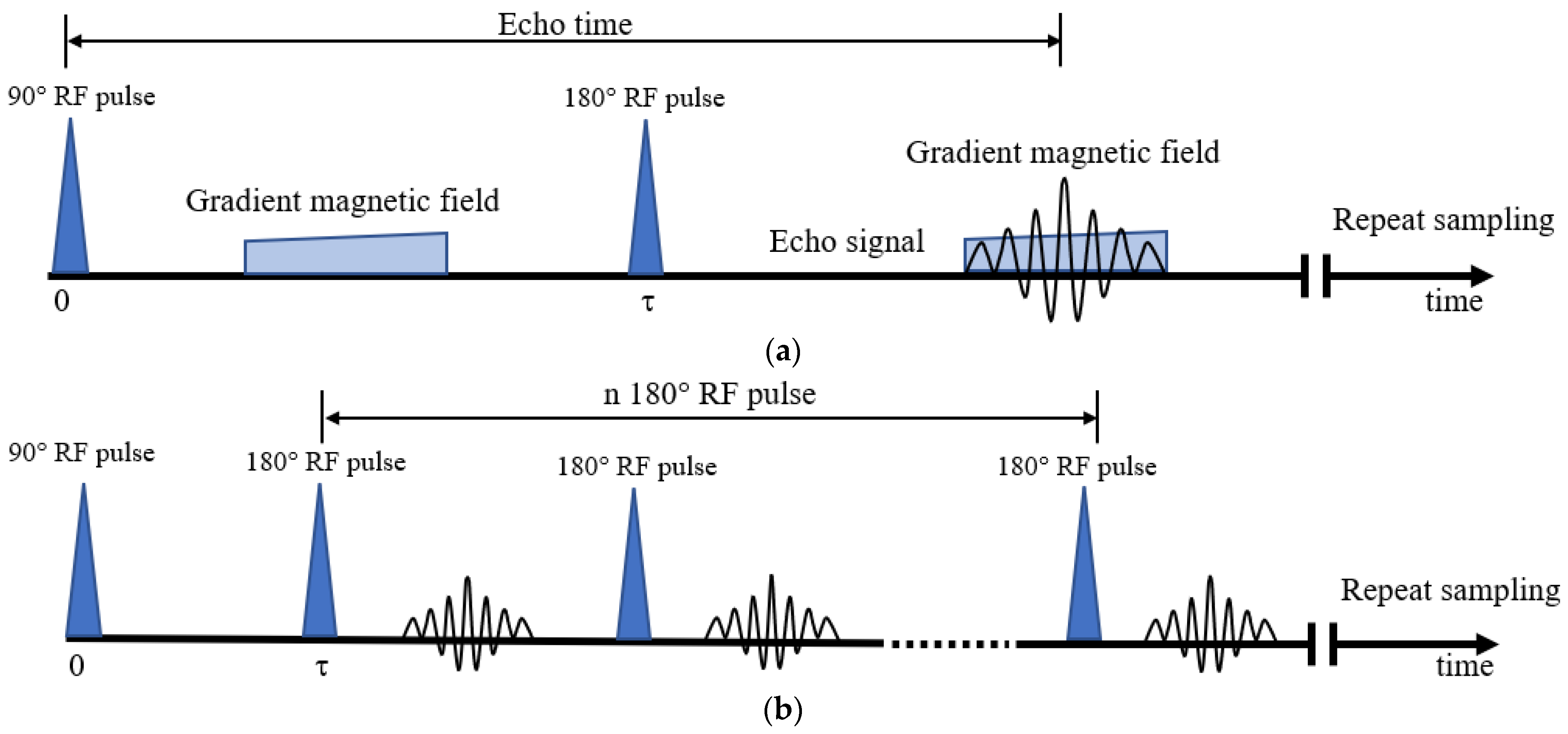

2.3.1. LF-NMR Test of 1D Frequency Coding Sequence

2.3.2. LF-NMR Test of CPMG

2.3.3. Slump and Compressive Strength Test

3. Results and Discussion

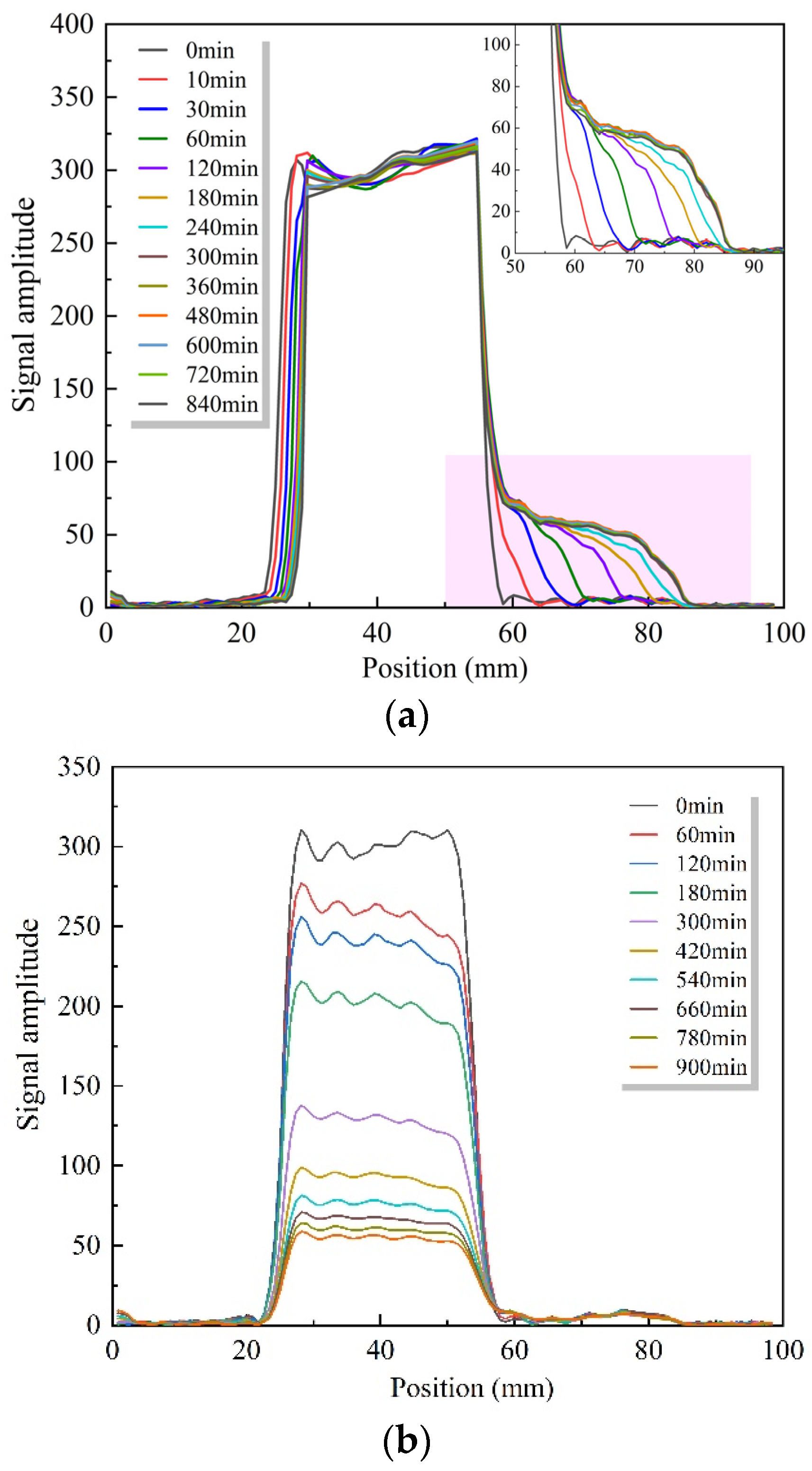

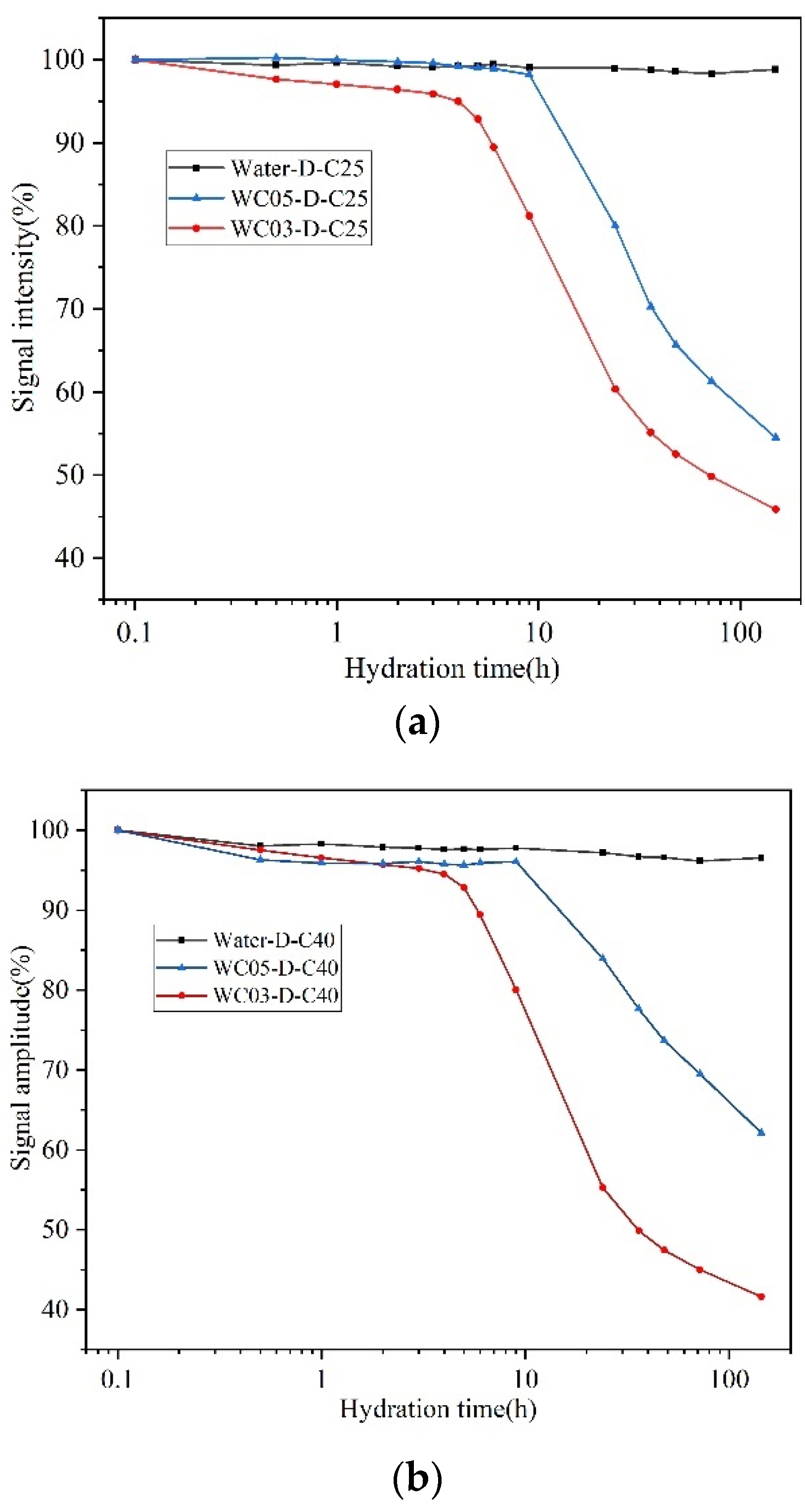

3.1. Experimental Results from 1D Frequency Coding Sequence

- (1)

- In order to obtain water signals in pores with pore size ≤ 100 nm, the echo interval time of the LF-NMR instrument should be set below 60 μs [29]. However, due to the limitation of the 1D frequency encoding sequence itself, the echo interval time in this experiment was set to 2.5 ms, so there is a possibility that a part of the signal from tiny pores was lost. There may be very little water migration between the SRA and fresh mortar, and the water preferentially enters the small pores inside the SRA and thus cannot be monitored. In contrast, there is a significant amount of water migration between the SRA and water, which is not affected by the accuracy of the measurement.

- (2)

- In high-strength recycled concrete with compressive strength greater than 60 MPa, the commonly used cement grades are P Ⅰ 52.5 or P Ⅱ 52.5, in which the clinker content is greater than 90% and the particle size is around 20 μm, resulting in fast cement hydration. After the contact between recycled aggregate and fresh mortar, the process of water absorption by the recycled aggregate and the process of cement hydration are carried out simultaneously, and the cement hydration consumes a large amount of free water rapidly. The w/c of high-strength recycled concrete is between 0.2 and 0.3, which is close to the theoretical minimum w/c required for full hydration of cement [39]. The rapid hydration of the cement leads to a reduction in the amount of water available in the mortar for absorption by the recycled aggregate, resulting in negligible actual water absorption by the recycled aggregate [33].

- (3)

- There are three main modes of water migration in silicate materials, including capillary processes, diffusion processes, and permeation under pressure gradients [40]. For unsaturated silicate materials, the capillary process is the most dominant migration mode. The relative humidity of water can be considered to remain constant when the recycled aggregates are in contact with pure water. Moisture migrates into the recycled aggregate under diffusion and capillary pressure until it fills all the open pores inside the recycled aggregate, which is the saturated state of water absorption of the recycled aggregate [41,42]. For the process of contact between the recycled aggregate and fresh mortar, the relative humidity of the fresh mortar decreases with its own hydration, and there may be a trace of water absorption of the recycled aggregate to make the internal humidity rise. At a certain moment, the relative humidity inside and outside the recycled aggregate reaches equilibrium, which is the maximum limit of water absorption of recycled aggregate in the mortar, and this maximum limit is much smaller than the saturated state of water absorption of recycled aggregate [43].

- (4)

- In high-strength concrete, the mortar has low porosity and few connecting pores, resulting in less migration of moisture within the mortar. After the recycled aggregate absorbs a trace amount of water from the surrounding mortar, the surrounding fresh mortar needs to be replenished with water from the more peripheral mortar by diffusion [44], which makes the amount of water available in the mortar for absorption by the recycled aggregate within a certain period of time much smaller than the amount of water that can be absorbed by the recycled aggregate in water [45].

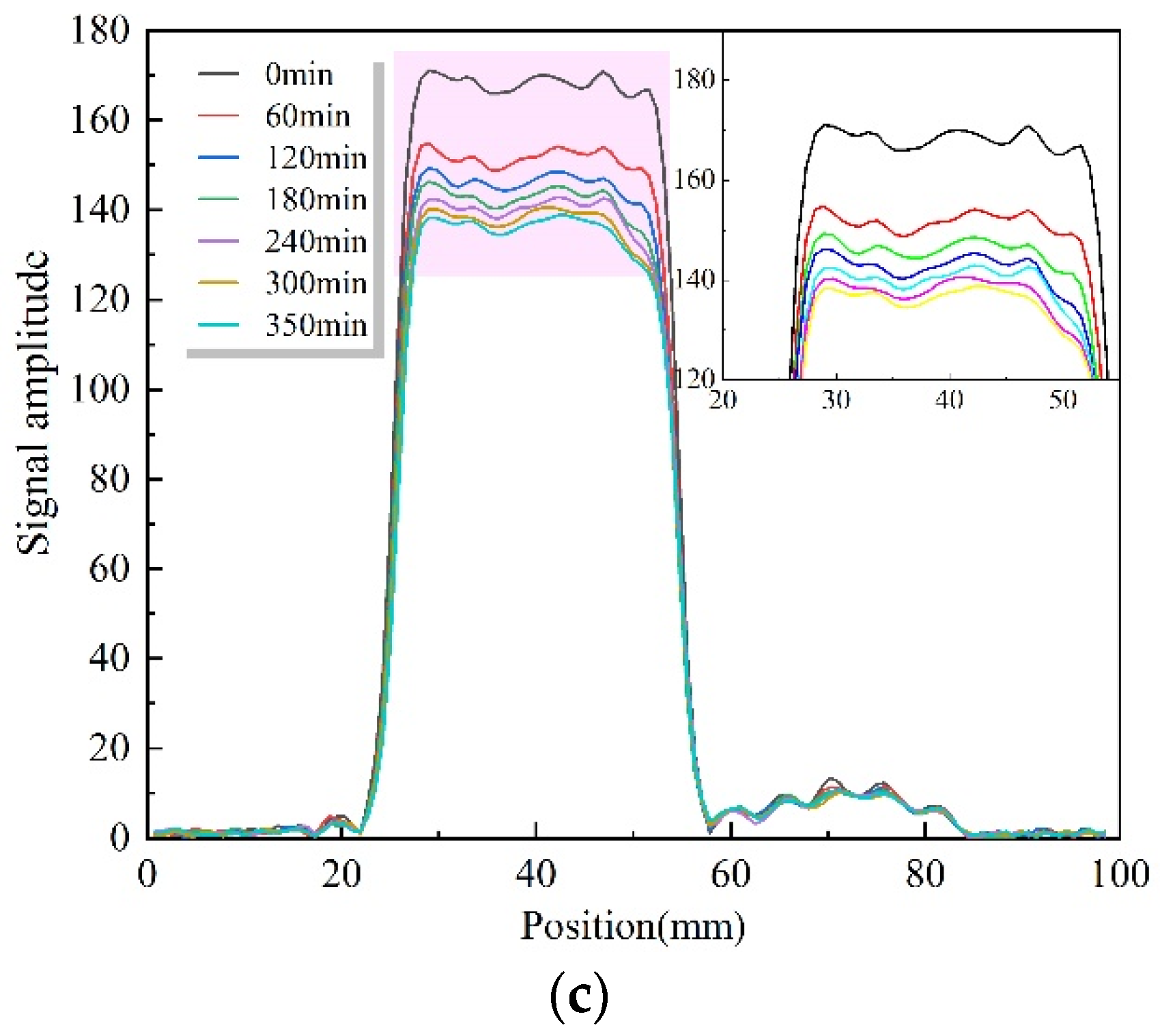

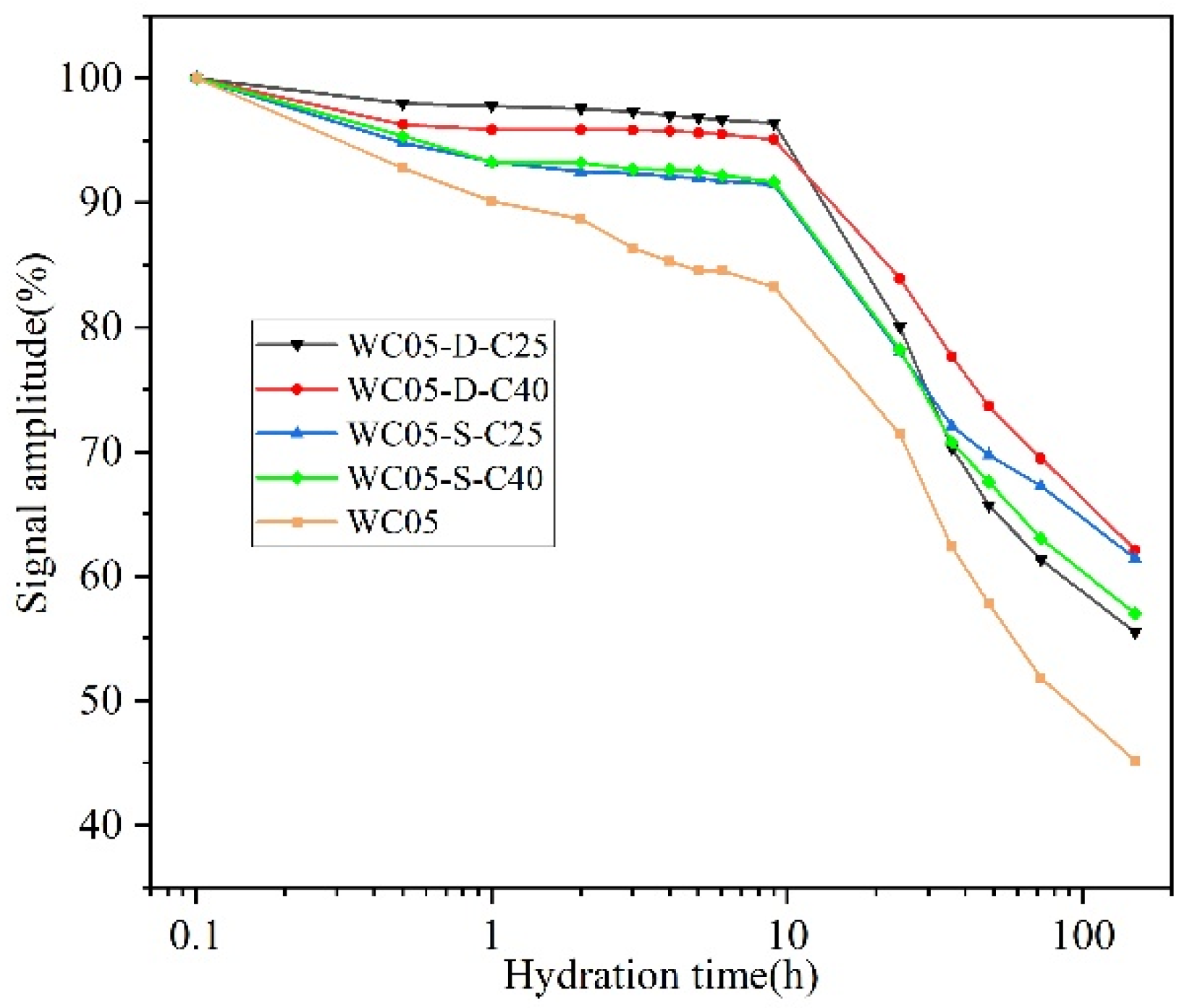

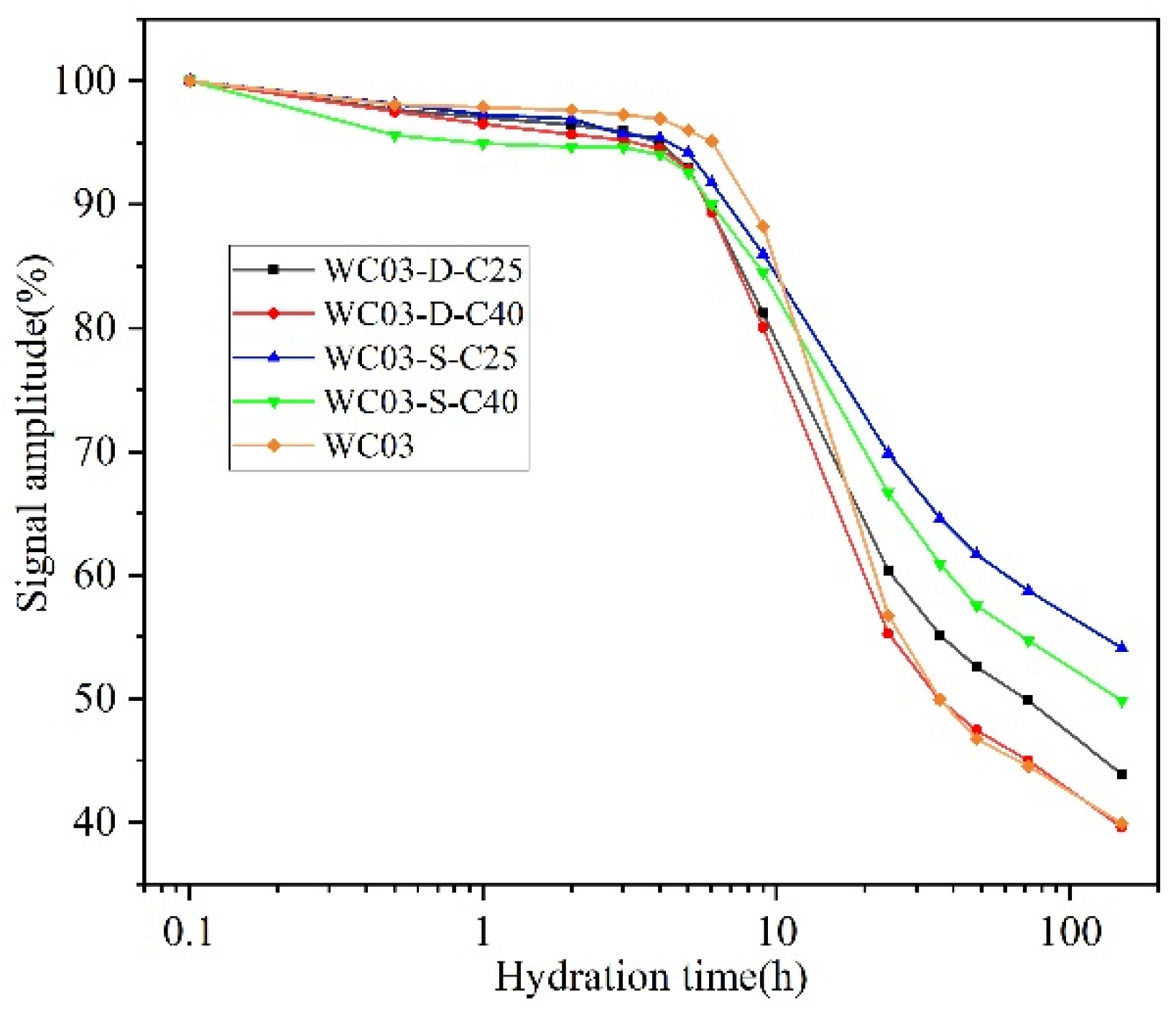

3.2. Experimental Results from CPMG

3.3. Workability

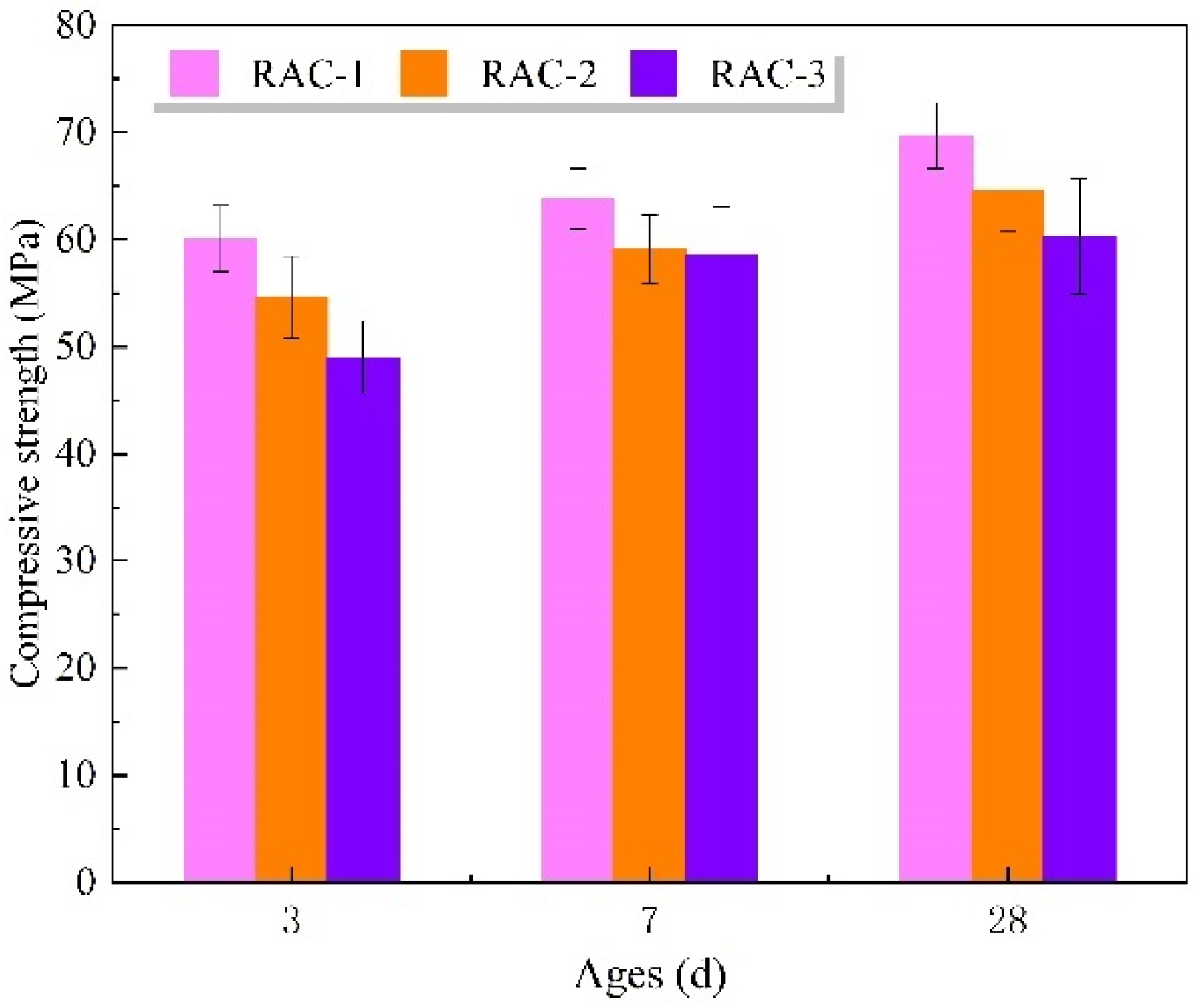

3.4. Compressive Strength

4. Conclusions

- (a)

- The 1D frequency coding sequence of LF-NMR can be applied to characterize the water absorption behavior of recycled aggregates, and the CPMG sequences can characterize the effect of recycled aggregates on cement hydration. LF-NMR imaging is a viable method for continuous nondestructive measurements.

- (b)

- When SRA is in contact with pure water, the depth of water migration in SRA increases with time and finally tends to be constant. When SRA is in contact with fresh mortar, little water migration occurs because the hydration of the cement in the mixture consumes a large amount of water, resulting in the inability of water to migrate through the capillary pressure into the recycled aggregate.

- (c)

- For the paste with high w/c, the addition of SRA with different strengths and water contents has a significant effect on cement hydration. Meanwhile for the low w/c paste, the strength and water content of SRA are of little impact on cement hydration. Low-strength recycled aggregates in the saturated face-dry state have the greatest adverse effect on cement hydration, and dry, high-strength recycled aggregates have almost no effect on cement hydration.

- (d)

- For high-strength RAC with a low w/c, WAC should be disregarded if the RCAs are strong enough and applied to fresh concrete in a dry state; otherwise, the compressive strength of the concrete will be reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cakir, O. Experimental analysis of properties of recycled coarse aggregate (RCA) concrete with mineral additives. Constr. Build. Mater. 2014, 68, 17–25. [Google Scholar] [CrossRef]

- Piccinali, A.; Diotti, A.; Plizzari, G.; Sorlini, S. Impact of Recycled Aggregate on the Mechanical and Environmental Properties of Concrete: A Review. Materials 2022, 15, 1818. [Google Scholar] [CrossRef] [PubMed]

- Rakesh Kumar Reddy, R.; Yaragal, S.C. A novel approach for optimizing the processing of recycled coarse aggregates. Constr. Build. Mater. 2023, 368, 130480. [Google Scholar] [CrossRef]

- Amario, M.; Rangel, C.S.; Pepe, M.; Toledo Filho, R.D. Optimization of normal and high strength recycled aggregate concrete mixtures by using packing model. Cem. Concr. Compos. 2017, 84, 83–92. [Google Scholar] [CrossRef]

- Du, T.; Chen, J.; Qu, F.; Li, C.; Zhao, H.; Xie, B.; Yuan, M.; Li, W. Degradation prediction of recycled aggregate concrete under sulphate wetting–drying cycles using BP neural network. Structures 2022, 46, 1837–1850. [Google Scholar] [CrossRef]

- Lei, B.; Xiong, Q.; Zhao, H.; Dong, W.; Tam, V.W.Y.; Sun, Z.; Li, W. Performance of asphalt mortar with recycled concrete powder under different filler-to-asphalt weight ratios. Case. Stud. Constr. Mat. 2023, 18, e01834. [Google Scholar] [CrossRef]

- Lei, B.; Yu, H.; Guo, Y.; Dong, W.; Liang, R.; Wang, X.; Lin, X.; Wang, K.; Li, W. Fracture behaviours of sustainable multi-recycled aggregate concrete under combined compression-shear loading. J. Build. Eng. 2023, 72, 106382. [Google Scholar] [CrossRef]

- Lei, B.; Yu, H.; Guo, Y.; Zhao, H.; Wang, K.; Li, W. Mechanical properties of multi-recycled aggregate concrete under combined compression-shear loading. Eng. Fail. Anal. 2023, 143, 106910. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, X.; Liu, W.; Zhao, B.; Wang, Q. Influence of the moisture states of aggregate recycled from waste concrete on the performance of the prepared recycled aggregate concrete (RAC)—A review. Constr. Build. Mater. 2022, 326, 126891. [Google Scholar] [CrossRef]

- Soares, D.; de Brito, J.; Ferreira, J.; Pacheco, J. Use of coarse recycled aggregates from precast concrete rejects: Mechanical and durability performance (vol 71, pg 263, 2014). Constr. Build. Mater. 2015, 100, 315. [Google Scholar] [CrossRef]

- Li, J.; Xiao, J.; Sun, Z. Properties of Recycled Coarse Aggregate and Its Influence on Recycled Concrete. J. Build. Mat. 2004, 7, 390–395. [Google Scholar]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Maimouni, H.; Remond, S.; Huchet, F.; Richard, P.; Thiery, V.; Descantes, Y. Quantitative assessment of the saturation degree of model fine recycled concrete aggregates immersed in a filler or cement paste. Constr. Build. Mater. 2018, 175, 496–507. [Google Scholar] [CrossRef]

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete—Extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867. [Google Scholar] [CrossRef]

- Castro, J.; Keiser, L.; Golias, M.; Weiss, J. Absorption and desorption properties of fine lightweight aggregate for application to internally cured concrete mixtures. Cem. Concr. Compos. 2011, 33, 1001–1008. [Google Scholar] [CrossRef]

- Fan, C.C.; Huang, R.; Hwang, H.; Chao, S.J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water absorption and chloride diffusivity of concrete under the coupling effect of uniaxial compressive load and freeze-thaw cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, J.; Wang, N.; Wu, C.; Zhang, X.; Wang, D.; Ma, Z. Combined Freeze-Thaw and Chloride Attack Resistance of Concrete Made with Recycled Brick-Concrete Aggregate. Materials 2021, 14, 7267. [Google Scholar] [CrossRef]

- GB/T 14685; Pebble and Crushed Stone of Construction. Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- BS EN 206; Concrete-Specification, Performance, Production and Conformity. British Standards Institution: London, UK, 2013.

- Leite, M.B.; do Figueire, J.G.L.; Lima, P.R.L. Workability study of concretes made with recycled mortar aggregate. Mater. Struct. 2013, 46, 1765–1778. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaili, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Agrela, F.; Sanchez de Juan, M.; Ayuso, J.; Geraldes, V.L.; Jimenez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef] [Green Version]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M.; Chan, C.H. New approach in measuring water absorption of recycled aggregates. Constr. Build. Mater. 2008, 22, 364–369. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Liu, J.P.; Xiao, J.Z.; Zhong, P.H. A method to determine water absorption of recycled fine aggregate in paste for design and quality control of fresh mortar. Constr. Build. Mater. 2019, 197, 30–41. [Google Scholar] [CrossRef]

- Feng, Q.; Liu, X.-J.; Peng, Z.-G.; Huo, J.-H.; Zheng, Y.; Liu, H. Characterization of the influence of Nanoparticles on Early Hydration of Oil Cement by Using Low Field NMR. Energ. Source Part A 2021, 43, 1202–1214. [Google Scholar] [CrossRef]

- She, A.M.; Ma, K.; Liao, G.; Yao, W.; Zuo, J.Q. Investigation of hydration and setting process in nanosilica-cement blended pastes: In situ characterization using low field nuclear magnetic resonance. Constr. Build. Mater. 2021, 304, 10. [Google Scholar] [CrossRef]

- She, A.; Yao, W. Probing the hydration of composite cement pastes containing fly ash and silica fume by proton NMR spin-lattice relaxation. Sci. China Technol. Sci. 2010, 53, 1471–1476. [Google Scholar] [CrossRef]

- Gummerson, R.J.; Hall, C.; Hoff, W.D.; Hawkes, R.; Holland, G.N.; Moore, W.S. Unsaturated Water-flow within Porous Materials Observed by NMR Imaging. Nature 1979, 281, 56–57. [Google Scholar] [CrossRef]

- Kopinga, K.; Pel, L. One-dimensional Scanning of Moisture in Porous Materials with NMR. Rev. Sci. Instrum. 1994, 65, 3673–3681. [Google Scholar] [CrossRef] [Green Version]

- Leech, C.; Lockington, D.; Dux, P. Unsaturated diffusivity functions for concrete derived from NMR images. Mater. Struct. 2003, 36, 413–418. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R.; Salas, A. Initial moisture and mixing effects on higher quality recycled coarse aggregate concrete. Constr. Build. Mater. 2015, 79, 83–89. [Google Scholar] [CrossRef]

- Therene, F.; Keita, E.; Nael-Redolfi, J.; Boustingorry, P.; Bonafous, L.; Roussel, N. Water absorption of recycled aggregates: Measurements, influence of temperature and practical consequences. Cem. Concr. Res. 2020, 137, 8. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, X.; Huang, Y.; Zhang, P.; Tian, Q.; Liu, J. Investigation of moisture transport in cement-based materials using low-field nuclear magnetic resonance imaging. Mag. Concrete. Res. 2021, 73, 252–270. [Google Scholar] [CrossRef]

- van der Heijden, G.H.A.; Huinink, H.P.; Pel, L.; Kopinga, K. One-dimensional scanning of moisture in heated porous building materials with NMR. J. Magn. Reson. 2011, 208, 235–242. [Google Scholar] [CrossRef]

- GB/T 50080; Standard for Test Method of Performance on Ordinary Fresh Concrete. Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- GB/T 50081; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates—Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Koenders, E.A.B.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- deOliveira, M.B.; Vazquez, E. The influence of retained moisture in aggregates from recycling on the properties of new hardened concrete. Waste Manag. 1996, 16, 113–117. [Google Scholar] [CrossRef]

- Domagala, L. The Effect of Lightweight Aggregate Water Absorption on the Reduction of Water-Cement Ratio in Fresh Concrete. In Proceedings of the 7th Scientific-Technical Conference Material Problems in Civil Engineering (MATBUD), Cracow, Poland, 22–24 June 2015; pp. 206–213. [Google Scholar]

- Ferreira, L.; de Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concrete. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- Eguchi, K.; Teranishi, K.; Narikawa, M. Study on Mechanism of Drying Shrinkage and Water Loss of Recycled Aggregate Concrete. J. Struct. Constr. Eng. 2003, 68, 1–7. [Google Scholar] [CrossRef]

- Omary, S.; Ghorbel, E.; Wardeh, G. Relationships between recycled concrete aggregates characteristics and recycled aggregates concretes properties. Constr. Build. Mater. 2016, 108, 163–174. [Google Scholar] [CrossRef]

- Hu, J.; Ge, Z.; Wang, K.J. Influence of cement fineness and water-to-cement ratio on mortar early-age heat of hydration and set times. Constr. Build. Mater. 2014, 50, 657–663. [Google Scholar] [CrossRef]

- Zhou, C.; Ren, F.; Zeng, Q.; Xiao, L.; Wang, W. Pore-size resolved water vapor adsorption kinetics of white cement mortars as viewed from proton NMR relaxation. Cem. Concr. Res. 2018, 105, 31–43. [Google Scholar] [CrossRef]

- Jin, D.; Lang, Z.; Yao, W. Analysis of Early Performance of Cement Paste by Low Field NMR. Appl. Sci. 2019, 9, 896. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.H.; Tyan, Y.Y.; Chang, T.P.; Chang, C.Y. An assessment of optimal mixture for concrete made with recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 1373–1380. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Das, P.K.; Tighe, S.L.; Baaj, H. Evaluation of of various treatment methods for enhancing the physical and morphological properties of coarse recycled concrete aggregate. Constr. Build. Mater. 2016, 112, 284–298. [Google Scholar] [CrossRef]

- Xiao, J.; Tang, Y.; Chen, H.; Zhang, H.; Xia, B. Effects of recycled aggregate combinations and recycled powder contents on fracture behavior of fully recycled aggregate concrete. J. Clean. Prod. 2022, 366, 132895. [Google Scholar] [CrossRef]

| Composition | CaO | SiO2 | MgO | SO3 | Al2O3 | K2O | Na2O | Fe2O3 |

|---|---|---|---|---|---|---|---|---|

| P.W 42.5 | 68.352 | 21.169 | 1.639 | 4.709 | 2.778 | 0.382 | 0.471 | 0.223 |

| P.W 52.5 | 72.172 | 15.956 | 3.909 | 3.835 | 1.844 | 0.804 | 0.274 | 0.267 |

| Coarse Aggregate | Grading (mm) | Apparent Density (kg/m3) | Crush Index (%) | Water Absorption (%) |

|---|---|---|---|---|

| RCA1 | 5~16.5 | 2580 | 10.6 | 6.4 |

| RCA2 | 16.5~31.5 | 2590 | 10.6 | 4.7 |

| Sample | w/c of Cement Paste | Water Content of SRA | Strength of SRA |

|---|---|---|---|

| Water-D-C25 | Water replace paste | dry | C25 |

| Water-D-C40 | Water replace paste | dry | C40 |

| WC03-D-C25 | 0.3 | dry | C25 |

| WC03-D-C40 | 0.3 | dry | C40 |

| WC03-S-C25 | 0.3 | SSD | C25 |

| WC03-S-C40 | 0.3 | SSD | C40 |

| WC05-D-C25 | 0.5 | dry | C25 |

| WC05-D-C40 | 0.5 | dry | C40 |

| WC05-S-C25 | 0.5 | SSD | C25 |

| WC05-S-C40 | 0.5 | SSD | C40 |

| WC03 | 0.3 | \ | \ |

| WC05 | 0.5 | \ | \ |

| Sample | Cement | Silica fume | Sand | RCAs | Water | PS | w/b |

|---|---|---|---|---|---|---|---|

| RAC-1 | 520 | 57 | 709 | 990 | 138 | 2.60 | 0.24 |

| RAC-2 | 520 | 57 | 709 | 990 | 183 | 1.56 | 0.32 |

| RAC-3 | 520 | 57 | 709 | 990 | 183 | 1.56 | 0.32 |

| Sample | WC03 | WC05 | Water |

|---|---|---|---|

| C25 | negative | negative | positive |

| C40 | negative | negative | positive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; She, A.; Yao, W. Investigation of Water Absorption Behavior of Recycled Aggregates and its Effect on Concrete Strength. Materials 2023, 16, 4505. https://doi.org/10.3390/ma16134505

Ding Y, She A, Yao W. Investigation of Water Absorption Behavior of Recycled Aggregates and its Effect on Concrete Strength. Materials. 2023; 16(13):4505. https://doi.org/10.3390/ma16134505

Chicago/Turabian StyleDing, Yangfei, Anming She, and Wu Yao. 2023. "Investigation of Water Absorption Behavior of Recycled Aggregates and its Effect on Concrete Strength" Materials 16, no. 13: 4505. https://doi.org/10.3390/ma16134505

APA StyleDing, Y., She, A., & Yao, W. (2023). Investigation of Water Absorption Behavior of Recycled Aggregates and its Effect on Concrete Strength. Materials, 16(13), 4505. https://doi.org/10.3390/ma16134505