Microstructure Evolution and Deformation Behavior of Extruded Mg-5Al-0.6Sc Alloy during Room and Elevated Temperature Tension Revealed by Ex-Situ EBSD and VPSC

Abstract

:1. Introduction

2. Materials and Methods

3. Results

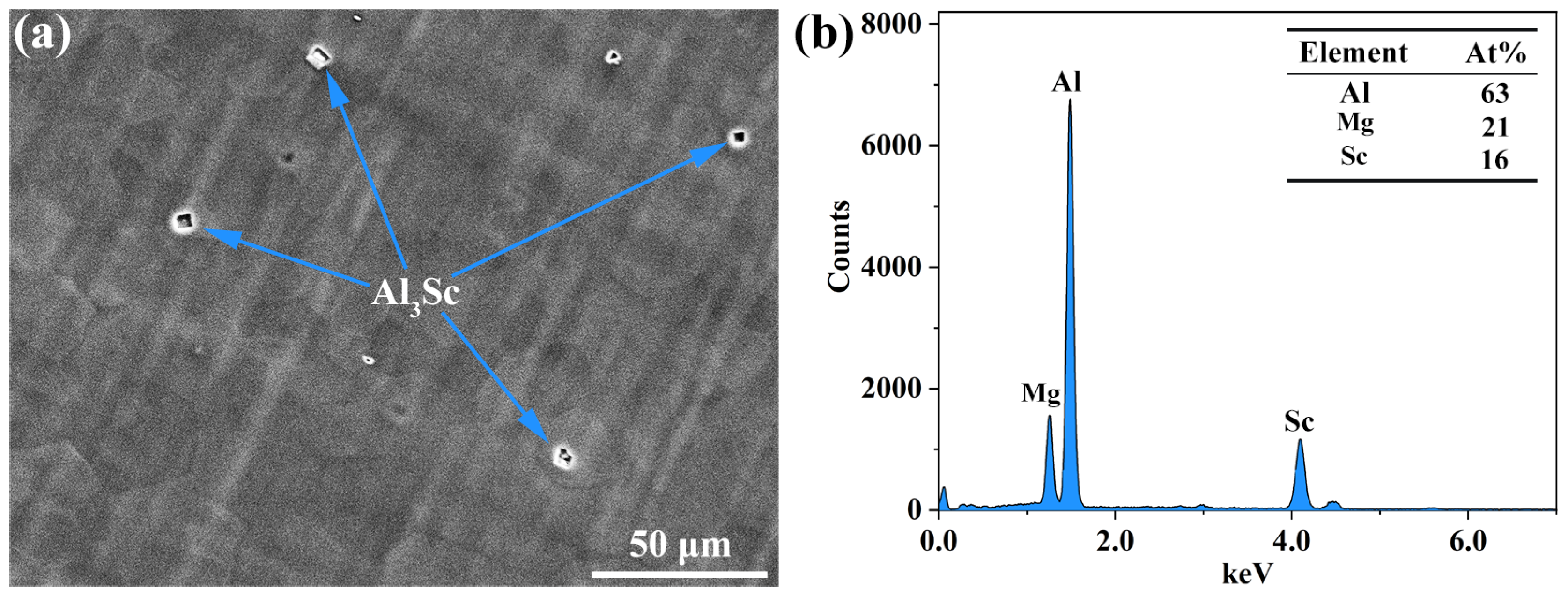

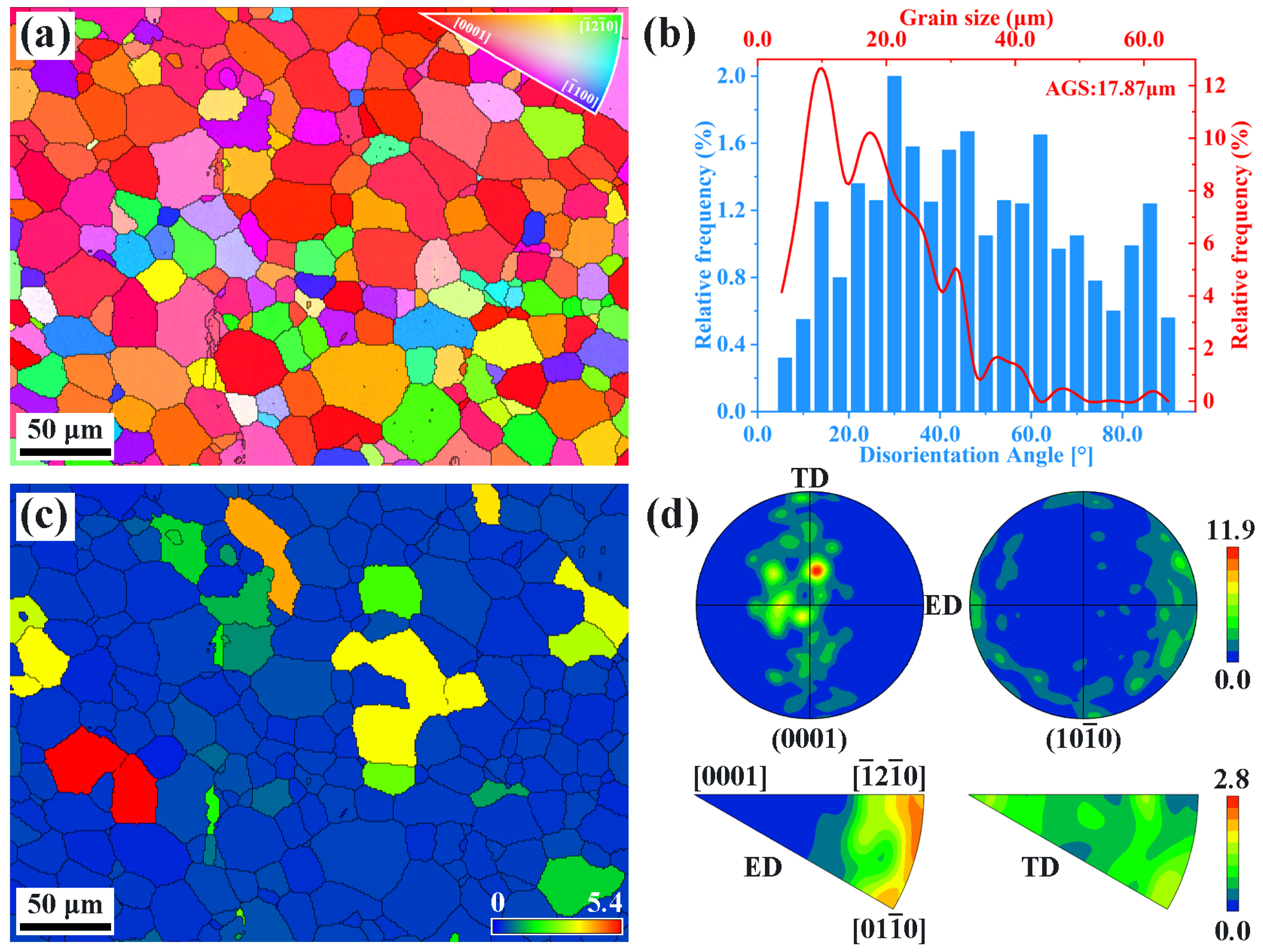

3.1. Initial Microstructure

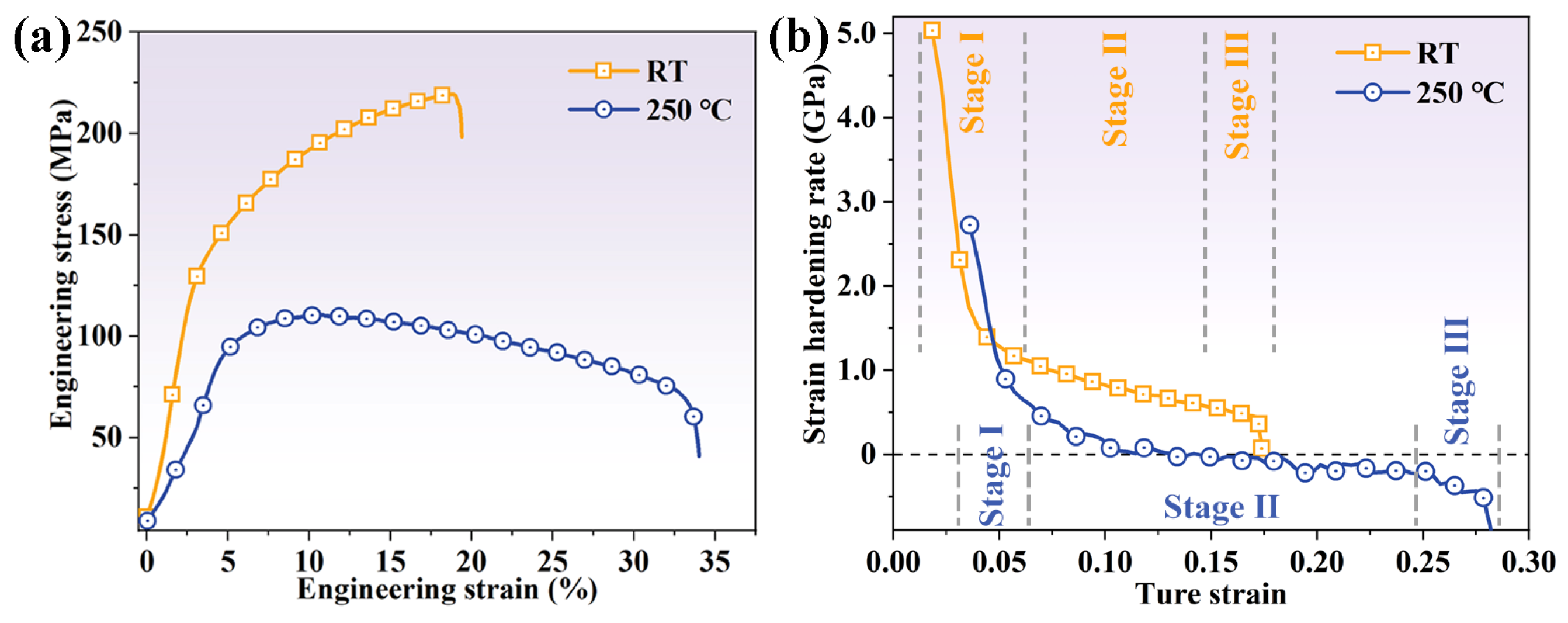

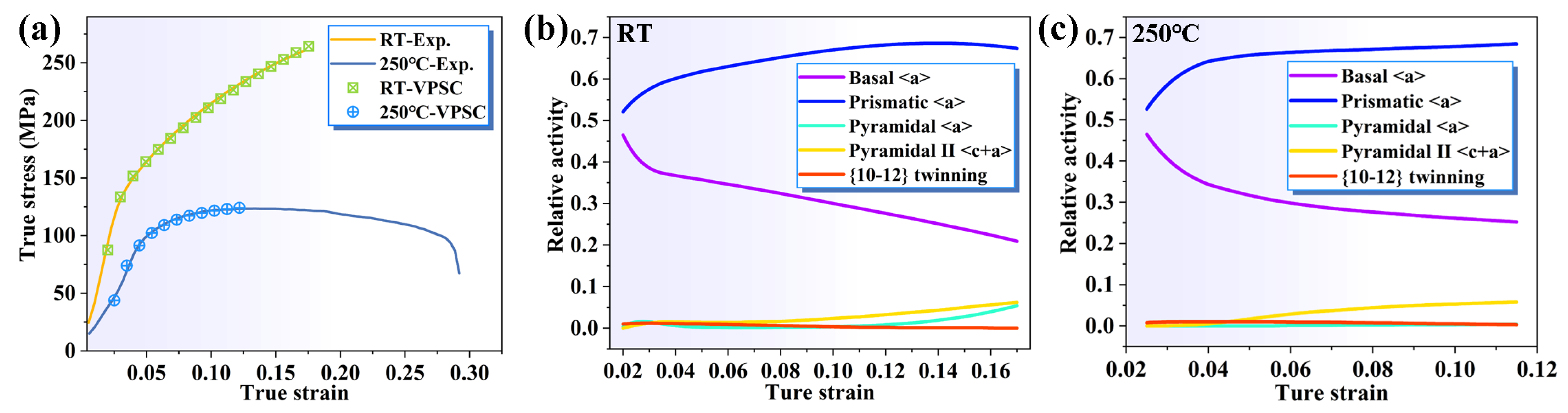

3.2. Engineering Stress–Strain Curve

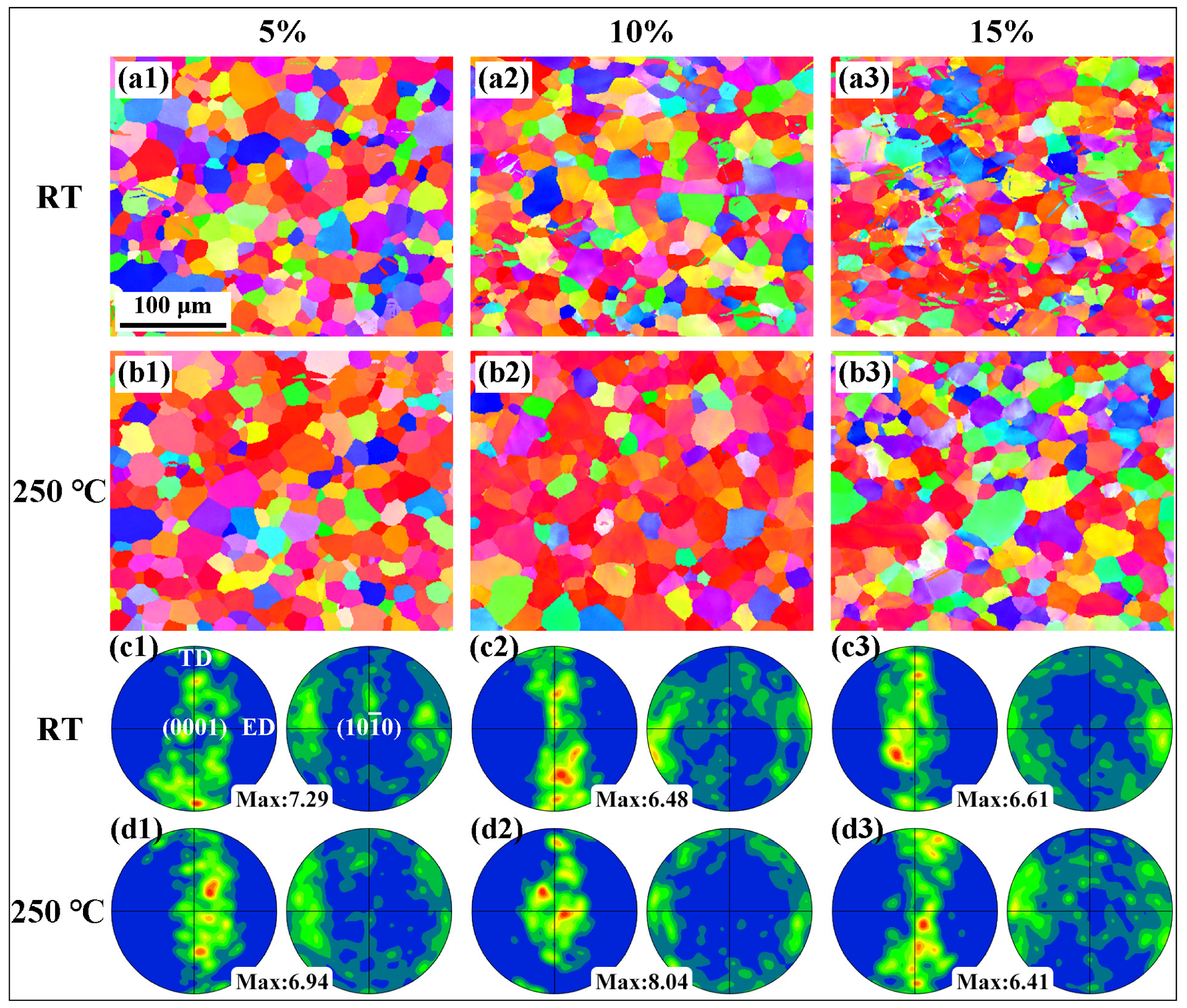

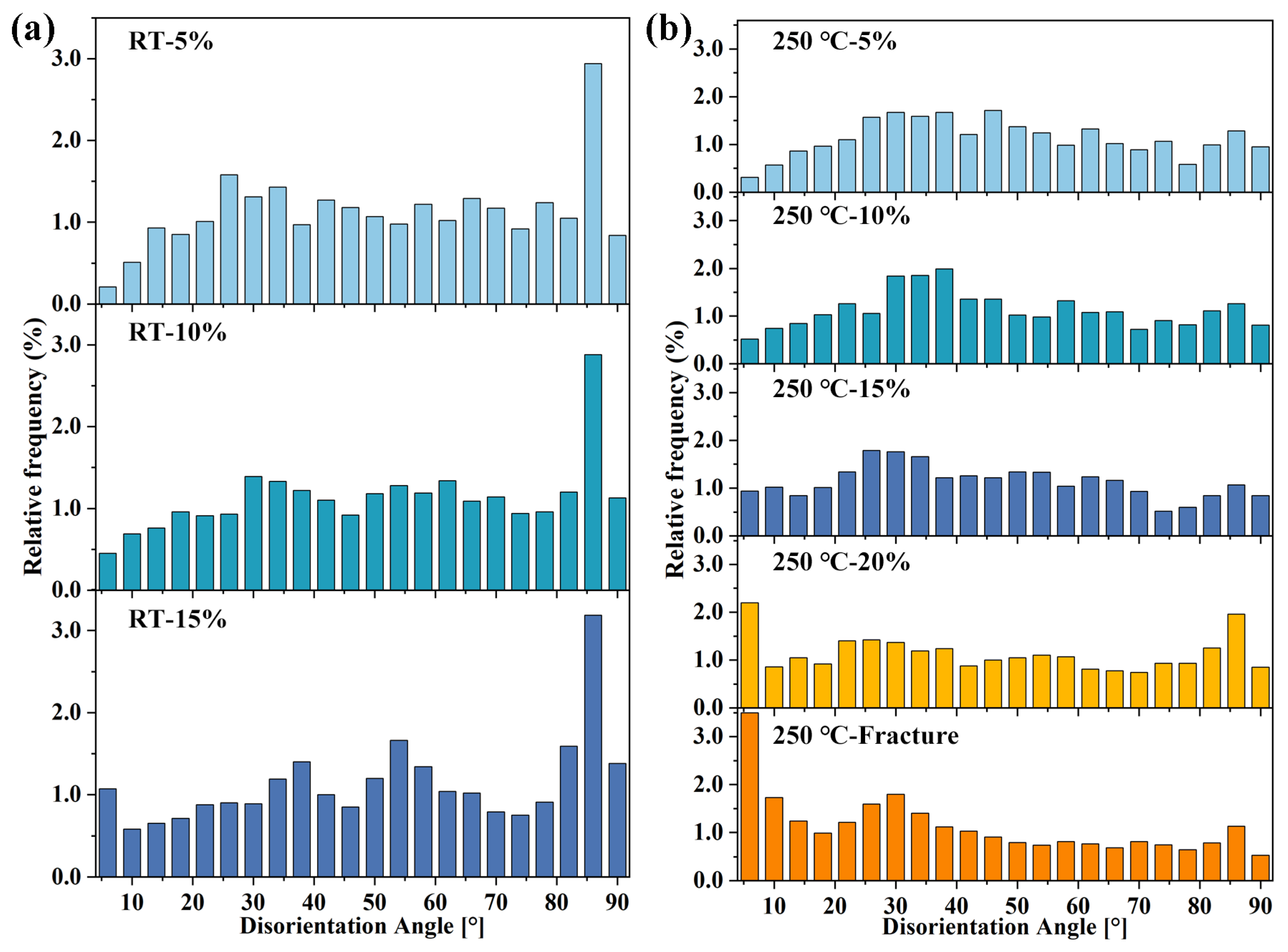

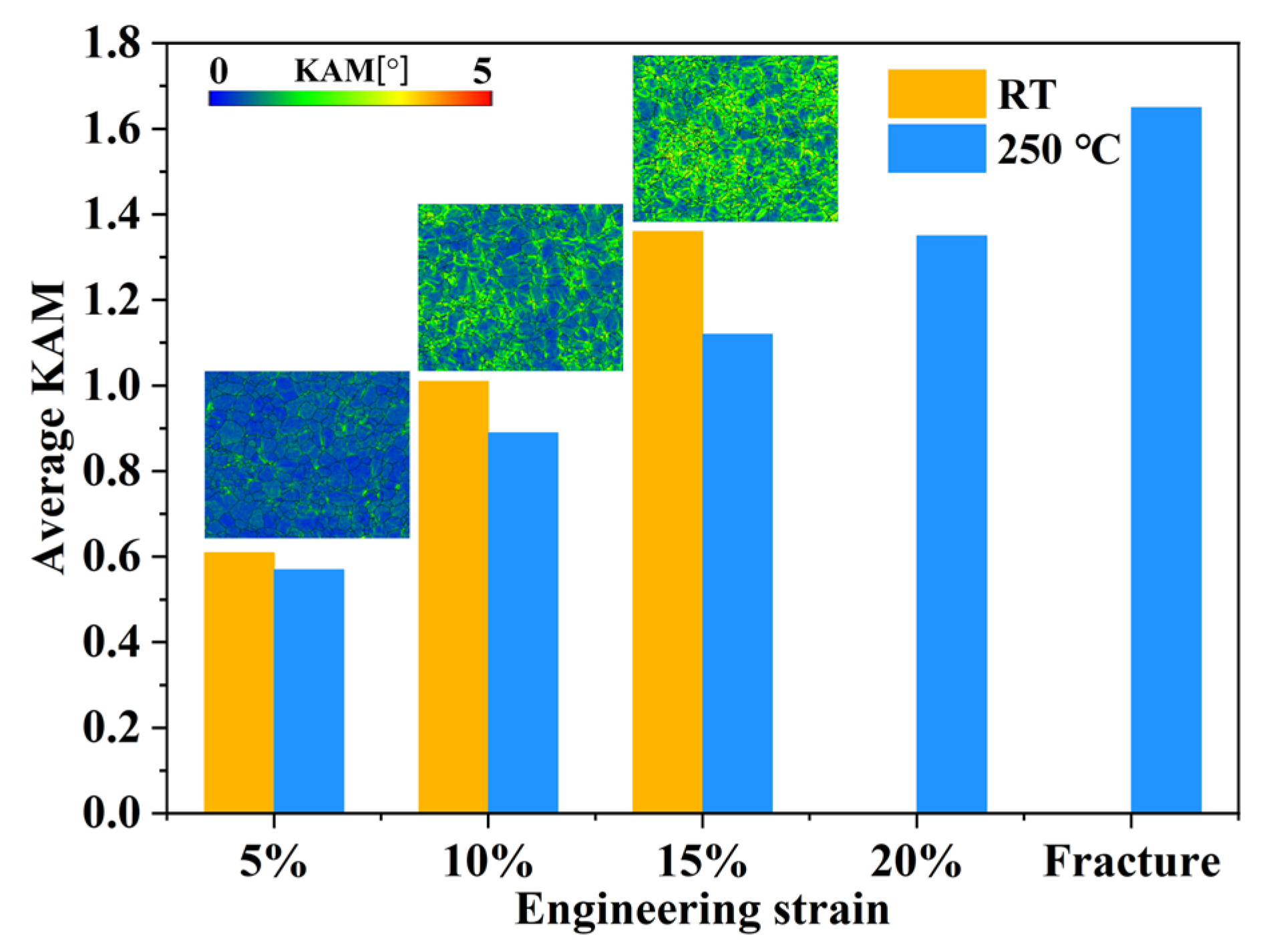

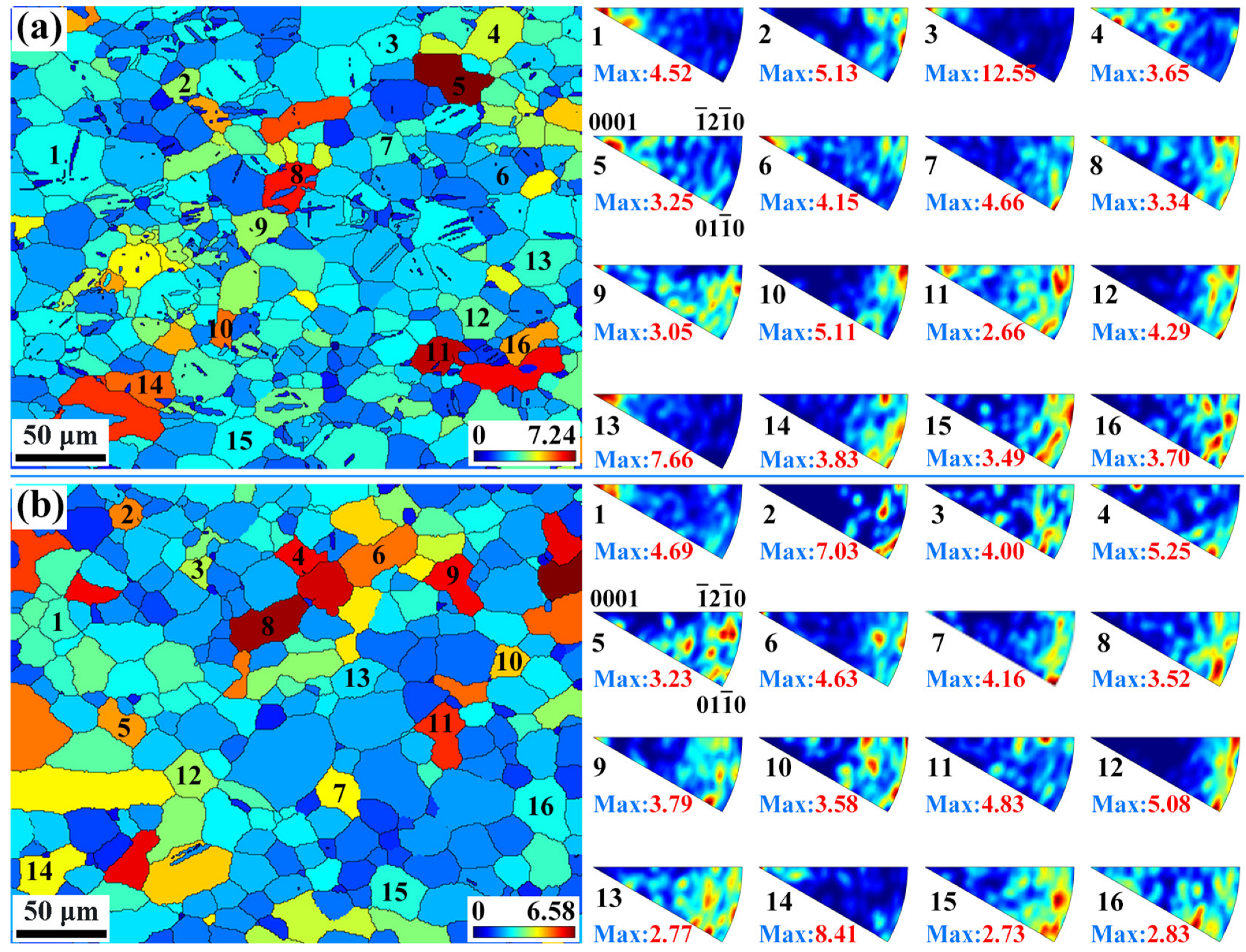

3.3. Microstructure Evolution

4. Discussion

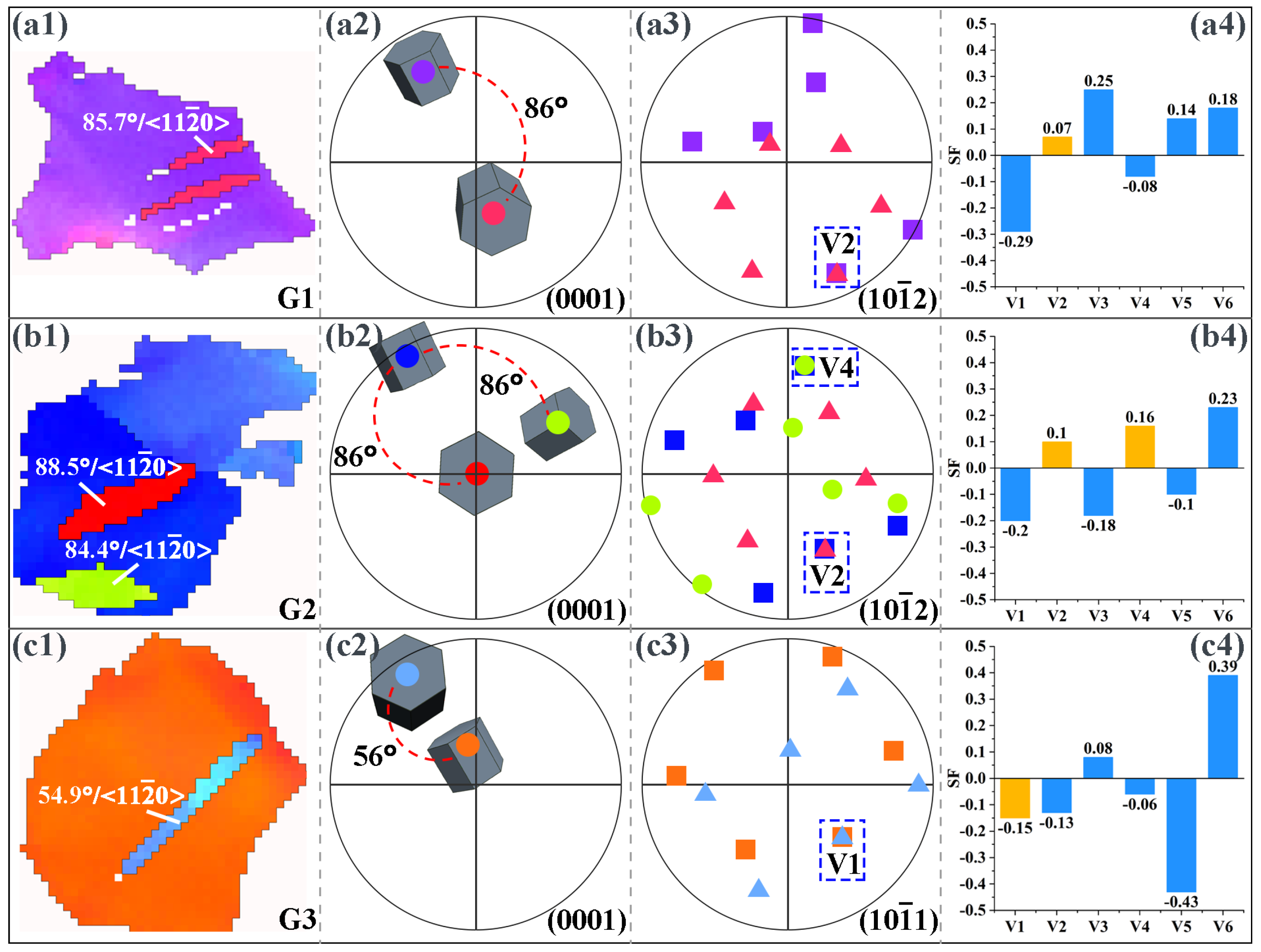

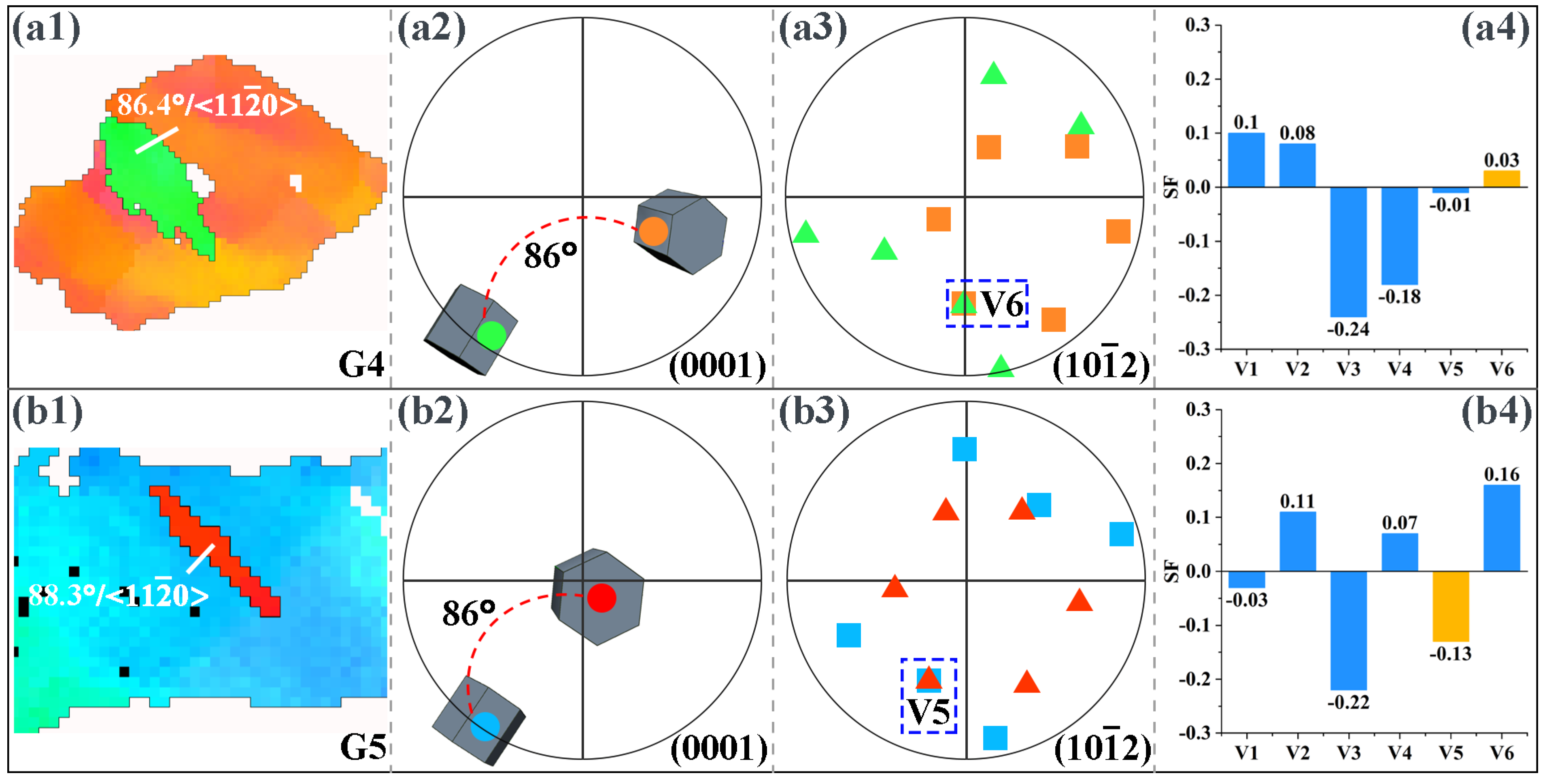

4.1. Twinning Behavior

4.2. Dislocation Slip

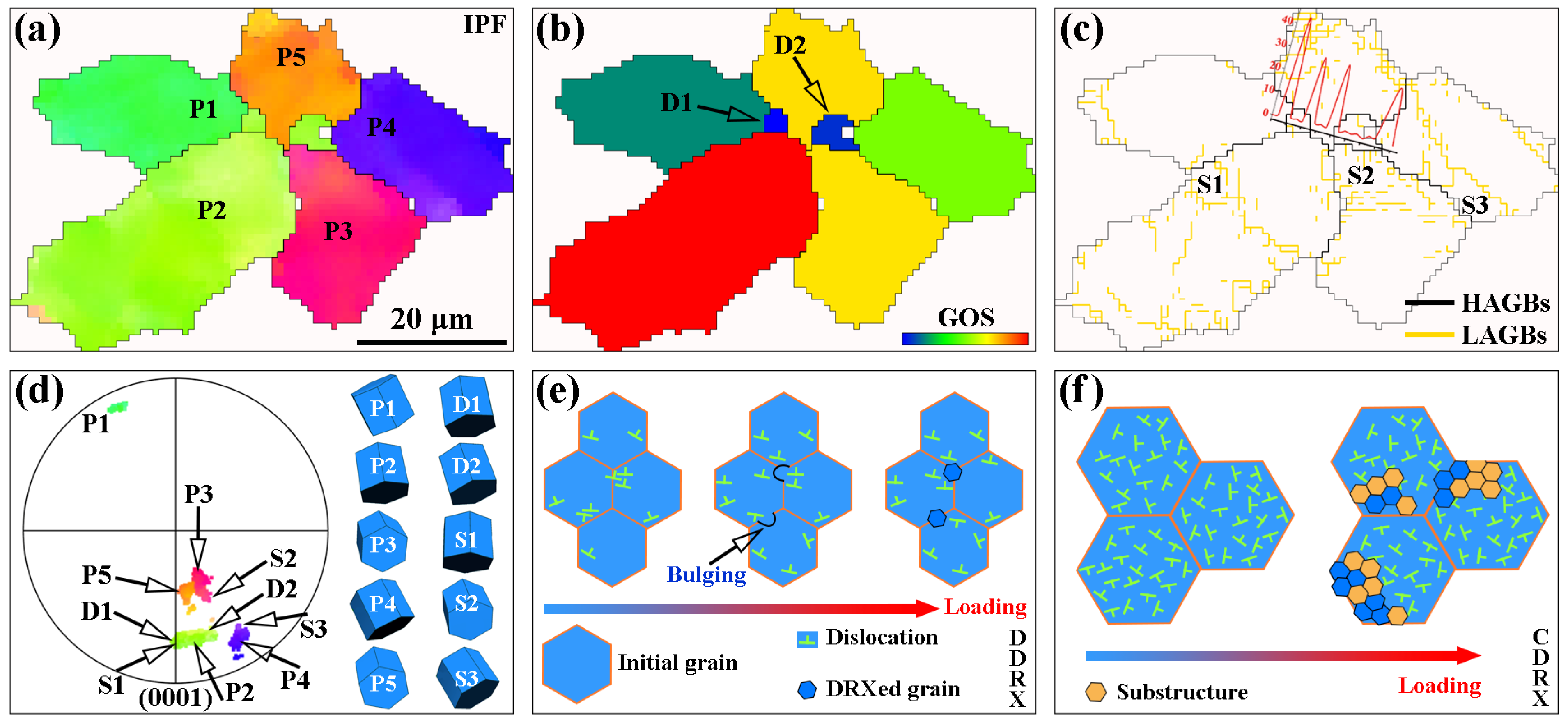

4.3. DRX Mechanism

5. Conclusions

- (1)

- The TYS, UTS, and EL of the extruded AS51 alloy at RT are 122.7 MPa, 219.3 MPa, and 19.7%, respectively. The TYS, UTS, and EL at 250 °C are 89.2 MPa, 110.3 MPa, and 33.2%, respectively. Compared to RT deformation, TYS and UTS decreased by 27.3% and 49.7%, respectively, while EL improved by 68.5%.

- (2)

- The extruded AS51 alloy displays continuous hardening behavior during the RT deformation of the alloy, and the late deformation at 250 °C leads to some softening due to the DRV and DRX, with the DRX mechanism being mainly DDRX and a low recrystallization fraction.

- (3)

- The main deformation mechanism of the extruded AS51 alloy at RT and 250 °C is dislocation slip, with prismatic <a> slip as the dominant deformation mode, and no significant changes in grain size and texture type occur.

- (4)

- The selection of twin variants is closely related to the local stress concentration. The relatively low activation of extension twins at 250 °C is partly attributed to the fact that the consumption of dislocations by DRV and DRX during deformation can effectively relax local stress concentrations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Q.; Li, Y.; Cao, F.; Qiu, D.; Yang, Y.; Wang, J.; Zhang, H.; Ying, T.; Ding, W.; Zeng, X. Towards Development of a High-Strength Stainless Mg Alloy with Al-Assisted Growth of Passive Film. Nat. Commun. 2022, 13, 5838. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Feng, Z.; Yu, T.; Luo, J.; Huang, T.; Wu, G.; Hansen, N.; Huang, X. Transitions in Mechanical Behavior and in Deformation Mechanisms Enhance the Strength and Ductility of Mg-3Gd. Acta Mater. 2020, 183, 398–407. [Google Scholar] [CrossRef]

- Qiu, D.; Zhang, M.X.; Taylor, J.A.; Kelly, P.M. A New Approach to Designing a Grain Refiner for Mg Casting Alloys and Its Use in Mg-Y-Based Alloys. Acta Mater. 2009, 57, 3052–3059. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly Solidified Powder Metallurgy Mg97Zn1Y2 Alloys with Excellent Tensile Yield Strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef] [Green Version]

- Stanford, N.; Marceau, R.K.W.; Barnett, M.R. The Effect of High Yttrium Solute Concentration on the Twinning Behaviour of Magnesium Alloys. Acta Mater. 2015, 82, 447–456. [Google Scholar] [CrossRef]

- Zhao, D.; Chen, X.; Ye, J.; Chen, T.; Dai, Y.; Liu, C.; Luo, Z.; Gao, S.; Zhang, J.; Yao, J.; et al. Simultaneously Improving Elastic Modulus and Damping Capacity of Extruded Mg-Gd-Y-Zn-Mn Alloy via Alloying with Si. J. Alloys Compd. 2019, 810, 151857. [Google Scholar] [CrossRef]

- Kim, J.K.; Sandlöbes, S.; Raabe, D. On the Room Temperature Deformation Mechanisms of a Mg-Y-Zn Alloy with Long-Period-Stacking-Ordered Structures. Acta Mater. 2015, 82, 414–423. [Google Scholar] [CrossRef]

- Kada, S.R.; Lynch, P.A.; Kimpton, J.A.; Barnett, M.R. In-Situ X-Ray Diffraction Studies of Slip and Twinning in the Presence of Precipitates in AZ91 Alloy. Acta Mater. 2016, 119, 145–156. [Google Scholar] [CrossRef]

- Wang, J.; Wei, F.; Shi, B.; Ding, Y.; Jin, P. The Effect of Y Content on Microstructure and Tensile Properties of the As-Extruded Mg–1Al–XY Alloy. Mater. Sci. Eng. A 2019, 765, 138288. [Google Scholar] [CrossRef]

- Minárik, P.; Král, R.; Čížek, J.; Chmelík, F. Effect of Different c/a Ratio on the Microstructure and Mechanical Properties in Magnesium Alloys Processed by ECAP. Acta Mater. 2016, 107, 83–95. [Google Scholar] [CrossRef]

- Li, X.; Le, Q.; Li, D.; Wang, P.; Jin, P.; Cheng, C.; Chen, X.; Ren, L. Hot Tensile Deformation Behavior of Extruded LAZ532 Alloy with Heterostructure. Mater. Sci. Eng. A 2021, 801, 140412. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Z.; Li, Q.; Chen, X.; Zhao, J.; Bao, J. Deformation Behavior Characterized by Reticular Shear Bands and Long Chain Twins in Mg-Gd-Nd(-Zn)-Zr Alloys. J. Mater. Res. Technol. 2021, 15, 5326–5342. [Google Scholar] [CrossRef]

- Zhang, Q.; Pang, H.; Li, Q.; Gui, Y.; Chen, X.; Li, X.; Chen, P.; Tan, J. {10–12} Twinning Relationship in Mg-Gd-Y(-Sn)-Zr Alloys under Uniaxial Compression at Room Temperature. Mater. Sci. Eng. A 2022, 835, 142679. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Lee, C.S. Role of {10–12} Twinning Characteristics in the Deformation Behavior of a Polycrystalline Magnesium Alloy. Acta Mater. 2010, 58, 5873–5885. [Google Scholar] [CrossRef]

- Li, J.; Dong, Z.; Yi, X.; Wu, D.; Chen, R. Twin Evolution in Cast Mg-Gd-Y Alloys and Its Dependence on Aging Heat Treatment. J. Magnes. Alloy. 2021, 801, 140412. [Google Scholar] [CrossRef]

- Sun, W.T.; Qiao, X.G.; Zheng, M.Y.; Xu, C.; Kamado, S.; Zhao, X.J.; Chen, H.W.; Gao, N.; Starink, M.J. Altered Ageing Behaviour of a Nanostructured Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr Alloy Processed by High Pressure Torsion. Acta Mater. 2018, 151, 260–270. [Google Scholar] [CrossRef] [Green Version]

- Jia, Y.; Jiang, S.; Tan, J.; Lu, Z.; Jiang, J.; Wang, X. The Evolution of Local Stress during Deformation Twinning in a Mg-Gd-Y-Zn Alloy. Acta Mater. 2022, 222, 117452. [Google Scholar] [CrossRef]

- Wandong, L.; Lihai, C.; Zhidong, F.; Mingwei, Z.; Xingquan, L.; Lei, Q.; Lisong, T.; Qiangguo, L. Age Hardening Response and Microstructure of Mg–8Sn–4Al Alloy with Ag, Sc Addition. Mater. Sci. Eng. A 2022, 850, 143596. [Google Scholar] [CrossRef]

- Liao, Q.; Jiang, Y.; Le, Q.; Chen, X.; Cheng, C.; Hu, K.; Li, D. Hot Deformation Behavior and Processing Map Development of AZ110 Alloy with and without Addition of La-Rich Mish Metal. J. Mater. Sci. Technol. 2021, 61, 1–15. [Google Scholar] [CrossRef]

- Gui, Y.; Ouyang, L.; Xue, Y.; Li, Q. Effect of Thermo-Mechanical Processing Parameters on the Dynamic Restoration Mechanism in an Mg-4Y-2Nd-1Sm-0.5Zr Alloy during Hot Compression. J. Mater. Sci. Technol. 2021, 90, 205–224. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, S.; Wang, J.; Chen, L.; Jin, P. Hot Deformation Behavior, Processing Map, Microstructure Evolution and Dynamic Recrystallization Mechanism of Mg-5Al-0.6Sc Alloy. J. Alloys Compd. 2022, 922, 166244. [Google Scholar] [CrossRef]

- Jahedi, M.; McWilliams, B.A.; Moy, P.; Knezevic, M. Deformation Twinning in Rolled WE43-T5 Rare Earth Magnesium Alloy: Influence on Strain Hardening and Texture Evolution. Acta Mater. 2017, 131, 221–232. [Google Scholar] [CrossRef]

- Fribourg, G.; Bréchet, Y.; Deschamps, A.; Simar, A. Microstructure-Based Modelling of Isotropic and Kinematic Strain Hardening in a Precipitation-Hardened Aluminium Alloy. Acta Mater. 2011, 59, 3621–3635. [Google Scholar] [CrossRef]

- Yuan, S.; Wang, J.; Zhang, L.; Jin, P. An Investigation of the Deformation and Cracking Mechanism of Mg–1Al–12Y Alloys Based on in-Situ SEM/EBSD Slip Trace Analysis. Mater. Sci. Eng. A 2022, 856, 144016. [Google Scholar] [CrossRef]

- Chapuis, A.; Driver, J.H. Temperature Dependency of Slip and Twinning in Plane Strain Compressed Magnesium Single Crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Pan, H.; Kang, R.; Li, J.; Xie, H.; Zeng, Z.; Huang, Q.; Yang, C.; Ren, Y.; Qin, G. Mechanistic Investigation of a Low-Alloy Mg–Ca-Based Extrusion Alloy with High Strength–Ductility Synergy. Acta Mater. 2020, 186, 278–290. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically Necessary Dislocations and Strain-Gradient Plasticity: A Few Critical Issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef] [Green Version]

- Yuan, S.; Wang, J.; Zhang, L.; Luan, S.; Jin, P. Effect of Long-Period Ordered Stacking on Twinning Behavior and Mechanical Properties of Mg-Al-Y Alloy during Uniaxial Hot Compression. J. Mater. Sci. Technol. 2023, 142, 152–166. [Google Scholar] [CrossRef]

- Yu, Q.; Shan, Z.W.; Li, J.; Huang, X.; Xiao, L.; Sun, J.; Ma, E. Strong Crystal Size Effect on Deformation Twinning. Nature 2010, 463, 335–338. [Google Scholar] [CrossRef]

- Fan, H.; Aubry, S.; Arsenlis, A.; El-Awady, J.A. Grain Size Effects on Dislocation and Twinning Mediated Plasticity in Magnesium. Scr. Mater. 2016, 112, 50–53. [Google Scholar] [CrossRef]

- Hua, S.; Jiang, Z.W.; Wan, Y.F.; Huang, G.H.; Zhou, H.; Zheng, J.; Wang, Q.D.; Yin, D.D. A Statistical Analysis of Compressive Deformation Mechanisms in an Extruded Mg–3Y Sheet. Mater. Sci. Eng. A 2021, 825, 141927. [Google Scholar] [CrossRef]

- Guo, C.; Xin, R.; Ding, C.; Song, B.; Liu, Q. Understanding of Variant Selection and Twin Patterns in Compressed Mg Alloy Sheets via Combined Analysis of Schmid Factor and Strain Compatibility Factor. Mater. Sci. Eng. A 2014, 609, 92–101. [Google Scholar] [CrossRef]

- Guan, D.; Wynne, B.; Gao, J.; Huang, Y.; Rainforth, W.M. Basal Slip Mediated Tension Twin Variant Selection in Magnesium WE43 Alloy. Acta Mater. 2019, 170, 1–14. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, M.; Shi, B.; Zhang, L.; Jin, P. Ex-Situ EBSD Investigation of the Reduced c/a Values and Work Hardening Behavior in Mg-4Li-1Al-0.5Y Alloy under Hot Compression. Mater. Sci. Eng. A 2020, 797, 140113. [Google Scholar] [CrossRef]

- Guan, D.; Rainforth, W.M.; Ma, L.; Wynne, B.; Gao, J. Twin Recrystallization Mechanisms and Exceptional Contribution to Texture Evolution during Annealing in a Magnesium Alloy. Acta Mater. 2017, 126, 132–144. [Google Scholar] [CrossRef]

- Zhu, Y.; Hou, D.; Li, Q. Quasi In-Situ EBSD Analysis of Twinning-Detwinning and Slip Behaviors in Textured AZ31 Magnesium Alloy Subjected to Compressive-Tensile Loading. J. Magnes. Alloy. 2022, 10, 956–964. [Google Scholar] [CrossRef]

- Ha, C.; Bohlen, J.; Zhou, X.; Brokmeier, H.G.; Kainer, K.U.; Schell, N.; Letzig, D.; Yi, S. Texture Development and Dislocation Activities in Mg-Nd and Mg-Ca Alloy Sheets. Mater. Charact. 2021, 175, 111044. [Google Scholar] [CrossRef]

- Woo, S.K.; Pei, R.; Al-Samman, T.; Letzig, D.; Yi, S. Plastic Instability and Texture Modification in Extruded Mg-Mn-Nd Alloy. J. Magnes. Alloy. 2022, 10, 146–159. [Google Scholar] [CrossRef]

- Chun, Y.B.; Davies, C.H.J. Investigation of Prism <a> Slip in Warm-Rolled AZ31 Alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 4113–4125. [Google Scholar] [CrossRef]

- Ouyang, L.; Gui, Y.; Li, Q.; Fan, Y. Isothermal Compression Bonding Mechanism and Mechanical Properties of WE43 Magnesium-Rare Earth Alloy. Mater. Sci. Eng. A 2021, 822, 141664. [Google Scholar] [CrossRef]

- Tomé, C.N.; Lebensohn, R.A.; Kocks, U.F. A Model for Texture Development Dominated by Deformation Twinning: Application to Zirconium Alloys. Acta Metall. Mater. 1991, 39, 2667–2680. [Google Scholar] [CrossRef] [Green Version]

- Lebensohn, R.A.; Tomé, C.N. A Self-Consistent Viscoplastic Model: Prediction of Rolling Textures of Anisotropic Polycrystals. Mater. Sci. Eng. A 1994, 175, 71–82. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Huang, Y.; Wang, Y.; Gan, W.; Wang, S.; Maawad, E.; Schell, N.; Hort, N. Investigations on the Tensile Deformation of Pure Mg and Mg–15Gd Alloy by in-Situ X-Ray Synchrotron Radiation and Visco-Plastic Self-Consistent Modeling. J. Magnes. Alloy. 2021, 11, 607–613. [Google Scholar] [CrossRef]

- Du, B.N.; Hu, Z.Y.; Sheng, L.Y.; Xu, D.K.; Qiao, Y.X.; Wang, B.J.; Wang, J.; Zheng, Y.F.; Xi, T.F. Microstructural Characteristics and Mechanical Properties of the Hot Extruded Mg-Zn-Y-Nd Alloys. J. Mater. Sci. Technol. 2021, 60, 44–55. [Google Scholar] [CrossRef]

- Sitdikov, O.; Kaibyshev, R. Dynamic Recrystallization in Pure Magnesium. Mater. Trans. 2001, 42, 1928–1937. [Google Scholar] [CrossRef] [Green Version]

| Conditions | Deformation Modes | 5% | 10% | 15% | 20% |

|---|---|---|---|---|---|

| RT | Basal <a> | 0.23 | 0.19 | 0.20 | |

| Prismatic <a> | 0.42 | 0.45 | 0.44 | ||

| Pyramidal <a> | 0.45 | 0.46 | 0.46 | ||

| Pyramidal II <c + a> | 0.43 | 0.44 | 0.43 | ||

| {10–12} twinning | 0.37 | 0.40 | 0.40 | ||

| 250 °C | Basal <a> | 0.24 | 0.21 | 0.21 | 0.20 |

| Prismatic <a> | 0.43 | 0.44 | 0.44 | 0.44 | |

| Pyramidal <a> | 0.45 | 0.46 | 0.45 | 0.46 | |

| Pyramidal II <c + a> | 0.43 | 0.44 | 0.44 | 0.43 | |

| {10–12} twinning | 0.37 | 0.40 | 0.39 | 0.39 |

| Conditions | Deformation Modes | ||||

|---|---|---|---|---|---|

| RT | Basal <a> | 8 | 12 | 930 | 103 |

| Prismatic <a> | 38 | 16 | 950 | 94 | |

| Pyramidal <a> | 47 | 52 | 800 | 51 | |

| Pyramidal II <c + a> | 82 | 67 | 950 | 42 | |

| {10–12} twinning | 16 | 0 | 0 | 0 | |

| 250 °C | Basal <a> | 4 | 28 | 400 | 0 |

| Prismatic <a> | 19 | 25 | 300 | 0 | |

| Pyramidal <a> | 40 | 25 | 350 | 0 | |

| Pyramidal II <c + a> | 61 | 20 | 450 | 0 | |

| {10–12} twinning | 9 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Luan, S.; Yuan, S.; Wang, J.; Chen, L.; Jin, P. Microstructure Evolution and Deformation Behavior of Extruded Mg-5Al-0.6Sc Alloy during Room and Elevated Temperature Tension Revealed by Ex-Situ EBSD and VPSC. Materials 2023, 16, 4534. https://doi.org/10.3390/ma16134534

Zhang L, Luan S, Yuan S, Wang J, Chen L, Jin P. Microstructure Evolution and Deformation Behavior of Extruded Mg-5Al-0.6Sc Alloy during Room and Elevated Temperature Tension Revealed by Ex-Situ EBSD and VPSC. Materials. 2023; 16(13):4534. https://doi.org/10.3390/ma16134534

Chicago/Turabian StyleZhang, Lei, Shiyu Luan, Shuai Yuan, Jinhui Wang, Lijia Chen, and Peipeng Jin. 2023. "Microstructure Evolution and Deformation Behavior of Extruded Mg-5Al-0.6Sc Alloy during Room and Elevated Temperature Tension Revealed by Ex-Situ EBSD and VPSC" Materials 16, no. 13: 4534. https://doi.org/10.3390/ma16134534