Empirical Compression Model of Ultra-High-Performance Concrete Considering the Effect of Cement Hydration on Particle Packing Characteristics

Abstract

:1. Introduction

2. Materials and Methods

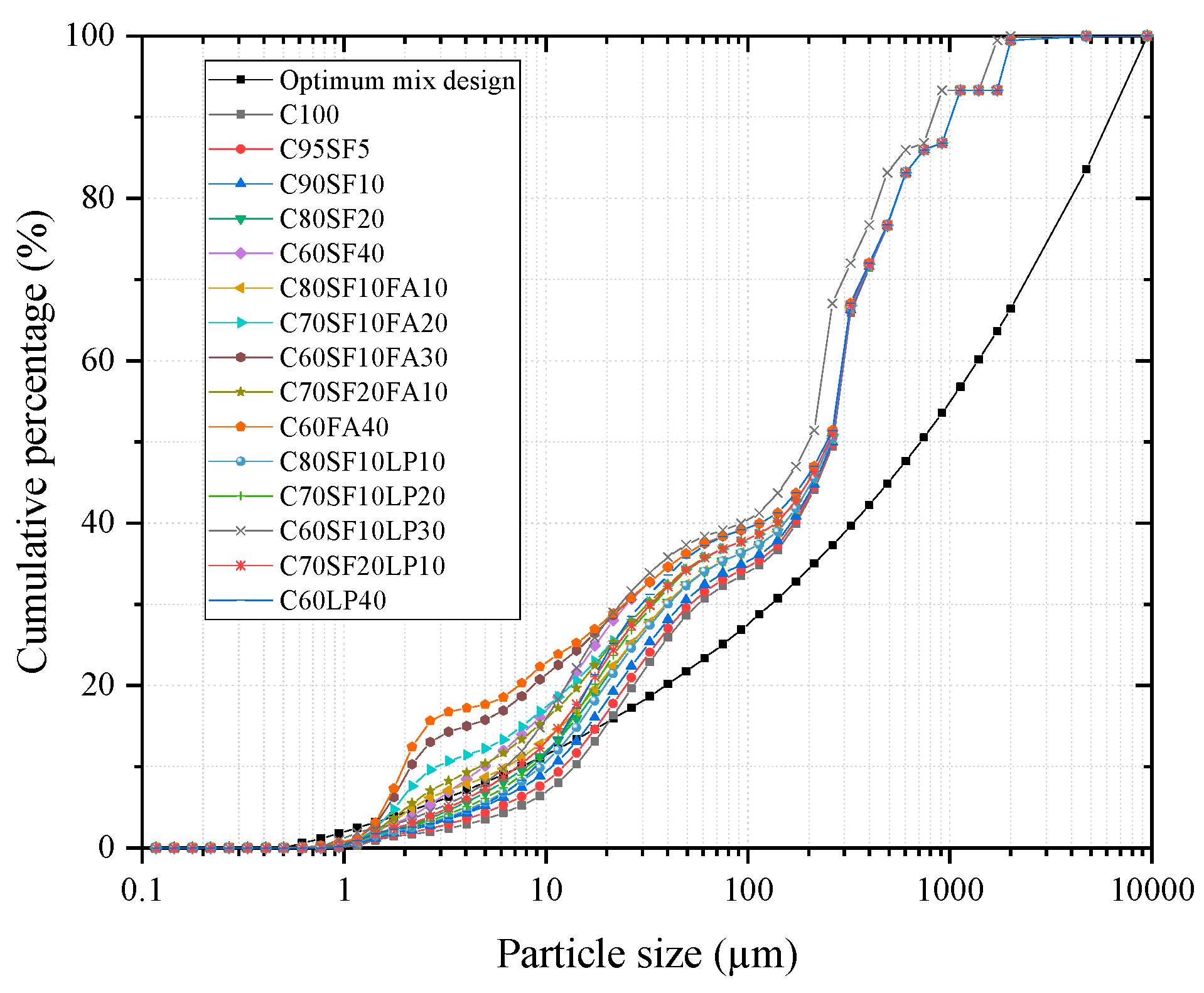

2.1. Mix Design

2.2. Preparation of UHPC and Curing

- (1)

- Put all dried powder materials and sand in a mixer for 60 s to mix.

- (2)

- Add water and SP to 80%, remix the sample for 360 s, and then stop the mixer for 30 s.

- (3)

- Mix water, SP, and steel fibers together; add the remaining ingredients, and continue mixing for a further 240 s.

3. Experimental Results of Compressive Strength

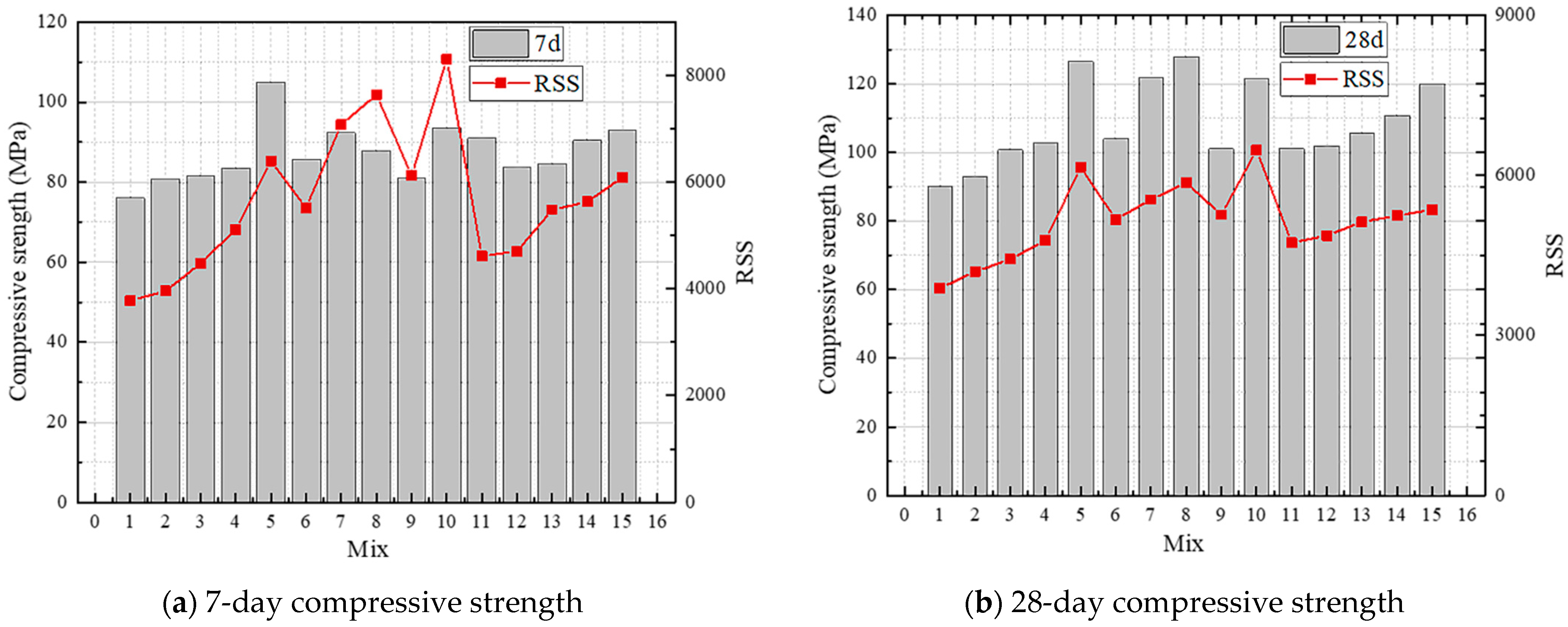

3.1. Experimental Results

3.2. Prediction of Strength Trend Based on the MAA Model

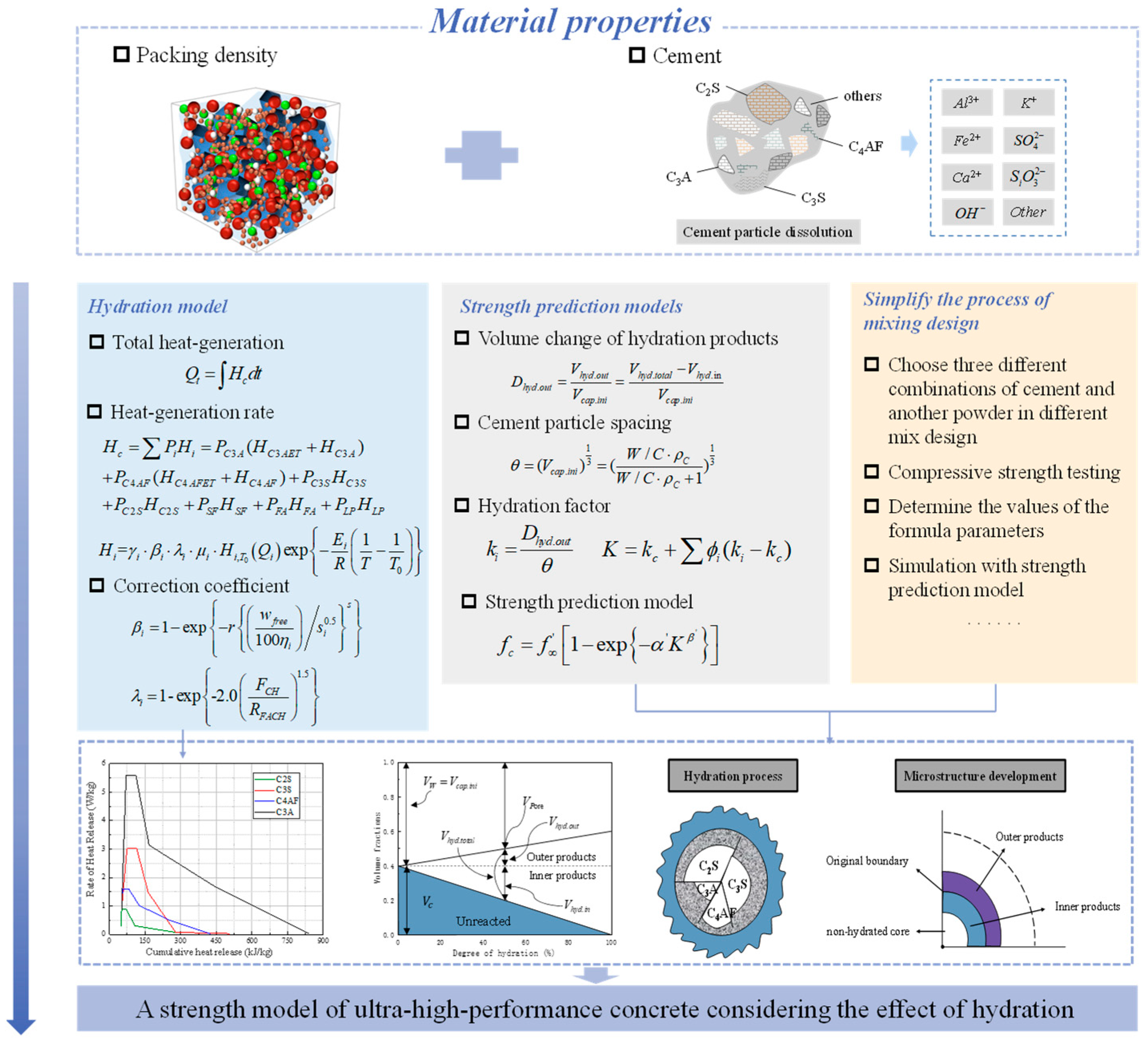

4. Multi-Component Hydration Model Considering the Influence of Different Powders

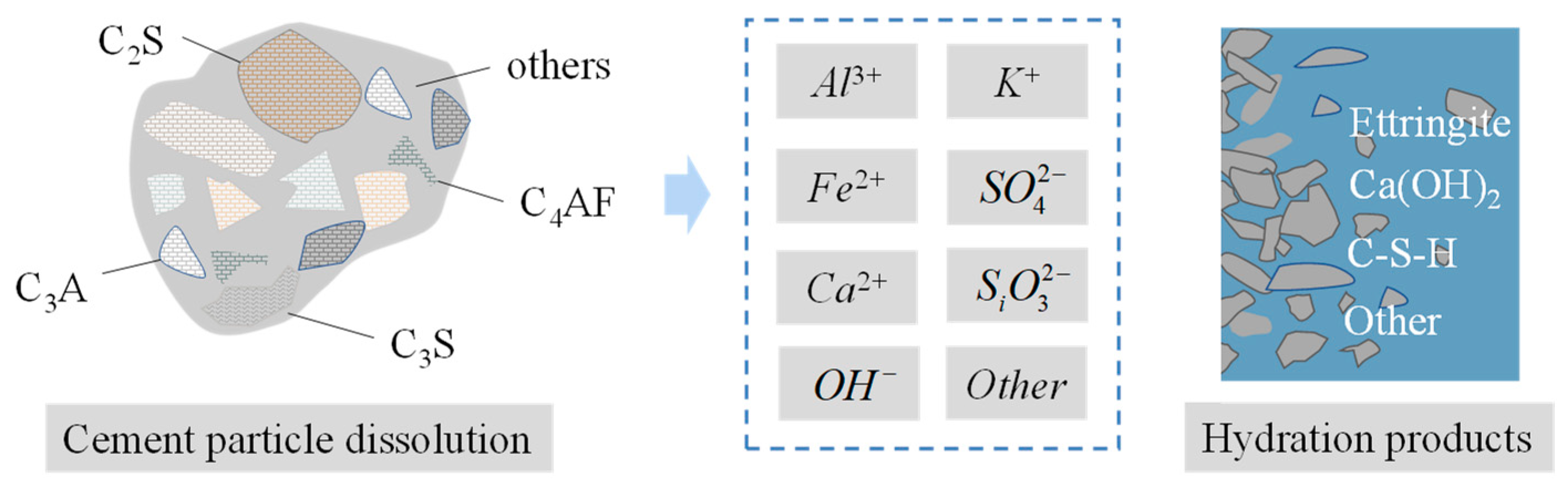

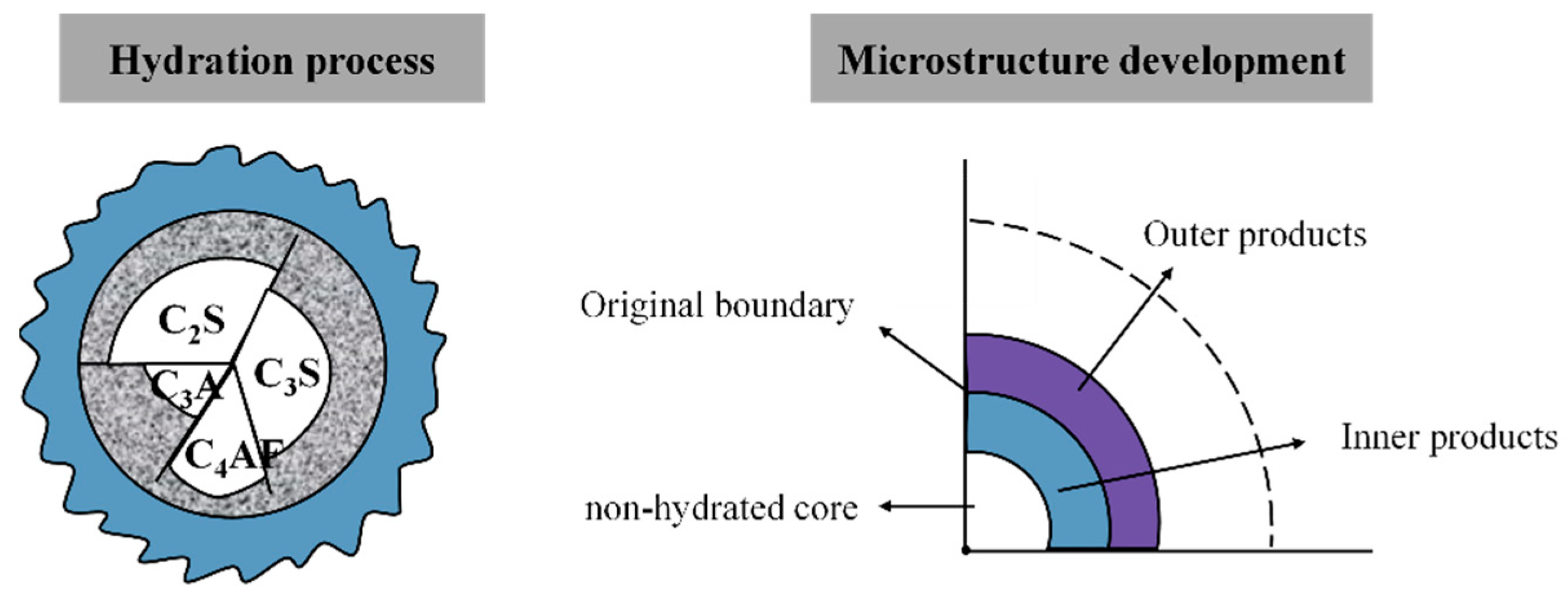

4.1. Hydration of Cement in Concrete

4.2. Effect of Fly Ash on Hydration

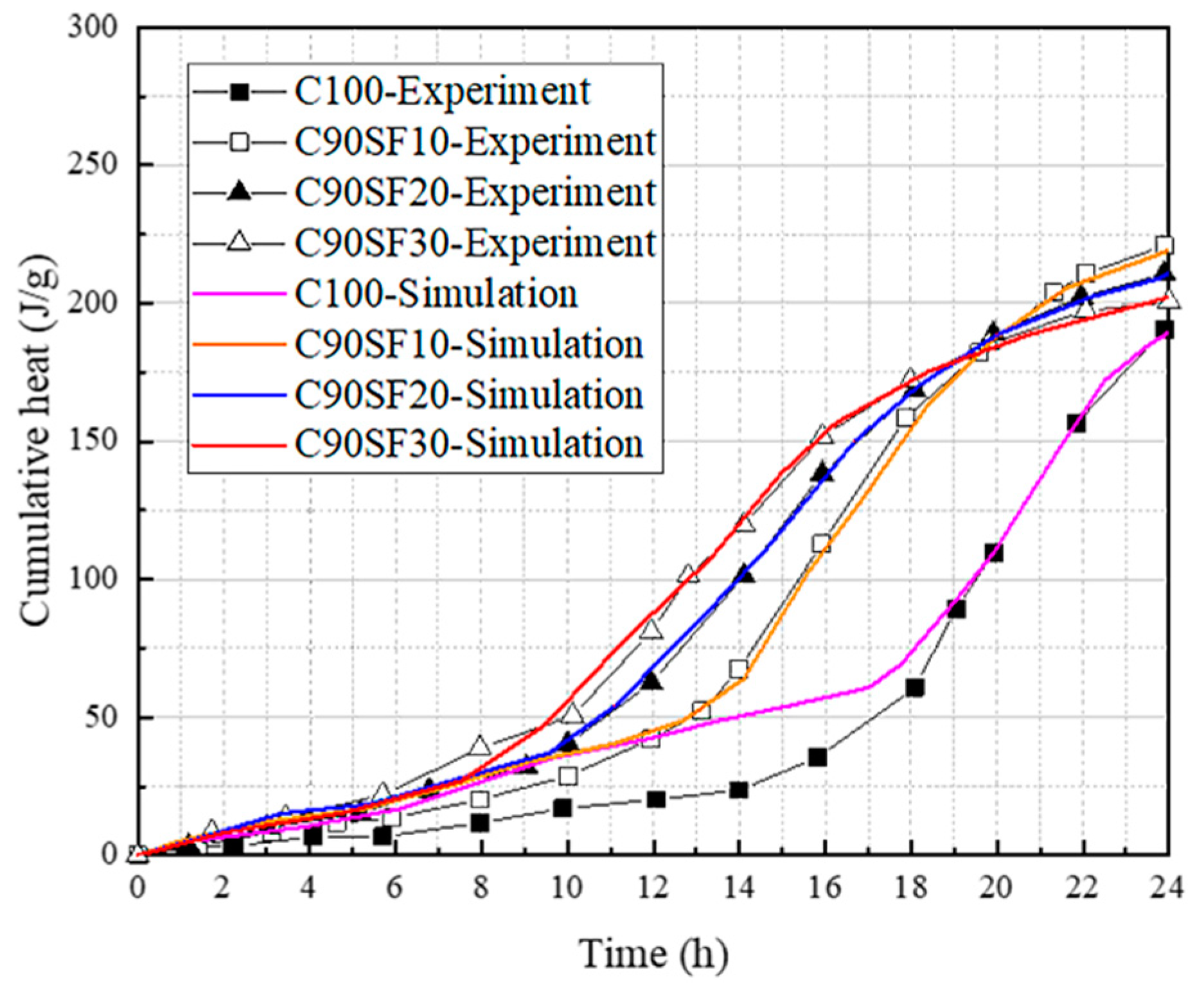

4.3. Effect of Silica Fume on Hydration

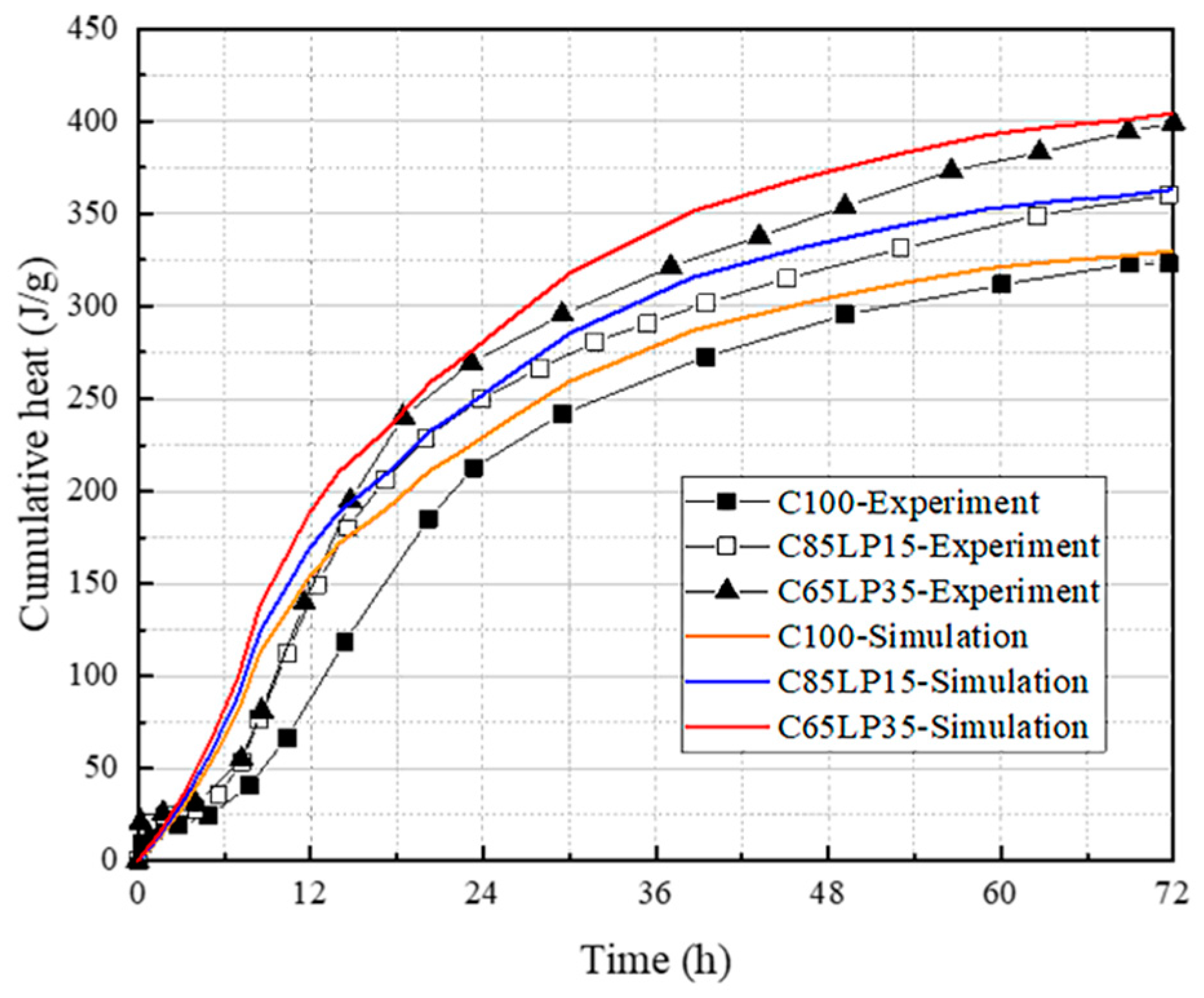

4.4. Effect of Limestone on Hydration

4.5. Simulation of Multi-Component Powders on Hydration

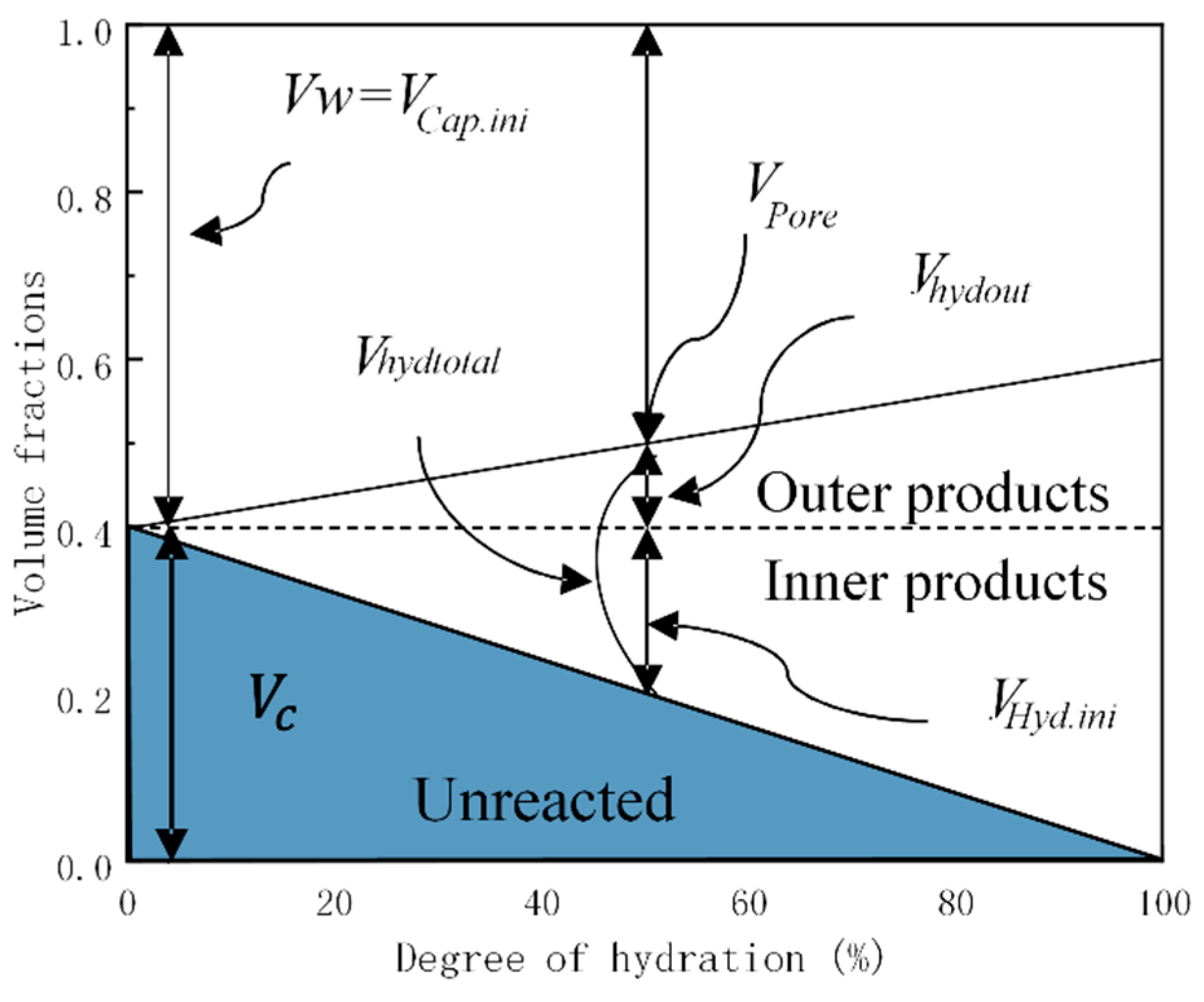

5. Porosity Development Model

5.1. Microscopic Influence of Hydration Products

5.2. Effect of Hydration Products on Packing Density

5.3. Empirical Strength Prediction Model

5.4. Simplified Mix Design Process

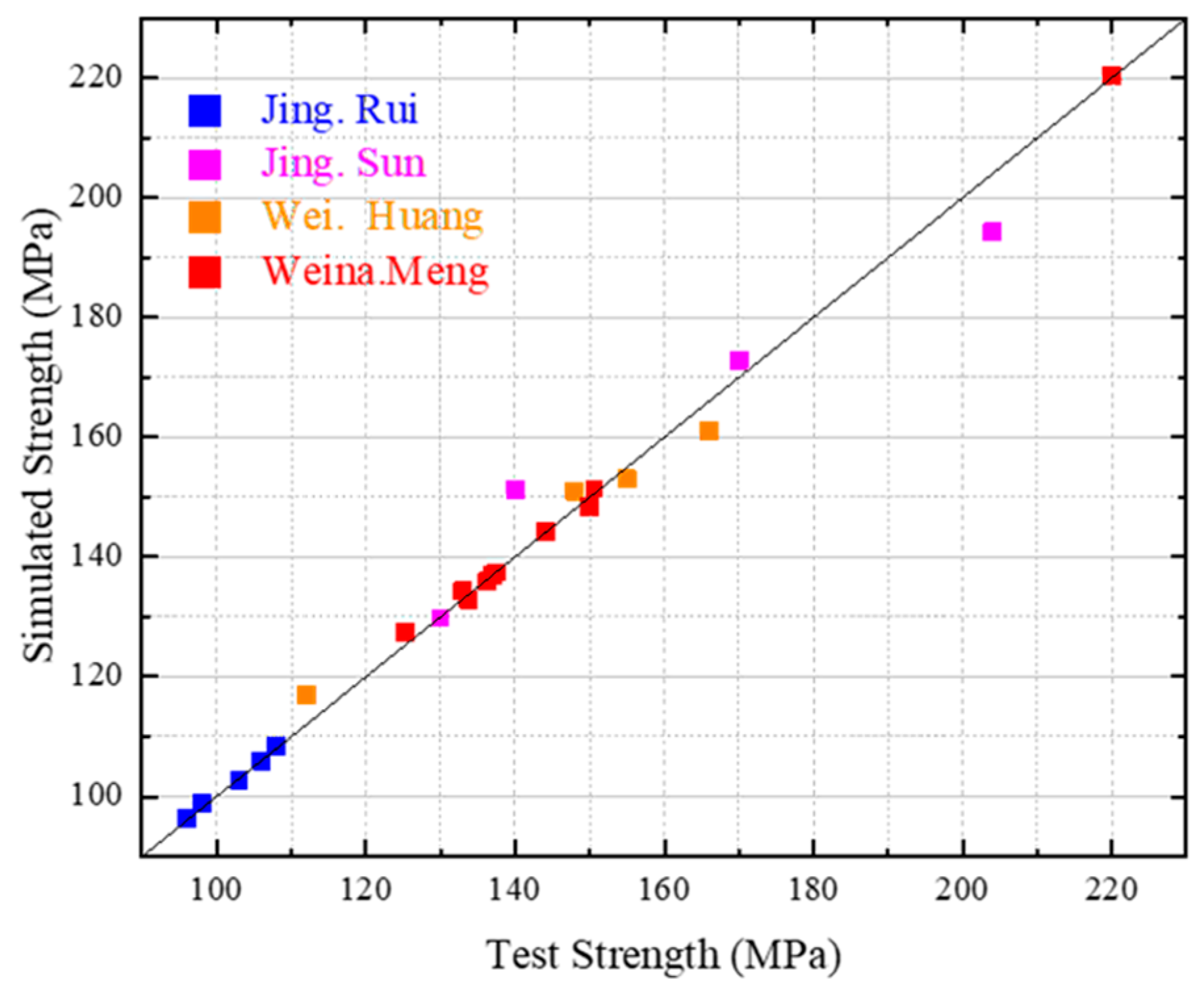

5.5. Validation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive Powder Concretes with High Ductility and 200–800 Mpa Compressive Strength. Int. Concr. Abstr. Portal 1994, 144, 507–518. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Kairong, H. Development trend and thinking of China highway tunnel in recent 10 years. China J. Highw. Transp. 2020, 33, 62–75. [Google Scholar]

- Zhang, Y. A discussion on external water pressure of tunnel lining. Mod. Tunn. Technol. 2003, 3, 1–4, 10. [Google Scholar] [CrossRef]

- Sadrossadat, E.; Basarir, H.; Karrech, A.; Elchalakani, M. Multi-objective mixture design and optimisation of steel fiber reinforced UHPC using machine learning algorithms and metaheuristics. Eng. Comput. 2021, 38, 2569–2582. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Sharif, A.M.; Ahmad, S.; Adekunle, S.K.; Al-Huri, M.; Sharif, A.M. Effect of hybridization of straight and hooked steel fibers and curing methods on the key mechanical properties of UHPC. J. Mater. Res. Technol. 2021, 15, 3222–3239. [Google Scholar] [CrossRef]

- Mezquida-Alcaraz, E.J.; Navarro-Gregori, J.; Martí-Vargas, J.R.; Serna-Ros, P. Effects of tension stiffening and shrinkage on the flexural behavior of reinforced UHPFRC beams. Case Stud. Constr. Mater. 2021, 15, e00746. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Alsalman, A.; Dang, C.N.; Martí-Vargas, J.R.; Hale, W.M. Mixture-proportioning of economical UHPC mixtures. J. Build. Eng. 2020, 27, 2352–7102. [Google Scholar] [CrossRef]

- Zhou, M.; Wu, Z.; Ouyang, X.; Hu, X.; Shi, C. Mixture design methods for ultra-high-performance concrete—A review. Cem. Concr. Compos. 2021, 124, 104242. [Google Scholar] [CrossRef]

- Stovall, T.; De Larrard, F.L.; Buil, M. Linear packing density model of grain mixtures. Powder Technol. 1986, 48, 1–12. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Zen, X.; Xie, Y.; Shang, T. Design of binder system of eco-efficient UHPC based on physical packing and chemical effect optimization. Constr. Build. Mater. 2021, 274, 121382. [Google Scholar] [CrossRef]

- Isa, M.; Pilakoutas, K.; Guadagnini, M. Determination of tensile characteristics and design of eco-efficient UHPC. Structures 2021, 32, 2174–2194. [Google Scholar] [CrossRef]

- Ghafari, E.; Bandarabadi, M.; Costa, H.; Júlio, E. Design of UHPC using artificial neural networks. In Brittle Matrix Composites; Woodhead Publishing: Sawston, CA, USA, 2012; pp. 61–69. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Mixture-proportioning of high-performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Fuller, W.B.; Thompson, S.E. The Laws of Proportioning Concrete. Trans. Am. Soc. Civ. Eng. 1907, 59, 67–143. [Google Scholar] [CrossRef]

- Furnas, C.C. Grading Aggregates—I.—Mathematical Relations for Beds of Broken Solids of Maximum Density. Ind. Eng. Chem. 1931, 23, 1052–1058. [Google Scholar] [CrossRef]

- Andreasen, A.H.M. Ueber die Beziehung zwischen Kornabstufung und Zwischenraum in Produkten aus losen Körnern (mit einigen Experimenten). Kolloid-Zeitschrift 1930, 50, 217–228. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Deng, S. A Review of Cement Hydration Research. GD Sci. Technol. 2015, 24, 61–62, 68. [Google Scholar]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Compos. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; White, G.; Nishizawa, T.; Igarashi, T.; Nawa, T.; Mao, J. State-of-the-art of interlocking concrete block pavement technology in Japan as a post-modern pavement. Constr. Build. Mater. 2019, 200, 713–755. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Kurdowski, W.; Nocuń-Wczelik, W. The tricalcium silicate hydration in the presence of active silica. Cem. Concr. Res. 1983, 13, 341–348. [Google Scholar] [CrossRef]

- Kadri, E.-H.; Duval, R. Hydration heat kinetics of concrete with silica fume. Constr. Build. Mater. 2009, 23, 3388–3392. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Marzouki, A.; Lecomte, A.; Beddey, A.; Diliberto, C.; Ben Ouezdou, M. The effects of grinding on the properties of Portland-limestone cement. Constr. Build. Mater. 2013, 48, 1145–1155. [Google Scholar] [CrossRef]

- Zelić, J.; Krstulović, R.; Tkalčec, E.; Krolo, P. Durability of the hydrated limestone-silica fume Portland cement mortars under sulphate attack. Cem. Concr. Res. 1999, 29, 819–826. [Google Scholar] [CrossRef]

- Stark, J.; Freyburg, E.; Löhmer, K. Investigations into the influence of limestone additions to portland cement clinker phases on the early phase of hydration. In Modern Concrete Materials: Binders, Additions and Admixtures; Thomas Telford Publishing: London, UK, 1999; pp. 69–77. [Google Scholar]

- Tsivilis, S.; Batis, G.; Chaniotakis, E.; Grigoriadis, G.; Theodossis, D. Properties and behavior of limestone cement concrete and mortar. Cem. Concr. Res. 2000, 30, 1679–1683. [Google Scholar] [CrossRef]

- Weng, J.K.; Langan, B.W.; Ward, M.A. Pozzolanic reaction in portland cement, silica fume, and fly ash mixtures. Can. J. Civ. Eng. 1997, 24, 754–760. [Google Scholar] [CrossRef]

- He, J.; Long, G.; Ma, K.; Xie, Y. Influence of fly ash or slag on nucleation and growth of early hydration of cement. Thermochim. Acta 2021, 701, 178964. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, T.; Guo, Y.; Wei, J.; Yu, Q. Effects of SCMs particles on the compressive strength of micro-structurally designed cement paste: Inherent characteristic effect, particle size refinement effect, and hydration effect. Powder Technol. 2018, 330, 1–11. [Google Scholar] [CrossRef]

- Maekawa, K.; Ishida, T.; Kishi, T. Multi-scale modeling of concrete performance integrated material and structural mechanics. J. Adv. Concr. Technol. 2003, 1, 91–126. [Google Scholar] [CrossRef]

- Maekawa, K.; Ishida, T.; Kishi, T. Multi-Scale Modeling of Structural Concrete; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Li, P.; Jiang, Z.; An, X.; Maekawa, K.; Du, S. Time-dependent retardation effect of epoxy latexes on cement hydration: Experiments and multi-component hydration model. Constr. Build. Mater. 2022, 320, 126282. [Google Scholar] [CrossRef]

- Wang, F.; Sun, X.; Tao, Z.; Pan, Z. Effect of silica fume on compressive strength of ultra-high-performance concrete made of calcium aluminate cement/fly ash based geopolymer. J. Build. Eng. 2022, 62, 105398. [Google Scholar] [CrossRef]

- Du, J.; Liu, Z.; Christodoulatos, C.; Conway, M.; Bao, Y.; Meng, W. Utilization of off-specification fly ash in preparing ultra-high-performance concrete (UHPC): Mixture design, characterization, and life-cycle assessment. Resour. Conserv. Recycl. 2022, 180, 106136. [Google Scholar] [CrossRef]

- Ozawa, K.; Maekawa, K.; Okamura, H. Development of high performance concrete. J. Fac. Eng. Univ. Tokyo Ser. B Jpn. 1992, 41, 3388–3392. [Google Scholar]

- Bahmani, H.; Mostofinejad, D. Microstructure of ultra-high-performance concrete (UHPC)—A review study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Shimomura, T.; Maekawa, K. Analysis of the drying shrinkage behaviour of concrete using a micromechanical model based on the micropore structure of concrete. Mag. Concr. Res. 1997, 49, 303–322. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Jung, S.H.; Choi, Y.C. Effects of the fineness of limestone powder and cement on the hydration and strength development of PLC concrete. Constr. Build. Mater. 2017, 135, 129–136. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Chaipanich, A.; Poon, C.S. Heat of hydration of Portland high-calcium fly ash cement incorporating limestone powder: Effect of limestone particle size. Constr. Build. Mater. 2014, 66, 410–417. [Google Scholar] [CrossRef]

- Jing, R.; Liu, Y.; Yan, P. Uncovering the effect of fly ash cenospheres on the macroscopic properties and microstructure of ultra high-performance concrete (UHPC). Constr. Build. Mater. 2021, 286, 122977. [Google Scholar] [CrossRef]

- Sun, J.; Wang, H. Effects of undisturbed fly ash on properties of ultra-high-performance concrete. Bull. Chin. Ceramic. Soc. 2022, 41, 209–217. [Google Scholar] [CrossRef]

- Huang, W.; Sun, W. Effects of limestone content on hydration evolution of ultra-high-performance concrete. J. South Univ. 2017, 47, 751–759. [Google Scholar]

- Meng, W.; Valipour, M.; Khayat, K.H. Optimization and performance of cost-effective ultra-high performance concrete. Mater. Struct. 2016, 50, 1–16. [Google Scholar] [CrossRef]

| Chemical Component | Content (wt.%) | Mineralogical Component | Content (wt.%) |

|---|---|---|---|

| CaO | 64.51 | C3S | 69.71 |

| SiO2 | 20.36 | C2S | 5.87 |

| Fe2O3 | 2.82 | C3A | 5.73 |

| Al2O3 | 3.96 | C4AF | 8.57 |

| SO3 | 2.61 | Gypsum | 4.44 |

| MgO | 2.26 | Arcanite | 1.4 |

| K2O | 1.22 | ||

| TiO2 | 0.496 | ||

| BaO | 0.379 | ||

| SrO | 0.226 | ||

| Na2O | 0.10 |

| Group | Code | Cement | Silica Fume | Fly Ash | Limestone Powder | Aggregate | Water | Superplasticizer | Steel Fiber |

|---|---|---|---|---|---|---|---|---|---|

| 1 | C100 | 1000 | 0 | 0 | 0 | 1100 | 180 | 30 | 157 |

| 2 | C95SF5 | 950 | 50 | 0 | 0 | 1100 | 180 | 30 | 157 |

| 3 | C90SF10 | 900 | 100 | 0 | 0 | 1100 | 180 | 30 | 157 |

| 4 | C80SF20 | 800 | 200 | 0 | 0 | 1100 | 180 | 30 | 157 |

| 5 | C60SF40 | 600 | 400 | 0 | 0 | 1100 | 180 | 30 | 157 |

| 6 | C80SF10FA10 | 800 | 100 | 100 | 0 | 1100 | 180 | 30 | 157 |

| 7 | C70SF10FA20 | 700 | 100 | 200 | 0 | 1100 | 180 | 30 | 157 |

| 8 | C60SF10FA30 | 600 | 100 | 300 | 0 | 1100 | 180 | 30 | 157 |

| 9 | C70SF20FA10 | 700 | 200 | 100 | 0 | 1100 | 180 | 30 | 157 |

| 10 | C60FA40 | 600 | 0 | 400 | 0 | 1100 | 180 | 30 | 157 |

| 11 | C80SF10LP10 | 800 | 100 | 0 | 100 | 1100 | 180 | 30 | 157 |

| 12 | C70SF10LP20 | 700 | 100 | 0 | 200 | 1100 | 180 | 30 | 157 |

| 13 | C60SF10LP30 | 600 | 100 | 0 | 300 | 1100 | 180 | 30 | 157 |

| 14 | C70SF20LP10 | 700 | 200 | 0 | 100 | 1100 | 180 | 30 | 157 |

| 15 | C60LP40 | 600 | 0 | 0 | 400 | 1100 | 180 | 30 | 157 |

| Group | Code | Compressive Strength (7 d) | Compressive Strength (28 d) | Slump Flow (mm) |

|---|---|---|---|---|

| 1 | C100 | 76 | 90 | 630 |

| 2 | C95SF5 | 80.7 | 92.8 | 550 |

| 3 | C90SF10 | 81.4 | 100.7 | 580 |

| 4 | C80SF20 | 83.5 | 102.6 | 650 |

| 5 | C60SF40 | 105 | 126.5 | 400 |

| 6 | C80SF10FA10 | 85.7 | 103.9 | 730 |

| 7 | C70SF10FA20 | 92.3 | 121.8 | 700 |

| 8 | C60SF10FA30 | 93.2 | 127.9 | 610 |

| 9 | C70SF20FA10 | 81.1 | 101 | 600 |

| 10 | C60FA40 | 93.5 | 121.6 | 750 |

| 11 | C80SF10LP10 | 91 | 101 | 650 |

| 12 | C70SF10LP20 | 83.8 | 101.7 | 710 |

| 13 | C60SF10LP30 | 84.6 | 105.6 | 730 |

| 14 | C70SF20LP10 | 90.4 | 110.8 | 620 |

| 15 | C60LP40 | 92.8 | 120 | 780 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Wang, X.; Cao, H. Empirical Compression Model of Ultra-High-Performance Concrete Considering the Effect of Cement Hydration on Particle Packing Characteristics. Materials 2023, 16, 4585. https://doi.org/10.3390/ma16134585

Li P, Wang X, Cao H. Empirical Compression Model of Ultra-High-Performance Concrete Considering the Effect of Cement Hydration on Particle Packing Characteristics. Materials. 2023; 16(13):4585. https://doi.org/10.3390/ma16134585

Chicago/Turabian StyleLi, Pengfei, Xiaoyan Wang, and Hanbo Cao. 2023. "Empirical Compression Model of Ultra-High-Performance Concrete Considering the Effect of Cement Hydration on Particle Packing Characteristics" Materials 16, no. 13: 4585. https://doi.org/10.3390/ma16134585