Effect of Thermal Treatments and Ion Substitution on Sintering and Crystallization of Bioactive Glasses: A Review

Abstract

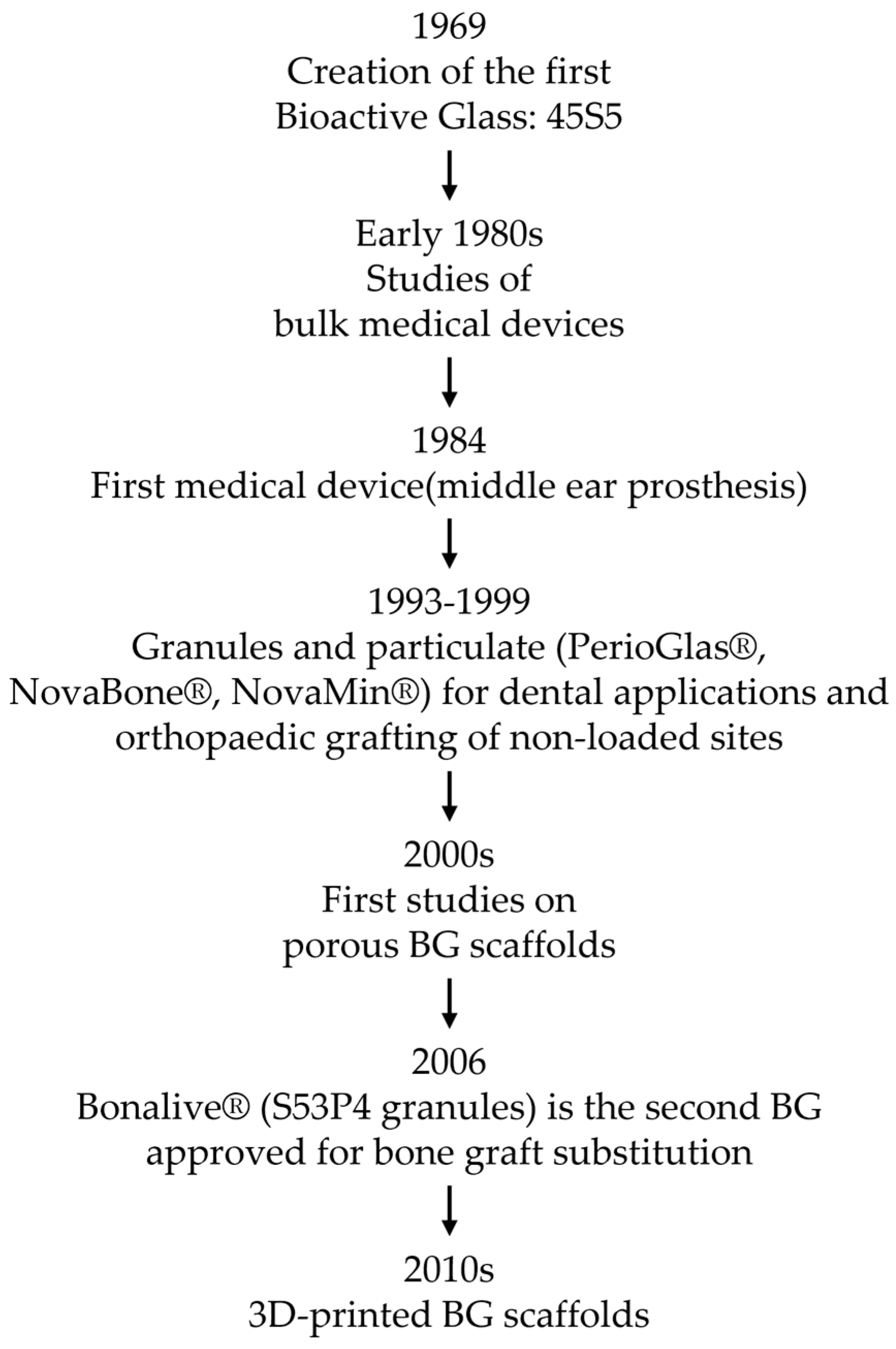

:1. Introduction

2. Why Thermal Treatments?

3. Effects of Crystallization of BGs

3.1. Crystallization of 45S5

3.2. Increasing the Thermal Stability of 45S5: The “Sol–Gel” Option?

4. The Effect of Thermal Treatments on Some Relevant Compositions

5. Ion Substitution to Improve Thermal Properties of BGs

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hench, L.L. The story of Bioglass®. J. Mater. Sci. Mater. Med. 2006, 17, 967–978. [Google Scholar] [CrossRef]

- Pedone, A.; Charpentier, T.; Malavasi, G.; Menziani, M.C. New Insights into the Atomic Structure of 45S5 Bioglass by Means of Solid-State NMR Spectroscopy and Accurate First-Principles Simulations. Chem. Mater. 2010, 22, 5644–5652. [Google Scholar] [CrossRef]

- Hench, L.L.; Wilson, J. Clinical Performance of Skeletal Prostheses, 1996th ed.; Chapman & Hall, Ed.; Springer: Dordrecht, The Netherlands, 1996; ISBN 978-94-011-0541-5. [Google Scholar]

- Hench, L.L.; Polak, J.M. Third-Generation Biomedical Materials. Science 2002, 295, 1014–1017. [Google Scholar] [CrossRef] [Green Version]

- Albrektsson, T.; Johansson, C. Osteoinduction, osteoconduction and osseointegration. Eur. Spine J. 2001, 10 (Suppl. S2), S96–S101. [Google Scholar] [CrossRef] [Green Version]

- Bohner, M.; Lemaitre, J. Can bioactivity be tested in vitro with SBF solution? Biomaterials 2009, 30, 2175–2179. [Google Scholar] [CrossRef] [Green Version]

- Kokubo, T.; Kushitani, H.; Sakka, S.; Kitsugi, T.; Yamamuro, T. Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W3. J. Biomed. Mater. Res. 1990, 24, 721–734. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef]

- Romero-Sánchez, L.B.; Marí-Beffa, M.; Carrillo, P.; Medina, M.; Díaz-Cuenca, A. Copper-containing mesoporous bioactive glass promotes angiogenesis in an in vivo zebrafish model. Acta Biomater. 2018, 68, 272–285. [Google Scholar] [CrossRef]

- Hu, M.; Fang, J.; Zhang, Y.; Wang, X.; Zhong, W.; Zhou, Z. Design and evaluation a kind of functional biomaterial for bone tissue engineering: Selenium/mesoporous bioactive glass nanospheres. J. Colloid Interface Sci. 2020, 579, 654–666. [Google Scholar] [CrossRef]

- Lindfors, N.; Geurts, J.; Drago, L.; Arts, J.J.; Juutilainen, V.; Hyvönen, P.; Suda, A.J.; Domenico, A.; Artiaco, S.; Alizadeh, C.; et al. Antibacterial Bioactive Glass, S53P4, for Chronic Bone Infections—A Multinational Study. Adv. Exp. Med. Biol. 2017, 971, 81–92. [Google Scholar] [CrossRef] [Green Version]

- Sergi, R.; Bellucci, D.; Cannillo, V. A Comprehensive Review of Bioactive Glass Coatings: State of the Art, Challenges and Future Perspectives. Coatings 2020, 10, 757. [Google Scholar] [CrossRef]

- Begum, A.N.; Rajendran, V.; Ylänen, H. Effect of thermal treatment on physical properties of bioactive glass. Mater. Chem. Phys. 2006, 96, 409–417. [Google Scholar] [CrossRef]

- Groh, D.; Döhler, F.; Brauer, D.S. Bioactive glasses with improved processing. Part 1. Thermal properties, ion release and apatite formation. Acta Biomater. 2014, 10, 4465–4473. [Google Scholar] [CrossRef] [PubMed]

- Lefebvre, L.; Gremillard, L.; Chevalier, J.; Zenati, R.; Bernache-Assolant, D. Sintering behaviour of 45S5 bioactive glass. Acta Biomater. 2008, 4, 1894–1903. [Google Scholar] [CrossRef]

- Baino, F.; Fiume, E. Mechanical characterization of 45S5 bioactive glass-derived scaffolds. Mater. Lett. 2019, 245, 14–17. [Google Scholar] [CrossRef]

- Brauer, D.S. Bioaktive Gläser: Struktur und Eigenschaften. Angew. Chem. 2015, 127, 4232–4254. [Google Scholar] [CrossRef]

- Hill, R.G.; Brauer, D.S. Predicting the bioactivity of glasses using the network connectivity or split network models. J. Non-Cryst. Solids 2011, 357, 3884–3887. [Google Scholar] [CrossRef]

- Watts, S.; Hill, R.; O’donnell, M.; Law, R. Influence of magnesia on the structure and properties of bioactive glasses. J. Non-Cryst. Solids 2010, 356, 517–524. [Google Scholar] [CrossRef] [Green Version]

- Hill, R.G.; Brauer, D.S. Predicting the glass transition temperature of bioactive glasses from their molecular chemical composition. Acta Biomater. 2011, 7, 3601–3605. [Google Scholar] [CrossRef]

- O’donnell, M.D. Predicting bioactive glass properties from the molecular chemical composition: Glass transition temperature. Acta Biomater. 2011, 7, 2264–2269. [Google Scholar] [CrossRef]

- Jones, J.R. Review of bioactive glass: From Hench to hybrids. Acta Biomater. 2013, 9, 4457–4486. [Google Scholar] [CrossRef] [PubMed]

- Boccaccini, A.R.; Chen, Q.; Lefebvre, L.; Gremillard, L.; Chevalier, J. Sintering, crystallisation and biodegradation behaviour of Bioglass®-derived glass–ceramics. Faraday Discuss. 2007, 136, 27–44. [Google Scholar] [CrossRef] [PubMed]

- Jones, J.R.; Gentleman, E.; Polak, J. Bioactive Glass Scaffolds for Bone Regeneration. Elements 2007, 3, 393–399. [Google Scholar] [CrossRef]

- Bellucci, D.; Cannillo, V.; Sola, A.; Chiellini, F.; Gazzarri, M.; Migone, C. Macroporous Bioglass®-derived scaffolds for bone tissue regeneration. Ceram. Int. 2011, 37, 1575–1585. [Google Scholar] [CrossRef]

- Chen, Q.; Mohn, D.; Stark, W.J. Optimization of Bioglass® Scaffold Fabrication Process. J. Am. Ceram. Soc. 2011, 94, 4184–4190. [Google Scholar] [CrossRef]

- Aguilar-Reyes, E.A.; León-Patiño, C.A.; Villicaña-Molina, E.; Macías-Andrés, V.I.; Lefebvre, L.-P. Processing and in vitro bioactivity of high-strength 45S5 glass-ceramic scaffolds for bone regeneration. Ceram. Int. 2017, 43, 6868–6875. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.Z.; Thompson, I.D.; Boccaccini, A.R. 45S5 Bioglass®-derived glass–ceramic scaffolds for bone tissue engineering. Biomaterials 2006, 27, 2414–2425. [Google Scholar] [CrossRef]

- Bose, S.; Roy, M.; Bandyopadhyay, A. Recent advances in bone tissue engineering scaffolds. Trends Biotechnol. 2012, 30, 546–554. [Google Scholar] [CrossRef] [Green Version]

- Deb, P.; Deoghare, A.B.; Borah, A.; Barua, E.; Das Lala, S. Scaffold Development Using Biomaterials: A Review. Mater. Today: Proc. 2018, 5, 12909–12919. [Google Scholar] [CrossRef]

- Gerhardt, L.-C.; Boccaccini, A.R. Bioactive Glass and Glass-Ceramic Scaffolds for Bone Tissue Engineering. Materials 2010, 3, 3867–3910. [Google Scholar] [CrossRef] [Green Version]

- Fiume, E.; Ciavattini, S.; Verné, E.; Baino, F. Foam Replica Method in the Manufacturing of Bioactive Glass Scaffolds: Out-of-Date Technology or Still Underexploited Potential? Materials 2021, 14, 2795. [Google Scholar] [CrossRef] [PubMed]

- Bellucci, D.; Sola, A.; Gentile, P.; Ciardelli, G.; Cannillo, V. Biomimetic coating on bioactive glass-derived scaffolds mimicking bone tissue. J. Biomed. Mater. Res. A 2018, 100A, 3259–3266. [Google Scholar] [CrossRef]

- Hornberger, H.; Virtanen, S.; Boccaccini, A. Biomedical coatings on magnesium alloys—A review. Acta Biomater. 2012, 8, 2442–2455. [Google Scholar] [CrossRef] [PubMed]

- Henao, J.; Poblano-Salas, C.; Monsalve, M.; Corona-Castuera, J.; Barceinas-Sanchez, O. Bio-active glass coatings manufactured by thermal spray: A status report. J. Mater. Res. Technol. 2019, 8, 4965–4984. [Google Scholar] [CrossRef]

- Garrido, B.; Dosta, S.; Cano, I.G. Bioactive glass coatings obtained by thermal spray: Current status and future challenges. Bol. Soc. Esp. Cer. Vid. 2022, 61, 516–530. [Google Scholar] [CrossRef]

- Tang, C.Y.; Tsui, C.P.; Janackovic, D.J.; Uskokovic, P.S. Nanomechanical Properties Evaluation of Bioactive Glass Coatings on Titanium Alloy Substrate. J. Optoelectron. Adv. Mat. 2006, 8, 1194–1199. [Google Scholar]

- Pawłowski, L. Thermal Spray Techniques. In The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2008; pp. 1–626. ISBN 978-0-471-49049-4. [Google Scholar]

- Gabbi, C.; Cacchioli, A.; Locardi, B.; Guadagnino, E. Bioactive glass coating: Physicochemical aspects and biological findings. Biomaterials 1995, 16, 515–520. [Google Scholar] [CrossRef]

- Krzyzanowski, M.; Bajda, S.; Liu, Y.; Triantaphyllou, A.; Mark Rainforth, W.; Glendenning, M. 3D analysis of thermal and stress evolution during laser cladding of bioactive glass coatings. J. Mech. Behav. Biomed. Mater. 2016, 59, 404–417. [Google Scholar] [CrossRef]

- Foppiano, S.; Marshall, S.J.; Saiz, E.; Tomsia, A.P.; Marshall, G.W. Functionally graded bioactive coatings: Reproducibility and stability of the coating under cell culture conditions. Acta Biomater. 2006, 2, 133–142. [Google Scholar] [CrossRef]

- Geesink, R.G.T. Experimental and Clinical Experience With Hydroxyapatite-Coated Hip Implants. Orthopedics 1989, 12, 1239–1242. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Berndt, C.C.; Gross, K.A.; Kucuk, A. Material fundamentals and clinical performance of plasma-sprayed hydroxyapatite coatings: A review. J. Biomed. Mater. Res. 2001, 58, 570–592. [Google Scholar] [CrossRef] [PubMed]

- Famery, R.; Richard, N.; Boch, P. Preparation of α- and β-tricalcium phosphate ceramics, with and without magnesium addition. Ceram. Int. 1994, 20, 327–336. [Google Scholar] [CrossRef]

- Habibovic, P.; Sees, T.M.; van den Doel, M.A.; van Blitterswijk, C.A.; De Groot, K. Osteoinduction by biomaterials—Physicochemical and structural influences. J. Biomed. Mater. Res. A 2006, 77, 747–762. [Google Scholar] [CrossRef] [PubMed]

- Sola, A.; Bellucci, D.; Raucci, M.G.; Zeppetelli, S.; Ambrosio, L.; Cannillo, V. Heat treatment of Na2O-CaO-P2O5-SiO2 bioactive glasses: Densification processes and postsintering bioactivity. J. Biomed. Mater. Res. A 2012, 100A, 305–322. [Google Scholar] [CrossRef]

- Nery, E.B.; LeGeros, R.Z.; Lynch, K.L.; Lee, K. Tissue Response to Biphasic Calcium Phosphate Ceramic with Different Ratios of HA/βTCP in Periodontal Osseous Defects. J. Periodontol. 1992, 63, 729–735. [Google Scholar] [CrossRef] [PubMed]

- Thompson, I.D.; Hench, L.L. Mechanical properties of bioactive glasses, glass-ceramics and composites. Proc. Inst. Mech. Eng. H 1998, 212, 127–136. [Google Scholar] [CrossRef]

- Jha, L.J.; Santos, J.D.; Knowles, J.C. Characterization of apatite layer formation on P2O5-CaO, P2O5-CaO-Na2O, and P2O5-CaO-Na2O-Al2O3 glass hydroxyapatite composites. J. Biomed. Mater. Res. 1996, 31, 481–486. [Google Scholar] [CrossRef]

- Knowles, J.C.; Bonfield, W. Development of a glass reinforced hydroxyapatite with enhanced mechanical properties. The effect of glass composition on mechanical properties and its relationship to phase changes. J. Biomed. Mater. Res. 1993, 27, 1591–1598. [Google Scholar] [CrossRef]

- Knowles, J.C.; Talal, S.; Santos, J.D. Sintering effects in a glass reinforced hydroxyapatite. Biomaterials 1996, 17, 1437–1442. [Google Scholar] [CrossRef]

- Baino, F.; Caddeo, S.; Vitale-Brovarone, C. Sintering effects of bioactive glass incorporation in tricalcium phosphate scaffolds. Mater. Lett. 2020, 274, 128010. [Google Scholar] [CrossRef]

- Cacciotti, I. Multisubstituted hydroxyapatite powders and coatings: The influence of the codoping on the hydroxyapatite performances. Int. J. Appl. Ceram. Technol. 2019, 16, 1864–1884. [Google Scholar] [CrossRef]

- Bellucci, D.; Sola, A.; Cannillo, V. Hydroxyapatite and tricalcium phosphate composites with bioactive glass as second phase: State of the art and current applications. J. Biomed. Mater. Res. A 2016, 104, 1030–1056. [Google Scholar] [CrossRef] [PubMed]

- Contreras Jaimes, A.T.; de Pablos-Martín, A.; Hurle, K.; Martins de Souza e Silva, J.; Berthold, L.; Kittel, T.; Boccaccini, A.R.; Brauer, D.S. Deepening our understanding of bioactive glass crystallization using TEM and 3D nano-CT. J. Eur. Ceram. Soc. 2021, 41, 4958–4969. [Google Scholar] [CrossRef]

- Peitl, O.; Dutra Zanotto, E.; Hench, L.L. Highly bioactive P2O5–Na2O–CaO–SiO2 glass-ceramics. J. Non-Cryst. Solids 2001, 292, 115–126. [Google Scholar] [CrossRef]

- Hashmi, M.U.; Shah, S.A.; Elkady, A.S. Effect of Sintering Time on Crystallization, Densification and in-Vitro Characteristics of Bioactive Glass Ceramics. Certif. Int. J. Eng. Sci. Innov. Technol. (IJESIT) 2008, 9001, 2319–5967. [Google Scholar]

- Döhler, F.; Groh, D.; Chiba, S.; Bierlich, J.; Kobelke, J.; Brauer, D.S. Bioactive glasses with improved processing. Part 2. Viscosity and fibre drawing. J. Non-Cryst. Solids 2016, 432, 130–136. [Google Scholar] [CrossRef]

- Arstila, H.; Vedel, E.; Hupa, L.; Hupa, M. Factors affecting crystallization of bioactive glasses. J. Eur. Ceram. Soc. 2007, 27, 1543–1546. [Google Scholar] [CrossRef]

- Arstila, H.; Hupa, L.; Karlsson, K.; Hupa, M. Influence of heat treatment on crystallization of bioactive glasses. J. Non-Cryst. Solids 2008, 354, 722–728. [Google Scholar] [CrossRef]

- Massera, J.; Fagerlund, S.; Hupa, L.; Hupa, M. Crystallization Mechanism of the Bioactive Glasses, 45S5 and S53P4. J. Am. Ceram. Soc. 2012, 95, 607–613. [Google Scholar] [CrossRef]

- Lefebvre, L.; Chevalier, J.; Gremillard, L.; Zenati, R.; Thollet, G.; Bernache-Assolant, D.; Govin, A. Structural transformations of bioactive glass 45S5 with thermal treatments. Acta Mater. 2007, 55, 3305–3313. [Google Scholar] [CrossRef] [Green Version]

- Clupper, D.; Hench, L. Crystallization kinetics of tape cast bioactive glass 45S5. J. Non-Cryst. Solids 2003, 318, 43–48. [Google Scholar] [CrossRef]

- Lin, C.-C.; Huang, L.-C.; Shen, P. Na2CaSi2O6–P2O5 based bioactive glasses. Part 1: Elasticity and structure. J. Non-Cryst. Solids 2005, 351, 3195–3203. [Google Scholar] [CrossRef]

- Bellucci, D.; Cannillo, V.; Sola, A. An overview of the effects of thermal processing on bioactive glasses. Sci. Sinter. 2010, 42, 307–320. [Google Scholar] [CrossRef]

- Thümmler, F.; Thomma, W. The sintering process. Met. Rev. 1967, 12, 69–108. [Google Scholar] [CrossRef]

- Bretcanu, O.; Chatzistavrou, X.; Paraskevopoulos, K.; Conradt, R.; Thompson, I.; Boccaccini, A.R. Sintering and crystallisation of 45S5 Bioglass® powder. J. Eur. Ceram. Soc. 2009, 29, 3299–3306. [Google Scholar] [CrossRef]

- Li, X.; Yang, C.; Chen, T.; Zhang, L.; Hayat, M.; Cao, P. Influence of powder shape on atomic diffusivity and resultant densification mechanisms during spark plasma sintering. J. Alloys Compd. 2019, 802, 600–608. [Google Scholar] [CrossRef]

- Chen, Q.Z.; Boccaccini, A.R.; Zhang, H.B.; Wang, D.Z.; Edirisinghe, M.J. Improved Mechanical Reliability of Bone Tissue Engineering (Zirconia) Scaffolds by Electrospraying. J. Am. Ceram. Soc. 2006, 89, 1534–1539. [Google Scholar] [CrossRef]

- Cacciotti, I.; Lombardi, M.; Bianco, A.; Ravaglioli, A.; Montanaro, L. Sol–gel derived 45S5 bioglass: Synthesis, microstructural evolution and thermal behaviour. J. Mater. Sci. Mater. Med. 2012, 23, 1849–1866. [Google Scholar] [CrossRef]

- Lombardi, M.; Gremillard, L.; Chevalier, J.; Lefebvre, L.; Cacciotti, I.; Bianco, A.; Montanaro, L. A Comparative Study between Melt-Derived and Sol-Gel Synthesized 45S5 Bioactive Glasses. Key Eng. Mater. 2013, 541, 15–30. [Google Scholar] [CrossRef]

- Nawaz, Q.; de Pablos-Martín, A.; Martins de Souza e Silva, J.; Hurle, K.; Jaimes, A.T.C.; Brauer, D.S.; Boccaccini, A.R. New insights into the crystallization process of sol-gel–derived 45S5 bioactive glass. J. Am. Ceram. Soc. 2020, 103, 4234–4247. [Google Scholar] [CrossRef]

- Hench, L.; LaTorre, G.; Andersson, Ö. The Kinetics of Bioactive Ceramics Part III: Surface Reactions for Bioactive Glasses compared with an Inactive Glass. Bioceramics 1991, 155–162. [Google Scholar] [CrossRef]

- Fagerlund, S.; Massera, J.; Moritz, N.; Hupa, L.; Hupa, M. Phase composition and in vitro bioactivity of porous implants made of bioactive glass S53P4. Acta Biomater. 2012, 8, 2331–2339. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Rahaman, M.N.; Hilmas, G.E.; Bal, B.S. Mechanical properties of bioactive glass (13-93) scaffolds fabricated by robotic deposition for structural bone repair. Acta Biomater. 2013, 9, 7025–7034. [Google Scholar] [CrossRef] [Green Version]

- Niiranen, H.; To¨rma¨la¨, P. Bioabsorbable polymer plates coated with bioactive glass spheres. J. Mater. Sci. Mater. Med. 1999, 10, 707–710. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Rahaman, M.N.; Bal, B.S.; Huang, W.; Day, D.E. Preparation and bioactive characteristics of a porous 13–93 glass, and fabrication into the articulating surface of a proximal tibia. J. Biomed. Mater. Res. Part A 2007, 82A, 222–229. [Google Scholar] [CrossRef]

- Fagerlund, S.; Massera, J.; Hupa, M.; Hupa, L. T–T–T behaviour of bioactive glasses 1–98 and 13–93. J. Eur. Ceram. Soc. 2012, 32, 2731–2738. [Google Scholar] [CrossRef]

- Bellucci, D.; Cannillo, V. A novel bioactive glass containing strontium and magnesium with ultra-high crystallization temperature. Mater. Lett. 2018, 213, 67–70. [Google Scholar] [CrossRef]

- Angioni, D.; Orrù, R.; Cao, G.; Garroni, S.; Bellucci, D.; Cannillo, V. Bioactivity enhancement by a ball milling treatment in novel bioactive glass-hydroxyapatite composites produced by spark plasma sintering. J. Eur. Ceram. Soc. 2023, 43, 1220–1229. [Google Scholar] [CrossRef]

- Bellucci, D.; Salvatori, R.; Anesi, A.; Chiarini, L.; Cannillo, V. SBF assays, direct and indirect cell culture tests to evaluate the biological performance of bioglasses and bioglass-based composites: Three paradigmatic cases. Mater. Sci. Eng. C 2019, 96, 757–764. [Google Scholar] [CrossRef]

- Bellucci, D.; Veronesi, E.; Dominici, M.; Cannillo, V. On the in Vitro Biocompatibility Testing of Bioactive Glasses. Materials 2020, 13, 1816. [Google Scholar] [CrossRef] [Green Version]

- Bellucci, D.; Veronesi, E.; Dominici, M.; Cannillo, V. A new bioactive glass with extremely high crystallization temperature and outstanding biological performance. Mater. Sci. Eng. C 2020, 110, 110699. [Google Scholar] [CrossRef]

- Westhauser, F.; Hohenbild, F.; Arango-Ospina, M.; Schmitz, S.I.; Wilkesmann, S.; Hupa, L.; Moghaddam, A.; Boccaccini, A.R. Bioactive Glass (BG) ICIE16 Shows Promising Osteogenic Properties Compared to Crystallized 45S5-BG. Int. J. Mol. Sci. 2020, 21, 1639. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.Y.; Hill, R.G.; Yue, S.; Nightingale, D.; Lee, P.; Jones, J. Melt-derived bioactive glass scaffolds produced by a gel-cast foaming technique. Acta Biomater. 2011, 7, 1807–1816. [Google Scholar] [CrossRef] [PubMed]

- Nommeots-Nomm, A.; Labbaf, S.; Devlin, A.; Todd, N.; Geng, H.; Solanki, A.K.; Tang, H.M.; Perdika, P.; Pinna, A.; Ejeian, F.; et al. Highly degradable porous melt-derived bioactive glass foam scaffolds for bone regeneration. Acta Biomater. 2017, 57, 449–461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Onodera, Y.; Takimoto, Y.; Hijiya, H.; Taniguchi, T.; Urata, S.; Inaba, S.; Fujita, S.; Obayashi, I.; Hiraoka, Y.; Kohara, S. Origin of the mixed alkali effect in silicate glass. NPG Asia Mater. 2019, 11, 75. [Google Scholar] [CrossRef] [Green Version]

- Crovace, M.C.; Soares, V.O.; Rodrigues, A.C.M.; Peitl, O.; Raucci, L.M.; de Oliveira, P.T.; Zanotto, E.D. Understanding the mixed alkali effect on the sinterability and in vitro performance of bioactive glasses. J. Eur. Ceram. Soc. 2021, 41, 4391–4405. [Google Scholar] [CrossRef]

- Moghanian, A.; Firoozi, S.; Tahriri, M. Synthesis and in vitro studies of sol-gel derived lithium substituted 58S bioactive glass. Ceram. Int. 2017, 43, 12835–12843. [Google Scholar] [CrossRef]

- Maçon, A.L.B.; Jacquemin, M.; Page, S.J.; Li, S.; Bertazzo, S.; Stevens, M.M.; Hanna, J.V.; Jones, J.R. Lithium-silicate sol–gel bioactive glass and the effect of lithium precursor on structure–property relationships. J. Sol-Gel Sci. Technol. 2017, 81, 84–94. [Google Scholar] [CrossRef] [Green Version]

- Marikani, A.; Maheswaran, A.; Premanathan, M.; Amalraj, L. Synthesis and characterization of calcium phosphate based bioactive quaternary P2O5–CaO–Na2O–K2O glasses. J. Non-Cryst. Solids 2008, 354, 3929–3934. [Google Scholar] [CrossRef]

- Cannillo, V.; Sola, A. Potassium-based composition for a bioactive glass. Ceram. Int. 2009, 35, 3389–3393. [Google Scholar] [CrossRef]

- Bellucci, D.; Cannillo, V.; Sola, A. Calcium and potassium addition to facilitate the sintering of bioactive glasses. Mater. Lett. 2011, 65, 1825–1827. [Google Scholar] [CrossRef]

- Massera, J.; Hupa, L. Influence of SrO substitution for CaO on the properties of bioactive glass S53P4. J. Mater. Sci. Mater. Med. 2014, 25, 657–668. [Google Scholar] [CrossRef] [PubMed]

- Fujikura, K.; Karpukhina, N.; Kasuga, T.; Brauer, D.S.; Hill, R.G.; Law, R.V. Influence of strontium substitution on structure and crystallisation of Bioglass® 45S5. J. Mater. Chem. 2012, 22, 7395–7402. [Google Scholar] [CrossRef]

- Bellucci, D.; Sola, A.; Salvatori, R.; Anesi, A.; Chiarini, L.; Cannillo, V. Role of magnesium oxide and strontium oxide as modifiers in silicate-based bioactive glasses: Effects on thermal behaviour, mechanical properties and in-vitro bioactivity. Mater. Sci. Eng. C 2017, 72, 566–575. [Google Scholar] [CrossRef]

- Diba, M.; Tapia, F.; Boccaccini, A.R.; Strobel, L.A. Magnesium-Containing Bioactive Glasses for Biomedical Applications. Int. J. Appl. Glas. Sci. 2012, 3, 221–253. [Google Scholar] [CrossRef]

- Jallot, E.; Moretto, P. Characterisation, by the PIXE Method, of Trace Elements During Physicochemical Reactions at the Periphery of Bioactive Glass Pastilles in Contact with Biological Fluids. Instrum. Sci. Technol. 2006, 34, 405–416. [Google Scholar] [CrossRef]

- Pérez-Pariente, J.; Balas, F.; Vallet-Regí, M. Surface and Chemical Study of SiO2·P2O5·CaO·(MgO) Bioactive Glasses. Chem. Mater. 2000, 12, 750–755. [Google Scholar] [CrossRef]

- Sergi, R.; Bellucci, D.; Salvatori, R.; Maisetta, G.; Batoni, G.; Cannillo, V. Zinc containing bioactive glasses with ultra-high crystallization temperature, good biological performance and antibacterial effects. Mater. Sci. Eng. C 2019, 104, 109910. [Google Scholar] [CrossRef]

- Kumar Srivastava, A.K.; Pyare, R. Characterization of ZnO substituted 45S5 Bioactive Glasses and Glass—Ceramics. J. Mater. Sci. Res. 2012, 1, 207–214. [Google Scholar] [CrossRef] [Green Version]

- Shruti, S.; Salinas, A.J.; Malavasi, G.; Lusvardi, G.; Menabue, L.; Ferrara, C.; Mustarelli, P.; Vallet-Regì, M. Structural and in vitro study of cerium, gallium and zinc containing sol–gel bioactive glasses. J. Mater. Chem. 2012, 22, 13698–13706. [Google Scholar] [CrossRef]

- Wetzel, R.; Bartzok, O.; Hupa, L.; Brauer, D. Low Mg or Zn substitution for improved thermal properties of Bioglass 45S5. Mater. Lett. 2019, 256, 126599. [Google Scholar] [CrossRef]

- Wetzel, R.; Blochberger, M.; Scheffler, F.; Hupa, L.; Brauer, D.S. Mg or Zn for Ca substitution improves the sintering of bioglass 45S5. Sci. Rep. 2020, 10, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Arepalli, S.K.; Tripathi, H.; Vyas, V.K.; Jain, S.; Suman, S.K.; Pyare, R.; Singh, S. Influence of barium substitution on bioactivity, thermal and physico-mechanical properties of bioactive glass. Mater. Sci. Eng. C 2015, 49, 549–559. [Google Scholar] [CrossRef] [PubMed]

- Khoeini, M.; Hesaraki, S.; Kolahi, A. Effect of BaO substitution for CaO on the structural and thermal properties of SiO2–B2O3–Al2O3–CaO–Na2O–P2O5 bioactive glass system used for implant coating applications. Ceram. Int. 2021, 47, 31666–31680. [Google Scholar] [CrossRef]

- Vyas, V.K.; Sampath Kumar, A.; Singh, S.P.; Pyare, R. Effect of Cobalt Oxide Substitution on Mechanical Behaviour and Elastic Properties of Bioactive Glass and Glass-Ceramics. Trans. Indian Ceram. Soc. 2016, 75, 12–19. [Google Scholar] [CrossRef]

- Kargozar, S.; Lotfibakhshaiesh, N.; Ai, J.; Samadikuchaksaraie, A.; Hill, R.G.; Shah, P.A.; Milan, P.B.; Mozafari, M.; Fathi, M.; Joghataei, M.T. Synthesis, physico-chemical and biological characterization of strontium and cobalt substituted bioactive glasses for bone tissue engineering. J. Non-Cryst. Solids 2016, 449, 133–140. [Google Scholar] [CrossRef] [Green Version]

- Vyas, V.; Kumar, A.; Prasad, S.; Ershad, M.; Singh, S.; Pyare, R. Preparation and Characterization of Cobalt Oxide Doped 45S5 Bioactive Glass-Ceramics. Bentham. Sci. Pub. 2015, 5, 86–92. [Google Scholar] [CrossRef]

- Kang, T.; Seo, J.; Ryu, J.; Kim, K.; Kwon, J. Improvement of the mechanical and biological properties of bioactive glasses by the addition of zirconium oxide (ZrO2) as a synthetic bone graft substitute. J. Biomed. Mater. Res. A 2021, 109, 1196–1208. [Google Scholar] [CrossRef]

- Moghanian, A.; Zohourfazeli, M.; Tajer, M.H.M. The effect of zirconium content on in vitro bioactivity, biological behavior and antibacterial activity of sol-gel derived 58S bioactive glass. J. Non-Cryst. Solids 2020, 546, 120262. [Google Scholar] [CrossRef]

- Cannillo, V.; Leonelli, C.; Boccaccini, A.R. Numerical models for thermal residual stresses in Al2O3 platelets/borosilicate glass matrix composites. Mater. Sci. Eng. A 2002, 323, 246–250. [Google Scholar] [CrossRef]

| BG | Glass Transition Temperature Tg | Crystallization Temperatures: Tc,onset (Onset) and Tc (Peak) | Ref. |

|---|---|---|---|

| 45S5 | 550 °C | Tc,onset = 610 °C | [62] |

| S53P4 | 561 °C | Tc = 748 °C | [61] |

| 13-93 | 612 °C | Tc,onset = 714 °C, Tc = 1038 °C | [77] |

| 1-98 | 608 °C | Tc,onset = 700 °C, Tc = 958 °C | [78] |

| BGMS10 | 670 °C | Tc,onset = 880 °C, Tc = 932 °C | [79] |

| Bio_MS | 638 °C | Tc,onset = 817 °C, Tc = 859 °C | [83] |

| ICIE16 | 575 °C | Tc,onset = 725 °C | [85] |

| Ion | Parent BG | Substituted Ion | Effect | Refs. |

|---|---|---|---|---|

| Mixed alkali metals | - | Na | Improved thermal stability | [14,88] |

| Improved mechanical properties | ||||

| Hinders crystallization | ||||

| Broader sintering window | ||||

| Li | 58S | Addition | Broader crystallization peak | [89] |

| Lower crystallization temperature (from 980 to 952 °C) | ||||

| New crystallized phase | ||||

| K | 45S5 | Na | Improved mechanical properties | [92] |

| Sr | S53P4 | Ca | Higher density (from 2.66 to 3.03 g/cm3) | [94] |

| New crystallized phase | ||||

| 45S5 | Ca | Lower glass transition temperature (from 539 to 497 °C) | [95] | |

| Lower crystallization temperature (from 665 to 641 °C) | ||||

| Mg | - | Ca | Lower glass transition temperature (with increasing Mg content) | [97] |

| Inhibit crystallization | ||||

| Less robust network | ||||

| - | Addition | More stable amorphous phase | [99] | |

| Zn | 45S5 | Ca | Lower glass transition temperature (from DTA plot) | [101,102] |

| Lower crystallization temperature (from DTA plot) | ||||

| Improved mechanical properties | ||||

| New crystallized phase (debated) | ||||

| BGMS10 | Mg | Lower glass transition temperature (from 670 to 631 °C) | [100] | |

| Lower crystallization temperature (from 880 to 847 °C) | ||||

| Ba | 45S5 | Si | Lower crystallization onset temperature (from 614 to 542 °C) | [105] |

| Lower crystallization temperature (from 760 to 681 °C) | ||||

| 45S5 | Ca | Lower glass transition temperature (from 652 to 641 °C) | [106] | |

| Lower crystallization temperature (from 853 to 811 °C) | ||||

| Reduced number of oxygen bonds | ||||

| Co | 45S5 | Si | Improved mechanical properties | [107] |

| Lower crystallization onset temperature (from 535 to 455 °C) | ||||

| Lower peak crystallization temperature (from 718 to 616 °C) | ||||

| Zr | 45S5 | Na | Improved mechanical properties | [110] |

| Increased number of bridging oxygen bonds |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mecca, F.G.; Bellucci, D.; Cannillo, V. Effect of Thermal Treatments and Ion Substitution on Sintering and Crystallization of Bioactive Glasses: A Review. Materials 2023, 16, 4651. https://doi.org/10.3390/ma16134651

Mecca FG, Bellucci D, Cannillo V. Effect of Thermal Treatments and Ion Substitution on Sintering and Crystallization of Bioactive Glasses: A Review. Materials. 2023; 16(13):4651. https://doi.org/10.3390/ma16134651

Chicago/Turabian StyleMecca, Francesco Gerardo, Devis Bellucci, and Valeria Cannillo. 2023. "Effect of Thermal Treatments and Ion Substitution on Sintering and Crystallization of Bioactive Glasses: A Review" Materials 16, no. 13: 4651. https://doi.org/10.3390/ma16134651

APA StyleMecca, F. G., Bellucci, D., & Cannillo, V. (2023). Effect of Thermal Treatments and Ion Substitution on Sintering and Crystallization of Bioactive Glasses: A Review. Materials, 16(13), 4651. https://doi.org/10.3390/ma16134651