Dimensional Stability and Reproducibility of Varying FFF Models for Aligners in Comparison to Plaster Models

Abstract

:1. Introduction

2. Materials and Methods

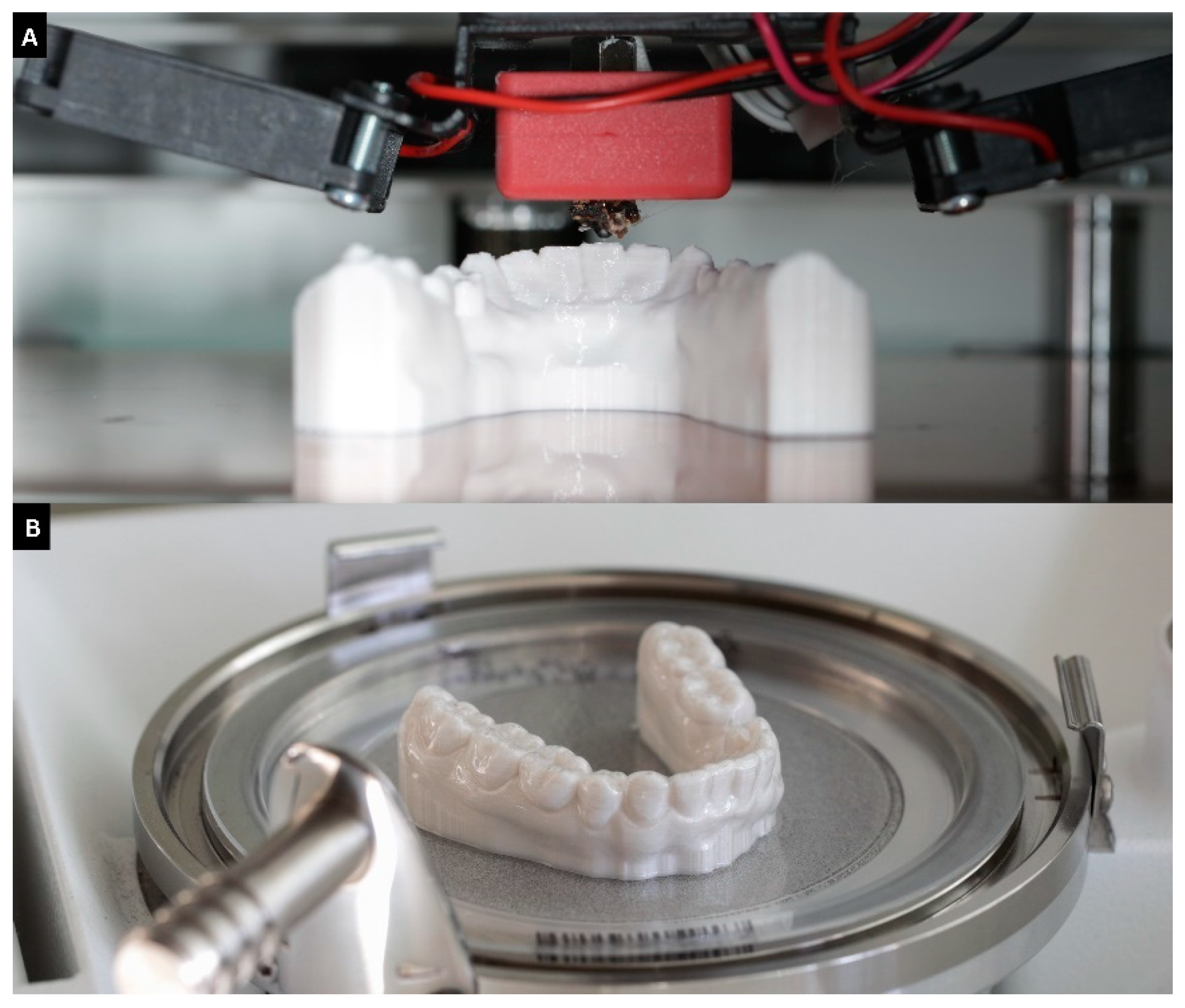

2.1. Fabrication of Models

2.2. Thermoforming of the Models

2.3. Digitization of Models

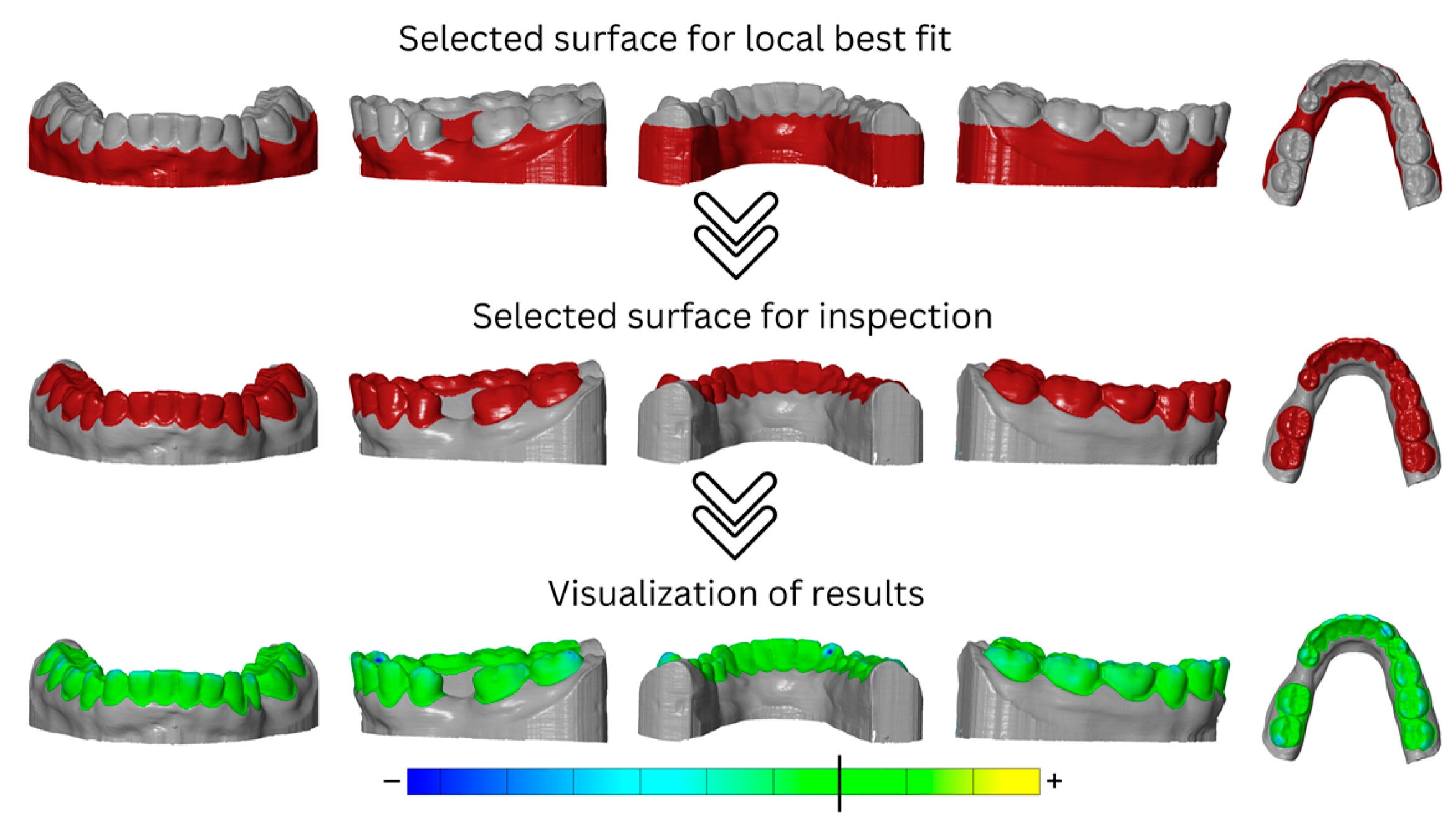

2.4. 3D Data Analysis Using Step Models

2.5. Statisical Analysis

3. Results

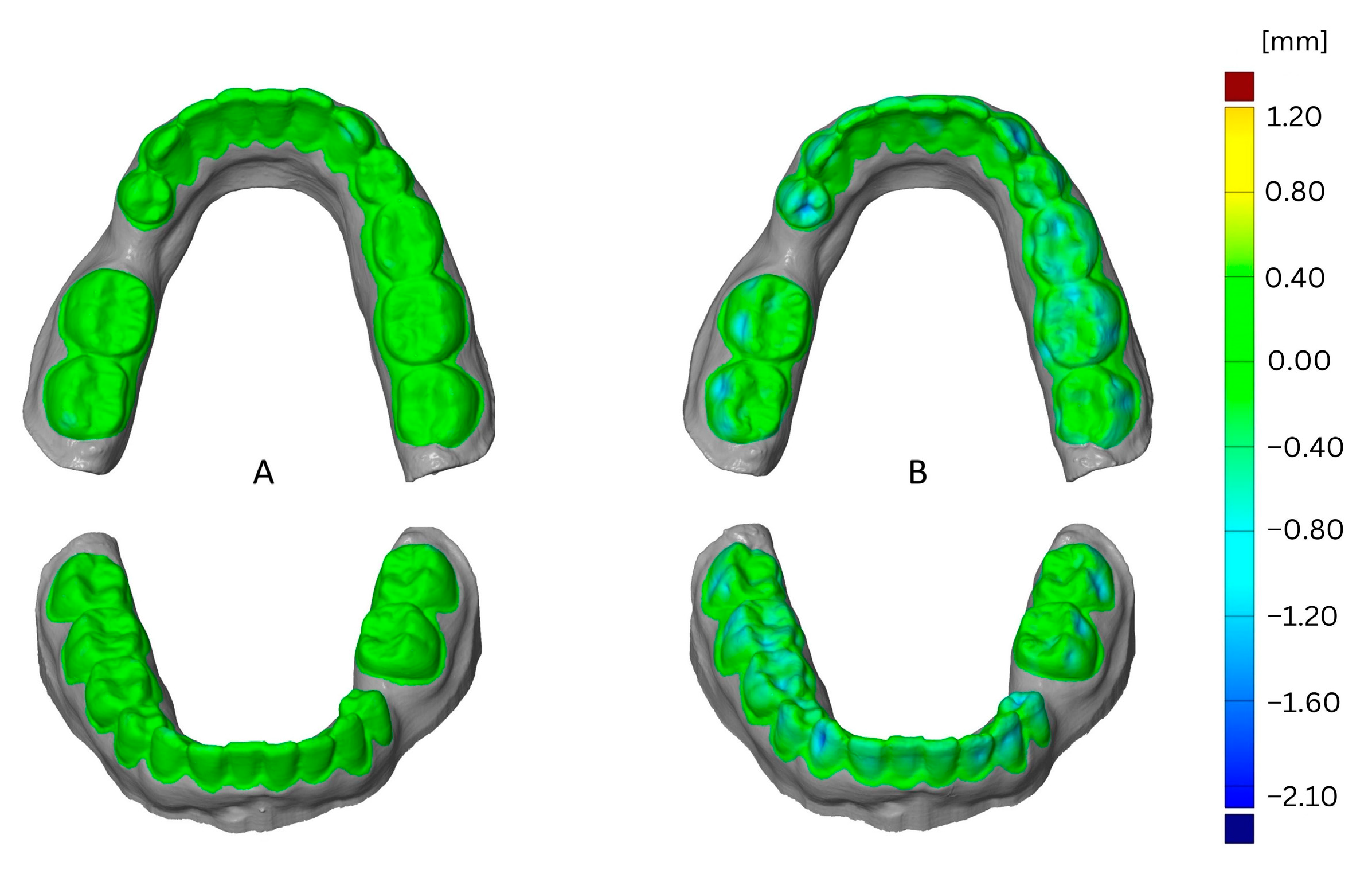

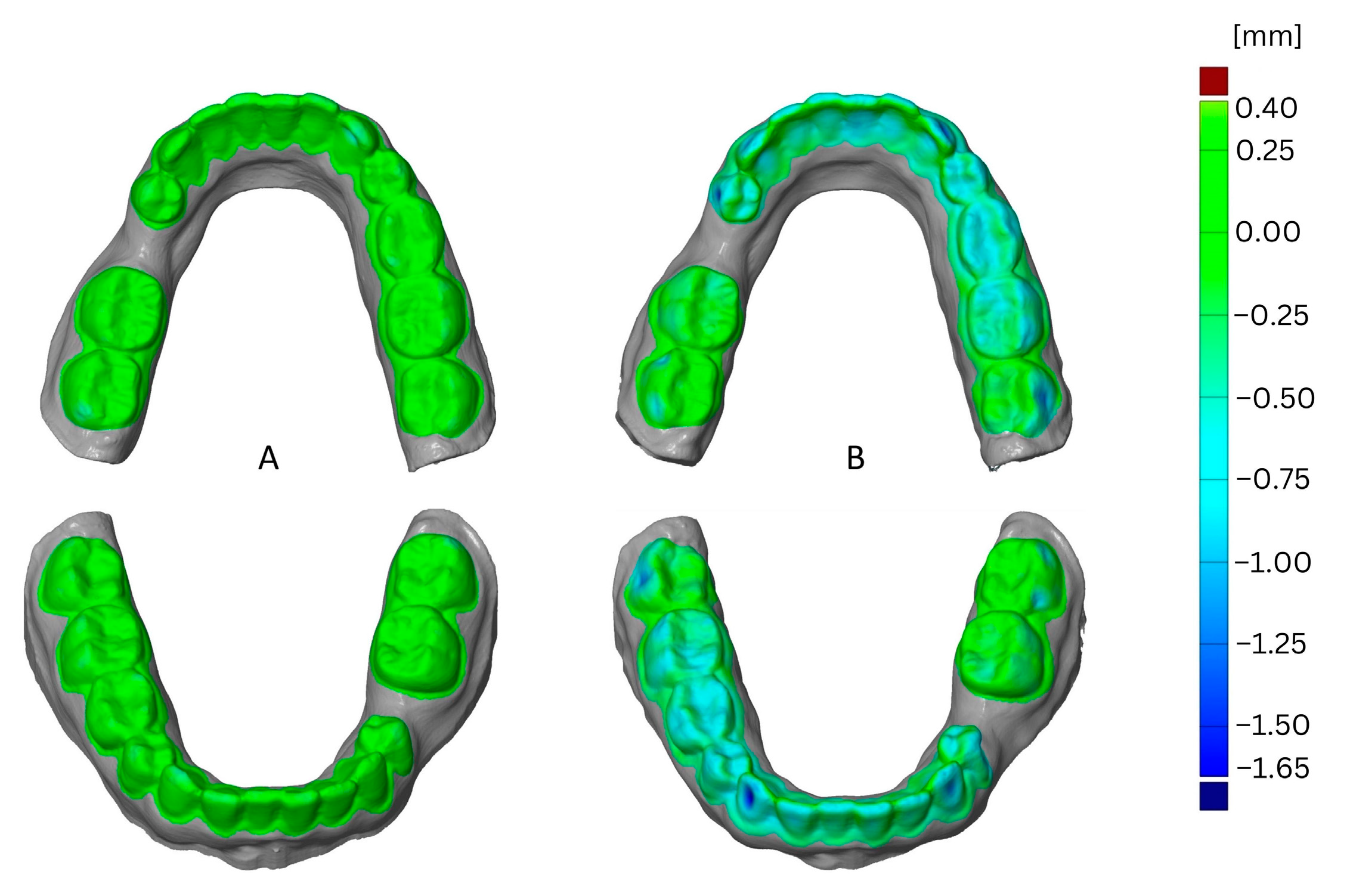

3.1. Impact of Thermoforming Foil

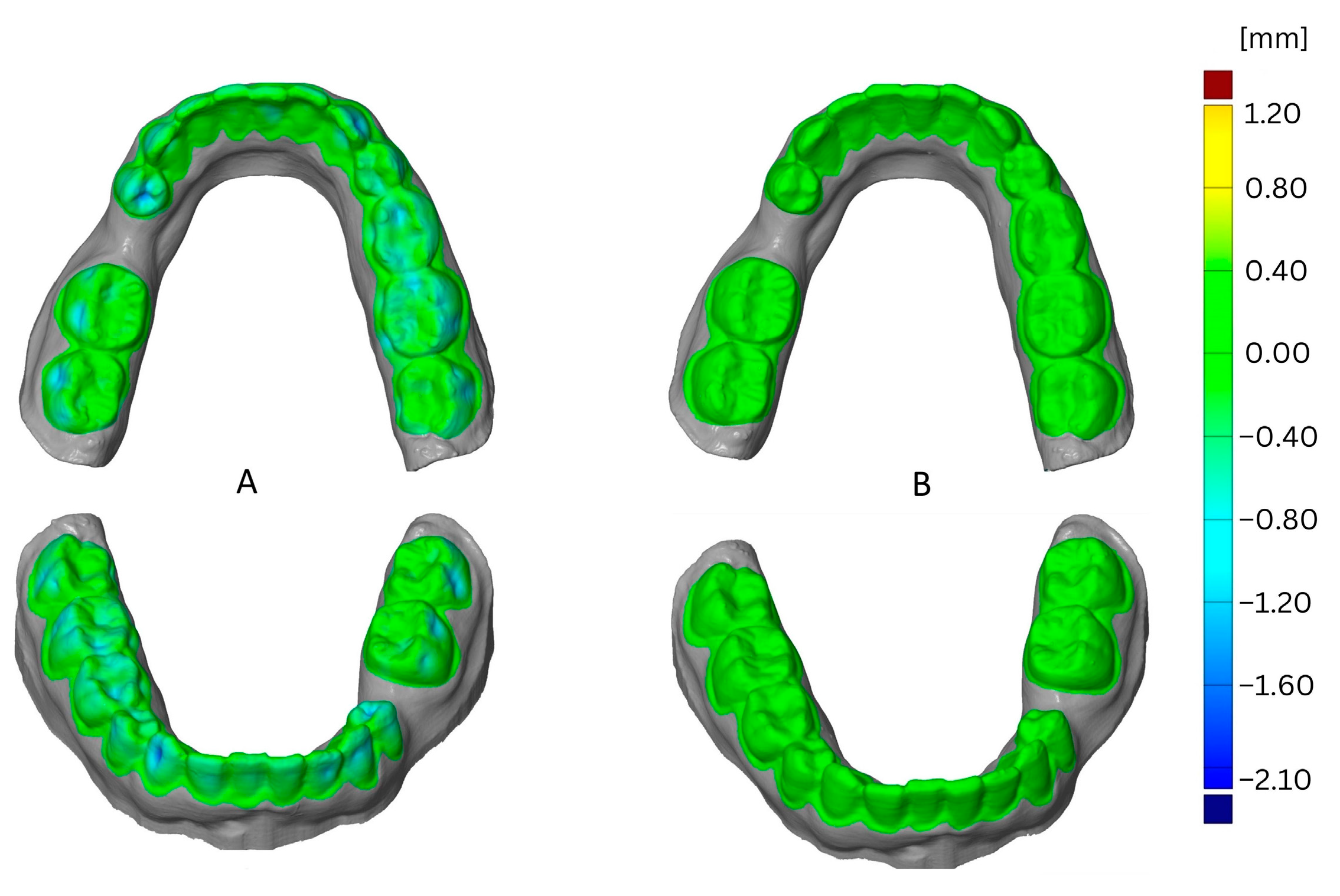

3.2. Impact of FFF Filament

3.3. Impact of Printing Parameter (Number of Loops)

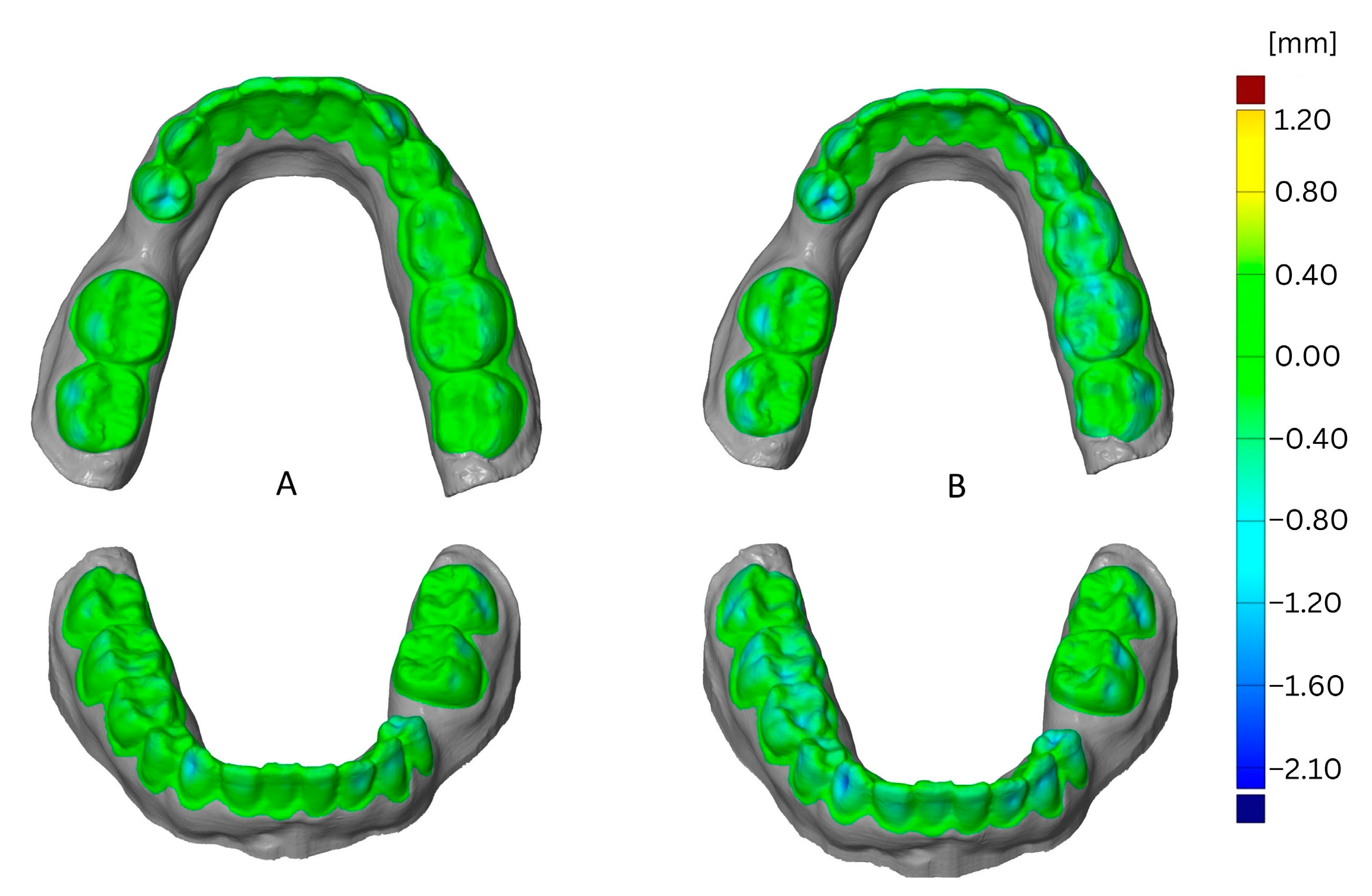

3.4. Impact of Thermoforming Cycles

3.5. Impact of Model Jaw

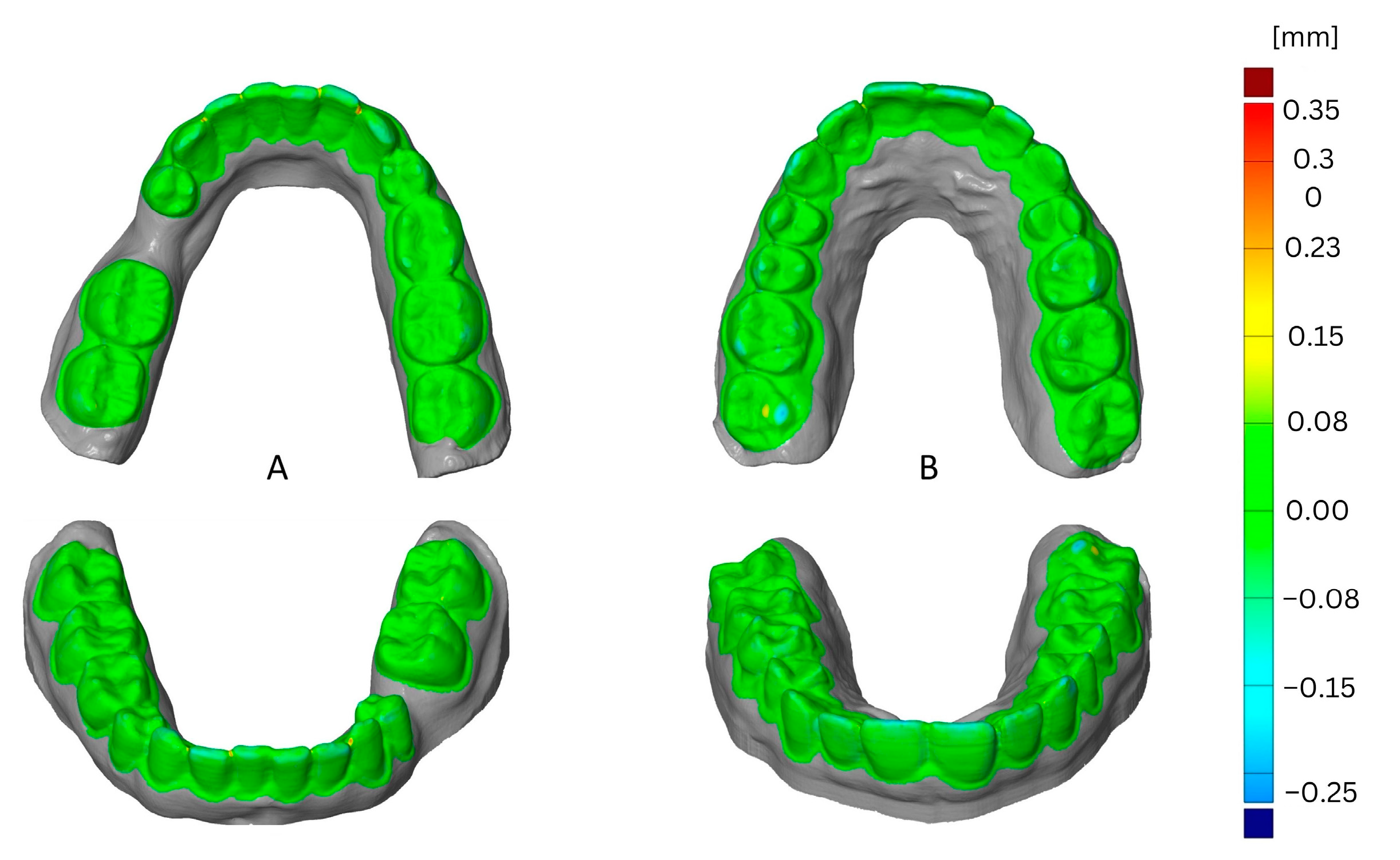

3.6. Comparison with Plaster Models

- All SIMPLEX aligner model models with the printing parameter of two, three, or four (default) loops and thermoformed on maxillary and mandibular (except four-loop models) models using aligner foil;

- All four-loop and sometimes three-loop SIMPLEX aligner models thermoformed on maxillary and mandibular models using Duran foil;

- All four-loop (default) maxillary models up to thermoforming cycle two and all four- (default) and three-loop Renfert PLA HT filament models thermoformed on mandibular models using aligner foil.

4. Discussion

4.1. Impact of Model Type and FFF Filament

4.2. Impact of Printing Parameters (Loop Counts)

4.3. Impact of Thermoforming Foil

5. Conclusions

- The initial set of FFF models are comparable to the gold standard “plaster models”, but the dimensional stability of FFF models decreases with increasing numbers of thermoforming cycles.

- Both the filament used and the loop count have a significant impact on dimensional stability, with Renfert PLA HT being less stable than the SIMPLEX aligner model filament, and with loop counts of three and four showing comparable dimensional stability for the Simplex aligner.

- The higher the layer thickness of the thermoforming foil, the greater the impact on the dimensional stability of FFF models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weir, T. Clear aligners in orthodontic treatment. Aust. Dent. J. 2017, 62, 58–62. [Google Scholar] [CrossRef] [Green Version]

- Rossini, G.; Parrini, S.; Castroflorio, T.; Deregibus, A.; Debernardi, C.L. Efficacy of clear aligners in controlling orthodontic tooth movement. A systematic review. Angle Orthod. 2015, 85, 881–889. [Google Scholar] [CrossRef] [Green Version]

- Tartaglia, G.M.; Mapelli, A.; Maspero, C.; Santaniello, T.; Serafin, M.; Farronato, M.; Caprioglio, A. Direct 3D Printing of Clear Orthodontic Aligners: Current State and Future Possibilities. Materials 2021, 14, 1799. [Google Scholar] [CrossRef] [PubMed]

- Ender, A.; Mehl, A. Accuracy of complete-arch dental impressions: A new method of measuring trueness and precision. J. Prosthet. Dent. 2013, 109, 121–128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sidhom, M.; Zaghloul, H.; El-Sayed Mosleh, I.; Eldwakhly, E. Effect of Different CAD/CAM Milling and 3D Printing Digital Fabrication Techniqus on the Accuracy of PMMA Workong Models and Vertical Marginal Fit of PMMA Provisional Dental Prosthesis: An In Vitro Study. Polymers 2022, 14, 1285. [Google Scholar] [CrossRef] [PubMed]

- Suryajaya, W.; Purbiati, M.; Ismah, N. Accuracy of digital dental models and three-dimensional printed dental models in linear measurements and Bolton analysis. F1000Research 2021, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Tavares Camardella, L.; Velella, O.V.; van Hezel, M.M.; Breuning, K.H. Accuracy of stereolithographically printed digital models compared to plaster models. J. Orofac. Orthop. 2017, 78, 394–402. [Google Scholar] [CrossRef] [PubMed]

- Tomita, Y.; Uechi, J.; Konno, M.; Sasamoto, S.; Iijima, M.; Mizoguchi, I. Accuracy of digital models generated by conventional impression/plaster-model methods and intraoral scanning. Dent. Mater. J. 2018, 37, 628–633. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kessler, A.; Hickel, R.; Reymus, M. 3D Printing in Dentistry—State of the Art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Etemad-Shahidi, Y.; Quallandar, O.B.; Evenden, J.; Alifui-Segbaya, F.; Ahmed, K.E. Accuracy of 3-Dimensionally Printed Full-Arch Dental Models: A Systematic Review. J. Clin. Med. 2020, 9, 3357. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-Y.; Shin, Y.-S.; Jung, H.-D.; Hwang, C.-J.; Baik, H.-S.; Cha, J.-Y. Precision and trueness of dental models manufactured with different 3-dimensional printing techniques. Am. J. Orthod. Dentofac. Orthop. 2018, 153, 144–153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Emir, F.; Ayyildiz, S. Accuracy evaluation of complete-arch models manufactured by three different 3D printing technologies: A three dimensional analysis. J. Prosthodont. Res. 2021, 65, 365–370. [Google Scholar] [CrossRef] [PubMed]

- Czajkowska, M.; Walejewska, E.; Zadrozny, Ł.; Wieczorek, M.; Swieszkowski, W.; Wagner, L.; Mijiritsky, E.; Markowski, J. Comparison of Dental Stone Models and Their 3D Printed Acrylic Replicas for the Accuracy and Mechanical Properties. Materials 2020, 13, 4066. [Google Scholar] [CrossRef] [PubMed]

- Tsolakis, I.A.; Gizani, S.; Panayi, N.; Antonopoulos, G.; Tsolakis, A.I. Three-Dimensional Printing Technology in Orthodontics for Dental Models: A Systematic Review. Children 2022, 9, 1106. [Google Scholar] [CrossRef] [PubMed]

- Gawel, A.; Stanislaw, K. The Study of Physico-Mechanical Properties of Polylactide Composites with Different Level of Infill Produced by the FDM Method. Polymers 2020, 12, 3056. [Google Scholar] [CrossRef] [PubMed]

- Dalaie, K.; Fatemi, S.M.; Ghaffari, S. Dynamic mechanical and thermal properties of clear aligners after thermoforming and aging. Prog. Orthod. 2021, 22, 15. [Google Scholar] [CrossRef] [PubMed]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of printing parameters on the thermal and mechanical properties of 3D-printed PLA and PETG, using fused deposition modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef] [PubMed]

- Valvez, S.; Silva, A.S.; Reis, P.N.B. Optimization of Printing Parameters to Maximize the Mechanical Properties of 3D-Printed PETG-Based Parts. Polymers 2022, 14, 2564. [Google Scholar] [CrossRef] [PubMed]

| Type of Material | Product Name | Material | Manufacturer | LOT |

|---|---|---|---|---|

| FFF Filament | Simplex aligner model | PETG | Renfert, Hilzingen, Germany | 17350300 |

| Renfert PLA HT | PLA | Renfert, Hilzingen, Germany | EP90213−1 L | |

| Plaster | Pico-rock 280 | N/A | Picodent, Wipperfürth, Germany | 220112507 |

| Thermoforming Sheet | CA® Pro+ Aligner (0.75 mm) | N/A | Scheu Dental, Iserlohn, Germany | 0522A |

| DURAN®+ (1.00 mm) | N/A | Scheu Dental, Iserlohn, Germany | 1022A |

| Size | 250 × 200 × 200mm |

| Layer resolution | ≥50 microns |

| Positioning precision (x, y, z) | 4 × 4 × 2 microns |

| Filament diameter | 1.75 mm |

| Printing speed | 50–200 mm/s |

| Type of extruder | Single, all-metal hot end |

| Nozzle operating temperature | 180–260 °C |

| Nozzle diameter | 0.4 mm |

| Ambient temperature | 15–32 °C |

| Heated building platform | 50–110 °C |

| Ventilation | Yes |

| Slicing software | SIMPLEX sliceware |

| Model Type | Thermoforming Foil | Model Jaw | Printing Parameters | Deviation in mm (Mean ± SD)/Relative Frequency (95% CI) | ||

|---|---|---|---|---|---|---|

| Thermoforming Cycle 1 | Thermoforming Cycle 2 | Thermoforming Cycle 3 | ||||

| SIMPLEX aligner model | CA® Pro+ Aligner | OK | Default (4 Loops) | −0.300 ± 0.052 * a;AB;i;I;1/100 (29;100) | −0.280 ± 0.079 a;B;i;I;1,2/100 (29;100) | −0.297 ± 0.067 b;B;I;2/100 (29;100) |

| 3 Loops | −0.217 ± 0.051 b;B;i;I/100 (29;100) | −0.233 ± 0.075 b;B;i;I/100 (29;100) | −0.257 ± 0.059 b;B;i;I/100 (29;100) | |||

| 2 Loops | −0.253 ± 0.051 b;AB;i;I/100 (29;100) | −0.277 ± 0.074 b;B;i;I/100 (29;100) | −0.277 ± 0.055 b;B;i;I/100 (29;100) | |||

| 1 Loop | −0.483 ± 0.178 b;A;ii;I/100 (29;100) | −0.543 ± 0.151 b;A;ii;I/100 (29;100) | −0.570 ± 0.161 b;A;ii;I/100 (29;100) | |||

| UK | Default (4 Loops) | −0.153 ± 0.042 b;A;i;I;†/100 (29;100) | −0.157 ± 0.038 b;B;i;I;2/100 (29;100) | −0.157 ± 0.021 b;B;ii;I;2/100 (29;100) | ||

| 3 Loops | −0.290 ± 0.040 a;A;i;I/100 (29;100) | −0.300 ± 0.010 a;AB;i;I/100 (29;100) | −0.313 ± 0.006 * a;AB;i;I/100 (29;100) | |||

| 2 Loops | −0.237 ± 0.093 b;A;ii;I/100 (29;100) | −0.257 ± 0.074 b;B;ii;I/100 (29;100) | −0.317 ± 0.081 b;AB;ii;I/100 (29;100) | |||

| 1 Loop | −0.593 ± 0.412 a;A;i;I/100 (29;100) | −0.713 ± 0.308 a;A;i;I/100 (29;100) | −0.720 ± 0.329 a;A;I/100 (29;100) | |||

| DURAN®+ | OK | Default (4 Loops) | −0.283 ± 0.081 a;B;i;I;1/100 (29;100) | −0.247 ± 0.051 b;B;i;I;1/100 (29;100) | N/A a;†/33.3 (0;91) | |

| 3 Loops | −0.430 ± 0.161 b;B;i;I/100 (29;100) | −0.383 ± 0.075 * b;B;i;I/100 (29;100) | −0.393 ± 0.101 a;A;i;I/100 (29;100) | |||

| 2 Loops | −0.670 ± 0.367 a;AB;i;I/100 (29;100) | −0.550 ± 0.170 b;B;i;I/100 (29;100) | −1.003 ± 0.794 b;A;i;I/100 (29;100) | |||

| 1 Loop | −1.123 ± 0.302 b;A;i;I/100 (29;100) | −1.373 ± 0.394 b;A;i;I/100 (29;100) | −1.450 ± 0.370 b;A;i;I/100 (29;100) | |||

| UK | Default (4 Loops) | −0.337 ± 0.120 b;B;i;I;1,2/100 (29;100) | −0.340 ± 0.115 b;B;i;I;2/100 (29;100) | −0.343 ± 0.111 b;A;i;I;2/100 (29;100) | ||

| 3 Loops | −0.337 ± 0.093 b;B;i;I/100 (29;100) | −0.423 ± 0.145 b;B;i;I/100 (29;100) | −0.453 ± 0.163 b;A;i;I/100 (29;100) | |||

| 2 Loops | −0.570 ± 0.171 a;B;i;I/100 (29;100) | −0.680 ± 0.165 a;B;i;I/100 (29;100) | −0.707 ± 0.162 a;A;i;I/100 (29;100) | |||

| 1 Loop | −1.447 ± 0.509 a;A;i;I/100 (29;100) | −1.895 ± 0.629 b;A;i;I/66.7 (9;100) | N/A b/33.3 (0;91) | |||

| Renfert PLA HT | CA® Pro+ Aligner | OK | Default (4 Loops) | −0.357 ± 0.006 * a;B;i;I;1/100 (29;100) | −0.400 ± 0.026 a;B;ii;II;1/100 (29;100) | −0.447 ± 0.006 * a;C;i;III;1/100 (29;100) |

| 3 Loops | −0.427 ± 0.085 a;B;ii;I 100 (29;100) | −0.490 ± 0.040 a;B;ii;I/100 (29;100) | −0.543 ± 0.031 a;B;I/100 (29;100) | |||

| 2 Loops | −0.400 ± 0.010 a;B;ii;II 100 (29;100) | −0.657 ± 0.067 a;A;I/100 (29;100) | −0.750 ± 0.036 a;A;I/100 (29;100) | |||

| 1 Loop | −1.390 ± 0.366 a;A 100 (29;100) | N/A a/33.3 (0;91) | N/A a/0 (0;71) | |||

| UK | Default (4 Loops) | −0.237 ± 0.015 a;B;ii;II;†/100 (29;100) | −0.300 ± 0.026 a;B;ii;I;1/100 (29;100) | −0.327 ± 0.015 a;A;ii;I;1/100 (29;100) | ||

| 3 Loops | −0.283 ± 0.012 * a;B;ii;I/100 (29;100) | −0.397 ± 0.098 * a;AB;ii;I/100 (29;100) | −0.067 ± 0.508 * a;A;i;I/100 (29;100) | |||

| 2 Loops | −0.393 ± 0.006 * a;AB;i;II/100 (29;100) | −0.557 ± 0.096 a;A;i;I;II/100 (29;100) | −0.617 ± 0.090 a;A;I/100 (29;100) | |||

| 1 Loop | −0.877 ± 0.426 a;A;ii/100 (29;100) | N/A a/33.3 (0;91) | N/A a/33.3 (0;91) | |||

| DURAN®+ | OK | Default (4 Loops) | −0.560 ± 0.156 a;A;i;I;1/100 (29;100) | −0.610 ± 0.036 a;B;i;I;1/100 (29;100) | −0.645 ± 0.078 * a;i;I;†/66.7 (9;100) | |

| 3 Loops | −0.863 ± 0.188 a;A;i;I/100 (29;100) | −0.973 ± 0.162 a;A;i;I/100 (29;100) | N/A a/33.3 (0;91) | |||

| 2 Loops | −0.967 ± 0.211 a;A;i/100 (29;100) | N/A a/33.3 (0;91) | N/A a/0 (0;71) | |||

| 1 Loop | N/A a/0 (0;71) | N/A a/0 (0;71) | N/A a/0 (0;71) | |||

| UK | Default (4 Loops) | −0.567 ± 0.042 a;B;i;II;1/100 (29;100) | −0.825 ± 0.050 a;A;i;I;1/66.7 (9;100) | −0.860 ± 0.087 a;B;i;I;1/100 (29;100) | ||

| 3 Loops | −0.973 ± 0.208 a;B;i;I/100 (29;100) | −1.160 ± 0.102 a;A;i;I/100 (29;100) | −1.230 ± 0.115 a;A;i;I/100 (29;100) | |||

| 2 Loops | −0.795 ± 0.148 a;B;i;I/66.7 (9;100) | −1.330 ± 0.311 a;A;i;I/66.7 (9;100) | N/A a/33.3 (0;91) | |||

| 1 Loop | −2.605 ± 0.262 a;A;i/66.7 (9;100) | N/A a/0 (0;71) | N/A a/0 (0;71) | |||

| Plaster | CA® Pro+ Aligner | OK | --- | −0.217 ± 0.015 i;I;2/100 (29;100) | −0.203 ± 0.021 i;I;2/100 (29;100) | −0.233 ± 0.065 i;I;2/100 (29;100) |

| UK | --- | −0.147 ± 0.049 i;I;†/100 (29;100) | −0.130 ± 0.036 ii;I;2/100 (29;100) | −0.177 ± 0.065 ii;I;2/100 (29;100) | ||

| DURAN®+ | OK | --- | −0.463 ± 0.586 * i;I;1/100 (29;100) | −0.467 ± 0.592 i;I;1/100 (29;100) | −0.430 ± 0.563 i;I;†/100 (29;100) | |

| UK | --- | −0.300 ± 0.121 i;I;2/100 (29;100) | −0.340 ± 0.115 i;I;2/100 (29;100) | −0.463 ± 0.095 i;I;2/100 (29;100) | ||

| Lower Jaw | Upper Jaw | |||

|---|---|---|---|---|

| Printing Time in hh:mm:ss (Percentage of Savings in Printing Time) | Filament Used in m (Percentage of Savings in Filament Used) | Printing Time in hh:mm:ss (Percentage of Savings in Printing Time) | Filament Used in m (Percentage of Savings in Filament Used) | |

| 4 Loops | 01:39:00 | 4.321 | 01:47:00 | 4.890 |

| 3 Loops | 01:35:00 (4%) | 3.967 (8%) | 01:39:00 (7%) | 4.541 (7%) |

| 2 Loops | 01:23:00 (16%) | 3.579 (17%) | 01:31:00 (15%) | 4.166 (15%) |

| 1 Loop | 01:16:00 (23%) | 3.152 (27%) | 01:25:00 (21%) | 3.757 (23%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lümkemann, N.; Klimenta, M.; Hoffmann, M.; Meinen, J.; Stawarczyk, B. Dimensional Stability and Reproducibility of Varying FFF Models for Aligners in Comparison to Plaster Models. Materials 2023, 16, 4835. https://doi.org/10.3390/ma16134835

Lümkemann N, Klimenta M, Hoffmann M, Meinen J, Stawarczyk B. Dimensional Stability and Reproducibility of Varying FFF Models for Aligners in Comparison to Plaster Models. Materials. 2023; 16(13):4835. https://doi.org/10.3390/ma16134835

Chicago/Turabian StyleLümkemann, Nina, Melisa Klimenta, Moritz Hoffmann, John Meinen, and Bogna Stawarczyk. 2023. "Dimensional Stability and Reproducibility of Varying FFF Models for Aligners in Comparison to Plaster Models" Materials 16, no. 13: 4835. https://doi.org/10.3390/ma16134835

APA StyleLümkemann, N., Klimenta, M., Hoffmann, M., Meinen, J., & Stawarczyk, B. (2023). Dimensional Stability and Reproducibility of Varying FFF Models for Aligners in Comparison to Plaster Models. Materials, 16(13), 4835. https://doi.org/10.3390/ma16134835