Effectiveness of Porcelain Polishing Methods on the Roughness and Color Stability of CAD–CAM Ceramics after Orthodontic Bracket Debonding

Abstract

1. Introduction

2. Materials and Methods

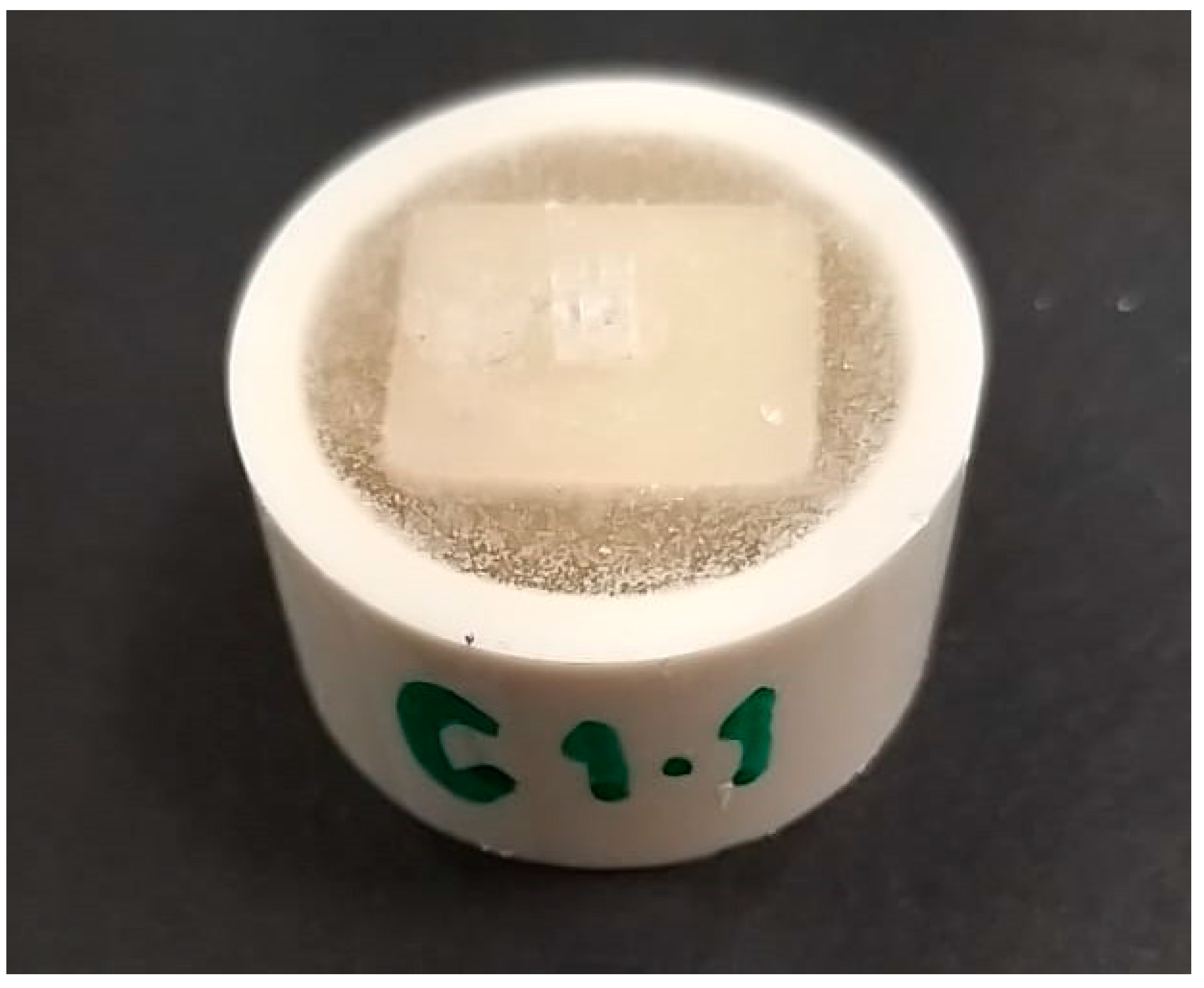

2.1. Ceramic Disc Groups

2.2. Ceramic Bracket Bonding and Debonding

2.3. Ceramic Surface Polishing

2.4. Surface Roughness and Color Measurement

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bach, G.K.G.; Torrealba, Y.; Lagravère, M.O. Orthodontic bonding to porcelain: A systematic review. Angle Orthod. 2013, 84, 555–560. [Google Scholar] [CrossRef]

- Datla, S.R.; Alla, R.K.; Alluri, V.R.; Babu, J.P.; Konakanchi, A. Dental ceramics: Part II-Recent advances in dental ceramics. Am. J. Mater. Eng. Technol. 2015, 3, 19–26. [Google Scholar]

- Baldissara, P.; Llukacej, A.; Ciocca, L.; Valandro, F.L.; Scotti, R. Translucency of zirconia copings made with different CAD/CAM systems. J. Prosthet. Dent. 2010, 104, 6–12. [Google Scholar] [CrossRef]

- VITA-Zahnfabrik. VITA SUPRINITY® Technical|Scientific Documentation, VITA SUPRINITY® PC-Glass Ceramic. Revolutionized. Available online: vita-zahnfabrik.com (accessed on 7 February 2023).

- Swain, M.; Coldea, A.; Bilkhair, A.; Guess, P. Interpenetrating network ceramic-resin composite dental restorative materials. Dent. Mater. 2015, 32, 34–42. [Google Scholar] [CrossRef] [PubMed]

- Mao, L.; Kaizer, M.R.; Zhao, M.; Guo, B.; Song, Y.F.; Zhang, Y. Graded ultra-translucent zirconia (5Y-PSZ) for strength and function-alities. J. Dental Res. 2018, 97, 1222–1228. [Google Scholar] [CrossRef] [PubMed]

- Arhun, N.; Arman, A. Effects of Orthodontic Mechanics on Tooth Enamel: A Review. Semin. Orthod. 2007, 13, 281–291. [Google Scholar] [CrossRef]

- Tholt, B.; Miranda-Júnior, W.G.; Prioli, R.; Thompson, J.; Oda, M.; Beatriz Tholt, B.; Tholta, W.G.; Miranda-Júniorb, R.; Priolic, J.T.; Odae, M. Surface Roughness in Ceramics with Different Finishing Techniques Using Atomic Force Microscope and Profilometer. Oper. Dent. 2006, 31, 442–449. [Google Scholar] [CrossRef]

- Tuncdemir, A.R.; Dilber, E.; Kara, H.B.; Ozturk, A.N. The Effects of Porcelain Polishing Techniques on the Color and Surface Texture of Different Porcelain Systems. Mater. Sci. Appl. 2012, 3, 294–300. [Google Scholar] [CrossRef]

- Paolone, G.; Mandurino, M.; Baldani, S.; Paolone, M.G.; Goracci, C.; Scolavino, S.; Gherlone, E.; Cantatore, G.; Gastaldi, G. Quantitative Volumetric Enamel Loss after Orthodontic Debracketing/Debonding and Clean-Up Procedures: A Systematic Review. Appl. Sci. 2023, 13, 5369. [Google Scholar] [CrossRef]

- Paolone, M.G.; Kaitsas, R.; Paolone, G.; Kaitsas, V. Lingual orthodontics and forced eruption: A means for osseous and tissue regeneration. Prog. Orthodont. 2008, 9, 46–57. [Google Scholar]

- Junior, O.O.; Buso, L.; Fujiy, F.H.; Lombardo, G.H.L.; Campos, F.; Sarmento, H.R.; Souza, R. Influence of polishing procedures on the surface roughness of dental ceramics made by different techniques. Gen. Dent. 2013, 61, e4–e8. [Google Scholar]

- Kaizer, M.R.; de Oliveira-Ogliari, A.; Cenci, M.S.; Opdam, N.J.; Moraes, R.R. Do nanofill or submicron composites show improved smoothness and gloss? A systematic review of in vitro studies. Dent. Mater. 2014, 30, e41–e78. [Google Scholar] [CrossRef]

- Ferracane, J.L.; Broome, J.C.; Hilton, T.J. A Contemporary Approach. Fundamentals of Operative Dentistry; Quintessence Publishing Co., Inc.: Hanover Park, IL, USA, 2013. [Google Scholar]

- Chu, F.C.; Frankel, N.; Smales, R.J. Surface roughness and flexural strength of self-glazed, polished, and reglazed In-Ceram/Vitadur Alpha porcelain laminates. Int. J. Prosthodont. 2001, 13, 66–71. [Google Scholar]

- Winchester, L. Direct Orthodontic Bonding to Porcelain: An In Vitro Study. Br. J. Orthod. 1991, 18, 299–308. [Google Scholar] [CrossRef]

- Rashid, H. Evaluation of the surface roughness of a standard abraded dental porcelain following different polishing techniques. J. Dent. Sci. 2012, 7, 184–189. [Google Scholar] [CrossRef]

- Yamockul, S.; Thamrongananskul, N.; Poolthong, S. Comparison of the surface roughness of feldspathic porcelain polished with a novel alumina-zirconia paste or diamond paste. Dent. Mater. J. 2016, 35, 379–385. [Google Scholar] [CrossRef]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.-G. Statistical power analyses using G*Power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef]

- Paul, S.; Peter, A.; Pietrobon, N.; Hämmerle, C.H.F. Visual and spectrophotometric shade analysis of human teeth. J. Dent. Res. 2002, 81, 578–582. [Google Scholar] [CrossRef]

- Zaher, A.R.; Abdalla, E.M.; Motie, M.A.A.; Rehman, N.A.; Kassem, H.; E Athanasiou, A. Enamel colour changes after debonding using various bonding systems. J. Orthod. 2012, 39, 82–88. [Google Scholar] [CrossRef]

- Vichi, A.; Louca, C.; Corciolani, G.; Ferrari, M. Color related to ceramic and zirconia restorations: A review. Dent. Mater. 2011, 27, 97–108. [Google Scholar] [CrossRef]

- Bollenl, C.M.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef] [PubMed]

- Vichi, A.; Fonzar, R.F.; Goracci, C.; Carrabba, M.; Ferrari, M. Effect of Finishing and Polishing on Roughness and Gloss of Lithium Disilicate and Lithium Silicate Zirconia Reinforced Glass Ceramic for CAD/CAM Systems. Oper. Dent. 2018, 43, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Jones, C.S.; Billington, R.W.; Pearson, G.J. The in vivo perception of roughness of restorations. Br. Dent. J. 2004, 196, 42–45. [Google Scholar] [CrossRef] [PubMed]

- Herion, D.T.; Ferracane, J.L.; Covell, D.A., Jr. Porcelain surface alterations and refinishing after use of two orthodontic bonding methods. Angle Orthod. 2010, 80, 167–174. [Google Scholar] [CrossRef]

- Özden, A.N.; Akaltan, F.; Can, G. Effect of surface treatments of porcelain on the shear bond strength of applied dual-cured cement. J. Prosthet. Dent. 1994, 72, 85–88. [Google Scholar] [CrossRef]

- Mohebi, S.; Shafiee, H.-A.; Ameli, N. Evaluation of enamel surface roughness after orthodontic bracket debonding with atomic force microscopy. Am. J. Orthod. Dentofac. Orthop. 2017, 151, 521–527. [Google Scholar] [CrossRef]

- Sasany, R.; Kunt, G.E.; Koca, M.F. Influence different polishing systems on roughness and colour stability of chairside CAD/CAM blocks with laminate veneer thickness. J. Appl. Biomater. Funct. Mater. 2022, 20. [Google Scholar] [CrossRef]

- Bourke, B.M.; Rock, W. Factors Affecting the Shear Bond Strength of Orthodontic Brackets to Porcelain. Br. J. Orthod. 1999, 26, 285–290. [Google Scholar] [CrossRef]

- Sarac, D.; Sarac, Y.S.; Yuzbasioglu, E.; Bal, S. The effects of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J. Prosthet. Dent. 2006, 96, 122–128. [Google Scholar] [CrossRef]

- Steiner, R.; Beier, U.S.; Heiss-Kisielewsky, I.; Engelmeier, R.; Dumfahrt, H.; Dhima, M. Adjusting dental ceramics: An in vitro evaluation of the ability of various ceramic polishing kits to mimic glazed dental ceramic surface. J. Prosthet. Dent. 2015, 113, 616–622. [Google Scholar] [CrossRef]

- Flury, S.; Lussi, A.; Zimmerli, B.; Flury, A.L.S.; Peutzfeldt, A. Performance of Different Polishing Techniques for Direct CAD/CAM Ceramic Restorations. Oper. Dent. 2010, 35, 470–481. [Google Scholar] [CrossRef] [PubMed]

- Karan, S.; Toroglu, M.S. Porcelain Refinishing with Two Different Polishing Systems after Orthodontic Debonding. Angle Orthod. 2008, 78, 947–953. [Google Scholar] [CrossRef] [PubMed]

- Anusavice, K.J.; Phillips, R.W. (Eds.) Phillip’s Science of Dental Materials, 11th ed.; Elsevier: St. Louis, MO, USA, 2003; pp. 660–667. [Google Scholar]

- Osorio, R.; Toledano, M.; García-Godoy, F. Enamel surface morphology after bracket debonding. ASDC J. Dent. Child. 1998, 65, 313–317. [Google Scholar] [PubMed]

- Martinez-Gomis, J.; Bizar, J.; Anglada, J.; Samsó, J.; Peraire, M. Comparative evaluation of four finishing systems on one ceramic surface. Int. J. Prosthodont. 2003, 16, 74–77. [Google Scholar] [PubMed]

- Kou, W.; Molin, M.; Sjogren, G. Surface roughness of five different dental ceramic core materials after grinding and polishing. J. Oral Rehabil. 2006, 33, 117–124. [Google Scholar] [CrossRef]

- Oz, A.Z.; Oz, A.A.; Ural, C.; Kaleli, N.; Duran, İ. Effectiveness of surface polishing after debonding of metal brackets from different CAD-CAM materials. J. Orofac. Orthoped./Fortschritte Kieferorthopädie 2023, 1–8. [Google Scholar] [CrossRef]

- Siddanna, G.D.; Dds, A.J.V.; Fierro, P.H.; Neiva, G.F.; Dds, D.J.F. Surface Evaluation of Resilient CAD/CAM ceramics after Contouring and Polishing. J. Esthet. Restor. Dent. 2021, 33, 750–763. [Google Scholar] [CrossRef]

- Ryba, T.M.; Dunn, W.J.; Murchison, D.F. Surface roughness of various packable composites. Oper. Dent. 2002, 27, 243–247. [Google Scholar]

- Shibasaki, N.; Cavalli, V.; Oliveira, M.C.; Barbosa, J.P.; Gomes Boriollo, M.F.; Marcondes Martins, L.R. Influence of Surface Treatment on the Physical Properties and Biofilm Formation of Zirconia-Reinforced Lithium Silicate Ceramics: In Vitro Trial. Int. J. Prosthodont. 2021. [Google Scholar] [CrossRef]

- Matzinger, M.; Hahnel, S.; Preis, V.; Rosentritt, M. Polishing effects and wear performance of chairside CAD/CAM materials. Clin. Oral Investig. 2018, 23, 725–737. [Google Scholar] [CrossRef]

- Lee, J.Y.; Jang, G.W.; Park, I.I.; Heo, Y.R.; Son, M.K. The effects of surface grinding and polishing on the phase transformation and flexural strength of zirconia. J. Adv. Prosthodont. 2019, 11, 1–6. [Google Scholar] [CrossRef]

- Sampaio-Fernandes, M.; Almeida, P.J.; Portugal, J.; Martins, R.C.; Figueiral, M.H. Effectiveness of ceramics chair-side polishing—2D and 3D roughness evaluation. Rev. Port. Estomatol. Med. Dentária Cir. Maxilofac. 2022, 63, 126–133. [Google Scholar] [CrossRef]

- Jum’ah, A.A.; Brunton, P.A.; Li, K.C.; Waddell, J.N. Simulated clinical adjustment and intra-oral polishing of two translucent, monolithic zirconia dental ceramics: An in vitro investigation of surface roughness. J. Dent. 2020, 101, 103447. [Google Scholar] [CrossRef]

- Ruyter, I.; Nilner, K.; Möller, B. Color stability of dental composite resin materials for crown and bridge veneers. Dent. Mater. 1987, 3, 246–251. [Google Scholar] [CrossRef]

- Johnston, W.; Kao, E. Assessment of Appearance Match by Visual Observation and Clinical Colorimetry. J. Dent. Res. 1989, 68, 819–822. [Google Scholar] [CrossRef]

- Wee, A.G.; Monaghan, P.; Johnston, W.M. Variation in color between intended matched shade and fabricated shade of dental porcelain. J. Prosthet. Dent. 2002, 87, 657–666. [Google Scholar] [CrossRef]

- Sarıkaya, I.; Hayran, Y. Effects of polishing on color stability and surface roughness of CAD-CAM ceramics. Meandros Med. Dent. J. 2018, 19, 153. [Google Scholar] [CrossRef]

- Seghi, R.; Hewlett, E.; Kim, J. Visual and Instrumental Colorimetric Assessments of Small Color Differences on Translucent Dental Porcelain. J. Dent. Res. 1989, 68, 1760–1764. [Google Scholar] [CrossRef]

- Öngül, D.; Şermet, B.; Balkaya, M.C. Visual and instrumental evaluation of color match ability of 2 shade guides on a ceramic system. J. Prosthet. Dent. 2012, 108, 9–14. [Google Scholar] [CrossRef]

- Khashayar, G.; Dozic, A.; Kleverlaan, C.; Feilzer, A. Data Comparison between Two Dental Spectrophotometers. Oper. Dent. 2012, 37, 12–20. [Google Scholar] [CrossRef]

- Moradi, M.; Moradinezhad, M.; Shamohammadi, M.; Hormozi, E.; Ghorani, A. Porcelain color alteration after orthodontic bonding using three different surface preparation methods. Dent. Res. J. 2018, 15, 180–184. [Google Scholar] [CrossRef]

- Ameli, N.; Talaei, R.; Saeedi, S.; Ghorbani, R.; Askari, B.A. Effect of two polishing systems on color and surface roughness of feldspathic porcelain following orthodontic bracket debonding and composite resin removal. APOS Trends Orthod. 2019, 9, 105–110. [Google Scholar] [CrossRef]

| Material | Composition | Manufacturer | Lot No. |

|---|---|---|---|

| Lithium disilicate (e.max®CAD) | SiO2, Li2O, K2O, P2O3, ZrO5, ZnO, Al2O3, MgO | Vita Zahnfabrik, Bad Säckingen, Germany | X15367 |

| Hybrid polymer-infiltrated ceramic (Enamic) | UDMA, TEGDMA, SiO2, Al2O3, Na2O, K2O, B2O3, Zr2O, CaO | Vita Zahnfabrik, Bad Säckingen, Germany | 59882 |

| Zirconia-reinforced glass ceramic (Suprinity) | SiO2, Li2O, K2O, P2O, Al2O3, ZrO2, CeO2, La2O | Vita Zahnfabrik, Bad Säckingen, Germany | 58081 |

| 5YTZP zirconia (Cercon xt) | DeguDent GmbH, Hanau-wolfgang, Germany | Dentsply Sirona | 18043031 |

| Group | Test Results | Before Bonding | Debonded | Polished | ||

|---|---|---|---|---|---|---|

| DT | KK | HDP | ||||

| LD-CAD | Ra | 0.185 ± 0.02 | 1.445 ± 0.20 | 0.196 ± 0.01 | 0.368 ± 0.03 | 0.379 ± 0.02 |

| Rq | 0.497 ± 0.05 | 2.136 ± 0.27 | 0.540 ± 0.04 | 0.773 ± 0.06 | 0.925 ± 0.04 | |

| ZLS | Ra | 0.306 ± 0.02 | 1.278 ± 0.38 | 0.457 ± 0.05 | 0.590 ± 0.04 | 0.628 ± 0.05 |

| Rq | 1.390 ± 0.46 | 2.560 ± 0.56 | 1.200 ± 0.12 | 1.451 ± 0.15 | 1.679 ± 0.22 | |

| PIC | Ra | 0.575 ± 0.07 | 4.057 ± 0.82 | 1.772 ± 0.14 | 2.192 ± 0.15 | 2.380 ± 0.11 |

| Rq | 2.627 ± 0.20 | 5.800 ± 0.77 | 2.680 ± 0.16 | 3.268 ± 0.30 | 3.248 ± 0.26 | |

| 5YZP | Ra | 0.234 ± 0.03 | 0.661 ± 0.09 | 0.300 ± 0.04 | 0.305 ± 0.03 | 0.385 ± 0.71 |

| Rq | 0.493 ± 0.02 | 1.014 ± 0.14 | 0.745 ± 0.05 | 0.729 ± 0.04 | 0.903 ± 0.05 | |

| Group | Debonded | DT | KK | HDP |

|---|---|---|---|---|

| LD-CAD | 4.36 ± 1.43 | 2.12 ± 1.15 | 1.59 ± 1.09 | 2.54 ± 1.40 |

| ZLS | 3.84 ± 1.70 | 1.73 ± 0.26 | 2.21 ± 0.56 | 2.47 ± 0.75 |

| PIC | 7.85 ± 1.31 | 1.45 ± 0.41 | 0.91 ± 0.30 | 1.47 ± 0.36 |

| 5YZP | 3.52 ± 1.28 | 0.87 ± 0.20 | 1.90 ± 0.65 | 1.82 ± 0.42 |

| Test | Resource | SS | Df | MS | F | p |

|---|---|---|---|---|---|---|

| Ra | Porcelain | 108.130 | 3 | 36.043 | 750.281 | 0.000 * |

| Polishing | 51.968 | 4 | 12.992 | 270.443 | 0.000 * | |

| Porcelain * Polishing | 29.043 | 12 | 2.420 | 50.380 | ||

| ΔE | Porcelain | 20.408 | 3 | 6.803 | 5.480 | 0.001 * |

| Polishing | 344.760 | 3 | 114.920 | 92.585 | 0.000 * | |

| Porcelain * Polishing | 121.827 | 9 | 13.536 | 10.906 | 0.000 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haralur, S.B.; Shiban, A.S.; Alqahtani, N.M. Effectiveness of Porcelain Polishing Methods on the Roughness and Color Stability of CAD–CAM Ceramics after Orthodontic Bracket Debonding. Materials 2023, 16, 4951. https://doi.org/10.3390/ma16144951

Haralur SB, Shiban AS, Alqahtani NM. Effectiveness of Porcelain Polishing Methods on the Roughness and Color Stability of CAD–CAM Ceramics after Orthodontic Bracket Debonding. Materials. 2023; 16(14):4951. https://doi.org/10.3390/ma16144951

Chicago/Turabian StyleHaralur, Satheesh B., Abdullah Saeed Shiban, and Nasser Mohammed Alqahtani. 2023. "Effectiveness of Porcelain Polishing Methods on the Roughness and Color Stability of CAD–CAM Ceramics after Orthodontic Bracket Debonding" Materials 16, no. 14: 4951. https://doi.org/10.3390/ma16144951

APA StyleHaralur, S. B., Shiban, A. S., & Alqahtani, N. M. (2023). Effectiveness of Porcelain Polishing Methods on the Roughness and Color Stability of CAD–CAM Ceramics after Orthodontic Bracket Debonding. Materials, 16(14), 4951. https://doi.org/10.3390/ma16144951