The Synergistic Lubrication Effects of h-BN and g-C3N4 Nanoparticles as Oil-Based Additives for Steel/Steel Contact

Abstract

:1. Introduction

2. Materials and Experiment

2.1. Materials

2.2. Preparation of g-C3N4

2.3. Characterization

2.4. Tests and Analysis

3. Results and Discussion

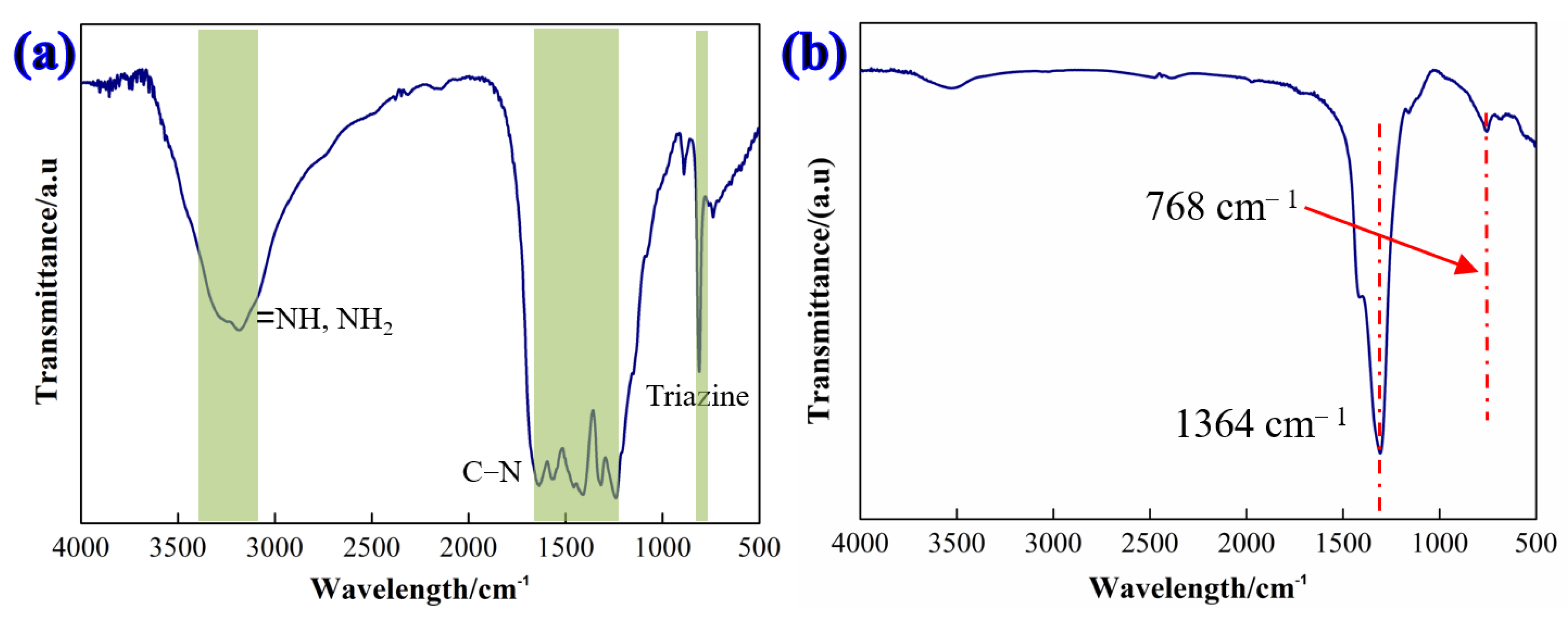

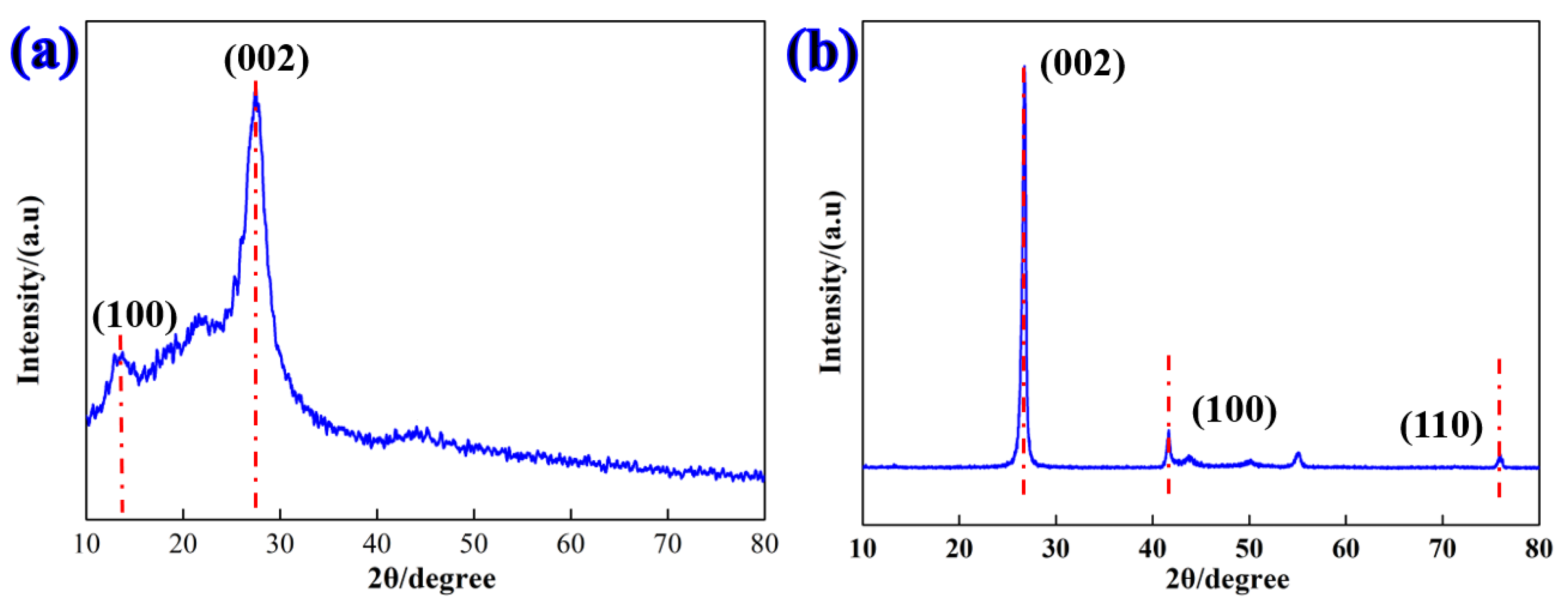

3.1. Microstructure of h-BN and g-C3N4 Particles

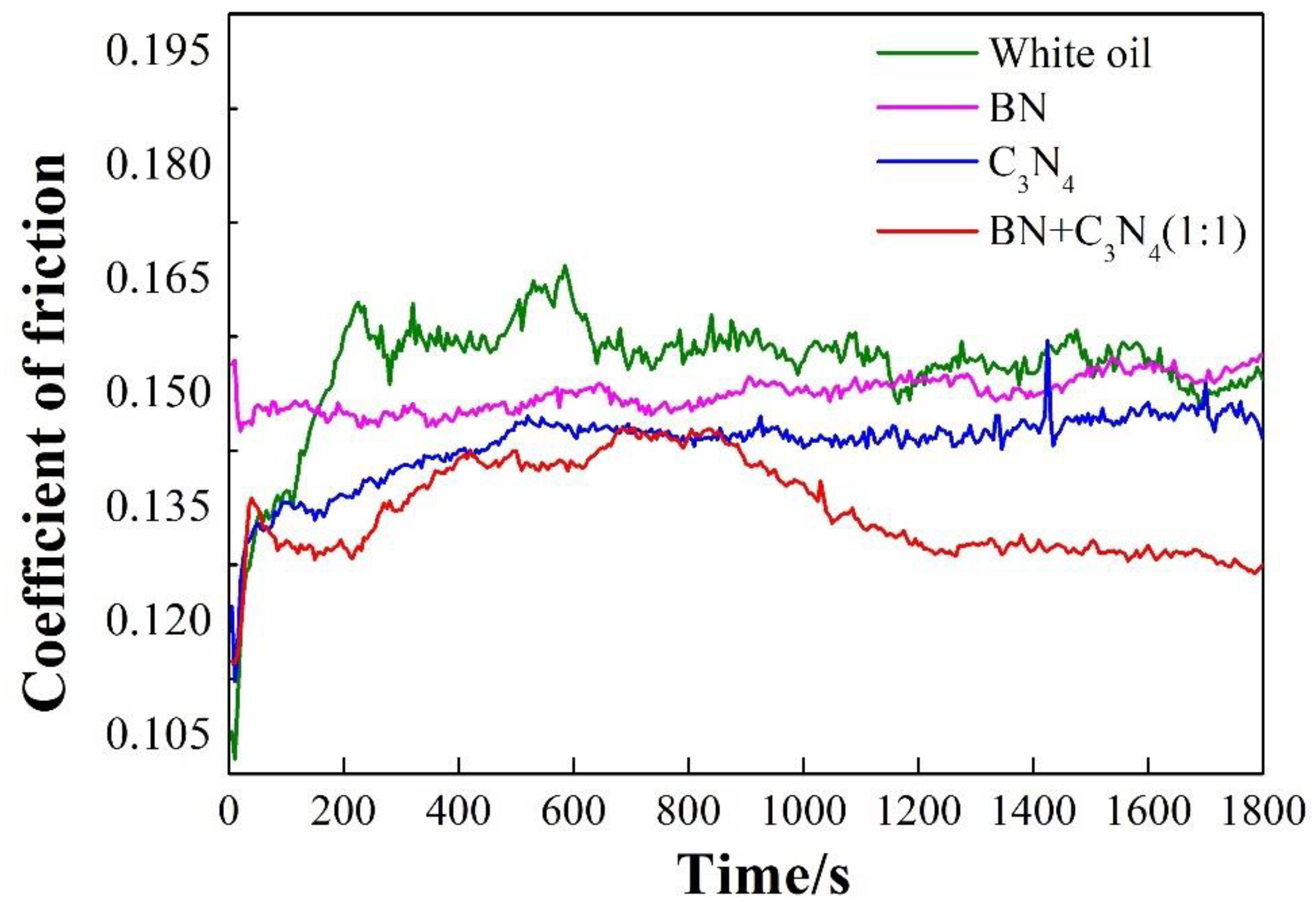

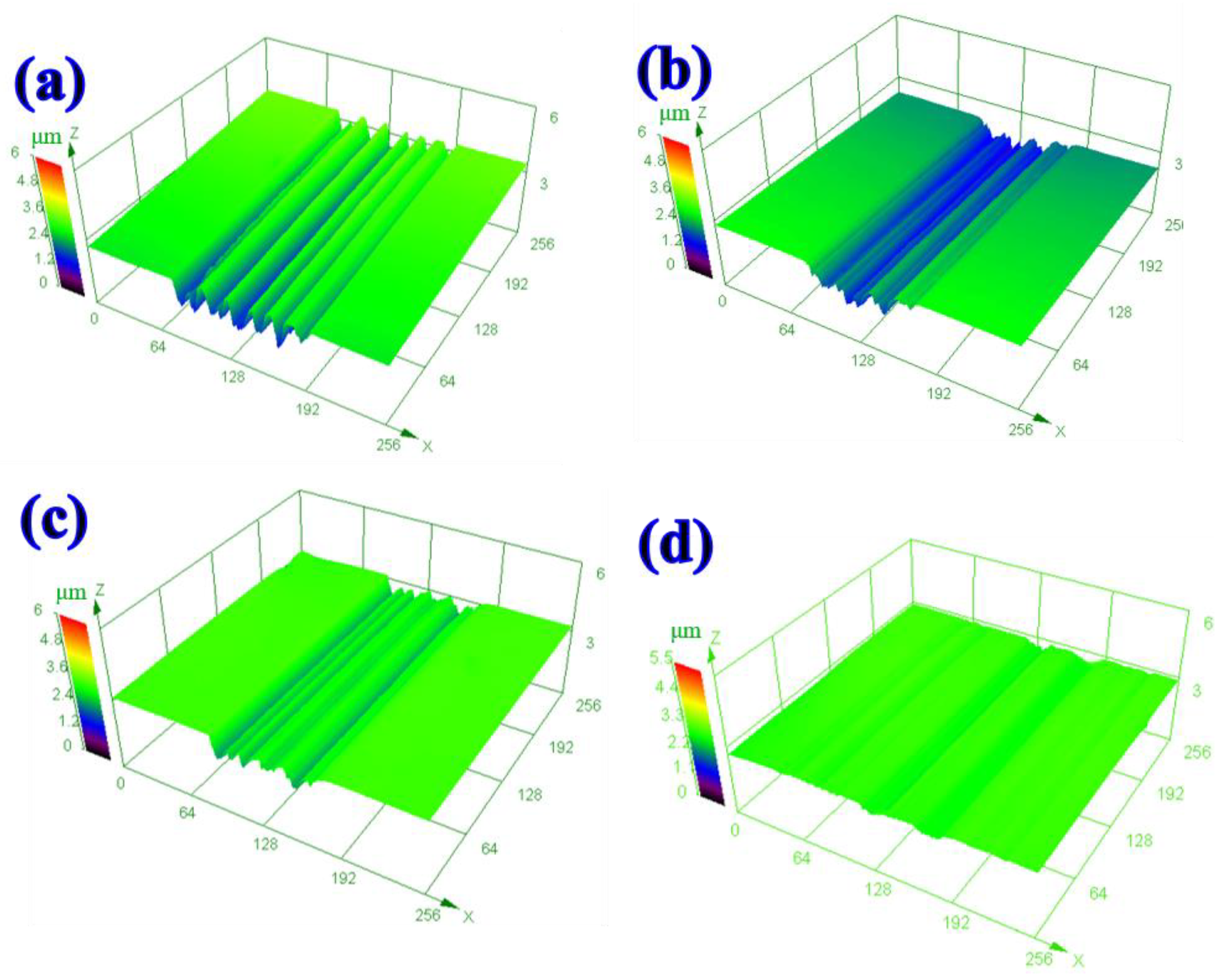

3.2. Tribological Properties

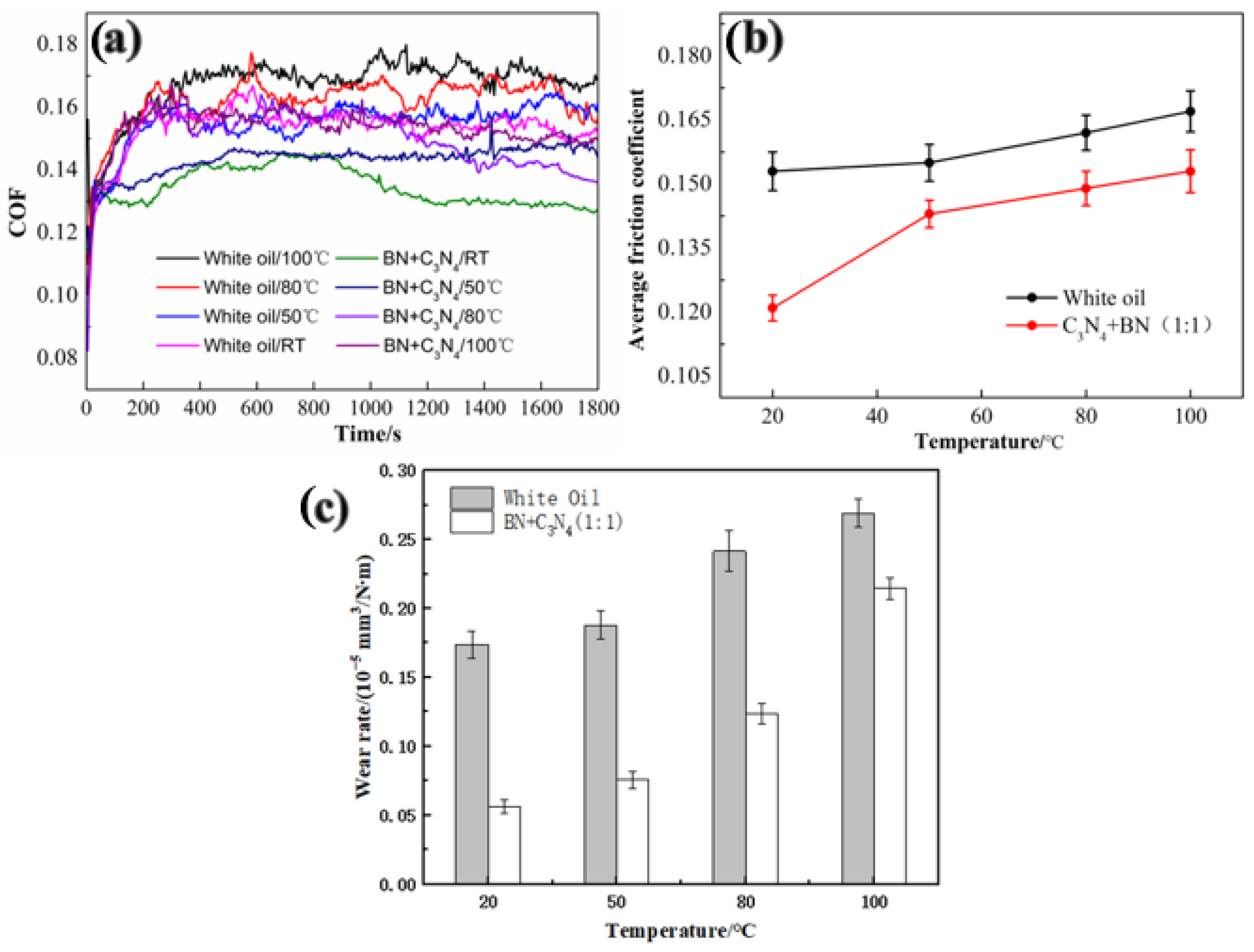

3.3. Effect of Temperature on the Tribological Properties of Oil Lubricants

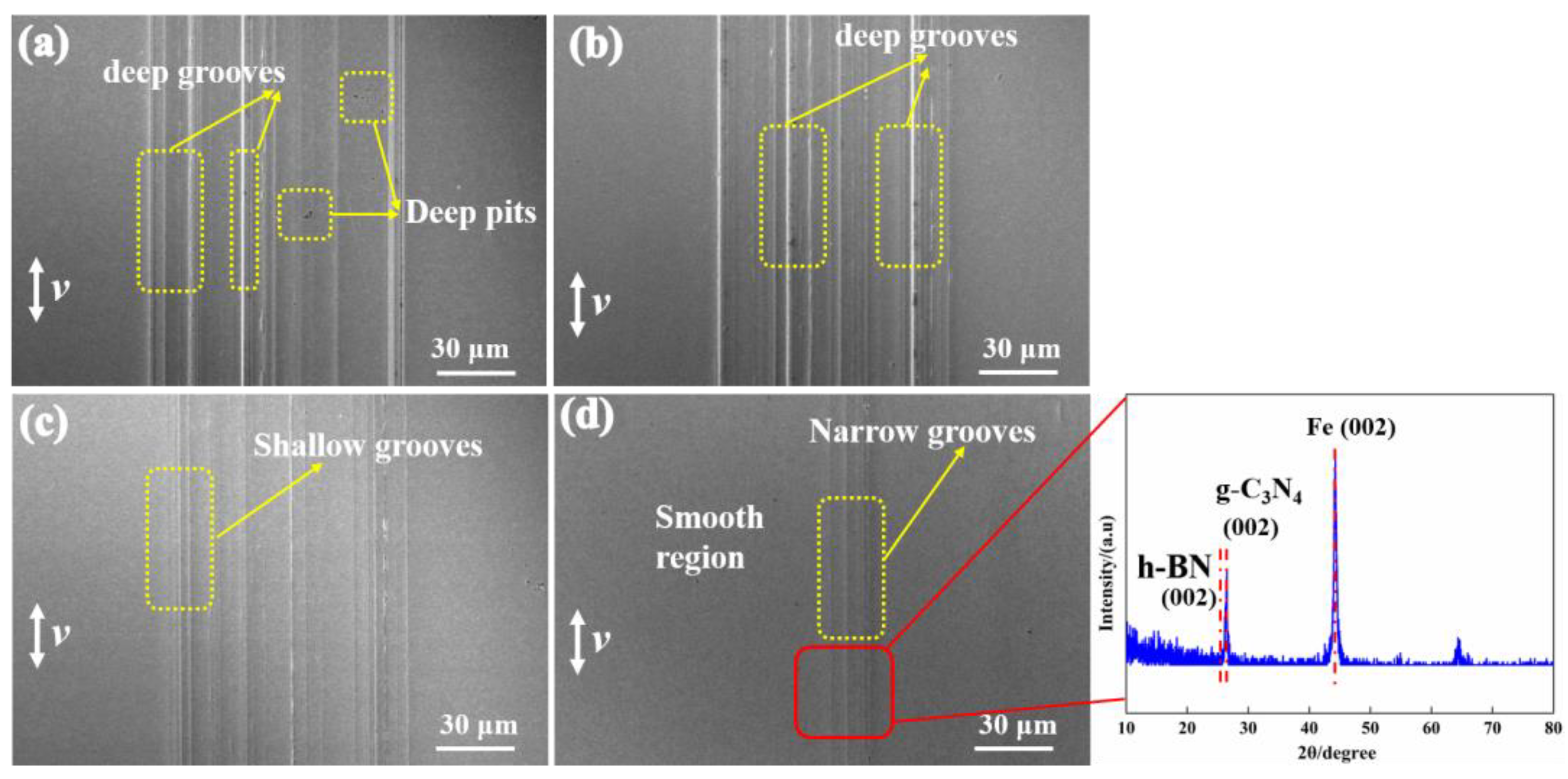

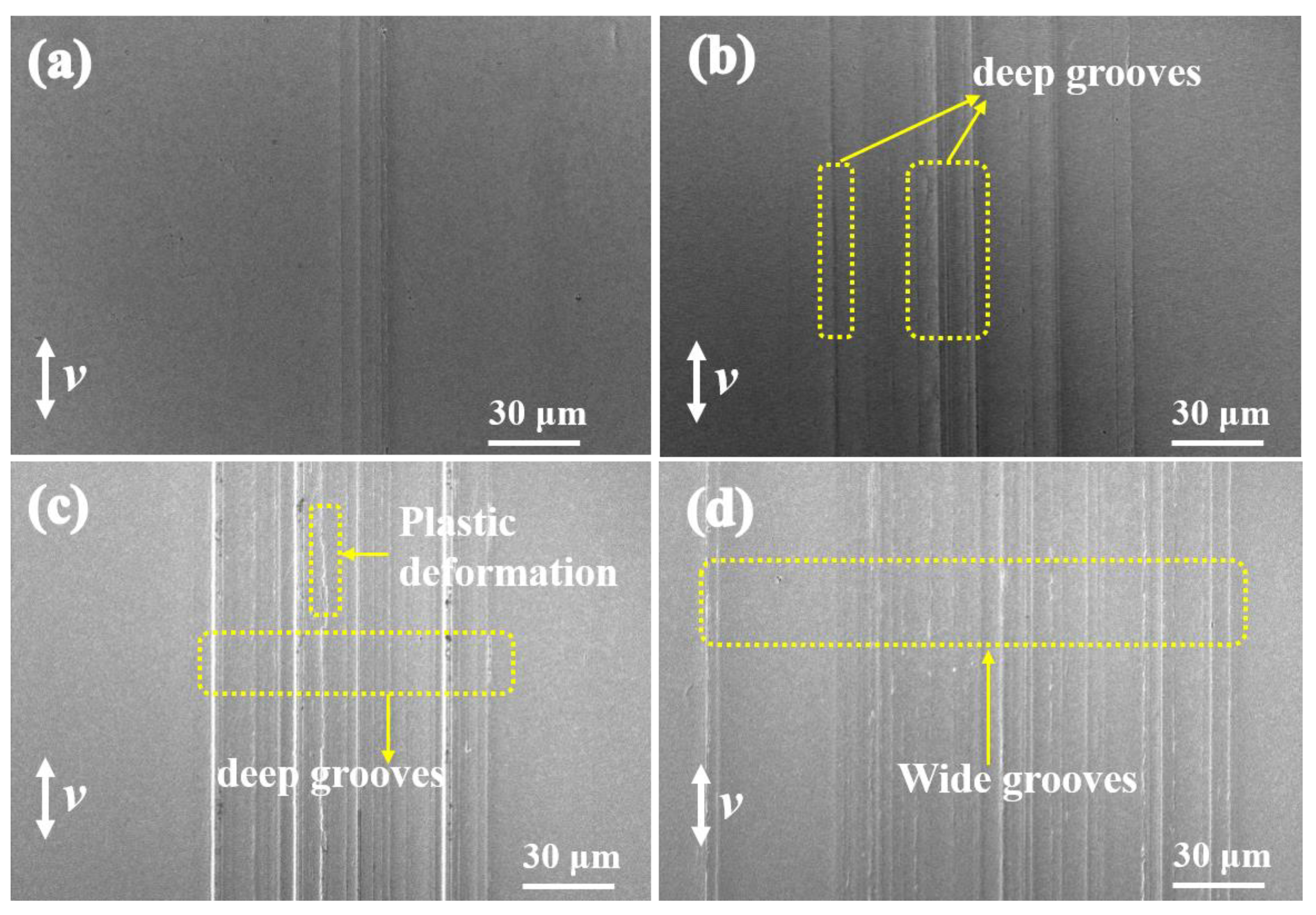

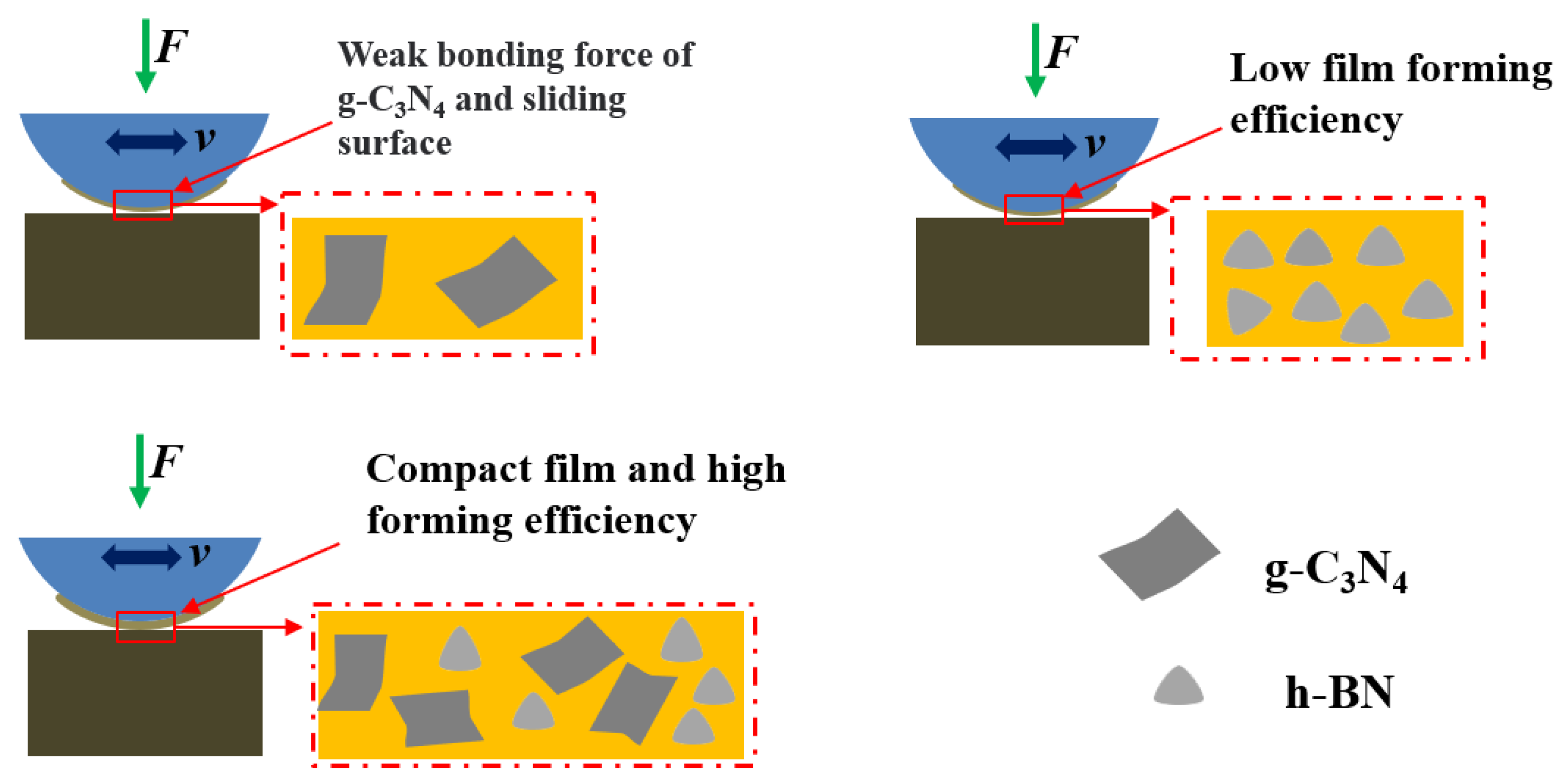

3.4. Tribological Mechanism

4. Conclusions

- (a)

- g-C3N4 nanoparticles were successfully prepared, and the nanosheets possess a high specific surface area; the diameter of the g-C3N4 nanoparticles was microscale.

- (b)

- After the addition of the solid additives, both the friction coefficient and wear loss of the disk decrease with the addition of various solid additives compared to the base oil. Additionally, the lubricant supplemented with g-C3N4 exhibits better tribological properties than that supplemented with h-BN. Furthermore, the oil-based lubricant supplemented with both g-C3N4 and h-BN (1:1 by weight) showed the lowest friction coefficient of 0.13, and the corresponding disk achieved the lowest wear rate of 0.06 × 10−5 mm3/(N·m). This can be attributed to the increased formation efficiency of the solid tribo-film due to the synergistic effect of g-C3N4 and h-BN.

- (c)

- However, increasing the temperature resulted in an increase in both wear and the friction coefficient for both the base oil the oil lubricant supplemented with g-C3N4 and h-BN. The loss of mechanical properties suffered by the sliding counterpart and reduction in oil film bearing capacity with increasing temperature are believed to be the major contributors for this.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, N.; Sinha, S.K. Tribological and mechanical analysis of hybrid epoxy based polymer composites with different in situ liquid lubricants (silicone oil, PAO and SN150 base oil). WEAR 2022, 504–505, 204404. [Google Scholar] [CrossRef]

- Emmanual, L.; Loganathan, M.; Karthikeyan, T. Machining studies on Monel K–500 using TiAlN coated tungsten carbide inserts under Ag nanoparticles incorporated modified pongamia pinnata oil lubrication. Mater. Res. Express 2022, 9, 076512. [Google Scholar] [CrossRef]

- Adachi, N.; Matsuo, Y.; Todaka, Y.; Fujimoto, M.; Hino, M.; Mitsuhara, M.; Oba, Y.; Shiihara, Y.; Umeno, Y.; Nishida, M. Effect of grain boundary on the friction coefficient of pure Fe under the oil lubrication. Tribol. Int. 2021, 155, 106781. [Google Scholar] [CrossRef]

- Thirumalai, R.; Senthilkumaar, J.S.; Selvarani, P.; Ramesh, S. Machining characteristics of Inconel 718 under several cutting conditions based on Taguchi method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 1889–1897. [Google Scholar] [CrossRef]

- Conradi, M.; Podgornik, B.; Kocijan, A.; Remškar, M.; Klobčar, D. Water versus Oil Lubrication of Laser-Textured Ti6Al4V Alloy upon Addition of MoS2 Nanotubes for Green Tribology. Materials 2022, 15, 2974. [Google Scholar] [CrossRef]

- Raina, A.; Irfan Ul Haq, M.; Anand, A.; Mohan, S.; Kumar, R.; Jayalakshmi, S.; Arvind Singh, R. Nanodiamond Particles as Secondary Additive for Polyalphaolefin Oil Lubrication of Steel-Aluminium Contact. Nanomaterials 2021, 11, 1438. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological performance of nanoparticles as lubricating oil additives. J. Nanopart. Res. 2016, 18, 223–231. [Google Scholar] [CrossRef]

- Trucco, D.; Vannozzi, L.; Teblum, E.; Telkhozhayeva, M.; Nessim, G.D.; Affatato, S. Graphene Oxide-Doped Gellan Gum–PEGDA Bilayered Hydrogel Mimicking the Mechanical and Lubrication Properties of Articular Cartilage. Adv. Healthc. Mater. 2021, 10, 873–881. [Google Scholar] [CrossRef]

- Kogovšek, J.; Kalin, M. Lubrication performance of graphene-containing oil on steel and DLC-coated surfaces. Tribol. Int. 2019, 138, 59–67. [Google Scholar] [CrossRef]

- Zhong, W.; Chen, S.; Ma, L.; Tong, Z. Tribological Properties of Carbon Fabric/Epoxy Composites Filled with FGr@MoS2 Hybrids under Dry Sliding Conditions. Materials 2022, 15, 7951. [Google Scholar] [CrossRef]

- Yu, K.; Zou, K.; Lang, H.; Peng, Y. Nanofriction characteristics of h-BN with electric field induced electrostatic interaction. Friction 2020, 9, 1–12. [Google Scholar] [CrossRef]

- Nasser, K.I.; Liñeira del Río, J.M.; Mariño, F.; López, E.R.; Fernández, J. Double hybrid lubricant additives consisting of a phosphonium ionic liquid and graphene nanoplatelets/hexagonal boron nitride nanoparticles. Tribol. Int. 2021, 163, 189–199. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K.R.S. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef]

- Meng, F.; Han, H.; Gao, X.; Yang, C.; Zheng, Z. Experiment study on tribological performances of GNPs/MoS2 coating. Tribol. Int. 2018, 118, 400–407. [Google Scholar] [CrossRef]

- Bobby, S.; Samad, M.A. Enhancement of tribological performance of epoxy bulk composites and composite coatings using micro/nano fillers: A review. Polym. Adv. Technol. 2017, 28, 633–644. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Jayashree, P.; Matějka, V.; Foniok, K.; Straffelini, G. Comparative Studies on the Dry Sliding Behavior of a Low-Metallic Friction Material with the Addition of Graphite and Exfoliated g-C3N4. Lubricants 2022, 10, 27. [Google Scholar] [CrossRef]

- Kumar, A.; Thakre, D.G.; Arya, K.P.; Jain, A.K. 2D Structured Nano-Sheets of Octadecylamine Grafted Graphitic-Carbon Nitride (g-C3N4) as Lubricant Additives. Macromol. Symp. 2017, 376, 9–17. [Google Scholar] [CrossRef]

- Richa, R.; Rose, A.C.; Thomas, A.; Korah, B.K. Recent Advances in Graphitic Carbon Nitrides (g-C3N4) as Photoluminescence Sensing Probe: A Review. ChemistrySelect 2022, 7, e202200876. [Google Scholar]

- Ye, J.; Khare, H.S.; Burris, D.L. Quantitative characterization of solid lubricant transfer film quality. Wear 2014, 316, 133–143. [Google Scholar] [CrossRef]

- Sharma, K.A.; Tiwari, K.A.; Dixit, R.A.; Singh, R.K. Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribol. Int. 2018, 119, 99–111. [Google Scholar] [CrossRef]

- Tucker, Z. The Performance of Translucent Silicon-Oxide Nanoparticle Lubricant Additives. Tribol. Lubr. Technol. 2017, 73, 32–34. [Google Scholar]

- He, G.; Li, Y.; Wu, L.; Wang, Y.; Liu, M.; Yuan, J.; Men, X. Synergy of core-shell Cu@rGO hybrids for significantly improved thermal and tribological properties of polyimide composites. Tribol. Int. 2021, 161, 91–105. [Google Scholar] [CrossRef]

- Li, X.; Chen, B.; Jia, Y.; Li, X.; Yang, J.; Li, C.; Yan, F. Enhanced tribological properties of epoxy-based lubricating coatings using carbon nanotubes-ZnS hybrid. Surf. Coat. Technol. 2018, 344, 154–162. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, L.; Xie, G.; Li, Z.; Chen, H.; Gong, H.; Xu, W.; Guo, D.; Luo, J. A review on tribology of polymer composite coatings. Friction 2021, 9, 429–470. [Google Scholar] [CrossRef]

- Ye, M.; Zhang, G.; Ba, Y.; Wang, T.; Wang, X.; Liu, Z. Microstructure and tribological properties of MoS2+Zr composite coatings in high humidity environment. Appl. Surf. Sci. 2016, 367, 140–146. [Google Scholar] [CrossRef]

- Su, F.; Chen, G.; Huang, P. Lubricating performances of graphene oxide and onion-like carbon as water-based lubricant additives for smooth and sand-blasted steel discs. Friction 2020, 8, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos, D.F.; Santiago, A.A.G.; Teodoro, M.D.; Motta, F.V.; Bomio, M.R.D. Investigation of the photocatalytic and optical properties of the SrMoO4/g-C3N4 heterostructure obtained via sonochemical synthesis with temperature control. J. Environ. Manag. 2023, 325, 116396. [Google Scholar] [CrossRef]

- Van, K.N.; Huu, H.T.; Nguyen Thi, V.N.; Le Thi, T.L.; Truong, D.H.; Truong, T.T.; Dao, N.N.; Vo, V.; Tran, D.L.; Vasseghian, Y. Facile construction of S-scheme SnO2/g-C3N4 photocatalyst for improved photoactivity. Chemosphere 2022, 289, 133120. [Google Scholar] [CrossRef]

- Hong, Y.; Shi, J.; Shi, W.; Fang, Z.; Chen, R.; Huang, Y. A facile and scalable route for synthesizing ultrathin carbon nitride nanosheets with efficient solar hydrogen evolution. Carbon 2018, 136, 160–167. [Google Scholar] [CrossRef]

- Kostoglou, N.; Polychronopoulou, K.; Rebholz, C. Thermal and chemical stability of hexagonal boron nitride (h-BN) nanoplatelets. Vacuum 2015, 112, 42–45. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, Q.; Xie, Z.; Tan, C.; Chen, P.; Zeng, Y.; Wang, F.; Liu, H.; Liu, Y.; Liu, G.; et al. Carbon nitride modified hexagonal boron nitride interface as highly efficient blue LED light-driven photocatalyst. Appl. Catal. B Environ. 2018, 238, 410–421. [Google Scholar] [CrossRef]

- Mao, J.; Zhao, J.; Wang, W.; He, Y.; Luo, J. Influence of the micromorphology of reduced graphene oxide sheets on lubrication properties as a lubrication additive. Tribol. Int. 2018, 119, 614–621. [Google Scholar] [CrossRef]

- Decrozant-Triquenaux, J.; Pelcastre, L.; Courbon, C.; Prakash, B.; Hardell, J. High temperature tribological behaviour of PVD coated tool steel and aluminium under dry and lubricated conditions. Friction 2021, 9, 802–821. [Google Scholar] [CrossRef]

- Gong, K.; Wu, X.; Zhao, G.; Wang, X. Nanosized MoS2 deposited on graphene as lubricant additive in polyalkylene glycol for steel/steel contact at elevated temperature. Tribol. Int. 2017, 110, 1–7. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, R.; Song, H.; Jia, X. Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Appl. Surf. Sci. 2018, 428, 630–639. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Liang, H.; Zhao, Z. Layered oil slip model for investigation of film thickness behaviours at high speed conditions. Tribol. Int. 2019, 131, 137–147. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, W.; Dong, J.; Chen, S.; Tong, Z. The Synergistic Lubrication Effects of h-BN and g-C3N4 Nanoparticles as Oil-Based Additives for Steel/Steel Contact. Materials 2023, 16, 4979. https://doi.org/10.3390/ma16144979

Zhong W, Dong J, Chen S, Tong Z. The Synergistic Lubrication Effects of h-BN and g-C3N4 Nanoparticles as Oil-Based Additives for Steel/Steel Contact. Materials. 2023; 16(14):4979. https://doi.org/10.3390/ma16144979

Chicago/Turabian StyleZhong, Wen, Jiazhi Dong, Siqiang Chen, and Zhe Tong. 2023. "The Synergistic Lubrication Effects of h-BN and g-C3N4 Nanoparticles as Oil-Based Additives for Steel/Steel Contact" Materials 16, no. 14: 4979. https://doi.org/10.3390/ma16144979

APA StyleZhong, W., Dong, J., Chen, S., & Tong, Z. (2023). The Synergistic Lubrication Effects of h-BN and g-C3N4 Nanoparticles as Oil-Based Additives for Steel/Steel Contact. Materials, 16(14), 4979. https://doi.org/10.3390/ma16144979