Cavitation Erosion Prevention Using Laser Shock Peening: Development of a Predictive Evaluation System

Abstract

:1. Introduction

2. Simulation and Experiment

2.1. LSP Modeling and Experiment

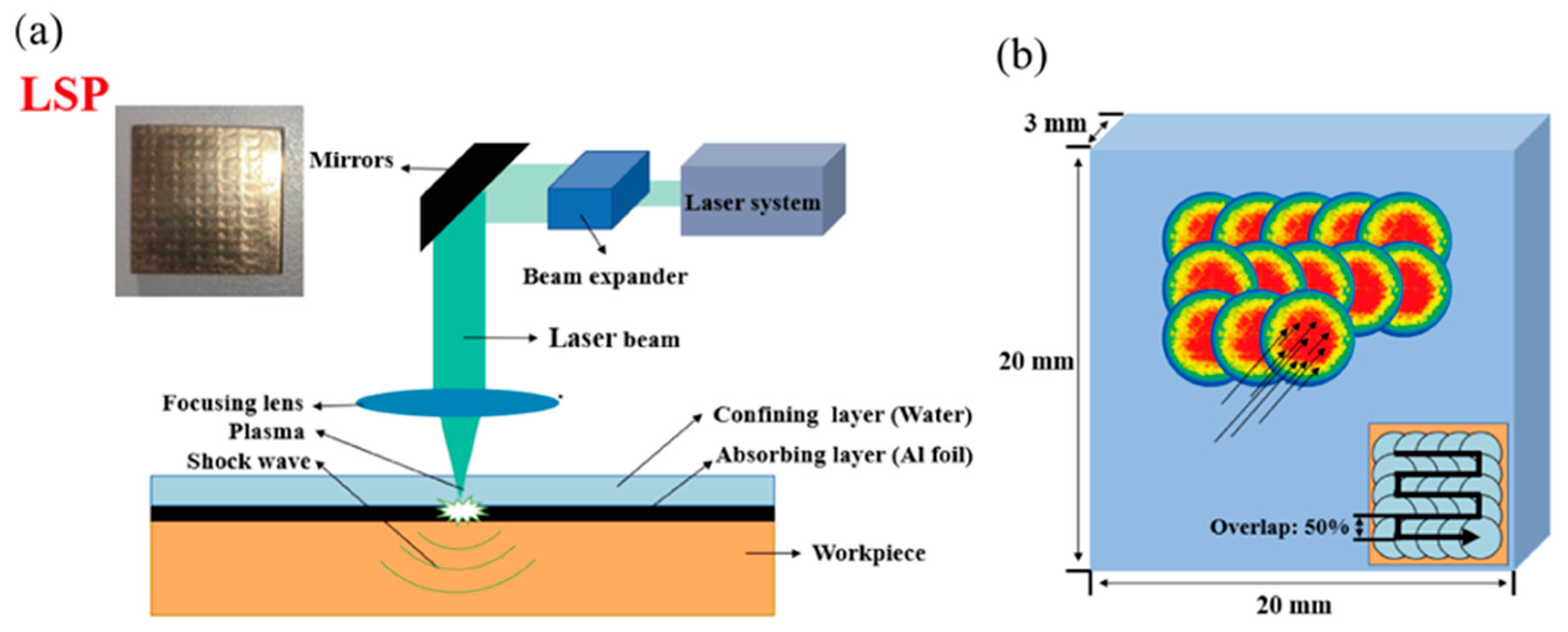

2.1.1. LSP Modeling

2.1.2. LSP Experiment

2.2. CE Modeling and Experiment

2.2.1. CE Modeling

2.2.2. CE Experiment

3. Results and Discussion

3.1. Comparison of LSP Simulation and Experimental Results

3.2. CE Simulation and Experimental Results

3.2.1. CE Simulation Results

3.2.2. CE Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bax, N.; Novaglio, C.; Maxwell, K.H.; Meyers, K.; McCann, J.; Jennings, S.; Frusher, S.; Fulton, E.A.; Nursey-Bray, M.; Fischer, M.; et al. Ocean Resource Use: Building the Coastal Blue Economy. Rev. Fish Biol. Fish. 2022, 32, 189–207. [Google Scholar] [CrossRef] [PubMed]

- Kappenthuler, S.; Seeger, S. Holistic Evaluation of the Suitability of Metal Alloys for Sustainable Marine Construction from a Technical, Economic and Availability Perspective. Ocean Eng. 2021, 219, 108378. [Google Scholar] [CrossRef]

- Dance, A. Ocean Explorer. Nature 2020, 588, 362. [Google Scholar] [CrossRef]

- Park, I.C.; Han, M.S.; Kim, S.J. Cavitation Damage Characteristics of Shot Peened ALBC3 Alloy. J. Nanosci. Nanotechnol. 2019, 19, 1111–1113. [Google Scholar] [CrossRef]

- Luo, Q.; Zhang, Q.; Qin, Z.; Wu, Z.; Shen, B.; Liu, L.; Hu, W. The Synergistic Effect of Cavitation Erosion and Corrosion of Nickel-Aluminum Copper Surface Layer on Nickel-Aluminum Bronze Alloy. J. Alloys Compd. 2018, 747, 861–868. [Google Scholar] [CrossRef]

- Rakhmonov, J.U.; Bahl, S.; Shyam, A.; Dunand, D.C. Cavitation-Resistant Intergranular Precipitates Enhance Creep Performance of θ′-Strengthened Al-Cu Based Alloys. Acta Mater. 2022, 228, 117788. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Phan, T.H.; Park, W.G. Numerical Investigation of Laser-Induced Cavitation Bubble Dynamics near a Rigid Surface Based on Three-Dimensional Fully Compressible Model. Int. J. Heat Mass Transf. 2022, 122853, 191. [Google Scholar] [CrossRef]

- Sreedhar, B.K.; Albert, S.K.; Pandit, A.B. Cavitation Damage: Theory and Measurements—A Review. Wear 2017, 372, 177–196. [Google Scholar] [CrossRef]

- Chen, F.; Du, J.; Zhou, S. Cavitation Erosion Behaviour of Incoloy Alloy 865 in NaCl Solution Using Ultrasonic Vibration. J. Alloys Compd. 2020, 831, 154783. [Google Scholar] [CrossRef]

- Siemek, K.; Eseev, M.K.; Horodek, P.; Kobets, A.G.; Kuziv, I.V. Defects Studies of Nickel Aluminum Bronze Subjected to Cavitation. Appl. Surf. Sci. 2021, 546, 149107. [Google Scholar] [CrossRef]

- Ribu, D.C.; Rajesh, R.; Thirumalaikumarasamy, D.; Kaladgi, A.R.; Saleel, C.A.; Nisar, K.S.; Shaik, S.; Afzal, A. Experimental Investigation of Erosion Corrosion Performance and Slurry Erosion Mechanism of HVOF Sprayed WC-10Co Coatings Using Design of Experiment Approach. J. Mater. Res. Technol. 2022, 18, 293–314. [Google Scholar] [CrossRef]

- Dinu, M.; Wang, K.; Mouele, E.S.M.; Parau, A.C.; Vladescu (Dragomir), A.; Liang, X.; Braic, V.; Petrik, L.F.; Braic, M. Effects of Film Thickness of ALD-Deposited Al2O3, ZrO2 and HfO2 Nano-Layers on the Corrosion Resistance of Ti(N,O)-Coated Stainless Steel. Materials 2023, 16, 2007. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Voisin, T.; Zhang, Y.; Forien, J.B.; Spadaccini, C.M.; McDowell, D.L.; Zhu, T.; Wang, Y.M. Microscale Residual Stresses in Additively Manufactured Stainless Steel. Nat. Commun. 2019, 10, 4338. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Huang, Y.; Zhang, W.; Ostendorf, A. Investigation of Multiple Laser Shock Peening on the Mechanical Property and Corrosion Resistance of Shipbuilding 5083Al Alloy under a Simulated Seawater Environment: Publisher’s Note. Appl. Opt. 2018, 57, 7352. [Google Scholar] [CrossRef] [PubMed]

- Soyama, H.; Kuji, C. Improving Effects of Cavitation Peening, using a Pulsed Laser or a Cavitating Jet, and Shot Peening on the Fatigue Properties of Additively Manufactured Titanium Alloy Ti6Al4V. Surf. Coat. Technol. 2022, 451, 129047. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Unal, O.; Jam, A.; Shao, S.; Guagliano, M.; Shamsaei, N. Superior Effects of Hybrid Laser Shock Peening and Ultrasonic Nanocrystalline Surface Modification on Fatigue Behavior of Additive Manufactured AlSi10Mg. Surf. Coat. Technol. 2023, 463, 129512. [Google Scholar] [CrossRef]

- Feng, A.; Wei, Y.; Liu, B.; Chen, C.; Pan, X.; Xue, J. Microstructure and Mechanical Properties of Composite Strengthened High-Chromium Cast Iron by Laser Quenching and Laser Shock Peening. J. Mater. Res. Technol. 2022, 20, 4342–4355. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Zhou, J. Characterization and Analysis on Micro-Hardness and Microstructure Evolution of Brass Subjected to Laser Shock Peening. Opt. Laser Technol. 2019, 115, 325–330. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Zhu, W.; Zhao, Y.; Liu, L.; Wang, Z.; Pan, H. Microstructural Response and Surface Mechanical Properties of TC6 Titanium Alloy Subjected to Laser Peening with Different Laser Energy. Opt. Laser Technol. 2023, 158, 108836. [Google Scholar] [CrossRef]

- Gu, J.; Luo, C.; Ma, P.; Xu, X.; Wu, Y.; Ren, X. Study on Processing and Strengthening Mechanisms of Mild Steel Subjected to Laser Cavitation Peening. Appl. Surf. Sci. 2021, 562, 150242. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, H.; Du, H.; Yao, Z. Investigation of Strain Fatigue Behavior for Inconel 625 with Laser Shock Peening. Materials 2022, 15, 7269. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Wang, C.; Tao, X.; Zhou, Y. Numerical Study on Laser Shock Peening of Pure Al Correlating with Laser Shock Wave. Materials 2022, 15, 7051. [Google Scholar] [CrossRef] [PubMed]

- Zabeen, S.; Preuss, M.; Withers, P.J. Evolution of a Laser Shock Peened Residual Stress Field Locally with Foreign Object Damage and Subsequent Fatigue Crack Growth. Acta Mater. 2015, 83, 216–226. [Google Scholar] [CrossRef] [Green Version]

- Chi, J.; Cai, Z.; Wan, Z.; Zhang, H.; Chen, Z.; Li, L.; Li, Y.; Peng, P.; Guo, W. Effects of Heat Treatment Combined with Laser Shock Peening on Wire and Arc Additive Manufactured Ti17 Titanium Alloy: Microstructures, Residual Stress and Mechanical Properties. Surf. Coat. Technol. 2020, 396, 125908. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, H.; Wang, S.; Huang, Y.; Chen, Y.; Zhang, W.; Ostendorf, A.; Zhou, X. Life Cycle Strengthening of High-Strength Steels by Nanosecond Laser Shock. Appl. Surf. Sci. 2021, 569, 151118. [Google Scholar] [CrossRef]

- Wang, C.Y.; Cheng, W.; Shao, Y.K.; Luo, K.Y.; Lu, J.Z. Cavitation Erosion Behaviour of AISI 420 Stainless Steel Subjected to Laser Shock Peening as a Function of the Coverage Layer in Distilled Water and Water-Particle Solutions. Wear 2021, 470, 203611. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, Z.; Li, X.; Zhang, L.; Li, R.; Jiang, R.; Dong, F. The Cavitation Erosion of Ultrasonic Sonotrode during Large-Scale Metallic Casting: Experiment and Simulation. Ultrason. Sonochem. 2018, 43, 29–37. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, Y.; Zhang, Y.; Zhang, X.; Zuo, L.; Yin, Y.; Pei, S. Investigation on Surface “Residual Stress Hole” of Thin Plate Subjected to Two Sided Laser Shock Processing. Opt. Laser Technol. 2022, 149, 107886. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Z.; Chen, B.; Zhang, Y.; Tong, J.; Fang, G.; Duan, S. Investigation on Residual Stress Distribution in Thin Plate Subjected to Two Sided Laser Shock Processing. Opt. Laser Technol. 2019, 111, 146–155. [Google Scholar] [CrossRef]

- McGinn, P.; Tretola, G.; Vogiatzaki, K. Unified Modeling of Cavitating Sprays Using a Three-Component Volume of Fluid Method Accounting for Phase Change and Phase Miscibility. Phys. Fluids 2022, 34, 082108. [Google Scholar] [CrossRef]

- Asano, Y.; Watanabe, H.; Noguchi, H. Effects of Cavitation on Kármán Vortex behind Circular-Cylinder Arrays: A Molecular Dynamics Study. J. Chem. Phys. 2020, 152, 034501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qin, Z.; Li, X.; Xia, D.H.; Zhang, Y.; Feng, C.; Wu, Z.; Hu, W. Effect of Compressive Stress on Cavitation Erosion-Corrosion Behavior of Nickel-Aluminum Bronze Alloy. Ultrason. Sonochem. 2022, 89, 106143. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, P.; Luo, X.; Dong, Z.; Zhang, S. Numerical Prediction of the Effect of Laser Shock Peening on Residual Stress and Fatigue Life of Ti-6Al-4V Titanium Alloy. Materials 2022, 15, 5503. [Google Scholar] [CrossRef]

- He, Z.; Li, C.; Zhao, S.; Cui, B.; Li, D.; Yu, H.; Chen, L.; Fu, T. Mathematical Model and Verification of Residual Stress Induced by Water Jet Peening. Metals 2019, 9, 936. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.Y.; Liang, C.C.; Teng, T.L.; Nguyen, A.T. A Numerical Study on High-Speed Water Jet Impact. Ocean Eng. 2013, 72, 98–106. [Google Scholar] [CrossRef]

- Rajesh, N.; Ramesh Babu, N. Multidroplet Impact Model for Prediction of Residual Stresses in Water Jet Peening of Materials. Mater. Manuf. Process. 2006, 21, 399–409. [Google Scholar] [CrossRef]

- Philipp, A.; Lauterborn, W. Cavitation Erosion by Single Laser-Produced Bubbles. J. Fluid Mech. 2000, 361, 75–116. [Google Scholar] [CrossRef]

- Brujan, E.A.; Matsumoto, Y. Collapse of Micrometer-Sized Cavitation Bubbles near a Rigid Boundary. Microfluid. Nanofluid. 2012, 13, 957–966. [Google Scholar] [CrossRef]

- Plesset, M.S.; Chapman, R.B. Chapman Collapse of an Initially Spherical Vapour Cavity in the Neighbourhood of a Solid Boundary. J. Fluid Mech. 1970, 47, 283–290. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Li, W.; Fu, Y.; Ye, Q.; Xu, Y.; Dong, X.; Hu, K.; Zou, Y. Finite Element Modelling for Temperature, Stresses and Strains Calculation in Linear Friction Welding of TB9 Titanium Alloy. J. Mater. Res. Technol. 2019, 8, 4797–4818. [Google Scholar] [CrossRef]

- Roth, C.C.; Mohr, D. Effect of Strain Rate on Ductile Fracture Initiation in Advanced High Strength Steel Sheets: Experiments and Modeling. Int. J. Plast. 2014, 56, 19–44. [Google Scholar] [CrossRef]

- Rooze, J.; Rebrov, E.V.; Schouten, J.C.; Keurentjes, J.T. Dissolved Gas and Ultrasonic Cavitation—A Review. Ultrason. Sonochem. 2013, 20, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Design of High-Entropy Alloy Coating for Cavitation Erosion Resistance by Different Energy-Induced Dynamic Cyclic Behaviors| ACS Applied Materials & Interfaces. Available online: https://pubs.acs.org/doi/10.1021/acsami.2c19210 (accessed on 18 June 2023).

- Song, S.; Yang, H.; Su, C.; Jiang, Z.; Lu, Z. Ultrasonic-Microwave Assisted Synthesis of Stable Reduced Graphene Oxide Modified Melamine Foam with Superhydrophobicity and High Oil Adsorption Capacities. Chem. Eng. J. 2016, 306, 504–511. [Google Scholar] [CrossRef]

- Mitelea, I.; Bordeaşu, I.; Pelle, M.; Crăciunescu, C. Ultrasonic Cavitation Erosion of Nodular Cast Iron with Ferrite-Pearlite Microstructure. Ultrason. Sonochem. 2015, 23, 385–390. [Google Scholar] [CrossRef] [PubMed]

- Nair, R.B.; Arora, H.S.; Mukherjee, S.; Singh, S.; Singh, H.; Grewal, H.S. Exceptionally High Cavitation Erosion and Corrosion Resistance of a High Entropy Alloy. Ultrason. Sonochem. 2018, 41, 252–260. [Google Scholar] [CrossRef]

- Rajput, A.; Ramkumar, J.; Mondal, K. Effect of Pearlitic Morphology with Varying Fineness on the Cavitation Erosion Behavior of Eutectoid Rail Steel. Ultrason. Sonochem. 2021, 71, 105399. [Google Scholar] [CrossRef]

- Hanke, S.; Beyer, M.; Silvonen, A.; dos Santos, J.F.; Fischer, A. Cavitation Erosion of Cr60Ni40 Coatings Generated by Friction Surfacing. Wear 2013, 301, 415–423. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Laser Energy (J) | Impact Times | Overlap Rate | Spot Diameter (mm) | Power Density (GW/cm2) | ||

|---|---|---|---|---|---|---|---|

| Sample | |||||||

| LSP-1 | 10 | 2 | 50% | 4 | 7.96 | ||

| LSP-2 | 10 | 2 | 50% | 6 | 3.54 | ||

| Parameter | ρ (g/cm3) | A (MPa) | B (MPa) | C | n | m |

|---|---|---|---|---|---|---|

| Value | 8.41 | 190 | 495.4 | 0.0021 | 0.54 | 1.45 |

| Elements | Cu | Sn | Pb | P | Fe | As | Zn |

|---|---|---|---|---|---|---|---|

| Percentage (wt%) | 59.0~61.0 | 0.8~1.3 | 0.05 | 0.01 | 0.10 | 0.03~0.06 | Balance |

| Distance | 4 μm | 15 μm |

|---|---|---|

| S (μm2) | 165.68 | 154.04 |

| H (μm) | 3.66 | 3.15 |

| PEEQ | 0.1927 | 0.1556 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Yao, H.; Ding, Z.; Zhou, Y.; Wei, P.; Yue, J.; Su, W.; Zhu, W. Cavitation Erosion Prevention Using Laser Shock Peening: Development of a Predictive Evaluation System. Materials 2023, 16, 5096. https://doi.org/10.3390/ma16145096

Li W, Yao H, Ding Z, Zhou Y, Wei P, Yue J, Su W, Zhu W. Cavitation Erosion Prevention Using Laser Shock Peening: Development of a Predictive Evaluation System. Materials. 2023; 16(14):5096. https://doi.org/10.3390/ma16145096

Chicago/Turabian StyleLi, Wenlong, Hongbing Yao, Zhipeng Ding, Yuanhang Zhou, Pengyu Wei, Jiang Yue, Wei Su, and Weihua Zhu. 2023. "Cavitation Erosion Prevention Using Laser Shock Peening: Development of a Predictive Evaluation System" Materials 16, no. 14: 5096. https://doi.org/10.3390/ma16145096

APA StyleLi, W., Yao, H., Ding, Z., Zhou, Y., Wei, P., Yue, J., Su, W., & Zhu, W. (2023). Cavitation Erosion Prevention Using Laser Shock Peening: Development of a Predictive Evaluation System. Materials, 16(14), 5096. https://doi.org/10.3390/ma16145096