Electron Beam Welding Process for Ti6Al-4V Titanium Alloy

Abstract

1. Introduction

2. Test Material Used

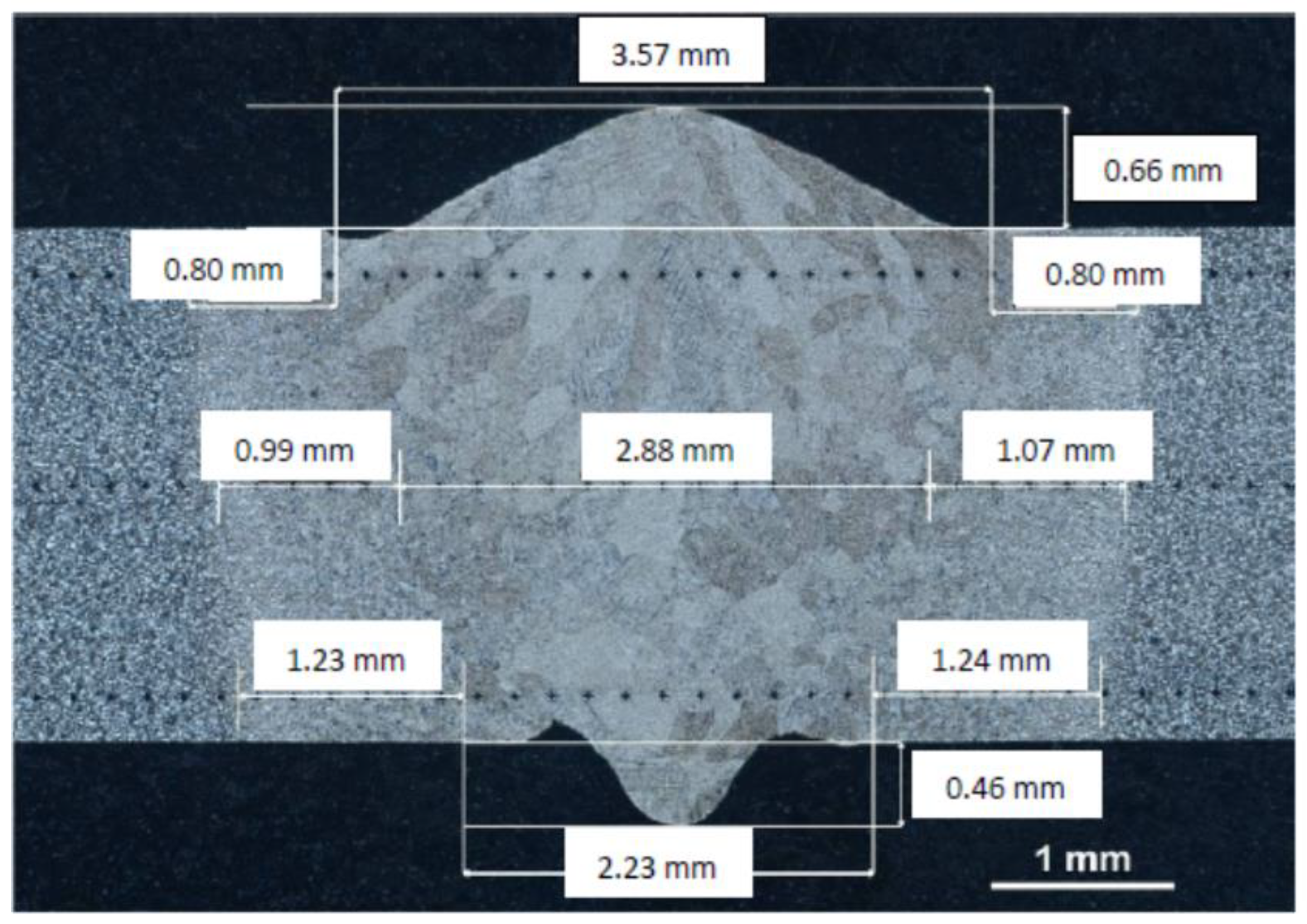

3. Non-Destructive Testing Analysis

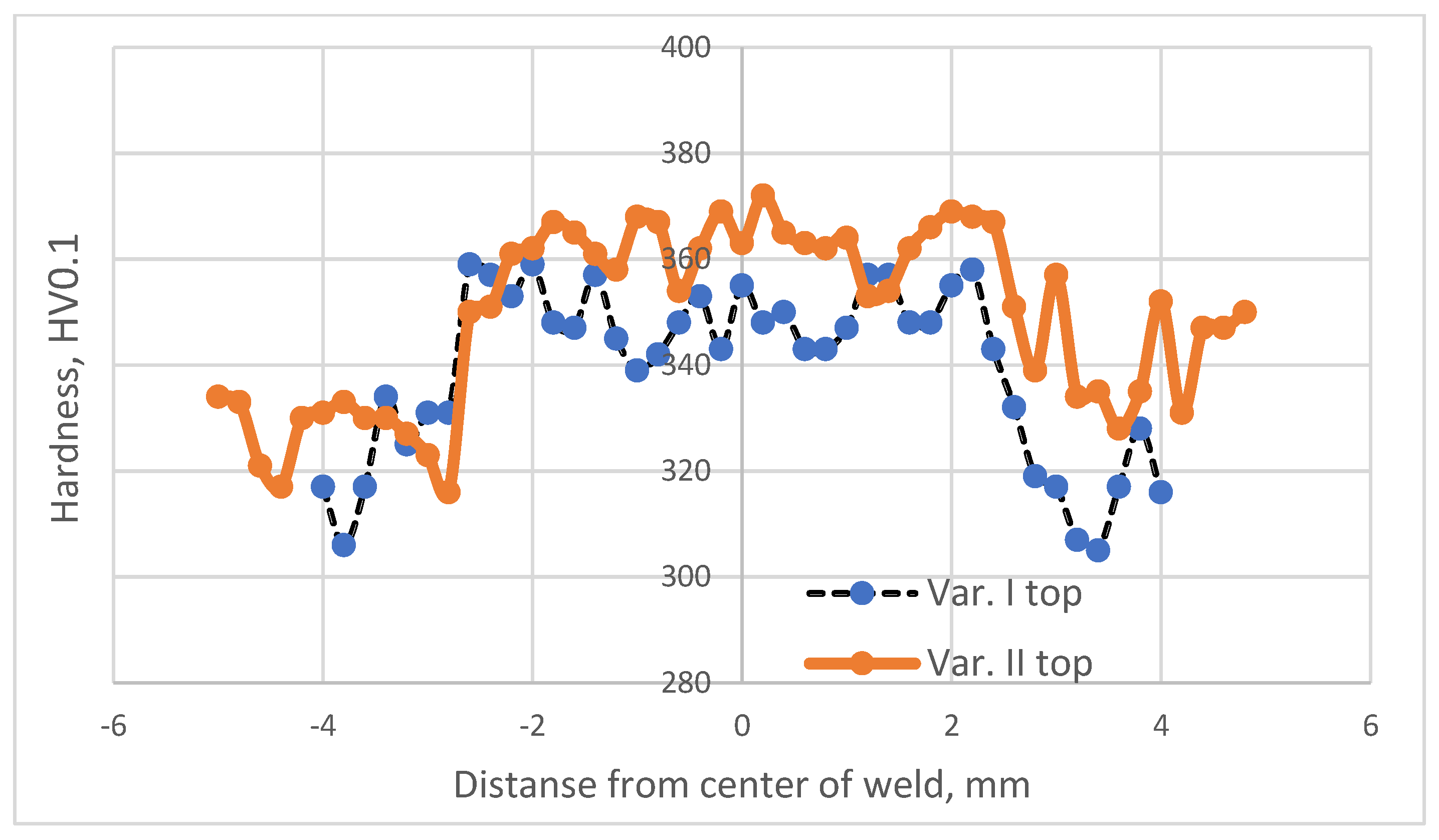

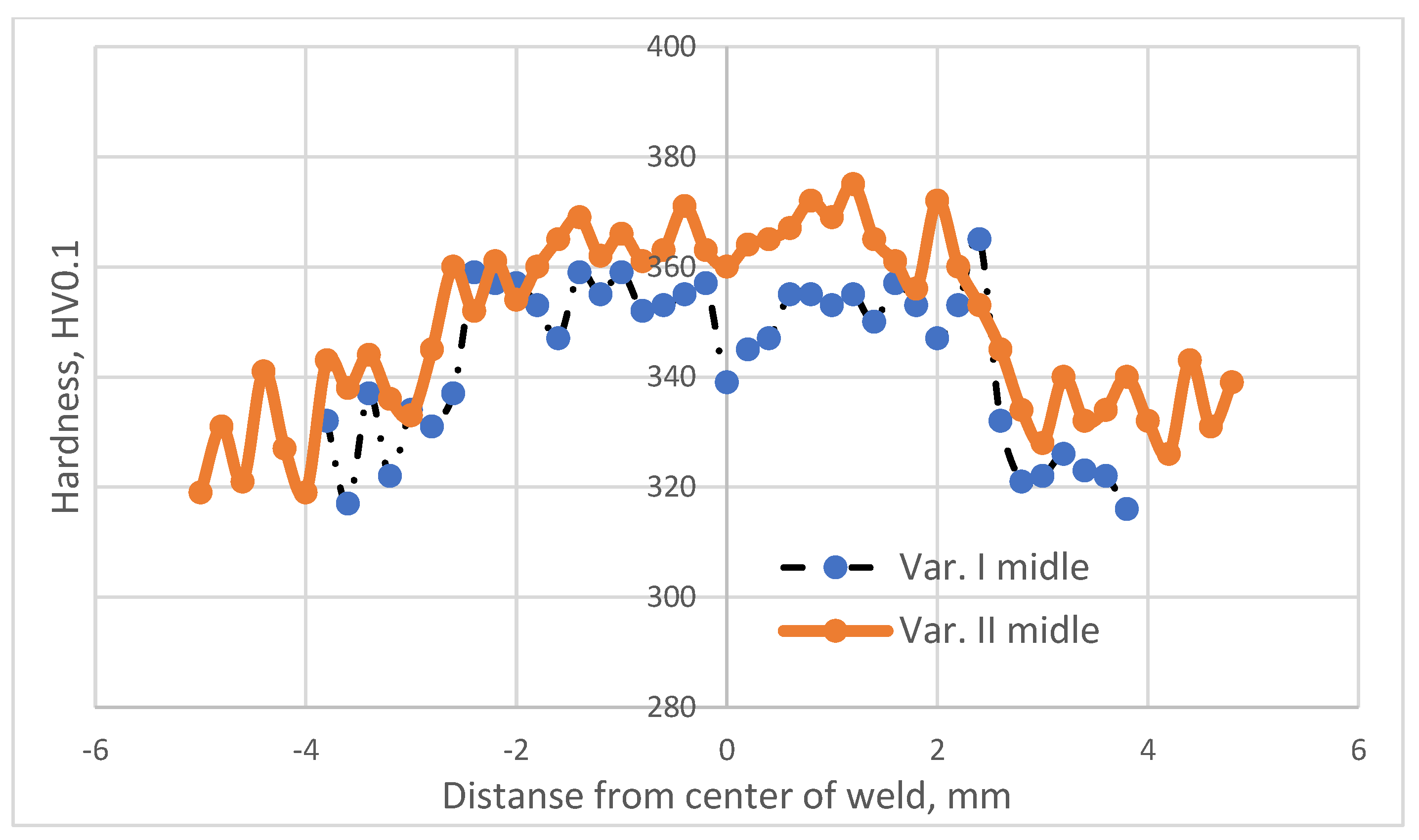

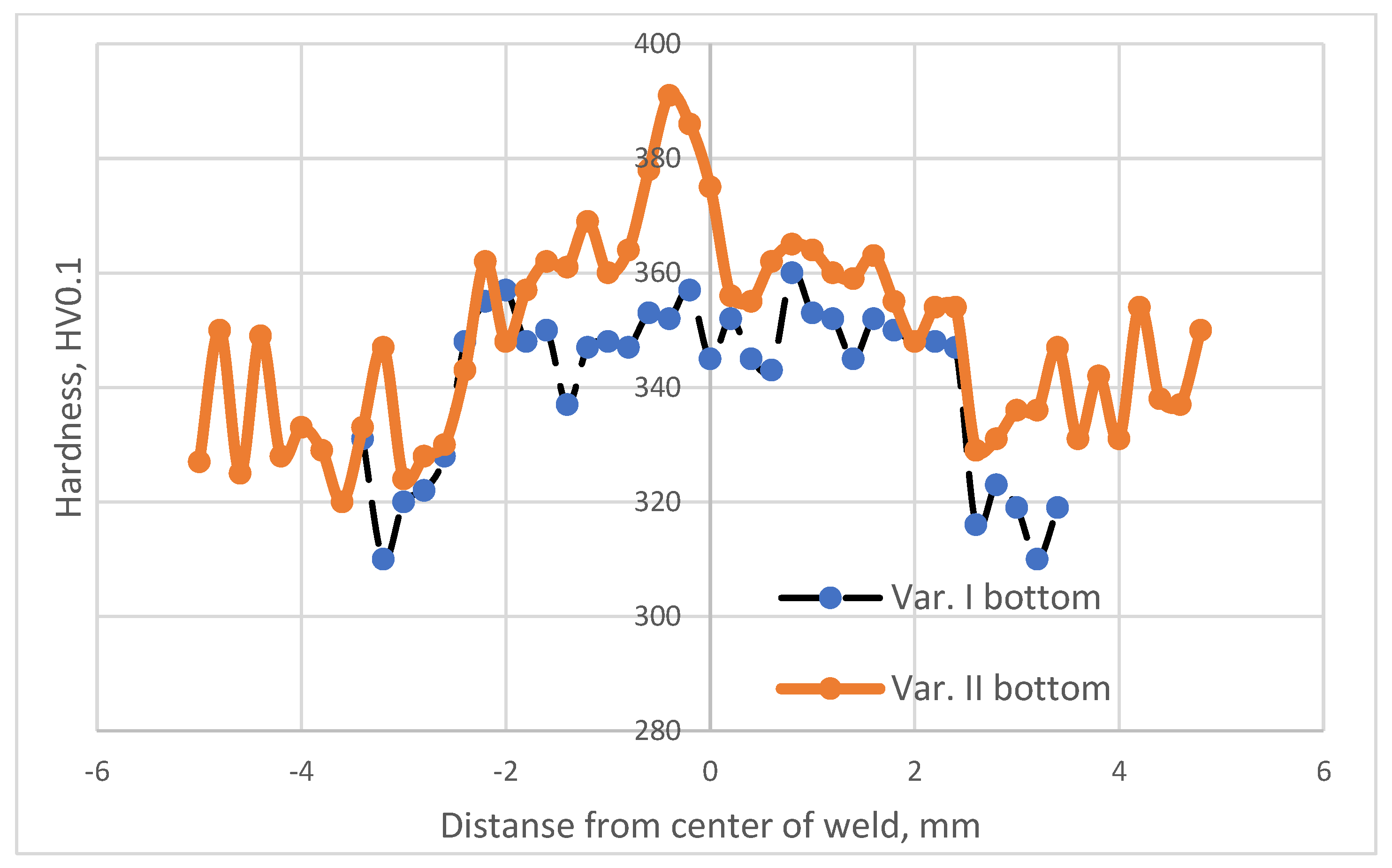

4. Microhardness Analysis

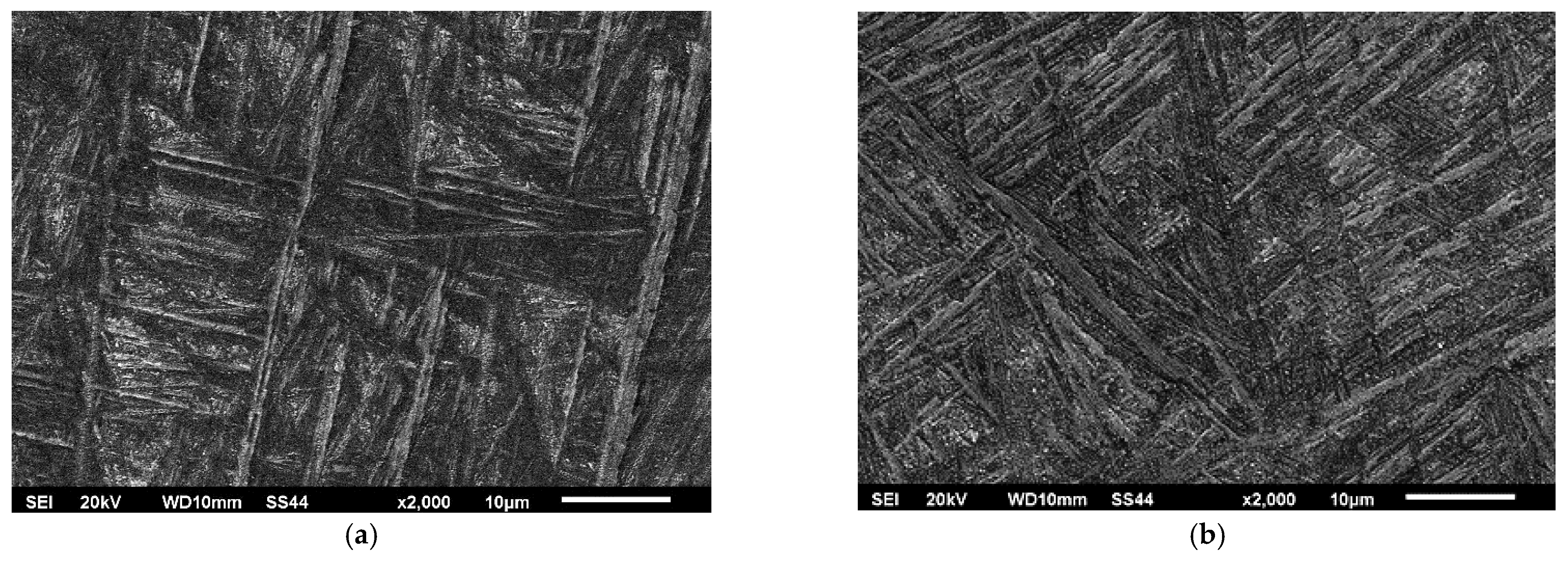

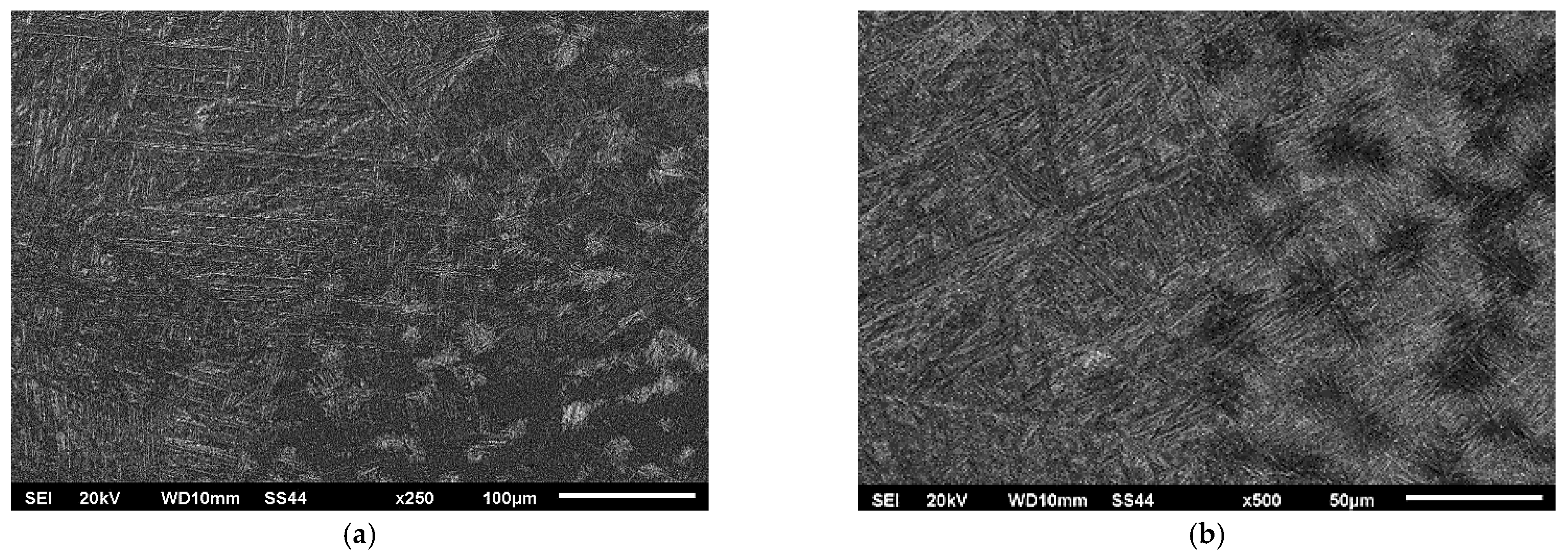

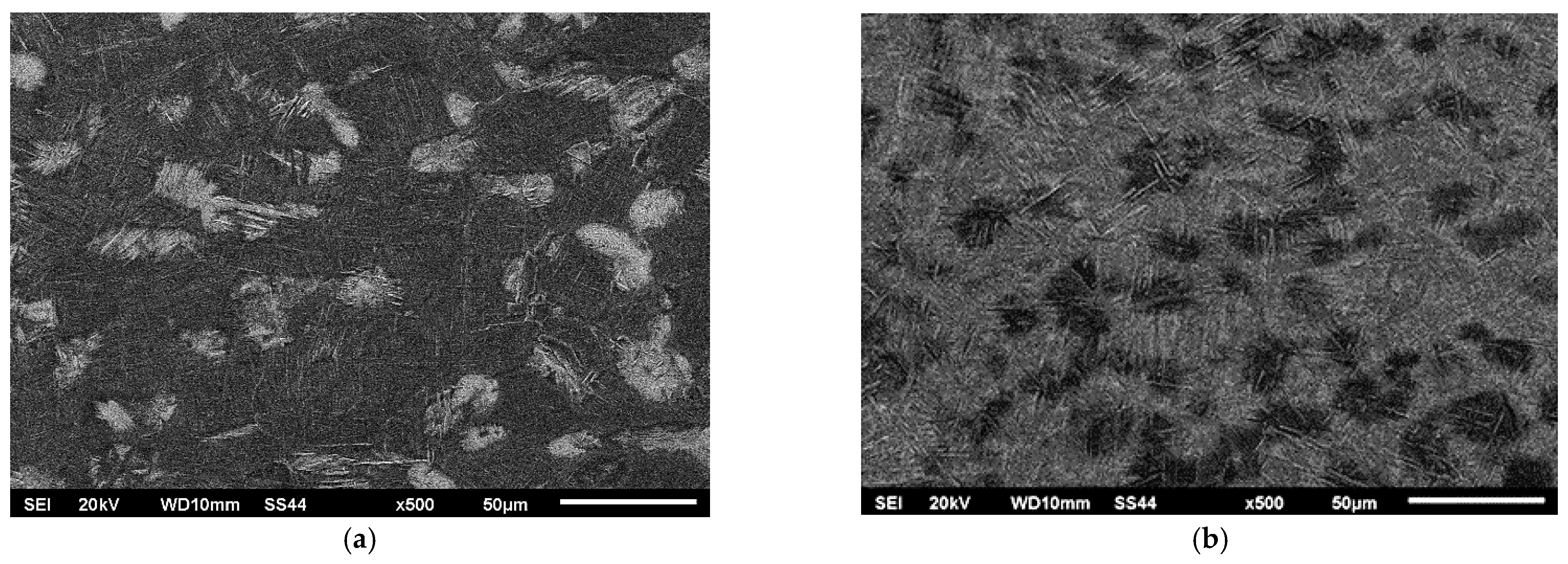

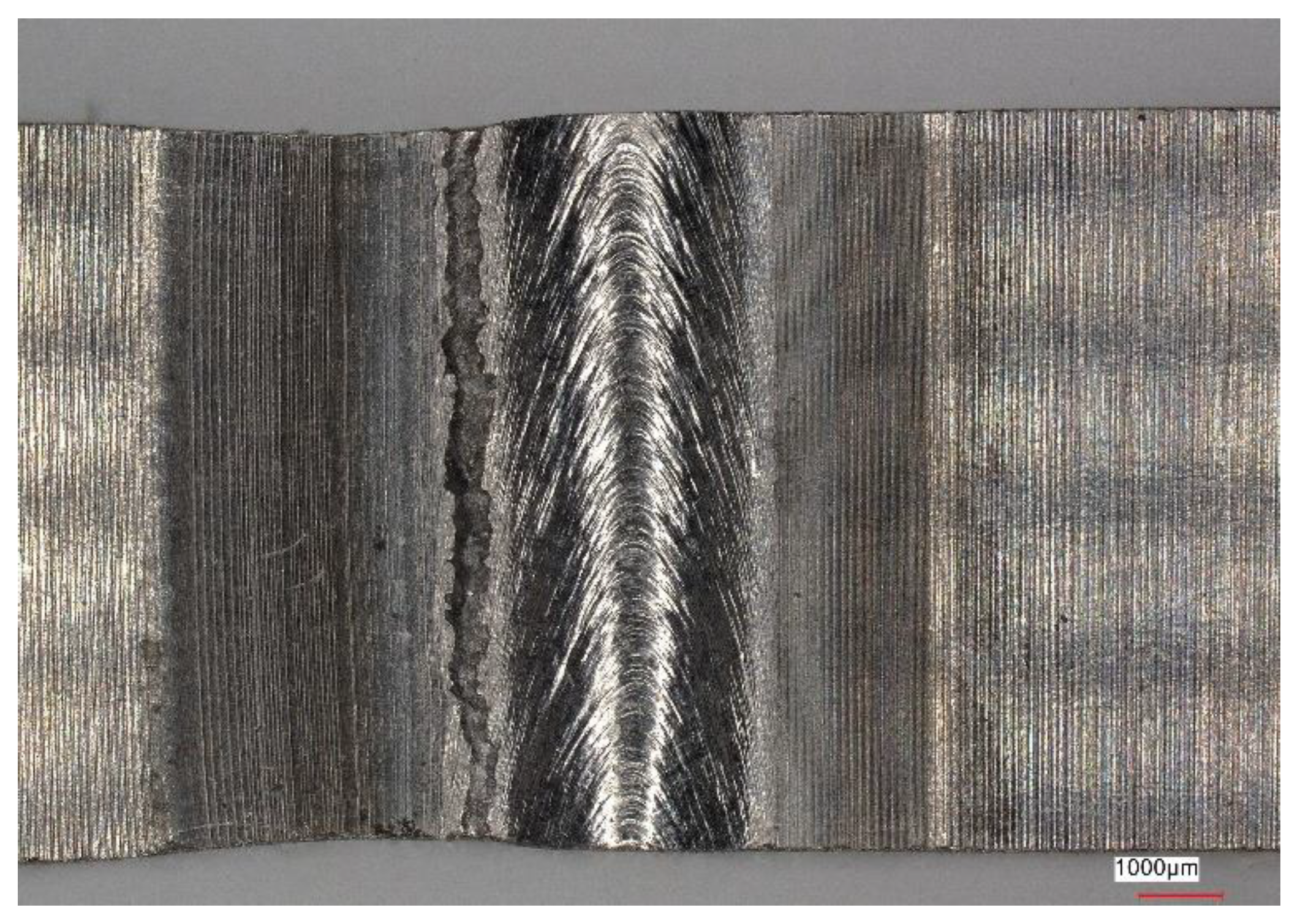

5. Microstructural Analysis of Weld and Heat-Affected Zones

6. Analysis of Weld Chemical Composition

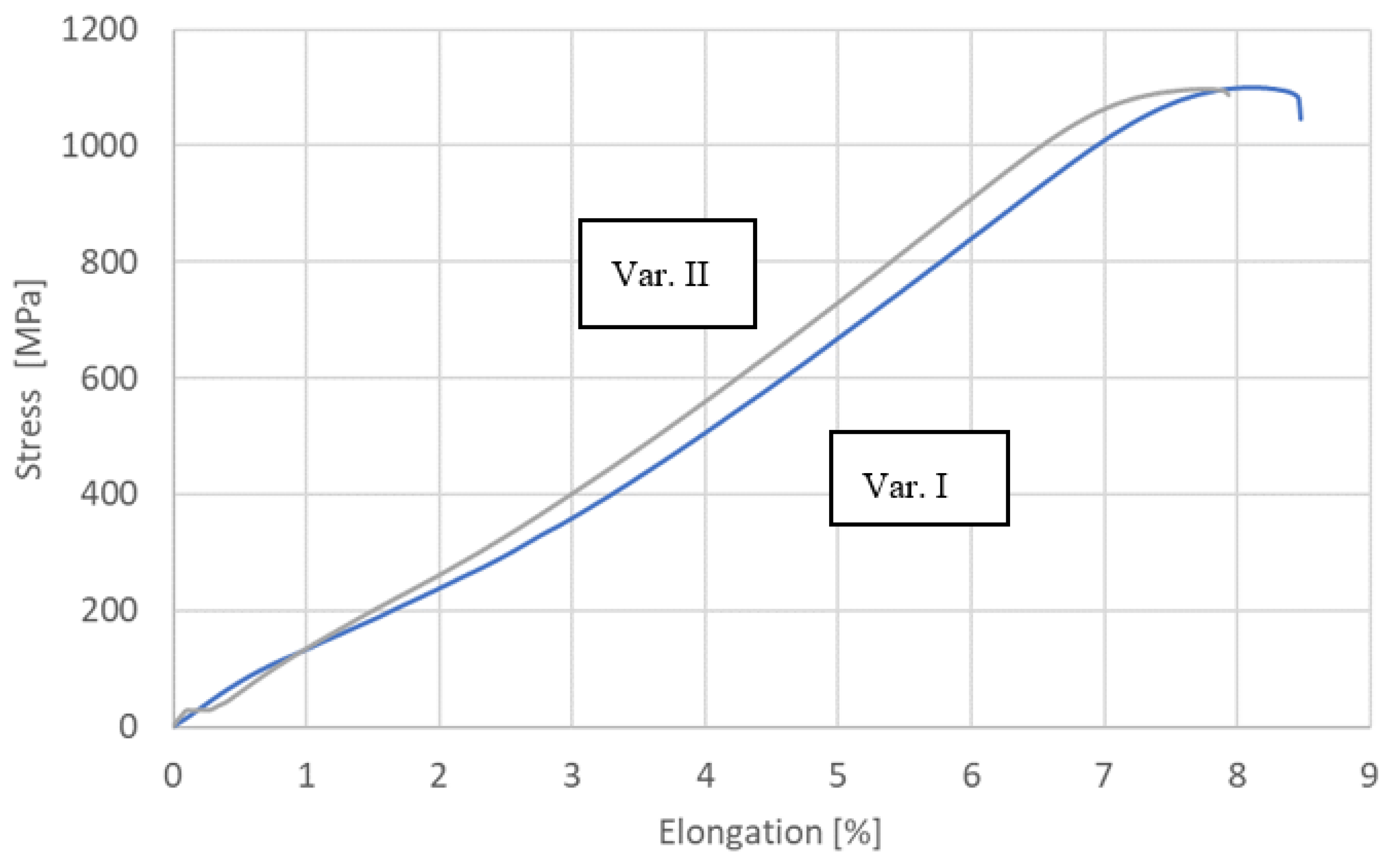

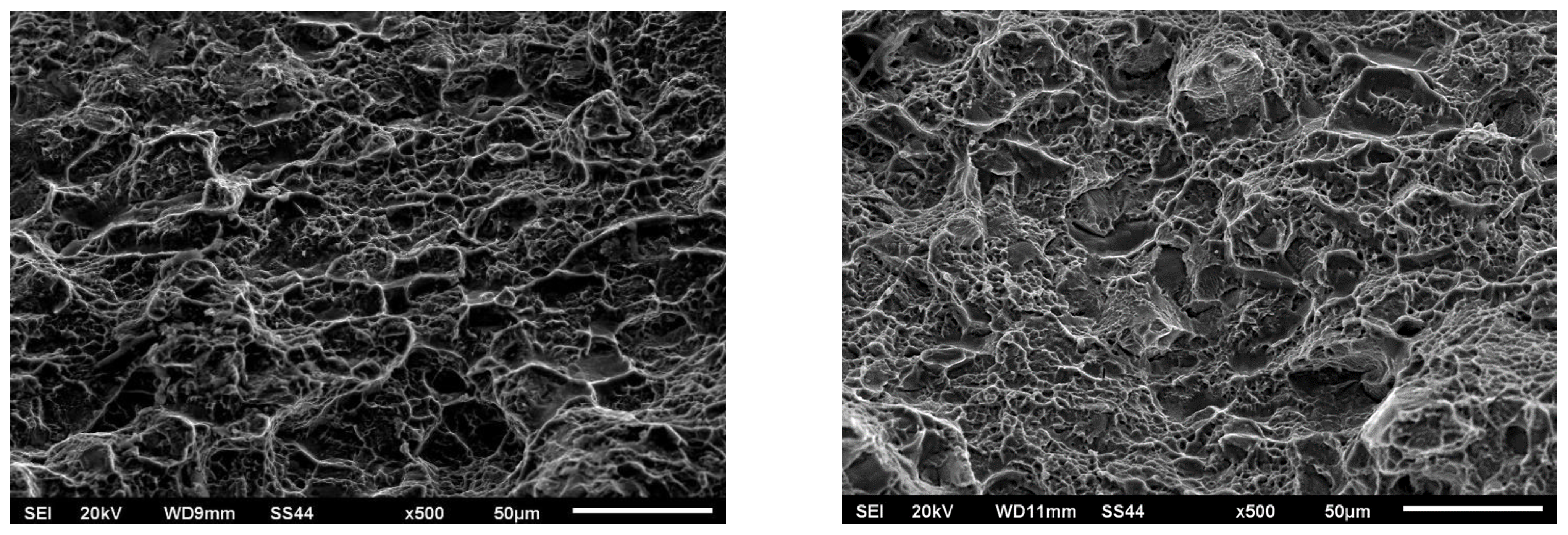

7. Analysis of Strength Properties

8. Conclusions

- Carrying out the electron beam welding process of Ti6Al-4V-grade titanium alloy at a speed of 8 mm/s allowed for the production of a weld that met the requirements of relevant standards in terms of flooding size, ridge height, and face height. The chosen speed of the EBW process ensured a weld without internal porosity, which is crucial for the suitability of welded components in aircraft engine construction.

- The subsequent heat-treatment process involving stress relieving at 590 °C for 2 h after the EBW process resulted in an approximate 4% increase in the microhardness compared to the untreated material. This phenomenon was attributed to the precipitation of supersaturated material, which occurred during the welding process, along with dispersions from phase α.

- No influence of grain boundaries on the resulting fusion line between the weld and the HAZ was observed during the electron beam welding process of the Ti6Al-4V-grade titanium alloy at a speed of 8 mm/s.

- Implementing the electron beam welding process for the Ti6Al-4V-grade titanium alloy at a speed of 8 mm/s under high vacuum conditions, as used in the study, led to depletion of the material in the face area. This depletion was primarily caused by the evaporation of one of the alloying elements (aluminum) due to its high vaporization tendency. However, reducing the speed of the EBW process did not result in a significant decrease in the aluminum content below the 6% limit, which determined the chemical composition of the alloy and its properties.

- The mechanical properties of the material after the EBW process alone and after the EBW process followed by heat treatment were comparable, with no differences in tensile strength observed. However, for samples subjected to the EBW process and subsequent heat treatment, a higher yield margin was determined as indicated by the R0.2/Rm ratio.

- The low speed of the electron beam welding process used in the research for the Ti6Al-4V-grade titanium alloy allowed for the production of material with the expected microstructural properties (such as the absence of discontinuities and internal defects) as well as the desired chemical composition.

- Carrying out the heat-treatment process involving stress relieving of the Ti6Al-4V-grade titanium alloy after the EBW process led to a weld with higher mechanical properties compared to materials that did not undergo the heat-treatment process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barreda, J.L.; Santamaram, F.; Azpiroz, X.; Irisarri, A.M.; Varona, J.M. Electron beam welded high thickness Ti–6Al–4V plates using filler material of similar and dissimilar composition to the base metal. Vaccum 2001, 62, 143–150. [Google Scholar] [CrossRef]

- Li, C.L.; Ye, W.J.; Mi, X.J.; Hui, S.X.; Lee, D.G.; Lee, Y.T. Development of Low Cost and Low Elastic Modulus of Ti-Al-Mo-Fe Alloys for Automotive Applications. Key Eng. Mater. 2013, 551, 114–117. [Google Scholar] [CrossRef]

- Boyer, R.R.; Briggs, R.D. The use of b titanium alloys in the aerospace industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Yang, H.; Fan, X.; Sun, Z.; Guo, L.; Zhan, M. Recent developments in plastic forming technology of titanium alloys. Sci. China Technol. Sci. 2011, 54, 490–501. [Google Scholar] [CrossRef]

- Fomin, F.; Froend, M.; Ventzke, V.; Alvarez, P.; Bauer, S.; Kashaev, N. Metallurgical aspects of joining commercially pure titanium to Ti-6Al-4V alloy in a T-joint configuration by laser beam welding. Int. J. Adv. Manuf. Technol. 2018, 97, 2019–2031. [Google Scholar] [CrossRef]

- Froend, M.; Fomin, F.; Riekehr, S.; Alvarez, P.; Zubiri, F.; Bauer, S.; Klusemann, B.; Kashaev, N. Fiber laser welding of dissimilar titanium (Ti-6Al-4V/cp-Ti) T-joints and their laser forming proces for aircraft application. Opt. Laser Technol. 2017, 96, 123–131. [Google Scholar] [CrossRef]

- Squillace, A.; Prisco, U.; Ciliberto, S.; Astarita, A. Effect of welding parameters on morphology and mechanical properties of Ti-6Al-4V laser beam welded butt joints. J. Mater. Process. Tech. 2012, 212, 427–436. [Google Scholar] [CrossRef]

- Ribeiro, A.C.N.; de Siqueira, R.H.M.; de Lima, M.S.F.; Giorjão, R.A.R.; Abdalla, A.J. Improvement weldability of dissimilar joints (Ti6Al4V/Al6013) for aerospace industry by laser beam welding. Int. J. Adv. Manuf. Technol. 2021, 116, 1053–1070. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J. Interfacial microstructure and mechanical property of Ti6Al4V/A6061 dissimilar joint by direct laser brazing without filler metal and groove. Mater. Sci. Eng. A 2013, 560, 111–120. [Google Scholar] [CrossRef]

- Liu, H.; Nakata, K.; Yamamoto, N.; Liao, J. Microstructural characteristics and mechanical properties in laser beam welds of Ti6Al4V alloy. J. Mater. Sci. 2012, 47, 1460–1470. [Google Scholar] [CrossRef]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A review on laser beam welding of titanium alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 1071–1098. [Google Scholar] [CrossRef]

- Li, Z.; Gobbi, S.; Norris, I.; Zolotovsky, S.; Richter, K. Laser welding techniques for titanium alloy sheet. J. Mater. Process. Technol. 1997, 65, 203–208. [Google Scholar] [CrossRef]

- Saresh, N.; Pillai, M.G.; Mathew, J. Investigations into the effects of electron beam welding on thick Ti–6Al–4V titanium alloy. J. Mater. Process. Technol. 2007, 192–193, 83–88. [Google Scholar] [CrossRef]

- Meshram, S.D.; Mohandas, T. A comparative evaluation of friction and electron beam welds of near-α titanium alloy. Mater. Des. 2010, 31, 2245–2252. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Jovanović, M.; Čamagić, I.; Sedmak, S.; Sedmak, A.; Burzić, Z. The Effect of Material Heterogeneity and Temperature on Impact Toughness and Fracture Resistance of SA-387 Gr. 91 Welded Joints. Materials 2022, 15, 1854. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Wu, J.; Liu, Z.; Ma, J.; Liu, Z.; Peng, W. Influence of Different Beam Oscillation Patterns in Electron Beam Welding of Niobium Sheets with Different Thickness. Materials 2022, 15, 3778. [Google Scholar] [CrossRef]

- Ozerov, M.; Povolyaeva, E.; Stepanov, N.; Ventzke, V.; Dinse, R.; Kashaev, N.; Zherebtsov, S. Laser Beam Welding of a Ti-15Mo/TiB Metal–Matrix Composite. Metals 2021, 11, 506. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, H.; Liu, H.; Chen, Y.; Kashif, K.M.; Wang, Q.; Liu, Y. Influence of Welded Pores on Very Long-Life Fatigue Failure of the Electron Beam Welding Joint of TC17 Titanium Alloy. Materials 2019, 12, 1825. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.-G.; Feng, J.-C. Influences of different filler metals on electron beam welding of titanium alloy to stainless steel. Trans. Nonferrous Met. Soc. China 2014, 24, 108–114. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X. Investigation on the microstructure and mechanical properties of Ti–6Al–4V alloy joints with electron beam welding. Mater. Des. 2012, 36, 663–670. [Google Scholar] [CrossRef]

- Rae, W.; Lomas, Z.; Jackson, M.; Rahimi, S. Measurements of residual stress and microstructural evolution in electron beam welded Ti-6Al-4V using multiple techniques. Mater. Charact. 2017, 132, 10–19. [Google Scholar] [CrossRef]

- Gao, F.; Li, P.; Jiang, P.; Liao, Z. The effect of constraint conditions on microstructure and properties of titanium alloy electron beam welding. Mater. Sci. Eng. A 2018, 721, 117–124. [Google Scholar] [CrossRef]

- Gao, F.; Yu, W.; Song, D.; Gao, Q.; Guo, L.; Liao, Z. Fracture toughness of TA31 titanium alloy joints welded by electron beam welding under constrained condition. Mater. Sci. Eng. A 2020, 772, 138612. [Google Scholar] [CrossRef]

- AWS D1.1; Structural Welding Code—Steel. American Welding Society (AWS): Miami, FL, USA, 2020.

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Sun, W.; Wang, S.; Wu, M.; Hong, M.; Chen, Y.; Xin, J.; Zhang, P.; Qin, Y.; Fang, N. Revealing tensile behaviors and fracture mechanism of Ti–6Al–4V titanium alloy electron-beam-welded joints using microstructure evolution and in situ tension observation. Mater. Sci. Eng. A 2021, 824, 141811. [Google Scholar] [CrossRef]

- EN ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

| Al, % | V, % | Fe, % | O, % | C, % | N, % | H, % | Y, % | Ti, % | |

|---|---|---|---|---|---|---|---|---|---|

| Min. | 5.50 | 3.50 | 0 | 0 | 0 | 0 | 0 | 0 | Remainder |

| Max. | 6.75 | 4.50 | 0.30 | 0.20 | 0.10 | 0.05 | 0.015 | 0.001 | Remainder |

| Welding Current (mA) | Welding Speed (mm/s) | Beam Oscillation (mm) | Beam Defocusing (mA) | Heat-Treatment Temperature (°C) | Heat-Treatment Time (h) | Atmosphere, Pressure (Pa) | |

|---|---|---|---|---|---|---|---|

| Variant I | 5.5 | 8 | 0 | +20 | - | - | - |

| Variant II | 5.5 | 8 | 0 | +20 | 590 | 2 | Ar, 1000 |

| Measuring Point No. | Element Weight Content in Chemical Composition, % | ||

|---|---|---|---|

| Al | Ti | V | |

| 1 | 7.79 | 88.78 | 3.43 |

| 2 | 7.32 | 88.55 | 4.12 |

| 3 | 6.5 | 90.03 | 3.47 |

| 4 | 8.33 | 88.09 | 3.58 |

| Average value | 7.48 | 88.86 | 3.65 |

| Measuring Point No. | Element Weight Content in Chemical Composition, % | ||

|---|---|---|---|

| Al | Ti | V | |

| 1 | 5.51 | 90.80 | 3.69 |

| 2 | 6.21 | 90.18 | 3.61 |

| 3 | 6.71 | 89.81 | 3.47 |

| 4 | 5.86 | 89.66 | 4.47 |

| Average value | 6.07 | 90.11 | 3.81 |

| Measuring Point No. | Element Weight Content in Chemical Composition, % | ||

|---|---|---|---|

| Al | Ti | V | |

| 1 | 7.65 | 88.83 | 3.52 |

| 2 | 7.44 | 88.91 | 3.65 |

| 3 | 7.53 | 88.30 | 4.17 |

| 4 | 7.33 | 89.01 | 3.66 |

| Average value | 7.48 | 88.76 | 3.75 |

| Variant | R0.2, MPa | Rm, MPa |

|---|---|---|

| I | 1092 | 1099 |

| II | 1084 | 1099 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wencel, Z.; Wiewiórowska, S.; Wieczorek, P.; Gontarz, A. Electron Beam Welding Process for Ti6Al-4V Titanium Alloy. Materials 2023, 16, 5174. https://doi.org/10.3390/ma16145174

Wencel Z, Wiewiórowska S, Wieczorek P, Gontarz A. Electron Beam Welding Process for Ti6Al-4V Titanium Alloy. Materials. 2023; 16(14):5174. https://doi.org/10.3390/ma16145174

Chicago/Turabian StyleWencel, Zbigniew, Sylwia Wiewiórowska, Paweł Wieczorek, and Andrzej Gontarz. 2023. "Electron Beam Welding Process for Ti6Al-4V Titanium Alloy" Materials 16, no. 14: 5174. https://doi.org/10.3390/ma16145174

APA StyleWencel, Z., Wiewiórowska, S., Wieczorek, P., & Gontarz, A. (2023). Electron Beam Welding Process for Ti6Al-4V Titanium Alloy. Materials, 16(14), 5174. https://doi.org/10.3390/ma16145174