5.1. Stress Extraction Method

There is no consistent definition of the nominal stress extraction method for the diaphragm’s arc opening area of an OSD in the field of steel bridge fatigue research. The existing nominal stress extraction methods for this detail are synthesized in this paper, along with selecting the nominal stress at 2 mm, 6 mm, 10 mm, 13 mm, and 15 mm away from the normal direction of the edge of the stress concentration point. The stress concentration point at the detail can be considered a hot spot through the basic idea of the HSS method. HSS is solved using multipoint linear interpolation and extrapolation. The corresponding fatigue life assessment is carried out with the help of the S–N curve recommended by IIW.

The extrapolation formula of the HSS method adopts the two-point interpolation linear extrapolation from Equation (3), suggested by DET Norske Veritas.

In this paper, the stress peak at point A in this area was used as the reference point for FEM analysis, and the nominal stresses at 2 mm, 6 mm, 10 mm, 13 mm, and 15 mm, respectively, away from point A and the HSS at this point were obtained.

Since the detailed stress responses under the most unfavorable longitudinal and transverse load cases are analyzed, only the nominal stress and HSS at all locations under LC4 load cases were extracted. For LC1 and LC7, only nominal stress and HSS at 6 mm were extracted for comparison. The schematic diagram of nominal stress and HSS extraction is represented in

Figure 20. These two evaluation methods do not consider the influence of nonlinear stress factors.

5.2. Stress Results Analysis of Arc Opening

Within a certain range of moving load, the second and third principal stresses near the peak point A of the diaphragm’s arc opening stress are negative, which can be analyzed from the FEM results. This suggests that point A is under biaxial compression within a certain range. Considering the third principal stress as the representative to evaluate the fatigue performance, the large absolute value of the third principal stress at nearby points can be determined. This also meets the requirements of stress-extracting parameters by using the nominal stress method and HSS method.

There is a marginal difference in the stress on the front and back of the stress peak at point A, due to the thickness of the plate. Stress extraction was carried out on the side with a larger value from the perspective of conservative fatigue assessment.

Figure 21 represents the variation curves of nominal stress and HSS at stress peak at point A under three load cases.

The stress level under LC4 is the highest for the nominal stress value and HSS value at 6 mm, and the stress level under LC7 is the lowest during the longitudinal and transverse loading of the entire moving loads, as shown in

Figure 21.

LC4 is the most unfavorable lateral loading position. The moving load center line is parallel to the connection between the web plate and the top plate at the side of the 6# U-rib and 5# U-rib. The position with the most unfavorable longitudinal loading is 140 mm away from the middle diaphragm plate (HGB2). The overall change in stress indicates an increasing trend at first, followed by a gradual decrease.

When the moving load is directly above the side diaphragm (HGB3), the principal stress at point A is a mere −2.54 MPa (considering the nominal stress at 6 mm under LC4). Compared with the most unfavorable loading case, the principal stress is reduced by 30.74 MPa, accounting for 7.64% of the stress.

When the moving load is 750 mm away from the right side of the diaphragm (HGB3), the principal stress is only −0.78 MPa. It can be inferred that only when the moving load acts within a certain range do the studied details have a better stress response.

The stress influence line of point A along the longitudinal bridge direction is roughly distributed in a triangular shape. It can be concluded from the stress response results that the length of the stress influence line is almost twice the total length of the longitudinal movement, which is 4.2 m. If the axle load in the fatigue vehicle is applied at the peak point of the stress influence line, the front and rear axles must be applied within 2.1 m on the left and right of the middle diaphragm to have a significant impact on the stress results, according to the arrangement of the most unfavorable loading scheme.

The influence of the front and rear axles on the stress response is not considered in this paper, and it is appropriate to only consider the middle axle for simulated loading. Under the three loading cases, the variation curves of the third principal stress at the stress peak point with the longitudinal moving load position are represented in

Figure 21. It can be analyzed from the stress distribution that the nominal stress and the HSS derived from two points have similar change trends. The HSS method is more conservative than the nominal stress method.

The values of the principal stresses under LC4 are mentioned in

Table 5. The nominal stress values reduce significantly with the increase in the normal distance of the opening edge, suggesting that the stress gradient at this point is large.

5.3. Displacement Results Analysis

Under the three lateral load cases in

Section 4.1, the displacement and deformation of the middle diaphragm (HGB2) under longitudinal load steps i = 2 (LC1) and i = 3 (LC4 and LC7) are represented in

Figure 22. When the moving load is exactly above the diaphragm, the diaphragm only produces in-plane deformation, and there is no out-of-plane bending stress on the diaphragm web, the in-plane membrane stress takes a major portion.

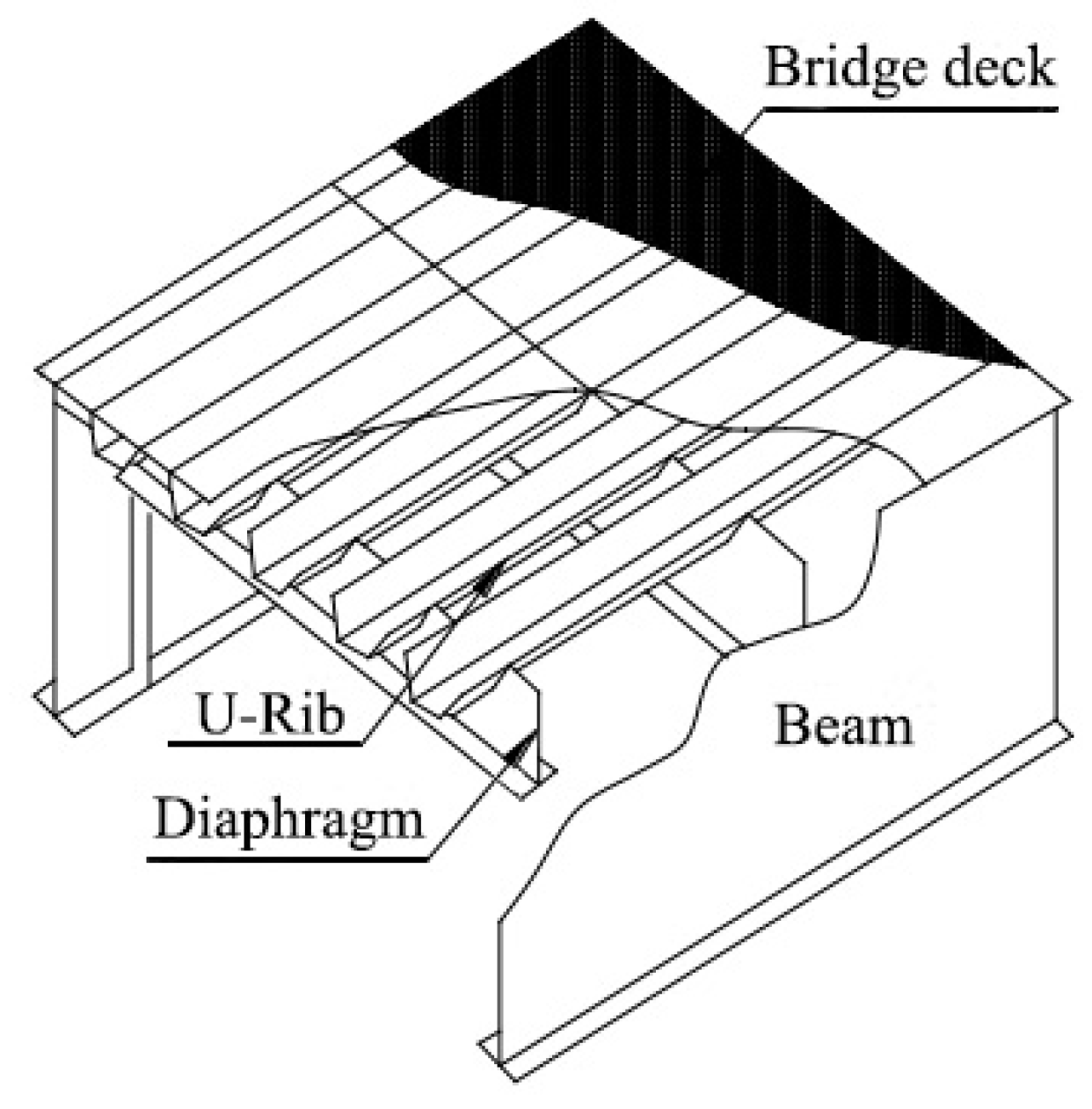

Figure 22 represents that there is a strong bending shear effect between the U-rib and the diaphragm in the plane. Some parts of the axial force and shear force in the diaphragm are transmitted through the longitudinal ribs. The transverse diaphragm and longitudinal rib affect each other. The middle part of the diaphragm is subject to the most significant compression, so the bending moment is the largest.

The closer to the end of the diaphragm, the more impactful the shear force is. The longitudinal ribs are twisted, leading to different stress signs on both sides of the longitudinal rib. Under the comprehensive influence of bending and shearing of the longitudinal rib and diaphragm, significant stress concentration occurs at the end of the weld and arc opening.

Simultaneously,

Figure 22a indicates that when the load is only acting on the top of the 6# U-rib, as the diaphragm is drilled to release the secondary bending stress at the welding between the diaphragm and the U-rib, the webs of the U-rib and the diaphragm are staggered in the vertical direction and squeezed in the horizontal direction, resulting in tensile stress at the two welds.

Figure 22b,c show that when the moving load deviates from the center line of the U-rib for loading, the U-rib is distorted, and its bottom generates lateral displacement. Furthermore, the diaphragm serves as an embedded boundary to limit displacement. The discontinuous embedded boundary around the U-ribs, on the other hand, causes significant out-of-plane deformation of the U-ribs, and the weld end and opening periphery are subject to higher secondary stress.

5.4. Stress Composition of Diaphragm’s Arc Opening Area

The moving load with an area of 305 mm × 175 mm acts directly above HGB2. The initial position is at the central axis of the 6# U-rib, and it then moves horizontally to the right with an amplitude of 25 mm each time. During the movement, point A with obvious stress concentration can be considered as the representative to determine the stress composition and change law in the diaphragm’s arc opening area.

The front side denotes the side with larger value where the peak stress point A of the middle diaphragm plate is closer to the moving load action position, and the back side denotes the side with a smaller value, away from the moving load action position.

Under the LC1, LC4, and LC7 load cases, the nominal principal stress at 6 mm from the normal direction of the edge of the arc opening at point A is analyzed. If the principal stress directions of the front and back sides of point A are roughly the same, it can be determined that

is obtained with the linear addition of in-plane stress and out-of-plane stress, and

denotes the difference between in-plane stress and out-of-plane stress. On this basis, the stress composition and variation law of point A are studied.

denotes the stress value at the side near the moving load’s action position at point A of the diaphragm plate, and denotes the stress value at the side away from the moving load’s action position at point A of the diaphragm plate.

If the principal stress directions of the two sides are different, they cannot be treated using the above methods but should be decomposed into normal stress and shear stress to conduct fatigue performance analysis.

It can be observed from

Figure 23a,c,e that the stress values on the front and back of the stress peak at point A are close. From the subsequent FEM calculation, it can be observed that the principal stress direction is basically the same, so the fatigue performance can be analyzed through the linear decomposition of the principal stress.

Figure 23a suggests that the stress at point A is negative, indicating that the point is under pressure. When the load moves to the right, it can be observed that the stress value changes significantly during the initial movement, with an increase of 2.53%. This indicates that the stress at the point of concern is closely related to the lateral action position of the moving load.

When the moving load shifts 75 mm to the right, the stress reaches the maximum value of −45.40 MPa, with an increase of 4.30%. At this time, the center of the moving load on one side coincides with the connection between the web of the 6# U-rib, which is near the 5# U-rib, and the top plate of the deck. Further, the moving load continues to move to the right three times (25 mm each time, 75 mm in total). It can be observed that the stress reduces significantly during the moving load movement (the decreases are 5.07%, 5.14%, and 8.36%, respectively), and eventually acts on the center line of the 6# U-rib and 5# U-rib relative to the web. The change in the moving load’s lateral action position has a significant local effect on its stress response. The local effect is related to the force transmitted by the weld between the U-rib and the diaphragm. The closer the moving load center is to the web of the U-rib on the side of point A, the greater the force transmitted by the weld, resulting in an increase in the stress level at point A. To sum up, LC4 is the most unfavorable load case in the transverse direction, and LC7 is the case with the minimum load effect.

As depicted in

Figure 23b, when the moving load moves laterally on the middle diaphragm, the out-of-plane stress of point A is 0, and the in-plane stress is dominant. Since the stiffening rib of the diaphragm is set at one side, the diaphragm structure is not completely symmetrical, so there is a small amount of out-of-plane stress. Starting from the corresponding transverse loading positions of LC1, LC4, and LC7, it moves 2100 mm longitudinally towards the side diaphragm (HGB3).

As highlighted in

Figure 23c,e,g, when the moving load moves longitudinally, the front stress (near the side of the moving load) of point A under all load cases is marginally greater than the back stress. When the center line of the load’s resultant force is 140 mm away from the middle diaphragm, the stresses on both sides of point A (under the LC4 load case) attain the highest level simultaneously. The main reason for this phenomenon is that when the load is directly above HGB2, the diaphragm plays a leading role in lateral diffusion, which decreases the in-plane stress level at point A. When the load deviates from HGB2 by a certain distance, the top plate is not supported by the diaphragm, leading to its low bending stiffness. The load effect is primarily transmitted to the weld between the U-ribs and the diaphragm longitudinally through the U-ribs, which enhances the stress concentration at point A.

It can be observed from the in-plane and out-of-plane stress distribution in

Figure 23d,f,h that under the three load cases, the maximum combined effect of in-plane and out-of-plane stress is located at the most unfavorable longitudinal loading position (load steps i = 2, i = 3, and i = 3, respectively). However, the proportion of out-of-plane stress can be ignored, as it is 0.01% under LC1, 0.26% under LC4, and 0.32% under LC7. When the moving load center acts in the middle of HGB2 and HGB3, the vertical downward deflection of the U-rib is the largest. At this time, the out-of-plane deformation and stress of the diaphragm web plate are at the maximum. The maximum out-of-plane stresses under the LC1, LC4, and LC7 load cases are −0.43 MPa, −0.44 MPa, and −0.40 MPa, respectively.

Under the LC1 load case, the proportion of out-of-plane stress is 1.46%, which is still negligible. Although the out-of-plane stress simultaneously reaches the peak, the in-plane and out-of-plane combined effect has been reduced to 67.9% under the most unfavorable loading. Under the LC4 load case, the out-of-plane stress accounts for 1.36%, and the in-plane and out-of-plane combined effect is reduced to 73.15% under the most unfavorable loading. In the case of LC7, the out-of-plane stress accounts for 1.32%, and the in-plane and out-of-plane combined effect is reduced to 78.19% under the most unfavorable loading.

In conclusion, the contribution of out-of-plane bending stress to the overall load effect is very small. Irrespective of the changes in the moving load position, the load effect in this area is primarily caused by in-plane stress.

Regardless of the influence of material properties, stress amplitude is the key factor in the fatigue evaluation of steel bridges. Therefore, it can be considered that the chief cause of fatigue cracking at the peak point A of a diaphragm’s arc opening is in-plane stress [

30,

39,

40,

41,

42,

43]. Out-of-plane stress has a minor effect on fatigue cracking at the peak point A.

5.5. Control Stress of Arc Opening’s Cracking

Theoretical computation value derivation was carried out for the longitudinal load step i = 3 under the LC4 load case. The six stress components of point A under the LC4 load case were extracted. The specific values are as follows:

Substituting (17) into Equation (8):

Substituting (16) and (18) into Equation (11):

Substituting (19) into Equation (10):

The angle between the maximum absolute principal stress and the X-axis is 101.37°, which represents the angle between the normal direction of the principal stress and the X-axis, which is 11.37°. The principal stress direction is 90.86° to the Z-axis of the longitudinal bridge, which confirms that the diaphragm’s arc opening area is primarily under in-plane stress.

For the most unfavorable longitudinal and transverse loading, the second and third principal stress directions around the diaphragm’s arc opening are highlighted in

Figure 24a. The third principal stress is parallel to the edge tangent. Within a certain distance from the edge normal, the direction of the third principal stress still maintains the original angle. The crack is located in the red square in

Figure 24b, and the crack length have been marked in the corresponding figure. The 159 # and 160 # measuring points are located above and below the crack, respectively.

The theoretical calculation results show that the normal direction of the principal stress has an included angle with a X-axis of 11.37°. The normal direction of the third principal stress at point A is 11.1° from the horizontal plane, according to the principal stress direction field computed using the FEM calculation results. This is similar to the fatigue test’s crack propagation angle of 12.8°. As shown in

Figure 25, the change curve of the third principal stress along the X-axis of the extraction path under the most unfavorable loading is drawn with the normal direction of the third principal stress as the X-axis direction.

It can be observed from the above figures that the third principal stress changes significantly along the normal direction of the opening edge. When the distance to the extracted nominal stress is more than 6 mm, the stress value reduces linearly, and the stress concentration effect decreases obviously. This suggests that the nominal stress is significantly affected by the location of stress extraction. Fatigue assessment based on the HSS method leads to relatively conservative results. The stress value is relatively stable and does not fluctuate significantly with the location of stress extraction.

The stress responses for the stress distribution at the free edge of the opening when the longitudinal load step i = 3 are shown in

Figure 26. The curved value of the extraction path is represented by the abscissa t in

Figure 26. Because of the significant stress concentration at the opening, the origin of the abscissa is set 10 mm ahead of point A.

In all three key load cases, the free edge of the diaphragm’s arc opening is under pressure. The peak stress occurs at t = 10 mm (point A) and at the symmetrical position on the other side. The stress decreases gradually with the increase in the thickness values, and the stress near the middle of the hole is almost zero. The region near the hot spot is in a biaxial compression state. The premise of fatigue crack growth is that the region is in a “pure tension” state. It is speculated that the total stress in this area may vary from compression to tension due to the influence of initial defects and welding residual tensile stress. Eventually, the cyclic action of higher stress amplitude results in the occurrence of fatigue cracking.

The calculation results state that the fatigue crack control stress at the peak point A of the diaphragm’s arc opening stress is the principal stress with a maximum absolute value, and the stress direction is tangential to the hole edge. Although the area is primarily compressed under the load, the residual tensile stress at the connection between the U-rib and the diaphragm causes it to have similar fatigue characteristics to the weld details. The reciprocating compressive stress around the diaphragm’s arc opening can also cause fatigue cracking.