Experimental Study on Cementless PET Mortar with Marble Powder and Iron Slag as an Aggregate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.3. Specimen Preparation

2.4. Test Methods

3. Results and Discussion

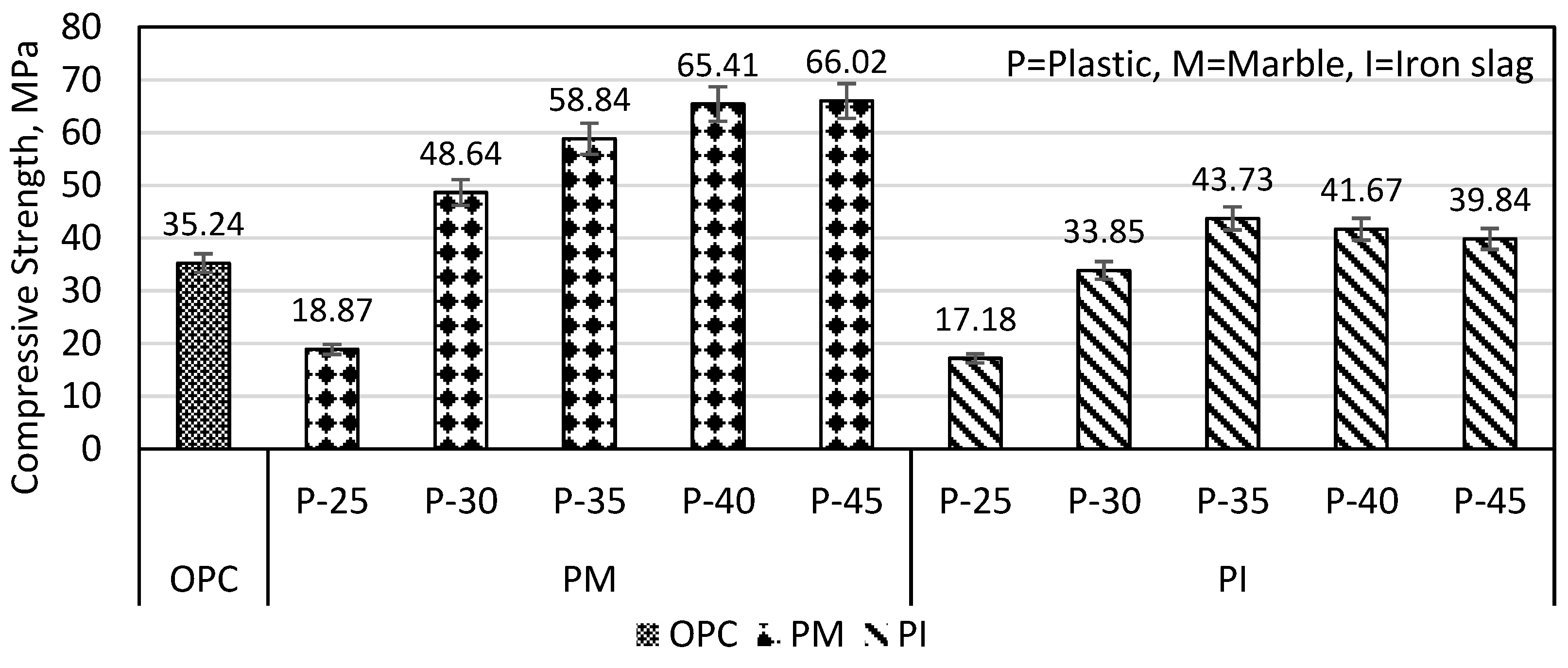

3.1. Effect of PET Content on Compressive Strength Behaviour

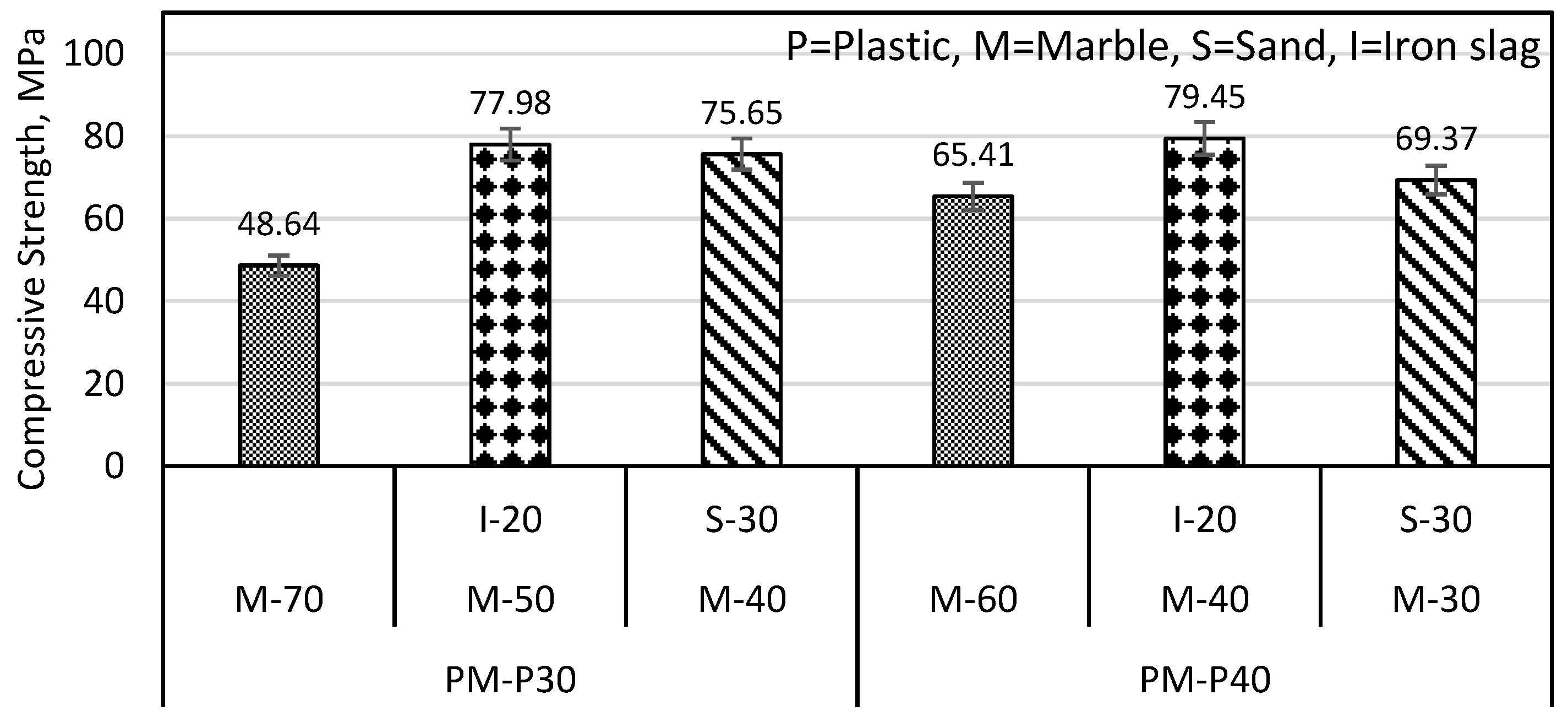

3.2. Sand, Marble, and Iron Slag Substitution Impact on PET Mortar Strength

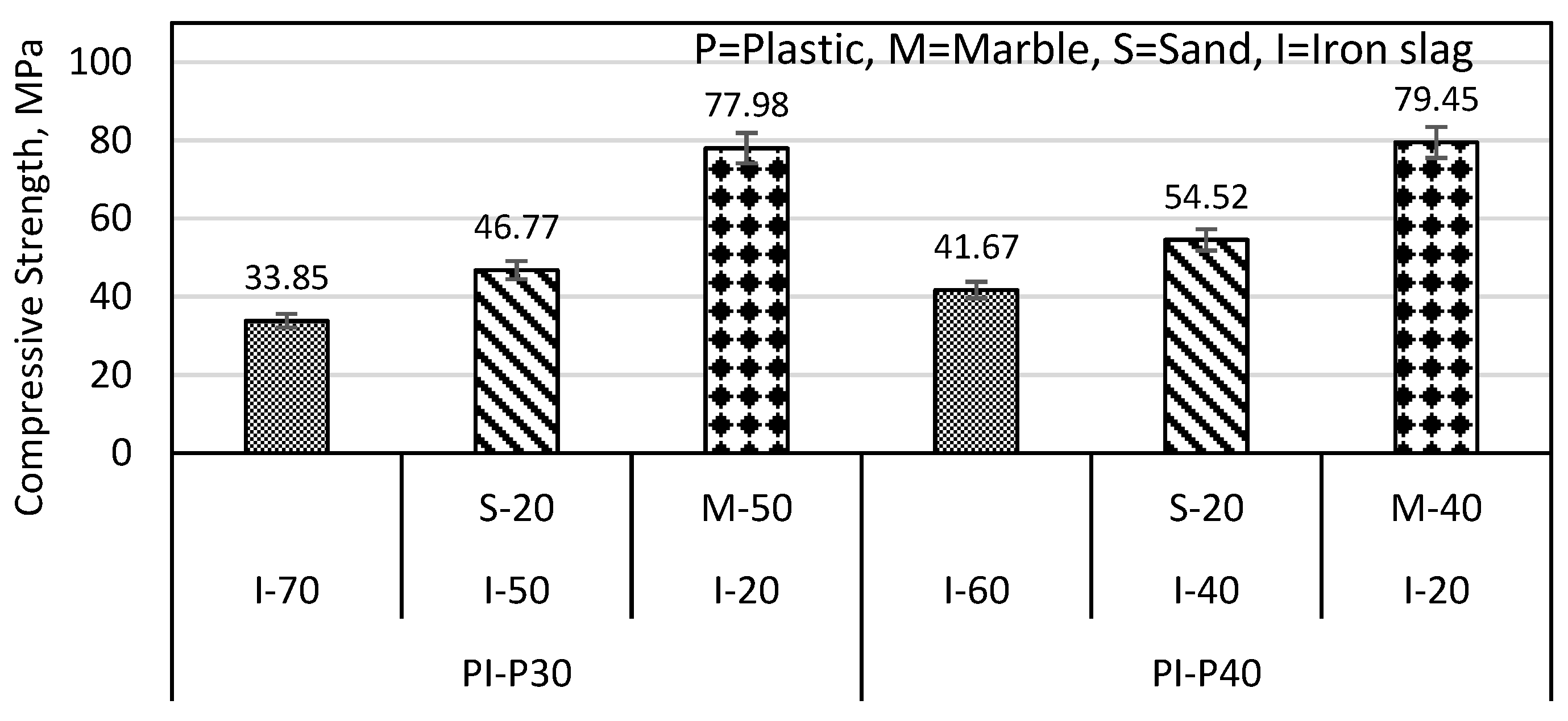

3.3. Impact of Ingredient Variation on Plastic Mortar Strength

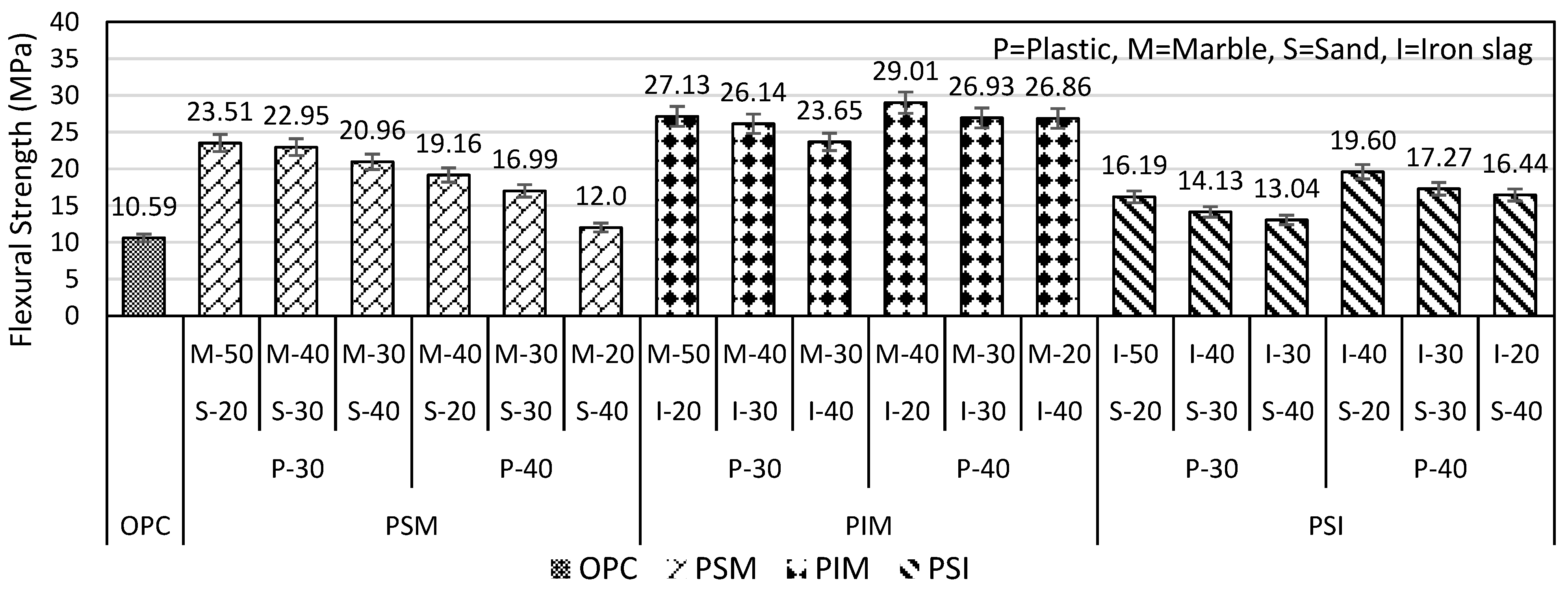

3.4. Flexural Strength of PET Mortar having Marble and Iron Slag

3.5. Effect of Sand Substitution on Flexural Response of PET Mortar

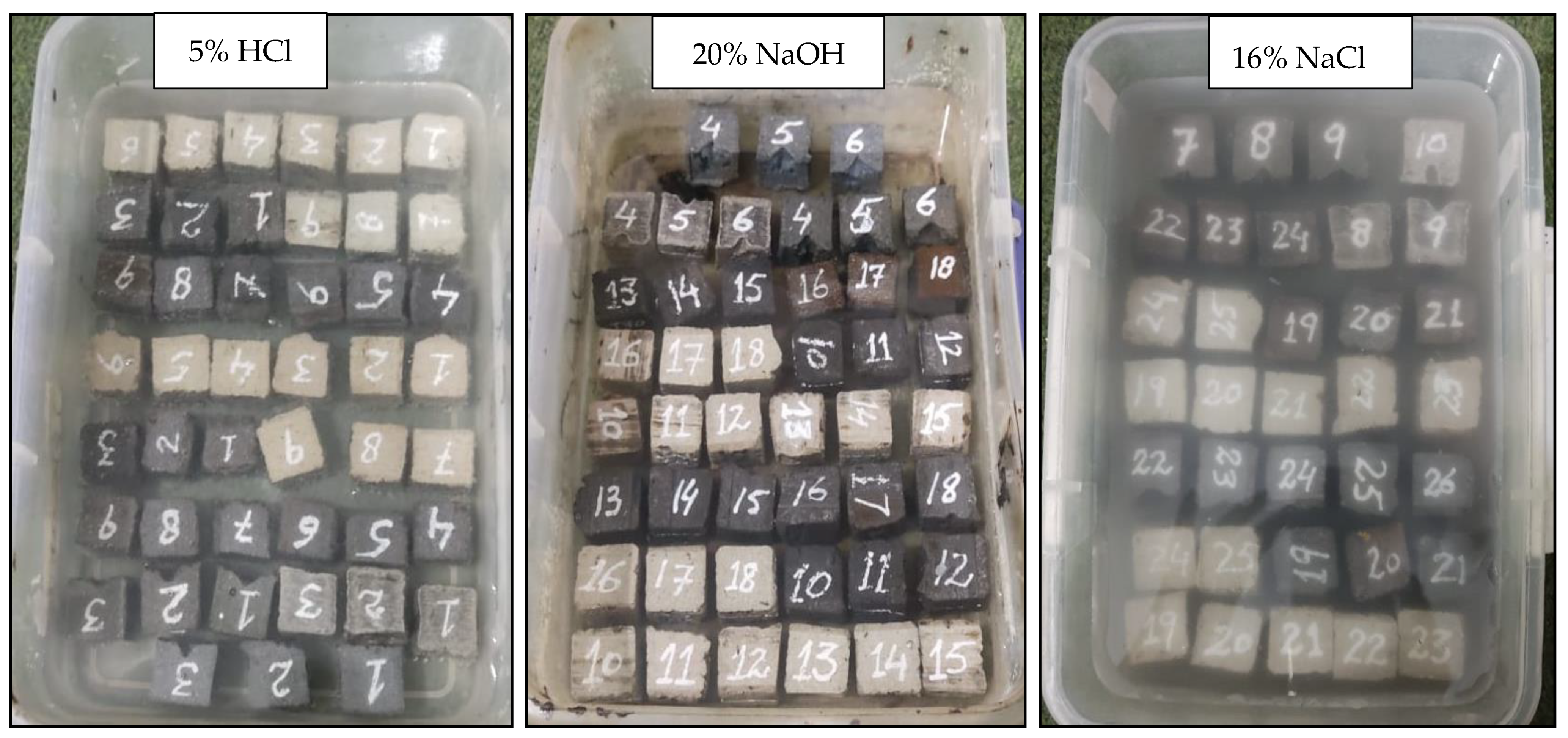

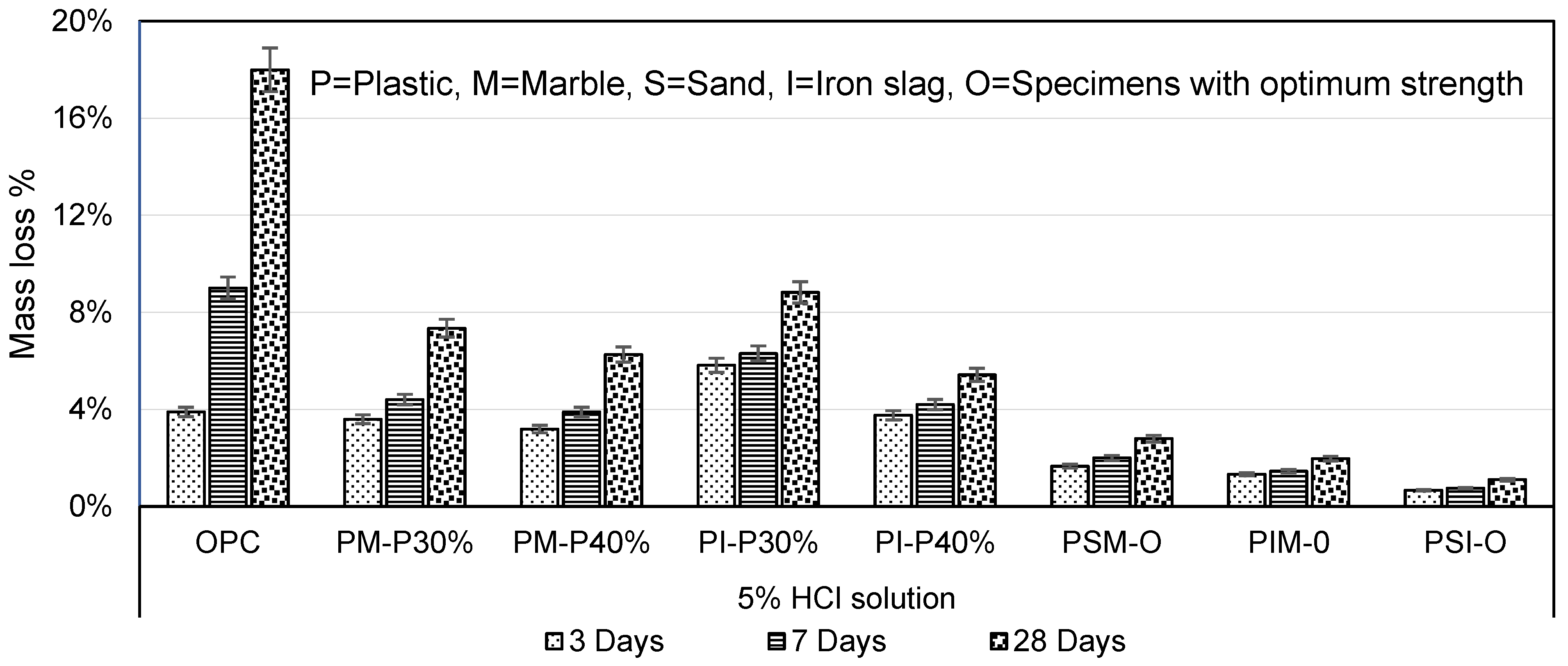

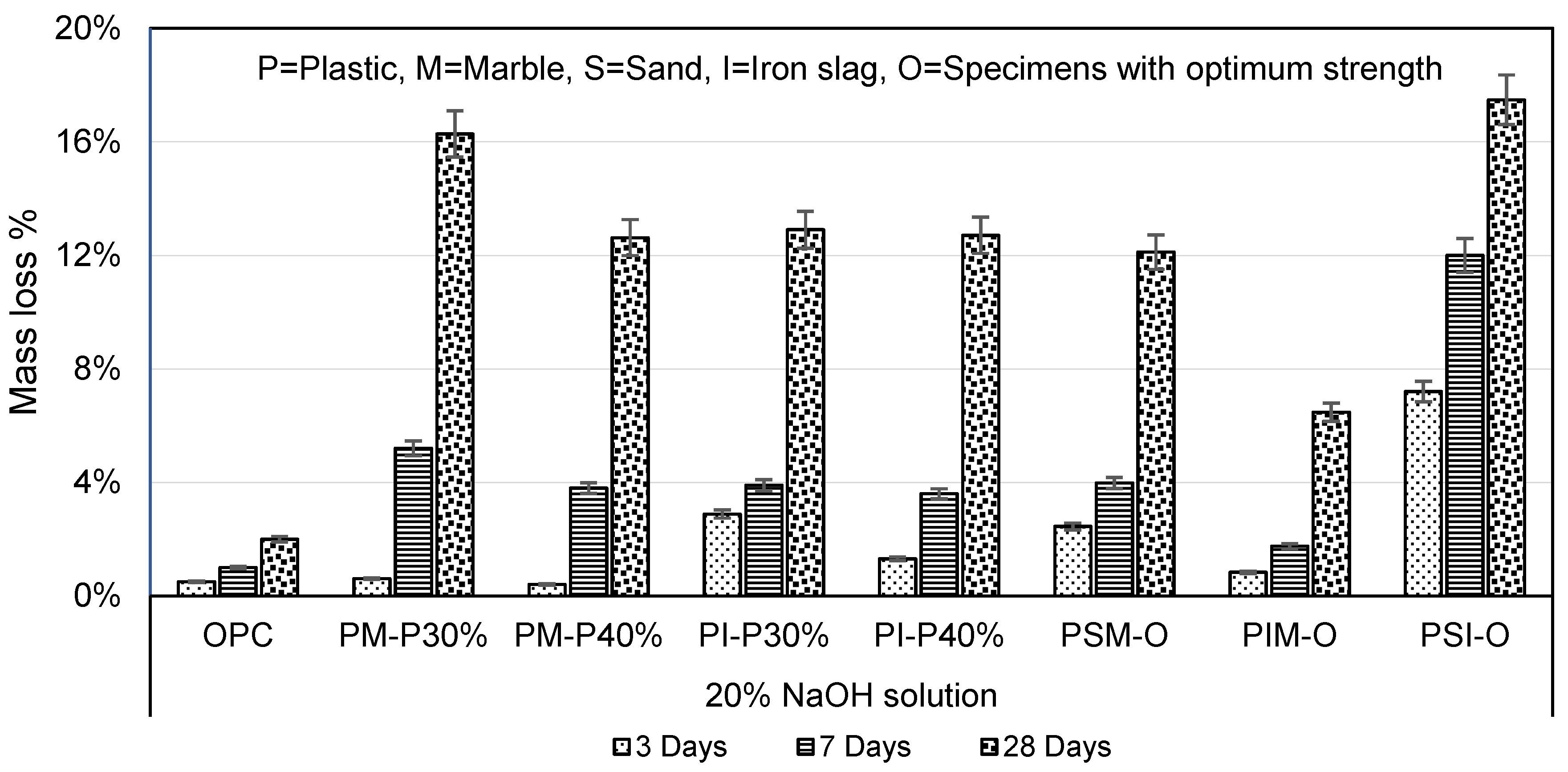

3.6. Effect of Aggressive Chemicals Environment on PET Mortar

3.6.1. Acidic Solution (5% HCl)

3.6.2. Basic Solution (20% NaOH)

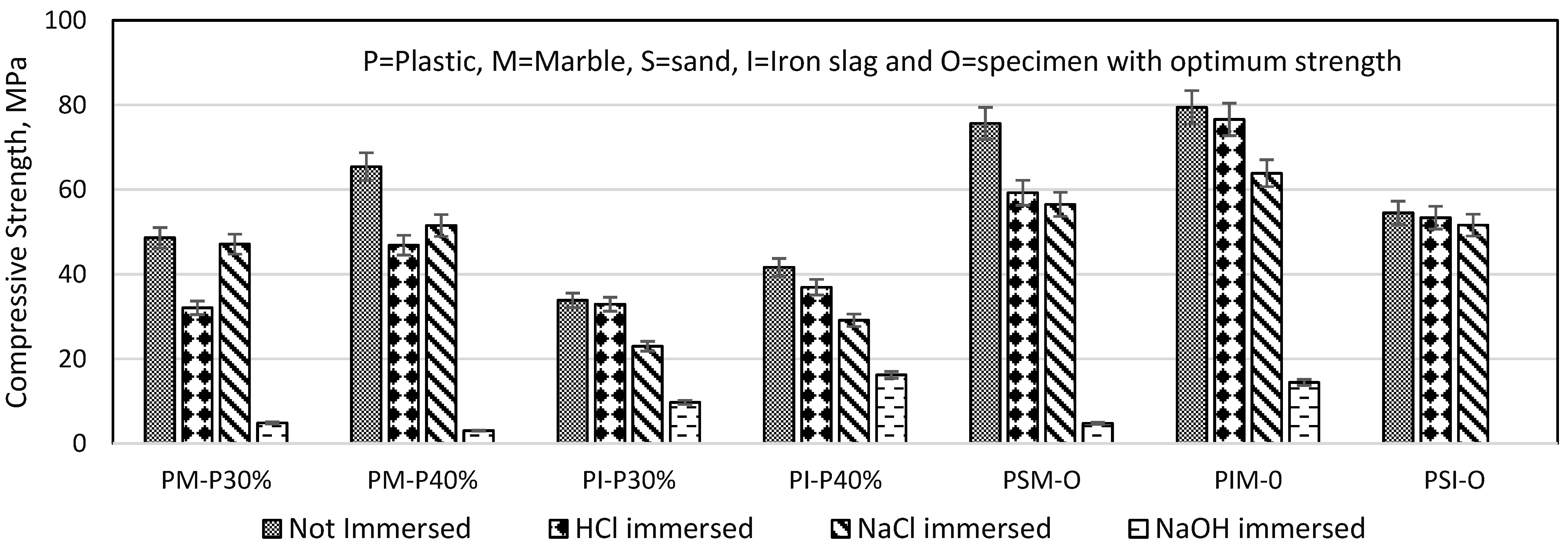

3.6.3. Saline Solution (16% NaCl)

3.7. Compressive Strength under Harsh Chemical Environment

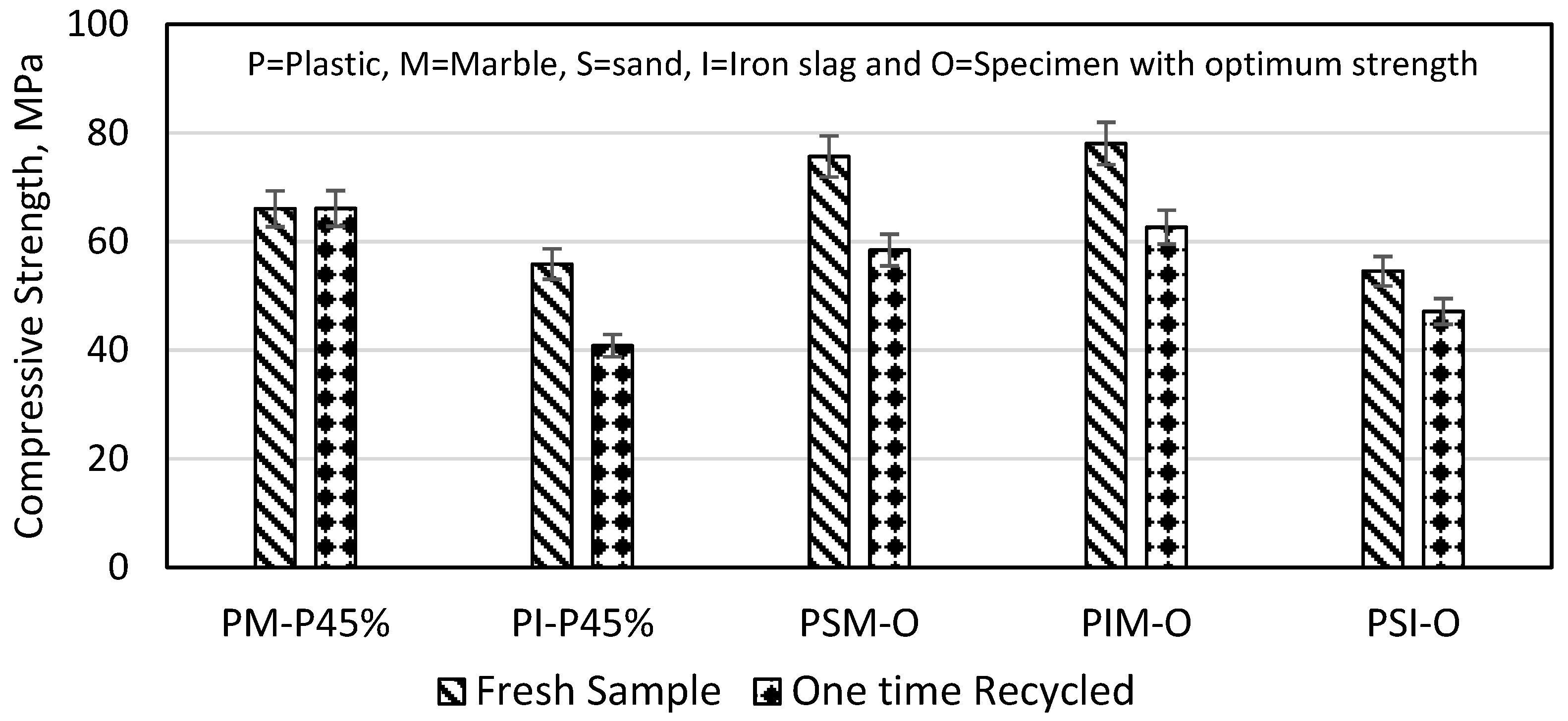

3.8. Recycling Effects on Plastic Mortar Compressive Strength

4. Conclusions

- The compressive and flexural strength of the PM specimen increased with increasing plastic content from 25 to 45%. The PI specimen’s compressive and flexural strength increased with increasing plastic content from 30 to 35% and reduced when plastic content further increased up to 45%. The optimum compressive strengths of PM, PI, PSM, PIM, and PSI specimens were 1.87, 1.24, 2.14, 2.25, and 1.54 times greater than that of the OPC mortar, respectively.

- In comparison to OPC mortar, all mixes of plastic mortar were more resistant to HCl and NaCl solution but less resistant to NaOH solution. Among different plastic mortar mixes, PIM mortar with optimum strength was relatively more resistant to NaOH and NaCl solutions. Though its mass loss in NaOH solution was still 3.23 times higher than that of the OPC mortar.

- Plastic mortar can be one-time recycled because the compressive strength degrades very negligibly after recycling. The decrease in compressive strength of one-time recycled plastic mortar containing marble was negligible, but a significant reduction in compressive strength was seen in the plastic mortar with iron slag.

- The compressive strength of plastic mortar decreased almost completely in a base solution but decreased less in an acid or saline solution. It is worth noting that PET mortar should be protected from NaOH base solution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNEP—UN Environment Programme. Available online: https://www.unep.org/ (accessed on 2 June 2023).

- NAPCOR. PET Is Not to Blame for Recycling Plant Fires—NAPCOR. 2022. Available online: https://napcor.com/blog/recycling-plant-fires/ (accessed on 5 June 2023).

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable Cement Production-Present and Future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; He, K.; Li, L.; Shen, S. Effect of Macro-, Micro- and Nano-Calcium Carbonate on Properties of Cementitious Composites—A Review. Materials 2019, 12, 781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, Z.; Zhang, X.; Ge, Z.; Jin, Z.; Han, J.; Pan, X. Mix Proportion Design and Mechanical Properties of Recycled PET Concrete. J. Test. Eval. 2015, 43, 344–352. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of Recycled Plastic in Concrete: A Review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Foti, D. Recycled Waste PET for Sustainable Fiber-Reinforced Concrete. In Use of Recycled Plastics in Eco-efficient Concrete; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar] [CrossRef]

- Jo, B.W.; Park, S.K.; Park, J.C. Mechanical Properties of Polymer Concrete Made with Recycled PET and Recycled Concrete Aggregates. Constr. Build. Mater. 2008, 22, 2281–2291. [Google Scholar] [CrossRef]

- Irwan, J.M.; Asyraf, R.M.; Othman, N.; Koh, H.B.; Annas, M.M.K.; Faisal, S.K. The Mechanical Properties of PET Fiber Reinforced Concrete from Recycled Bottle Wastes. Adv. Mater. Res. 2013, 795, 347–351. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Romero, P.; Zhang, H.; Huang, M.; Lai, F. Unsaturated Polyester Resin Concrete: A Review. Constr. Build. Mater. 2019, 228, 116709. [Google Scholar] [CrossRef]

- Vanitha, S.; Natarajan, V.; Praba, M. Utilisation of Waste Plastics as a Partial Replacement of Coarse Aggregate in Concrete Blocks. Indian J. Sci. Technol. 2015, 8, 1–6. [Google Scholar] [CrossRef]

- Faraj, R.H.; Sherwani, A.F.H.; Daraei, A. Mechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Plastic Particles. J. Build. Eng. 2019, 25, 100808. [Google Scholar] [CrossRef]

- Jain, A.; Siddique, S.; Gupta, T.; Jain, S.; Sharma, R.K.; Chaudhary, S. Fresh, Strength, Durability and Microstructural Properties of Shredded Waste Plastic Concrete. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2019, 43, 455–465. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Chung, J.S.; Cho, S.K. Effects of Waste PET Bottles Aggregate on the Properties of Concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Use of Waste Plastic in Concrete Mixture as Aggregate Replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef] [PubMed]

- Pezzi, L.; De Luca, P.; Vuono, D.; Chiappetta, F.; Nastro, A. Concrete Products with Waste’s Plastic Material (Bottle, Glass, Plate). Mater. Sci. Forum 2006, 514–516 Pt 2, 1753–1757. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of Post-Consumer Waste Plastic in Cementitious Concrete Composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Adeboje, A.O.; Kupolati, W.K.; Sadiku, E.R.; Ndambuki, J.M.; Kambole, C. Experimental Investigation of Modified Bentonite Clay-Crumb Rubber Concrete. Constr. Build. Mater. 2020, 233, 117187. [Google Scholar] [CrossRef]

- Jassim, A.K. Recycling of Polyethylene Waste to Produce Plastic Cement. Procedia Manuf. 2017, 8, 635–642. [Google Scholar] [CrossRef]

- Al-manaseer, A.A.; Dalal, T.R. Concrete Containing Plastic Aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of Coal Gangue as Coarse Aggregates in Structural Concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Kim, Y.J.; Lachemi, M. Characteristics of Mortar and Concrete Containing Fine Aggregate Manufactured from Recycled Waste Polyethylene Terephthalate Bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Singh, S.; Shukla, A.; Brown, R. Pullout Behavior of Polypropylene Fibers from Cementitious Matrix. Cem. Concr. Res. 2004, 34, 1919–1925. [Google Scholar]

- Foti, D. Use of Recycled Waste Pet Bottles Fibers for the Reinforcement of Concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Elhag, A.B.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Mahdi, F.; Abbas, H.; Khan, A.A. Strength Characteristics of Polymer Mortar and Concrete Using Different Compositions of Resins Derived from Post-Consumer PET Bottles. Constr. Build. Mater. 2010, 24, 25–36. [Google Scholar] [CrossRef]

- Thiam, M.; Fall, M.; Diarra, M.S. Mechanical Properties of a Mortar with Melted Plastic Waste as the Only Binder: Influence of Material Composition and Curing Regime, and Application in Bamako. Case Stud. Constr. Mater. 2021, 15, e00634. [Google Scholar] [CrossRef]

- Kumi-Larbi, A.; Yunana, D.; Kamsouloum, P.; Webster, M.; Wilson, D.C.; Cheeseman, C. Recycling Waste Plastics in Developing Countries: Use of Low-Density Polyethylene Water Sachets to Form Plastic Bonded Sand Blocks. Waste Manag. 2018, 80, 112–118. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, R.; Zhang, K.; Gao, Z.; Li, P. Physical and Mechanical Properties of Mortar Using Waste Polyethylene Terephthalate Bottles. Constr. Build. Mater. 2013, 44, 81–86. [Google Scholar] [CrossRef]

- Ge, Z.; Yue, H.; Sun, R. Properties of Mortar Produced with Recycled Clay Brick Aggregate and PET. Constr. Build. Mater. 2015, 93, 851–856. [Google Scholar] [CrossRef]

- Rasheed, M.F.; Rahim, A.; Irfan-ul-Hassan, M.; Ali, B.; Ali, N. Sulfur Concrete Made with Waste Marble and Slag Powders: 100% Recycled and Waterless Concrete. Environ. Sci. Pollut. Res. 2022, 29, 65655–65669. [Google Scholar] [CrossRef]

- ASTM D6913-04R2009; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2004. [CrossRef]

- ASTM D 854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/c0348-21.html (accessed on 4 July 2023).

- ASTM C349; Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure). ASTM International: West Conshohocken, PA, USA, 2018.

- Rebeiz, K.S.; Rosett, J.W.; Craft, A.P. Strength Properties of Polyester Mortar Using PET and Fly Ash Wastes. J. Energy Eng. 1996, 122, 10–20. [Google Scholar] [CrossRef]

- Shaaban, I.G.; Rizzuto, J.P.; El-nemr, A.; Bohan, L.; Ahmed, H.; Tindyebwa, H. Mechanical Properties and Air Permeability of Concrete Containing Waste Tires Extracts. J. Mater. Civ. Eng. 2021, 33, 04020472. [Google Scholar] [CrossRef]

- Noui, A.; Bouglada, M.S.; Belagraa, L.; Achour, Y.; Abderazak, B. Study of the Mechanical Behavior and Durability of Mortars Based on Prepared Sand. Min. Sci. 2020, 27, 47–59. [Google Scholar] [CrossRef]

- Humam, T.; Siddique, R. Properties of Mortar Incorporating Iron Slag. Issue 2013, 23, 53. [Google Scholar]

- Benosman, A.S.; Mouli, M.; Taibi, H.; Belbachir, M.; Senhadji, Y. Resistance of Polymer (PET)-Mortar Composites to Aggressive Solutions. Int. J. Eng. Res. Africa 2011, 5, 1–15. [Google Scholar] [CrossRef]

- Drechsler, M.; Graham, A. Geopolymers—An Innovative Materials Technology Bringing Resource Sustainability to Construction and Mining Industries An Innovative Materials Technology Bringing Resource Sustainability to Construction and Mining Industries. In Proceedings of the Institute of Quarrying Australia, 48th Conference, Adelaide, Australia, 12 October 2005. [Google Scholar] [CrossRef]

- Althoey, F. Compressive Strength Reduction of Cement Pastes Exposed to Sodium Chloride Solutions: Secondary Ettringite Formation. Constr. Build. Mater. 2021, 299, 123965. [Google Scholar] [CrossRef]

- Won, J.P.; Jang, C.I.; Lee, S.W.; Lee, S.J.; Kim, H.Y. Long-Term Performance of Recycled PET Fibre-Reinforced Cement Composites. Constr. Build. Mater. 2010, 24, 660–665. [Google Scholar] [CrossRef]

| Aggregate Type | Specific Gravity, Gs (ASTM D 854-14) [33] | Coefficient of Uniformity, Cu (ASTM D 6913) [32] | Coefficient of Curvature, Cc (ASTM D 6913) [32] |

|---|---|---|---|

| Sand | 2.71 | 2.25 | 1.046 |

| Marble Powder | 2.66 | 3.72 | 1.09 |

| Iron Slag | 3.56 | 6.06 | 1.42 |

| River Sand | Marble Powder | Iron Slag | |

|---|---|---|---|

| Element | Weight % | Weight % | Weight % |

| O | 57.53 | 45.92 | 51.31 |

| Mg | 0.38 | 0.31 | - |

| Al | 8.7 | - | 5.26 |

| Si | 20.27 | - | 4.01 |

| Na | 10.05 | - | - |

| K | 0.42 | - | 0.33 |

| Ca | 0.28 | 32.87 | 0.46 |

| Fe | 1.42 | 0.21 | 10.84 |

| C | - | 20.69 | 27.79 |

| Specimens with Two Ingredients (by Weight) | ||||

|---|---|---|---|---|

| Type of Plastic Mortar | Mixture ID | Plastic % | Iron Slag % | Marble % |

| Plastic + Marble powder | PM-P25 | 25 | - | 75 |

| PM-P30 | 30 | - | 70 | |

| PM-P35 | 35 | - | 65 | |

| PM-P40 | 40 | - | 60 | |

| PM-P45 | 45 | - | 55 | |

| Plastic + Iron slag | PI-P25 | 25 | - | 75 |

| PI-P30 | 30 | - | 70 | |

| PI-P35 | 35 | - | 65 | |

| PI-P40 | 40 | - | 60 | |

| PI-P45 | 45 | - | 55 | |

| Specimens with Three Ingredients (by Weight) | ||||

| Type of Plastic Mortar | Mixture ID | Sand % | Iron Slag % | Marble % |

| Plastic 30% + sand and marble | PSM-P30 | 20 | - | 50 |

| 30 | - | 40 | ||

| 40 | - | 30 | ||

| Plastic 40% + sand and marble | PSM-P40 | 20 | - | 40 |

| 30 | - | 30 | ||

| 40 | - | 20 | ||

| Plastic 30% + iron slag and marble | PIM-P30 | - | 20 | 50 |

| - | 30 | 40 | ||

| - | 40 | 30 | ||

| Plastic 40% + iron slag and marble | PIM-P40 | - | 20 | 40 |

| - | 30 | 30 | ||

| - | 40 | 20 | ||

| Plastic 30% + sand and iron slag | PSI-P30 | 20 | 50 | - |

| 30 | 40 | - | ||

| 40 | 30 | - | ||

| Plastic 40% + sand and iron slag | PSI-P40 | 20 | 40 | - |

| 30 | 30 | - | ||

| 40 | 20 | - | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, S.U.; Rahim, A.; Md Yusoff, N.I.; Khan, A.H.; Tabassum, S. Experimental Study on Cementless PET Mortar with Marble Powder and Iron Slag as an Aggregate. Materials 2023, 16, 5267. https://doi.org/10.3390/ma16155267

Khan SU, Rahim A, Md Yusoff NI, Khan AH, Tabassum S. Experimental Study on Cementless PET Mortar with Marble Powder and Iron Slag as an Aggregate. Materials. 2023; 16(15):5267. https://doi.org/10.3390/ma16155267

Chicago/Turabian StyleKhan, Shahid Ullah, Abdur Rahim, Nur Izzi Md Yusoff, Ammad Hassan Khan, and Saadia Tabassum. 2023. "Experimental Study on Cementless PET Mortar with Marble Powder and Iron Slag as an Aggregate" Materials 16, no. 15: 5267. https://doi.org/10.3390/ma16155267

APA StyleKhan, S. U., Rahim, A., Md Yusoff, N. I., Khan, A. H., & Tabassum, S. (2023). Experimental Study on Cementless PET Mortar with Marble Powder and Iron Slag as an Aggregate. Materials, 16(15), 5267. https://doi.org/10.3390/ma16155267