The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Panels

2.3. Characterization of the Manufactured Panels

2.4. Statistical Analysis

3. Results and Discussion

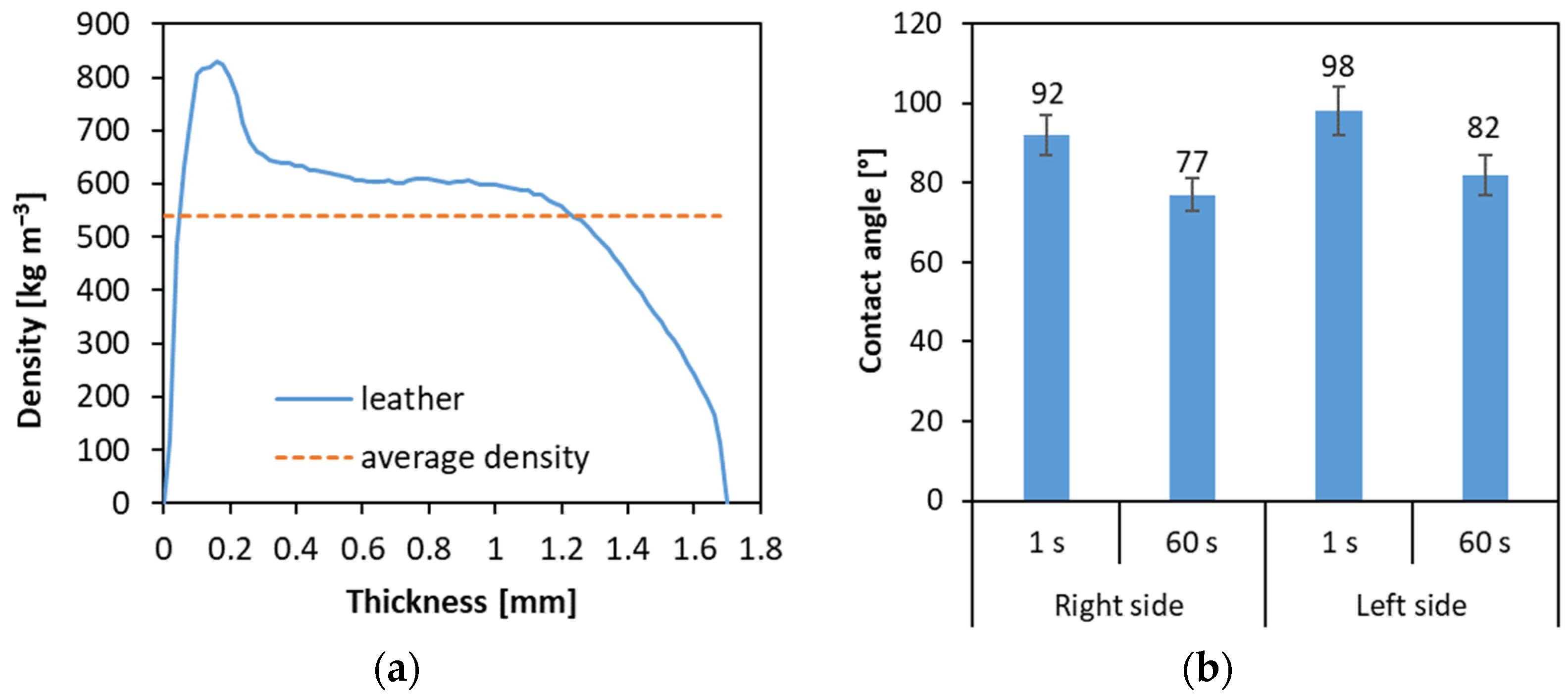

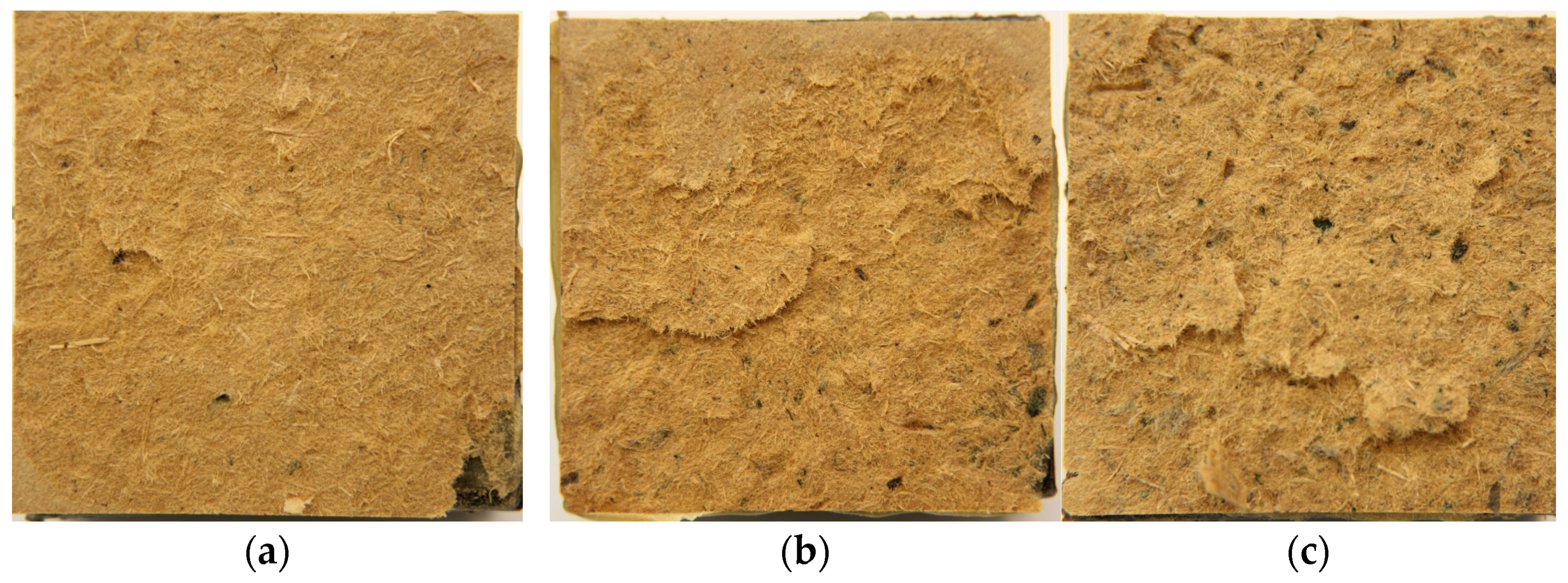

3.1. Natural Leather Raw Material Characterization

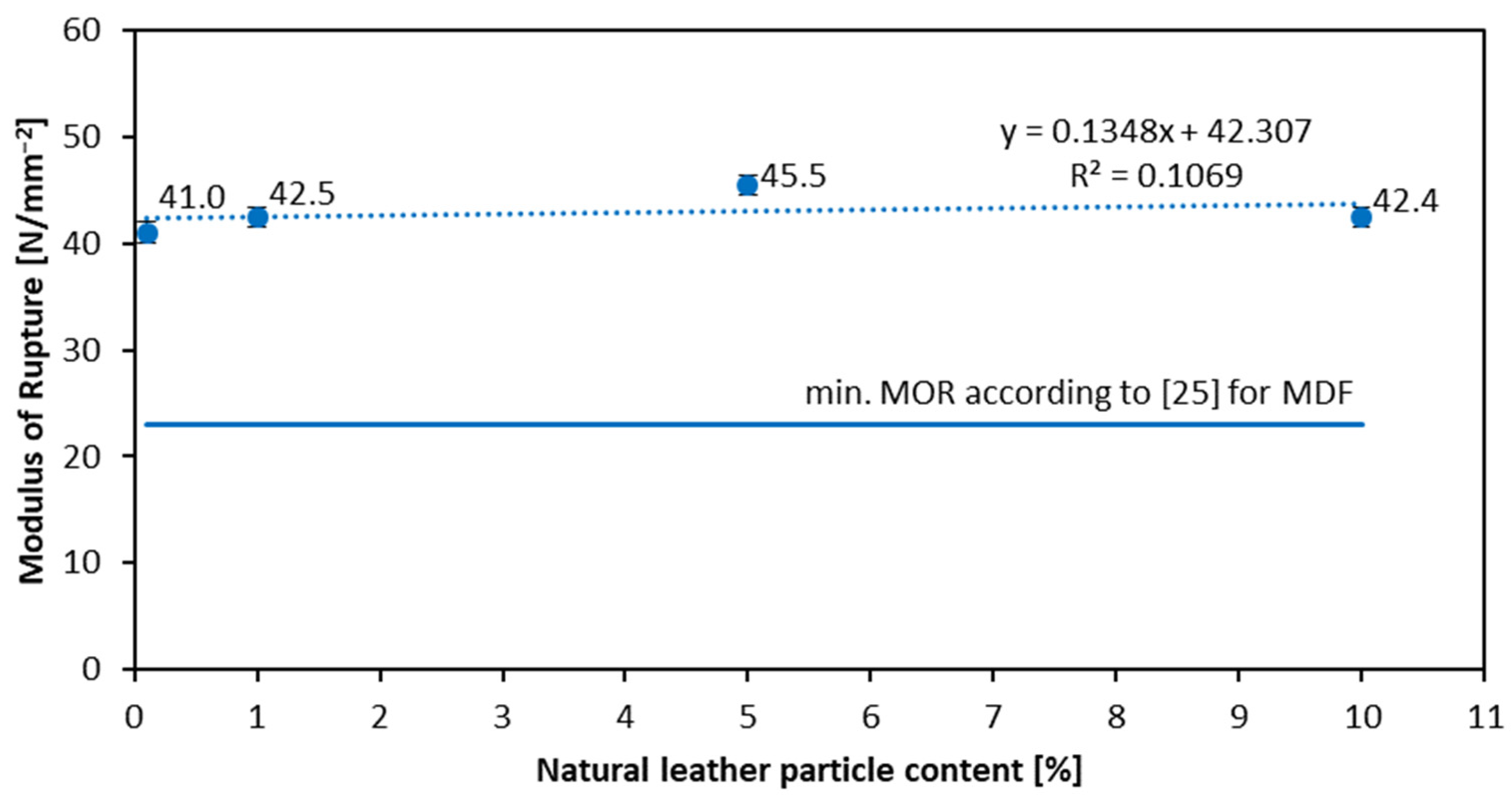

3.2. Modulus of Rupture and Modulus of Elasticity

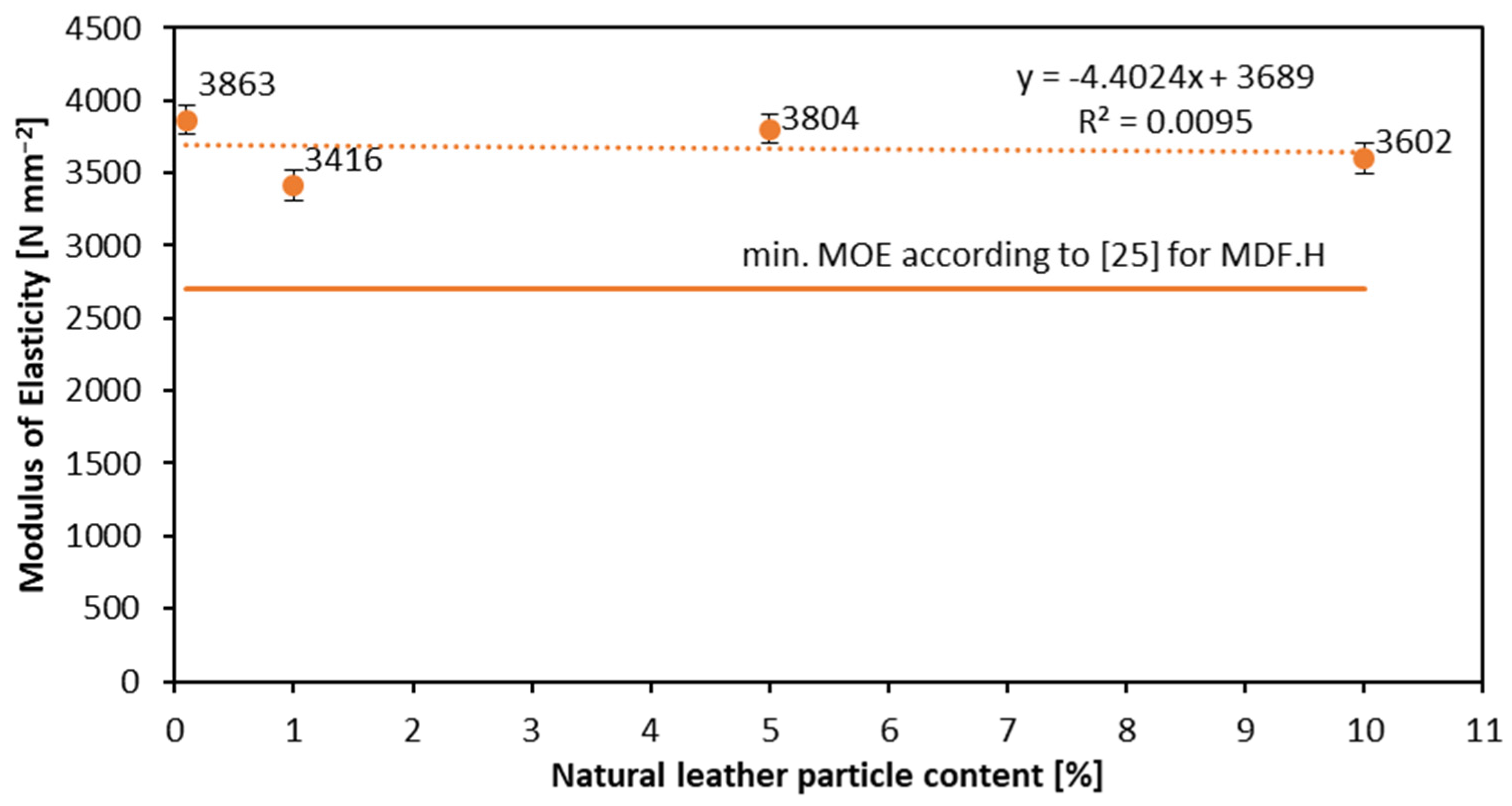

3.3. Screw Withdrawal Resistance and Internal Bonding

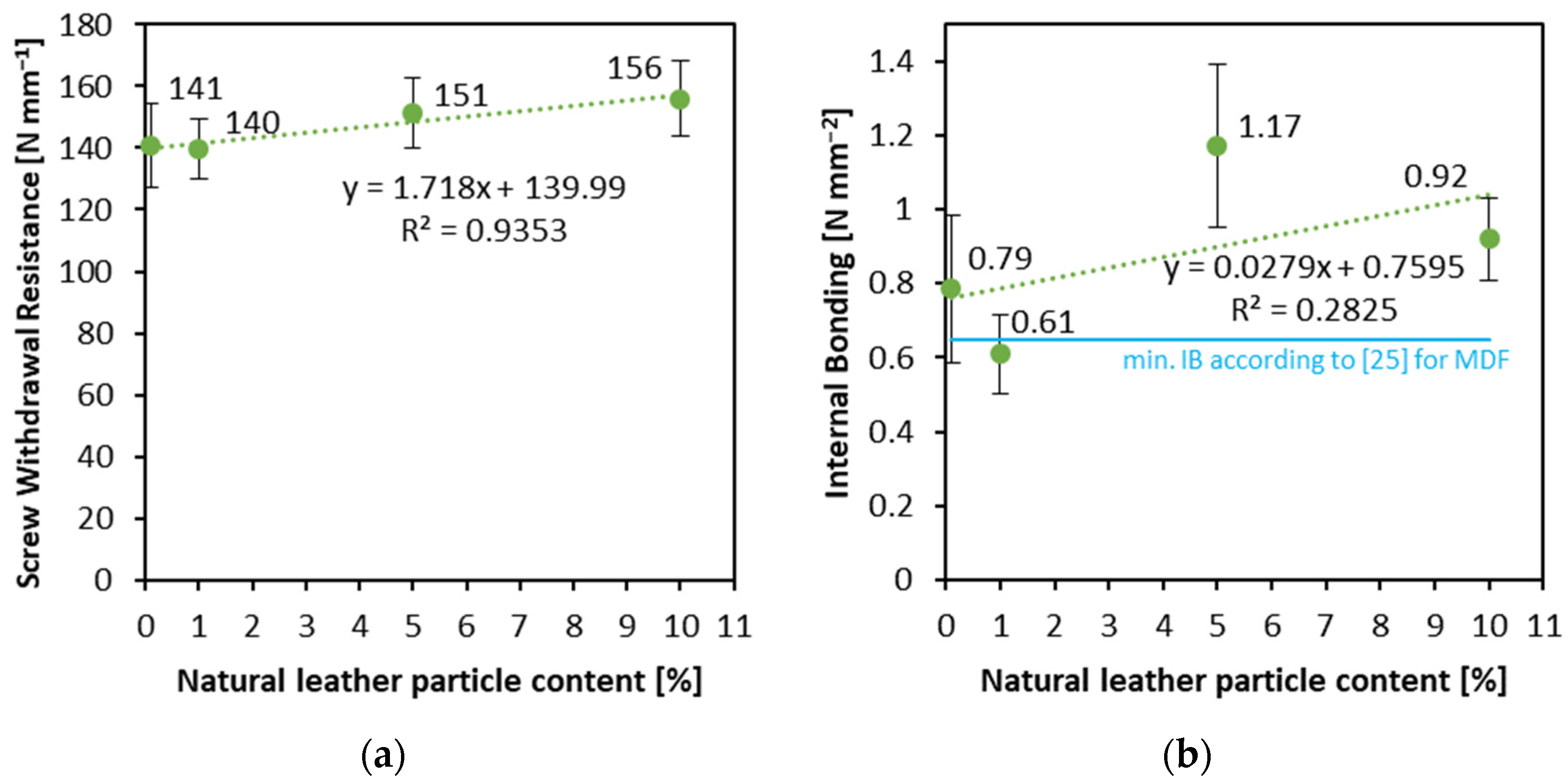

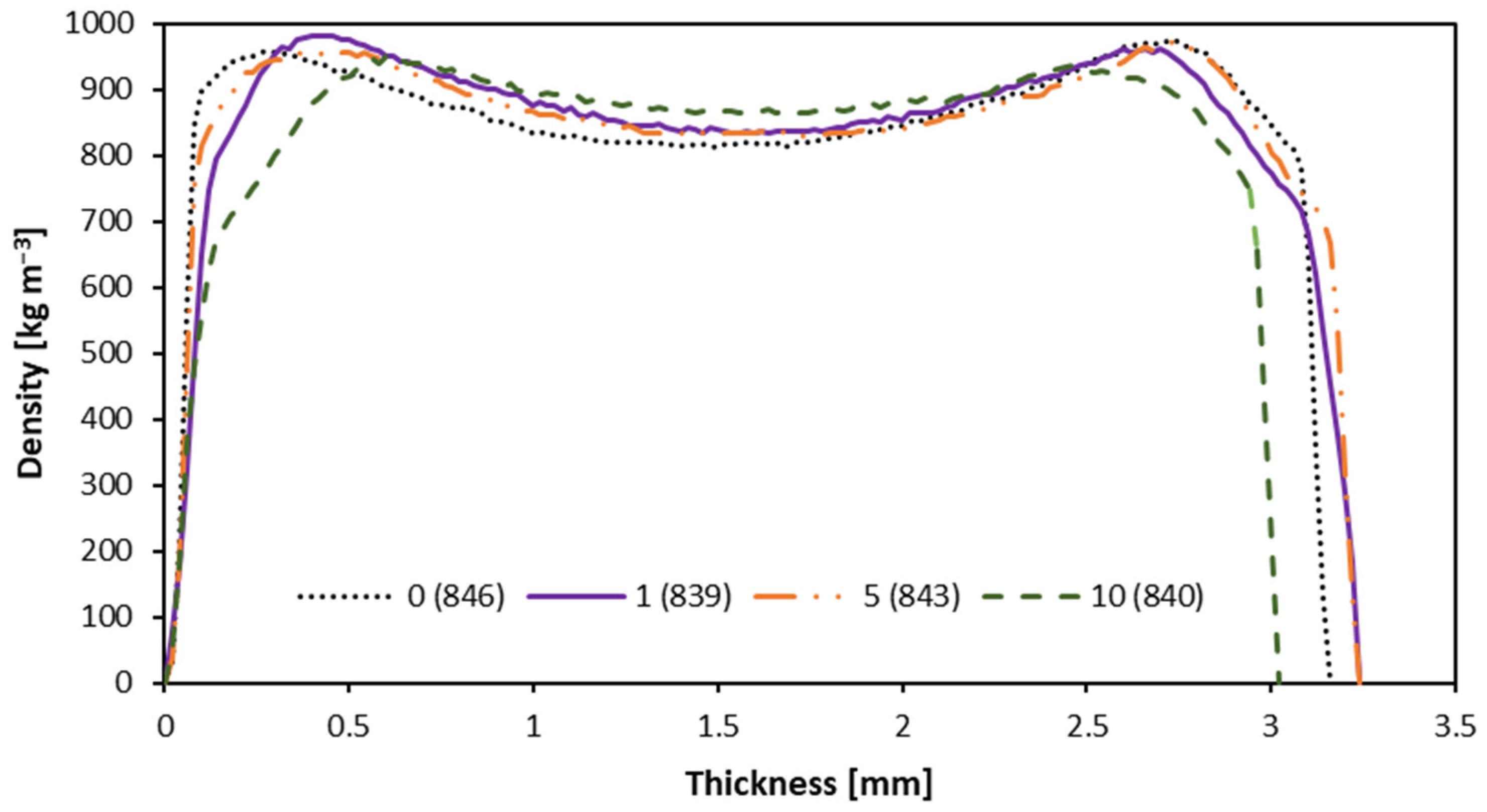

3.4. Density Profile

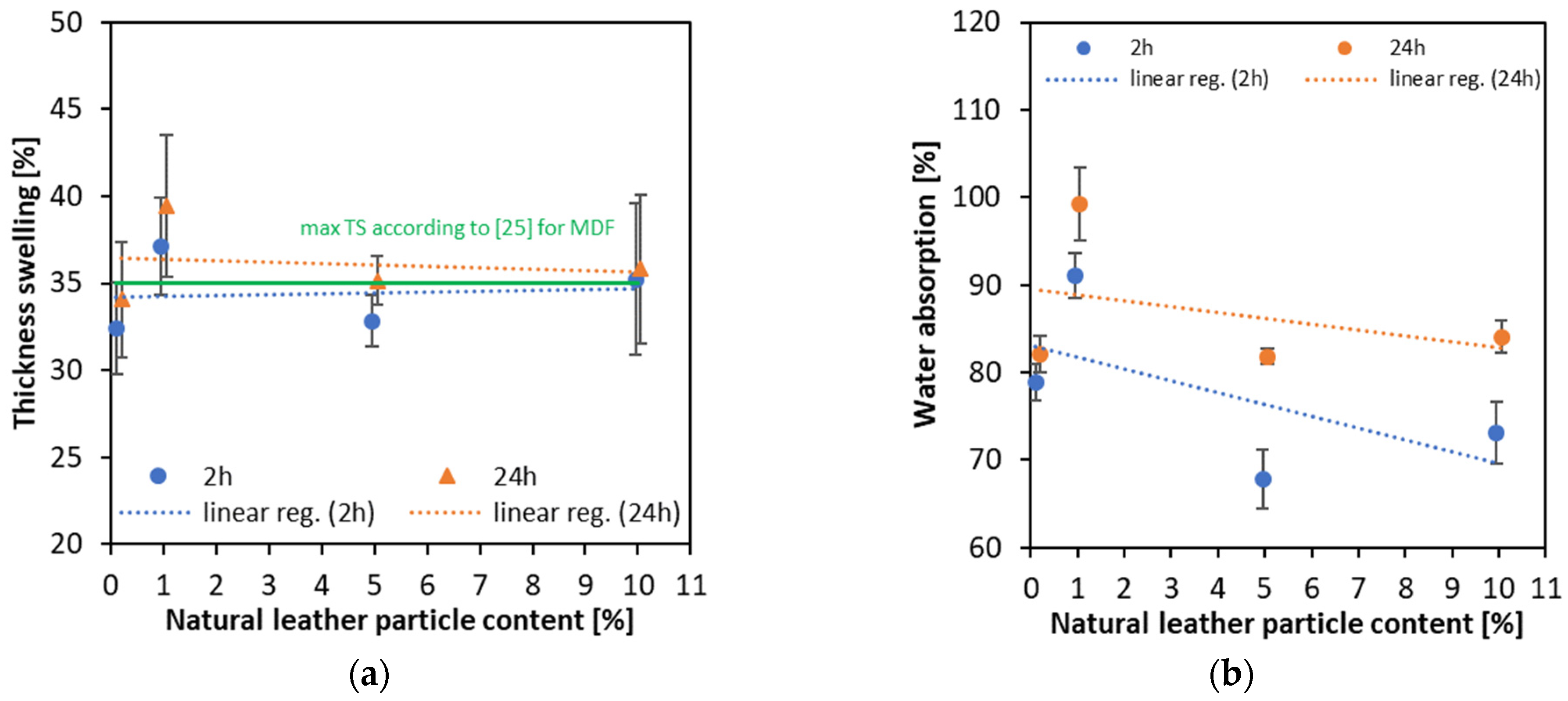

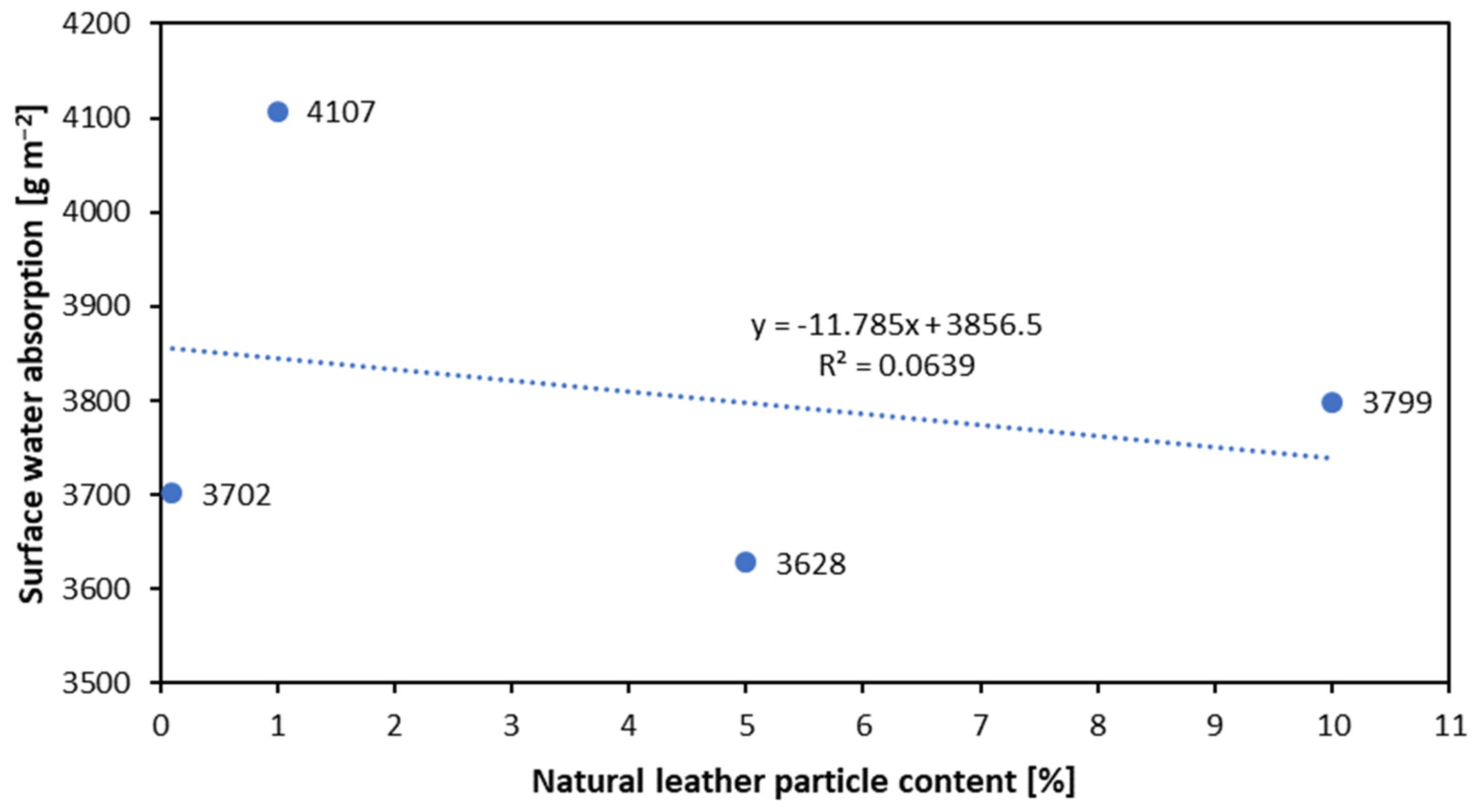

3.5. Thickness Swelling, Water Absorption and Surface Water Absorption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EN 316; Wood Fibre Boards—Definition, Classification and Symbols. European Committee for Standardization: Brussels, Belgium, 2009.

- Ratajczak, E. Zrównoważona Gospodarka Zasobami Surowca Drzewnego w Polsce. Konsumpcja Rozw. 2014, 2, 15–27. [Google Scholar]

- FAO & UNEP. The State of the World’s Forests Forests, 2020. Biodiversity and People—In Brief; FAO & UNEP: Rome, Italy, 2020. [Google Scholar]

- Suzano Paper Consumption Worldwide from 2021 to 2032. Available online: https://www.statista.com/statistics/1089078/demand-paper-globally-until-2030/ (accessed on 15 July 2023).

- Vaahtera, E. Wood Imports and the Exports Value of Forest Industry Decreased in 2022. Available online: https://www.luke.fi/en/news/wood-imports-and-the-exports-value-of-forest-industry-decreased-in-2022 (accessed on 15 July 2023).

- Czachor, G.; Bohdziewicz, J. Wpływ Komponentu Słomy Na Właściwości Mechaniczne Płyt Pilśniowych. Inżynieria Rol. Inst. Inżynierii Rol. 2010, 1, 133–138. [Google Scholar]

- Kowalska, E.; Kijeńska, M. Odpady Sztucznej Skóry i Tkanin Obiciowych. Recykling 2009, 5, 28–29. [Google Scholar]

- Orlikowska, K. 8 Wyzwań Stojących Przed Producentami Mebli Tapicerowanych w Polsce. Available online: https://gpd24.pl/wiadomosci/8-wyzwan-stojacych-przed-producentami-mebli-tapicerowanych-w-polsce/ (accessed on 10 July 2023).

- Rindler, A.; Solt, P.; Barbu, M. Comparison between HB and HDF Made from Waste Leather. For. Prod. J. 2015, 65, S39–S47. [Google Scholar]

- Nemli, G.; Odabaş-Serin, Z.; Özdemir, F.; Ayrılmış, N. Potential Use of Textile Dust in the Middle Layer of Three-Layered Particleboards as an Eco-Friendly Solution. BioResources 2019, 14, 120–127. [Google Scholar] [CrossRef]

- Hemati, S.; Udayakumar, S.; Wesley, C.; Biswal, S.; Nur-A-Tomal, M.S.; Sarmadi, N.; Pahlevani, F.; Sahajwalla, V. Thermal Transformation of Secondary Resources of Carbon-Rich Wastes into Valuable Industrial Applications. J. Compos. Sci. 2023, 7, 8. [Google Scholar] [CrossRef]

- Suchorab, B.; Wronka, A.; Kowaluk, G. Towards circular economy by valorization of waste upholstery textile fibers in fibrous wood-based composites production. Eur. J. Wood Wood Prod. 2023, 81, 571–577. [Google Scholar] [CrossRef]

- Rácz, I.; Kátoli, G.; Alpar, T.; Fáczán, T. MDF/HDF Production from Plantation Wood Species. Drv. Ind. 2010, 61, 183–191. [Google Scholar]

- Stefan, D.S.; Bosomoiu, M.; Constantinescu, R.R.; Ignat, M. Composite Polymers from Leather Waste to Produce Smart Fertilizers. Polymers 2021, 13, 4351. [Google Scholar] [CrossRef]

- Pu, H.; Shu, C.; Dai, R.; Chen, H.; Shan, Z. Mechanical, thermal and acoustical characteristics of composite board kneaded by leather fiber and semi-liquefied bamboo. Constr. Build. Mater. 2022, 340, 127702. [Google Scholar] [CrossRef]

- Kowaluk, G. Properties of Lignocellulosic Composites Containing Regenerated Cellulose Fibers. Bioresources 2014, 9, 5339–5348. [Google Scholar] [CrossRef] [Green Version]

- Taghiyari, H.R.; Majidi, R.; Esmailpour, A.; Samadi, Y.S.; Jahangiri, A.; Papadopoulos, A.N. Engineering Composites Made from Wood and Chicken Feather Bonded with UF Resin Fortified with Wollastonite: A Novel Approach. Polymers 2020, 12, 857. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- EN 827; Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 323; Wood-Based Panels—Determination of Density. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 320; Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screws. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317; Particleboards and Fiberboards—Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 622-5; Fiberboards. Specifications. Requirements for Dry Process Boards (MDF). European Committee for Standardization: Brussels, Belgium, 2009.

- Krzysik, F. Nauka o Drewnie; Państwowe Wydawnictwo Naukowe: Warszawa, Poland, 1975. [Google Scholar]

- Yu, Q.; Pan, X.; Yang, Z.; Zhang, L.; Cao, J. Effects of the Surface Roughness of Six Wood Species for Furniture Production on the Wettability and Bonding Quality of Coating. Forests 2023, 14, 996. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Krišťák, Ľ.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef] [PubMed]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, L.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef]

- Sala, C.M.; Robles, E.; Kowaluk, G. Influence of the Addition of Spruce Fibers to Industrial-Type High-Density Fiberboards Produced with Recycled Fibers. Waste Biomass- Valorization 2021, 12, 4033–4042. [Google Scholar] [CrossRef]

- Henke, M.; Lis, B.; Krystofiak, T. Evaluation of Surface Roughness Parameters of HDF for Finishing under Industrial Conditions. Materials 2022, 15, 6359. [Google Scholar] [CrossRef] [PubMed]

- Sala, C.M.; Kowaluk, G. An impact of surface spray and pressing temperature on the properties of high density fibreboards. Ann. WULS, For. Wood Technol. 2020, 112, 36–53. [Google Scholar] [CrossRef]

| Panel Code | Natura Leather Particle Content in the Panel [%] 1,2 | Face Layers Wood Fiber Content [g] | Core Layer Leather Particle/Wood Fiber Content [g] | Resination [%] |

|---|---|---|---|---|

| 0% 1/reference | 0 | 72.2 | 0.0/153.4 | 12 |

| 1% | 1 | 72.2 | 2.3/151.2 | 12 |

| 5% | 5 | 72.2 | 11.3/142.1 | 12 |

| 10% | 10 | 72.2 | 22.6/130.9 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartoszuk, K.; Kowaluk, G. The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards. Materials 2023, 16, 5340. https://doi.org/10.3390/ma16155340

Bartoszuk K, Kowaluk G. The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards. Materials. 2023; 16(15):5340. https://doi.org/10.3390/ma16155340

Chicago/Turabian StyleBartoszuk, Katarzyna, and Grzegorz Kowaluk. 2023. "The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards" Materials 16, no. 15: 5340. https://doi.org/10.3390/ma16155340

APA StyleBartoszuk, K., & Kowaluk, G. (2023). The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards. Materials, 16(15), 5340. https://doi.org/10.3390/ma16155340