1. Introduction

Today, worldwide, but especially in the highly and medium-developed countries, there is a change in the lifestyle of the population. On one hand, more and more activities are taking place inside buildings and, on the other hand, there is a growing awareness of the need for sustainable use of natural resources, reduced energy consumption and reduced environmental impact [

1]. In this context, there is a strong orientation towards identifying new possibilities and developing new, more efficient, user-friendly and eco-friendly building materials. Various development possibilities are also being explored in the area of materials for thermal insulation of buildings, especially as the disadvantages of one of the most widely used thermal insulation materials, expanded or extruded polystyrene, are now well-known. Although it is relatively cheap, easily accessible and performs well in terms of thermal insulation, it is characterised by very low biodegradability; dangerous behaviour in the event of fire, forming burning droplets and releasing a lot of smoke; and a negative impact on indoor air quality by reducing the air and water vapour permeability of walls. In other words, it no longer allows the walls to “breathe” and leads to a “sealing” of the indoor environment, a reduction in the degree of ventilation, thus contributing to the creation of favourable conditions for the appearance and growth of mould, algae, lichens or other films of micro-organisms on the surface of the building [

2,

3]. This leads to a reduction in the quality of the air in the inhabited space and thus to health consequences for the population.

The literature highlights the overall negative impact on the health of users through the term “sick building syndrome (SBS)”, which is the negative manifestation of the population working, partially or totally, inside buildings affected by microorganism deposits, due to the degradation of indoor air quality through contamination with spores and toxins [

1,

4,

5,

6]. The most common mycotoxins identified in indoor air and the bodies of the population living in the contaminated environment are produced by moulds such as

Cladosporium,

Acremonium,

Alternaria,

Periconia,

Curvularia,

Rhizopus,

Mucor,

Streptomyces,

Penicillium,

Aspergillus,

Stachybotrys,

Fusarium, and

Myrothecium [

7,

8,

9,

10], known to be genotoxic, immunotoxic, hepatotoxic, mutagenic; and potentially carcinogenic mycotoxins are ochratoxin [

7] (OCT), aflatoxin B1 [

9] and trichothecene [

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19].

The thermo-physical characteristics of thermal insulation materials used in the building industry include properties such as thermal conductivity, specific heat capacity, density and thermal diffusivity. These characteristics specify the efficiency of a material in terms of its ability to absorb, transfer and retain heat. Collectively, these properties contribute to a building’s energy efficiency and ability to maintain a comfortable indoor temperature, thereby reducing the need for artificial heating or cooling. The literature points to the possibility of developing materials for the thermal insulation of buildings which, in addition to their specific performance, offer some advantages in terms of opening up new opportunities for implementing the concept of the Circular Economy. However, these “alternative” insulating materials, as of 2017, only accounted for 13% of the market, and mostly comprise non-woven, fibre mattresses made from recycled plastics (the most common being polyethylene terephthalate (PET), polypropylene (PP) and polyvinyl chloride (PVC)); fibres from recycled industrial textile waste, animal or vegetable fibres (sheep wool, flax and hemp fibres, cotton wool); and/or other waste, including cellulosic waste from agricultural or industrial waste [

20,

21,

22,

23,

24]. Of these, insulation materials made from agricultural raw materials, also called “bio-based insulation material”, accounted for only 6% (2012), 8% (2017) and 10% (2020) of the insulation materials market, with expectations encouraged by EU policies of 13% in 2030, of which 40–50% should be based on wood and other cellulosic materials [

24]. At present, most reports in the literature focus on the methods of making such thermal insulation materials and their physical, mechanical and thermal efficiency performance, fewer on durability and very few on the impact on indoor air quality [

24].

Depending on their nature, insulating materials are characterised by a thermal conductivity coefficient, λ, with values ranging from 0.024–0.07 W/mK [

20]. The thermal performance of insulation made of homogeneous materials, simple or combined, is usually evaluated by the following parameters: thermal conductivity, thermal transmittance, thermal diffusivity and specific heat [

25]. For the most commonly used thermal insulation materials, the current thermal conductivity coefficient range is between 0.030–0.040 W/mK for expanded polystyrene and mineral wool, 0.020–0.030 W/mK for polyurethane-based thermal insulation and 0.033–0.044 W/mK for glass fibre-based insulation [

26].

Hadded et al. [

23] studied recycled textiles in terms of thermo-physical characteristics (thermal conductivity and thermal diffusivity). Danihelová et al. [

27] conducted a study on the performance of recycled technical textiles showing that, in line with other reports [

28], mattresses made of recycled waste fibres of a vegetable or animal nature can be good thermal insulators, characterised by a thermal conductivity coefficient around 0.033 W/mK. The results of their research have shown that recycled textiles have competitive thermal properties and can be used as an alternative to the “classic” building insulation materials (extruded polystyrene or mineral wool). Thus, the thermal conductivity of these insulating materials increases with increasing temperature, identifying, for example, a thermal conductivity coefficient, λ, for recycled denim insulation that varies in the range 0.032 ÷ 0.036 W/mK in the temperature range 10 °C ÷ −30 °C and decreases with increasing density. In the same context, Valverde et al. [

29] analysed the influence of the density of the thermal insulation product made by recycling textile waste on the thermal conductivity coefficient, indicating a non-linear variation, with the highlighting of a density range for which the thermal insulation performance is superior. Patnaik and Mvubua [

30] created panels from layers of unspun wool, (coring wool (CW)—15 mm thick and 66.66 kg/m

3 and dorper wool (DW)—17 mm thick and 58.82 km/m

3), reinforced by interlacing. From the point of view of thermal conductivity, the recorded values indicate that an increase in temperature leads to an increase in thermal conductivity from 0.030 W/mK (at −5 °C) to 0.034 W/mK (at 35 °C)—for the CW sample and from 0.031 W/mK (at −5 °C) to 0.034 W/mK (at 35 °C)—for the DW sample. Zeinab et al. [

28] analysed heat transfer through different types of non-woven fabrics. They studied the dependence of thermal conductivity on the thickness and density of polyester and polypropylene fibre insulation boards and concluded that, based on the measured value of thermal conductivity (approx. 0.033 W/mK), the non-woven materials analysed were suitable for use as thermal insulation material. A collective at the Brno University of Technology, Czech Republic [

31] analysed the behaviour of thermal insulation boards made of recycled polypropylene R-PP and 5–20% bi-component polyvinyl chloride PVC fibres. It was concluded that in this case the thermal conductivity coefficient, λ, increases with increasing test temperature, temperature difference and density, and a product density of min. 150 kg/m

3 provides sufficient physico-mechanical performance to allow in-situ vertical handling and positioning of the thermal insulation boards. Patnaik et al. [

30] developed and analysed a proposal for a non-woven thermal insulation material based on 50% wool and 50% recycled R-PP fibres, which showed good thermal insulation performance and biological resistance.

Over time, a number of criteria have been established to assess the quality of one insulating material against another. In addition to thermal insulation performance, aspects such as impact on human health from production to end-of-life, dust or fibre emissions, biopersistence, operational safety, environmental impact, fire performance, fire toxicity, affordability in terms of price and purchase, durability and use are now being analysed. Although the development of innovative thermal insulation materials based on recycled waste would apparently solve many problems, the most important of which is the further implementation of the concept of the Circular Economy, while at the same time reducing energy consumption for indoor comfort and reducing environmental impact, a number of other challenges and difficulties arise. Thus, most of these materials, especially those developed by recovering agro-industrial wastes or by-products, are highly sensitive to water and water vapour. At the same time, because of their structure—they are often made in the form of non-woven or loose material (which requires supporting structures when put into operation)—they have a low stability of shape and dimensions. This type of material frequently weighs under its own weight, mechanical strengths are low; therefore, it is also sensitive in terms of thermal insulation performance (this is also influenced by dimensional and density aspects) [

32]. Consequently, they are often conditioned by their location inside buildings, unlike the most commonly used thermal insulation materials such as expanded/extruded polystyrene or mineral wool.

Therefore, with both advantages and disadvantages, innovative thermal insulation materials, developed by recycling waste or industrial by-products, represent an area of interest with potential for exploitation, but which requires further research.

In terms of the possibilities for recycling cellulosic waste into thermal insulation materials, the advantage of these materials is that, as they are often in bulk, they can be used to insulate areas that are difficult to access for the application of other forms of insulation material (boards, panels, etc.) [

32]. However, these cellulosic waste insulations, in addition to their sensitivity to water, have a very low resistance to fire, which makes it necessary to identify methods of improvement, some of which use the properties of aerogel-based composites [

26]. Other studies have shown that the thermal conductivity of cellulose thermal insulation is influenced by moisture content during use, with thermal conductivity increasing with increasing moisture content. The percentage increase in thermal conductivity is higher than the increase in humidity [

32]. Vejelis et al. estimate that a 1% increase in the adsorbed hygroscopic moisture content induces a 1.25–1.5%, or even 2%, increase in the λ [

33,

34]. As cellulose fibres are dried, their strength increases and porosity decreases, which also influences thermal insulation performance [

35,

36,

37].

Research by Talukdar et al. [

38] showed that the thermal conductivity coefficient, measured for a temperature range between 10 °C and 30 °C at an average temperature value of 22.5 °C, varies according to a polynomial function with respect to moisture content (Ø), as shown in Equation (1):

where a, b, c and d are coefficients determined experimentally with the following values: a = 0.092482655, b = 0.15480621, c = 0.066517733, d = 0.1296168.

In the same trend, Sandberg [

39] analysed the variation in the thermal conductivity coefficient as a function of the water absorption of the thermal insulation material, identifying a linear equation of the form:

where w is the amount of water absorbed per unit volume of cellulose, kg/m

3.

In cellulosic material, water can exist in three different ways: non-freezing bound water, present in the large pores and between the fibres; non-freezing bound water, present in the mycopores of the fibre; and bound water in the hemicellulose. Experimental research has shown that capillary water tends to be lost faster than absorbed water, which induces the advantage that such materials contribute to the regulation of indoor air humidity, i.e., in low humidity conditions, they can release water; and in high humidity conditions, they can retain it [

40]. However, there is a risk that under conditions of high humidity for a relatively long period, especially in cold climates, the cellulosic material may form an environment favourable to the growth of mould, which makes antifungal treatment necessary [

34]. The most common antifungal treatments, which also have a role in increasing fire resistance, were those based on borax, boric acid, aluminium sulphate or ammonium sulphate, most commonly applied by wet spraying [

41,

42]. However, it is now known that these treatments have limited durability, may impact on human health and are not environmentally friendly; therefore, more effective methods are being sought that are resistant to accidental water infiltration and have low environmental impact and that comply with the EU Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation to avoid threatening human health and the environment.

From the information presented, we can identify, on one hand, the interest that the potential for revalorization of waste and industrial by-products holds in the investigation of possibilities for creating eco-innovative insulation materials. On the other hand, a series of difficulties arise due to the high degree of diversity in the type and quality of the raw material, leading to notable variations in the performance of the eco-innovative product intended for thermal insulation.

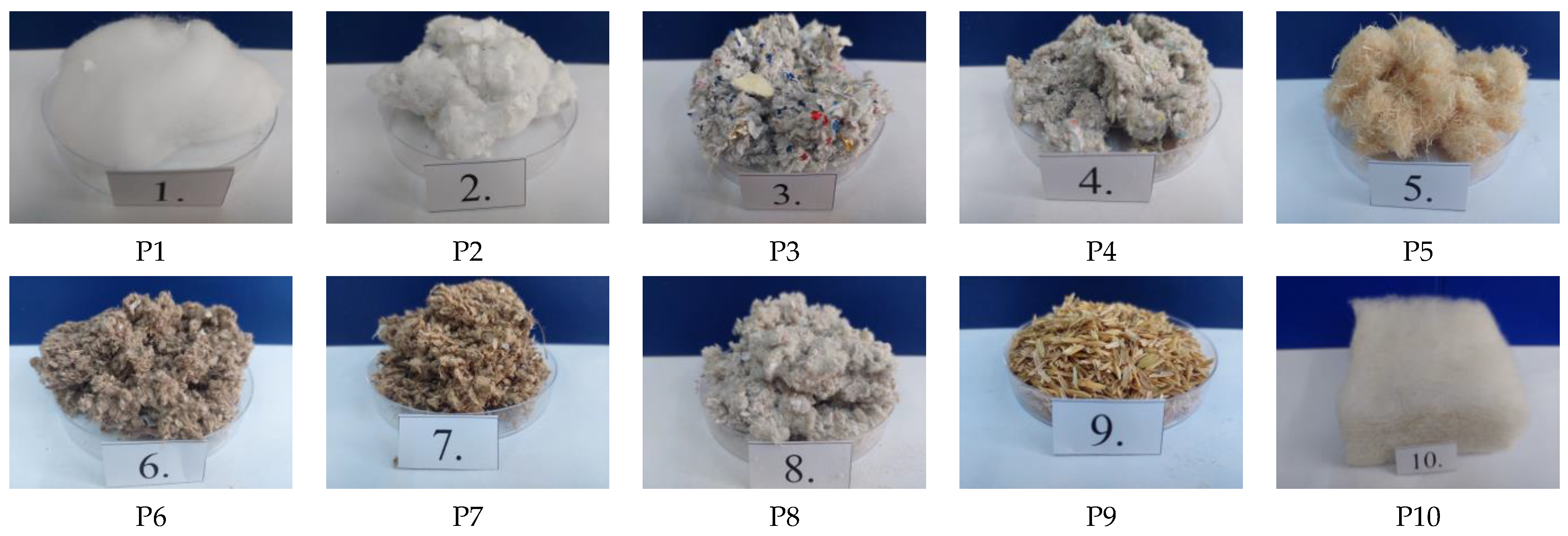

This study aimed to analyse a set of 10 types of “niche” thermal-insulation materials, produced using recycled cellulosic or agro-industrial wastes, available on the building materials market. The comparative analysis was carried out from the point of view of thermal insulation performance, simultaneously with water vapour sorption/desorption capacity and resistance to the action of moulds, all of which have implications in terms of indoor air quality. The study achieves several objectives, as follows:

It provides a comparative analysis of the performance of a variety of thermal insulation materials that are available in the national and European construction materials market;

The study highlights concrete possibilities for integrating waste;

It contributes to establishing a positive environment for interdisciplinary research. This is done by simultaneously highlighting the characteristics of these materials from the viewpoint of their application field (thermal insulation of buildings), as well as the potential impact of their use on indoor air quality, and, consequently, the long-term effects on public health. This includes aspects such as resistance to fungi and other microorganism activity. This approach promotes a deeper understanding and emphasises the necessity to evaluate the performance of construction materials—in this case, thermal insulation materials—not only from the perspective of the response they provide to the requirements of their application field but also through a broader analysis. This wider analysis considers environmental impacts (such as opportunities for recycling waste, the inclusion of agricultural by-products), durability, and effects on the hygiene, safety and security conditions of the population. Historically, such analyses were mainly focused on compatibility with the field of use. However, today, in line with sustainable development strategies founded on the three core pillars (economic, social and environmental) endorsed at both European and global levels, all these requirements form an integral part of the evaluation of all materials designated for use in construction;

Last but not least, the study seeks to improve the supportive theoretical framework. This is beneficial especially for the practical implementation of technological transfer from applied research to the production of thermal insulation materials. These materials have a high potential for recycling waste or agro-industrial by-products and are optimised from a thermal efficiency point of view and for the necessary treatments to ensure safe and hygienic use.

3. Results and Discussion

The results of the experimental research on thermal insulation performance including water vapour sorption/desorption capacity and resistance to mould growth, all of which have implications for indoor air quality, showed similarities and differences between the 10 types of materials analysed. These specific behaviours of each material type are believed to have been influenced by several factors, of which the characteristics of the raw material used to make the material is the main one.

3.1. Characterisation of Materials in Terms of Thermal Insulation Efficiency

Heat transfer through a solid sample of material primarily occurs through conduction and convection mechanisms, as is already established [

56,

57,

58,

59]. Convection is affected by the arrangement and volume of air gaps between particles [

60,

61], while conduction is influenced by the contact area and number of contact points between solid particles [

62]. These mechanisms collectively determine how heat is transferred. As the density of a material increases due to subsidence, the size of air voids decreases and the number of contact points between particles increases. Therefore, when compressing a uniformly air-filled material, the convective component of the heat transfer is reduced, while the conduction is increased due to improved connectivity between the solid parts [

63,

64]. For thermal insulators that incorporate recycled textile fibres [

25,

29] or natural fibrous insulation material, byproducts from the agricultural industry [

60,

64], polynomial correlations between thermal conductivity and density have been already presented. The test results from the present research indicate that compression of a low-density product with uniformly distributed air gaps leads to a significant decrease in thermal conductivity, as seen for the products P1, P2, P5, and P10 in

Figure 3. Compression produces a sharp decline in convective heat flow in the initial segment of the density range, specifically between the natural density of the material and approximatively 40 kg/m

3. For this interval, the reduction in convective heat flow surpasses the increase in the conductive part of heat transfer. However, after a certain density threshold is reached, the rate of increase in heat transfer through conduction surpasses the decrease in convection; therefore, the value of thermal conductivity rises. For easier comparison of the evolution of the thermal conductivity coefficient depending on density, for the dry situation (a), versus conditioned at 23 °C ± (0.25 ÷ 0.3) °C and RH (50 ± 1)% (b), the graphical representation for each of the analysed thermal insulation materials was made while maintaining the same scale (on the X and Y axes).

Increasing material density leads to different variations in thermal conductivity, depending on the type of material. Thus, in the case of samples P1, P2, P10, the increase in density initially causes a reduction in the thermal conductivity coefficient, with a tendency to linearise, possibly with the recording of a minimum value on the graph λ = f(density) marked by an inflection point. A similar trend, with the existence of an inflection point on the λ = f(density) graph, but without a linearisation tendency, i.e., with the existence of an inflection point, is also recorded for the materials P4, P5, P6, P9. It should be noted, however, that in these cases the zone of decrease and existence of the inflection point is more evident, followed by a zone of increase in the thermal conductivity coefficient with increasing density. This trend is particularly evident in dry samples. Testing these materials after they have been conditioned at 50% RH, the λ = f(density) variation graph undergoes changes, generally emphasising the existence of the inflection (minimum) point. Therefore, it is considered that, in the case of these materials, increasing the density to a material-specific value may have beneficial effects by reducing the thermal conductivity coefficient. Above this optimum density value, the effect on the coefficient of thermal conductivity is either not significant (λ increases by less than 10%, e.g., sample P1) or even negative (λ increases by more than 10%, e.g., samples P2, P4, P6).

An entirely different aspect is presented by the λ = f(density) curves for samples P3, P7 and P8. In the case of these materials, an increase in the thermal conductivity coefficient is clearly identified as the density increases, both for tests on dry samples and material conditioned at 50% RH. Therefore, in these cases a densification of the material, either as a result of compaction under its own weight or by the way it is laid, induces disadvantages in terms of thermal insulation performance, all the more evident as the temperature difference, warm zone-cold zone, is greater (more obviously identified on the graph of sample P8 conditioned at 50% RH where the distance between the λ = f(density) curve recorded at the 10 °C test temperature is far removed from the λ = f(density) curve recorded at 23 °C).

A comparative analysis of the values recorded for each dry tested material, respectively, after conditioning at 50% RH, shows that, in general, the existence of moisture content in the material leads to slight increases in the thermal efficiency indicator. Exceptions are recorded in the case of testing at 10 °C for samples P3, P4, P5, P8.

Increasing the test temperature of the material (10 °C, 23 °C or 40 °C) generally results, for each material analysed, both dry and conditioned at 50% RH, in a similar appearance and parallel positioning of the λ = f(density) graphs; the higher the test temperature, the higher the thermal conductivity coefficient. Therefore, it is estimated that the benefit obtained by using such materials is greater the lower the temperature, which contributes to obtaining a benefit on the quality of indoor comfort and energy consumption, especially in cold climates.

By analysing the thermal performance indicator, λ, as a function of the macroscopic structure of the material, some similarities in behaviour can be identified. For example, samples P1, P2 and P5, cellulose thermal insulation materials with a fibre-bound appearance and even P10, which is a fibre composite, show λ = f(density) graphs with a similar appearance. Therefore, it is considered that the type, raw material, structure, density and moisture content are important factors influencing the thermal insulation performance, being in correlation with previous studies [

38].

The functions showing the variation of the thermal conductivity coefficient with respect to density are shown in

Table 3, and those showing the variation of the coefficient of thermal conductivity with respect to the mean temperature of the samples during the test are shown in

Table 4. It should be noted that, in order to achieve a correct degree of appreciation of the variation function, the condition was imposed that the correlation factor R

2 > 0.9. On the basis of these functions, at value 0 of the derivative of the function, it is possible to determine the density value for which the thermal conductivity coefficient is minimum, as shown in

Table 5. Thus, it can be said that an increase of 149.1% (P1), 83.9% (P2), 41.6% (P4), 116.0% (P5), 54.3% (P6), 5.8% (P9), 325.1% (P10), respectively, will lead to a reduction of the thermal conductivity coefficient recorded on dry material, at 10 °C, λ

10,ct., by 13.2% (P1), 7.4% (P2), 0.7% (P4), 8.2% (P5), 5.2% (P6), 3.5% (P9), 22.4% (P10), representing the highest benefit that can be obtained in this way. As can be seen, in some cases, this effort to increase the material density is substantially beneficial and justified; in other cases, it is less significant in terms of improving thermal performance. An exception is recorded for the P3 material for which the identified function is linear, continuously increasing. In this case, no benefit of reducing thermal conductivity can be obtained by increasing the material density; the λ

10,ct. value recorded experimentally at natural density being the lowest of the set of experimental values. Similarly, the P8 material is identified as an exception whose density, theoretically, should be reduced by 4.4% in order to achieve an optimal conductivity coefficient λ

10,ct. Although these theoretical conclusions exist, reducing the natural density of the materials (case P3 and P8) is hardly possible from a practical, implementation point of view, possibly requiring interventions in the manufacturing technology. Another exception was the P7 material, for which, although apparently polynomial functions were identified, it turned out that the evolution of the λ = f(density) curve is increasing and with the increase in the density of the material, the thermal conductivity coefficient also increases, the subsidence even under its own weight having a negative effect. In fact, of all the materials analysed, P7 is considered to have the lowest quality, being inhomogeneous, with frequent agglomerations of material, which could be one of the explanations for this behaviour: not only the type of source material but also the quality of its processing, the homogeneity of the final product, have a great influence on the thermal insulation performance.

By comparing the experimentally obtained thermal conductivity coefficient of the materials with general values characteristic of commonly used thermal insulation materials or cellulose-based thermal insulation materials reported in the literature [

32] (

Table 6), it is judged that in terms of efficiency as an insulating material, P1–P10 materials correspond to the intended field of use.

These findings align with similar results documented in the specialised literature [

25,

46,

60,

65,

66,

67].

3.2. Characterisation of Materials in Terms of Hygroscopicity Performance

The hygroscopicity of the thermal insulation materials evaluated was analysed using as a measurable indicator the variation of the specimen mass as a function of relative air humidity, w(%) = f(RH(%)). The average amount of adsorbed/desorbed water, expressed as a percentage of constant specimen mass, for each material type is shown in

Figure 4; the sorption/desorption curves are shown in

Figure 5.

Analysing the evolution of the indicators presented in

Figure 4, it can be said that, in general, for all the 10 types of material analysed, there is a relative constancy of the sorption phenomenon, with a slightly increasing trend, up to and including RH 75%. When the specimens are exposed to RH 90%, the sorption phenomenon is greatly amplified for all materials, with the most evident intensification of sorption being recorded for P5 and P7 materials. Subsequently, going through the relative humidity decrease diagram induces, as expected, the desorption phenomenon in each material type. In this area, a hindrance of water loss is noticed at RH 75%. Specifically, it is shown that materials exposed to RH 75% in the desorption zone (gradual RH decrease) store more water than the same specimens in the situation where they have crossed the sorption diagram (gradual RH increase). Therefore, part of the water adsorbed at maximum RH (90%) is no longer delivered to the environment when RH is reduced to 75%. A similar phenomenon occurs for samples P9 and P10 in the RH 60–30% range. For all the other materials, in the desorption zone at RH 60%, 45% or 30%, there is a strong reduction of stored water, i.e., a very good capacity to release water as the relative humidity decreases.

Analysing the positioning of the sorption/desorption curves with respect to each other (

Figure 5), for the case of P1–P8 materials, the existence of an intersection point is observed each time. Initially the sorption curve has a relatively linear evolution and is placed above the desorption curve. In the vicinity of relative air humidity RH = 60% (with small variations from one material to another) and up to RH = 90%, the position of the curves changes, the desorption curve being placed above. This behaviour indicates the strong influence that the relative humidity has on the ability of these materials to regulate the humidity of the indoor environment. On the other hand, the behaviour of P9 and P10 materials is different. In these cases, the intersection of the two curves, sorption and desorption, is no longer recorded, the sorption curve being placed below the desorption curve. This behaviour indicates the limited capacity of these materials to release the stored water in order to contribute to the regulation of this parameter under conditions of reduced relative humidity of the air in the interior space.

By analysing the behaviour of all 10 material types, it can be hypothesised that the type of material and its characteristics significantly influence its ability to contribute to air humidity regulation (indoor air quality parameter).

On the other hand, according to the literature, due to the limited capacity to release adsorbed moisture, there is a possibility of accumulation of this moisture in the insulation material. This accumulation of moisture not only does not help to regulate the humidity of the air in the interior space but may even lead to the creation of an environment favourable to the growth of mould, as shown in studies carried out mainly in northern climates [

43,

44,

45,

68,

69,

70]. Therefore, considering that residual humidity contributes to creating a suitable environment for the development of microorganisms, as presented in

Section 3.2, it is considered that the analysed thermal insulation materials would be more suitable for use for the function of thermal insulation rather than for the function of regulating the humidity of the air in the interior space, by applying a vapour diffusion barrier to avoid mass transfer to the thermal insulation layer.

3.3. Characterisation of Materials in Terms of Resistance to the Action of Micro-Organisms

As the samples of materials analysed were taken from the footprint of the building materials, it is not possible in this case to analyse whether the existence of an antifungal treatment influences their behaviour. The existence of this antifungal treatment, as well as details of the treatment solution, is specific to each manufacturer and often confidential information, which provides elements that contribute to the degree of competitiveness among the manufacturers of these niche materials.

3.3.1. The Risk of Mould Growth If Thermal Insulation Materials Are Exposed to High Humidity Conditions

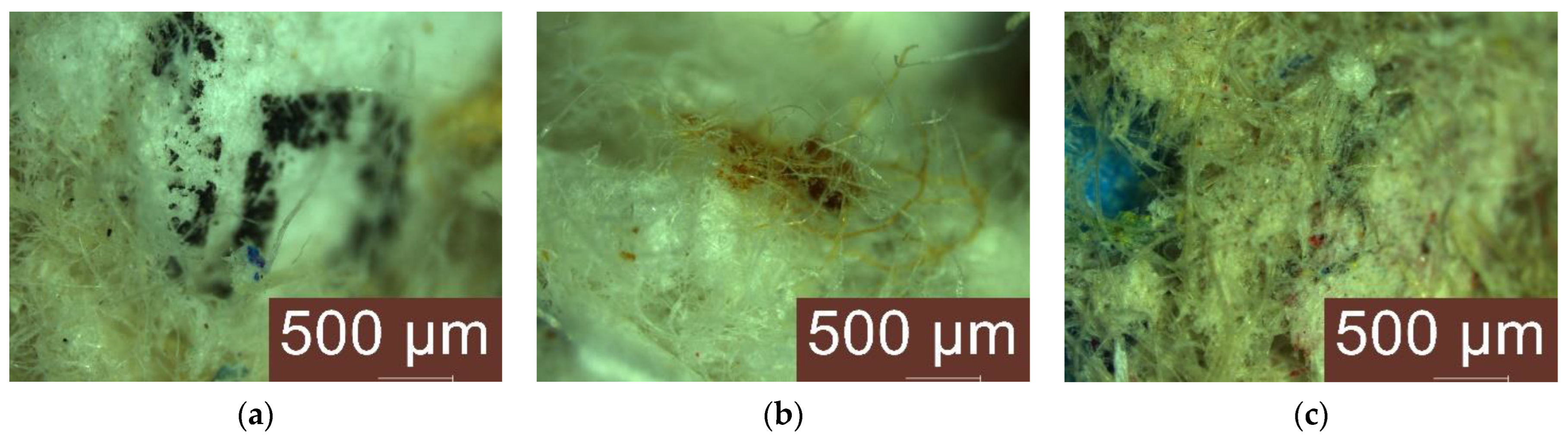

Visual and microscopic analysis of thermal insulation materials made by recycling selected agro-industrial wastes were carried out after 5 days, 10 days, 15 days, 20 days, 25 days and 28 days, respectively, of exposure under conditions of high humidity and constant temperature. The experimental results are shown in

Figure 6 and summarised in

Table 7 by indicating the rating class of fungal growth and performance category in terms of nutrient content conducive to the growth of micro-organisms, according to SR EN ISO 846 [

55].

Visual analysis, without optical magnification means, indicates a superficial degradation of the materials; they show slight changes in appearance, mostly in terms of colour, with a “slightly moist and damp” appearance.

Microscopic analysis of the materials showed signs of mould growth from the evaluation after exposure to damp conditions for 5 days in the case of samples P3 and P4, and from the evaluation after 10 days in the case of samples P2, P6, P8, P9. Evaluation after exposure for 15 days in a wet environment showed the presence of mould in all samples except P1. Moreover, in this sample P1, increased resistance was observed, with the first signs of mould being microscopically identified only after 28 days of exposure in a wet environment.

On the other hand, the microscopic analysis of the samples showed, in general, quantitative growth in mould from one evaluation to the next, with some of the samples being classified in the next class of fungal growth rating, i.e., class 2. Due to the shape of the material, most of which is loose, it is very difficult to assess the mould surface area proportionally, but for all these samples classified in fungal growth rating class 2, a material performance category of minimum 2 can be assumed, i.e., the material can be assessed as containing nutrients that allow mould growth.

Of the 10 materials analysed, none was identified as having a behaviour compatible with maintaining fungal growth rating class 0 (no sign of growth on microscopic examination) and performance category in terms of nutrient content conducive to the growth of microorganisms 0 (not a nutrient medium for microorganisms—inert or fungistatic). Therefore, it is considered that for all the cases analysed an antifungal treatment is required or, if this treatment existed in the production process, it is insufficient. Also, based on the results, it is considered necessary that, when these products are put into operation, the technology should provide for the use of specific protections to reduce the contact of the material with the humidity in the environment.

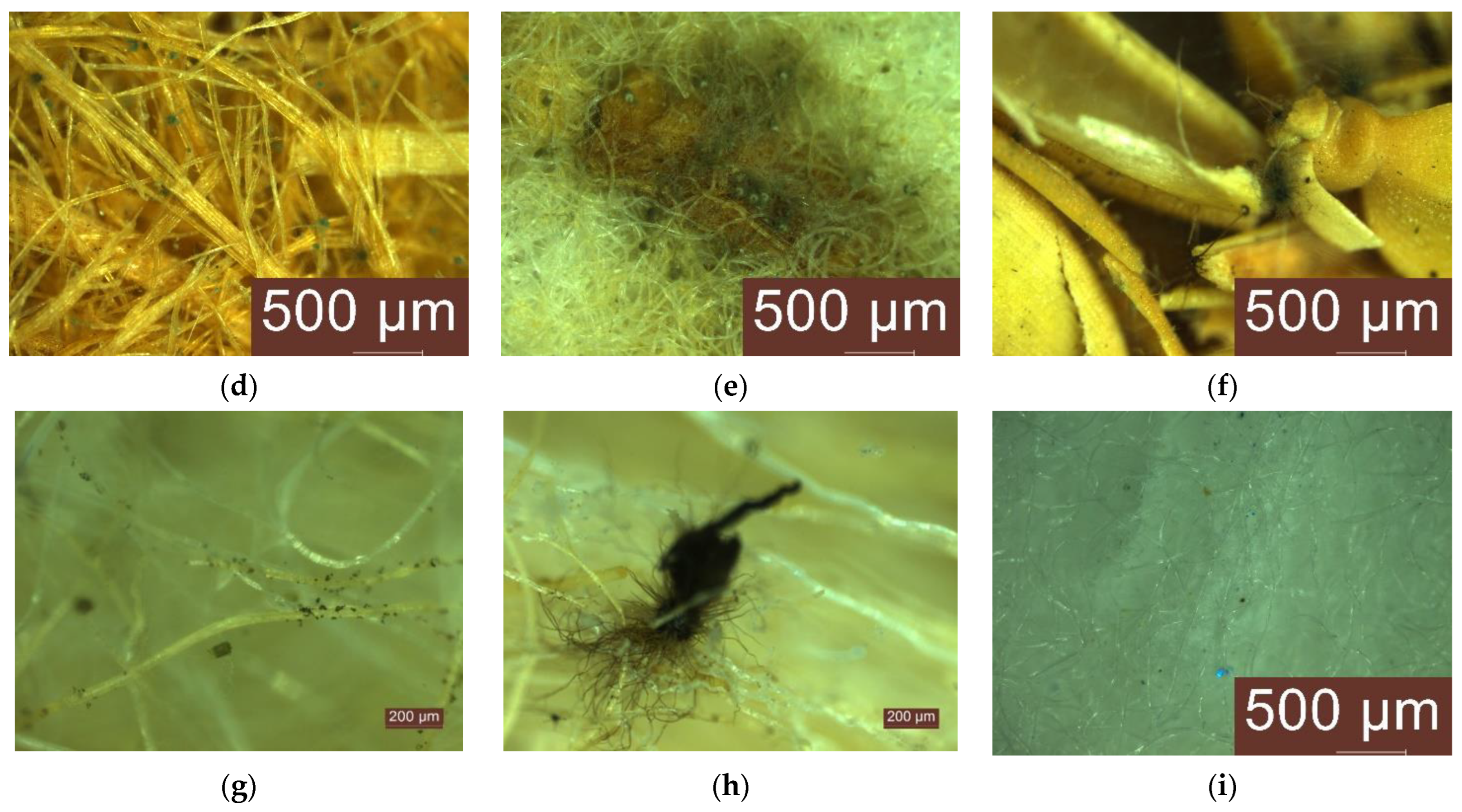

3.3.2. Resistance of Heat-Insulating Materials under Conditions Contaminated with Micro-Organisms

Both cultivation techniques showed an interesting behaviour of the tested insulation. The test for native microflora revealed the growth of fungi on all the insulations, regardless of the type (

Table 8 and shown in

Figure 7). Sample P1 showed class 2 growth of native fungi, with the development of small colonies around the insulation. The same class was established in inoculated conditions, both fungal species showing growth but with colonies under 1 cm in diameter. Sample P2 permitted the development of numerous colonies around the insulation, with the native microflora established as class 4, but in controlled inoculation, this insulation maintained the colonies of both species under 1 cm in diameter. The third type of insulation showed multiple small colonies (class 3), which developed as native microflora. In controlled inoculation, this insulation did not permit the growth of

Penicillium notatum, unlike

Aspergillus niger which proliferated on media. Insulation P4 showed abundant mycelium growth (native microflora), but blocked the development of

A. niger. The same insulation restricted the development of

P. notatum as a long and thin colony. The P5 insulation did not permit the development of either inoculated species but was sensitive to the native microflora test—where multiple confluent colonies were observed. The same results were obtained for insulations P6 and P7 in the native test, both showing high dimension colonies. The inoculation test for both insulations showed medium resistance to fungal contaminants, with small colonies developed—under 1 cm in diameter. Insulation P8 was considered as class 4 resistant to native microflora test, compared to insulations P9 and P10, which were considered as class 5. All three insulations showed well-developed colonies emerged from the insulation up to the complete coverage of fungal mycelium. In terms of controlled inoculation, all three insulations showed a different reaction. Insulation P8 was affected by both inoculated species, each having an equal share on culture media. Both P9 and P10 showed a resistance to

P. notatum, but no resistance to

A. niger.

3.4. Benefits and Challenges of Loose-Fill Insulation in Construction

Loose-fill insulation has become popular due to its installation facility, cost-effectiveness, and suitability for insulating rather complex spaces. For example, insulating the voids between roof rafter structures is greatly accelerated when blowing loose-fill insulation, compared to the more labor-intensive installation of traditional insulation [

57] that presents as rolls or boards. A remarkable use of loose-fill insulation is for house attics, a process proven to be quick and that minimises material waste [

71]. The installation process of this thermal insulation method is simple, which helps reduce labour costs and makes it cost-effective overall. These features are appealing to construction companies and other relevant stakeholders. As a result of the specific behaviour and efficiency of eco-innovative thermal insulation materials, in the specialised literature, some reviews indicate the possibility of use, for example, for bedroom wall insulation (which could provide benefits of even 5–30% in terms of energy consumption) as indicated by [

72,

73]. Other studies [

74,

75] suggest that this insulation material would be suitable for insulating buildings with air conditioning and humidity control systems.

Additionally, incorporating loose-fill insulation aligns with sustainable and environmentally conscious construction practices. However, sourcing and producing these insulating materials locally is crucial to meet the eco-friendly goals. This approach significantly reduces both environmental and transportation costs associated with the product. By doing so, we can minimise transportation’s carbon footprint while also strengthening local economies. It is important to note that produced loose-fill insulating materials may have unique properties due to variations in local resources [

76,

77] and manufacturing techniques [

78,

79]. One target of this research is to present some differences, where similar products or identical raw materials used in conjunction with different technologies yield notably different results. Consequently, conducting thorough testing of these products is vital to ensure their quality, performance, and safety. Thorough testing can identify the product’s characteristics, such as thermal conductivity and density, allowing these materials to be used where they perform best.