A Discrete-Finite Element Analysis Model Based on Almen Intensity Test for Evaluation of Real Shot Peening Residual Stress

Abstract

1. Introduction

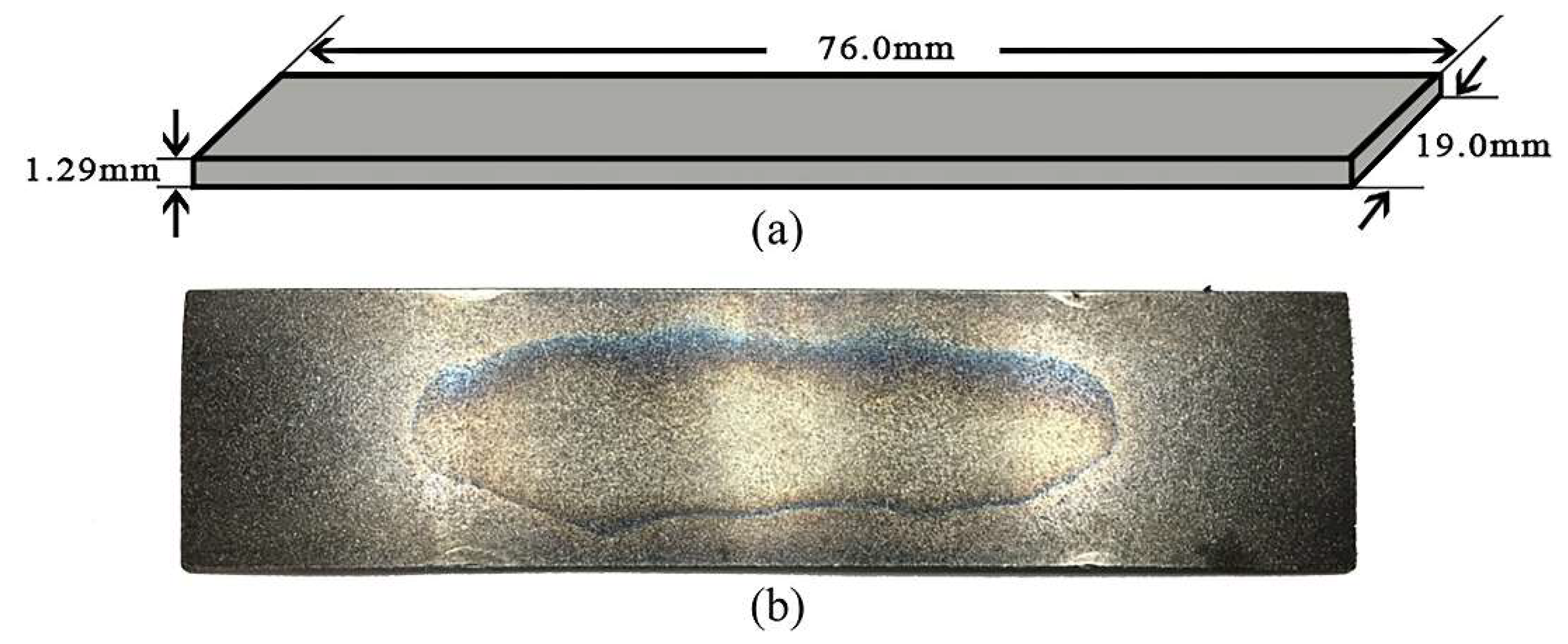

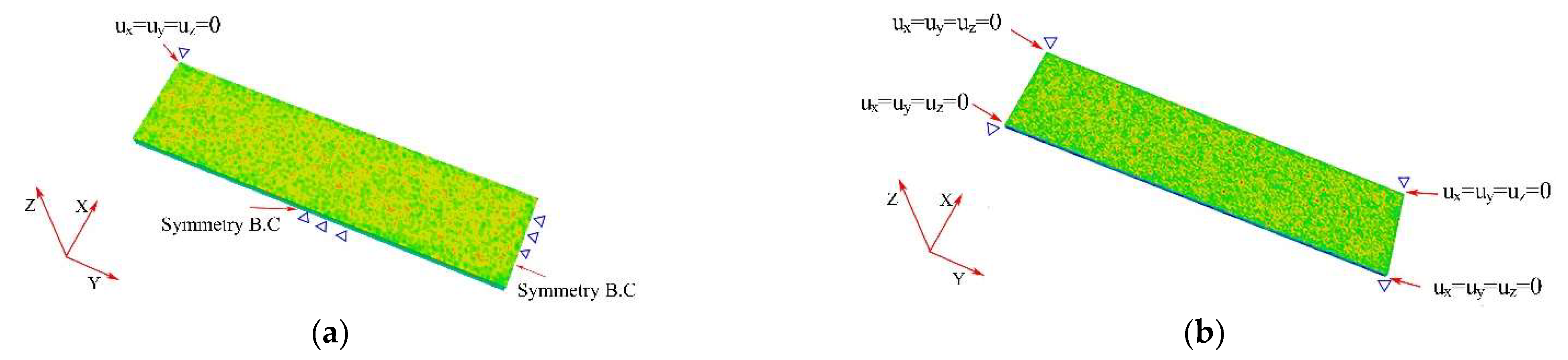

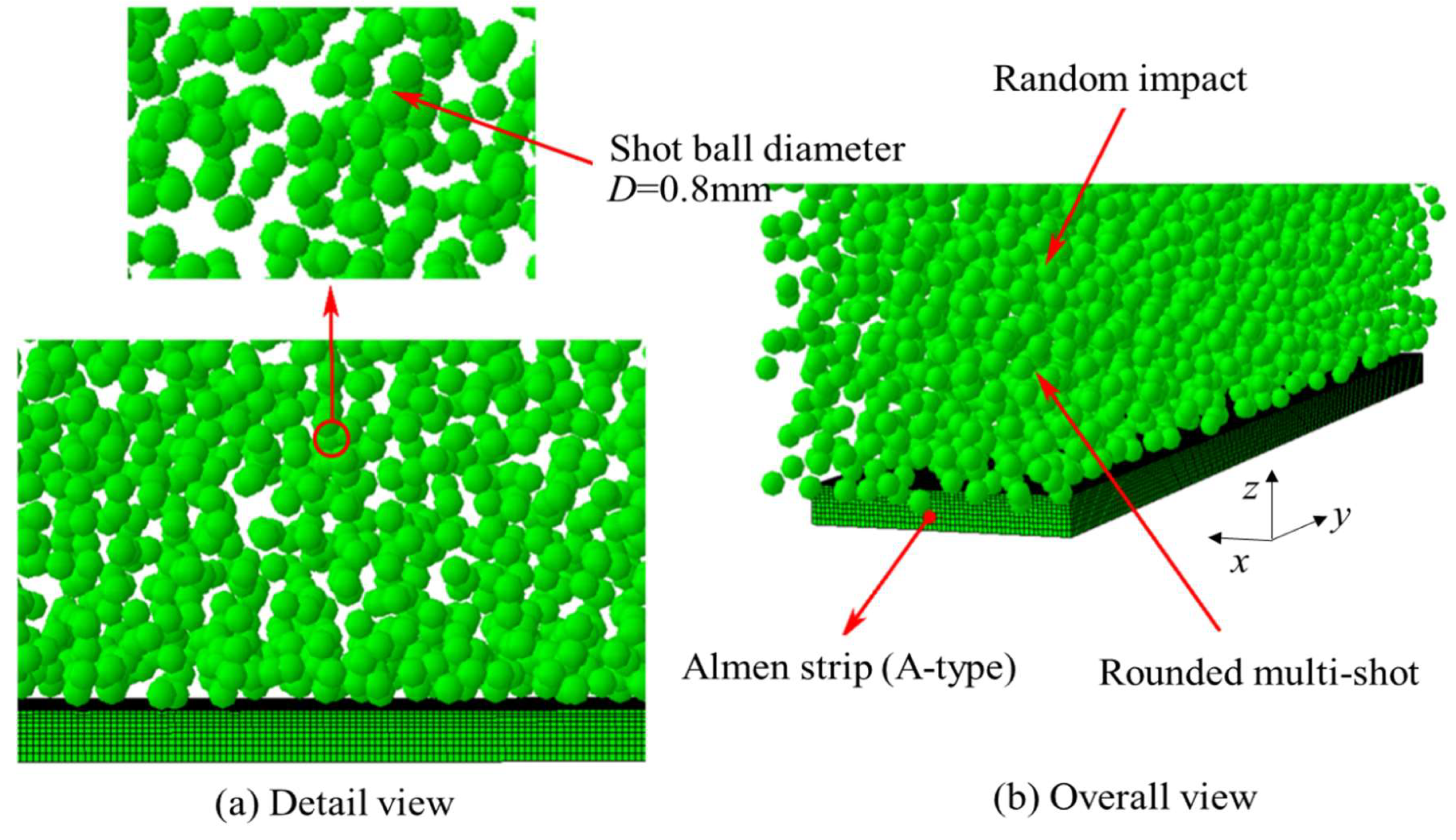

2. Almen Intensity Simulation and Experimental Verification

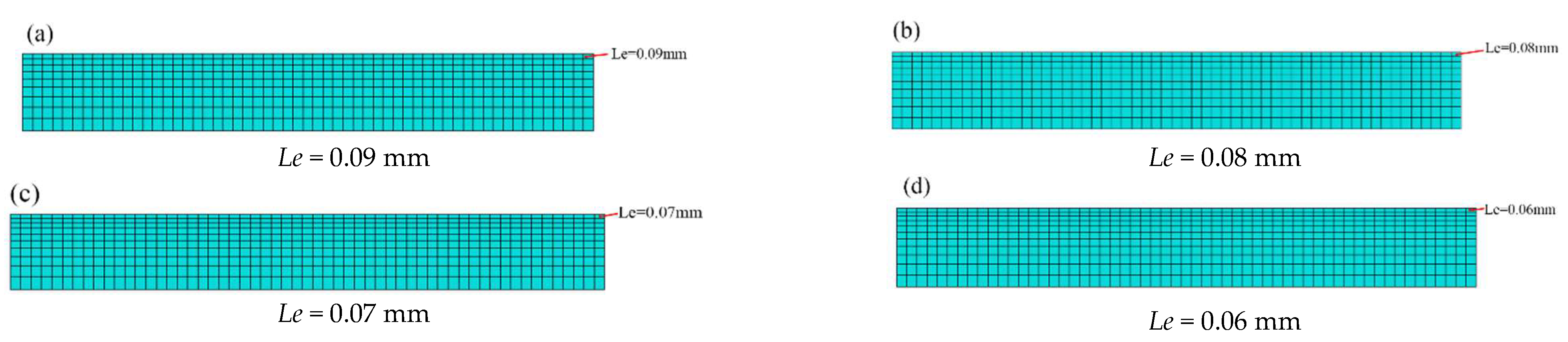

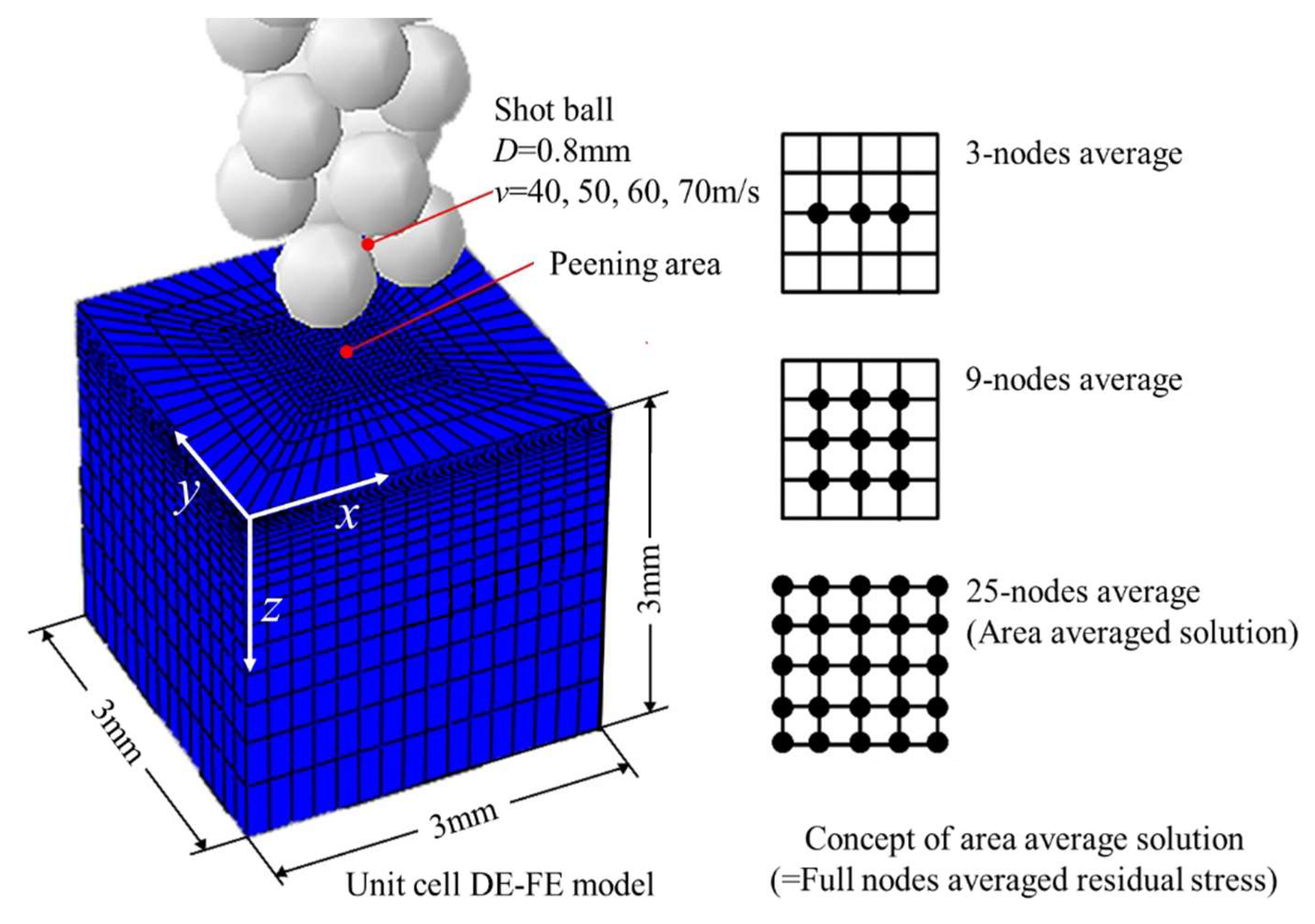

2.1. Almen Intensity by DE-FE Analysis

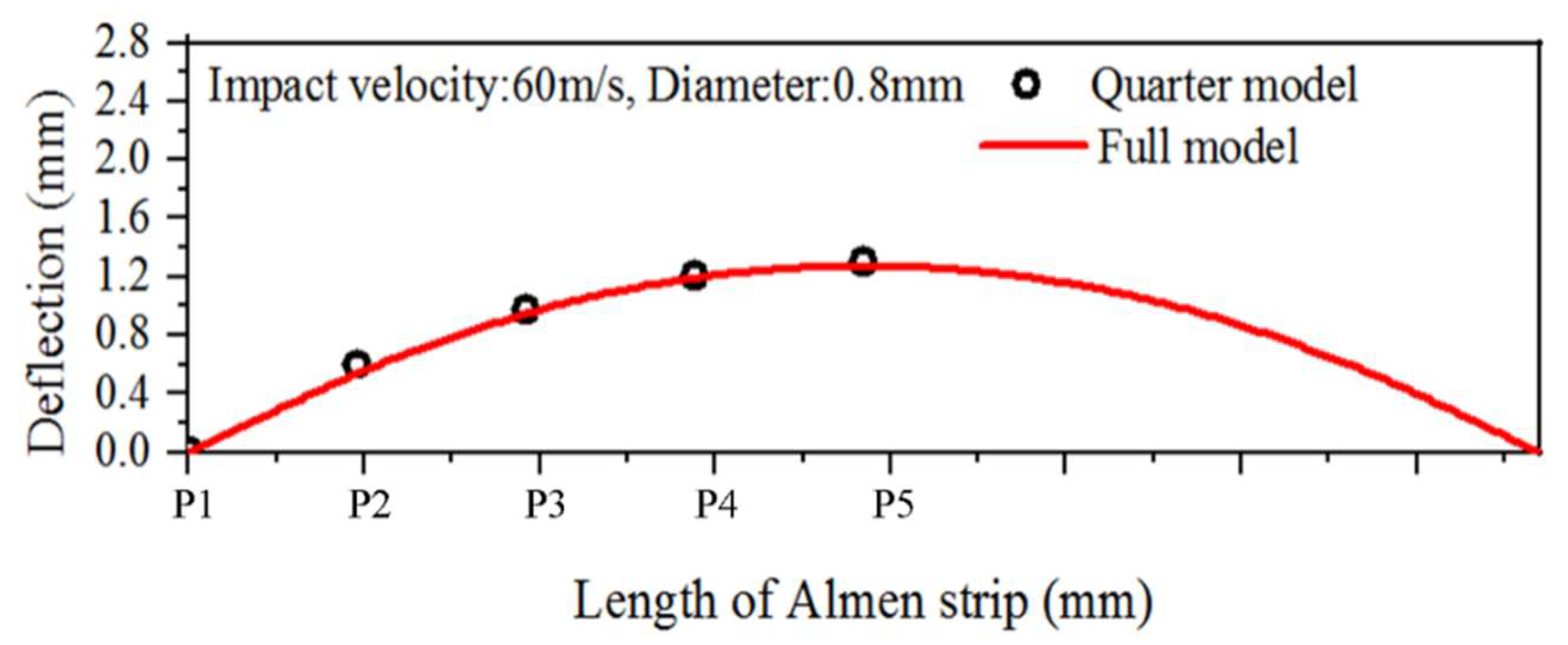

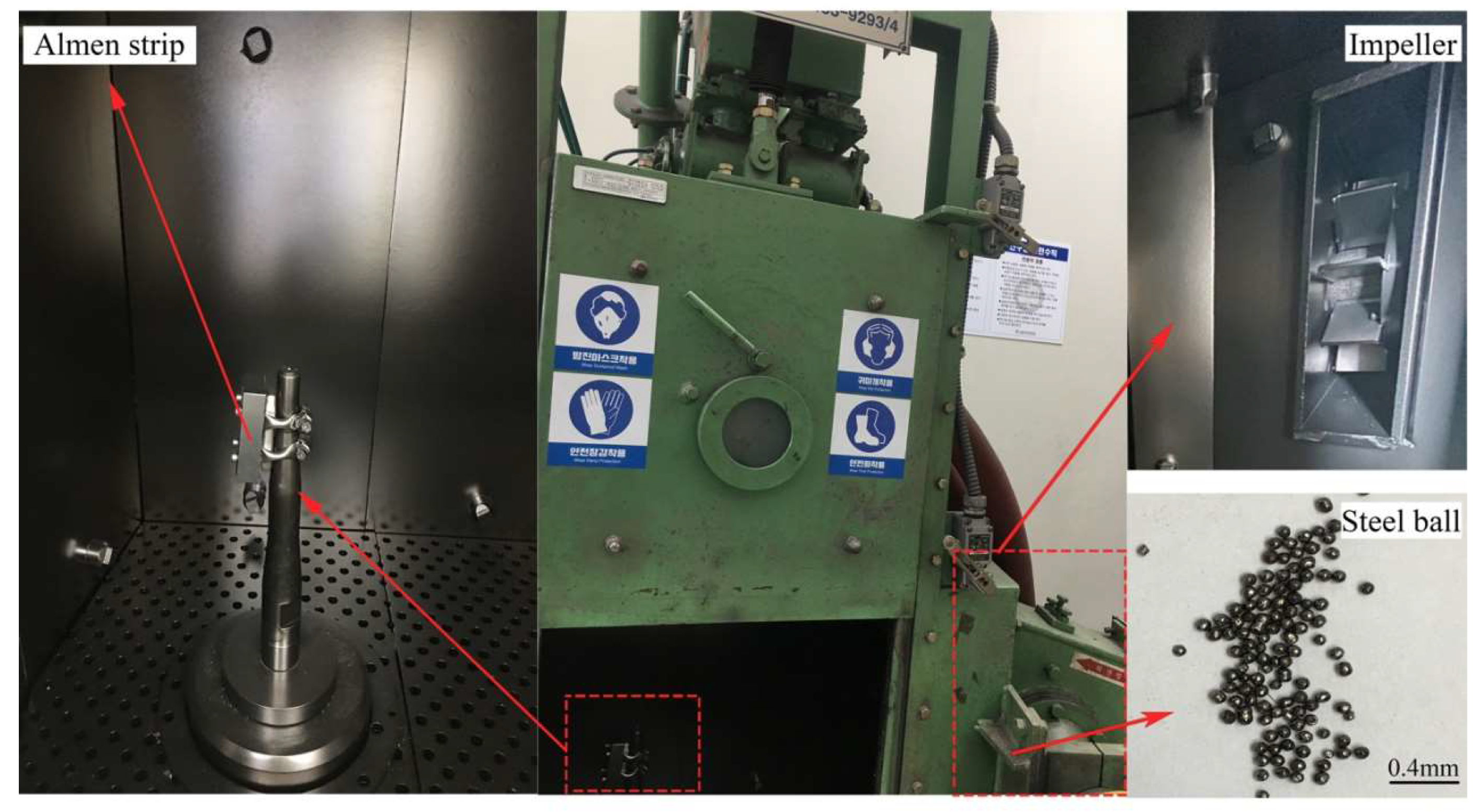

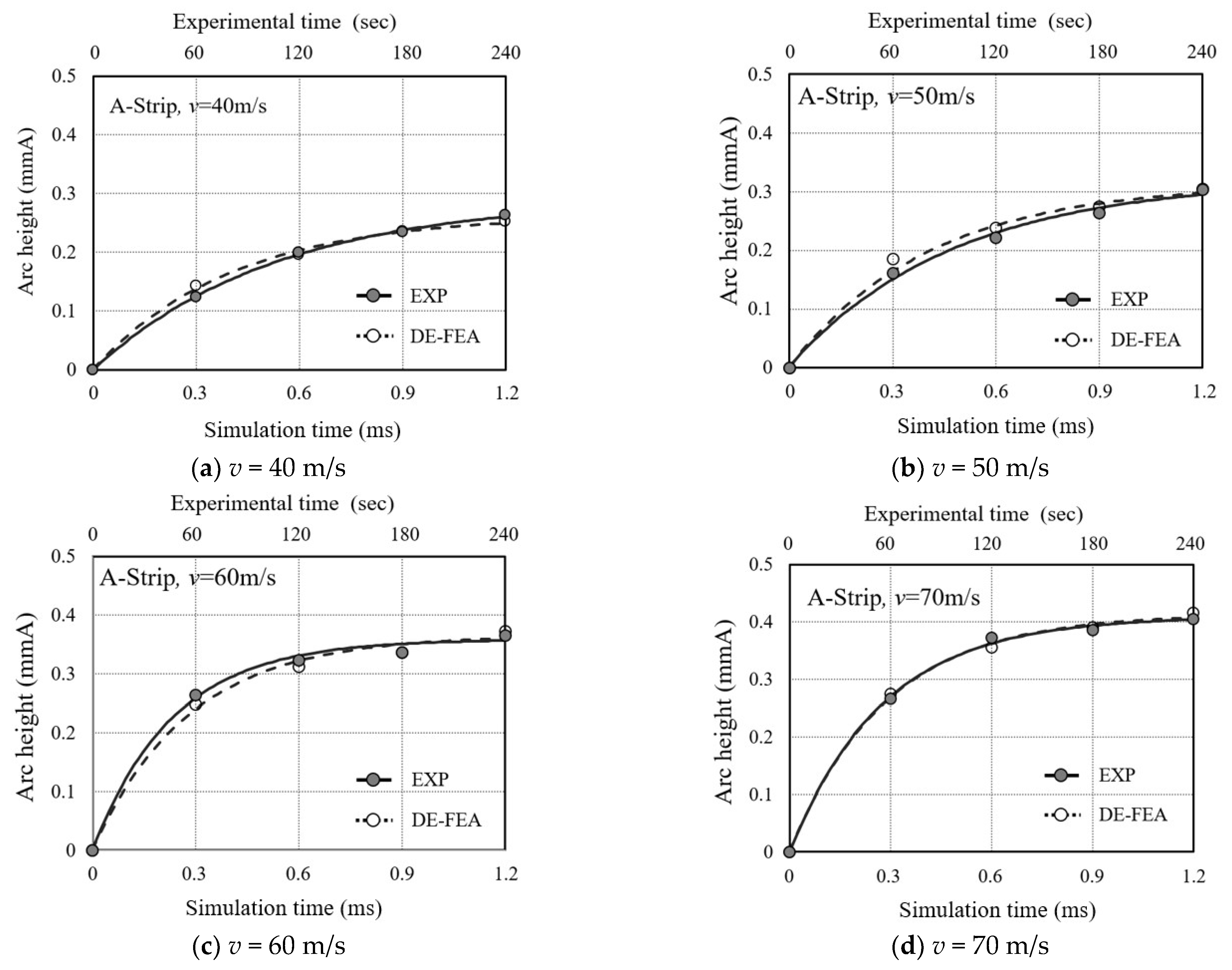

2.2. Experimental Effectiveness of the Almen Intensity Simulation

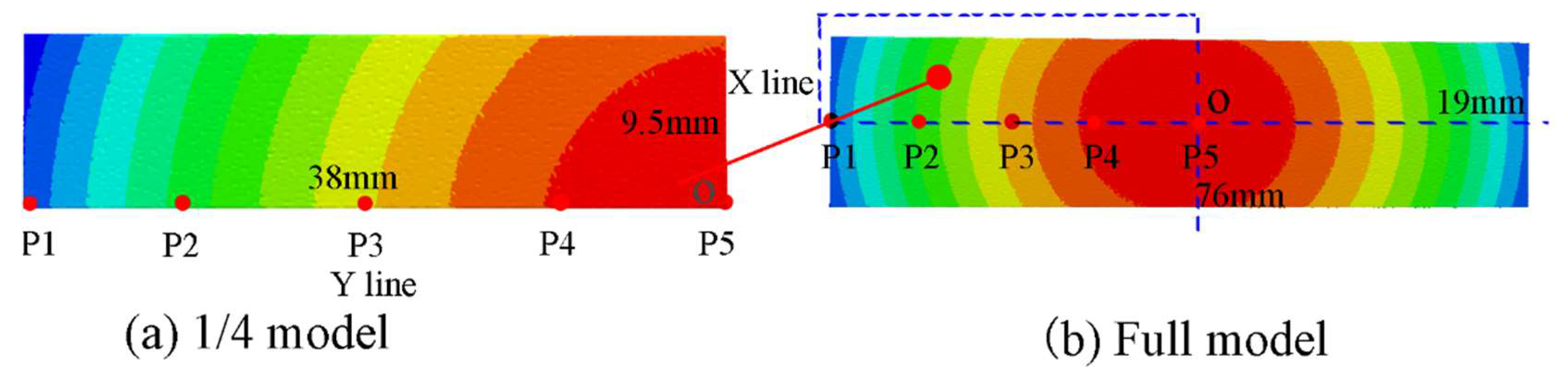

3. Analytical Peening Residual Stress and Its Experimental Verification

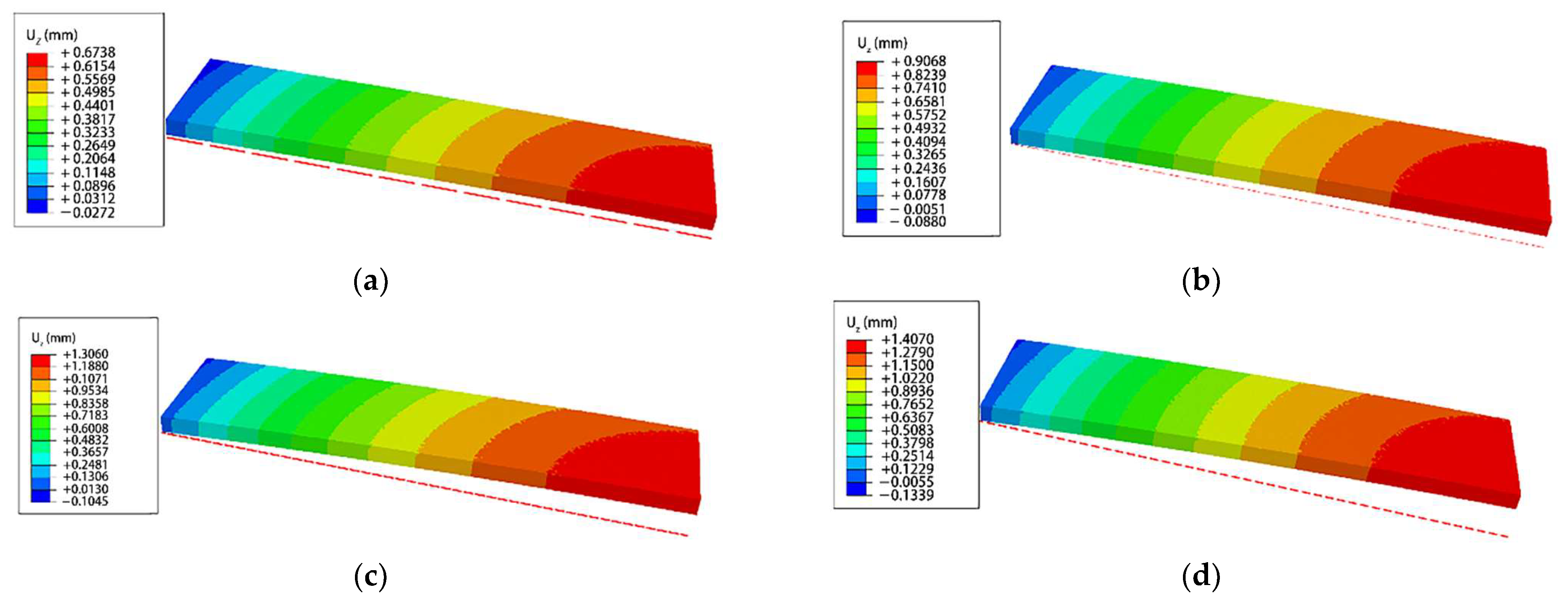

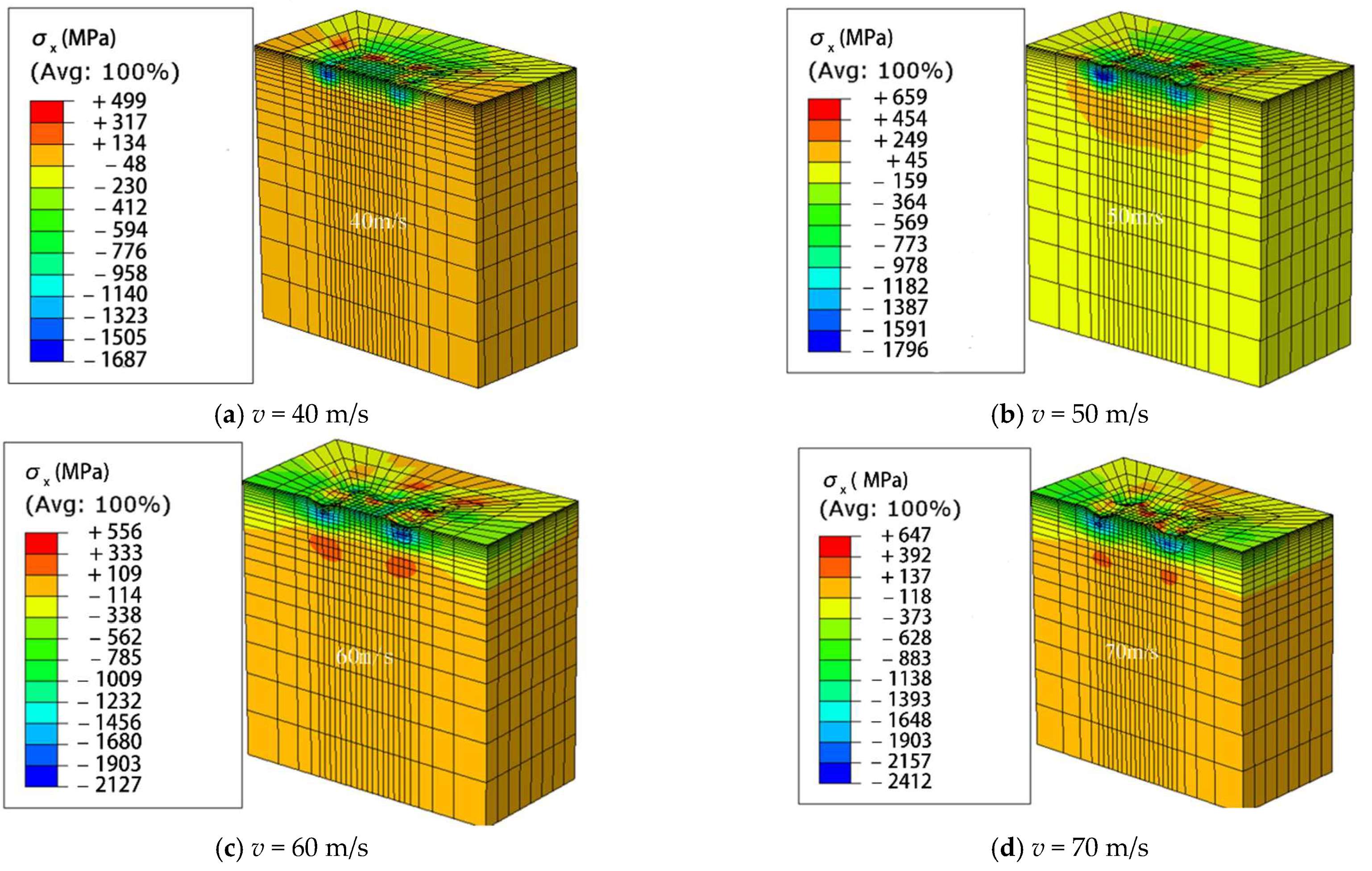

3.1. Peening Residual Stress by the DE-FE Analysis

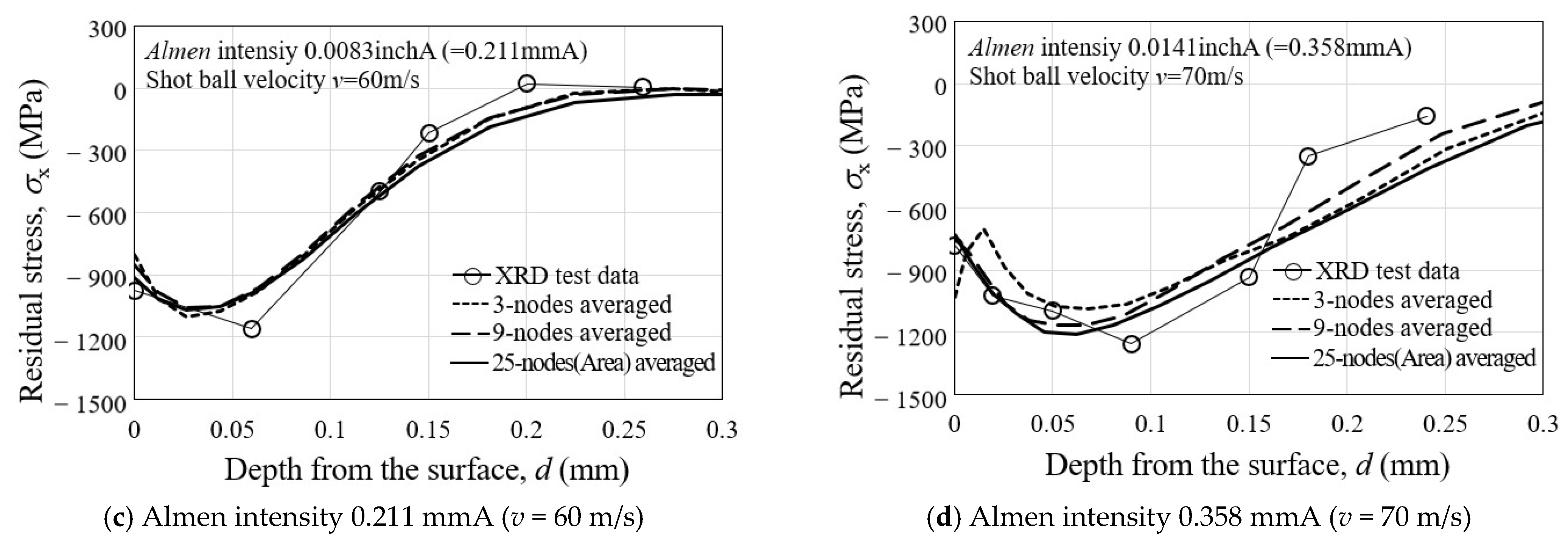

3.2. Experimental Verification of Peening Residual Stress

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, D.; Tian, T.; Wang, X.; Mao, J.; Xiao, Z.; Wang, R. Surface hardening analysis for shot peened GH4720Li superalloy using a DEM-FEM coupling RV simulation method. Int. J. Mech. Sci. 2021, 209, 106689. [Google Scholar] [CrossRef]

- Xia, B.; Wang, B.; Zhang, P.; Ren, C.; Duan, Q.; Li, X.; Zhang, Z. Improving the high-cycle fatigue life of a high-strength spring steel for automobiles by suitable shot peening and heat treatment. Int. J. Fatigue 2022, 161, 106891. [Google Scholar] [CrossRef]

- Gan, J.; Gao, Z.A.; Wang, Y.; Wang, Z.; Wu, W. Small-Scale Experimental Investigation of Fatigue Performance Improvement of Ship Hatch Corner with Shot Peening Treatments by Considering Residual Stress Relaxation. J. Mar. Sci. Eng. 2021, 9, 419. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, L.; Zhu, L.; Li, Y.; Hong, T.; Yang, W.; Shan, X. State of the Art and Perspectives on Surface-Strengthening Process and Associated Mechanisms by Shot Peening. Coatings 2023, 13, 859. [Google Scholar] [CrossRef]

- Bagherifard, S. Enhancing the Structural Performance of Lightweight Metals by Shot Peeing. Adv. Eng. Mater. 2019, 21, 1801140. [Google Scholar] [CrossRef]

- Bianchetti, C.; Delbergue, D.; Bocher, P.; Lévesque, M.; Brochu, M. Analytical fatigue life prediction of shot peened AA 7050-T7451. Int. J. Fatigue 2019, 118, 271–281. [Google Scholar] [CrossRef]

- Lin, J.; Ma, N.; Lei, Y.; Murakawa, H. Measurement of residual stress in arc welded lap joints by cosα X-ray diffraction method. J. Mater. Process. Technol. 2017, 243, 387–394. [Google Scholar] [CrossRef]

- Maleki, E.; Farrahi, G.H.; Reza Kashyzadeh, K.; Unal, O.; Gugaliano, M.; Bagherifard, S. Effects of Conventional and Severe Shot Peening on Residual Stress and Fatigue Strength of Steel ALSI 1060 and Residual Stress Relaxation Due to Fatigue Loading: Experimnetal and Numerical Simulation. Met. Mater. Int. 2021, 27, 2575–2591. [Google Scholar] [CrossRef]

- Zhan, K.; Wu, Y.; Li, J.; Zhao, B.; Yan, Y.; Xie, L.; Ji, V. Investigation on surface layer characteristics of shot peened graphene reinforced Al composite by X-ray diffraction method. Appl. Surf. Sci. 2018, 435, 1257–1264. [Google Scholar] [CrossRef]

- Kim, T.; Lee, H.; Hyun, H.C.; Jung, S. A simple but effective FE model with plastic shot for evaluation of peening residual stress and its experimental validation. Mater. Sci. Eng. A 2011, 528, 5945–5954. [Google Scholar] [CrossRef]

- Meguid, S.A.; Shagal, G.; Stranart, J.C. 3D FE analysis of peening of strain-rate sensitive materials using multiple impingement model. Int. J. Impact Eng. 2002, 27, 119–134. [Google Scholar]

- Miao, H.Y.; Larose, S.; Perron, C.; Lévesque, M. On the potential applications of a 3D random finite element model for the simulation of shot peening. Adv. Eng. Softw. 2009, 40, 1023–1038. [Google Scholar] [CrossRef]

- Kim, T.; Lee, H.; Jung, S.; Lee, J.H. A 3D model with plastic shot for evaluation of equi-biaxial peening residual stress due to multi-impacts. Surf. Coat. Technol. 2012, 206, 3125–3136. [Google Scholar] [CrossRef]

- Gangaraj, S.M.H.; Guagliano, M.; Farrahi, G.H. An approach to relate shot peening finite element simulation to the actual coverage. Surf. Coat. Technol. 2014, 243, 39–45. [Google Scholar] [CrossRef]

- Xiao, X.; Tong, X.; Liu, Y.; Zhao, R.; Gao, G.; Li, Y. Prediction of shot peen forming effects with single and repeated impacts. Int. J. Mech. Sci. 2018, 137, 182–194. [Google Scholar]

- Lin, Q.; Liu, H.; Zhu, C.; Parker, R.G. Investigation on the effect of shot peening coverage on the surface integrity. Appl. Surf. Sci. 2019, 489, 66–72. [Google Scholar]

- Majzoobi, G.H.; Azizi, R.; Nia, A.A. A three-dimensional simulation of shot peening process using multiple shot impacts. J. Mater. Process. Technol. 2005, 164, 1226–1234. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. On the shot peening surface coverage and its assessment by mens of finite element simulation: A critical review and some original developments. Appl. Surf. Sci. 2012, 259, 186–194. [Google Scholar] [CrossRef]

- Wang, C.; Wang, L.; Wang, X.; Xu, Y. Numerical study of grain refinement induced by severe shot peeing. Int. J. Mech. Sci. 2018, 146, 280–294. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. Numerical and experimental analysis of surface roughness by shot peening. Appl. Surf. Sci. 2012, 258, 6831–6840. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, J.; Ding, H.; Shao, W.; Zhao, X.; Liu, H.; Jiang, T. A numerical and experimental investigation on the evolution of three-dimensional surface topography of 12Cr2Ni4A steel in shot peeing. J. Manuf. Process. 2021, 70, 259–270. [Google Scholar] [CrossRef]

- Tu, F.; Delbergue, D.; Miao, H.; Klotz, T.; Brochu, M.; Bocher, P.; Levesque, M. A sequential DEM-FEM coupling method for shot peening simulation. Surf. Coat. Technol. 2017, 319, 200–212. [Google Scholar] [CrossRef]

- Bhuvaraghan, B.; Srinivasan, S.M.; Maffeo, B.; McCLain, R.D.; Potdar, Y.; Prakash, O. Shot peening simulation using discrete and finite element methods. Adv. Eng. Softw. 2010, 41, 1266–1276. [Google Scholar] [CrossRef]

- Edward, A.B.; Heyns, P.S.; Kok, S. A Numerical Investigation of a Single-Shot in DEM-FEM Approach to Shot Peening Simulation. Metals 2019, 9, 1183. [Google Scholar] [CrossRef]

- Jebahi, M.; Gakwaya, A.; Lévesque, J.; Mechri, O.; Ba, K. Robust methodology to simulate real shot peeing precess using discrete-continuum coupling method. Int. J. Mech. Sci. 2016, 107, 21–33. [Google Scholar]

- Zhao, J.; Tang, J.; Zhou, W.; Jiang, T.; Liu, H.; Xing, B. Numerical modeling and experimental verification of residual stress distribution evolution of 12Cr2Ni4A steel generated by shot peening. Surf. Coat. Technol. 2022, 430, 127993. [Google Scholar]

- Murugaratnam, K.; Utili, S.; Petrinic, N. A combined DEM-FEM numerical method for Shot Peening parameter optimization. Adv. Eng. Softw. 2015, 79, 13–26. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, S.; Wu, T.; Zhou, Z.; Zhang, W. An evaluation on SP surface property by means of combined FEM-DEM shot dynamics simulation. Adv. Eng. Softw. 2018, 115, 283–296. [Google Scholar] [CrossRef]

- Zhang, Y.; Lai, F.; Qu, S.; Ji, V.; Liu, H.; Li, X. Effect of shot peening on residual stress distribution and tribological behaviors of 17Cr2Ni2MoVNb steel. Surf. Coat. Technol. 2020, 386, 125497. [Google Scholar] [CrossRef]

- Guagliano, M. Relating Almen intensity to residual stresses induced by shot peening: A numerical approach. J. Mater. Process. Technol. 2001, 110, 277–286. [Google Scholar] [CrossRef]

- Gariépy, A.; Miao, H.Y.; Lévesque, M. Simulation of the shot peeing process with variable shot diameters and impacting velocities. Adv. Eng. Softw. 2017, 114, 121–133. [Google Scholar] [CrossRef]

- Wang, C.; Li, W.; Jiang, J.; Chao, X.; Zeng, W.; Xu, J.; Yang, J. An Improved Approach to Direct Simulation of an Actual Almen Shot Peening Intensity Test with a Large Number of Shots. Materials 2020, 13, 5088. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Lee, Y.; He, S.; Jia, W.; Zhao, J. Analysis of the Influence of High Peening Coverage on Almen Intensity and Residual Compressive Stress. Appl. Sci. 2019, 10, 105. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Z.; Gan, J.; Yang, Y.; Wang, X.; He, J.; Gan, X. The study of universality of a method for predicting surface nanocrystallization after high energy shot peening based on finite element analysis. Surf. Coat. Technol. 2019, 358, 617–627. [Google Scholar] [CrossRef]

- Gariépy, A.; Larose, S.; Perron, C.; Lévesque, M. Shot peening and peen forming finite element modelling—Towards a quantitatie mothod. Int. J. Solids Struct. 2011, 48, 2859–2877. [Google Scholar] [CrossRef]

- AMahmoudi, A.H.; Ghasemi, A.; Farrahi, G.H.; Sherafatnia, K. A comprehensive experimental and numerical study on redistribution of residual stresses by shot peeing. Mater. Des. 2016, 90, 478–487. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, H.; Zhu, C.; Chen, D.; Zhou, S. Effects of different shot peening parameters on residual stress, surface roughness and cell size. Surf. Coat. Technol. 2020, 398, 126054. [Google Scholar] [CrossRef]

- Kim, T.; Lee, J.H.; Lee, H.; Cheong, S.K. An area-average approach to peening residual stress under multi-impacts using a three-dimensional symmetry-cell finite element model with plastic shots. Mater. Des. 2010, 31, 50–59. [Google Scholar] [CrossRef]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

| Material | E (GPa) | Poisson’s Ratio | ρ (kg/m3) | A (MPa) | B (MPa) | n | m | Tm (K) | Tr (K) | C |

|---|---|---|---|---|---|---|---|---|---|---|

| SAE 1070 | 205 | 0.29 | 7800 | 1408 | 600.8 | 0.234 | 1.0 | 1793 | 298 | 0.0134 |

| Shot ball | 210 | 0.30 | 7800 |

| Analysis Time t (ms) | Arc Height (mmA) | |||

|---|---|---|---|---|

| 40 m/s | 50 m/s | 60 m/s | 70 m/s | |

| 0.3 ms | 0.124 | 0.161 | 0.243 | 0.266 |

| 0.6 ms | 0.198 | 0.221 | 0.322 | 0.371 |

| 0.9 ms | 0.233 | 0.254 | 0.335 | 0.401 |

| 1.2 ms | 0.243 | 0.293 | 0.361 | 0.438 |

| Exposure Time t (s) | Arc Height (mmA) | |||

|---|---|---|---|---|

| v = 40 m/s | v = 50 m/s | v = 60 m/s | v = 70 m/s | |

| 60 | 0.143 | 0.185 | 0.246 | 0.275 |

| 120 | 0.197 | 0.238 | 0.312 | 0.355 |

| 180 | 0.235 | 0.274 | 0.336 | 0.390 |

| 240 | 0.252 | 0.304 | 0.372 | 0.416 |

| Material | E (GPa) | Poisson’s Ratio | ρ (kg/m3) | A (MPa) | B (MPa) | n | m | Tm (K) | Tr (K) | C |

|---|---|---|---|---|---|---|---|---|---|---|

| AISI4340 | 210 | 0.30 | 7800 | 1498 | 943.8 | 0.260 | 1.03 | 1793 | 298 | 0.014 |

| Shot ball | 210 | 0.30 | 7800 |

| Shot Ball Velocity (m/s) | Arc Height (mmA) | Analysis σsrcs/MPa | XRD Test [39] σsrcs/MPa | Error (%) |

|---|---|---|---|---|

| 40 | 0.069 | −922.986 | −929.961 | 0.75 |

| 50 | 0.160 | −874.086 | −917.51 | 4.73 |

| 60 | 0.211 | −911.864 | −975.828 | 6.55 |

| 70 | 0.358 | −730.179 | −781.25 | 6.53 |

| Shot Ball Velocity (m/s) | Arc Height (mmA) | Analysis σsrcs/MPa | XRD Test [39] σsrcs/MPa | Error (%) |

|---|---|---|---|---|

| 40 | 0.069 | −944.677 | −929.961 | 1.58 |

| 50 | 0.160 | −1041.03 | −1010.89 | 2.98 |

| 60 | 0.211 | −1067.78 | −1159.84 | 7.93 |

| 70 | 0.358 | −1211.59 | −1256.25 | 3.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Park, Y.; Kim, T. A Discrete-Finite Element Analysis Model Based on Almen Intensity Test for Evaluation of Real Shot Peening Residual Stress. Materials 2023, 16, 5472. https://doi.org/10.3390/ma16155472

Wang C, Park Y, Kim T. A Discrete-Finite Element Analysis Model Based on Almen Intensity Test for Evaluation of Real Shot Peening Residual Stress. Materials. 2023; 16(15):5472. https://doi.org/10.3390/ma16155472

Chicago/Turabian StyleWang, Chengan, Yujin Park, and Taehyung Kim. 2023. "A Discrete-Finite Element Analysis Model Based on Almen Intensity Test for Evaluation of Real Shot Peening Residual Stress" Materials 16, no. 15: 5472. https://doi.org/10.3390/ma16155472

APA StyleWang, C., Park, Y., & Kim, T. (2023). A Discrete-Finite Element Analysis Model Based on Almen Intensity Test for Evaluation of Real Shot Peening Residual Stress. Materials, 16(15), 5472. https://doi.org/10.3390/ma16155472