Enhanced Thermoelectric Properties of Nb-Doped Ti(FeCoNi)Sb Pseudo-Ternary Half-Heusler Alloys Prepared Using the Microwave Method

Abstract

:1. Introduction

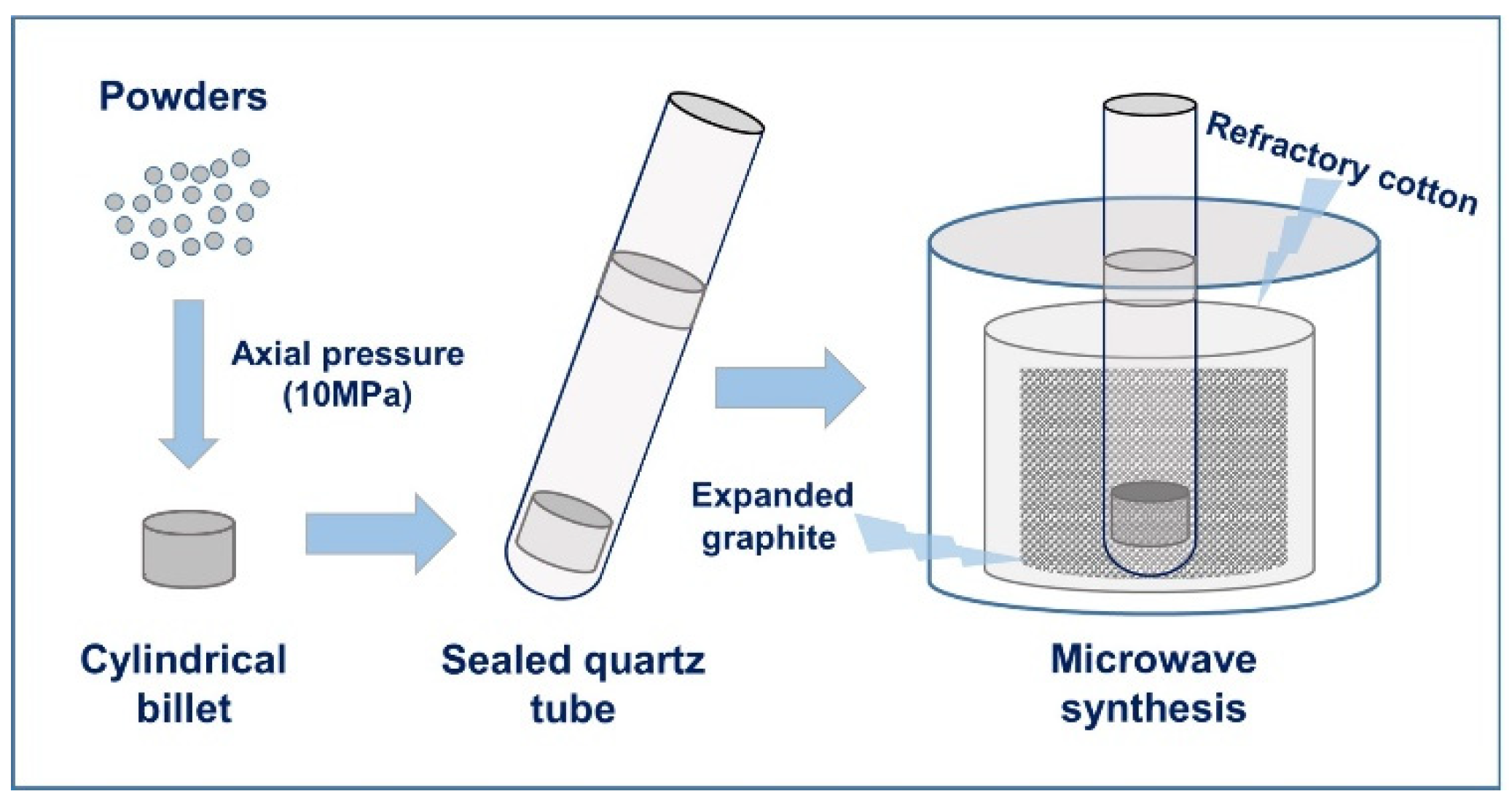

2. Materials and Methods

3. Results and Discussion

3.1. Phase Analysis

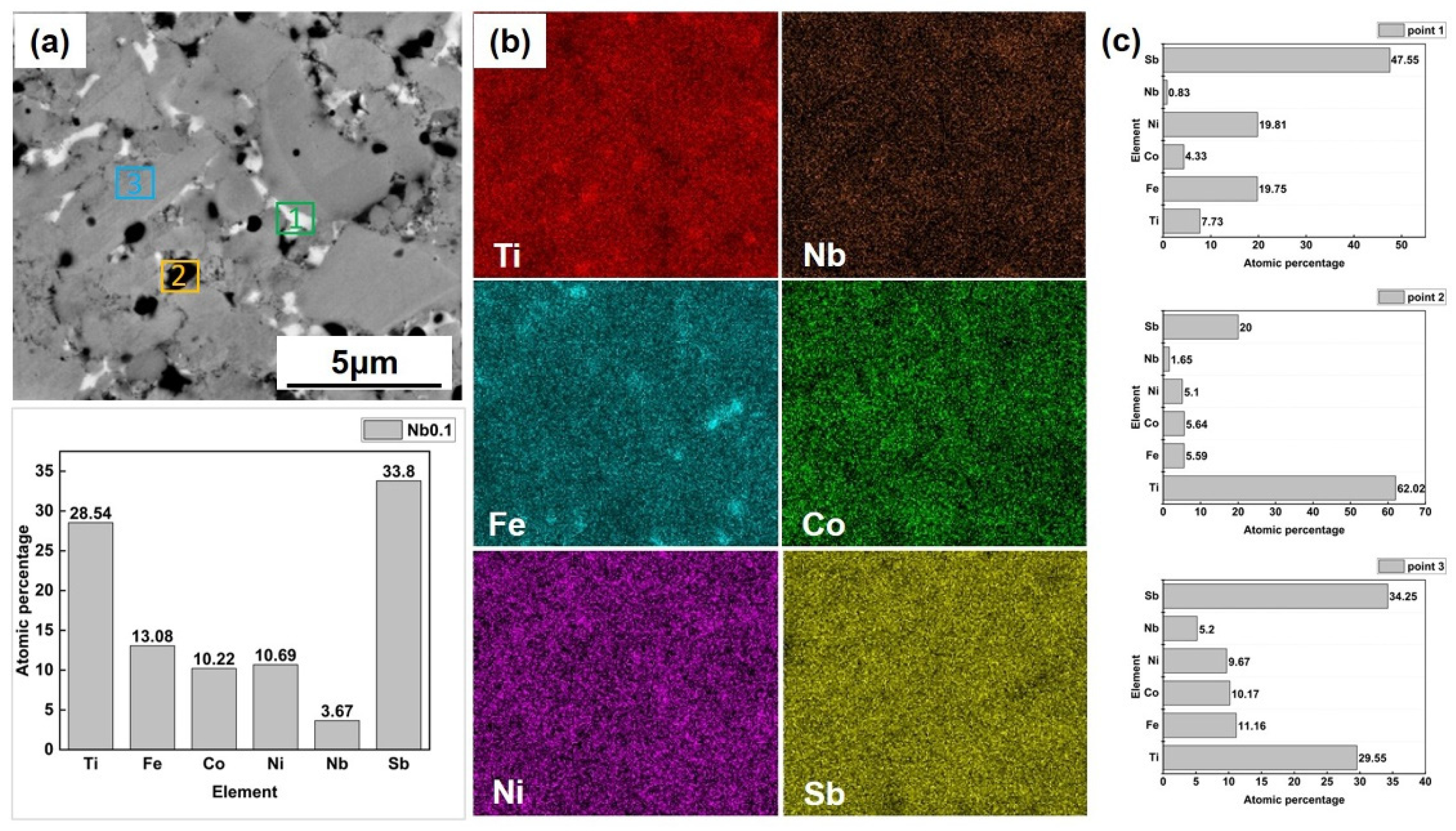

3.2. Microstructural Characterization

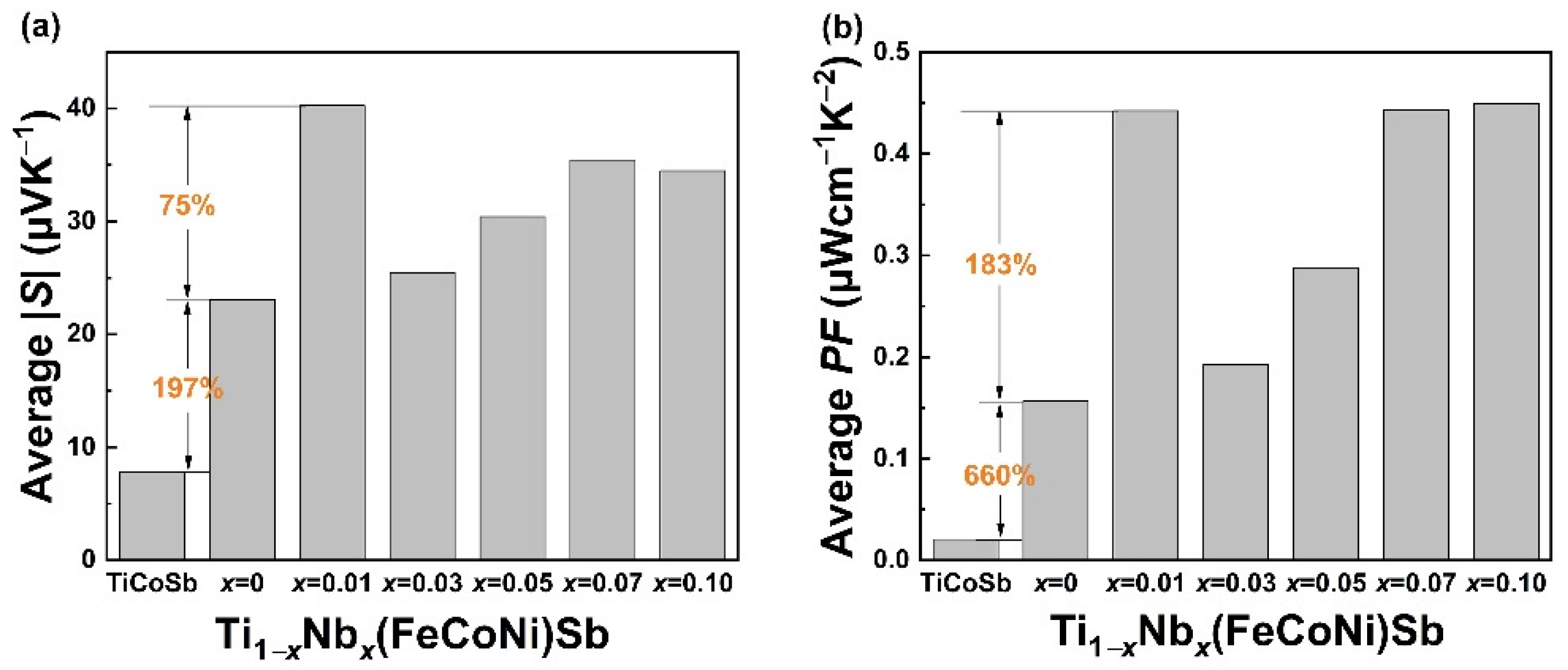

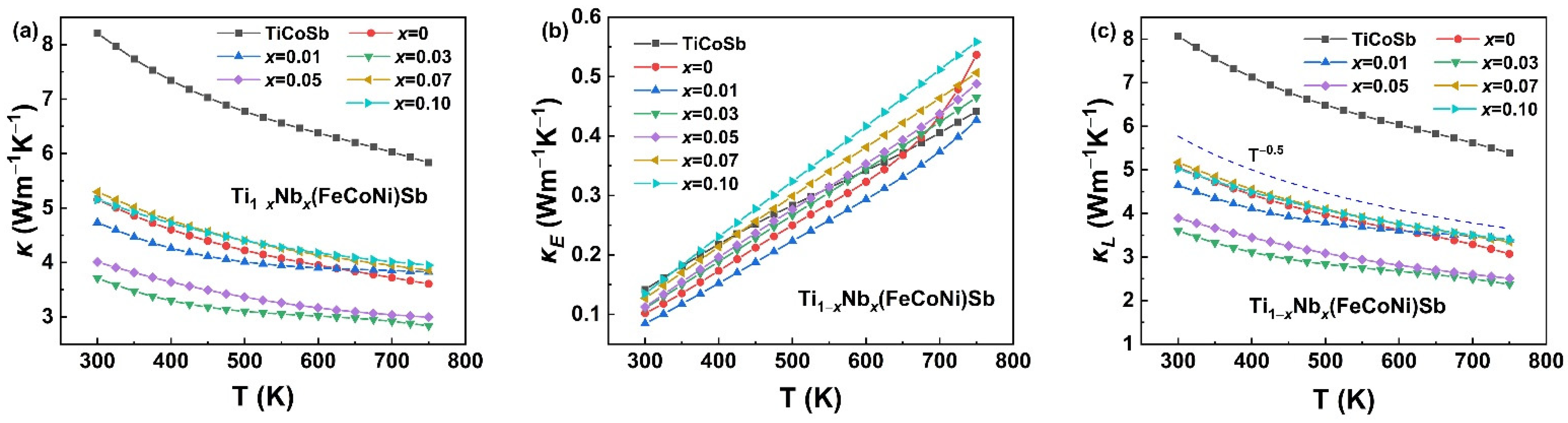

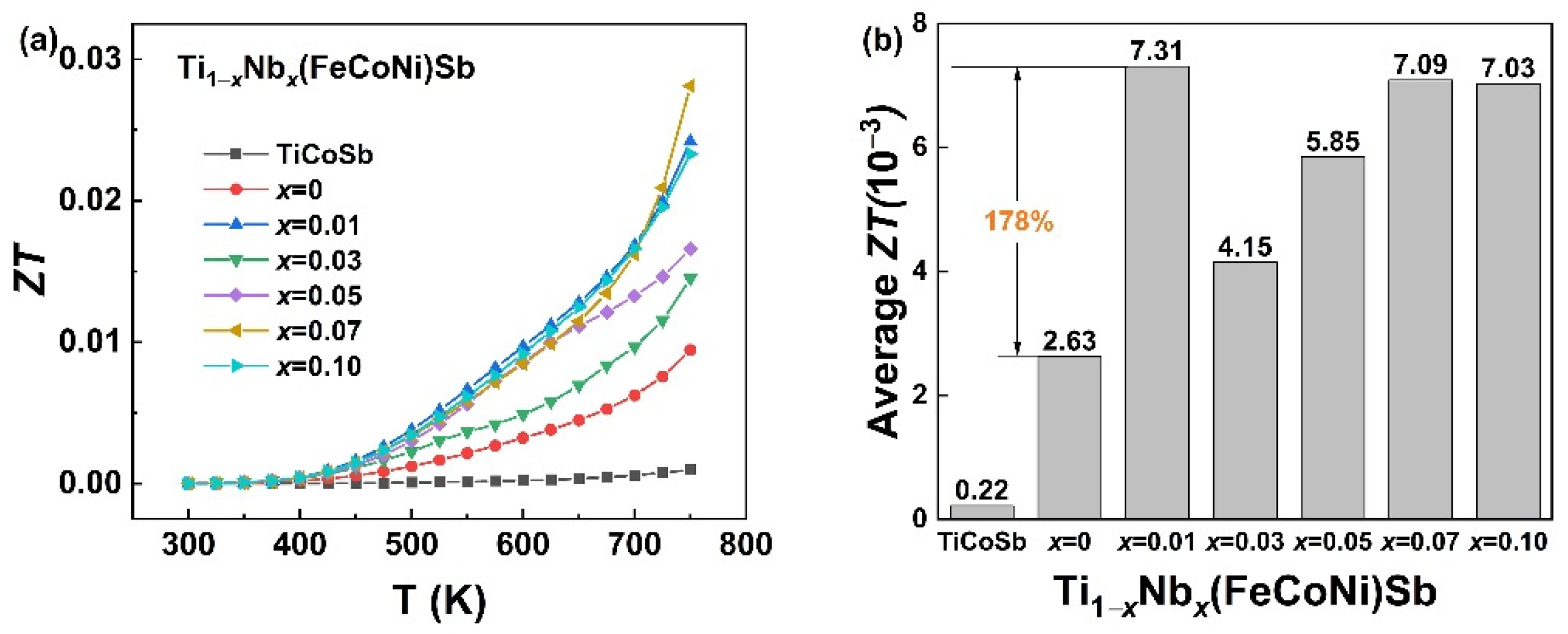

3.3. Thermoelectric Transport Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Riffat, S.B.; Ma, X. Thermoelectrics: A review of present and potential applications. Appl. Therm. Eng. 2003, 23, 913–935. [Google Scholar] [CrossRef]

- Shi, X.; He, J. Thermopower and harvesting heat. Science 2021, 371, 343–344. [Google Scholar] [CrossRef] [PubMed]

- Uher, C.; Yang, J.; Hu, S.; Morelli, D.; Meisner, G. Transport properties of pure and doped MNiSn (M = Zr, Hf). Phys. Rev. B 1999, 59, 8615. [Google Scholar] [CrossRef]

- He, J.; Tritt, T.M. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef] [Green Version]

- DiSalvo, F.J. Thermoelectric cooling and power generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef]

- Gayner, C.; Kar, K.K. Recent advances in thermoelectric materials. Prog. Mater. Sci. 2016, 83, 330–382. [Google Scholar] [CrossRef]

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Pope, A.; Littleton, R., IV; Tritt, T.M.; Ponnambalam, V.; Xia, Y.; Poon, S. Effect of Sb doping on the thermoelectric properties of Ti-based half-Heusler compounds, TiNiSn1−xSbx. Appl. Phys. Lett. 2000, 77, 2476–2478. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, Z.; Kang, H.; Chen, Z.; Guo, E.; Liu, D.; Yang, F.; Li, R.; Jiang, X.; Wang, T. Enhanced thermoelectric performance of Zr1−xTaxNiSn Half-Heusler alloys by diagonal-rule doping. ACS Appl. Mater. Interfaces 2019, 12, 3773–3783. [Google Scholar] [CrossRef]

- Chen, J.L.; Yang, H.; Liu, C.; Liang, J.; Miao, L.; Zhang, Z.; Liu, P.; Yoshida, K.; Chen, C.; Zhang, Q. Strategy of Extra Zr Doping on the Enhancement of Thermoelectric Performance for TiZrxNiSn Synthesized by a Modified Solid-State Reaction. ACS Appl. Mater. Interfaces 2021, 13, 48801–48809. [Google Scholar] [CrossRef]

- Tan, G.; Liu, W.; Chi, H.; Su, X.; Wang, S.; Yan, Y.; Tang, X.; Wong-Ng, W.; Uher, C. Realization of high thermoelectric performance in p-type unfilled ternary skutterudites FeSb2+xTe1−x via band structure modification and significant point defect scattering. Acta Mater. 2013, 61, 7693–7704. [Google Scholar] [CrossRef]

- Ning, S.; Huang, S.; Zhang, Z.; Qi, N.; Jiang, M.; Chen, Z.; Tang, X. Band convergence boosted high thermoelectric performance of Zintl compound Mg3Sb2 achieved by biaxial strains. J. Mater. 2022, 8, 1086–1094. [Google Scholar] [CrossRef]

- Guo, S.; Anand, S.; Brod, M.K.; Zhang, Y.S.; Snyder, G.J. Conduction band engineering of half-Heusler thermoelectrics using orbital chemistry. J. Mater. Chem. A 2022, 10, 3051–3057. [Google Scholar] [CrossRef]

- Li, F.; Bo, L.; Zhang, R.; Liu, S.; Zhu, J.; Zuo, M.; Zhao, D. Enhanced thermoelectric properties of Te doped polycrystalline Sn0.94Pb0.01Se. Nanomaterials 2022, 12, 1575. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, Q.; Wang, L.; Jiang, W.; Chen, L. Enhanced thermoelectric performance of Se-doped PbTe bulk materials via nanostructuring and multi-scale hierarchical architecture. J. Alloys Compd. 2017, 725, 563–572. [Google Scholar] [CrossRef]

- Kang, H.B.; Poudel, B.; Li, W.J.; Lee, H.; Saparamadu, U.; Nozariasbmarz, A.; Kang, M.; Gupta, A.; Heremans, J.; Priya, S. Decoupled phononic-electronic transport in multi-phase n-type Half-Heusler nanocomposites enabling efficient high temperature power generation. Mater. Today 2020, 36, 63–72. [Google Scholar] [CrossRef]

- Bo, L.; Zhang, R.; Zhao, H.; Hou, Y.; Wang, X.; Zhu, J.; Zhao, L.; Zuo, M.; Zhao, D. Achieving High Thermoelectric Properties of Cu2Se via Lattice Softening and Phonon Scattering Mechanism. ACS Appl. Energy Mater. 2022, 5, 6453–6461. [Google Scholar] [CrossRef]

- Sun, Y.X.; Qiu, W.B.; Zhao, L.W.; He, H.; Yang, L.; Chen, L.Q.; Deng, H.; Shi, X.M.; Tang, J. Defects engineering driven high power factor of ZrNiSn-based Half-Heusler thermoelectric materials. Chem. Phys. Lett. 2020, 755, 137770–137776. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex Thermoelectric Materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.; He, R.; Chen, S.; Zhang, H.; Dahal, K.; Zhou, H.; Wang, H.; Zhang, Q.; Ren, Z. A new n-type half-Heusler thermoelectric material NbCoSb. Mater. Res. Bull. 2015, 70, 773–778. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharya, S.; Skove, M.J.; Russell, M.; Tritt, T.M.; Xia, Y.; Ponnambalam, V.; Poon, S.J.; Thadhani, N. Effect of boundary scattering on the thermal conductivity of TiNiSn-based half-Heusler alloys. Phys. Rev. B 2008, 77, 184203. [Google Scholar] [CrossRef]

- Berry, T.; Fu, C.; Auffermann, G.; Fecher, G.H.; Schnelle, W.; Serrano-Sanchez, F.; Yue, Y.; Liang, H.; Felser, C. Enhancing Thermoelectric Performance of TiNiSn half-Heusler Compounds via Modulation Doping. Chem. Mater. 2017, 29, 7042–7048. [Google Scholar] [CrossRef]

- Hu, C.; Xia, K.; Fu, C.; Zhao, X.; Zhu, T. Carrier Grain Boundary Scattering in Thermoelectric Materials. Energy Environ. Sci. 2022, 15, 1406–1422. [Google Scholar] [CrossRef]

- Ghosh, T.; Dutta, M.; Sarkar, D.; Biswas, K. Insights into low thermal conductivity in inorganic materials for thermoelectrics. J. Am. Chem. Soc. 2022, 144, 10099–10118. [Google Scholar] [CrossRef]

- Zhang, X.L.; Li, S.; Zou, B.; Xu, P.F.; Song, Y.L.; Xu, B.; Wang, Y.F.; Tang, G.D.; Yang, S. Significant enhancement in thermoelectric properties of Half-Heusler compound TiNiSn by grain boundary engineering. J. Alloys Compd. 2022, 901, 163686–163693. [Google Scholar] [CrossRef]

- Toberer, E.S.; Zevalkink, A.; Snyder, G.J. Phonon engineering through crystal chemistry. J. Mater. Chem. 2011, 21, 15843–15852. [Google Scholar] [CrossRef] [Green Version]

- Jiang, B.; Wang, W.; Liu, S.; Wang, Y.; Wang, C.; Chen, Y.; He, J. High figure-of-merit and power generation in high-entropy GeTe-based thermoelectrics. Science 2022, 377, 208–213. [Google Scholar] [CrossRef]

- Luo, Y.B.; Hao, S.Q.; Cai, S.T.; Slade, T.J.; Luo, Z.Z.; Dravid, V.P.; Wolverton, C.; Yan, Q.Y.; Kanatzidis, M.G. High Thermoelectric Performance in the New Cubic Semiconductor AgSnSbSe3 by High-Entropy Engineering. J. Am. Chem. Soc. 2020, 142, 15187–15198. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, H.; Wu, Y.; Liu, X.J.; Lu, Z.P. Thermoelectric high-entropy alloys with low lattice thermal conductivity. RSC Adv. 2020, 6, 52164–52170. [Google Scholar] [CrossRef]

- Wang, X.Y.; Yao, H.H.; Zhang, Z.W.; Li, X.F.; Chen, C.; Yin, L.; Hu, K.N.; Yan, Y.R.; Li, Z.; Yu, B.; et al. Enhanced Thermoelectric Performance in High Entropy Alloys Sn0.25Pb0.25Mn0.25Ge0.25Te. ACS Appl. Mater. Interfaces 2021, 13, 18638–18647. [Google Scholar] [CrossRef]

- Anand, S.; Wood, M.; Xia, Y.; Wolverton, C.; Snyder, G.J. Double half-heuslers. Joule 2019, 3, 1226–1238. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, S.; Wu, Y.; Mao, J.; Zhu, Q.; Zhu, H.; Pei, Y.; Sui, J.; Zhang, Y.; Ren, Z. Design of high-performance disordered half-Heusler thermoelectric materials using 18-electron rule. Adv. Funct. Mater. 2019, 29, 1905044. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Chen, C.; Xue, W.; Xie, X.; Cao, F.; Sui, J.; Wang, Y.; Liu, X.; Zhang, Q. Enhanced Thermoelectric Properties in p-Type Double Half-Heusler Ti2−yHfyFeNiSb2−xSnx Compounds. Phys. Status Solidi A 2020, 217, 2000096. [Google Scholar] [CrossRef]

- Luo, P.; Mao, Y.; Li, Z.; Zhang, J.; Luo, J. Entropy engineering: A simple route to both p-and n-type thermoelectrics from the same parent material. Mater. Today Phys. 2022, 26, 100745. [Google Scholar] [CrossRef]

- Wang, Q.; Xie, X.; Li, S.; Zhang, Z.; Li, X.; Yao, H.; Chen, C.; Cao, F.; Sui, J.; Liu, X. Enhanced thermoelectric performance in Ti(Fe, Co, Ni)Sb pseudo-ternary Half-Heusler alloys. J. Mater. 2021, 7, 756–765. [Google Scholar] [CrossRef]

- Baghurst, D.; Chippindale, A.; Mingos, D.M.P. Microwave syntheses for superconducting ceramics. Nature 1988, 332, 311. [Google Scholar] [CrossRef]

- Agostino, A.; Volpe, P.; Castiglioni, M.; Truccato, M. Microwave synthesis of MgB2 superconductor. Mater. Res. Innov. 2004, 8, 75–77. [Google Scholar] [CrossRef]

- Wong, W.L.E.; Karthik, S.; Gupta, M. Development of high performance Mg–Al2O3 composites containing Al2O3 in submicron length scale using microwave assisted rapid sintering. Mater. Sci. Technol. 2005, 21, 1063–1070. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, R.P.; BO, L.; Li, F.J.; Hou, Y.B.; Zuo, M.; Zhao, D.G. Effects of different pressing process on the microstructure and thermoelectric properties of TiNiSn1−xTex Half-Heusler alloy prepared by microwave method. JOM 2022, 74, 4250–4257. [Google Scholar] [CrossRef]

- Lekse, J.W.; Stagger, T.J.; Aitken, J.A. Microwave metallurgy: Synthesis of intermetallic compounds via microwave irradiation. Chem. Mater. 2007, 19, 3601–3603. [Google Scholar] [CrossRef]

- Biswas, K.; Muir, S.; Subramanian, M.A. Rapid microwave synthesis of indium filled skutterudites: An energy efficient route to high performance thermoelectric materials. Mater. Res. Bull. 2011, 46, 2288–2290. [Google Scholar] [CrossRef]

- Wang, Y.P.; Wang, W.Y.; Zhao, H.Y.; Bo, L.; Wang, L.; Li, F.J.; Zuo, M.; Zhao, D.G. Rapid microwave synthesis of Cu2Se thermoelectric material with high conductivity. Funct. Mater. Lett. 2021, 14, 2151008. [Google Scholar] [CrossRef]

- Birkel, C.S.; Zeier, W.G.; Douglas, J.E.; Lettiere, B.R.; Mills, C.E.; Seward, G.; Stucky, G.D. Rapid microwave preparation of thermoelectric TiNiSn and TiCoSb Half-Heusler compounds. Chem. Mater. 2012, 24, 2558–2565. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Li, Y.; Xu, L.; Yang, J.; Wan, R.; Long, H. Microwave synthesis and sintering of TiNiSn thermoelectric bulk. J. Alloys Compd. 2016, 660, 166–170. [Google Scholar] [CrossRef]

- Savary, E.; Gascoin, F.; Marinel, S. Fast synthesis of nanocrystalline Mg2Si by microwave heating: A new route to nano-structured thermoelectric materials. Dalton Trans. 2010, 39, 11074–11080. [Google Scholar] [CrossRef]

- Hmood, A.; Kadhim, A.; Hassan, H.A. Influence of Yb-doping on the thermoelectric properties of Pb1−xYbxTe alloy synthesized using solid-state microwave. J. Alloys Compd. 2012, 520, 1–6. [Google Scholar] [CrossRef]

- Rong, Z.Z.; Fan, X.A.; Yang, F.; Cai, X.Z.; Han, X.W.; Li, G.Q. Microwave activated hot pressing: A new opportunity to improve the thermoelectric properties of n-type Bi2Te3−xSex bulks. Mater. Res. Bull. 2016, 83, 122–127. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.-I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef]

- Yan, J.; Liu, F.; Ma, G.; Gong, B.; Zhu, J.; Wang, X.; Ao, W.; Zhang, C.; Li, Y.; Li, J. Suppression of the lattice thermal conductivity in NbFeSb-based half-Heusler thermoelectric materials through high entropy effects. Scr. Mater. 2018, 157, 129–134. [Google Scholar] [CrossRef]

- Ren, W.; Zhu, H.; Zhu, Q.; Saparamadu, U.; He, R.; Liu, Z.; Mao, J.; Wang, C.; Nielsch, K.; Wang, Z.; et al. Ultrahigh power factor in thermoelectric system Nb0.95M0.05FeSb (M = Hf, Zr, and Ti). Adv. Sci. 2018, 5, 1800278. [Google Scholar] [CrossRef]

- Douglas, J.E.; Birkel, C.S.; Miao, M.S.; Torbet, C.J.; Stucky, G.D.; Pollock, T.M.; Seshadri, R. Enhanced thermoelectric properties of bulk TiNiSn via formation of a TiNi2Sn second phase. Appl. Phys. Lett. 2012, 101, 183902. [Google Scholar] [CrossRef]

- Schrade, M.; Berland, K.; Eliassen, S.N.; Guzik, M.N.; Echevarria-Bonet, C.; Sørby, M.H.; Jenuš, P.; Hauback, B.C.; Tofan, R.; Gunnæs, A.E. The role of grain boundary scattering in reducing the thermal conductivity of polycrystalline XNiSn (X = Hf, Zr, Ti) half-Heusler alloys. Sci. Rep. 2017, 7, 13760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aversano, F.; Palumbo, M.; Ferrario, A.; Boldrini, S.; Fanciulli, C.; Baricco, M.; Castellero, A. Role of secondary phases and thermal cycling on thermoelectric properties of TiNiSn Half-Heusler alloy prepared by different processing routes. Intermetallics 2022, 127, 106988. [Google Scholar] [CrossRef]

- Xia, K.; Liu, Y.; Anand, S.; Snyder, G.J.; Xin, J.; Yu, J.; Zhao, X.; Zhu, T. Enhanced Thermoelectric Performance in 18-Electron Nb0.8CoSb Half-Heusler Compound with Intrinsic Nb Vacancies. Adv. Funct. Mater. 2018, 28, 1705845. [Google Scholar] [CrossRef]

- Xie, H.; Wang, H.; Fu, C.; Liu, Y.; Snyder, G.J.; Zhao, X.; Zhu, T. The intrinsic disorder related alloy scattering in ZrNiSn half-Heusler thermoelectric materials. Sci. Rep. 2014, 4, 6888. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karati, A.; Hariharan, V.; Ghosh, S.; Prasad, A.; Nagini, M.; Guruvidyathri, K.; Mallik, R.C.; Shabadi, R.; Bichler, L.; Murty, B. Thermoelectric properties of Half-Heusler high-entropy Ti2NiCoSn1−xSb1+x (x = 0.5, 1) alloys with VEC > 18. Scr. Mater. 2020, 186, 375–380. [Google Scholar] [CrossRef]

- Fistul, V.I. Heavily Doped Semiconductors; Springer Science & Business Media: Berlin, Germany, 2012; Volume 1. [Google Scholar]

- Tsujii, N.; Mori, T. High thermoelectric power factor in a carrier-doped magnetic semiconductor CuFeS2. Appl. Phys. Express 2013, 6, 043001. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, Y.; Fu, C.; Heremans, J.P.; Snyder, J.G.; Zhao, X. Compromise and synergy in high-efficiency thermoelectric materials. Adv. Mater. 2017, 29, 1605884. [Google Scholar] [CrossRef]

- Wang, R.F.; Li, S.; Xue, W.H.; Chen, C.; Wang, Y.M.; Liu, X.J.; Zhang, Q. Enhanced thermoelectric performance of n-type TiCoSb half-Heusler by Ta doping and Hf alloying. Rare Met. 2021, 40, 40–47. [Google Scholar] [CrossRef]

- Karati, A.; Mukherjee, S.; Mallik, R.C.; Shabadi, R.; Murty, B.S.; Varadaraju, U.V. Simultaneous increase in thermopower and electrical conductivity through Ta-doping and nanostructuring in half-Heusler TiNiSn alloys. Materialia 2019, 7, 100410. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, R.; Bos, J.W.G.; Reece, M.J. Synthesis and thermoelectric properties of high-entropy half-Heusler MFe1−xCoxSb (M=equimolar Ti, Zr, Hf, V, Nb, Ta). J. Alloys Compd. 2022, 892, 162045. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Vishwakarma, A.; Bhardwaj, R.; Johari, K.K.; Gahtori, B.; Dhar, A. Enhanced thermoelectric performance in p-type ZrCoSb based half-Heusler alloys employing nanostructuring and compositional modulation. J. Mater. 2019, 5, 94–102. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S.S. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Johari, K.K.; Sharma, D.K.; Verma, A.K.; Bhardwaj, R.; Chauhan, N.S.; Kumar, S.; Singh, M.N.; Bathula, S.; Gahtori, B. In Situ Evolution of Secondary Metallic Phases in Off-Stoichiometric ZrNiSn for Enhanced Thermoelectric Performance. ACS Appl. Mater. Interfaces 2022, 14, 19579–19593. [Google Scholar] [CrossRef] [PubMed]

| Composition | Density (g/cm3) | Relative Density (%) | Carrier Concentration (1020 cm−3) | Mobility (cm2v−1s−1) |

|---|---|---|---|---|

| TiCoSb | 7.133 | 95.70 | 4.673 | 2.885 |

| Ti(FeCoNi)Sb | 7.104 | 95.30 | 1.471 | 5.914 |

| Ti0.99Nb0.01(FeCoNi)Sb | 7.093 | 95.16 | 1.562 | 5.451 |

| Ti0.97Nb0.03(FeCoNi)Sb | 7.184 | 96.38 | 1.866 | 4.873 |

| Ti0.95Nb0.05(FeCoNi)Sb | 7.254 | 97.32 | 2.185 | 4.467 |

| Ti0.93Nb0.07(FeCoNi)Sb | 7.315 | 98.13 | 2.454 | 4.239 |

| Ti0.90Nb0.10(FeCoNi)Sb | 7.331 | 98.39 | 2.787 | 3.966 |

| Composition | HH (%) | Fe (%) | FeSb (%) |

|---|---|---|---|

| Ti(FeCoNi)Sb | 95.1 | 4.9 | ~ |

| Ti0.99Nb0.01(FeCoNi)Sb | 94.6 | 5.4 | ~ |

| Ti0.97Nb0.03(FeCoNi)Sb | 92.8 | 7.2 | ~ |

| Ti0.95Nb0.05(FeCoNi)Sb | 90.3 | 9.7 | ~ |

| Ti0.93Nb0.07(FeCoNi)Sb | 84.5 | 11.3 | 4.2 |

| Ti0.90Nb0.10(FeCoNi)Sb | 79.1 | 13.6 | 7.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Kong, J.; Hou, Y.; Zhao, L.; Zhu, J.; Li, C.; Zhao, D. Enhanced Thermoelectric Properties of Nb-Doped Ti(FeCoNi)Sb Pseudo-Ternary Half-Heusler Alloys Prepared Using the Microwave Method. Materials 2023, 16, 5528. https://doi.org/10.3390/ma16165528

Zhang R, Kong J, Hou Y, Zhao L, Zhu J, Li C, Zhao D. Enhanced Thermoelectric Properties of Nb-Doped Ti(FeCoNi)Sb Pseudo-Ternary Half-Heusler Alloys Prepared Using the Microwave Method. Materials. 2023; 16(16):5528. https://doi.org/10.3390/ma16165528

Chicago/Turabian StyleZhang, Ruipeng, Jianbiao Kong, Yangbo Hou, Linghao Zhao, Junliang Zhu, Changcun Li, and Degang Zhao. 2023. "Enhanced Thermoelectric Properties of Nb-Doped Ti(FeCoNi)Sb Pseudo-Ternary Half-Heusler Alloys Prepared Using the Microwave Method" Materials 16, no. 16: 5528. https://doi.org/10.3390/ma16165528