Effect of Sepiolite on the Field-Dependent Normal Force of Magnetorheological Grease

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.1.1. Raw Materials

2.1.2. Principle of the Experiment

- (1)

- saponification reaction of 12-hydroxystearic acid and sebacic acid to generate lithium-based complex;

- (2)

- reaction of isopropyl aluminum alcoholate, benzoic acid, and 12-hydroxystearic acid to form the aluminum-based complex;

- (3)

- thickening of dimethyl silicone oil with the lithium-based complex and aluminum-based complex to form lithium–aluminum-based grease. Prior to thickening, carbonyl iron powder is added to produce ALC, and ALC is combined with sepiolite to form ALCH.

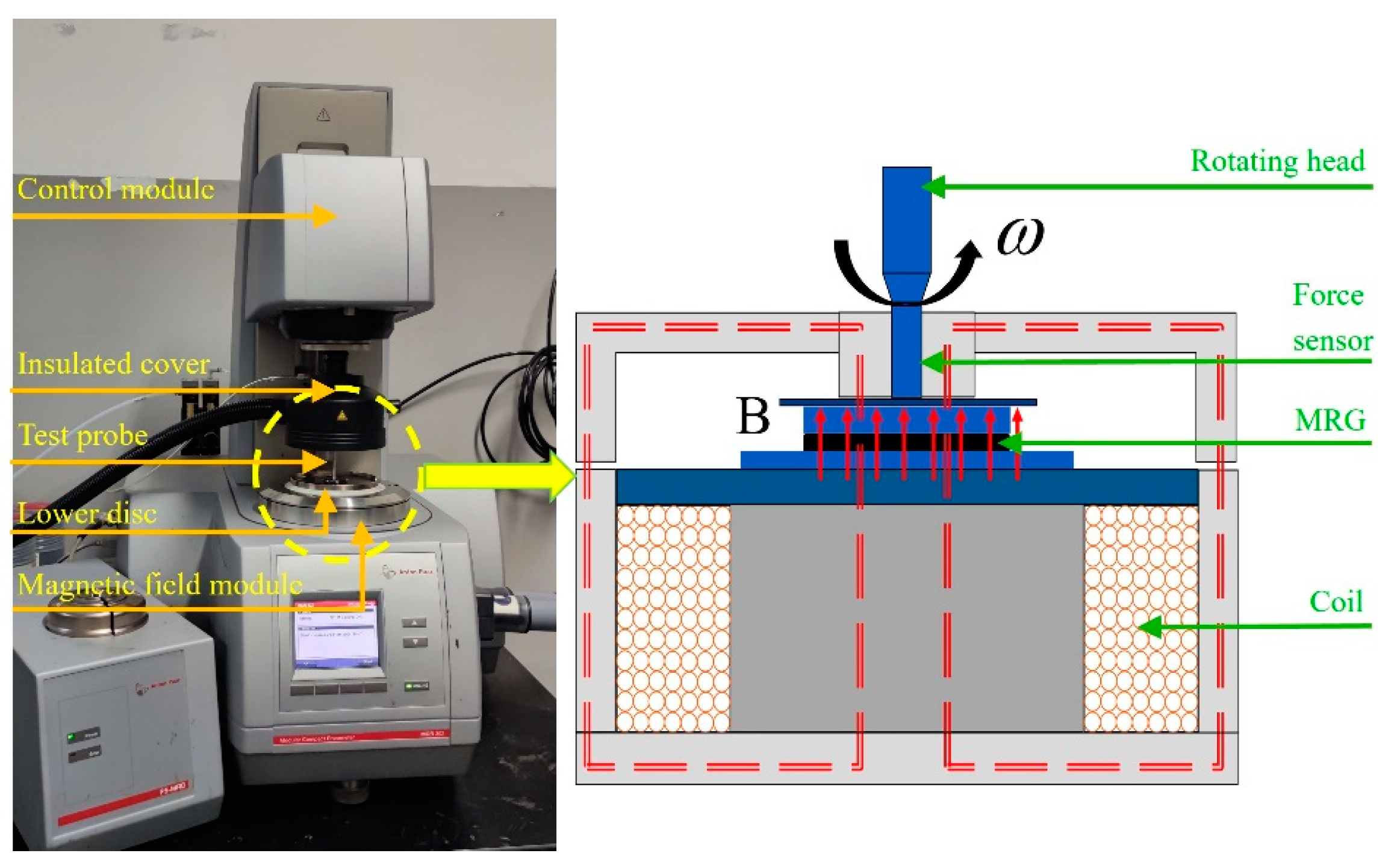

2.2. Test Equipment and Experimental Principle

3. Results and Analysis

3.1. Normal Force of ALC and ALCH in Steady-State Mode

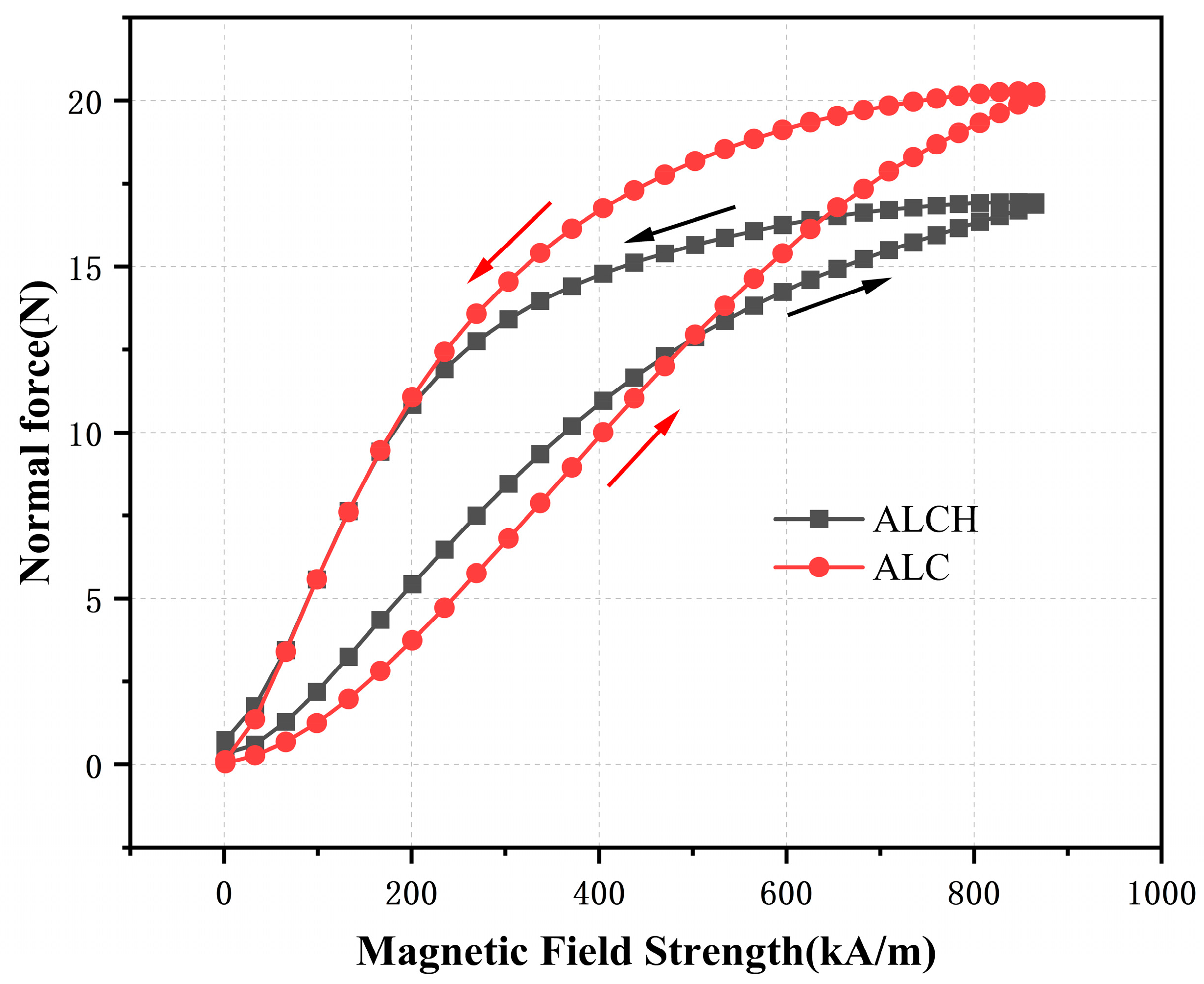

3.1.1. The Effect of Magnetic Fields on Normal Forces

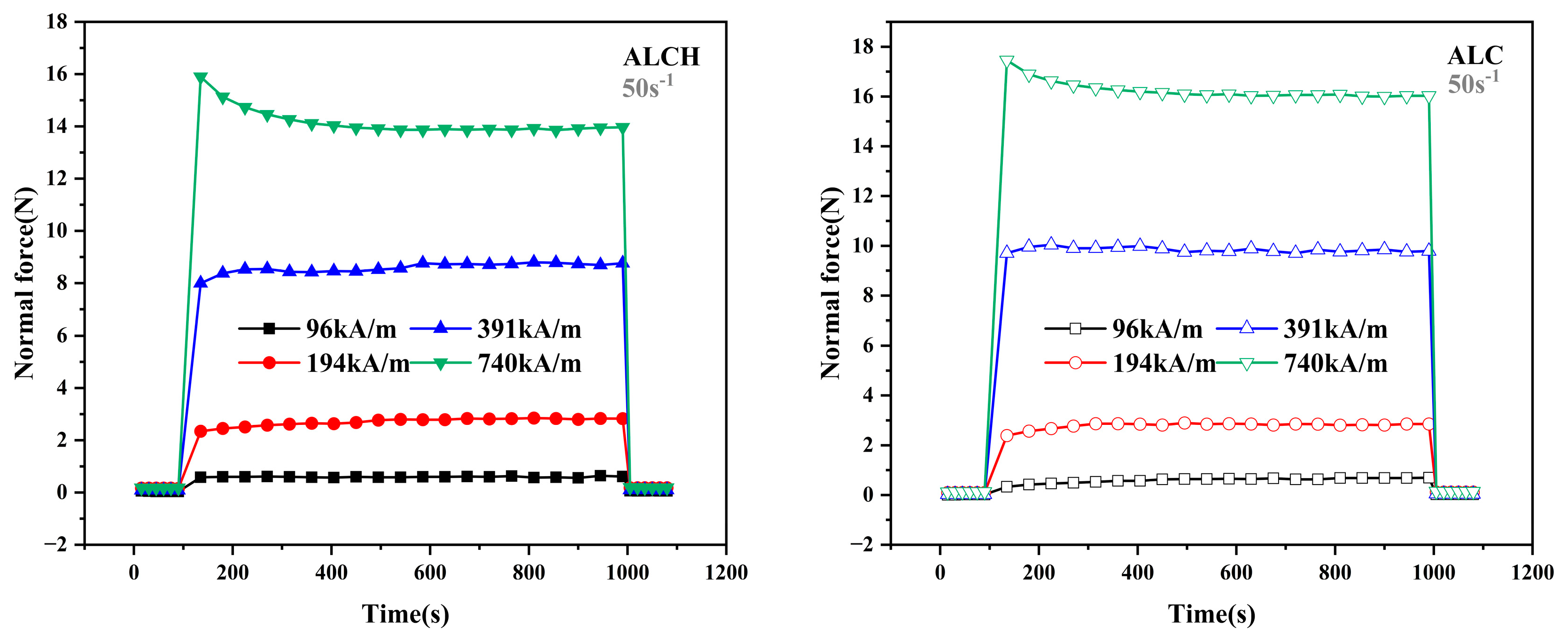

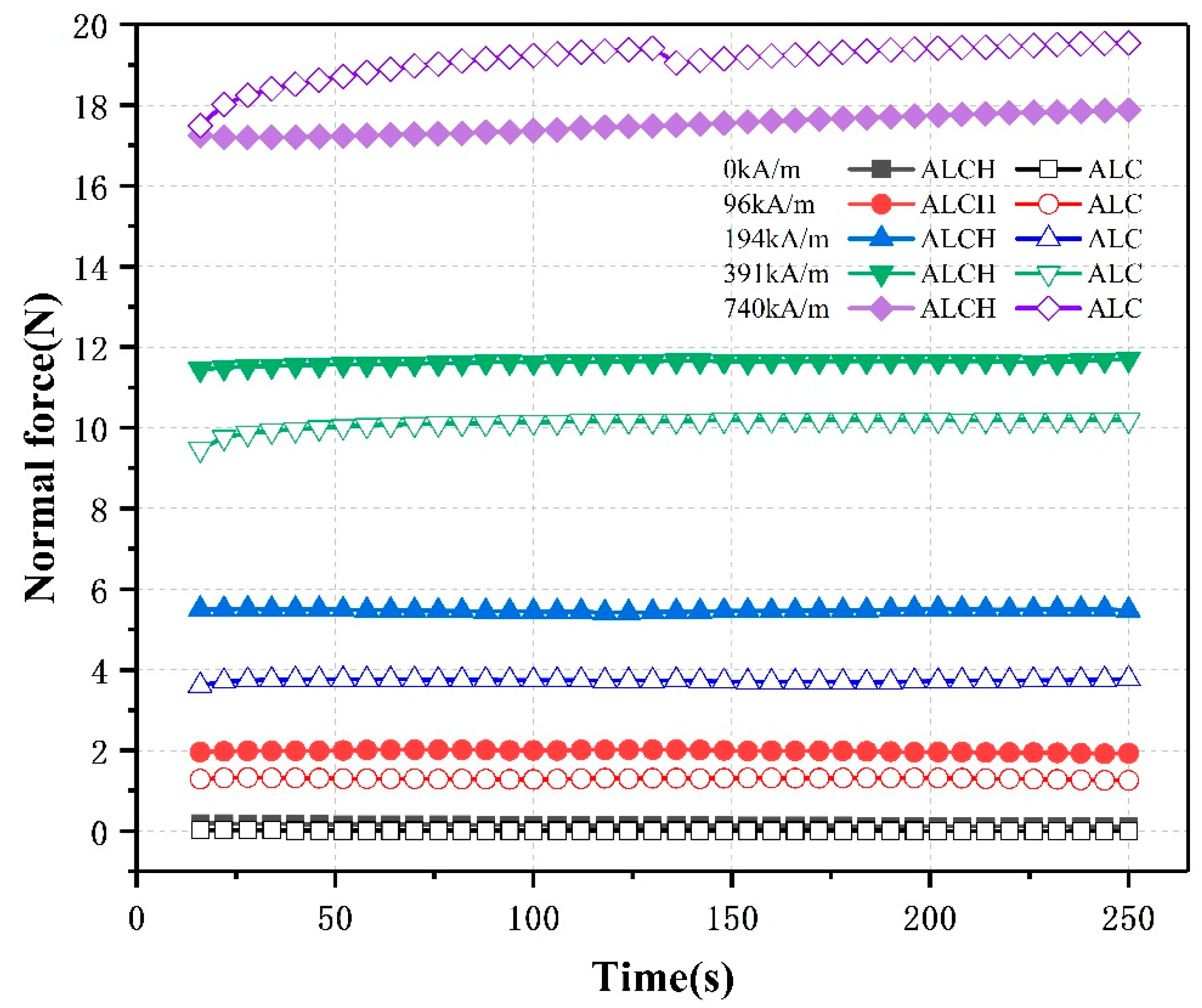

3.1.2. The Effect of Time on Normal Forces

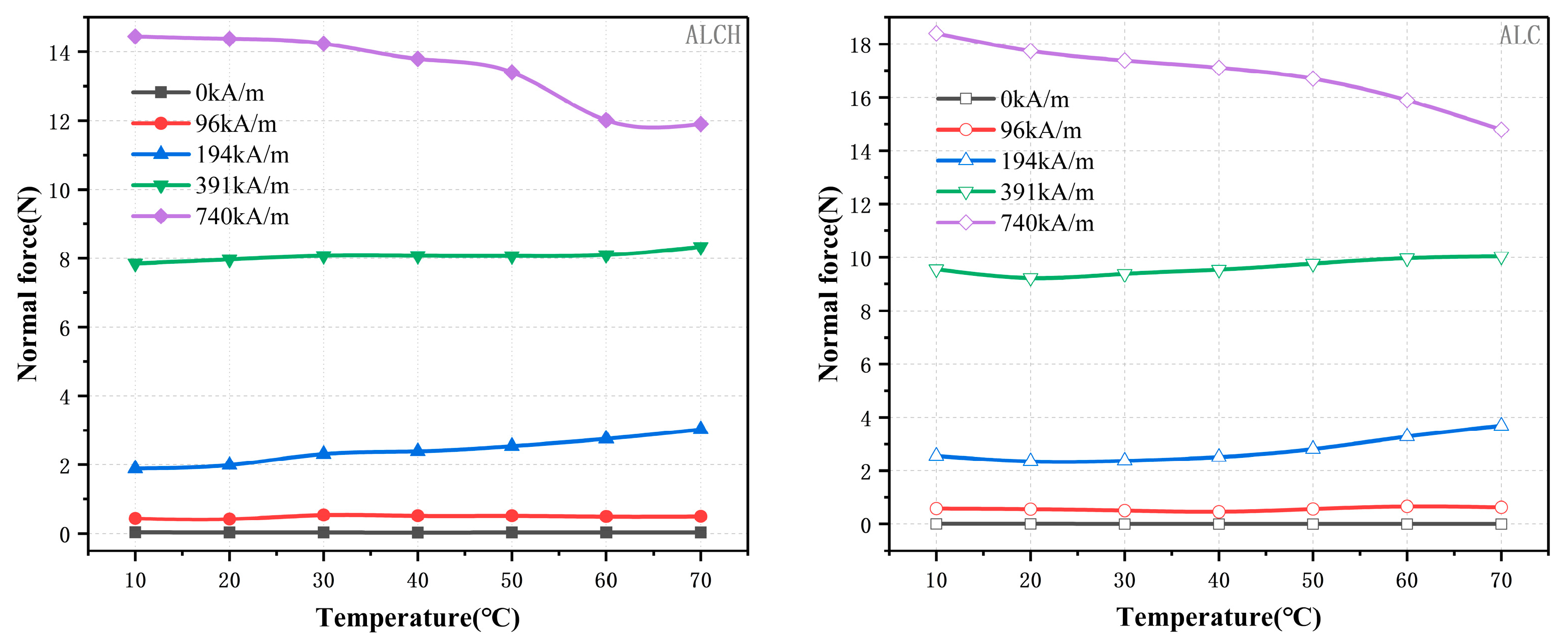

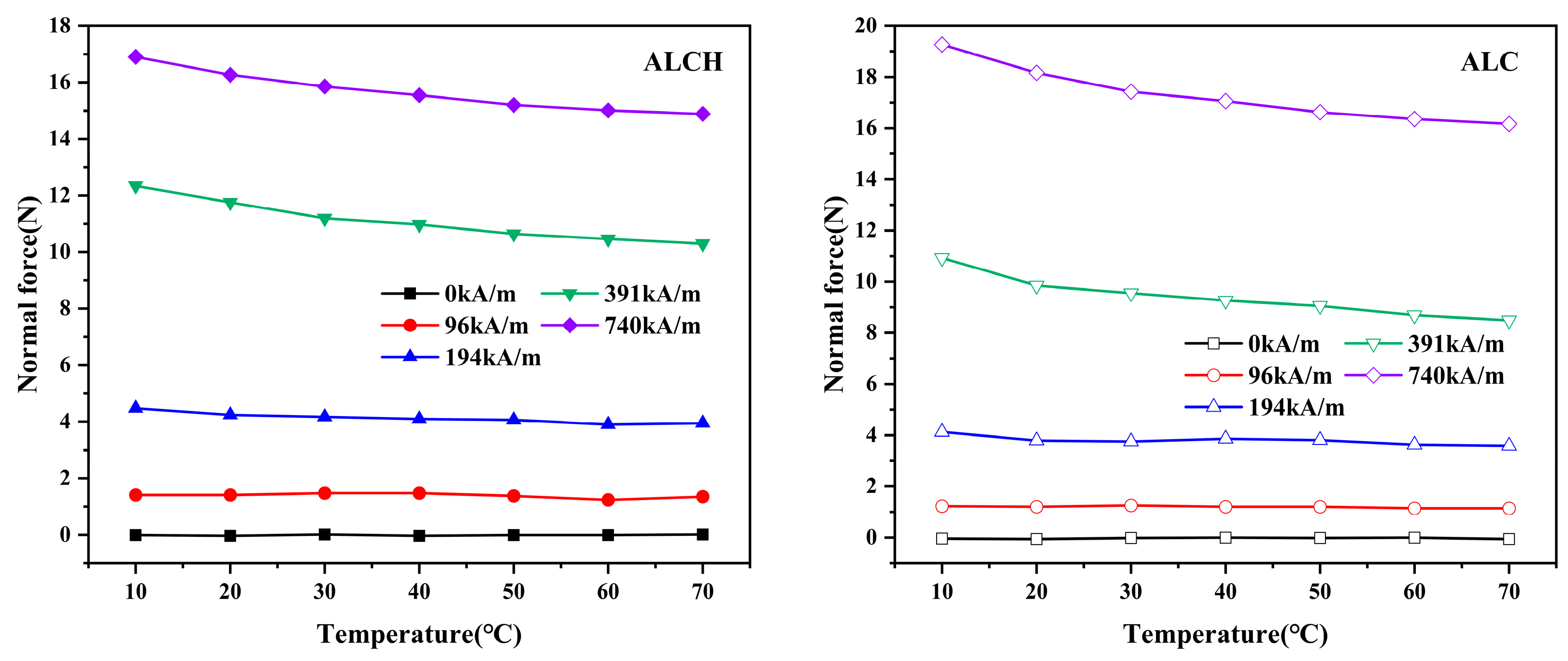

3.1.3. The Effect of Temperature on Normal Forces

3.1.4. The Effect of Shear Rate on Normal Forces

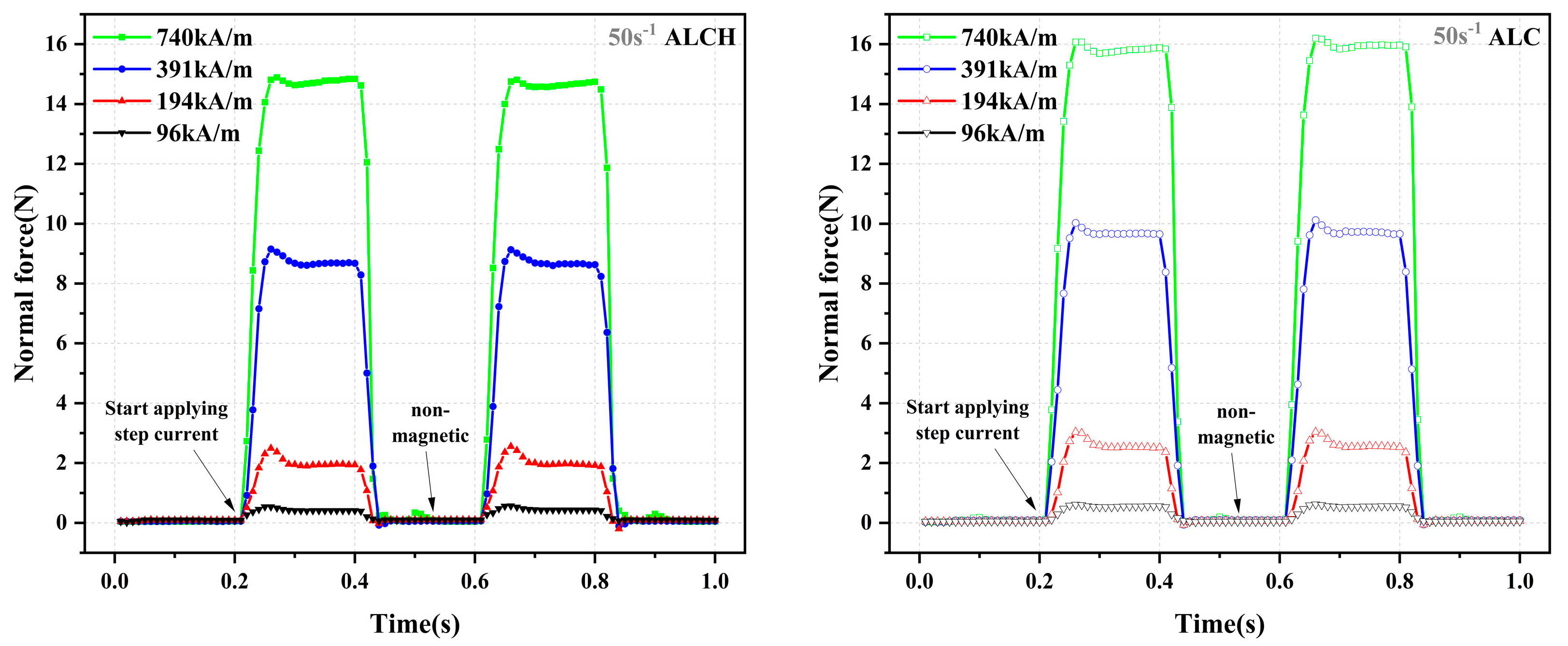

3.1.5. Transient Response

3.2. Normal Force of ALC and ALCH in Oscillation Mode

3.2.1. The Effect of Magnetic Fields on Normal Forces

3.2.2. The Effect of Time on Normal Forces

3.2.3. The Effect of Temperature on Normal Forces

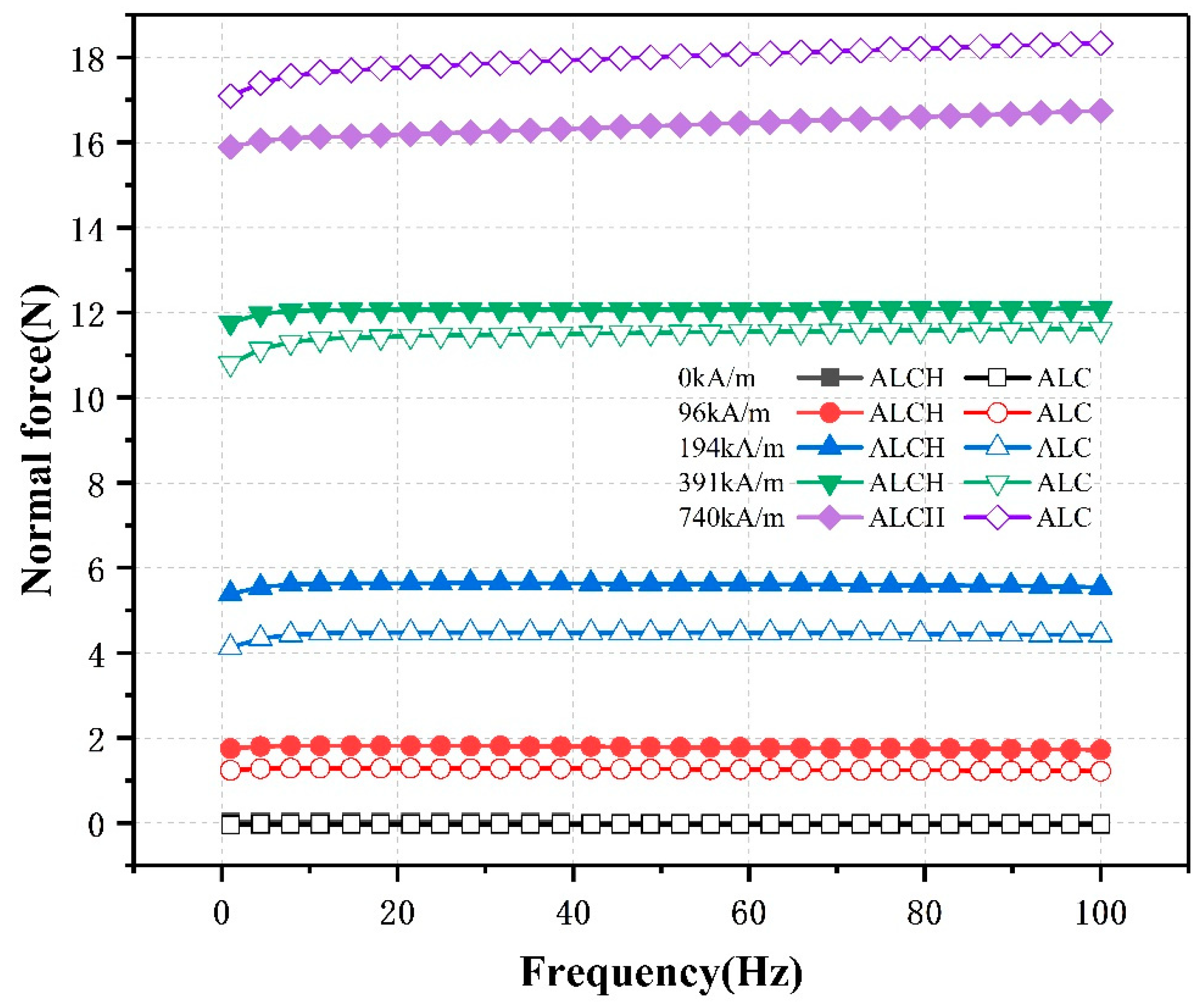

3.2.4. The Effect of Frequency on Normal Forces

3.2.5. The Effect of Strain Amplitude on Normal Force

4. Conclusions

- (1)

- Under steady shear mode, ALC exhibits higher normal force than ALCH at the same magnetic field intensity. The range of normal force variations for ALCH is 10% smaller than for ALC at 860 kA/m. This is because after the addition of sepiolite, the more complex three-dimensional structure composed of sepiolite fibers and soap fibers exacerbates the destruction of the chain structure of the particles. Meanwhile the field-dependent normal force limitations of sepiolite on MRG are not disturbed by temperature, time, and shear rate. The normal force remains steady with time course in the medium–weak magnetic field, and remains steady after showing a decreasing trend at 740 kA/m; the shear rate leads to a decrease in the normal force, but different equilibriums are reached at different magnetic field strengths.

- (2)

- Under oscillatory shear mode, ALC exhibits higher normal force than ALCH at high magnetic fields, but lower normal force at medium and weak magnetic fields. The range of normal force changes for ALCH is 30% less than for ALC. This is because at lower strain amplitudes, as the magnetic field increases, the main contributor of the normal force gradually changes from the fiber structure to the magnetic particle chain. The normal force is almost independent of time and frequency, but a critical value of the strain amplitude exists, which divides the change of normal force with amplitude into two regions: rising and stable.

- (3)

- The effect of temperature on the normal force is mainly manifested under high magnetic field, and the increase in temperature leads to the decrease in normal force under high magnetic field, which is due to the fact that the particle chain is more constrained by the magnetic field under the high intensity magnetic field, and the Brownian motion caused by the increase in temperature will have a negative effect on the particle chain, causing the decrease in normal force. However, sepiolite improves the stability of the normal force in steady state and oscillatory modes by 30% and 36% respectively, indicating that sepiolite is able to reduce the sensitivity to temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohamad, N.; Mazlan, S.A.; Ubaidillah Choi, S.-B.; Nordin, M.F.M. The Field-Dependent Rheological Properties of Magnetorheological Grease Based on Carbonyl-Iron-Particles. Smart Mater. Struct. 2016, 25, 095043. [Google Scholar] [CrossRef]

- Wanning, Z.; Xufeng, D.; Hao, H.; Min, Q. Enhanced magnetorheological effect and sedimentation stability of bimodal magnetorheological fluids doped with iron nanoparticles. J. Intell. Mater. Syst. Struct. 2021, 32, 1271–1277. [Google Scholar]

- Dong, J.; Ye, X.; Lv, Z.; Wang, H.; Wang, J. Temperature effects and a prediction method of field-dependent yield stress in graphite magnetorheological grease. Colloids Surf. A: Physicochem. Eng. Asp. 2023, 673, 131850. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Zhang, G.; Wang, J. Effect of temperature on rheological properties of lithium-based magnetorheological grease. Smart Mater. Struct. 2019, 28, 035002. [Google Scholar] [CrossRef]

- Zhijiang, G.; Kin, W.P.; Jing, Z.; Xingqi, H.; Xinbo, M.; Zhengchao, X. Design of compensatory backstepping controller for nonlinear magnetorheological dampers. Appl. Math. Model. 2023, 114, 318–337. [Google Scholar]

- Guo, H.; Liu, L.; Zhu, X.; Chang, S.; Xu, Z. Design of an Electromagnetic Variable Valve Train with a Magnetorheological Buffer. Energies 2019, 12, 3999. [Google Scholar] [CrossRef] [Green Version]

- Shuyou, W.; Fei, C.; Zuzhi, T.; Aimin, L.; Xiangfan, W. Design, experiment, and performance analysis of magnetorheological clutch with uniform magnetic field distribution along the radial direction for tension control. Rev. Sci. Instrum. 2021, 92, 125006. [Google Scholar]

- Byung-Keun, S.; Seong-Woo, H.; Bo-Gyu, K.; Seung-Bok, C. A new design of small-sized magnetorheological brakes based on the mixed mode operation for high torque efficiency. Smart Mater. Struct. 2021, 30, 117001. [Google Scholar]

- Poddar, P.; Wilson, J.L.; Srikanth, H.; Yoo, J.H.; Wereley, N.M.; Kotha, S.; Barghouty, L.; Radhakrishnan, R. Nanocomposite Magneto-Rheological Fluids with Uniformly Dispersed Fe Nanoparticles. J. Nanosci. Nanotechnol. 2004, 4, 192–196. [Google Scholar] [CrossRef]

- Berasategi, J.; Gomez, A.; Bou-Ali, M.M.; Gutiérrez, J.; Barandiarán, J.M.; Beketov, I.V.; Safronov, A.P.; Kurlyandskaya, G.V. Fe nanoparticles produced by electric explosion of wire for new generation of magneto-rheological fluids. Smart Mater. Struct. 2018, 27, 045011. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, G.; Wang, H.; Ye, X.; Wang, J. Influence of Kinematic Viscosity of Base Oil on Magnetorheological Grease. J. Shanghai Jiaotong Univ. (Sci.) 2022. [Google Scholar] [CrossRef]

- Abdul Aziz, S.A.; Mazlan, S.A.; Ubaidillah, U.; Shabdin, M.K.; Yunus, N.A.; Nordin, N.A.; Choi, S.-B.; Rosnan, R.M. Enhancement of Viscoelastic and Electrical Properties of Magnetorheological Elastomers with Nanosized Ni-Mg Cobalt-Ferrites as Fillers. Materials 2019, 12, 3531. [Google Scholar] [CrossRef] [Green Version]

- Sun, M.; Li, X.; Zhou, Z.; Deng, R.; Chen, X.; Wang, J.; Mao, R. Influence of Magnetic Field and Temperature on Rheological Behavior of Magnetorheological Gel. Materials 2022, 15, 8070. [Google Scholar] [CrossRef]

- Yoon, J.-Y.; Hong, S.-W.; Park, Y.-J.; Kim, S.-H.; Kim, G.-W.; Choi, S.-B. Tunable Young’s Moduli of Soft Composites Fabricated from Magnetorheological Materials Containing Microsized Iron Particles. Materials 2020, 13, 3378. [Google Scholar] [CrossRef]

- Maurya, C.S.; Sarkar, C. Synthesis and characterization of novel flake-shaped carbonyl iron and water-based magnetorheological fluids using laponite and oleic acid with enhanced sedimentation stability. J. Intell. Mater. Syst. Struct. 2021, 32, 1624–1639. [Google Scholar] [CrossRef]

- Chae, H.S.; Piao, S.H.; Maity, A.; Choi, H.J. Additive role of attapulgite nanoclay on carbonyl iron-based magnetorheological suspension. Colloid Polym. Sci. 2015, 293, 89–95. [Google Scholar] [CrossRef]

- Dong, Y.Z.; Han, W.J.; Choi, H.J. Additive effect of rod-like magnetite/sepiolite composite particles on magnetorheology. J. Ind. Eng. Chem. 2021, 93, 210–215. [Google Scholar] [CrossRef]

- Dong, Y.Z.; Piao, S.H.; Choi, H.J. Fe3O4/sepiolite magnetic composite particles and their magneto- responsive characteristics. Colloid Polym. Sci. 2018, 296, 11–19. [Google Scholar] [CrossRef]

- Milde, R.; Moucka, R.; Sedlacik, M.; Pata, V. Iron-Sepiolite High-Performance Magnetorheological Polishing Fluid with Reduced Sedimentation. Int. J. Mol. Sci. 2022, 23, 12187. [Google Scholar] [CrossRef] [PubMed]

- Ahamed, R.; Ferdaus, M.M.; Li, Y. Advancement in energy harvesting magneto-rheological fluid damper: A review. Korea-Australia Rheol. J. 2016, 28, 355–379. [Google Scholar] [CrossRef]

- Hajalilou, A.; Mazlan, S.; Lavvafi, H.; Kamyar, S. Field Responsive Fluids as Smart Materials; Springer: Singapore, 2016. [Google Scholar]

- Vicente, J.D.; Gonzalez-Caballero, F.; Bossis, G.; Volkova, O. Normal force study in concentrated carbonyl iron magnetorheological suspensions. J. Rheol. 2002, 46, 1295–1303. [Google Scholar] [CrossRef]

- See, H.; Tanner, R. Shear rate dependence of the normal force of a magnetorheological suspension. Rheol. Acta 2003, 42, 166–170. [Google Scholar] [CrossRef]

- Laun, H.M.; Gabriel, C.; Schmidt, G. Primary and secondary normal stress differences of a magnetorheological fluid (MRF) up to magnetic flux densities of 1T. J. Non-Newton. Fluid Mech. 2007, 148, 47–56. [Google Scholar] [CrossRef]

- Guo, C.; Gong, X.; Xuan, S.; Zhang, Y.; Jiang, W. An experimental investigation on the normal force behavior of magnetorheological suspensions. Korea-Aust. Rheol. J. 2012, 24, 171–180. [Google Scholar] [CrossRef]

- Guo, C.; Gong, X.; Xuan, S.; Zong, L.; Peng, C. Normal forces of magnetorheological fluids under oscillatory shear. J. Magn. Magn. Mater. 2012, 324, 1218–1224. [Google Scholar] [CrossRef]

- López-López, M.T.; Kuzhir, P.; Durán, J.D.G.; Bossis, G. Normal stresses in a shear flow of magnetorheological suspensions: Viscoelastic versus Maxwell stresses. J. Rheol. 2010, 54, 1119–1136. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, A. Sepiolite: Properties and uses. In Developments in Sedimentology; Elsevier: Amsterdam, The Netherlands, 1984; Volume 37, pp. 253–287. [Google Scholar]

- Preisinger, A. Sepiolite and related compounds: Its stability and application. Clays Clay Miner. 1961, 10, 365–371. [Google Scholar] [CrossRef]

- Suárez, M.; García-Romero, E. Variability of the surface properties of sepiolite. Appl. Clay Sci. 2012, 67, 72–82. [Google Scholar] [CrossRef] [Green Version]

- Qian, K.; Wang, H.; Ye, X.; Du, M.; Wang, J. Rheological properties of lithium-aluminum mixed-soap-based magnetorheological greases with clay minerals. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132134. [Google Scholar] [CrossRef]

- Ju, B.; Yu, M.; Fu, J.; Zheng, X.; Liu, S. Magnetic Field-Dependent Normal Force of Magnetorheological Gel. Ind. Eng. Chem. Res. 2013, 52, 11583–11589. [Google Scholar] [CrossRef]

- Liu, X.; Ye, D.; Gao, X.; Li, F.; Sun, M.; Zhang, H.; Tu, T.; Yu, H. Normal force for static and steady shear mode in magnetorheological fluid. J. Magn. Magn. Mater. 2016, 398, 137–140. [Google Scholar] [CrossRef]

- Lan, Y. Design, Analysis and Experimental Study of Automotive Multi-Disc Magnetorheological Brake [Master]; Hefei University of Technology: Hefei, China, 2019. (In Chinese) [Google Scholar]

- Ye, X.; Wang, G.; Huang, X. Characterisation of normal force on magnetorheological lipids in oscillatory shear mode. J. Hunan Univ. Nat. Sci. Ed. 2020, 47, 49–56. (In Chinese) [Google Scholar]

- Zhang, G.; Wang, H.X.; Ouyang, Q.; Wang, J.; Zhen, J. Study on the rheological properties of magnetorheological gel based on silicone and Herschel-Bulkley model parameter identification. J. Hunan Univ. (Nat. Sci.) 2018, 45, 62–71. (In Chinese) [Google Scholar]

- Ye, X.; Wang, W.; Wang, J. The influence of temperature on the rheological properties of composite lithium-based magnetorheological grease. J. Intell. Mater. Syst. Struct. 2022, 33, 2336–2345. [Google Scholar] [CrossRef]

- Gong, X.; Guo, C.; Xuan, S.; Liu, T.; Zong, L.; Peng, C. Oscillatory normal forces of magnetorheological fluids. Soft Matter 2012, 8, 5256–5261. [Google Scholar] [CrossRef]

| Reagent Name | Specification | Manufacturer |

|---|---|---|

| Dimethyl silicone oil (kinematic viscosity 100 mm2/s) | PMX-200 | Dow Corning Silicone Co., Ltd., Midland, MI, USA |

| Carbonyl iron powder | SQ | Provided by BASF in Ludwigshafen, Germany |

| 12-hydroxystearic acid | H-00994 | Tianjin Heowns Biochem Technologies, LLC., Tianjin, China |

| Sebacic acid | S-00200 | Tianjin Heowns Biochem Technologies, LLC., Tianjin, China |

| Lithium hydroxide monohydrate | P02315 | Shanghai Dingfen Chemical Technology Co., Ltd., Shanghai, China |

| Diphenylamine | M03782 | Shanghai Myrell Chemical Technology Co., Ltd., Shanghai, China |

| Aluminum isopropyl alcohol | CP | Sinopharm Chemical Reagent Co., Ltd., Beijing, China |

| Benzoic acid | AR | Sinopharm Chemical Reagent Co., Ltd., Beijing, China |

| Sepiolite | Sep-01 | Guzhang Shanlin Shiyu Mineral Products Co., Ltd., Changzhou, China |

| Sample | Parameter | |||||||

|---|---|---|---|---|---|---|---|---|

| k | α | R1 | P1 | P2 | P3 | P4 | R2 | |

| ALC | 0.02232 | 1.005 | 0.9722 | −5.016 × 10−8 | 5.473 × 10−5 | 0.01136 | −0.6095 | 0.99711 |

| ALCH | 0.01264 | 1.068 | 0.97556 | −4.766 × 10−8 | 5.612 × 10−5 | 0.005356 | −0.3147 | 0.99811 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, M.; Wang, H.; Ye, X.; Qian, K.; Wang, J. Effect of Sepiolite on the Field-Dependent Normal Force of Magnetorheological Grease. Materials 2023, 16, 5627. https://doi.org/10.3390/ma16165627

Du M, Wang H, Ye X, Qian K, Wang J. Effect of Sepiolite on the Field-Dependent Normal Force of Magnetorheological Grease. Materials. 2023; 16(16):5627. https://doi.org/10.3390/ma16165627

Chicago/Turabian StyleDu, Mengwei, Huixing Wang, Xudan Ye, Kun Qian, and Jiong Wang. 2023. "Effect of Sepiolite on the Field-Dependent Normal Force of Magnetorheological Grease" Materials 16, no. 16: 5627. https://doi.org/10.3390/ma16165627