Thermal Stability and Hot Corrosion Performance of the AlCoCrFeNi2.1 High-Entropy Alloy Coating by Laser Cladding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Preparation

2.3. Coating Characterization

2.4. Hot Corrosion Test

3. Results and Discussion

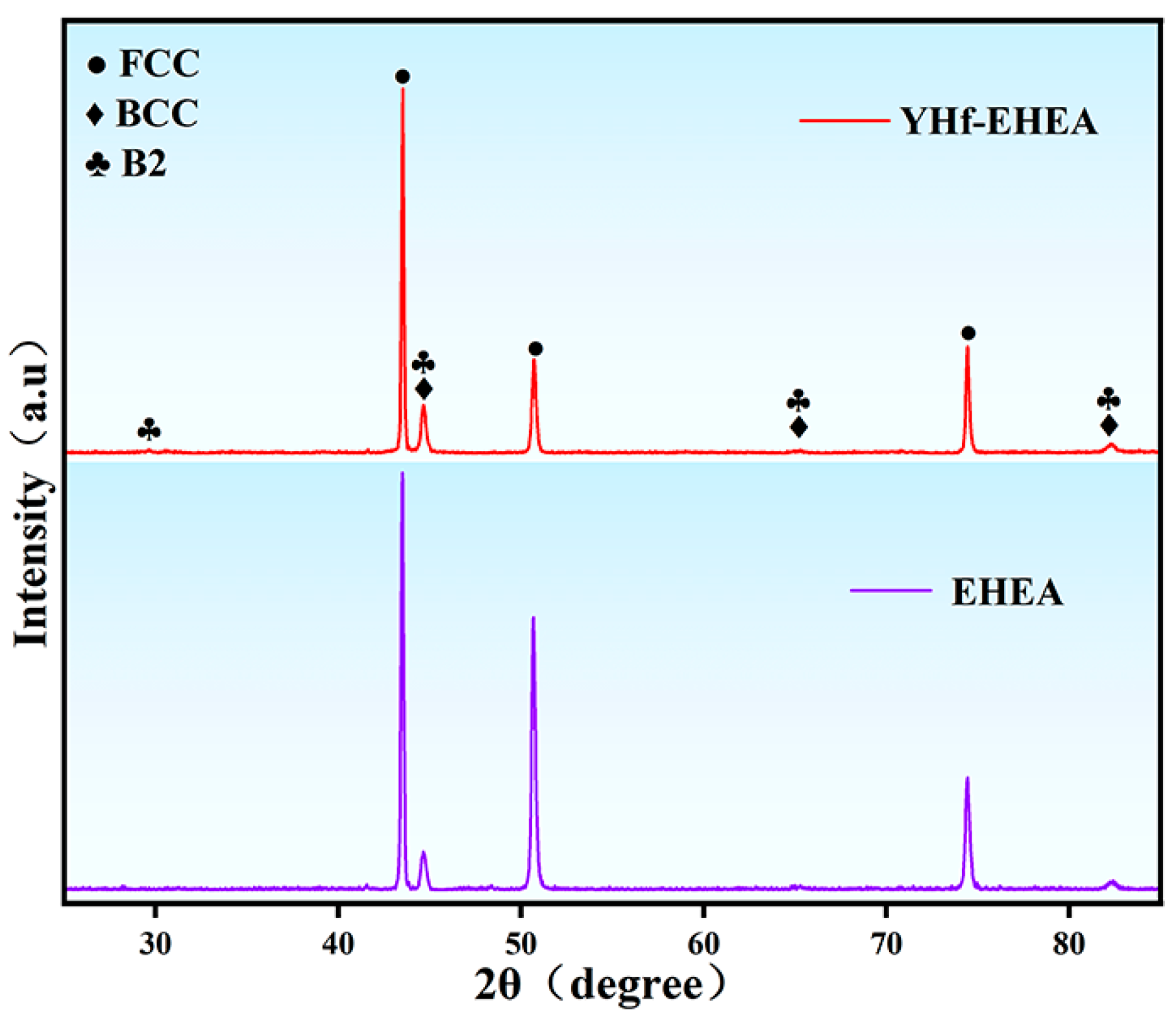

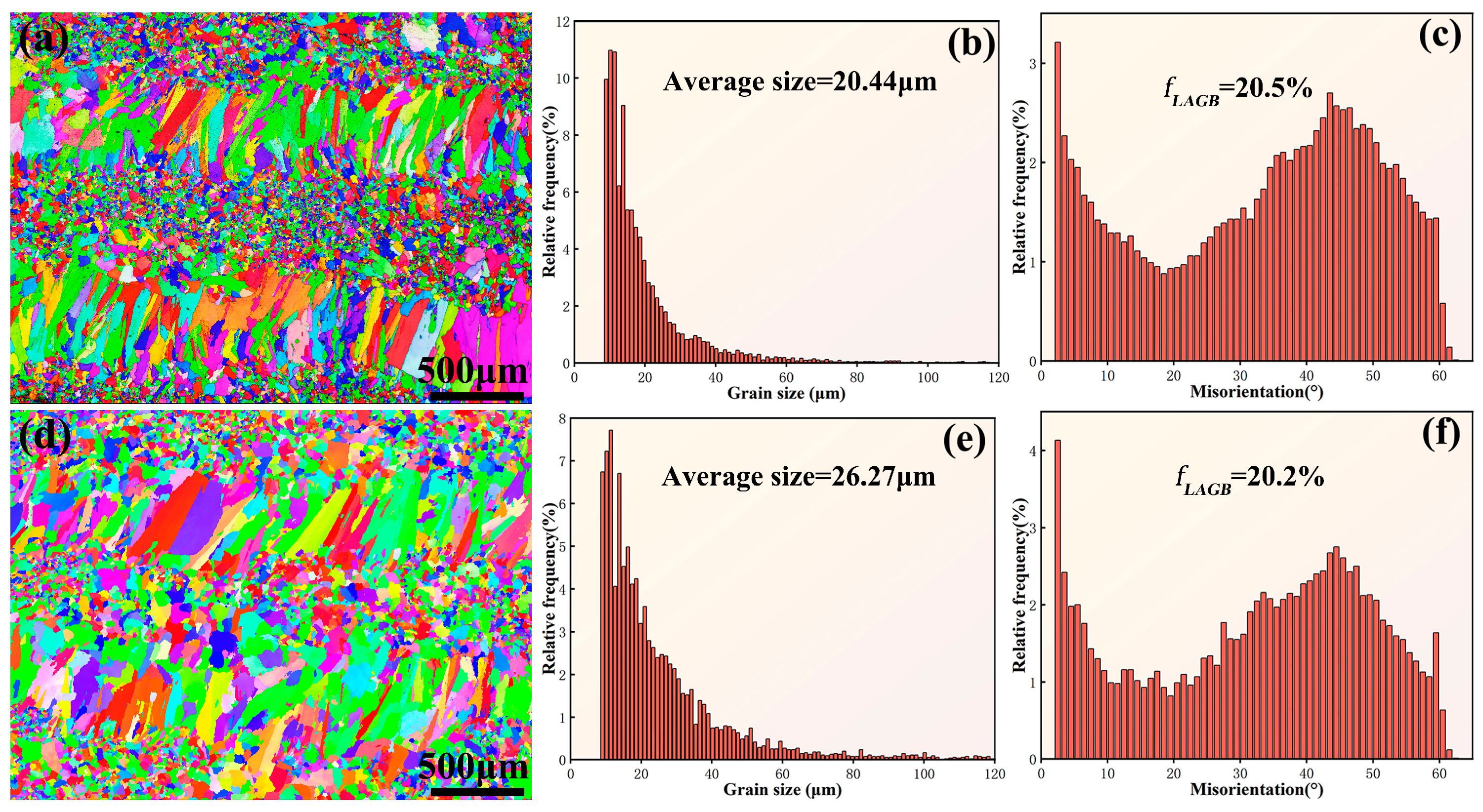

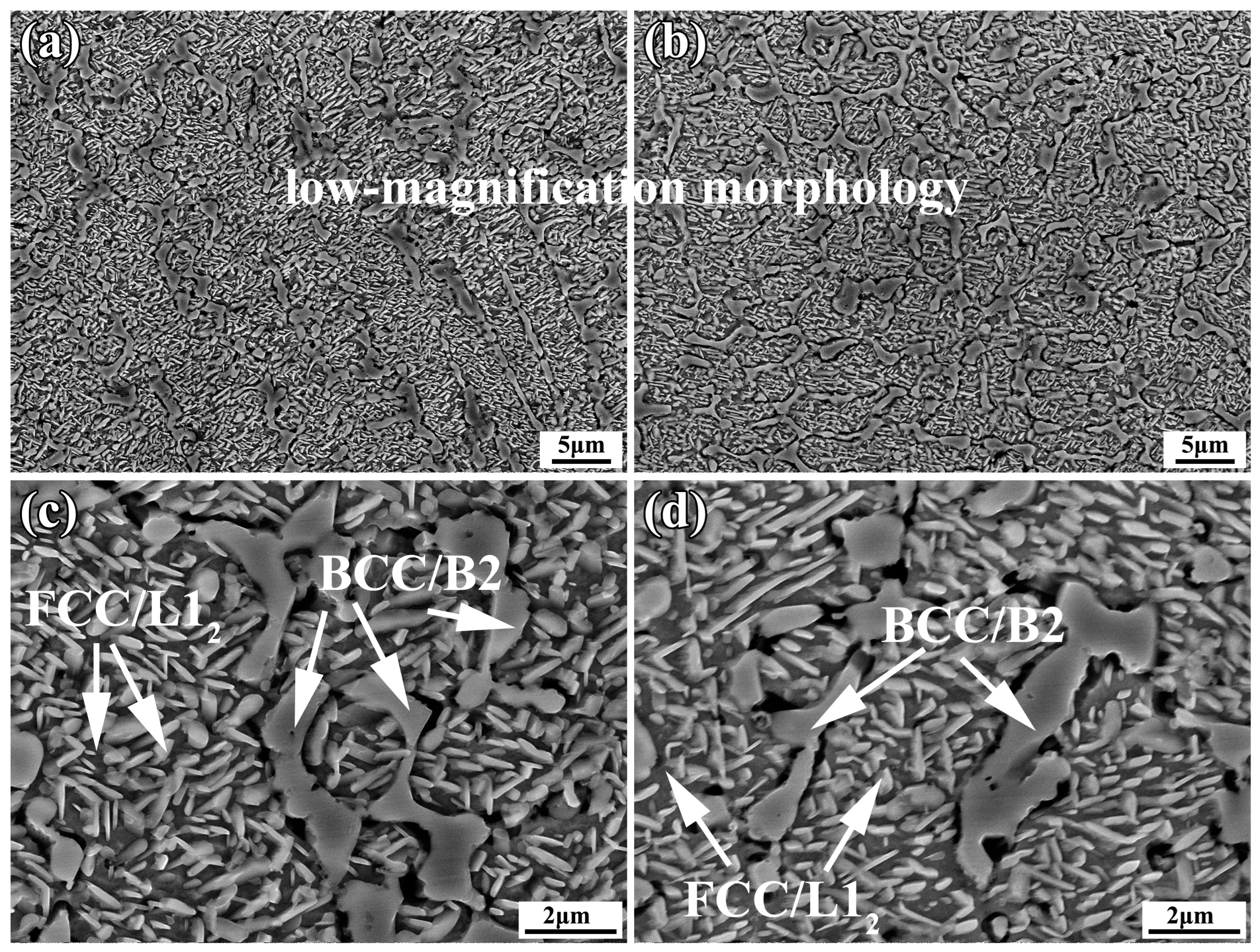

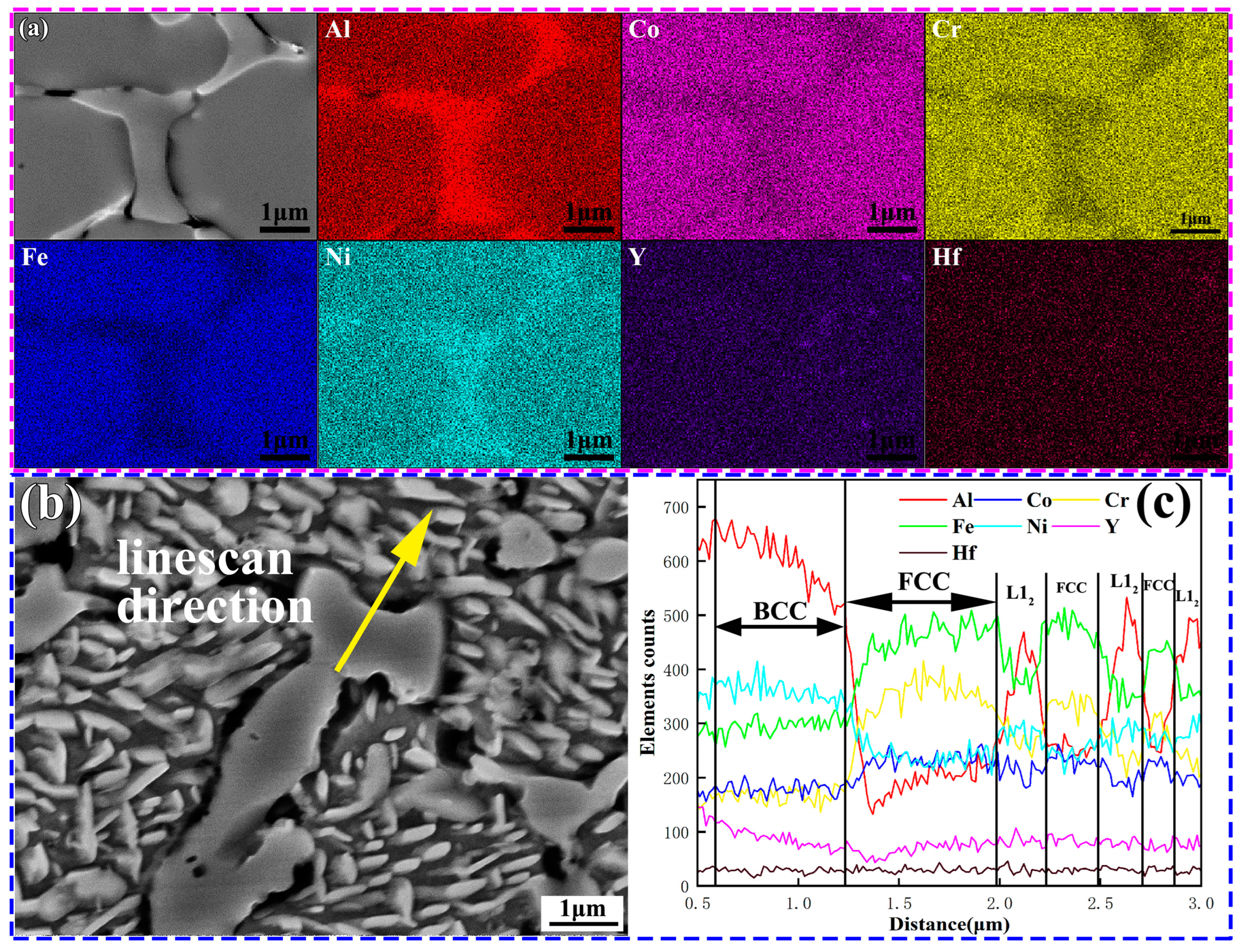

3.1. Microstructure of the Coatings

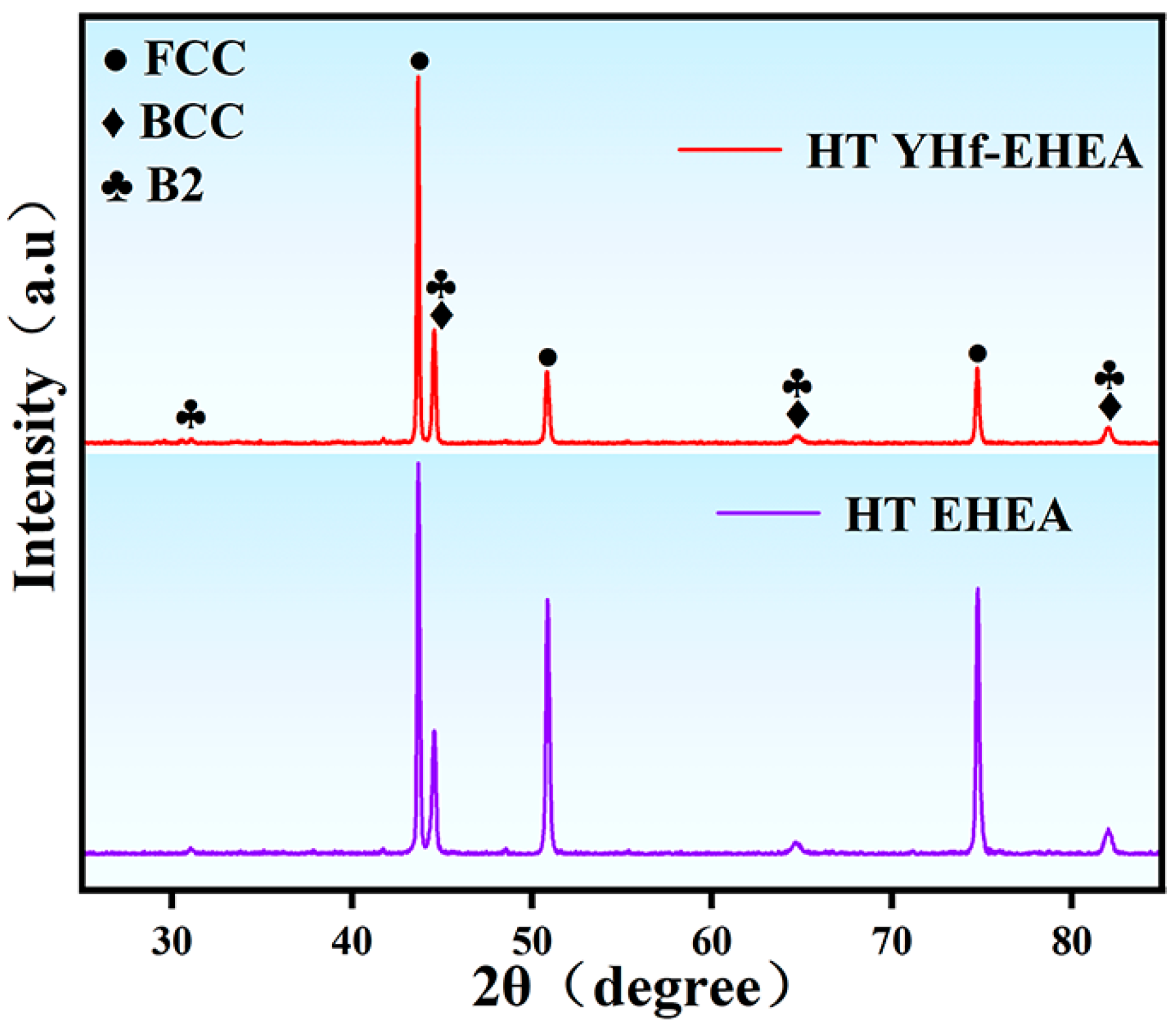

3.2. Thermal Stability of the Coatings

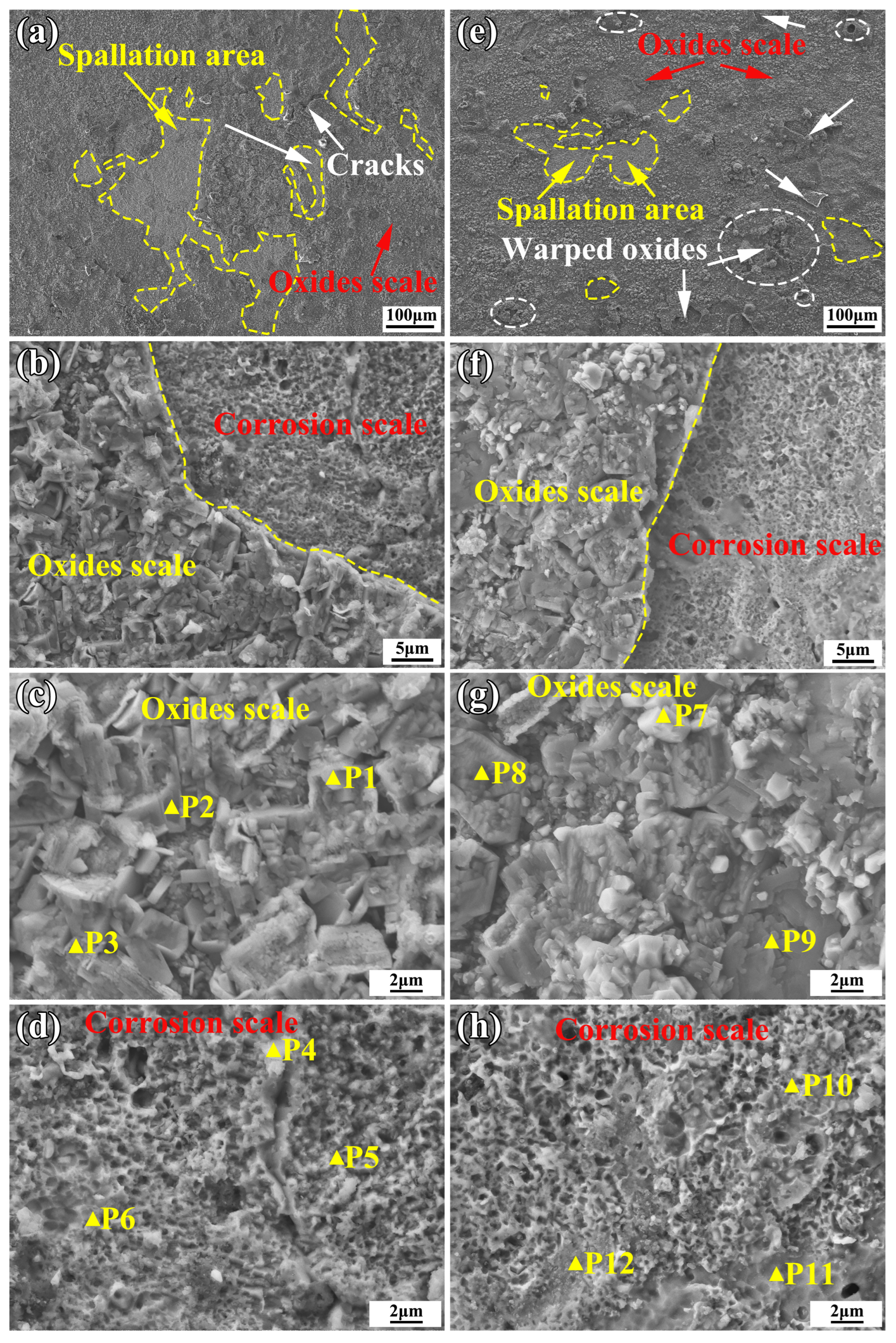

3.3. Hot Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Injeti, G. Identification of a smart bond coating for gas turbine engine applications. J. Coat. Technol. Res. 2008, 5, 385–391. [Google Scholar] [CrossRef]

- Habibi, H.; Guo, S. Evolution of Hot Corrosion Behavior of YSZ-Ta2O5 Composites with Different YSZ/Ta2O5 Ratios. Int. J. Appl. Ceram. Technol. 2015, 12, 542–550. [Google Scholar] [CrossRef]

- Mahajan, S.; Chhibber, R. Hot corrosion studies of boiler steels exposed to different molten salt mixtures at 950 °C. Eng. Fail. Anal. 2019, 99, 210–224. [Google Scholar] [CrossRef]

- Zhang, M.; Feng, Y.; Wang, Y.; Niu, Y.; Xin, L.; Li, Y.; Su, J.; Zhu, S.; Wang, F. Corrosion Behaviors of Nitride Coatings on Titanium Alloy in NaCl-Induced Hot Corrosion. Acta Metall. Sin. 2021, 34, 1434–1446. [Google Scholar] [CrossRef]

- Mitoraj-Królikowska, M.; Godlewska, E. Hot corrosion behaviour of (γ+ α2)-Ti-46Al-8Nb (at.%) and α-Ti-6Al-1Mn (at.%) alloys. Corros. Sci. 2017, 115, 18–29. [Google Scholar] [CrossRef]

- Yan, H.-J.; Xia, J.-J.; Wu, L.-K.; Cao, F.-H. Hot Corrosion Behavior of Ti45Al8.5Nb Alloy: Effect of Anodization and Pre-oxidation. Acta Met. Sin. (Engl. Lett.) 2022, 35, 1531–1546. [Google Scholar] [CrossRef]

- Yu, M.; Cui, T.; Zhou, D.; Li, R.; Pu, J.; Li, C. Improved oxidation and hot corrosion resistance of the NiSiAlY alloy at 750 °C. Mater. Today Commun. 2021, 29, 102939. [Google Scholar] [CrossRef]

- Li, C.; Xu, X.; Wang, S.; Tabie, V.M.; Yang, S.; Zhang, T.; Liu, Y. High-temperature oxidation and hot corrosion behavior of the Cr-modified aluminide coating obtained by a Thermal Diffusion process. Mater. Res. Express 2019, 6, 086444. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Nie, J.; Bai, P.; Liang, Z.; Wei, S.; Cai, J.; Guan, Q. Hot corrosion behavior of a NiCoCrAlY coating fabricated by laser cladding on 17-4PH stainless steel. Eng. Fail. Anal. 2022, 133, 105962. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, S.; Gong, J.; Sun, X.; Sun, C. Preparation and Hot Corrosion Behavior of a NiCrAlY + AlNiY Composite Coating. J. Mater. Sci. Technol. 2016, 32, 587–592. [Google Scholar] [CrossRef]

- Jafari, R.; Sadeghi, E. High-temperature corrosion performance of HVAF-sprayed NiCr, NiAl, and NiCrAlY coatings with alkali sulfate/chloride exposed to ambient air. Corros. Sci. 2019, 160, 108066. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Z.; Ren, P.; Wang, Q.; Bao, Z.; Zhu, S.; Li, W. Hot corrosion behavior of Pt+Hf co-modified NiAl coating in the mixed salt of Na2SO4-NaCl at 900 °C. Corros. Sci. 2020, 167, 108527. [Google Scholar] [CrossRef]

- Zhang, P.; Li, X.-H.; Moverare, J.; Peng, R.L. The iron effect on hot corrosion behaviour of MCrAlX coating in the presence of NaCl at 900 °C. J. Alloys Compd. 2020, 815, 152381. [Google Scholar] [CrossRef]

- Lu, Y.P.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.J.; Wang, T.M.; Wen, B.; Wang, Z.J.; Jie, J.C.; Cao, Z.Q.; et al. A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Hu, W.; Liao, B.; Wan, S.; Kang, L.; Guo, X. Corrosion behavior of AlCoCrFeNi2.1 eutectic high-entropy alloy in Cl− containing solution. J. Alloys Compd. 2023, 938, 168609. [Google Scholar]

- Chen, X.; Kong, J.; Li, J.; Feng, S.; Li, H.; Wang, Q.; Liang, Y.; Dong, K.; Yang, Y. High-strength AlCoCrFeNi2.1 eutectic high entropy alloy with ultrafine lamella structure via additive manufacturing. Mater. Sci. Eng. A 2022, 854, 143816. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Li, L.; Chen, Y.; Liu, X.; Zhao, X.; Guo, F. Y-Hf co-doped AlCoCrFeNi2.1 eutectic high-entropy alloy with excellent oxidation and spallation resistance under thermal cycling conditions at 1100 °C and 1200 °C. Corros. Sci. 2021, 187, 109515. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Chen, Y.; Li, L.; Liu, X.; Xiao, W.; Ni, N.; Zhao, X.; Guo, F.; Xiao, P. Y-doped AlCoCrFeNi2.1 eutectic high-entropy alloy with excellent oxidation resistance and structure stability at 1000 °C and 1100 °C. Corros. Sci. 2021, 180, 109191. [Google Scholar] [CrossRef]

- Vo, T.D.; Tran, B.; Tieu, A.K.; Wexler, D.; Deng, G.; Nguyen, C. Effects of oxidation on friction and wear properties of eutectic high-entropy alloy AlCoCrFeNi2.1. Tribol. Int. 2021, 160, 107017. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Duan, X.; Han, T.; Guan, X.; Wang, Y.; Su, H.; Ming, K.; Wang, J.; Zheng, S. Cooperative effect of Cr and Al elements on passivation enhancement of eutectic high-entropy alloy AlCoCrFeNi2.1 with precipitates. J. Mater. Sci. Technol. 2023, 136, 97–108. [Google Scholar] [CrossRef]

- Wu, M.; Setiawan, R.C.; Li, D.Y. Benefits of passive element Ti to the resistance of AlCrFeCoNi high-entropy alloy to corrosion and corrosive wear. Wear 2022, 492–493, 204231. [Google Scholar] [CrossRef]

- Geantă, V.; Voiculescu, I.; Istrate, B.; Vrânceanu, D.M.; Ciocoiu, R.; Cotruț, C.M. The Influence of Chromium Content on the Structural and Mechanical Properties of AlCrxFeCoNi High Entropy Alloys. Int. J. Eng. Res. Afr. 2018, 37, 23–28. [Google Scholar] [CrossRef]

- Jawańska, M.; Dąbrowa, J.; Bik, M.; Cieślak, G.; Jeleń, P.; Mroczka, K.; Wyrwa, J.; Rogal, Ł.; Gil, A.; Galetz, M.; et al. Role of the rare-earth elements effect in transforming the oxidation behavior of Al oCrFeNi high entropy alloys. Corros. Sci. 2023, 222, 111412. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Y.; Zhang, H.; Ni, N.; Li, L.; He, L.; Mu, R.; Zhao, X.; Guo, F. Y/Hf-doped AlCoCrFeNi high-entropy alloy with ultra oxidation and spallation resistance. Corros. Sci. 2020, 166, 108426. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Lu, J.; Li, L.; Huang, A.; Zhang, H.; Fan, X.; Zhang, X.; Zhao, X. A comparative study on the oxidation behavior of Y-, Hf-and YHf-doped NiCoCrAl alloys: Effect of reactive elements. Corros. Sci. 2023, 218, 111160. [Google Scholar] [CrossRef]

- Unocic, K.A.; Pint, B.A. Oxidation behavior of co-doped NiCrAl alloys in dry and wet air. Surf. Coat. Technol. 2013, 237, 8–15. [Google Scholar] [CrossRef]

- Ding, P.; Mao, A.; Zhang, X.; Jin, X.; Wang, B.; Liu, M.; Gu, X. Preparation, characterization and properties of multicomponent AlCoCrFeNi2.1 powder by gas atomization method. J. Alloys Compd. 2017, 721, 609–614. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Wang, S.; Chen, S.; Jia, Y.; Hu, Z.; Huang, H.; Yang, Z.; Dong, A.; Zhu, G.; Wang, D.; Shu, D.; et al. FCC-L12 ordering transformation in equimolar FeCoNiV multi-principal element alloy. Mater. Des. 2019, 168, 107648. [Google Scholar] [CrossRef]

- Cheng, Q.; Zhang, Y.; Xu, X.; Wu, D.; Guo, S.; Nieh, T.; Chen, J. Mechanistic origin of abnormal annealing-induced hardening in an AlCoCrFeNi2.1 eutectic multi-principal-element alloy. Acta Mater. 2023, 252, 118905. [Google Scholar] [CrossRef]

- Li, L.; Lu, J.; Liu, X.; Dong, T.; Zhao, X.; Yang, F.; Guo, F. AlxCoCrFeNi high entropy alloys with superior hot corrosion resistance to Na2SO4+ 25% NaCl at 900 °C. Corros. Sci. 2021, 187, 109479. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Li, L.; Huang, A.; Liu, X.; Chen, Y.; Zhang, X.; Guo, F.; Zhao, X. Y-Hf co-doped Al1.1CoCr0.8FeNi high-entropy alloy with excellent oxidation resistance and nanostructure stability at 1200 °C. Scr. Mater. 2021, 203, 114105. [Google Scholar] [CrossRef]

- Antunes, R.A.; De Oliveira, M.C.L. Corrosion in biomass combustion: A materials selection analysis and its interaction with corrosion mechanisms and mitigation strategies. Corros. Sci. 2013, 76, 6–26. [Google Scholar] [CrossRef]

- Mohanty, B.P.; Shores, D.A. Role of chlorides in hot corrosion of a cast Fe–Cr–Ni alloy. Part I: Experimental studies. Corros. Sci. 2004, 46, 2893–2907. [Google Scholar] [CrossRef]

- Goebel, J.A.; Pettit, F.S. Na2SO4-induced accelerated oxidation (hot corrosion) of nickel. Met. Trans. 1970, 1, 1943–1954. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Wu, Y.; Chen, C.; Li, Y.; Zhou, W.; Ren, X. Effect of surface morphology and microstructure on the hot corrosion behavior of TiC/IN625 coatings prepared by extreme high-speed laser cladding. Corros. Sci. 2022, 201, 110271. [Google Scholar] [CrossRef]

| Elements | Al | Co | Cr | Fe | Ni | Y | Hf | O |

|---|---|---|---|---|---|---|---|---|

| AlCoCrFeNi2.1 | 8.45 | 18.56 | 16.64 | 17.89 | Bal. | - | - | 0.018 |

| AlCoCrFeNi2.1YHf | 8.34 | 18.14 | 16.28 | 17.64 | Bal. | 0.55 | 0.45 | 0.031 |

| Elements | C | Si | Mn | P | S | Cr | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Percent | 0.44 | 0.27 | 0.60 | 0.018 | 0.007 | 0.017 | 0.009 | 0.009 | Bal. |

| Content | Parameters | Content | Parameters |

|---|---|---|---|

| Laser power | 2000 (W) | Working distance | 16 (mm) |

| Scanning speed | 25 (mm/s) | Protective gas flow rate | 14 (L/min) |

| Feeding rate | 17 (g/min) | Transported gas flow rate | 1.5 (L/min) |

| Spot diameter | 2 (mm) | Overlap ratio | 50% |

| Points | O | Al | Cr | Fe | Co | Ni | S |

|---|---|---|---|---|---|---|---|

| 1 | 28.24 | 8.57 | 17.93 | 42.93 | 0 | 2.34 | 0 |

| 2 | 46.50 | 43.47 | 3.28 | 5.40 | 0.54 | 0.81 | 0 |

| 3 | 45.47 | 43.78 | 4.68 | 6.07 | 0 | 0 | 0 |

| 4 | 53.09 | 40.97 | 3.19 | 2.09 | 0 | 0.67 | 0 |

| 5 | 17.44 | 10.63 | 12.66 | 19.02 | 14.00 | 24.81 | 1.43 |

| 6 | 9.89 | 9.12 | 13.62 | 22.34 | 15.87 | 28.61 | 0.53 |

| 7 | 48.29 | 8.09 | 4.26 | 28.09 | 7.52 | 3.74 | 0 |

| 8 | 49.48 | 40.53 | 4.35 | 5.64 | 0 | 0 | 0 |

| 9 | 50.73 | 36.76 | 4.45 | 6.88 | 0.38 | 0.79 | 0 |

| 10 | 7.82 | 6.25 | 14.83 | 23.95 | 16.09 | 31.05 | 0 |

| 11 | 6.31 | 5.74 | 15.10 | 24.71 | 15.50 | 30.17 | 0 |

| 12 | 12.14 | 9.55 | 13.53 | 21.94 | 16.66 | 32.48 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Ji, Y.; Yang, B. Thermal Stability and Hot Corrosion Performance of the AlCoCrFeNi2.1 High-Entropy Alloy Coating by Laser Cladding. Materials 2023, 16, 5747. https://doi.org/10.3390/ma16175747

Zhang L, Ji Y, Yang B. Thermal Stability and Hot Corrosion Performance of the AlCoCrFeNi2.1 High-Entropy Alloy Coating by Laser Cladding. Materials. 2023; 16(17):5747. https://doi.org/10.3390/ma16175747

Chicago/Turabian StyleZhang, Li, Yan Ji, and Bin Yang. 2023. "Thermal Stability and Hot Corrosion Performance of the AlCoCrFeNi2.1 High-Entropy Alloy Coating by Laser Cladding" Materials 16, no. 17: 5747. https://doi.org/10.3390/ma16175747

APA StyleZhang, L., Ji, Y., & Yang, B. (2023). Thermal Stability and Hot Corrosion Performance of the AlCoCrFeNi2.1 High-Entropy Alloy Coating by Laser Cladding. Materials, 16(17), 5747. https://doi.org/10.3390/ma16175747