Milling Mechanism and Chattering Stability of Nickel-Based Superalloy Inconel 718

Abstract

:1. Introduction

2. Modeling of Milling Forces

2.1. Modeling of Milling Forces of Ball-End Milling Cutter

2.2. Recognition Experiment of Milling Force Coefficients

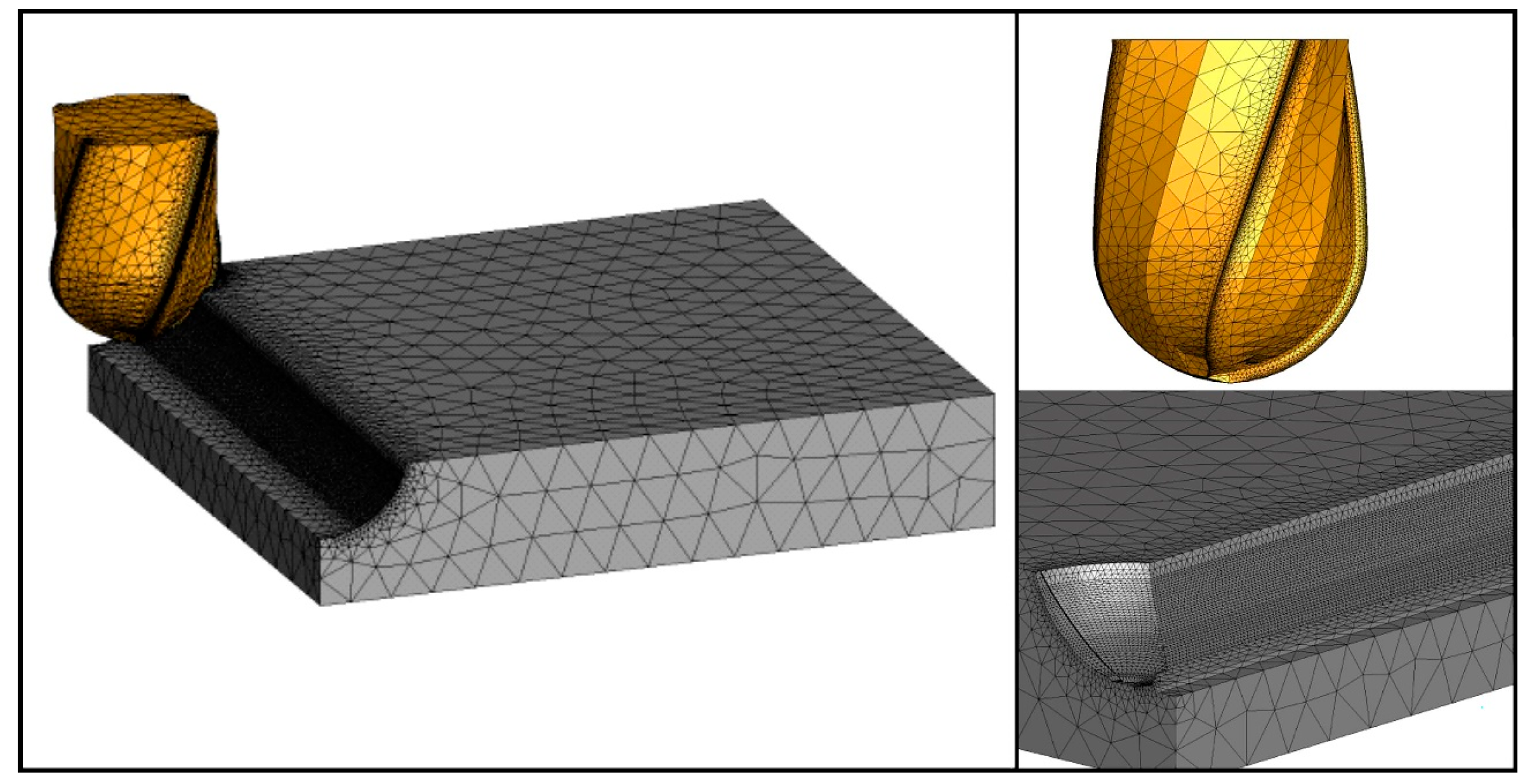

3. Finite Element Analysis of Milling of Inconel 718

3.1. Methodology of Finite Element Analysis

3.2. Result of Finite Element Analysis

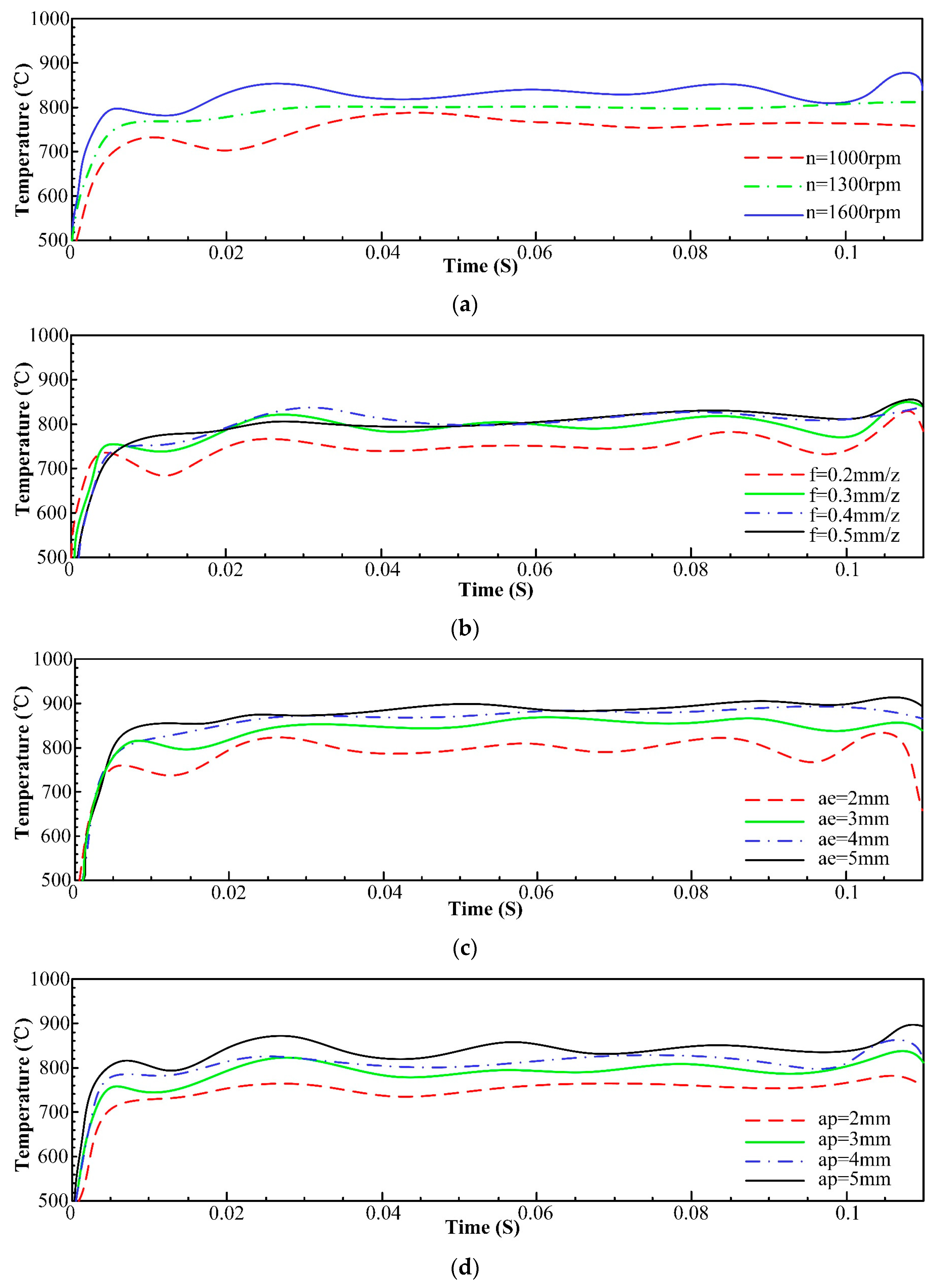

3.2.1. Temperature Field Analysis of Milling Process

3.2.2. Stress Field Analysis of Milling Process

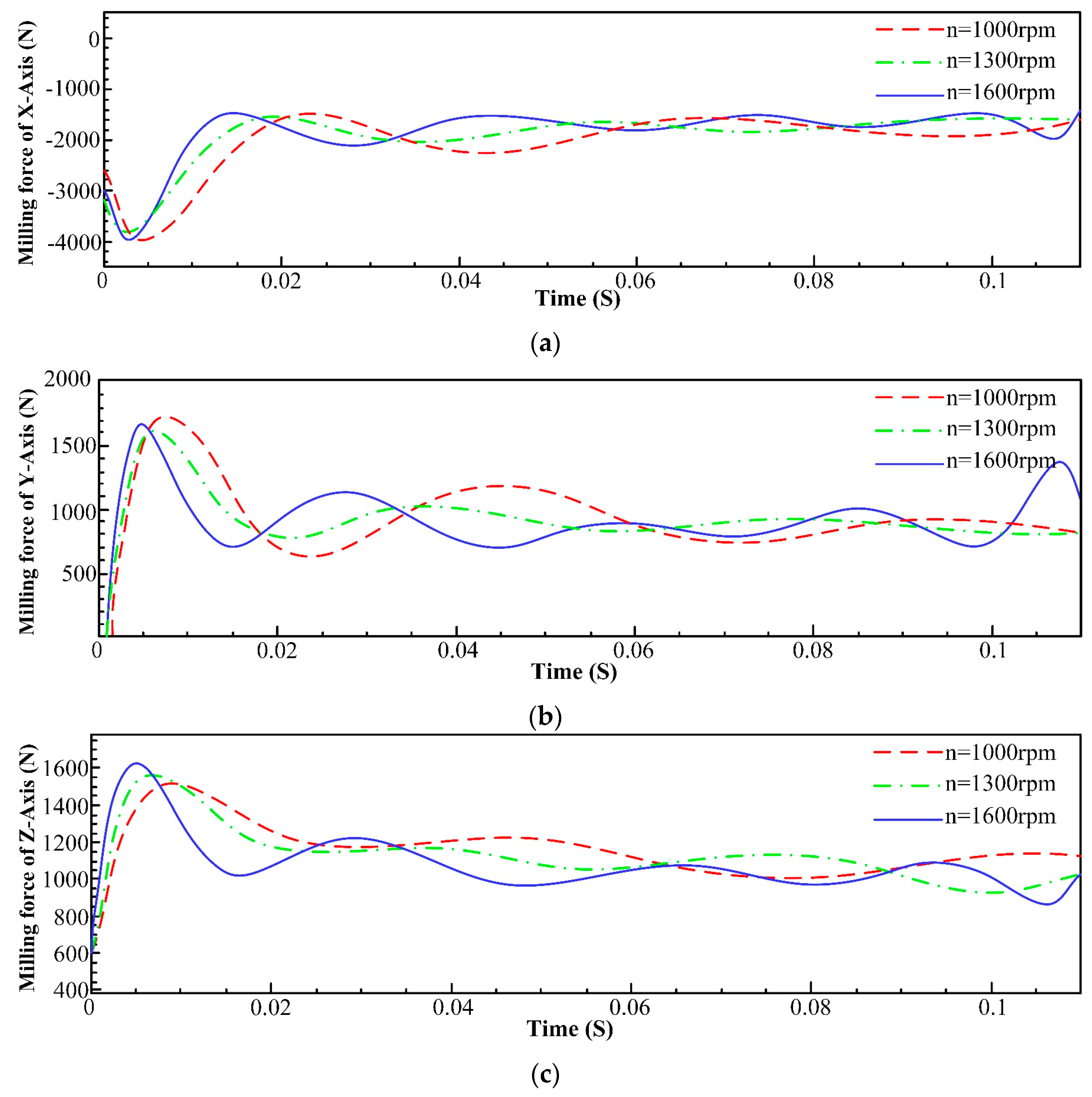

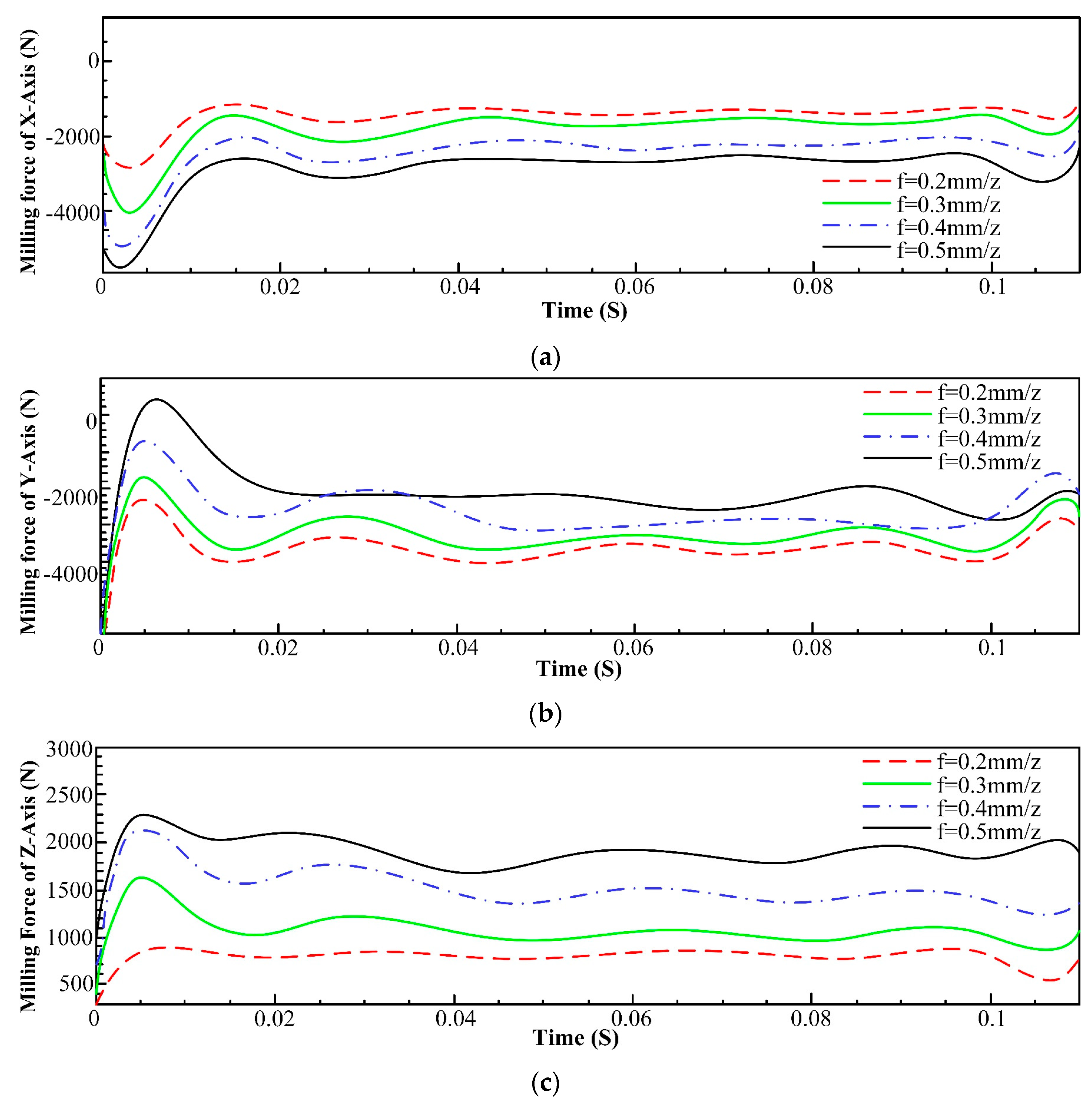

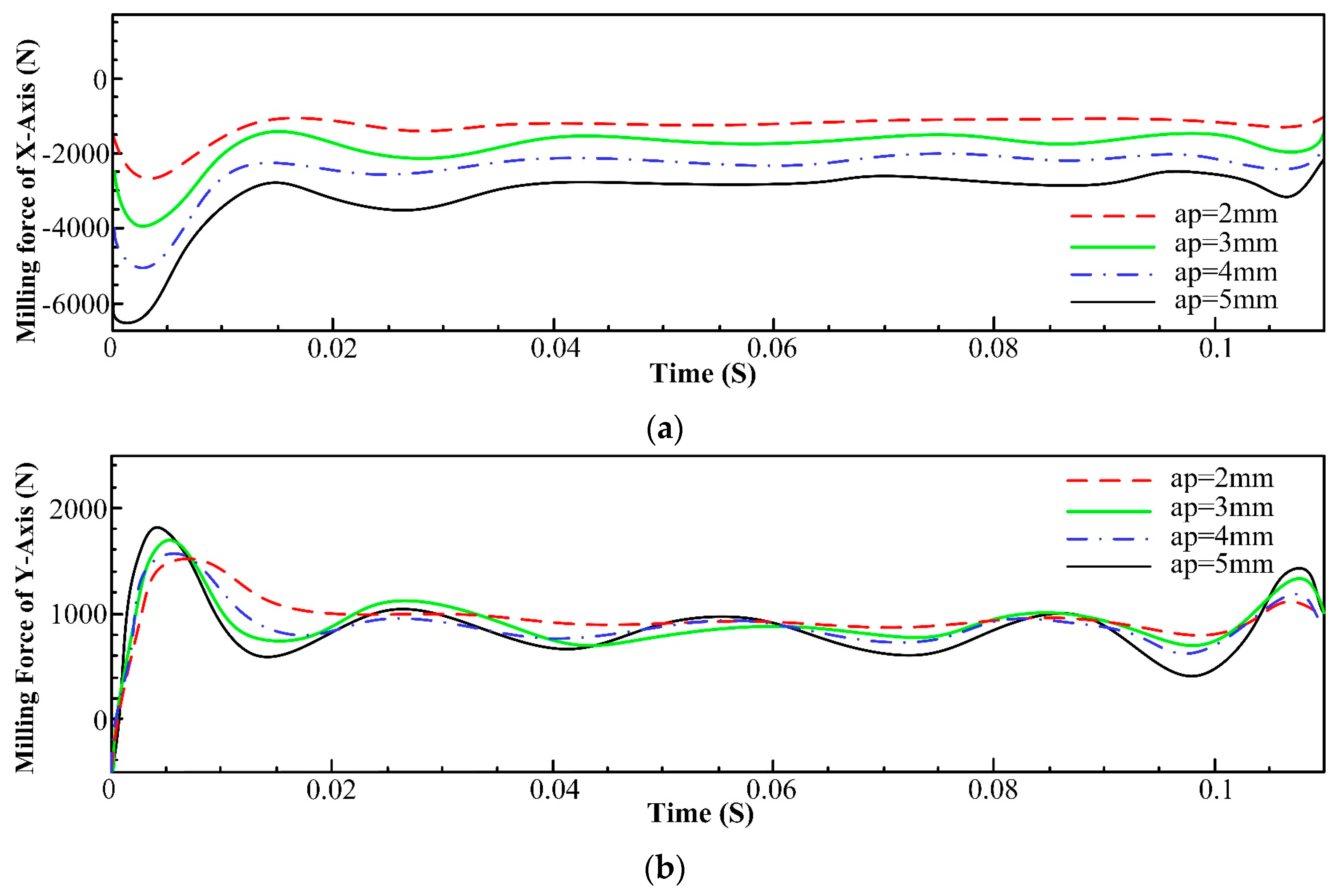

3.2.3. Force Analysis of Milling Process

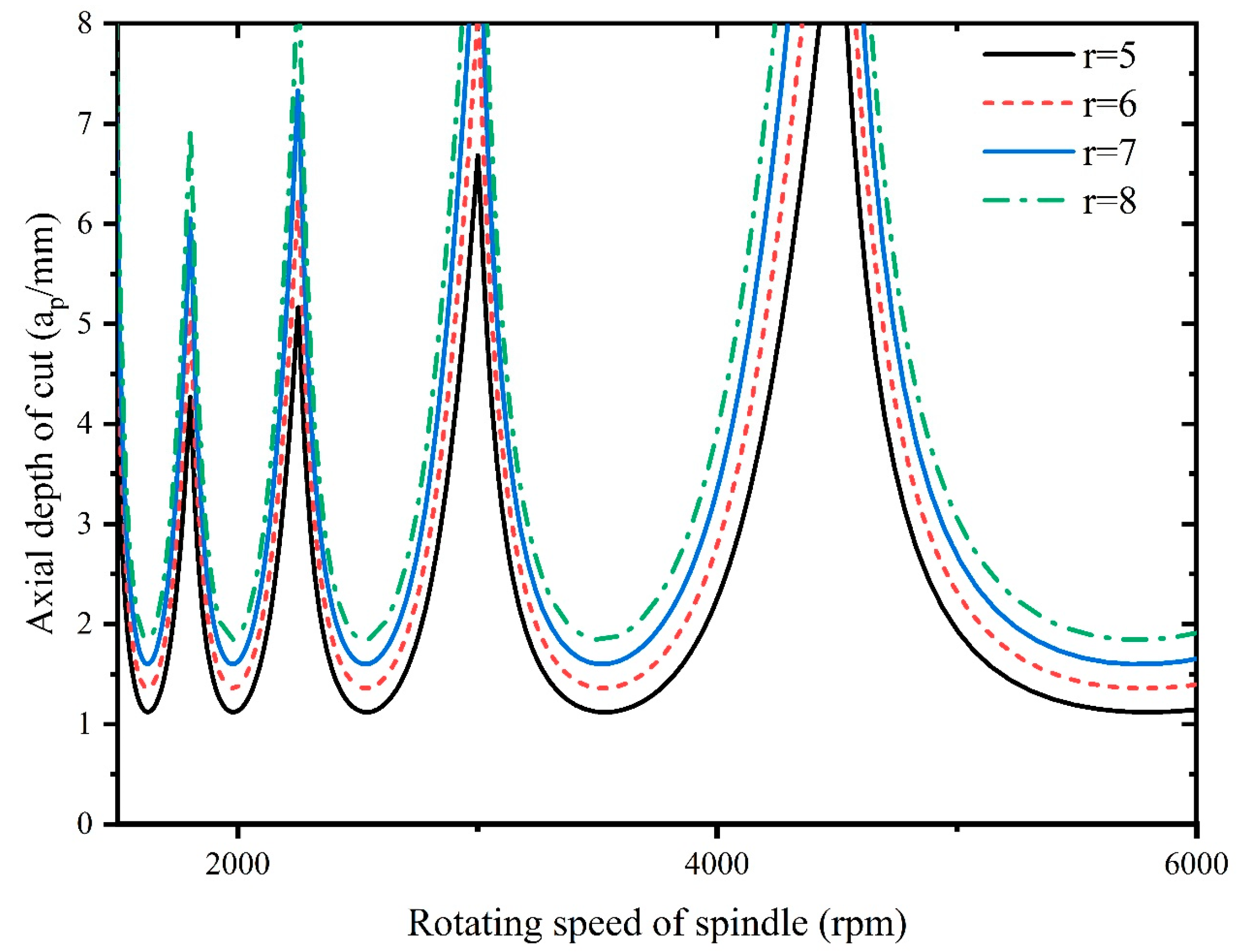

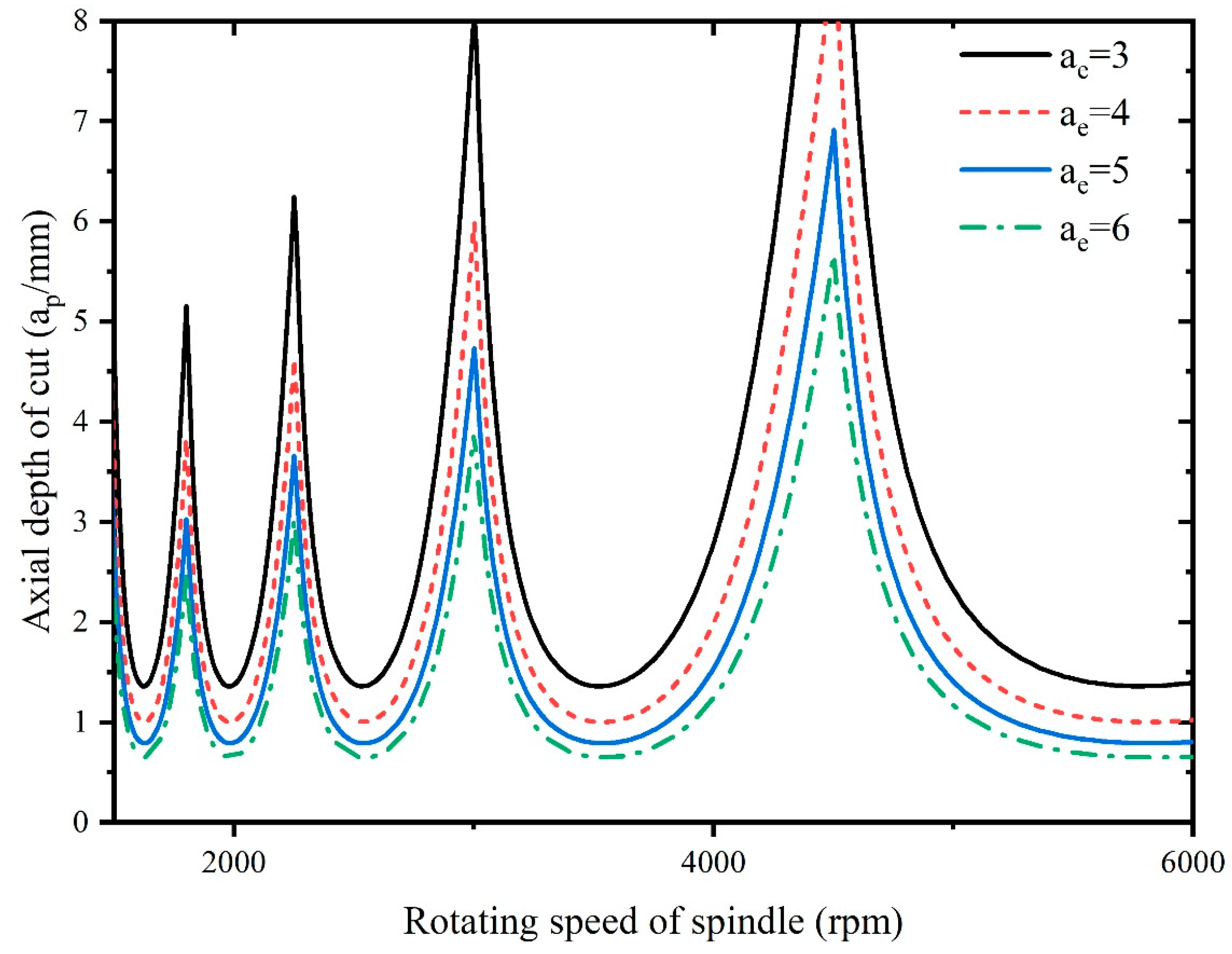

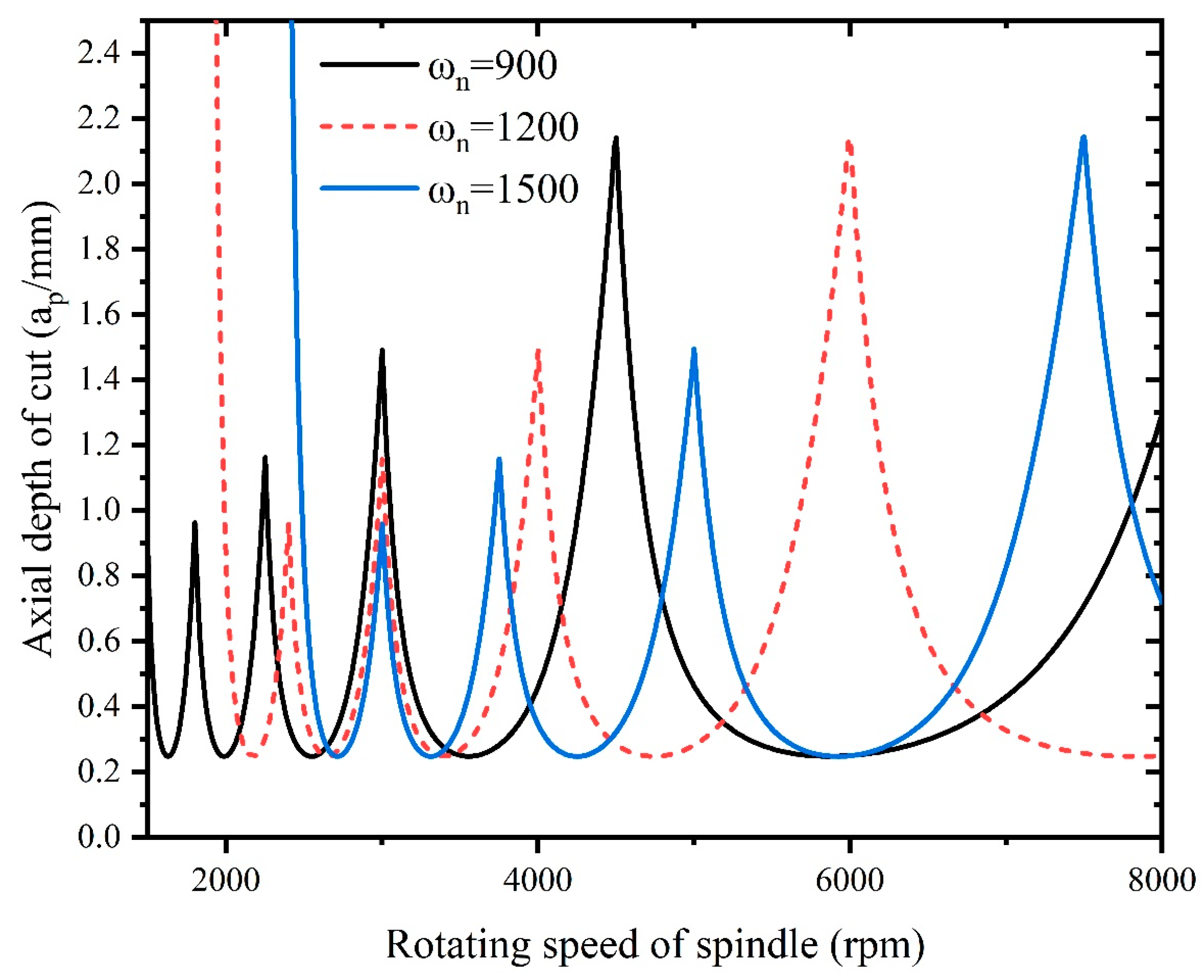

4. Analysis of Milling Stability

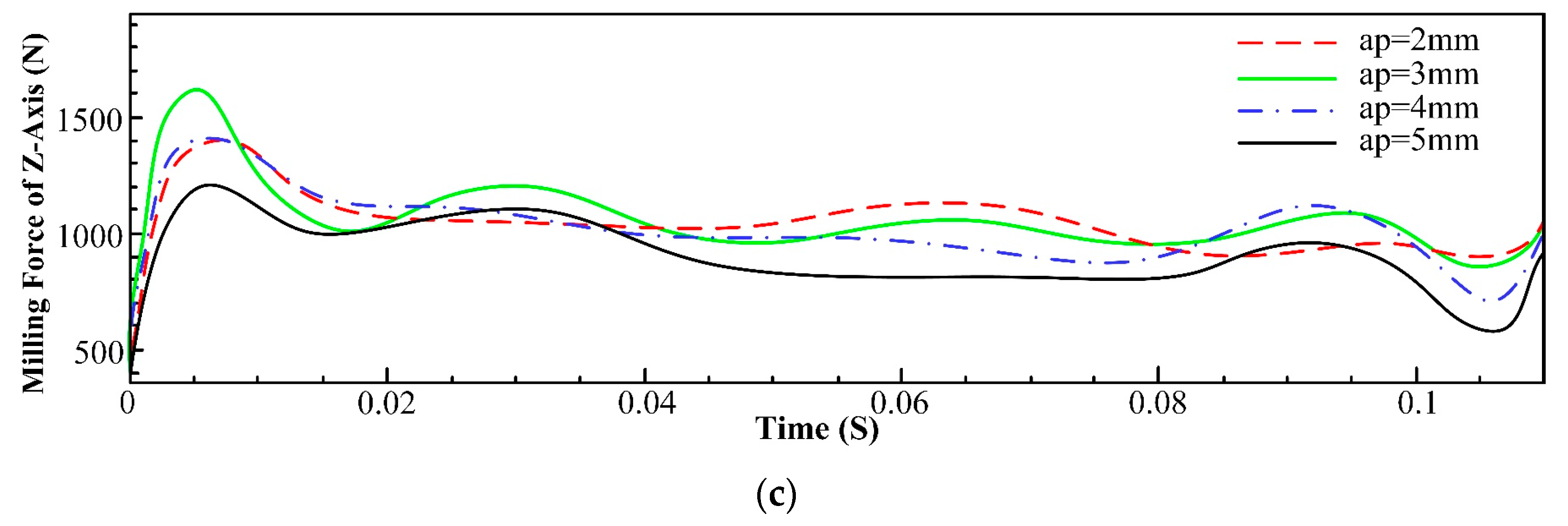

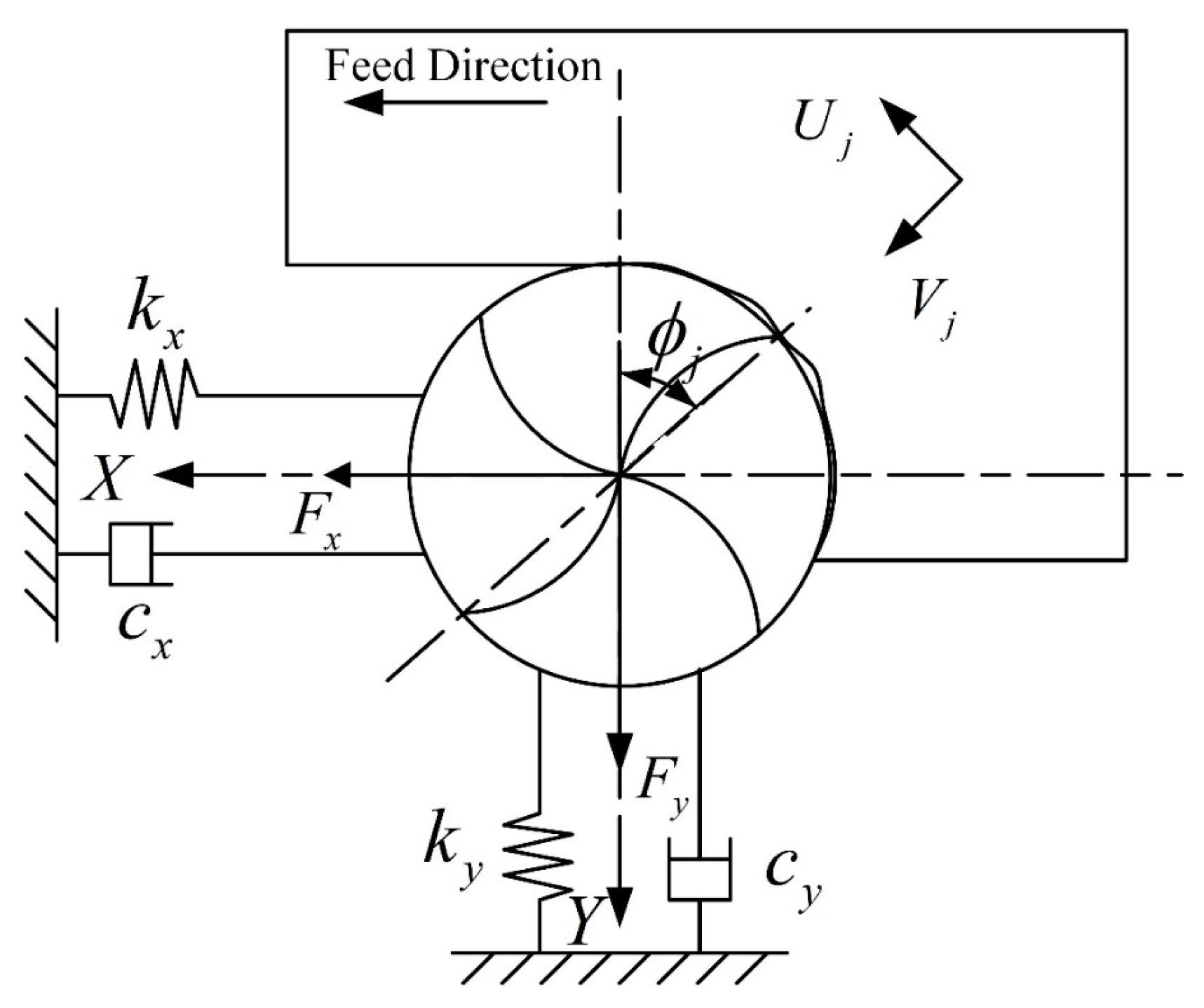

4.1. Establishment of Dynamic Equation for Milling Inconel 718

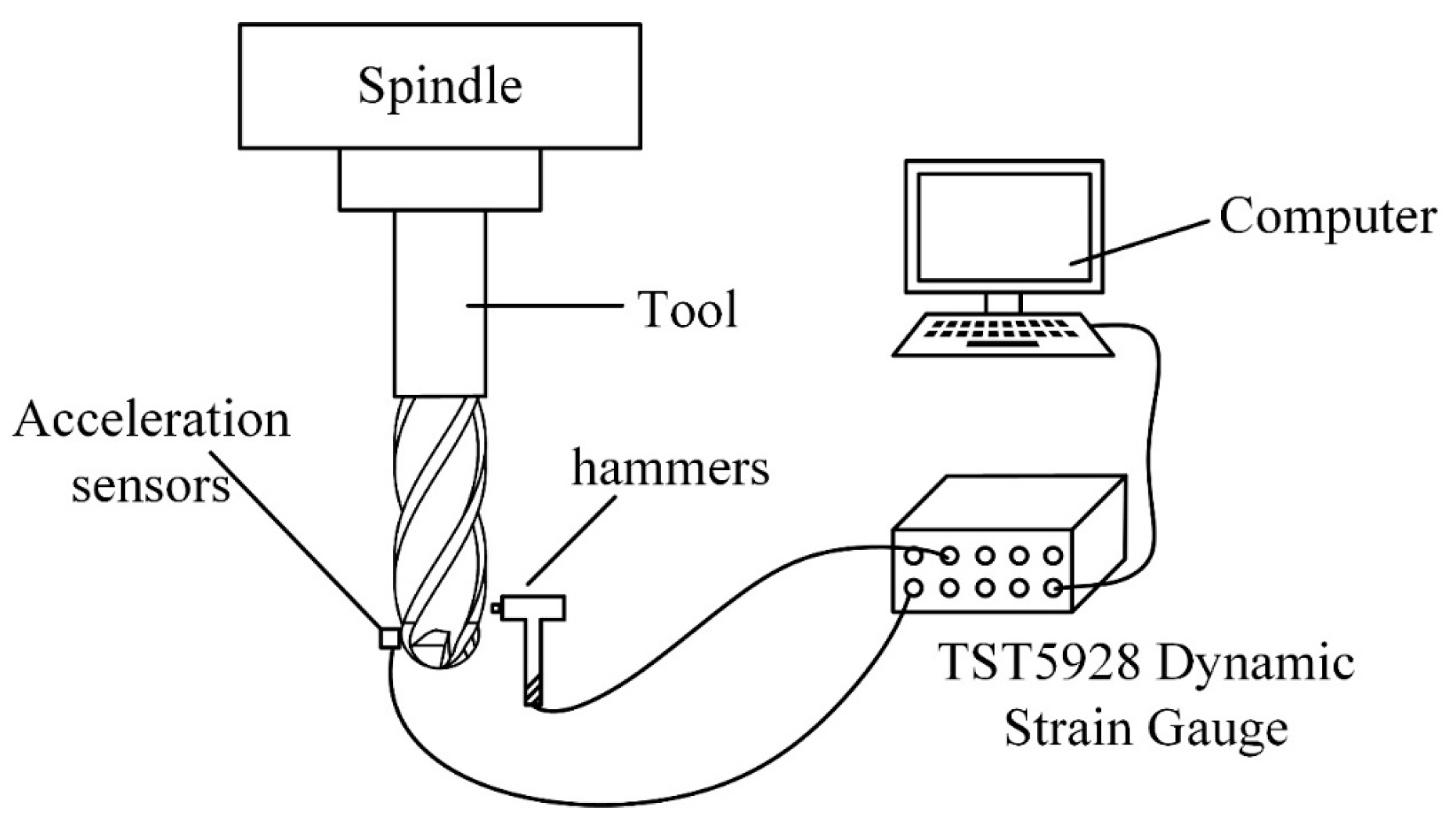

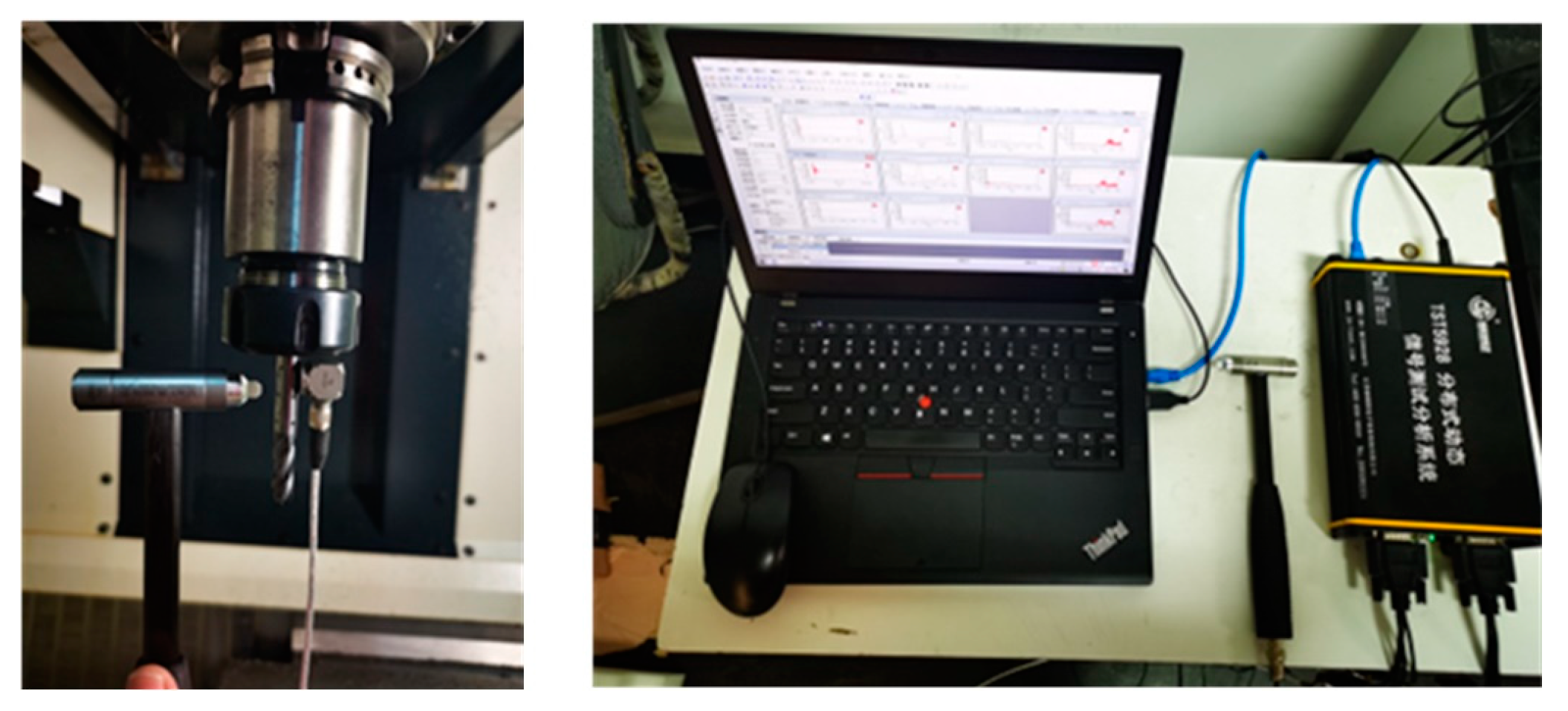

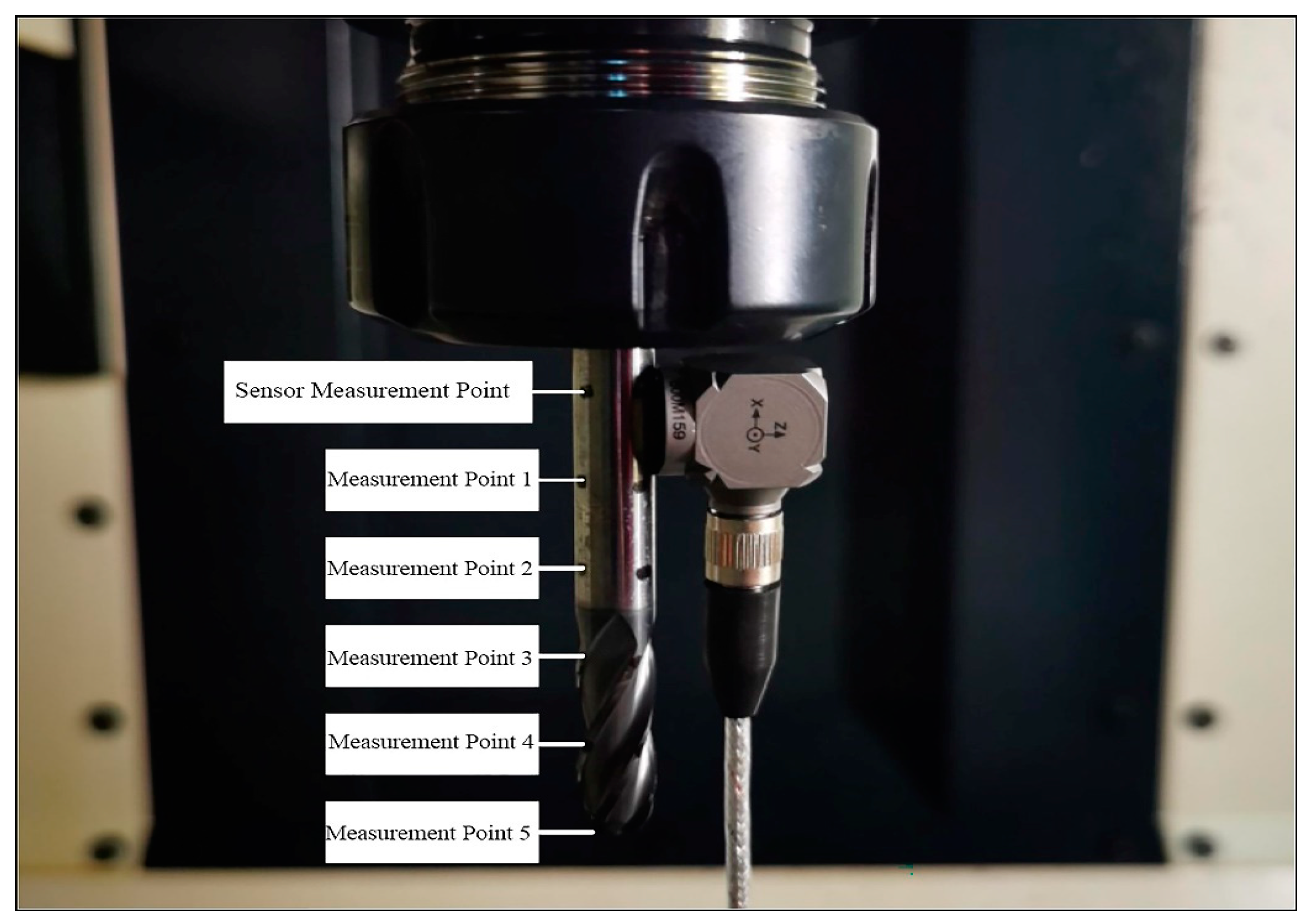

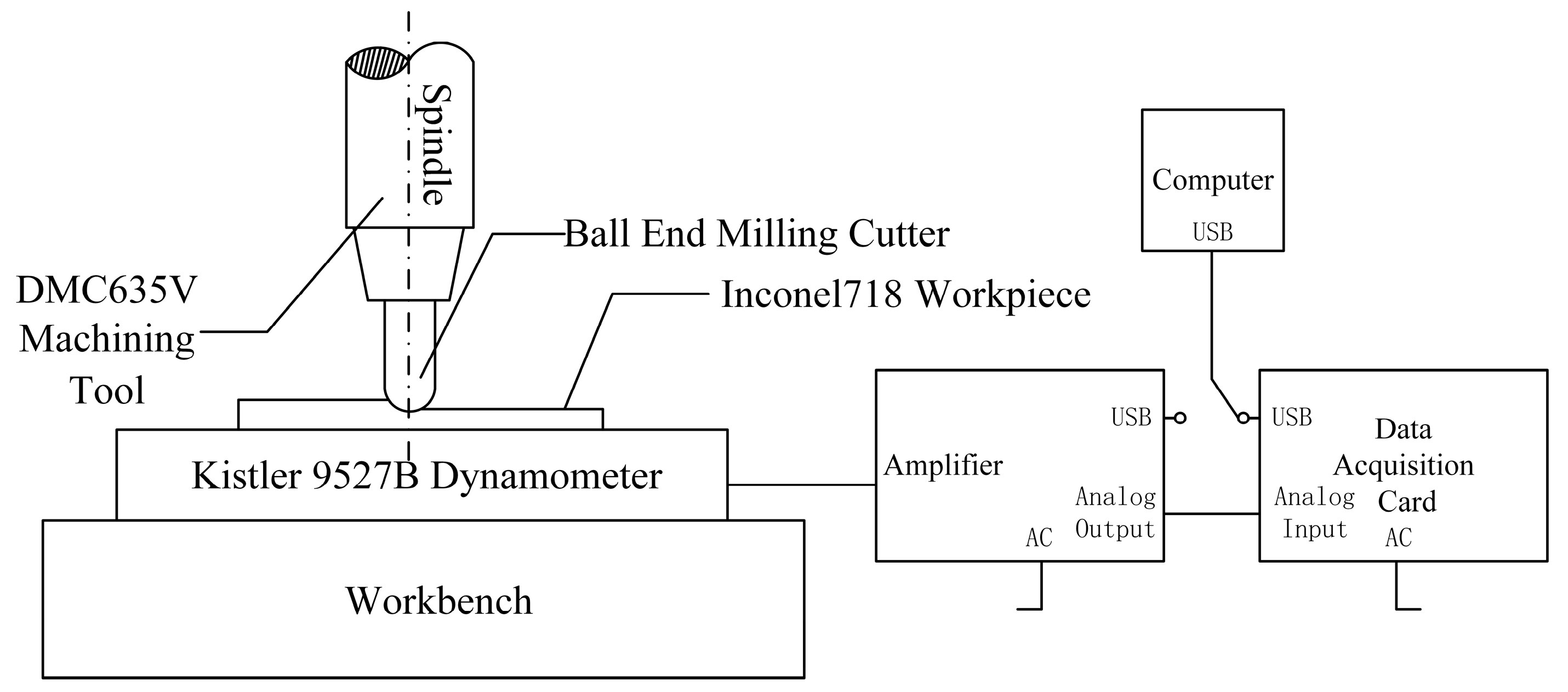

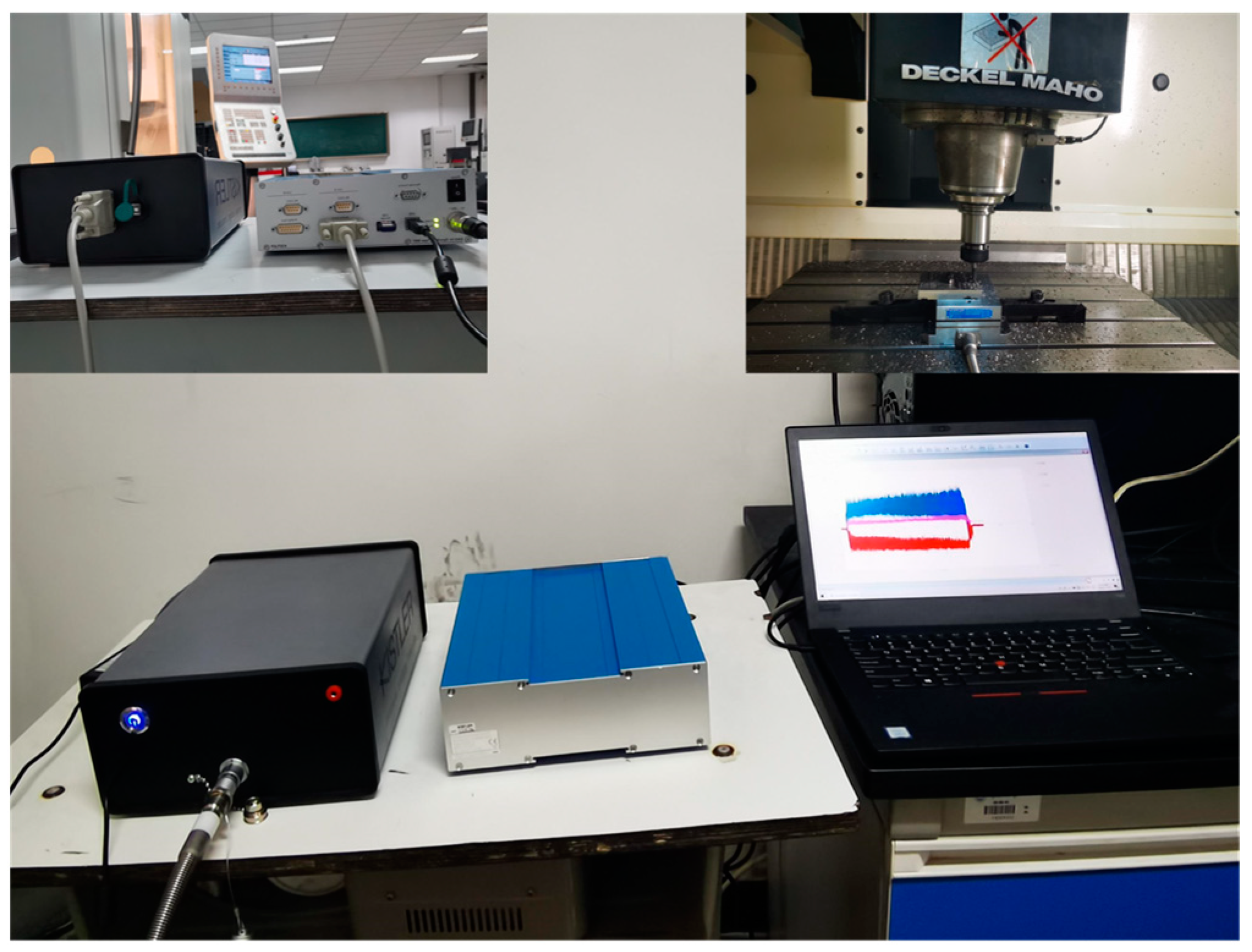

4.2. Methodology of the Modal Experiment

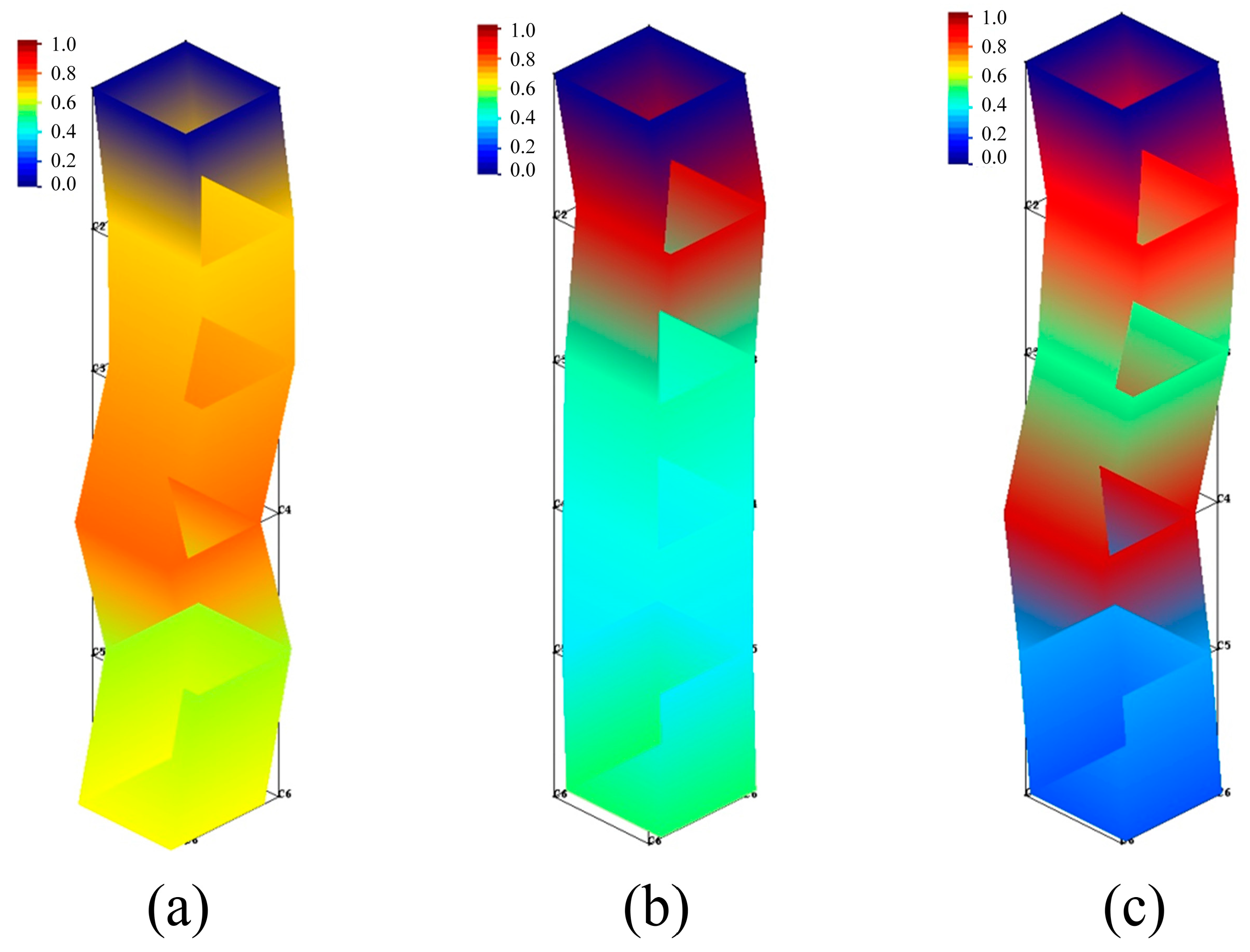

4.3. The Result of Modal Experiment

5. Milling Experiment of Inconel 718 and Parameter Optimization

5.1. Methodology of Milling Experiment

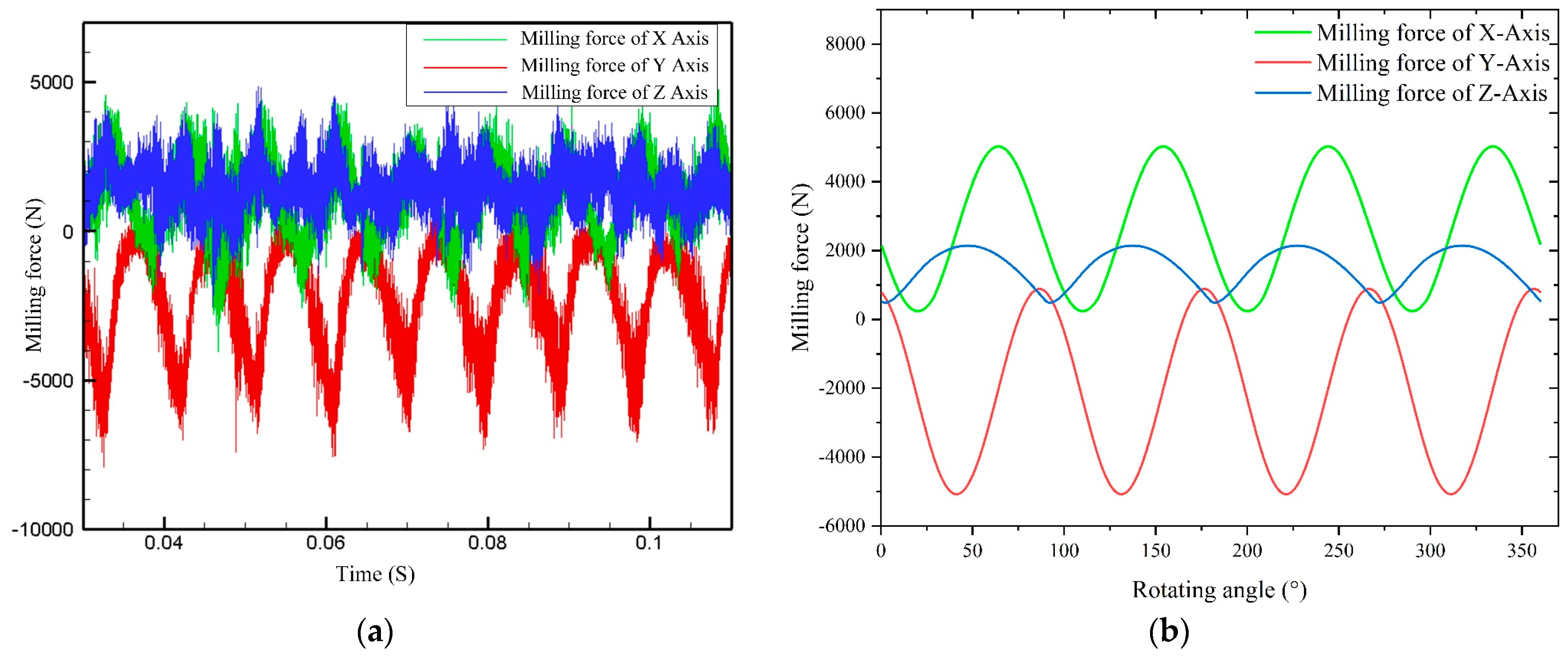

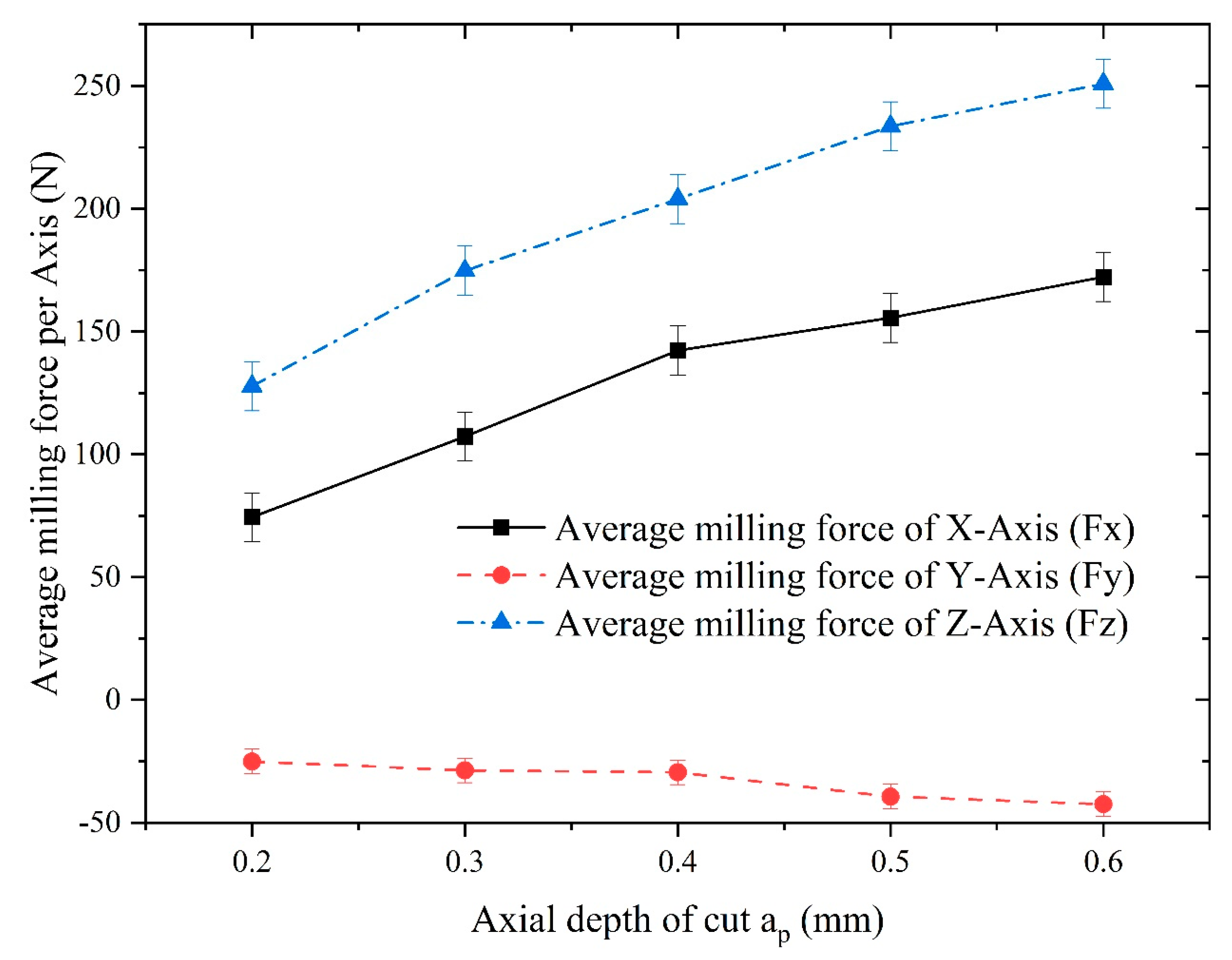

5.2. Results of the Analysis of the Single Factor Experiment

5.3. Results Analysis of the Orthogonal Experiments

- Axial depth of cut was the most influential factor on the average milling force for the x-axis, followed by feed per tooth and spindle speed.

- Feed per tooth was the most influential factor on the average milling force for the y-axis, followed by axial depth of cut and spindle speed.

- Axial depth of cut was the most influential factor on the average milling force for the z-axis, followed by the feed per tooth and spindle speed.

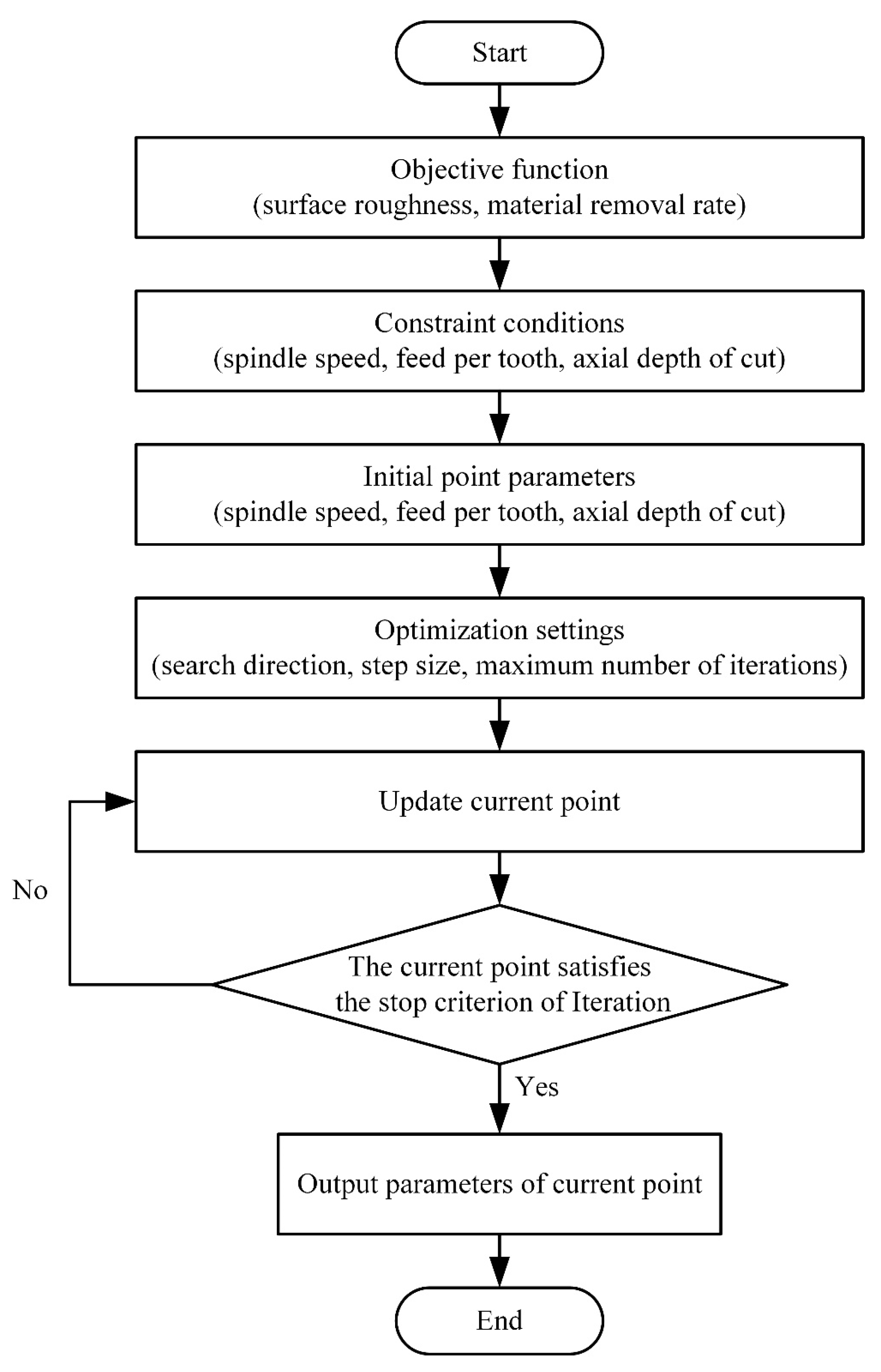

5.4. Establishment of Optimization Objective Function

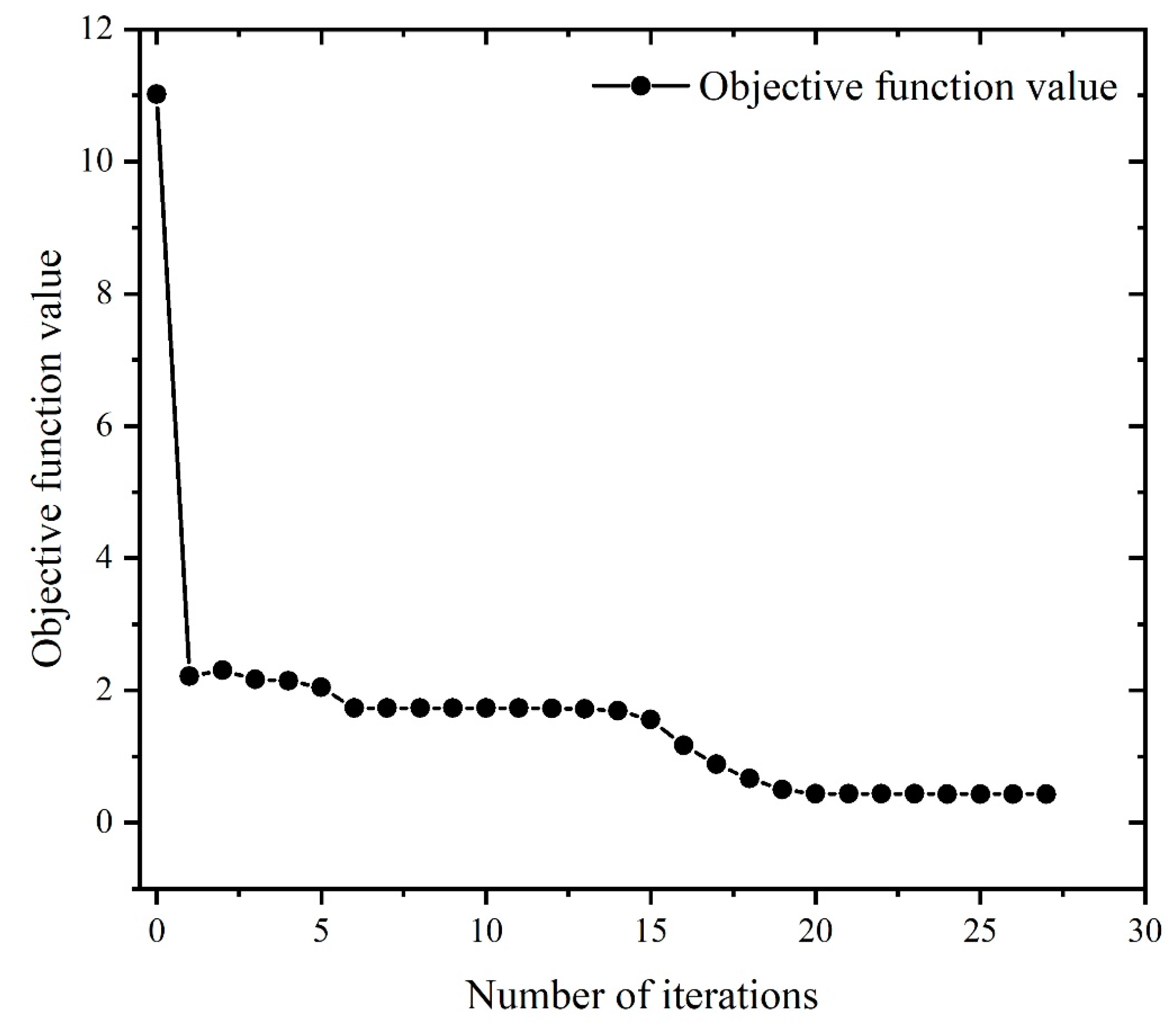

5.5. Optimization Results Analysis

6. Conclusions

- The finite element analysis revealed notable temperature increases in the machining zone with rising spindle speed, radial and axial depths of cut, and feed per tooth. Tool stress, influenced mainly by feed per tooth and radial and axial depths of cut, exhibited significant changes. While spindle speed moderately affected milling force for each axis, the feed per tooth and radial depth of cut substantially increased forces in the x-, y-, and x-axes.

- Chattering stability was investigated, with tool radius enhancement aiding stability, while radial depth of cut undermined it. An improved damping ratio enhances stability, while the system’s inherent ability to resist vibrations or chatter improves with the increase in natural frequency.

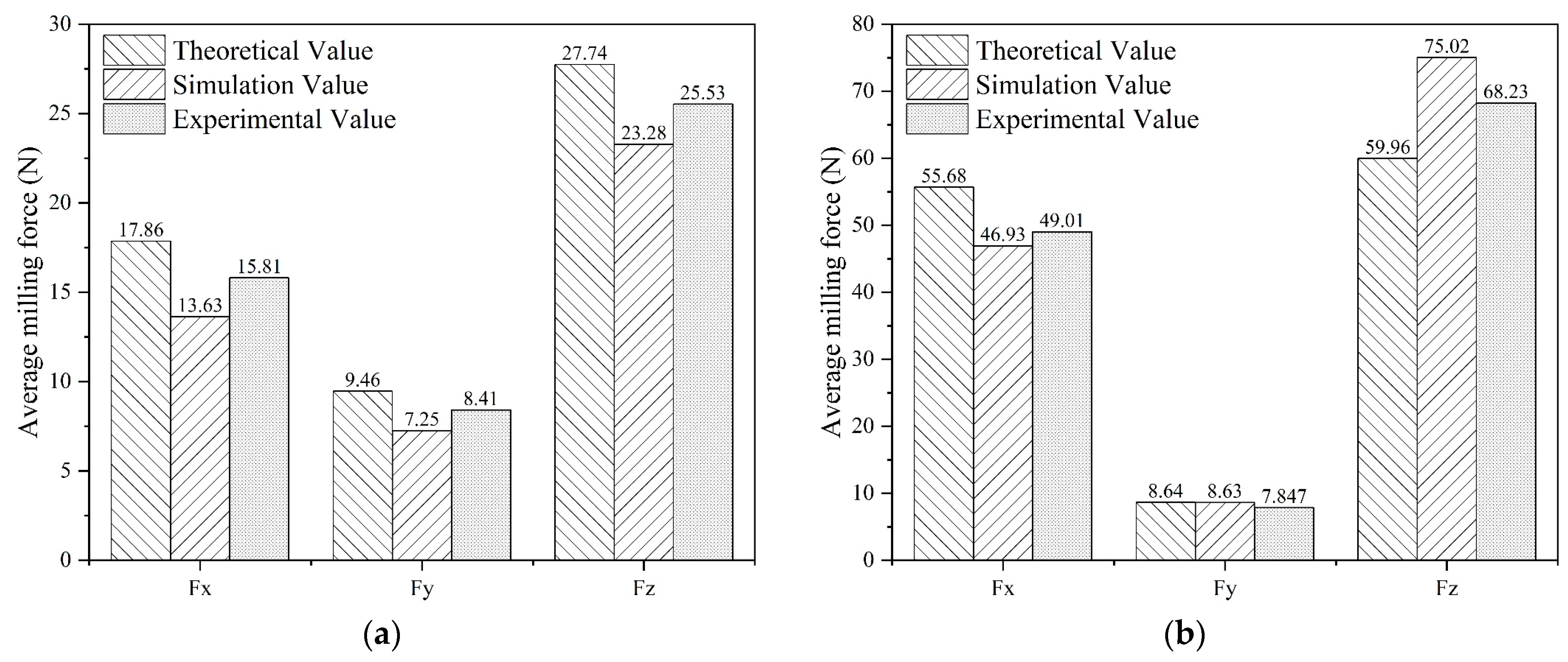

- Validation against experiments and calculated results from the milling force model and finite element analysis exhibited minor deviations.

- The machining parameters optimized using the fmincon algorithm: for minimum surface roughness, spindle speed of 3999.63 rpm, feed rate of 80.01 mm/min, axial depth of cut of 0.25 mm, and yield surface roughness of 0.43 μm; for maximum material removal rate, spindle speed of 4000 rpm, feed speed of 700 mm/min, axial depth of cut of 2.54 mm, and yield of 58,788.32 mm³/min. Joint optimization yields, spindle speed of 3199.2 rpm, feed speed of 80 mm/min, and axial depth of cut of 0.25 mm with a surface roughness of 3.5 μm and material removal rate of 4199.2 mm³/min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| The differential tangential cutting force (N) | |

| The differential radial cutting force (N) | |

| The differential axial cutting force (N) | |

| Tangential shearing force coefficient (N/mm2) | |

| Radial shearing force coefficient (N/mm2) | |

| Axial shearing force coefficient (N/mm2) | |

| Tangential edge force coefficient (N/mm) | |

| Radial edge force coefficient (N/mm) | |

| Axial edge force coefficient (N/mm) | |

| The instantaneous chip thickness at immersion angle (mm) | |

| The instantaneous edge length of the cutting segment (mm) | |

| The instantaneous chip width (mm) | |

| The cutting force in feed direction (N) | |

| The cutting force in normal direction (N) | |

| The cutting force in axial direction (N) | |

| The average cutting force in the feed direction (N) | |

| The average cutting force in the normal direction (N) | |

| The average cutting force in the axial direction (N) | |

| , | The components of linear model force in the feed direction (N) |

| , | The components of linear model force in the normal direction (N) |

| , | The components of linear model force in the axial direction (N) |

| Workpiece material flow stress | |

| Strain enhancement function | |

| Strain rate effect function | |

| Thermal softening function | |

| Strain rate | |

| Temperature | |

| Initial yield stress | |

| Plastic strain | |

| Reference plastic strain | |

| Cut-off strain value | |

| Contingency strengthening index | |

| Instantaneous strain increment | |

| Material failure strain | |

| , | Mass of machine–tool system in the x- and y-directions |

| , | Damping of machine–tool system in the x- and y-directions |

| , | Stiffness of machine–tool system in the x- and y-directions |

| , | Cutting force components acting on the tooth in the x- and y-directions |

| Dynamic displacement of the cutter in the previous cycle | |

| Dynamic displacement of the cutter in the current cycle | |

| Unit step function | |

| Direct transfer function in the x-direction | |

| Direct transfer function in the y-direction | |

| Cross-transfer function in the x-direction | |

| Cross-transfer function in the y-direction | |

| Speed of milling process | |

| Rotating speed of spindle | |

| Feed per tooth | |

| Radial depth of cut | |

| Axial depth of cut |

Appendix A

References

- Zhou, Y.; Ma, L.; Gong, Y.; Zhang, L.; Yin, G.; Sun, Y. Study on the mechanism of chip forming and the microhardness of micro-grinding nickel-based single-crystal superalloy. Int. J. Adv. Manuf. Technol. 2019, 103, 281–295. [Google Scholar] [CrossRef]

- Thellaputta, G.R.; Chandra, P.S.; Rao, C.S.P. Machinability of Nickel Based Superalloys: A Review. Mater. Today Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Miller, S. Advanced materials mean advanced engines. Interdiscip. Sci. Rev. 1996, 21, 117–129. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Mansoz, B.; Bortoluci Ormastroni, L.M.; Rame, J.; Schwalbe, C.; Vamsi, K.V.; Caron, P.; Cormier, J.; Pettinari-Sturmel, F. Tensile behavior of single crystal nickel-based superalloys at 650 °C. Intermetallics 2023, 161, 107976. [Google Scholar] [CrossRef]

- Ge, Y.; Zhu, Z.; Wang, D. Electrochemical Dissolution Behavior of the Nickel-Based Cast Superalloy K423A in NaNO3 Solution. Electrochim. Acta 2017, 253, 379–389. [Google Scholar] [CrossRef]

- Ogino, S.; Ohashi, T.; Kasuya, N.; Yoshida, M. Tensile rate dependency of mechanical properties of inconel 718 nickel-based superalloy around solidus temperature. Nippon. Kinzoku Gakkaishi 2013, 77, 170–173. [Google Scholar] [CrossRef]

- Alabort, E.; Reed, R.C.; Barba, D. Combined modelling and miniaturised characterisation of high-temperature forging in a nickel-based superalloy. Mater. Des. 2018, 160, 683–697. [Google Scholar] [CrossRef]

- Xu, D.; Liao, Z.; Axinte, D.; Sarasua, J.A.; M’Saoubi, R.; Wretland, A. Investigation of surface integrity in laser-assisted machining of nickel based superalloy. Mater. Des. 2020, 194, 108851. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, W.; Chung, S.; Ryu, H.J. Effects of TiC on the microstructure refinement and mechanical property enhancement of additive manufactured Inconel 625/TiC metal matrix composites fabricated with novel core-shell composite powder. J. Mater. Sci. Technol. 2023, 164, 13–26. [Google Scholar] [CrossRef]

- Sharma, P.; Kishore, K.; Sinha, M.K.; Singh, V. Electrical discharge machining of nickel-based superalloys: A comprehensive review. Int. J. Mater. Eng. Innov. 2022, 13, 157–190. [Google Scholar] [CrossRef]

- Khanna, N.; Kshitij, G.; Solanki, M.; Bhatt, T.; Patel, O.; Uysal, A.; Sarıkaya, M. In pursuit of sustainability in machining thin walled α-titanium tubes: An industry supported study. Sustain. Mater. Technol. 2023, 36, e00647. [Google Scholar] [CrossRef]

- Guimaraes, M.C.R.; Fogagnolo, J.B.; Paiva, J.M.; Veldhuis, S.; Diniz, A.E. The impact of the cutting parameters and tool condition on surface integrity when milling Inconel 625. J. Mater. Res. Technol. 2023, 25, 1944–1958. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Ding, T.; Zhang, S.; Wang, Y.; Zhu, X. Empirical models and optimal cutting parameters for cutting forces and surface roughness in hard milling of AISI H13 steel. Int. J. Adv. Manuf. Technol. 2010, 51, 45–55. [Google Scholar] [CrossRef]

- Shi, L.; Liu, E.F.; Zhang, Y.; Chen, P.; Li, Z.B. The simulation of cutting force of free-form surface machining with ball-end milling cutter. In Proceedings of the 2009 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 2314–2318. [Google Scholar]

- Bergmann, J.A.; Wöste, F.; Wiederkehr, P. An analysis of the sensitivity of cutting force coefficients and their influence on the variability of stability diagrams. Prod. Eng. 2023, 17, 407–414. [Google Scholar] [CrossRef]

- Zhao, M.; Zhu, J.; Song, S.; Xue, B.; Zhao, B. Influence of machining parameters in longitudinal-torsional ultrasonic vibration milling titanium alloy for milling force. Int. J. Adv. Manuf. Technol. 2022, 123, 3587–3597. [Google Scholar] [CrossRef]

- Newby, G.; Venkatachalam, S.; Liang, S.Y. Empirical analysis of cutting force constants in micro-end-milling operations. J. Mater. Process. Technol. 2007, 192–193, 41–47. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, T.; Yan, L. Analytical model of milling forces based on time-variant sculptured shear surface. Int. J. Mech. Sci. 2016, 115–116, 190–201. [Google Scholar] [CrossRef]

- Madajewski, M.; Wojciechowski, S.; Znojkiewicz, N.; Twardowski, P. Hybrid Numerical-Analytical Approach for Force Prediction in End Milling of 42CrMo4 Steel. In Advances in Manufacturing II; Springer International Publishing: Cham, Switzerland, 2019; pp. 223–232. [Google Scholar]

- Huang, W.; Li, X.; Wang, B.; Chen, J.; Zhou, J. An analytical index relating cutting force to axial depth of cut for cylindrical end mills. Int. J. Mach. Tools Manuf. 2016, 111, 63–67. [Google Scholar] [CrossRef]

- Kao, Y.-C.; Nguyen, N.-T.; Chen, M.-S.; Huang, S.-C. A combination method of the theory and experiment in determination of cutting force coefficients in ball-end mill processes. J. Comput. Des. Eng. 2015, 2, 233–247. [Google Scholar] [CrossRef]

- Kaneko, K.; Nishida, I.; Sato, R.; Shirase, K. Virtual milling force monitoring method based on in-process milling force prediction model to eliminate predetermination of cutting coefficients. Procedia CIRP 2018, 77, 22–25. [Google Scholar] [CrossRef]

- Li, S.-J.; Zhou, Y.-F.; Jin, R.-C.; Ji, Z. Dynamic Force Modelling for a Ball-End Milling Cutter Based on the Merchant Oblique Cutting Theory. Int. J. Adv. Manuf. Technol. 2001, 17, 477–483. [Google Scholar] [CrossRef]

- Falta, J.; Sulitka, M.; Zeman, P. An analytical formulation of ZOA-based machining stability for complex tool geometries: Application to 5-axis ball-end milling. Int. J. Adv. Manuf. Technol. 2022, 123, 1499–1519. [Google Scholar] [CrossRef]

- Yongheng, D.; Shujuan, L.; Xiantao, H.; Pengyang, L.; Yan, L.; Qi, L. Modeling on the milling force of ball-end milling cutter based on Z-MAP method. Chin. J. Mech. Eng. 2019, 55, 201–212. [Google Scholar] [CrossRef]

- Soo, S.L.; Dewes, R.C.; Aspinwall, D.K. 3D FE modelling of high-speed ball nose end milling. Int. J. Adv. Manuf. Technol. 2010, 50, 871–882. [Google Scholar] [CrossRef]

- Soo, S.L.; Aspinwall, D.K.; Dewes, R.C. Three-dimensional finite element modelling of high-speed milling of Inconel 718. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1555–1561. [Google Scholar] [CrossRef]

- Filho, A.F.; da Silva, L.R.R.; de Souza Ruzzi, R.; Costa, E.S.; Sales, W.F.; Jackson, M.J.; Machado, Á.R. Influence of milling direction in the machinability of Inconel 718 with submicron grain cemented carbide tools. Int. J. Adv. Manuf. Technol. 2019, 105, 1343–1355. [Google Scholar] [CrossRef]

- Haijun, H.; Yazhou, S.; Zesheng, L. Simulation and experiment of cutting force in ultrasonic torsional vibration assisted micro-milling. In Proceedings of the 5th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Design, Manufacturing, and Testing of Micro- and Nano-Optical Devices and Systems, Dalian, China, 26–29 April 2010; p. 76570T. [Google Scholar]

- Pratap, T.; Patra, K.; Dyakonov, A.A. Modeling cutting force in micro-milling of Ti-6Al-4V titanium alloy. Procedia Eng. 2015, 129, 134–139. [Google Scholar] [CrossRef]

- Molaiekiya, F.; Stolf, P.; Paiva, J.M.; Bose, B.; Goldsmith, J.; Gey, C.; Engin, S.; Fox-Rabinovich, G.; Veldhuis, S.C. Influence of process parameters on the cutting performance of SiAlON ceramic tools during high-speed dry face milling of hardened Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 105, 1083–1098. [Google Scholar] [CrossRef]

- Pengfei, D.; Jie, Z.; Wang, X.; Yangyang, S.; Ming, Q. Finite Element Method Simulation on Milling Forces of Super Alloy GH4169. In Proceedings of the 2013 Fourth International Conference on Intelligent Systems Design and Engineering Applications, Zhangjiajie, China, 6–7 November 2013; pp. 322–324. [Google Scholar]

- Azeem, M.M.; Wang, Q.; Li, Z.; Zhang, Y. Dislocation-oxide interaction in Y2O3 embedded Fe: A molecular dynamics simulation study. Nucl. Eng. Technol. 2020, 52, 337–343. [Google Scholar] [CrossRef]

- Azeem, M.M.; Li, Z.; Wang, Q.; Zubair, M. Molecular dynamics studies and irradiation effects in ODSS alloys. Int. J. Nucl. Energy Sci. Technol. 2018, 12, 381–399. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, S.; Lin, Z.; Yue, X.; Gao, Y.; Zhang, S.; Yang, H. Investigation on the mechanism of micro-milling CoCrFeNiAlX high entropy alloys with end milling cutters. Vacuum 2023, 211, 111939. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Michailidis, N.; Gerardis, S.; Katirtzoglou, G.; Lili, E.; Pappa, M.; Brizuela, M.; Garcia-Luis, A.; Cremer, R. Correlation of the impact resistance of variously doped CrAlN PVD coatings with their cutting performance in milling aerospace alloys. Surf. Coat. Technol. 2008, 203, 781–785. [Google Scholar] [CrossRef]

- Kim, E.J.; Lee, C.M. A study on the optimal machining parameters of the induction assisted milling with Inconel 718. Materials 2019, 12, 233. [Google Scholar] [CrossRef] [PubMed]

- Altintaş, Y.; Budak, E. Analytical prediction of stability lobes in milling. CIRP Ann. 1995, 44, 357–362. [Google Scholar] [CrossRef]

- Merdol, S.; Altintas, Y. Multi frequency solution of chatter stability for low immersion milling. J. Manuf. Sci. Eng. 2004, 126, 459–466. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, L.; Zhang, X.; Ding, H. Second-order full-discretization method for milling stability prediction. Int. J. Mach. Tools Manuf. 2010, 50, 926–932. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, L.; Zhang, X.; Ding, H. A full-discretization method for prediction of milling stability. Int. J. Mach. Tools Manuf. 2010, 50, 502–509. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G.; Turi, J. On the higher-order semi-discretizations for periodic delayed systems. J. Sound Vib. 2008, 313, 334–341. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G. Semi-discretization method for delayed systems. Int. J. Numer. Methods Eng. 2002, 55, 503–518. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G. Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int. J. Numer. Methods Eng. 2004, 61, 117–141. [Google Scholar] [CrossRef]

- Sun, L.; Zheng, K.; Liao, W. Chatter suppression and stability analysis of rotary ultrasonic milling titanium alloy thin-walled workpiece. Int. J. Adv. Manuf. Technol. 2022, 118, 2193–2204. [Google Scholar] [CrossRef]

- Gajera, H.; Djavanroodi, F.; Kumari, S.; Abhishek, K.; Bandhu, D.; Saxena, K.K.; Ebrahimi, M.; Prakash, C.; Buddhi, D. Optimization of Selective Laser Melting Parameter for Invar Material by Using JAYA Algorithm: Comparison with TLBO, GA and JAYA. Materials 2022, 15, 8092. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zhang, J.F.; Feng, P.F.; Yu, D.W.; Wu, Z.J. Determination of Constitutive Equation Parameters for Face Milling 3-D Simulation via Pressure Bar and Orthogonal Cutting Tests. Mater. Sci. Forum 2012, 723, 136–142. [Google Scholar] [CrossRef]

- Li, B.; Hu, Y.; Wang, X.; Li, C.; Li, X. An Analytical Model of Oblique Cutting with Application to End Milling. Mach. Sci. Technol. 2011, 15, 453–484. [Google Scholar] [CrossRef]

- Tao, F. The Experiment of Cutting Performance of Polished Cemented Carbide Insert in Cutting Nickel-Based Superalloy. Master’s Thesis, Xiangtan University, Xiangtan, China, 2017. [Google Scholar]

| Experiment No. | (mm/z) | Feed Speed (mm/min) | |||

|---|---|---|---|---|---|

| 1 | 0.02 | 80 | 76.88 | −59.25 | 11.97 |

| 2 | 0.04 | 160 | 174.5 | −210.7 | 44.67 |

| 3 | 0.06 | 240 | 251.7 | −378.8 | 133.1 |

| 4 | 0.08 | 320 | 314.1 | −572.0 | 265.2 |

| 5 | 0.10 | 400 | 353.4 | −720.6 | 430.1 |

| 6 | 0.12 | 480 | 421.6 | −830.1 | 552.3 |

| Shearing Force Coefficient (N/mm2) | Value | Edge Force Coefficient (N/mm2) | Value |

|---|---|---|---|

| −15,934.72 | 149.15 | ||

| −6636.28 | −51.95 | ||

| 8949.06 | −159.45 |

| Rotating Speed of Spindle n (rpm) | (mm/z) | (mm) | (mm) |

|---|---|---|---|

| 1000 | 0.2 | 2 | 2 |

| 1300 | 0.3 | 3 | 3 |

| 1600 | 0.4 | 4 | 4 |

| - | 0.5 | 5 | 5 |

| Cut-Off Strain | Strain Enhancement Index n | ||

|---|---|---|---|

| 3.6 MPa | 0.3 | 9.55 |

| Linear Cut-Off Temperature | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.998 | 20 °C | 1050 °C | 1298 °C |

| 25.5 | 25.5 | 1 s−1 | 1 × 107 s−1 |

| Modal Order | Natural Frequency (Hz) | Damping Ratio (%) |

|---|---|---|

| First order of x-direction | 935.06 | 0.049 |

| Second order of x-direction | 1235.96 | 0.036 |

| Third order of x-direction | 1567.99 | 0.093 |

| First order of y-direction | 911.87 | 0.045 |

| Second order of y-direction | 1233.52 | 0.059 |

| Third order of y-direction | 1539.92 | 0.050 |

| Experiment No. | Rotating Speed of Spindle N (r/min) | Feed per Tooth (mm/z) | Axial Depth of Cut (mm) |

|---|---|---|---|

| 1 | 1000/1200/1400/1600/1800 | 0.02 | 0.4 |

| 2 | 1000 | 0.02/0.04/0.06/0.08/0.10 | 0.4 |

| 3 | 1000 | 0.02 | 0.2/0.3/0.4/0.5/0.6 |

| Experiment No. | Rotating Speed of Spindle N (rpm) | Feed per Tooth (mm/z) | Axial Depth of Cut (mm) |

|---|---|---|---|

| 1 | 800 | 0.015 | 0.1 |

| 2 | 800 | 0.03 | 0.2 |

| 3 | 800 | 0.045 | 0.3 |

| 4 | 800 | 0.06 | 0.4 |

| 5 | 1000 | 0.015 | 0.2 |

| 6 | 1000 | 0.03 | 0.1 |

| 7 | 1000 | 0.045 | 0.4 |

| 8 | 1000 | 0.06 | 0.3 |

| 9 | 1200 | 0.015 | 0.3 |

| 10 | 1200 | 0.03 | 0.4 |

| 11 | 1200 | 0.045 | 0.1 |

| 12 | 1200 | 0.06 | 0.2 |

| 13 | 1400 | 0.015 | 0.4 |

| 14 | 1400 | 0.03 | 0.3 |

| 15 | 1400 | 0.045 | 0.2 |

| 16 | 1400 | 0.06 | 0.1 |

| Experiment No. | Parameters of Experiment | Result of Experiment (N) | |||||

|---|---|---|---|---|---|---|---|

| Rotating Speed of Spindle n (rpm) | Feed per Tooth (mm/z) | Axial Depth of Cut (mm) | |||||

| 1 | 800 | 0.015 | 0.1 | 15.81 | 8.410 | 25.53 | 31.18 |

| 2 | 800 | 0.03 | 0.2 | 49.01 | −7.847 | 68.23 | 84.37 |

| 3 | 800 | 0.045 | 0.3 | 85.91 | −18.33 | 107.4 | 138.75 |

| 4 | 800 | 0.06 | 0.4 | 131.0 | −28.87 | 137.0 | 191.74 |

| 5 | 1000 | 0.015 | 0.2 | 57.65 | −15.96 | 87.60 | 106.08 |

| 6 | 1000 | 0.03 | 0.1 | 39.64 | −8.765 | 65.59 | 77.14 |

| 7 | 1000 | 0.045 | 0.4 | 58.2 | 42.99 | 70.62 | 101.11 |

| 8 | 1000 | 0.06 | 0.3 | 118.4 | −13.09 | 148.7 | 190.53 |

| 9 | 1200 | 0.015 | 0.3 | 79.75 | −16.09 | 117.9 | 143.25 |

| 10 | 1200 | 0.03 | 0.4 | 121.9 | −24.2 | 157.3 | 200.47 |

| 11 | 1200 | 0.045 | 0.1 | 38.06 | −9.168 | 66.27 | 76.97 |

| 12 | 1200 | 0.06 | 0.2 | 53.36 | 35.24 | 69.54 | 94.47 |

| 13 | 1400 | 0.015 | 0.4 | 86.23 | 2.896 | 120.7 | 148.37 |

| 14 | 1400 | 0.03 | 0.3 | 54.12 | 40.37 | 82.35 | 106.49 |

| 15 | 1400 | 0.045 | 0.2 | 87.04 | −23.66 | 134.8 | 162.19 |

| 16 | 1400 | 0.06 | 0.1 | 66.65 | −12.69 | 101.1 | 121.76 |

| Experiment No. | Milling Force | Theoretical Result (N) | Experimental Result (N) | Relative Error (%) |

|---|---|---|---|---|

| 1 | 17.86 | 15.81 | 12.97 | |

| 9.46 | 8.41 | 12.49 | ||

| 27.74 | 25.53 | 8.66 | ||

| 2 | 55.68 | 49.01 | 13.61 | |

| 8.64 | 7.847 | 10.11 | ||

| 59.96 | 68.23 | 12.12 | ||

| 3 | 80.36 | 85.91 | 6.46 | |

| 19.99 | 18.33 | 9.06 | ||

| 97.27 | 107.4 | 9.43 | ||

| 4 | 144.22 | 131 | 10.09 | |

| 30.74 | 28.87 | 6.48 | ||

| 123.98 | 137 | 9.50 |

| Experiment No. | Milling Force | FEA Result (N) | Experimental Result (N) | Relative Error (%) |

|---|---|---|---|---|

| 1 | 13.63 | 15.81 | 13.80 | |

| 7.25 | 8.41 | 13.79 | ||

| 23.28 | 25.53 | 8.81 | ||

| 2 | 46.93 | 49.01 | 4.24 | |

| 8.63 | 7.847 | 9.98 | ||

| 75.02 | 68.23 | 9.95 | ||

| 3 | 91.02 | 85.91 | 5.95 | |

| 16.97 | 18.33 | 7.42 | ||

| 121.34 | 107.4 | 12.98 | ||

| 4 | 119.35 | 131 | 8.89 | |

| 32.76 | 28.87 | 13.47 | ||

| 149.8 | 137 | 9.34 |

| Spindle Speed (rpm) | Feed Speed (mm/min) | Axial Depth of Cut (mm) | Surface Roughness R (μm) | |

|---|---|---|---|---|

| Initial Value | 1000 | 100 | 1.2 | 11 |

| Optimized Value | 3999.63 | 80.01 | 0.25 | 0.43 |

| Spindle Speed (rpm) | Feed Speed (mm/min) | Axial Depth of Cut (mm) | Material Removal Rate (mm3/min) | |

|---|---|---|---|---|

| Initial Value | 1000 | 100 | 1.2 | 1049.79 |

| Optimized Value | 4000 | 700 | 2.54 | 58,788.32 |

| Spindle Speed (rpm) | Feed per Tooth (mm/z) | Axial Depth of Cut (mm) | Material Removal Rate (mm3/min) | Surface Roughness (μm) | |

|---|---|---|---|---|---|

| Initial Value | 1000 | 100 | 1.2 | 10,498 | 11 |

| Optimized Value | 3199.2 | 80 | 0.25 | 4199.2 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Zhang, Y.; Qiao, H. Milling Mechanism and Chattering Stability of Nickel-Based Superalloy Inconel 718. Materials 2023, 16, 5748. https://doi.org/10.3390/ma16175748

Zheng J, Zhang Y, Qiao H. Milling Mechanism and Chattering Stability of Nickel-Based Superalloy Inconel 718. Materials. 2023; 16(17):5748. https://doi.org/10.3390/ma16175748

Chicago/Turabian StyleZheng, Jin, Yaoman Zhang, and Hanying Qiao. 2023. "Milling Mechanism and Chattering Stability of Nickel-Based Superalloy Inconel 718" Materials 16, no. 17: 5748. https://doi.org/10.3390/ma16175748

APA StyleZheng, J., Zhang, Y., & Qiao, H. (2023). Milling Mechanism and Chattering Stability of Nickel-Based Superalloy Inconel 718. Materials, 16(17), 5748. https://doi.org/10.3390/ma16175748