Average and Local Effect of Thermal Fatigue on the Coefficients of the Thermal Expansion of a Complex Continuous Composite Fibre Used for Car Clutch Facing: A Multi-Technique Study

Abstract

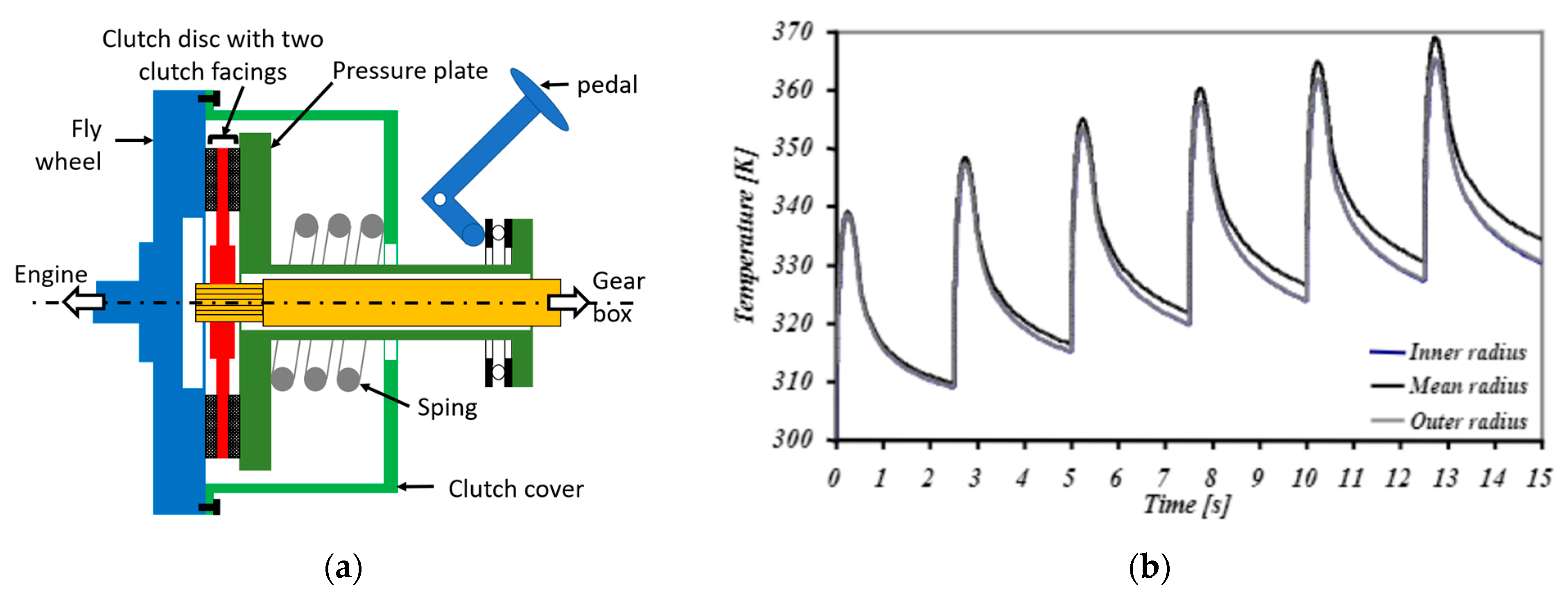

:1. Introduction

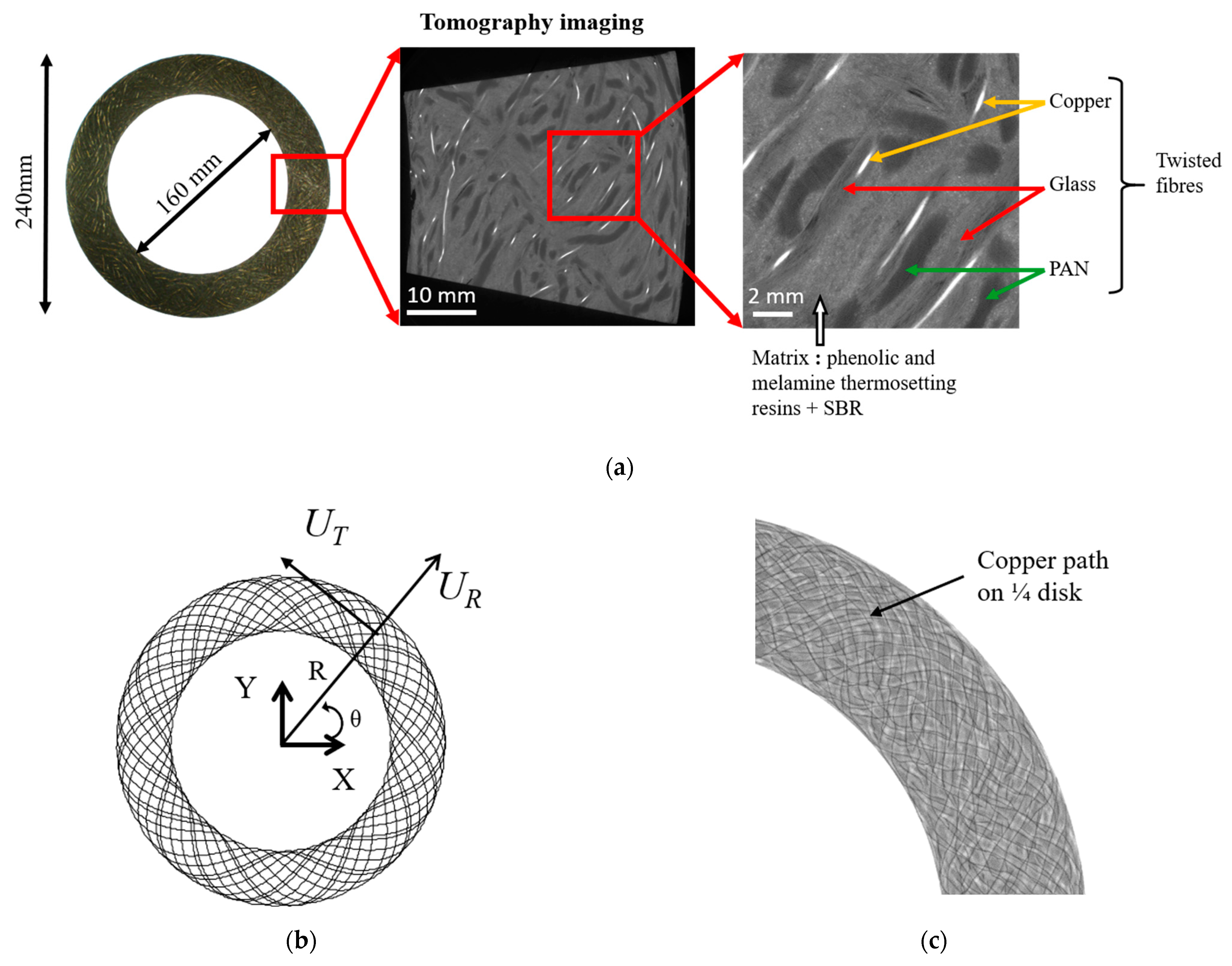

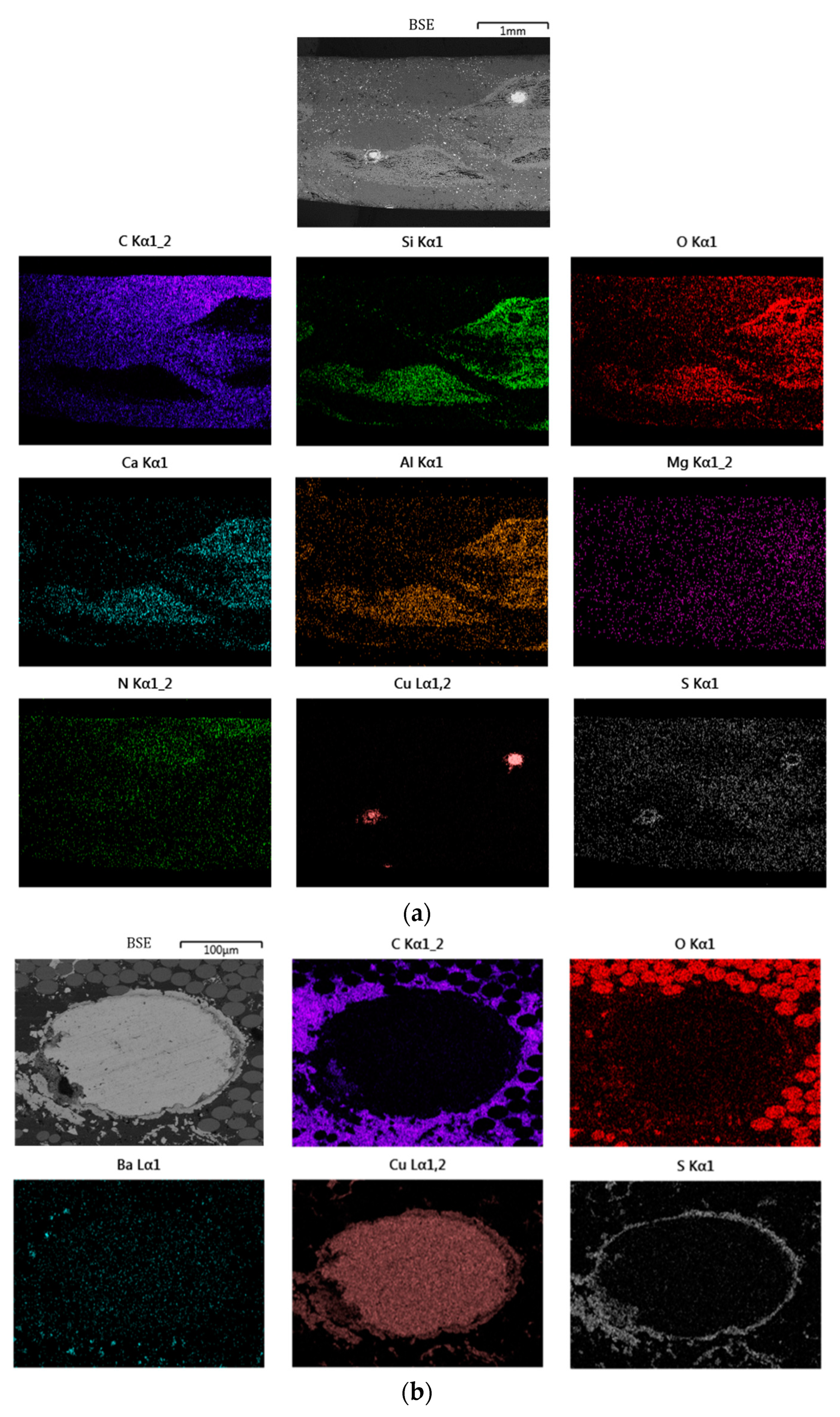

2. Materials and Methods

2.1. Clutch Facing Material

- Impregnation: twisted fibres are impregnated with the resin mixture. Once impregnated, the yarns pass through an oven to release the solvents.

- Preforming: a weighed quantity of pre-impregnated wire is taken from the spool and fed to a vertically translating nozzle which projects the wire onto a rotating plate.

- Hot-pressing: the formed parts are placed in moulds, grooved to the required dimensions and then pressure-baked at a temperature of 190 °C for a few minutes.

- Curing: the material is overbaked up to two times at temperatures of 250 °C for at least 4 h.

- Machining: the clutch facings are ground, marked and drilled.

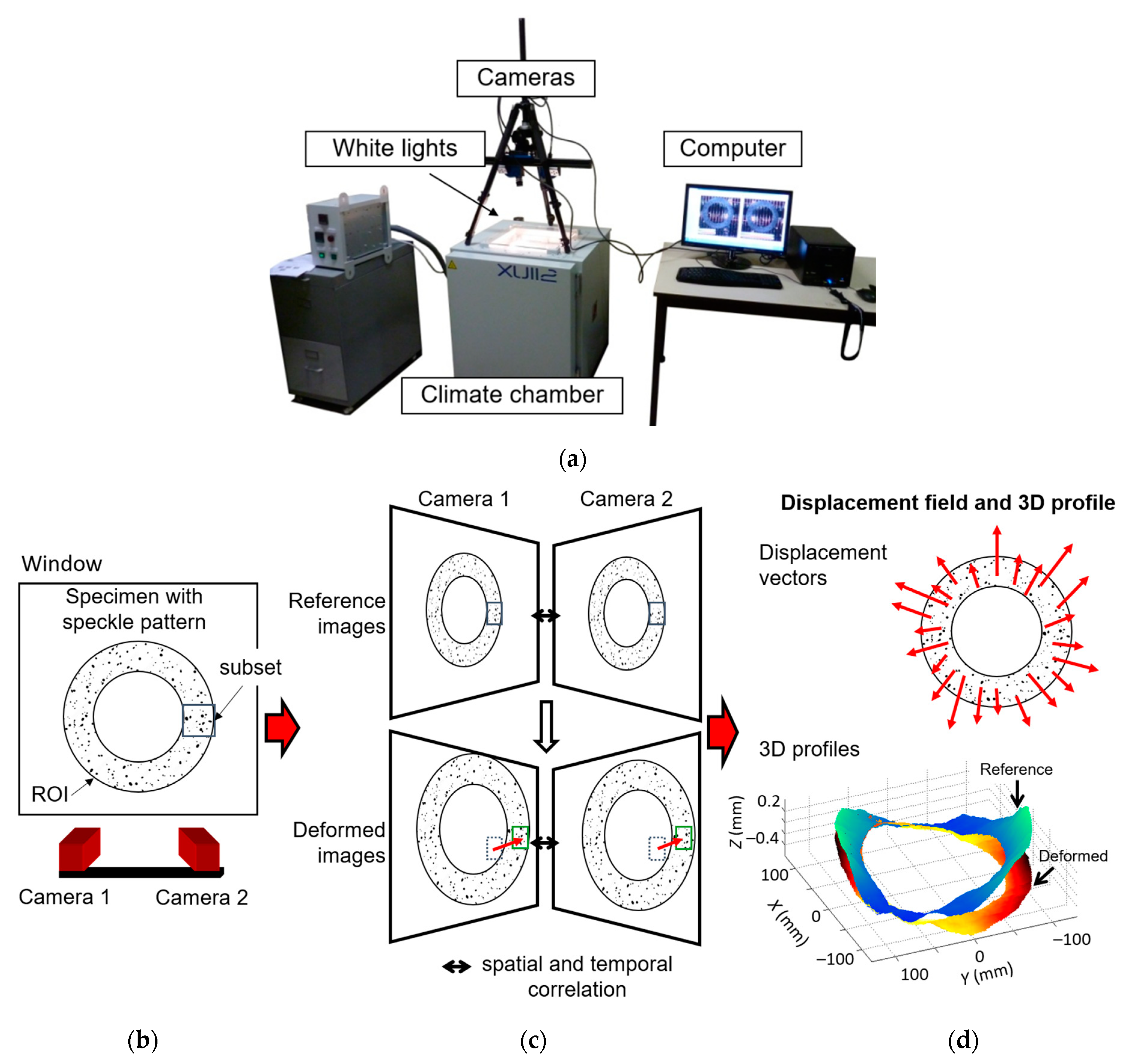

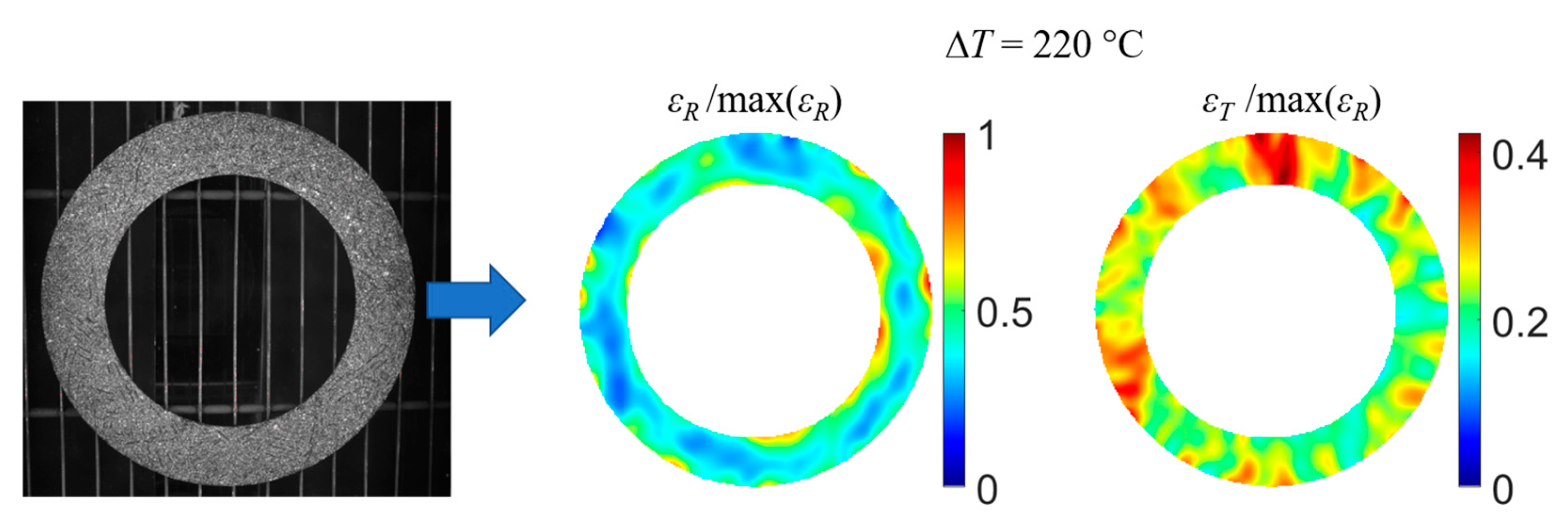

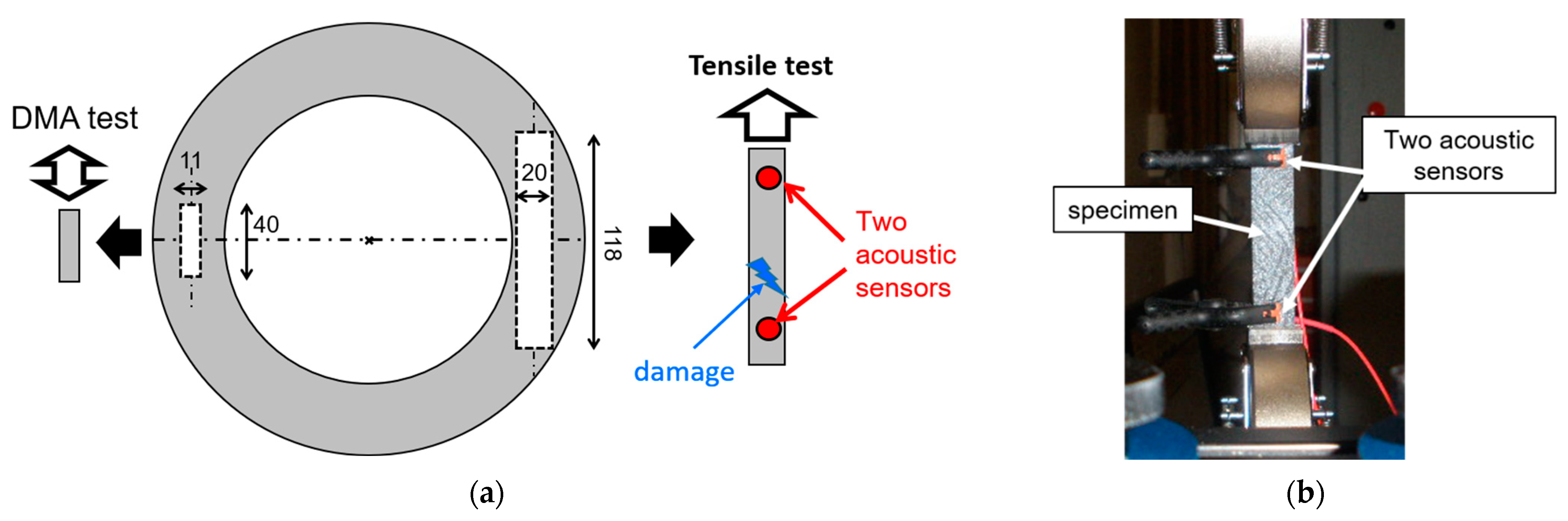

2.2. Experimental Set-Up and Post-Processing for Measuring CTE Fields Evolutions

2.2.1. Experimental Set-Up

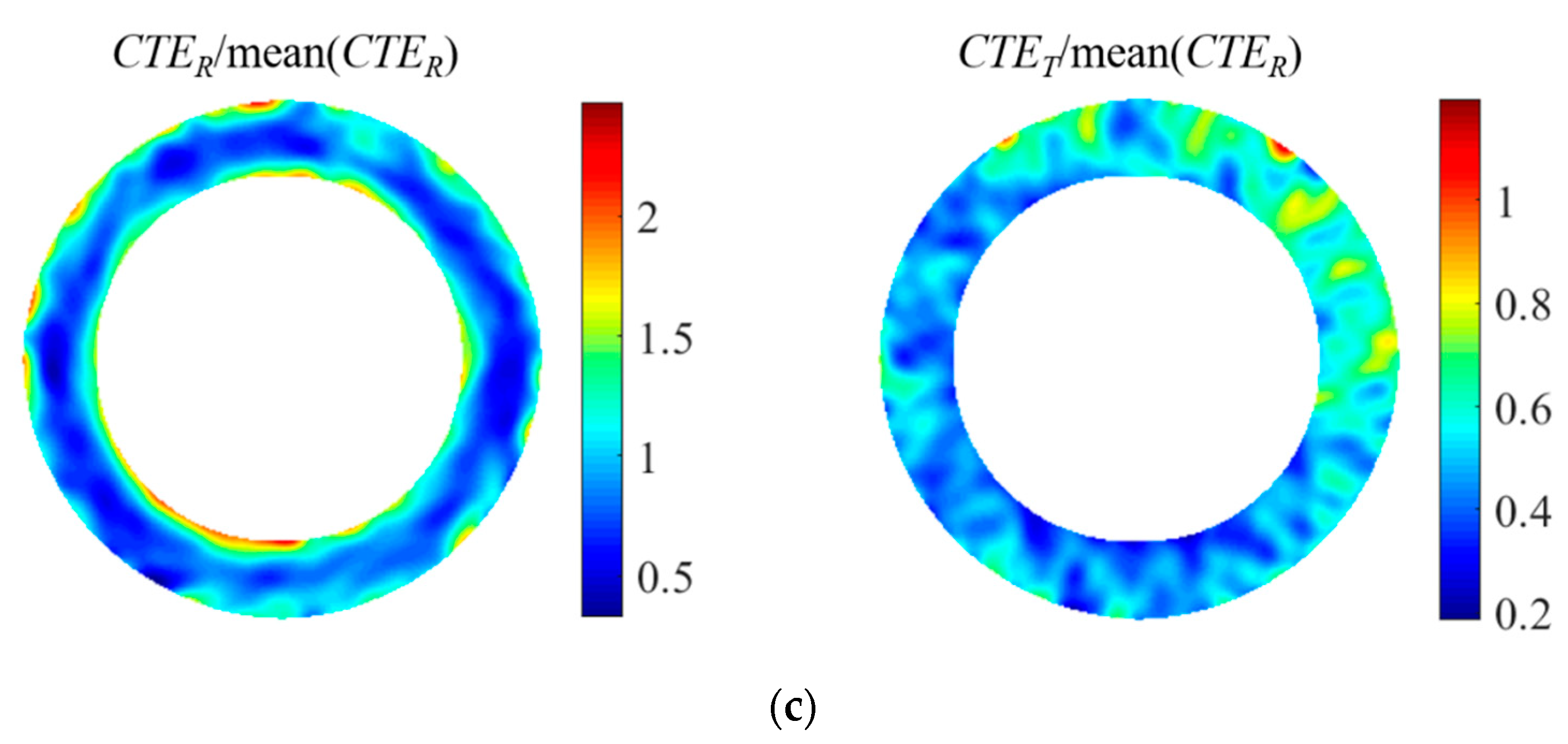

2.2.2. Coefficients of Thermal Expansion

2.2.3. Experimental Procedure and Post-Processing for CTE Measurements

- The CTER essentially depends on the radius R (Figure 2b), being maximum at the ends of the track and minimum in the centre,

- The CTET is close to an average value, despite some inhomogeneities due to material heterogeneity, which will be discussed later.

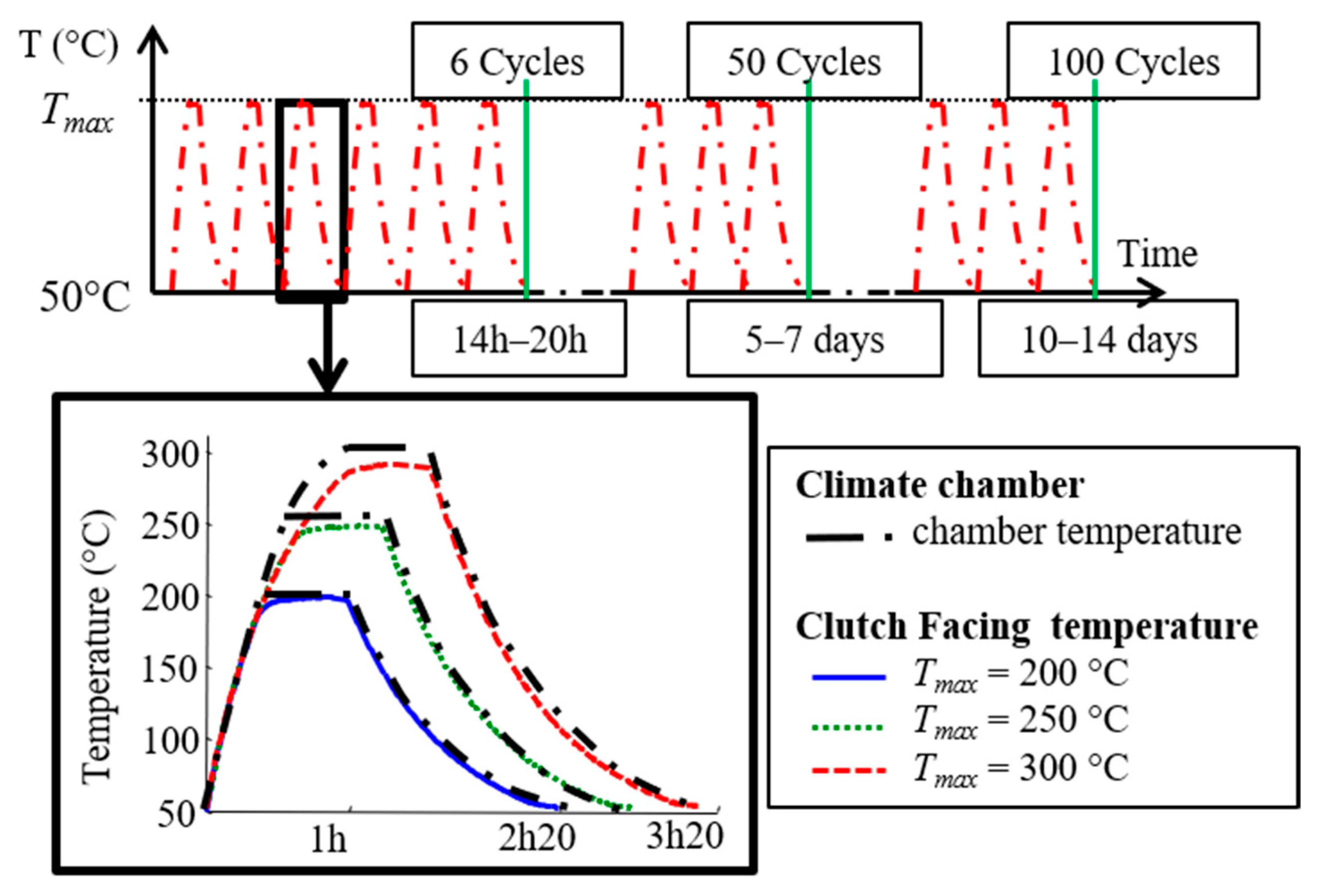

2.2.4. Thermal Cycling Procedure

2.3. Material and Damage Characterisations

2.3.1. Surface Crack Measurement and Weight Loss

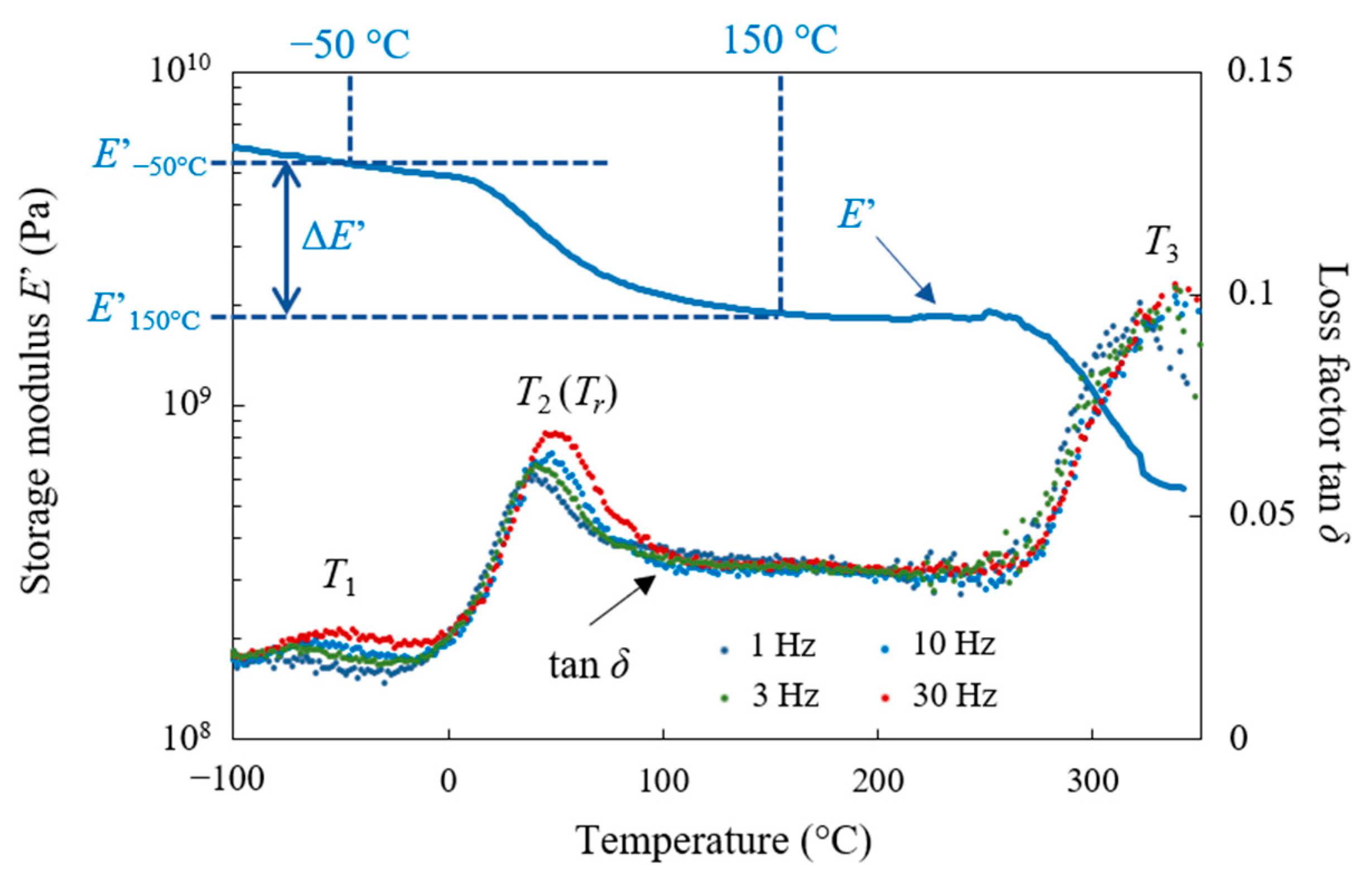

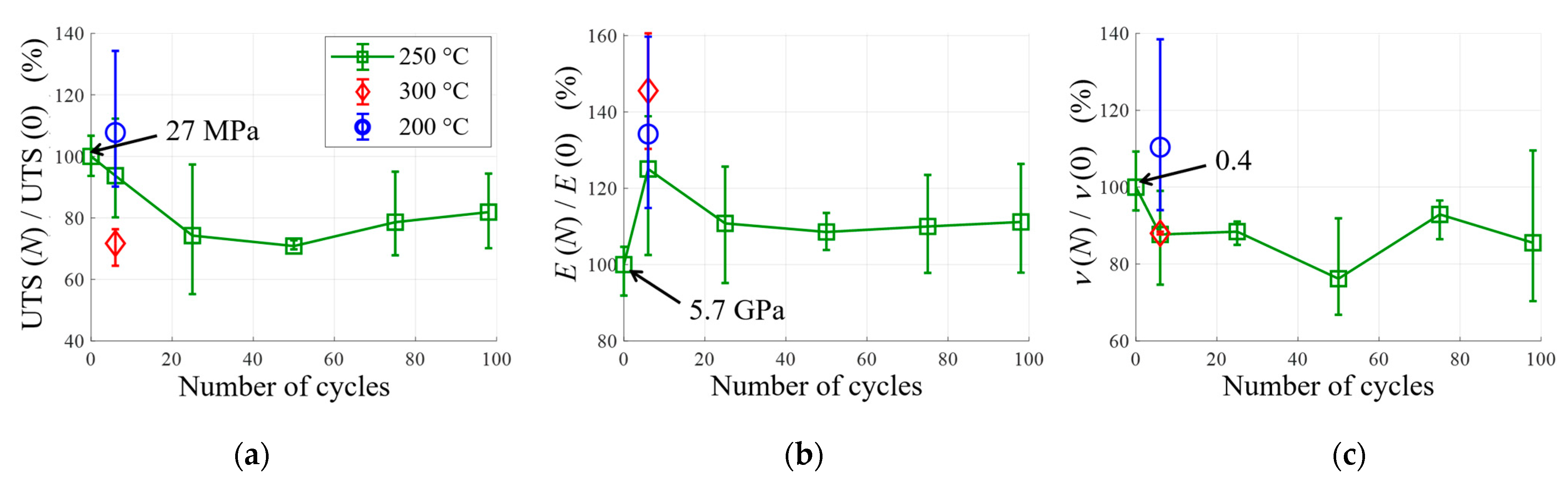

2.3.2. Dynamic Mechanical Analysis

- the relaxation temperature: Tr

- the storage moduli at fixed temperatures below and above Tr (−50 °C and −150 °C): E′−50°C and E′150°C

- the storage modulus difference: ΔE′= E′−50°C − E′150°C

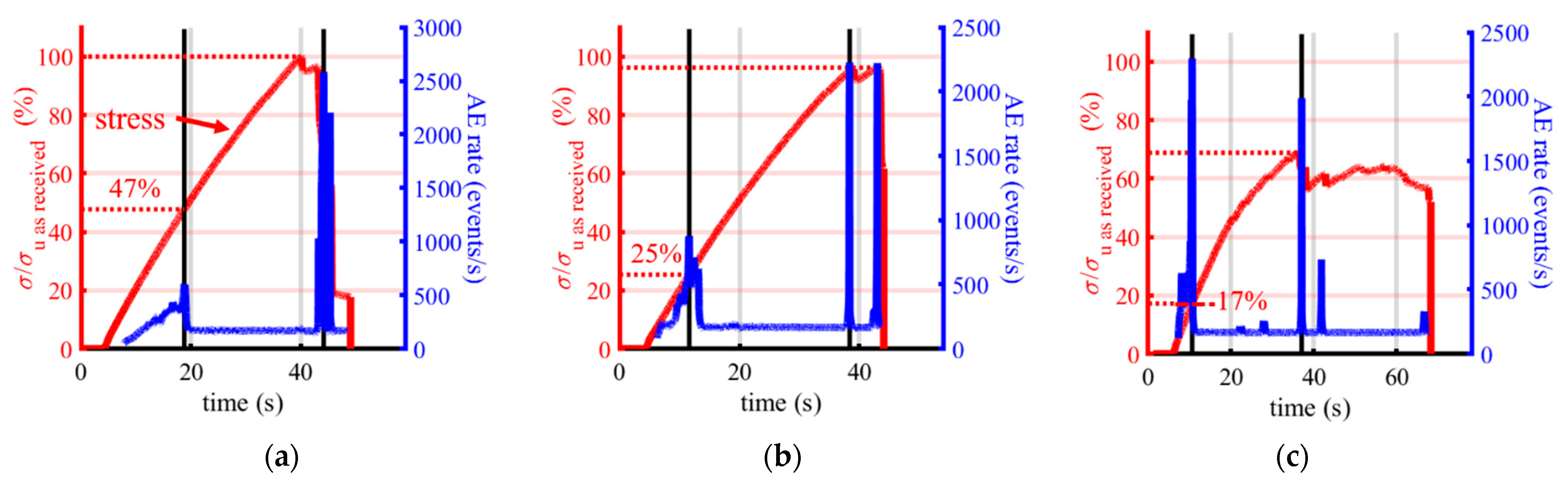

2.3.3. Damage Measurements with Acoustic Emission

3. Results and Discussion

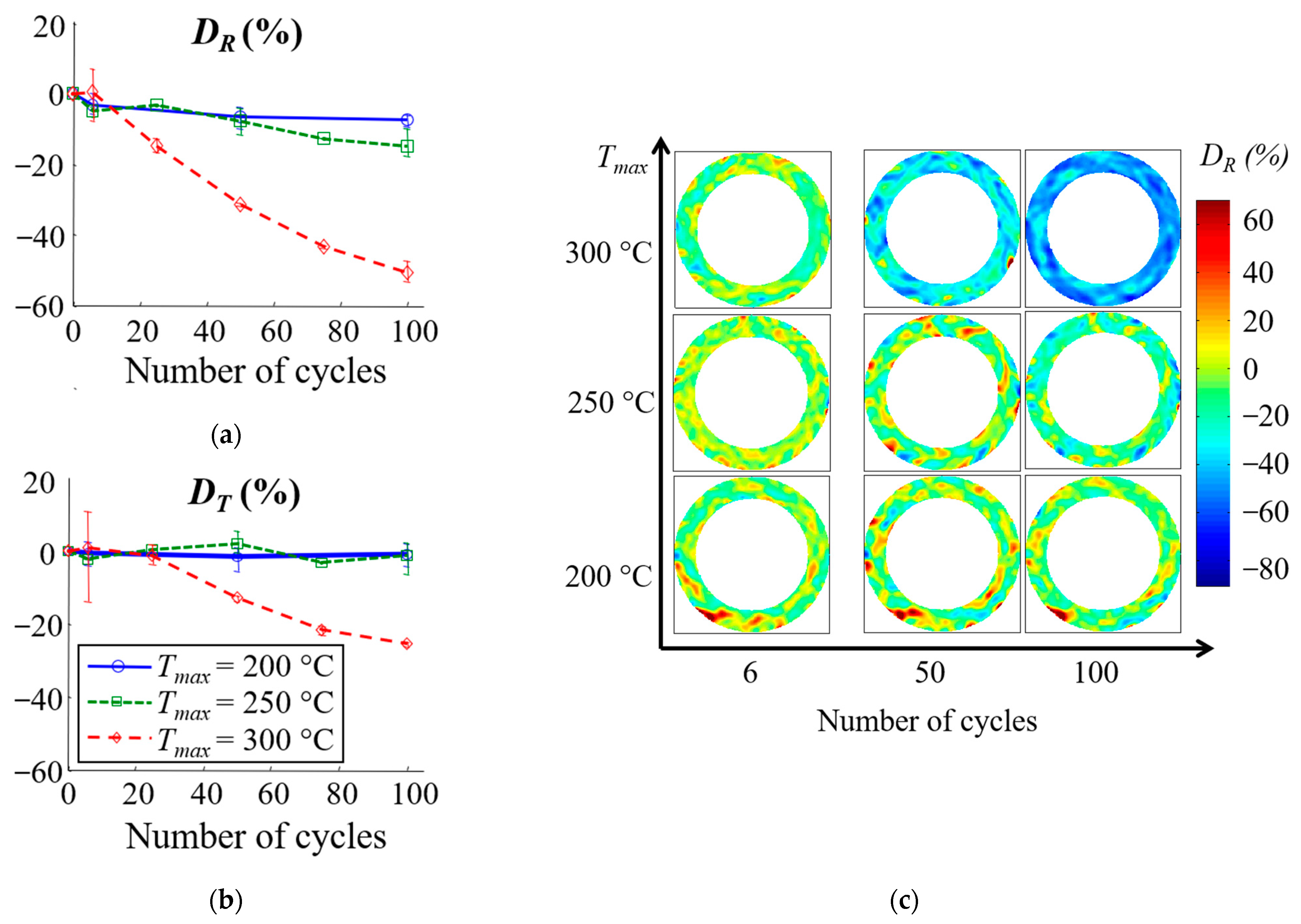

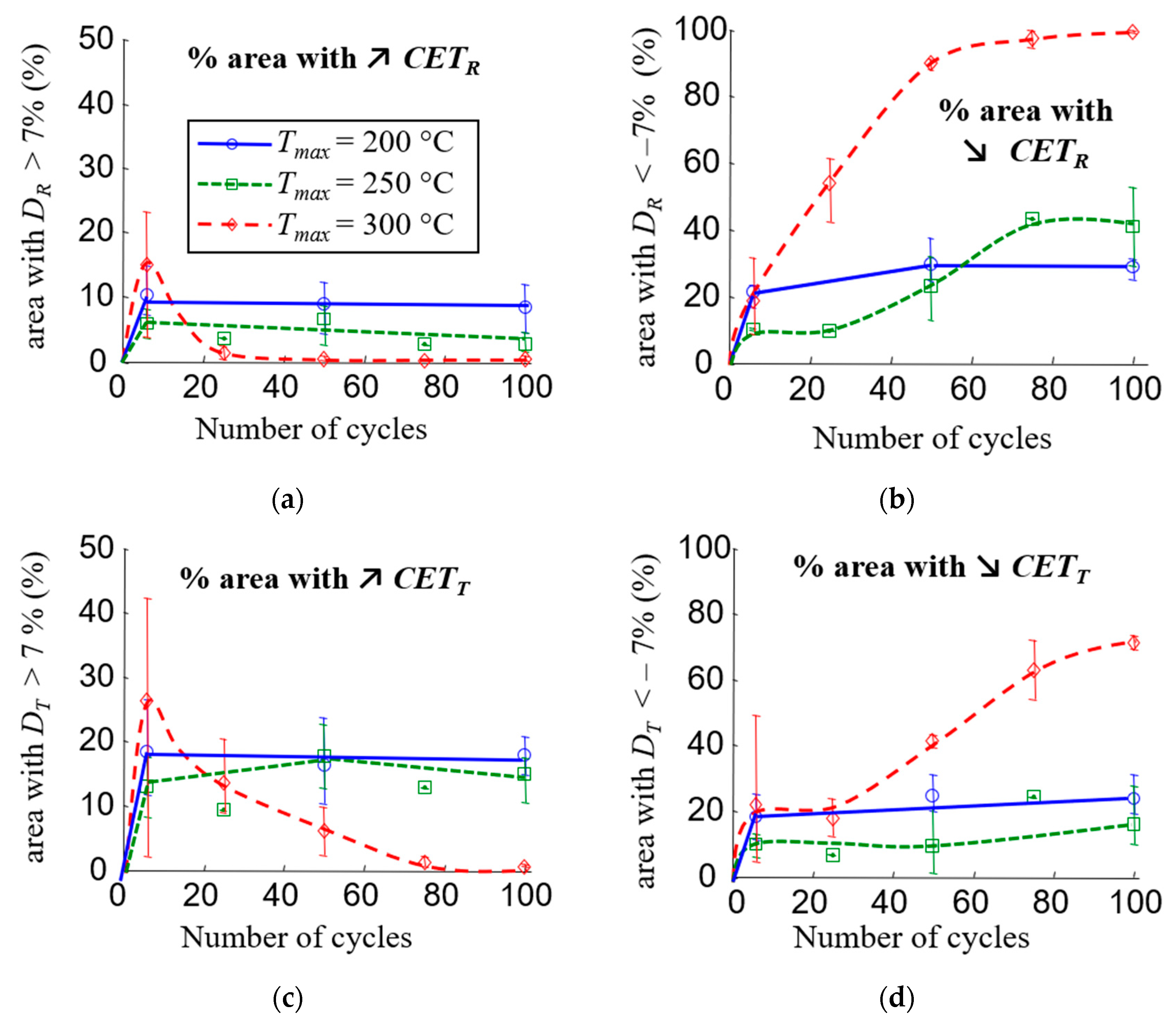

3.1. CTE Evolution

- the difference in the thermal expansion of the fibres and the matrix can lead to crack initiation;

- thermo-chemical reactions in the matrix can lead to the changes in the mechanical properties of the matrix but also to cracking.

3.2. Root Causes of the CTE Evolution

3.2.1. Surface Cracking

3.2.2. Weight Loss and DMA Analysis

3.2.3. Highlighting of Volume Damage: Ageing, Cracking and Mechanical Properties

3.2.4. Summary

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| α | Coefficient of the thermal expansion tensor |

| ΔT | Temperature variation |

| ΔE′ | Drop in storage modulus |

| ɛ | Strain |

| ɛT, ɛR | Tangential and radial strains |

| ν | Poisson’s ratio |

| θ | Polar angle in the polar coordinate system |

| A0 | Track width (clutch facing) |

| AE | Acoustic Emission |

| BSE | Backscattered Electron Detection |

| CTE | Coefficients of thermal expansion |

| CTER, CTET | Radial and tangential coefficients of thermal expansion |

| Di | Damage variable |

| DR, DT | Radial and tangential damage variable |

| DIC | Digital image correlation |

| DISC | Digital Image Stereo-Correlation |

| DMA | Dynamical mechanical analysis |

| Dout, Din | Outer and inner diameters (clutch facing) |

| EDS | Energy Dispersive Spectroscopy |

| E* | Complex Young modulus |

| E′ | Storage Young Modulus |

| E″ | Loss Young Modulus |

| Lb | Preforming ratio (clutch facing) |

| N | Number of cycles |

| NBR | Nitrile Butadiene Rubber |

| R0 | Mean radius of the clutch facing |

| ROI | Region of interest |

| SBR | Styrene Butadiene Rubber |

| SEM | Scanning Electron Microscope |

| tan δ | Loss modulus |

| Tg | Glass transition temperature |

| Ti | Relaxation temperature |

| TGA | Thermogravimetric analysis |

| UTS | Ultimate Tensile Strength |

| Ur, Ut | Radial and tangential strain directions |

References

- Abdullah, O.I.; Schlattmann, J.; Senatore, A.; Sabri, L.A.; Al-Sahb, W.S.A. Effect of Sliding Speed on the Thermal Stresses of Single-Disk Friction Clutches. J. Fail. Anal. Prev. 2020, 20, 1534–1540. [Google Scholar] [CrossRef]

- Faidh-Allah, M.H. Numerical and Finite Element Contact Temperature Analysis of Friction Material’s Type Effect on a Thermal Transient Behavior of a Single-Disc Dry Clutch. Tribologia 2017, 271, 35–43. [Google Scholar] [CrossRef]

- Biczó, R.; Kalácska, G.; Mankovits, T. Effects of Automotive Test Parameters on Dry Friction Fiber-Reinforced Clutch Facing Surface Microgeometry and Wear. Polymers 2021, 13, 3896. [Google Scholar] [CrossRef] [PubMed]

- Faidh-Allah, M.H. The Temperature Distribution in Friction Clutch Disc under Successive Engagements. Tribol. Ind. 2018, 40, 92. [Google Scholar] [CrossRef]

- Biczó, R.; Kalácska, G.; Mankovits, T. Micromechanical Model and Thermal Properties of Dry-Friction Hybrid Polymer Composite Clutch Facings. Materials 2020, 13, 4508. [Google Scholar] [CrossRef] [PubMed]

- Bezzazi, M.; Khamlichi, A.; Jabbouri, A.; Reis, P.; Davim, J.P. Experimental Characterization of Frictional Behaviour of Clutch Facings Using Pin-on-Disk Machine. Mater. Des. 2007, 28, 2148–2153. [Google Scholar] [CrossRef]

- Khamlichi, A.; Bezzazi, M.; Parrón Vera, M.A. Optimizing the Thermal Properties of Clutch Facings. J. Mater. Process. Technol. 2003, 142, 634–642. [Google Scholar] [CrossRef]

- Flament, C.; Berthel, B.; Salvia, M.; Grosland, G.; Alix, I. Characterization of the Thermal Behavior of a Complex Composite (Clutch Facing) Combining Digital Image Stereo Correlation and Numerical Approach. Materials 2022, 15, 2582. [Google Scholar] [CrossRef]

- Gkinis, T.; Rahmani, R.; Rahnejat, H.; O’Mahony, M. Heat Generation and Transfer in Automotive Dry Clutch Engagement. J. Zhejiang Univ. Sci. A 2018, 19, 175–188. [Google Scholar] [CrossRef]

- Cakmak, T.; Kilic, M. Estimation of Friction Surface Temperature of a Dry Clutch. Int. J. Heavy Veh. Syst. 2020, 27, 683–702. [Google Scholar] [CrossRef]

- Gkinis, T.; Rahmani, R.; Rahnejat, H. Integrated Thermal and Dynamic Analysis of Dry Automotive Clutch Linings. Appl. Sci. 2019, 9, 4287. [Google Scholar] [CrossRef]

- Yu, L.; Ma, B.; Chen, M.; Li, H.; Zhang, H.; Liu, J. Thermodynamic Differences of Different Friction Pairs in a Multidisc Clutch Caused by Spline Friction: Numerical Simulation and Experimental Verification. Tribol. Trans. 2019, 62, 724–736. [Google Scholar] [CrossRef]

- Stojanovic, N.; Abdullah, O.I.; Rakisheva, Z.B.; Lattieff, F.A.; Hashim, E.T. The Effect of Applied Pressure Function on Thermo-Elastic Problem in the Dry Friction Clutches. J. Fail. Anal. Prev. 2020, 20, 2145–2152. [Google Scholar] [CrossRef]

- Majeed, M.H.; Kadhim, D.E.; Abdullah, O.I.; Schlattmann, J. Numerical Analysis of Thermal Problem in Dry Friction Clutches Based on the Interactive Design Approach. Int. J. Interact. Des. Manuf. 2020, 14, 1091–1101. [Google Scholar] [CrossRef]

- Wu, G.; Li, P. Thermo-Mechanical Coupling Characteristics of Dry Clutch Under Different Automotive Starting Modes. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference; American Society of Mechanical Engineers, Boston, MA, USA, 20—23 August 2020; Volume 83938, p. V004T04A027. [Google Scholar]

- Wang, Y.; Li, Y.; Li, N.; Sun, H.; Wu, C.; Zhang, T. Time-Varying Friction Thermal Characteristics Research on a Dry Clutch. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 510–517. [Google Scholar] [CrossRef]

- Pisaturo, M.; Senatore, A. Simulation of Engagement Control in Automotive Dry-Clutch and Temperature Field Analysis through Finite Element Model. Appl. Therm. Eng. 2016, 93, 958–966. [Google Scholar] [CrossRef]

- Jin, Y.; Chen, L.; Cheng, C. Transient Thermal Behavior of Dry Clutch under Non-Uniform Pressure Condition; SAE Technical Paper; SAE International: Pittsburgh, PA, USA, 2020. [Google Scholar]

- Zagrodzki, P. Thermoelastic Instability in Friction Clutches and Brakes–Transient Modal Analysis Revealing Mechanisms of Excitation of Unstable Modes. Int. J. Solids Struct. 2009, 46, 2463–2476. [Google Scholar] [CrossRef]

- Pica, G.; Cervone, C.; Senatore, A.; Lupo, M.; Vasca, F. Dry Dual Clutch Torque Model with Temperature and Slip Speed Effects. Intell. Ind. Syst. 2016, 2, 133–147. [Google Scholar] [CrossRef]

- Awrejcewicz, J.; Grzelczyk, D. Modeling and Analysis of Thermal Processes in Mechanical Friction Clutch—Numerical and Experimental Investigations. Int. J. Struct. Stab. Dyn. 2013, 13, 1340004. [Google Scholar] [CrossRef]

- Rahul, R.; Pugazhenthi, R.; Antony, E.J.; Viswanath, B.; Selvan, A. Mathematical Modelling of Temperature Rise in Clutch and Design, Analysis and Fabrication of Cooling System for Clutch. Int. J. Sci. Eng. Res. 2015, 6, 603. [Google Scholar]

- Abdullah, O.I.; Schlattmann, J.; Majeed, M.H.; Sabri, L.A. The Distribution of Frictional Heat Generated between the Contacting Surfaces of the Friction Clutch System. Int. J. Interact. Des. Manuf. 2019, 13, 487–498. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J. The Correction Factor for Rate of Energy Generated in the Friction Clutches under Uniform Pressure Condition. J. Adv. Theor. Appl. Mech. 2012, 5, 277–290. [Google Scholar]

- Al-Shabibi, A.M. The Thermo-Mechanical Behavior in Automotive Brake and Clutch Systems. In New Trends and Developments in Automotive System Engineering; IntechOpen: London, UK, 2011; ISBN 9533075171. [Google Scholar]

- Abdullah, O.I.; Abd Al-Sahb, W.; Al-Shabibi, A.M. Thermoelastic Analysis of Multi-Disc Clutches Using Finite Element Method. Q. Tribol. 2014, 257, 9–24. [Google Scholar]

- Kulkarni, A.; Mahale, R.; Kannan, C. Wear Based Lifetime Estimation of a Clutch Facing Using Coupled Field Analysis. Int. J. Automot. Mech. Eng. 2021, 18, 9292–9304. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J. Thermal Behavior of Friction Clutch Disc Based on Uniform Pressure and Uniform Wear Assumptions. Friction 2016, 4, 228–237. [Google Scholar] [CrossRef]

- Sherza, J.S.; Hussain, I.Y.; Abdullah, O.I. Finite Element Simulation of Thermal Behavior of Dry Friction Clutch System during the Slipping Period. J. Mech. Contin. Math. Sci. 2019, 14, 41–58. [Google Scholar] [CrossRef]

- Al-Zubaidi, S.; Senatore, A.; Abdullah, O.I.; Scuotto, N. Effect of Sliding Speed on the Thermal Fields and Frictional Behaviours of Asbestos-Free Frictional Materials Used for Dry Clutch System. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 881, p. 12086. [Google Scholar]

- Pisaturo, M.; Senatore, A. Thermal Compensation Control Strategy in Automated Dry Clutch Engagement Dynamics and Launch Manoeuvre. Int. J. Automot. Technol. 2019, 20, 1089–1101. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Sabri, L.A.; Al-Sahb, W.A. Finite Element Analysis of the Thermal Behaviour of Single-Disc Clutches during Repeated Engagements. Tribologia 2016, 2, 9–24. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J.; Lytkin, M. Effect of Surface Roughness on the Thermoelastic Behaviour of Friction Clutches. FME Trans. 2015, 43, 241–248. [Google Scholar]

- Abdullah, O.I.; Rasham, A.M.; Jobair, H.K. The Influence of Frictional Facing Thickness on the Contact Pressure Distribution of Multi-Disc Dry Clutches. FME Trans. 2018, 46, 33–38. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Ellangovan, S. Dry Sliding Wear Characteristics of Glass–Epoxy Composite Filled with Silicon Carbide and Graphite Particles. Wear 2012, 296, 491–496. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Ye, L.; Friedrich, K. Tribological Properties of High Temperature Resistant Polymer Composites with Fine Particles. Tribol. Int. 2007, 40, 1170–1178. [Google Scholar] [CrossRef]

- Olifirov, L.K.; Stepashkin, A.A.; Sherif, G.; Tcherdyntsev, V.V. Tribological, Mechanical and Thermal Properties of Fluorinated Ethylene Propylene Filled with Al-Cu-Cr Quasicrystals, Polytetrafluoroethylene, Synthetic Graphite and Carbon Black. Polymers 2021, 13, 781. [Google Scholar] [CrossRef]

- Rangaswamy, H.; Chandrashekarappa, M.P.G.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Experimental Investigation and Optimization of Compression Moulding Parameters for MWCNT/Glass/Kevlar/Epoxy Composites on Mechanical and Tribological Properties. J. Mater. Res. Technol. 2021, 15, 327–341. [Google Scholar] [CrossRef]

- Bajpai, A.; Saxena, P.; Kunze, K. Tribo-Mechanical Characterization of Carbon Fiber-Reinforced Cyanate Ester Resins Modified With Fillers. Polymers 2020, 12, 1725. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, L.; Yin, T.; Luo, Z.; Li, H.; Qi, L. A New Kind of Resin-Based Wet Friction Material: Non-Woven Fabrics with Isotropic Fiber Networks as Preforms. Friction 2021, 9, 92–103. [Google Scholar] [CrossRef]

- Bakry, M.; Mousa, M.O.; Ali, W.Y. Friction and Wear of Friction Composites Reinforced by Natural Fibres. Materwiss. Werksttech. 2013, 44, 21–28. [Google Scholar] [CrossRef]

- Koranteng, K.; Shaahu, J.-S.; Chengnan, M.; Li, H.; Yi, Y.-B. The Performance of Cu-Based Friction Material in Dry Clutch Engagement. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1114–1123. [Google Scholar] [CrossRef]

- Senthil Gavaskar, S.; Karthick, K.; Bibin, C. Statistical Analysis on Hardness of Clutch Facing at Various Stages in Clutch Face Manufacturing. Mater. Today Proc. 2021, 46, 3730–3734. [Google Scholar] [CrossRef]

- Jabbar, N.A.; Hussain, I.Y.; Abdullah, O.I. Thermal and Thermoelastic Problems in Dry Friction Clutch: A Comprehensive Review. Heat Transf. 2021, 50, 7855–7878. [Google Scholar] [CrossRef]

- Forsyth, D.S.; Kasap, S.O.; Wacker, I.; Yannacopoulos, S. Thermal Fatigue of Composites: Ultrasonic and SEM Evaluations. J. Eng. Mater. Technol. 1994, 116, 113–120. [Google Scholar] [CrossRef]

- Odegard, G.M.; Bandyopadhyay, A. Physical Aging of Epoxy Polymers and Their Composites. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1695–1716. [Google Scholar] [CrossRef]

- Struik, L.C.E. Physical Aging in Plastics and Other Glassy Materials. Polym. Eng. Sci. 1977, 17, 165–173. [Google Scholar] [CrossRef]

- Hu, H.W. Physical Aging in Long Term Creep of Polymeric Composite Laminates. J. Mech. 2007, 23, 245–252. [Google Scholar] [CrossRef]

- Sullivan, J.L. Creep and Physical Aging of Composites. Compos. Sci. Technol. 1990, 39, 207–232. [Google Scholar] [CrossRef]

- Kong, E.S.W.; Lee, S.M.; Nelson, H.G. Physical Aging in Graphite/Epoxy Composites. Polym. Compos. 1982, 3, 29–33. [Google Scholar] [CrossRef]

- Pascault, J.-P.; Sautereau, H.; Verdu, J.; Williams, R.J.J. Thermosetting Polymers, 1st ed.; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Yu, Q.; Chen, P.; Gao, Y.; Mu, J.; Chen, Y.; Lu, C.; Liu, D. Effects of Vacuum Thermal Cycling on Mechanical and Physical Properties of High Performance Carbon/Bismaleimide Composite. Mater. Chem. Phys. 2011, 130, 1046–1053. [Google Scholar] [CrossRef]

- Katunin, A. Thermal Fatigue of Polymeric Composites under Repeated Loading. J. Reinf. Plast. Compos. 2012, 31, 1037–1044. [Google Scholar] [CrossRef]

- Rasoldier, N.; Colin, X.; Verdu, J.; Bocquet, M.; Olivier, L.; Chocinski-Arnault, L.; Lafarie-Frenot, M.C. Model Systems for Thermo-Oxidised Epoxy Composite Matrices. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1522–1529. [Google Scholar] [CrossRef]

- Lafarie-Frenot, M.C.; Grandidier, J.C.; Gigliotti, M.; Olivier, L.; Colin, X.; Verdu, J.; Cinquin, J. Thermo-Oxidation Behaviour of Composite Materials at High Temperatures: A Review of Research Activities Carried out within the COMEDI Program. Polym. Degrad. Stab. 2010, 95, 965–974. [Google Scholar] [CrossRef]

- Shaoquan, W.; Shangli, D.; Yu, G.; Yungang, S. Thermal Ageing Effects on Mechanical Properties and Barely Visible Impact Damage Behavior of a Carbon Fiber Reinforced Bismaleimide Composite. Mater. Des. 2017, 115, 213–223. [Google Scholar] [CrossRef]

- Musto, P.; Ragosta, G.; Russo, P.; Mascia, L. Thermal-Oxidative Degradation of Epoxy and Epoxy-Bismaleimide Networks: Kinetics and Mechanism. Macromol. Chem. Phys. 2001, 202, 3445–3458. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Bian, C.; Zhong, Y.; Jing, X. Effect of Chemical Structure and Cross-Link Density on the Heat Resistance of Phenolic Resin. Polym. Degrad. Stab. 2015, 111, 239–246. [Google Scholar] [CrossRef]

- Zavatta, N.; Rondina, F.; Falaschetti, M.P.; Donati, L. Effect of Thermal Ageing on the Mechanical Strength of Carbon Fibre Reinforced Epoxy Composites. Polymers 2021, 13, 2006. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Experimental Investigation of the Microstructures and Tensile Properties of Polyacrylonitrile-Based Carbon Fibers Exposed to Elevated Temperatures in Air. J. Eng. Fiber. Fabr. 2019, 14, 1558925019850010. [Google Scholar] [CrossRef]

- Feih, S.; Manatpon, K.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Strength Degradation of Glass Fibers at High Temperatures. J. Mater. Sci. 2009, 44, 392–400. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. A Review on the Thermal Characterisation of Natural and Hybrid Fiber Composites. Polymers 2021, 13, 4425. [Google Scholar] [CrossRef]

- Sai Shravan Kumar, P.; Viswanath Allamraju, K. A Review Of Natural Fiber Composites [Jute, Sisal, Kenaf]. Mater. Today Proc. 2019, 18, 2556–2562. [Google Scholar] [CrossRef]

- Scola, D.A. A Study of the Thermo-Oxidative Process and Stability of Graphite and Glass/PMF Polyimide Composites BT. In The Role of the Polymeric Matrix in the Processing and Structural Properties Composite Materials; Seferis, J.C., Nicolais, L., Eds.; Springer US: Boston, MA, USA, 1983; pp. 159–169. ISBN 978-1-4615-9293-8. [Google Scholar]

- Pochiraju, K.; Tandon, G.P. Interaction of Oxidation and Damage in High Temperature Polymeric Matrix Composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1931–1940. [Google Scholar] [CrossRef]

- Chung, K.; Seferis, J.C.; Nam, J.-D. Investigation of Thermal Degradation Behavior of Polymeric Composites: Prediction of Thermal Cycling Effect from Isothermal Data. Compos. Part A Appl. Sci. Manuf. 2000, 31, 945–957. [Google Scholar] [CrossRef]

- Schoeppner, G.A.; Tandon, G.P.; Ripberger, E.R. Anisotropic Oxidation and Weight Loss in PMR-15 Composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 890–904. [Google Scholar] [CrossRef]

- Vu, D.Q.; Gigliotti, M.; Lafarie-Frenot, M.C. The Effect of Thermo-Oxidation on Matrix Cracking of Cross-Ply [0/90]S composite Laminates. Compos. Part A Appl. Sci. Manuf. 2013, 44, 114–121. [Google Scholar] [CrossRef]

- Colin, X.; Mavel, A.; Marais, C.; Verdu, J. Interaction between Cracking and Oxidation in Organic Matrix Composites. J. Compos. Mater. 2005, 39, 1371–1389. [Google Scholar] [CrossRef]

- Awaja, F.; Zhang, S.; Tripathi, M.; Nikiforov, A.; Pugno, N. Cracks, Microcracks and Fracture in Polymer Structures: Formation, Detection, Autonomic Repair. Prog. Mater. Sci. 2016, 83, 536–573. [Google Scholar] [CrossRef]

- Khajeh, A.; Mustapha, F.; Sultan, M.T.H.; Bánhegyi, G.; Karácsony, Z.; Baranyai, V. The Effect of Thermooxidative Aging on the Durability of Glass Fiber-Reinforced Epoxy. Adv. Mater. Sci. Eng. 2015, 2015, 372354. [Google Scholar] [CrossRef]

- Lafarie-Frenot, M.C.; Rouquié, S.; Ho, N.Q.; Bellenger, V. Comparison of Damage Development in C/Epoxy Laminates during Isothermal Ageing or Thermal Cycling. Compos. Part A Appl. Sci. Manuf. 2006, 37, 662–671. [Google Scholar] [CrossRef]

- Zrida, H.; Fernberg, P.; Ayadi, Z.; Varna, J. Microcracking in Thermally Cycled and Aged Carbon Fibre/Polyimide Laminates. Int. J. Fatigue 2017, 94, 121–130. [Google Scholar] [CrossRef]

- Ratna, D.; Banthia, A.K. Rubber Toughened Epoxy. Macromol. Res. 2004, 12, 11–21. [Google Scholar] [CrossRef]

- Soares, B.G.; Livi, S. Novel Techniques for the Preparation of Different Epoxy/Rubber Blends BT. In Handbook of Epoxy Blends; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E.M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 29–67. ISBN 978-3-319-40043-3. [Google Scholar]

- Derakhshandeh, B.; Shojaei, A.; Faghihi, M. Effects of Rubber Curing Ingredients and Phenolic-Resin on Mechanical, Thermal, and Morphological Characteristics of Rubber/Phenolic-Resin Blends. J. Appl. Polym. Sci. 2008, 108, 3808–3821. [Google Scholar] [CrossRef]

- Liu, W.-W.; Ma, J.-J.; Zhan, M.-S.; Wang, K. The Toughening Effect and Mechanism of Styrene-Butadiene Rubber Nanoparticles for Novolac Resin. J. Appl. Polym. Sci. 2015, 132, 41533. [Google Scholar] [CrossRef]

- Zaghdoudi, M.; Kömmling, A.; Jaunich, M.; Wolff, D. Scission, Cross-Linking, and Physical Relaxation during Thermal Degradation of Elastomers. Polymers 2019, 11, 1280. [Google Scholar] [CrossRef]

- Rezig, N.; Bellahcene, T.; Aberkane, M.; Nait Abdelaziz, M. Thermo-Oxidative Ageing of a SBR Rubber: Effects on Mechanical and Chemical Properties. J. Polym. Res. 2020, 27, 339. [Google Scholar] [CrossRef]

- Choi, S.-S.; Kim, J.-C. Lifetime Prediction and Thermal Aging Behaviors of SBR and NBR Composites Using Crosslink Density Changes. J. Ind. Eng. Chem. 2012, 18, 1166–1170. [Google Scholar] [CrossRef]

- Gardziella, A.; Pilato, L.A.; Knop, A. Phenolic Resins: Chemistry, Applications, Standardization, Safety and Ecology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 3662041014. [Google Scholar]

- Saffar, A.; Shojaei, A. Effect of Rubber Component on the Performance of Brake Friction Materials. Wear 2012, 274–275, 286–297. [Google Scholar] [CrossRef]

- Lee, T.I.; Kim, M.S.; Kim, T.S. Contact-Free Thermal Expansion Measurement of Very Soft Elastomers Using Digital Image Correlation. Polym. Test. 2016, 51, 181–189. [Google Scholar] [CrossRef]

- Bing, P.; Hui-min, X.; Tao, H.; Asundi, A. Measurement of Coefficient of Thermal Expansion of Films Using Digital Image Correlation Method. Polym. Test. 2009, 28, 75–83. [Google Scholar] [CrossRef]

- Eitner, U.; Köntges, M.; Brendel, R. Use of Digital Image Correlation Technique to Determine Thermomechanical Deformations in Photovoltaic Laminates: Measurements and Accuracy. Sol. Energy Mater. Sol. Cells 2010, 94, 1346–1351. [Google Scholar] [CrossRef]

- Grédiac, M. The Use of Full-Field Measurement Methods in Composite Material Characterization: Interest and Limitations. Compos. Part A Appl. Sci. Manuf. 2004, 35, 751–761. [Google Scholar] [CrossRef]

- Robert, L.; Nazaret, F.; Cutard, T.; Orteu, J.-J. Use of 3-D Digital Image Correlation to Characterize the Mechanical Behavior of a Fiber Reinforced Refractory Castable. Exp. Mech. 2007, 47, 761–773. [Google Scholar] [CrossRef]

- Shi, Z.; Zou, C.; Zhou, F.; Zhao, J. Analysis of the Mechanical Properties and Damage Mechanism of Carbon Fiber/Epoxy Composites under UV Aging. Materials 2022, 15, 2919. [Google Scholar] [CrossRef]

- Barré, S.; Benzeggagh, M.L. On the Use of Acoustic Emission to Investigate Damage Mechanisms in Glass-Fibre-Reinforced Polypropylene. Compos. Sci. Technol. 1994, 52, 369–376. [Google Scholar] [CrossRef]

- Quispitupa, A.; Shafiq, B.; Just, F.; Serrano, D. Acoustic Emission Based Tensile Characteristics of Sandwich Composites. Compos. Part B Eng. 2004, 35, 563–571. [Google Scholar] [CrossRef]

- Loutas, T.H.; Kostopoulos, V. Health Monitoring of Carbon/Carbon, Woven Reinforced Composites. Damage Assessment by Using Advanced Signal Processing Techniques. Part I: Acoustic Emission Monitoring and Damage Mechanisms Evolution. Compos. Sci. Technol. 2009, 69, 265–272. [Google Scholar] [CrossRef]

- Biot, C. Method of Fabrication of a Friction Material and in Particular of a Friction Ring for a Friction Disc of a Clutch and Friction Ring of a Clutch. Patent EP0965770B1, 17 June 1998. [Google Scholar]

- Zhang, X.; Li, K.-Z.; Li, H.-J.; Fu, Y.-W.; Fei, J. Tribological and Mechanical Properties of Glass Fiber Reinforced Paper-Based Composite Friction Material. Tribol. Int. 2014, 69, 156–167. [Google Scholar] [CrossRef]

- Kumar, M.; Bijwe, J. Non-Asbestos Organic (NAO) Friction Composites: Role of Copper; Its Shape and Amount. Wear 2011, 270, 269–280. [Google Scholar] [CrossRef]

- Wassilkowska, A.; Czaplicka-Kotas, A.; Bielski, A.; Zielina, M. An Analysis of the Elemental Composition of Micro-Samples Using EDS Technique. Czas. Tech. 2014, 2014, 133–148. [Google Scholar]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Lipińska, M.; Rybiński, P.; Syrek, B. Synergistic Effect of Mica, Glass Frit, and Melamine Cyanurate for Improving Fire Resistance of Styrene-Butadiene Rubber Composites Destined for Ceramizable Coatings. Coatings 2019, 9, 170. [Google Scholar] [CrossRef]

- Banerjee, A.; Dutta, M.; Bhowmick, A.K.; Laha, T. Effect of Sn on the Adhesion between Cu–Sn Alloy Coated Steel and Styrene Butadiene Based Rubber. ISIJ Int. 2014, 54, 671–676. [Google Scholar] [CrossRef]

- Sutton, M.; Orteu, J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements, 1st ed.; Springer US: Boston, MA, USA, 2009; ISBN 978-0-387-78746-6. [Google Scholar]

- Garcia, D. Mesure de Formes et de Champs de Déplacements Tridimensionnels Par Stéréo-Corrélation D’Images; Ecole des Mines d’Albi: Toulouse, France, 2001. [Google Scholar]

- Lyons, J.S.; Liu, J.; Sutton, M.A. High-Temperature Deformation Measurements Using Digital-Image Correlation. Exp. Mech. 1996, 36, 64–70. [Google Scholar] [CrossRef]

- Flament, C.; Salvia, M.; Berthel, B.; Crosland, G. Digital Image Correlation Applied to Thermal Expansion of Composites. In Proceedings of the 19th International Conference on Composite Materials (ICCM-19), Montreal, QC, Canada, 28 July–2 August 2013; Van Hoa, S., Hubert, P., Eds.; IEEE: Montreal, QC, Canada, 2013; pp. 5235–5243. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980; ISBN 0471048941. [Google Scholar]

- Kechaou, B.; Salvia, M.; Benzarti, K.; Turki, C.; Fakhfakh, Z.; Tréheux, D. Role of Fiber/Matrix Interphases on Dielectric, Friction, and Mechanical Properties of Glass Fiber-Reinforced Epoxy Composites. J. Compos. Mater. 2011, 46, 131–144. [Google Scholar] [CrossRef]

- Kechaou, B.; Salvia, M.; Beaugiraud, B.; Juvé, D.; Fakhfakh, Z.; Treheux, D. Mechanical and Dielectric Characterization of Hemp Fibre Reinforced Polypropylene (HFRPP) by Dry Impregnation Process. eXPRESS Polym. Lett. 2010, 4, 171–182. [Google Scholar] [CrossRef]

- Emirkhanian, R.; Salvia, M.; Ferreira, J.; Jaffrezic, N.; Chazeau, L.; Mazzoldi, A. Characterisation of Thermal Relaxations of Polyaniline Fibers by Dynamic Mechanical Thermal Analysis. Mater. Sci. Eng. C 2006, 26, 227–231. [Google Scholar] [CrossRef]

- Roche, N.; Ichchou, M.N.; Salvia, M.; Chettah, A. Dynamic Damping Properties of Thermoplastic Elastomers Based on EVA and Recycled Ground Tire Rubber. J. Elastomers Plast. 2011, 43, 317–340. [Google Scholar] [CrossRef]

- Camino, G.; Alba, E.; Buonfico, P.; Vikoulov, K. Thermal Behavior of Elastomer—Resin Mixtures Used as Friction Materials. J. Appl. Polym. Sci. 2001, 82, 1346–1351. [Google Scholar] [CrossRef]

- Flament, C.; Salvia, M.; Berthel, B.; Crosland, G. Local Strain and Damage Measurements on a Composite with Digital Image Correlation and Acoustic Emission. J. Compos. Mater. 2015, 50, 1989–1996. [Google Scholar] [CrossRef]

- Mechraoui, S.E.; Laksimi, A.; Benmedakhene, S. Reliability of Damage Mechanism Localisation by Acoustic Emission on Glass/Epoxy Composite Material Plate. Compos. Struct. 2012, 94, 1483–1494. [Google Scholar] [CrossRef]

- Pollock, A.A. Acoustic Emission—2. Acoustic Emission Amplitudes. Non-Destr. Test. 1973, 6, 264–269. [Google Scholar] [CrossRef]

- Morscher, G.N.; Godin, N. Use of Acoustic Emission for Ceramic Matrix Composites. Ceram. Matrix Compos. 2014, 569–590. [Google Scholar] [CrossRef]

- Hatta, H.; Takei, T.; Taya, M. Effects of Dispersed Microvoids on Thermal Expansion Behavior of Composite Materials. Mater. Sci. Eng. A 2000, 285, 99–110. [Google Scholar] [CrossRef]

- Fellah, M.; Tounsi, A.; Amara, K.H.; Adda Bedia, E.A. Effect of Transverse Cracks on the Effective Thermal Expansion Coefficient of Aged Angle-Ply Composites Laminates. Theor. Appl. Fract. Mech. 2007, 48, 32–40. [Google Scholar] [CrossRef]

- Lu, T.J.; Hutchinson, J.W. Effect of Matrix Cracking and Interface Sliding on the Thermal Expansion of Fibre-Reinforced Composites. Composites 1995, 26, 403–414. [Google Scholar] [CrossRef]

- Bowles, D.E. Effect of Microcracks on the Thermal Expansion of Composite Laminates. J. Compos. Mater. 1984, 18, 173–187. [Google Scholar] [CrossRef]

- Barbin, W.W.; Rodgers, M.B. 9—The Science of Rubber Compounding. In Science and Technology of Rubber, 3rd ed.; Mark, J.E., Erman, B., Eirich, F.R., Eds.; Elsevier: Amsterdam, The Netherlands, 1994; Volume 11, pp. 419–469. ISBN 978-0-08-051667-7. [Google Scholar]

- Beattie, A.G. Acoustic Emission Non-Destructive Testing of Structures Using Source Location Techniques; Sandia National Laboratories: Livermore, CA, USA, 2013.

| Material | CTE (×10−6 K−1) | Young’s Modulus E (GPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|

| PAN | 80–90 | 17–19 | 200–420 |

| E glass fibre | 4.9–5.1 | 73 | 2000–2500 |

| Copper fibre | 17 | 122–128 | 300–400 |

| Phenolic/Melamine | 120–125 | 2–4 | 30–60 |

| SBR + Carbon Black | 160–180 | 0.004–0.006 | 16–26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flament, C.; Berthel, B.; Salvia, M.; Graton, O.; Alix, I. Average and Local Effect of Thermal Fatigue on the Coefficients of the Thermal Expansion of a Complex Continuous Composite Fibre Used for Car Clutch Facing: A Multi-Technique Study. Materials 2023, 16, 5833. https://doi.org/10.3390/ma16175833

Flament C, Berthel B, Salvia M, Graton O, Alix I. Average and Local Effect of Thermal Fatigue on the Coefficients of the Thermal Expansion of a Complex Continuous Composite Fibre Used for Car Clutch Facing: A Multi-Technique Study. Materials. 2023; 16(17):5833. https://doi.org/10.3390/ma16175833

Chicago/Turabian StyleFlament, Camille, Bruno Berthel, Michelle Salvia, Olivier Graton, and Isabelle Alix. 2023. "Average and Local Effect of Thermal Fatigue on the Coefficients of the Thermal Expansion of a Complex Continuous Composite Fibre Used for Car Clutch Facing: A Multi-Technique Study" Materials 16, no. 17: 5833. https://doi.org/10.3390/ma16175833

APA StyleFlament, C., Berthel, B., Salvia, M., Graton, O., & Alix, I. (2023). Average and Local Effect of Thermal Fatigue on the Coefficients of the Thermal Expansion of a Complex Continuous Composite Fibre Used for Car Clutch Facing: A Multi-Technique Study. Materials, 16(17), 5833. https://doi.org/10.3390/ma16175833