Influence of Undergarments on the Comfort Level of Scoliosis Brace Wearers

Abstract

:1. Introduction

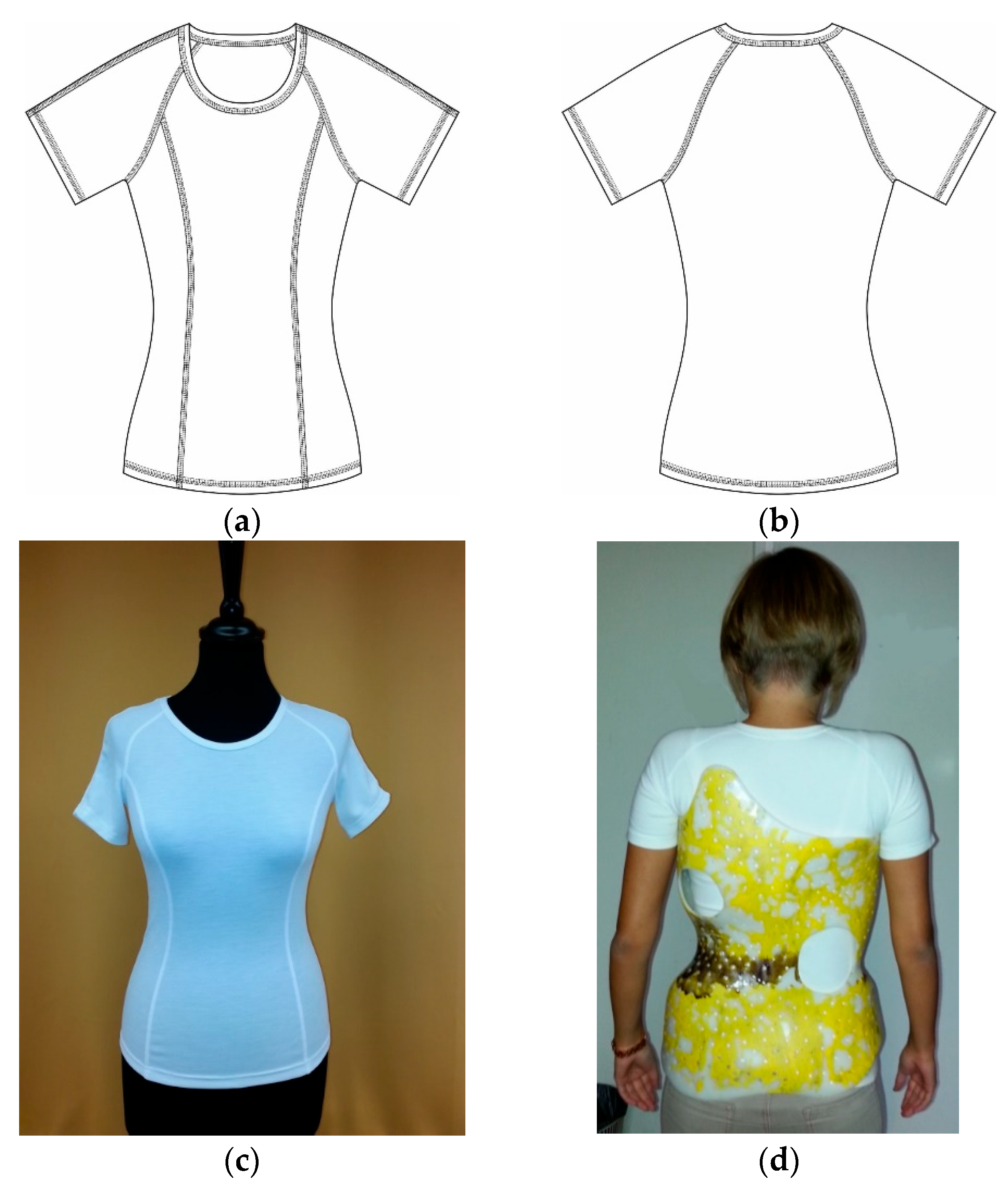

2. Materials

3. Methods

- 15 min of preparation and acclimatization without data collection;

- 20 min of rest (seated position);

- 20 min of walking at a speed of 2.5 km/h on the treadmill;

- 15 min of rest (seated position);

- 5 min of walking on the treadmill at a speed of 3.5 km/h.

4. Results

5. Subjective Assessment

6. Discussion

- General thermo-physiological aspects: Good moisture absorption and moisture transmission properties, high air permeability, and advantageous temperature balancing capability.

- Mechanical properties: High elastic elongation and high abrasion resistance.

- Thermo-physiological test results: Lower body weight decrease, and lower perspiration rate of the test person, and suitability of the T-shirts at different temperatures.

- Subjective evaluation by the test persons.

- Availability off the shelf.

- Acceptable price-to-value ratio.

- Being environmentally friendly.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Von Heideken, J.; Iversen, M.D.; Gerdhem, P. Rapidly increasing incidence in scoliosis surgery over 14 years in a nationwide sample. Eur. Spine J. 2018, 27, 286–292. [Google Scholar] [CrossRef]

- Asher, M.A.; Burton, D.C. Adolescent idiopathic scoliosis: Natural history and long term treatment effects. Scoliosis 2006, 1, 2. [Google Scholar] [CrossRef]

- Hawes, M.C.; O’Brien, J.P. The transformation of spinal curvature into spinal deformity: Pathological processes and implication for treatment. Scoliosis 2006, 1, 3. [Google Scholar] [CrossRef]

- Landauer, F.; Wimmer, C.; Behensky, H. Estimating the final outcome of brace treatment for idiopathic thoracic scoliosis at 6-month follow-up. Pediatr. Rehabil. 2003, 6, 201–207. [Google Scholar] [CrossRef]

- Weiss, H.R.; Moramarco, M. Scoliosis–treatment indications according to current evidence. OA Musculoskelet. Med. 2003, 1, 2013-03. [Google Scholar]

- Weiss, H.R.; Werkmann, M. Rate of surgery in a sample of patients fulfilling the SRS inclusion criteria treated with a Chêneau Brace of actual Standard. Stud. Health Technol. Inform. 2012, 176, 407–410. [Google Scholar] [CrossRef]

- Rigo, M. Radiological and cosmetic improvement 2 years after brace weaning—A case report. Pediatr. Rehabil. 2003, 6, 195–199. [Google Scholar] [CrossRef]

- Grivas, T.B.; Kaspiris, A. European Braces Widely Used for Conservative Scoliosis Treatment. Stud. Health Technol. Inform. 2010, 158, 157–166. [Google Scholar] [CrossRef]

- Wong, M.S.; Cheng, J.C.Y.; Lam, T.P.; Ng, B.K.W.; Sin, S.W.; Lee-Shum, S.L.F.; Chow, D.H.K.; Tam, S.Y.P. The effect of rigid versus flexible spinal orthosis on the clinical efficacy and acceptance of the patients with adolescent idiopathic scoliosis. Spine 2008, 33, 1360–1365. [Google Scholar] [CrossRef]

- Weiss, H.-R.; Moramarco, M. Remodelling of trunk and backshape deformities in patients with scoliosis using standardized asymmetric computer-aided design/computer-aided manufacturing braces. Hard Tissue 2013, 2, 14. [Google Scholar] [CrossRef]

- Nagy Szabó, O. Wear Comfort Improvement of Medical Aids Used for Spine Deformity Treatment. Ph.D. Thesis, University of West Hungary, Sopron, Hungary, 2014. Available online: http://doktori.nyme.hu/484/3/nagyne_szabo_orsolya_angoltezis.pdf (accessed on 29 June 2023).

- Gaál, Z.; Antal, Á.; Tamás, P. Scoliosis Testing Featuresonthe Basis of Electronically Generated Moire Patterns. In Proceedings of the 8th IEEE International Symposium on Applied Machine Intelligence and Informatics, Herlany, Slovakia, 28–30 January 2010; pp. 335–340. [Google Scholar]

- Bogdán, C.; Magony, A.D.; Birkfellner, W.; Antal, Á.; Tunyogi-Csapó, M. Segmentation of Moiré Fringes of Scoliotic Spines Using Filtering and Morphological Operations. Acta Polytech. Hungarica 2023, 20, 223–241. [Google Scholar] [CrossRef]

- Liu, P.-Y.; Yip, J.; Yick, K.L.; Yuen, C.-W.M.; Ng, S.-P.; Tse, C.-Y.; Lawa, D. An Ergonomic Flexible Girdle Design for Preteen and Teenage Girls with Early Scoliosis. J. Fiber Bioeng. Inform. 2014, 7, 233–246. [Google Scholar] [CrossRef]

- Introducing the Brace Maker Ferenc Marlok. Available online: https://www.youtube.com/watch?v=Mlvfol4-Nv (accessed on 2 May 2023). (In Hungarian).

- Gregor-Svetec, D.; Szentgyörgyvölgyi, R.; Borbély, Á. Tensile and surface properties of foils made from LDPE. In Proceedings of the 5th International Symposium on Novelties in Graphics, University of Ljubljana, Ljubljana, Slovenia, 27–29 May 2010; pp. 689–694. [Google Scholar]

- Nagy Szabó, O. Chêneau Brace Air Permeability Test. In Proceedings of the International Joint Conference on Environmental and Light Industry Technologies, Budapest, Hungary, 23–24 November 2017; pp. 195–204. [Google Scholar]

- Tomaszewski, R.; Janowska, M. Psychological aspect of scoliosis treatment in children. Stud. Health Technol. Inform. 2012, 176, 428–432. [Google Scholar] [CrossRef] [PubMed]

- Nagy Szabó, O.; Koleszár, A. Garments under brace life quality improve affect experiment of technology and physiology. Biomech. Hungarica 2013, 6, 67–74. [Google Scholar] [CrossRef]

- Nagy Szabó, O.; Koleszár, A. Special underwear for young girls having scolosis problem. In Proceedings of the XXIV Micro CAD International Scientific Conference, Miskolc, Hungary, 18–20 March 2010; pp. 37–43. [Google Scholar]

- Csanák, E. The CAL: Cognitive, apperceptive and representative aspects of fashion design—Side note to neuroaesthetic theory. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 172008. [Google Scholar] [CrossRef]

- Wenzel, K.; Antal, Á.; Molnár, J.; Tóth, B.; Tamás, P. New Optical Equipment in 3D Surface Measuring. J. Autom. Mob. Robot. Intell. Syst. 2009, 4, 29–32. Available online: https://www.jamris.org/index.php/JAMRIS/article/view/38/38 (accessed on 29 June 2023).

- Geršak, J.; Halász, M.; Nagy Szabó, O.; Koleszár, A. 3D body datas integration in functional wear under brace. In Proceedings of the 12th AUTEX World Textile Conference, Zadar, Croatia, 13–15 June 2012; pp. 1023–1028. [Google Scholar]

- Nagy Szabó, O.; Koleszár, A.; Halász, M.; Geršak, J. Functional Textiles Under Brace. In Proceedings of the International Joint Conference on Environmental and Light Industry Technologies, Budapest, Hungary, 21–22 November 2011; pp. 441–445. [Google Scholar]

- Lang, M.; Müller, A. Climate socket—Focusing on Thermal Comfort in the Prosthetic Socket. In Abstract Book of ISPO World Congress, Lyon, France, 22–25 June 2015. p. 331. Available online: https://journals.sagepub.com/doi/pdf/10.1177/0309364615591101 (accessed on 29 June 2023).

- Gao, C.; Kuklane, K.; Holmér, I. Cooling vests with phase change material packs: The effects of temperature gradient, mass and covering area. Ergonomics 2010, 53, 716–723. [Google Scholar] [CrossRef]

- Arezes, P.M.; Neves, M.M.; Teixeira, S.F.; Lerao, C.P.; Cunha, J.I. Testing thermal comfort of trekking boots: An objective and subjective evaluation. Appl. Ergon. 2013, 44, 557–565. [Google Scholar] [CrossRef]

- Rossi, R.M.; Bolli, W.P. Phase Change Materials for Impruvement of Heat Protection. Adv. Eng. Mater. 2005, 7, 368–373. [Google Scholar] [CrossRef]

- Udayraj; Talukdar, P.; Das, A.; Alagirusamy, R. Heat and mass transfer through thermal protective clothing—A review. Int. J. Therm. Sci. 2016, 106, 32–56. [Google Scholar] [CrossRef]

- Phelps, H.; Sidhu, H. A mathematical model for heat transfer in fire fighting suits containing phase change materials. Fire Saf. J. 2015, 74, 43–47. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Neves, R.M.; Monticeli, F.M.; Agnol, L.D. Smart Fabric Textiles: Recent Advances and Challenges. Textiles 2022, 2, 582–605. [Google Scholar] [CrossRef]

- Shim, H.; McCullough, E.; Jones, B. Using phase change materials in clothing. Textile Res. J. 2001, 71, 495–502. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Das, B.; Das, A.; Kothari, V.K.; Fanguiero, R.; de Araújo, M. Effect of fibre diameter and cross-sectional shape on moisture transmission through fabrics. Fibres Polym. 2008, 9, 225–231. [Google Scholar] [CrossRef]

- Varshneya, R.K.; Kothari, V.K.; Dhamija, S. A study on thermophysiological comfort properties of fabrics in relation to constituent fibre fineness and cross-sectional shapes. J. Text. Inst. 2010, 101, 495–505. [Google Scholar] [CrossRef]

- Firšt Rogale, S.; Rogale, D. Advanced Materials for Clothing and Textile Engineering. Materials 2023, 16, 3407. [Google Scholar] [CrossRef]

- AATCC TM 195-2012; Liquid Moisture Management Properties of Textile Fabrics. The American Association of Textile Chemists and Colorists (AATCC): Research Triangle Park, NC, USA, 2012.

- AATCC TM 197-2013; Vertical Wicking of Textiles. The American Association of Textile Chemists and Colorists (AATCC): Research Triangle Park, NC, USA, 2013.

- ASTM D4158-01; Standard Guide for Abrasion Resistance of Textile Fabrics (Uniform Abrasion). ASTM International: West Conshohocken, PA, USA, 2001.

- ISO 9237:1995; Textiles—Determination of Permeability of Fabrics to Air. ISO: Geneva, Switzerland, 1995.

- ISO 13934-2:2000; Textiles—Tensile properties of fabrics—Part 2: Determination of maximum force using the grab method. ISO: Geneva, Switzerland, 2014.

- ISO 9886:2004; Ergonomics—Evaluation of Thermal Strain by Physiological Measurements. ISO: Geneva, Switzerland, 2014.

- Muthu, S.S. (Ed.) Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Woodhead Publishing Series in Textiles: Number 172; Woodhead Publishing: Cambridge, UK, 2015; ISBN 978-0-08-100187-5. [Google Scholar]

| Kind of Knitted Fabric | Textile Composition | Structure of Fabrics | Thick-ness [mm] | Mass [g/m2] | Yarn Count [Tex] | Course Density [Piece/10 mm] | Wale Density [Piece/10 mm] | PCM Melt Peak [°C] (Nominal Data) | PCM Storage Capacity [J/g] (Nominal Data) |

|---|---|---|---|---|---|---|---|---|---|

| Cotton | 97% cotton 3% elastane | Single weft-knitted | 0.64 | 242 | 19.3 | 26 | 16 | - | - |

| MW-C01 | 100% PES with silver ions, and special filament cross-section | Double pique-knitted | 0.73 | 168 | 13.0 | 17 | 12 |  Special filament cross-section | |

| OU-W02 | 66% cotton 28% viscose with PCM capsules 6% elastane | Single weft-knitted | 0.64 | 198 | 15.7 | 28 | 18 | 24–27 | >2.5 |

| OU-F03 | 95% cotton 5% elastane coating: silicon with PCM capsules | Single weft-knitted | 0.65 | 146 | 16.4 | 22 | 17 | 26–30 | >6 |

| OU-B04 | 66% lyocell 28% viscose with PCM capsules 6% elastane | Single weft-knitted | 0.66 | 175 | 15.6 | 26 | 17 | 24–27 | >2.5 |

| OU-C05 | 59% PES 39% viscose with PCM capsules 2% elastane | Rib weft-knitted | 0.68 | 192 | 22.4 | 20 | 16 | no data | no data |

| Kind of Knitted Fabric | Water Absorption mw [%] | Water- Wicking Speed vw [mm/min] | Thickness Loss hav [%] | Air Perme-ability Q | Thermal Conductivity | Deformation Due to Tensile Force/50 mm | |

|---|---|---|---|---|---|---|---|

| 0.5 N Wale Direction ε [%] | 2.8 N Course Direction ε [%] | ||||||

| Cotton | 186 | 3.6 | 7.8 | 14.8 | 0.0565 | 5.2 | 17.7 |

| MW-C01 | 300 | 3.5 | 4.1 | 210.3 | 0.0508 | 2.4 | 11.6 |

| OU-W02 | 233 | 3.8 | 6.3 | 28.9 | 0.0513 | 5.7 | 22.3 |

| OU-F03 | 254 | 2.7 | 12.7 | 51.7 | 0.0515 | 8.6 | 26.4 |

| OU-B04 | 218 | 1.3 | 8.9 | 99.6 | 0.0525 | 9.1 | 27.6 |

| OU-C05 | 226 | 2.6 | 4.4 | 141.4 | 0.0516 | 3.3 | 27.5 |

| Kind of Knitted Fabric | Order According to the Girls | Sum | Ranking |

|---|---|---|---|

| Cotton | 1, 1, 2, 2, 2, 2, 2, 3, 3, 3, 3, 3 | 27 | 2 |

| OU-F03 | 1, 1, 2, 2, 2, 3, 3, 3, 3, 3, 3, 3 | 29 | 3 |

| OU-B04 | 1, 1, 1, 1, 1, 1, 1, 1, 2, 2, 2, 2 | 16 | 1 |

| OU-C05 | 4, 4, 4, 4, 4, 4, 4, 4, 4, 4, 4, 4 | 48 | 4 |

| Kind of Knitted Fabric | Order According to the Girls | Sum | Ranking |

|---|---|---|---|

| Cotton | 1, 1, 1, 1, 2, 2, 2, 2, 3, 3, 3, 3 | 24 | 2 |

| OU-F03 | 2, 2, 2, 2, 3, 3, 3, 3, 3, 3, 3, 3 | 32 | 3 |

| OU-B04 | 1, 1, 1, 1, 1, 1, 1, 1, 2, 2, 2, 2 | 16 | 1 |

| OU-C05 | 4, 4, 4, 4, 4, 4, 4, 4, 4, 4, 4, 4 | 48 | 4 |

| Kind of Knitted Fabric | Order According to the Girls | Sum | Ranking |

|---|---|---|---|

| Cotton | 1, 1, 1, 1, 1, 1, 1, 2, 2, 2, 3, 3 | 19 | 1 |

| OU-F03 | 2, 2, 2, 2, 2, 2, 2, 3, 3, 3, 3, 3 | 29 | 3 |

| OU-B04 | 1, 1, 1, 1, 1, 2, 2, 3, 3, 3, 3, 3 | 24 | 2 |

| OU-C05 | 4, 4, 4, 4, 4, 4, 4, 4, 4, 4, 4, 4 | 48 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagy Szabó, O.; Geršak, J.; Koleszár, A.; Halász, M. Influence of Undergarments on the Comfort Level of Scoliosis Brace Wearers. Materials 2023, 16, 5925. https://doi.org/10.3390/ma16175925

Nagy Szabó O, Geršak J, Koleszár A, Halász M. Influence of Undergarments on the Comfort Level of Scoliosis Brace Wearers. Materials. 2023; 16(17):5925. https://doi.org/10.3390/ma16175925

Chicago/Turabian StyleNagy Szabó, Orsolya, Jelka Geršak, András Koleszár, and Marianna Halász. 2023. "Influence of Undergarments on the Comfort Level of Scoliosis Brace Wearers" Materials 16, no. 17: 5925. https://doi.org/10.3390/ma16175925

APA StyleNagy Szabó, O., Geršak, J., Koleszár, A., & Halász, M. (2023). Influence of Undergarments on the Comfort Level of Scoliosis Brace Wearers. Materials, 16(17), 5925. https://doi.org/10.3390/ma16175925