Experimental Study on the Mechanical Properties and Influencing Factors of Glass Fiber-Reinforced Permeable Concrete

Abstract

:1. Introduction

2. Test Materials and Test Process

2.1. Test Materials

2.2. Experimental Mix Ratio Design

2.3. Sample Preparation

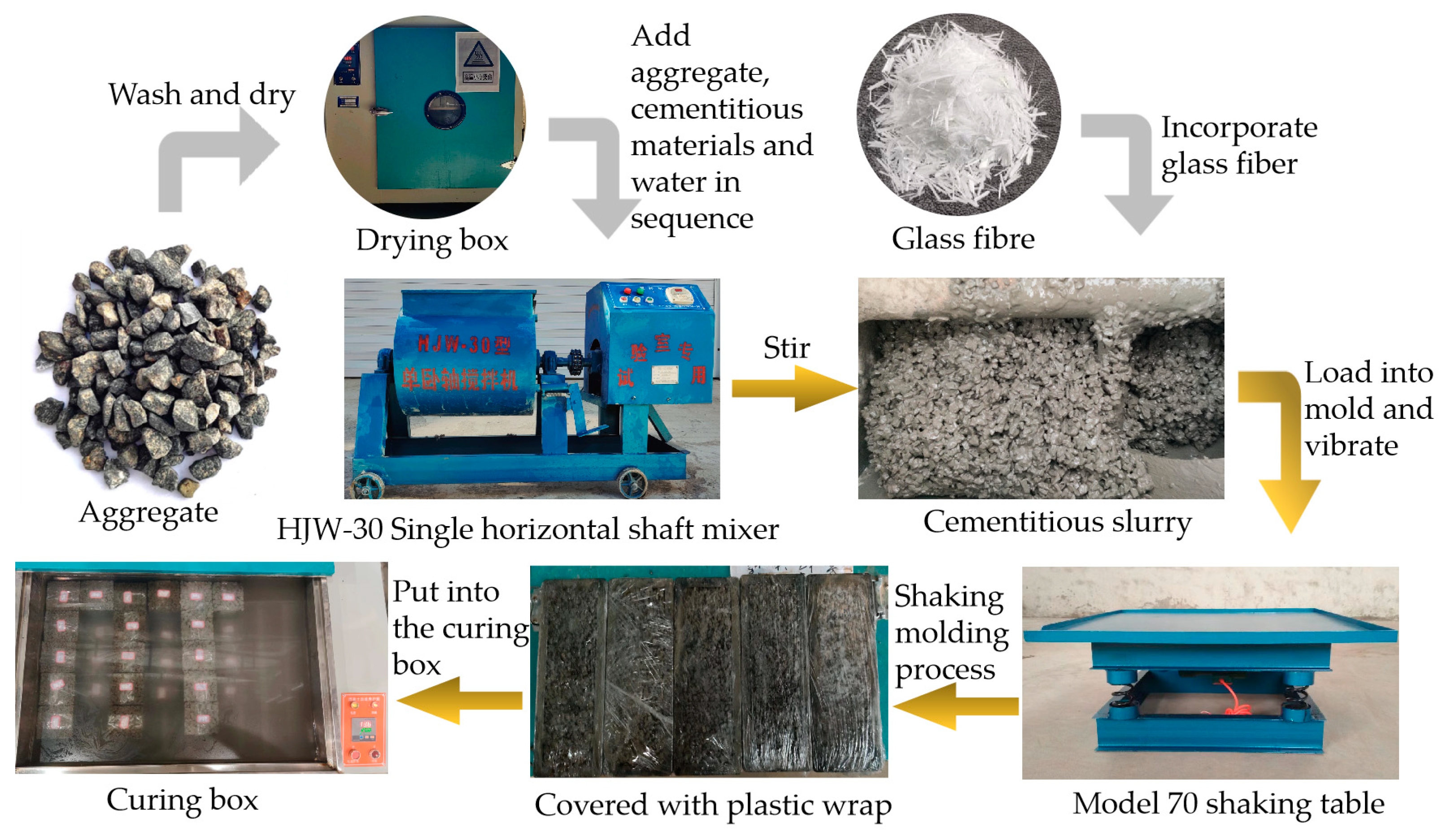

- All of the aggregates used in the test were cleaned, with the aim of removing surface sand and impurities, dried, and sieved through a drying oven to obtain a single size.

- An HJW-30 single horizontal shaft mixer was used to mix the cement and auxiliary cementitious materials for 30 s first, and then, the aggregate was added with continual mixing for 90 s to ensure that the materials were fully mixed.

- After the dry material was mixed evenly, the water-reducing agent and water were added, and mixing continued for 90 s.

- The glass fibers were soaked in 1.5% polycarboxylic acid water-reducing agent solution for 5 min, and then, the fibers were taken out and dried. The dried fibers were divided into 3–5 equal parts to achieve the best possible dispersion of the glass short-cut fibers. In the mixing process of step 3, one part of the glass fiber was evenly sprinkled in the mixture, and the fiber was added while mixing and then the step was repeated until all the glass fibers were mixed in to ensure that the fibers were well dispersed in the mixture.

- Shaking and molding test was performed using a Tianjin Qingda Testing Instrument Manufacturing Co., Ltd. (Tianjin, China) product of a 70-type shaker with a vibration frequency of 2860 times/min. The mold was placed on the shaking table and a 50 mm-high baffle was placed around the outer edge of the mold. The finished slurry was then injected into the mold up to 2/3 of the baffle, and the switch was turned on to shake the mixture for the desired amount of time. After shaking, the baffle was removed. A scraper was used to gently scrape off the excess slurry and flatten the top surface.

- After, the specimen was poured and covered with plastic film to prevent water loss. Then, it was left for three days at room temperature before the specimen was removed from the mold. After the specimens were removed from the molds, they were placed in a curing box at a constant temperature of 20 °C until the required age for the test.

2.4. Test Methods

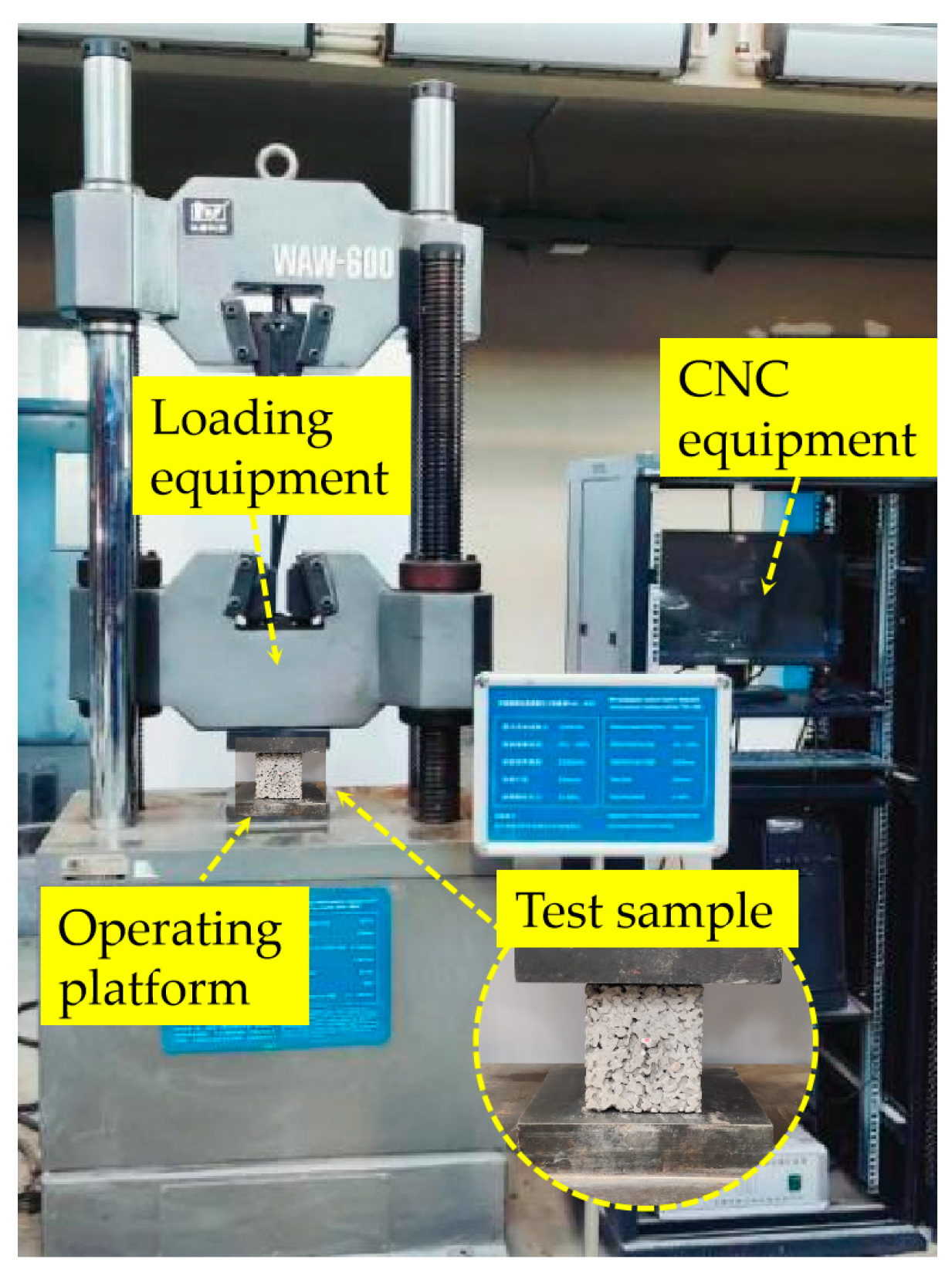

2.4.1. Unconfined Compressive Strength Test

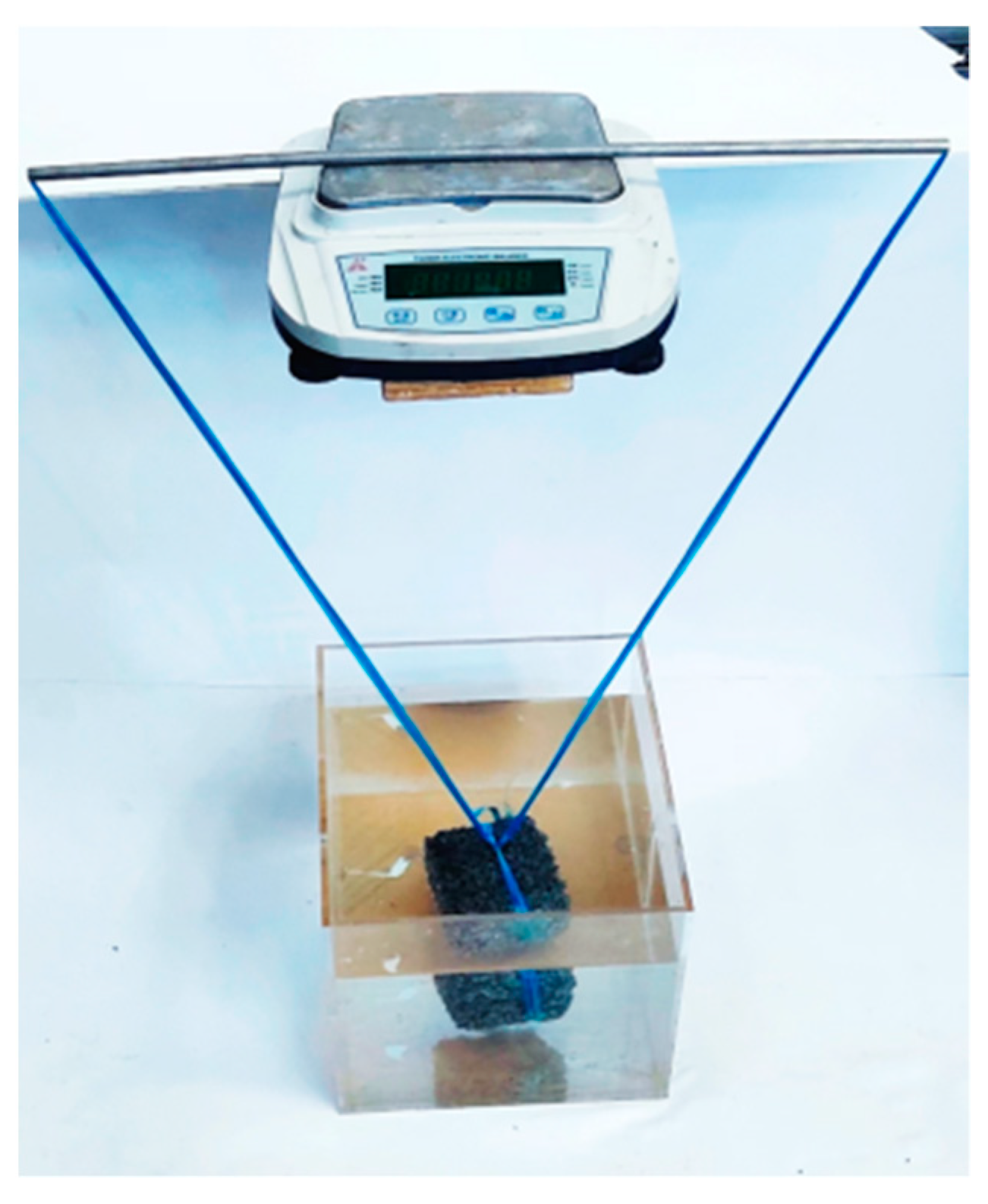

2.4.2. Porosity Measurement

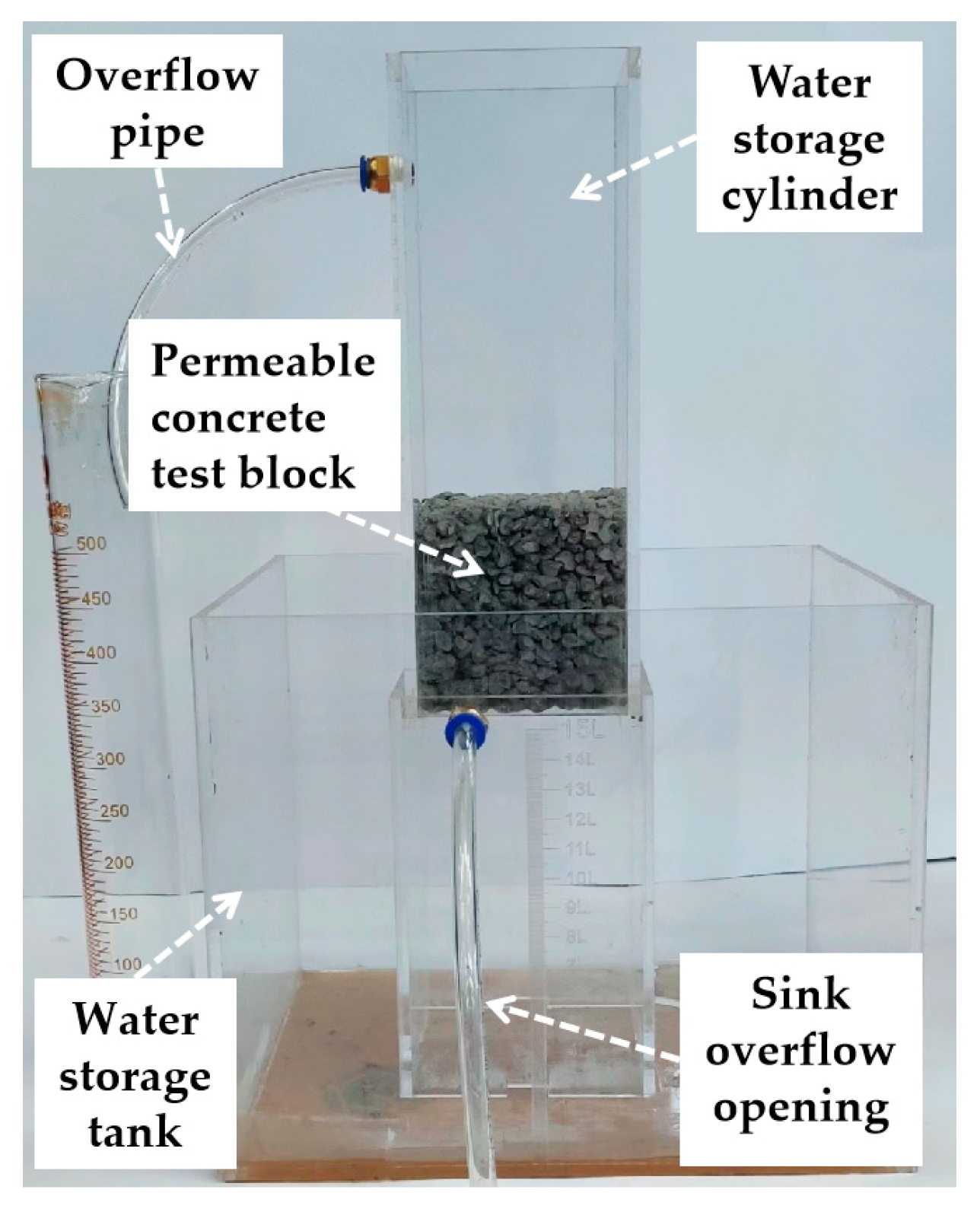

2.4.3. Measurement of Water Permeability Coefficient

2.4.4. Scanning Electron Microscopy

3. Results and Discussion

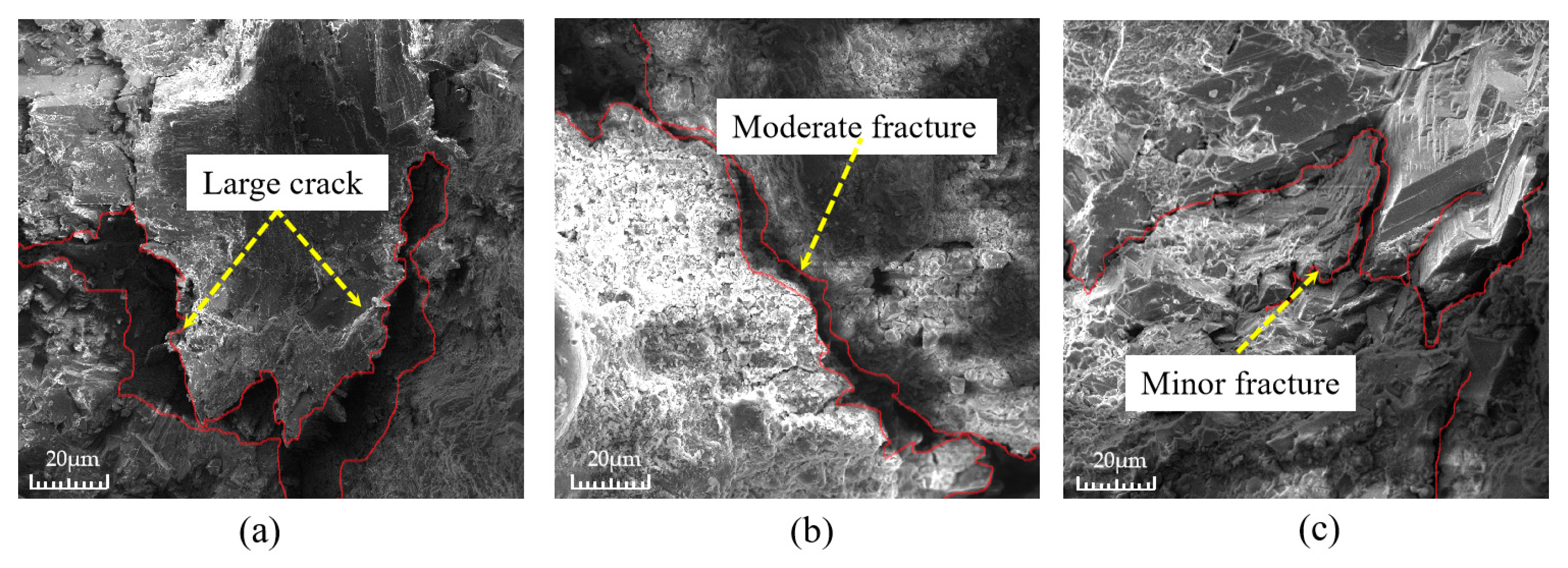

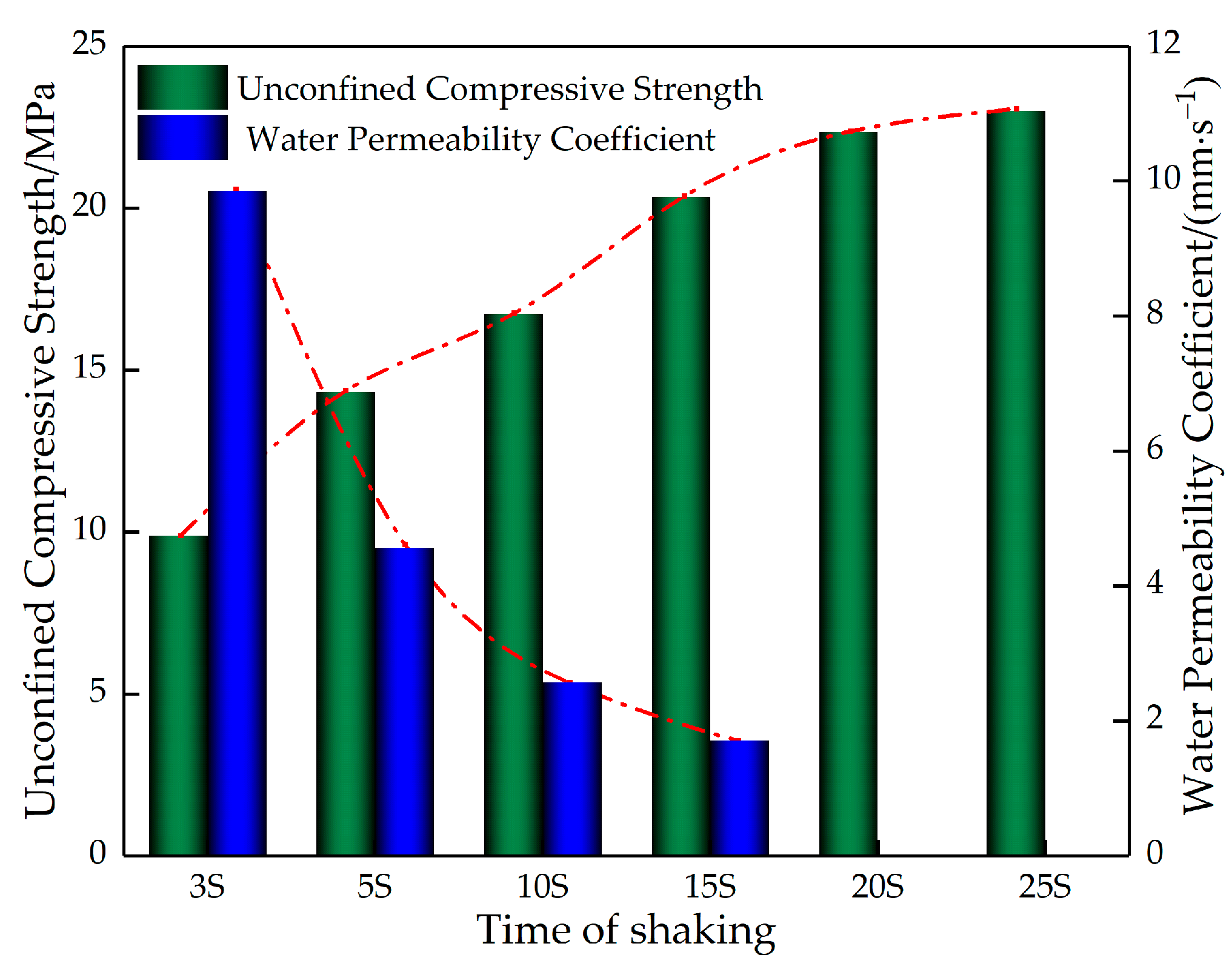

3.1. Influence of Shaking Time on the Performance of Permeable Concrete

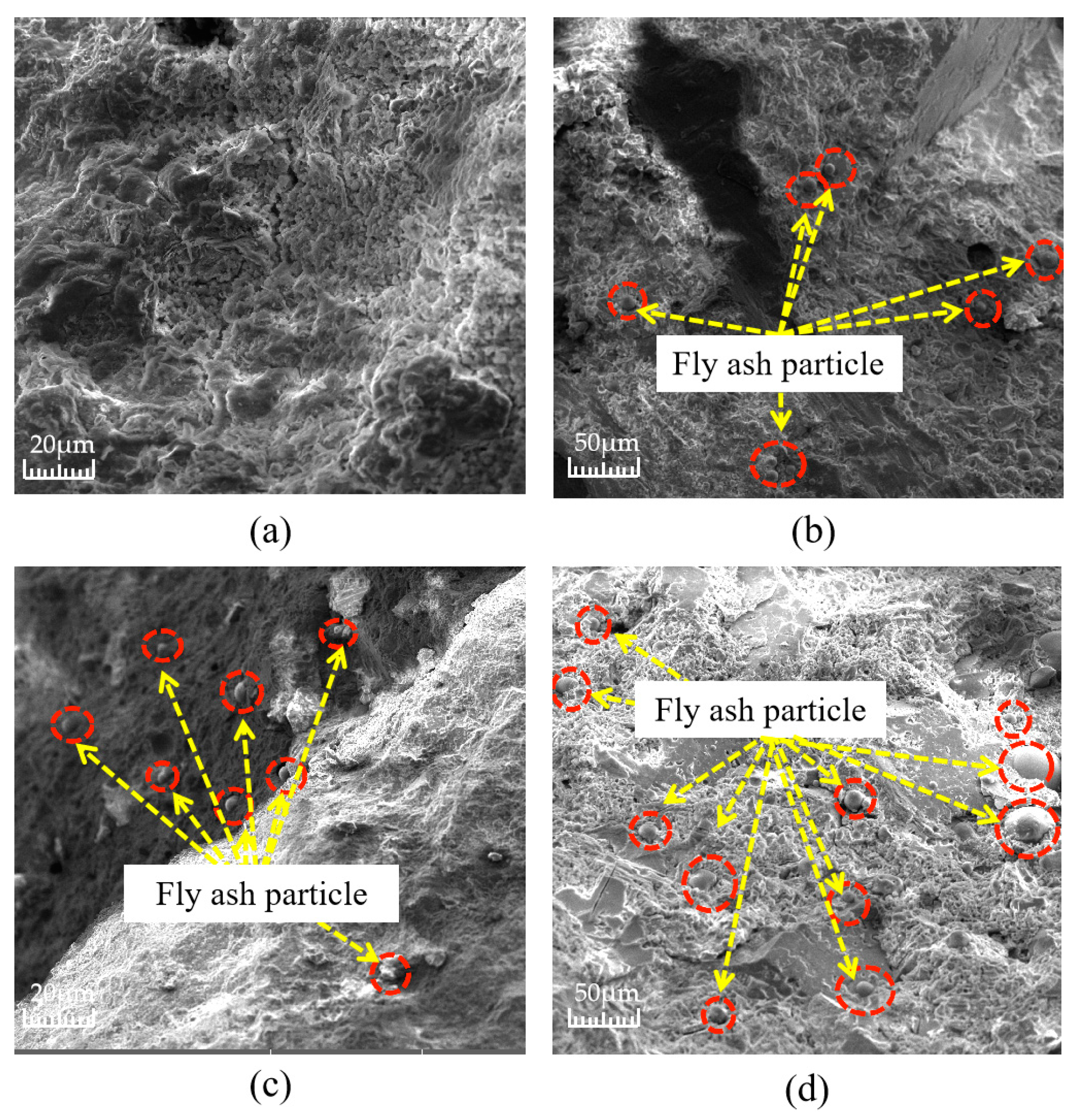

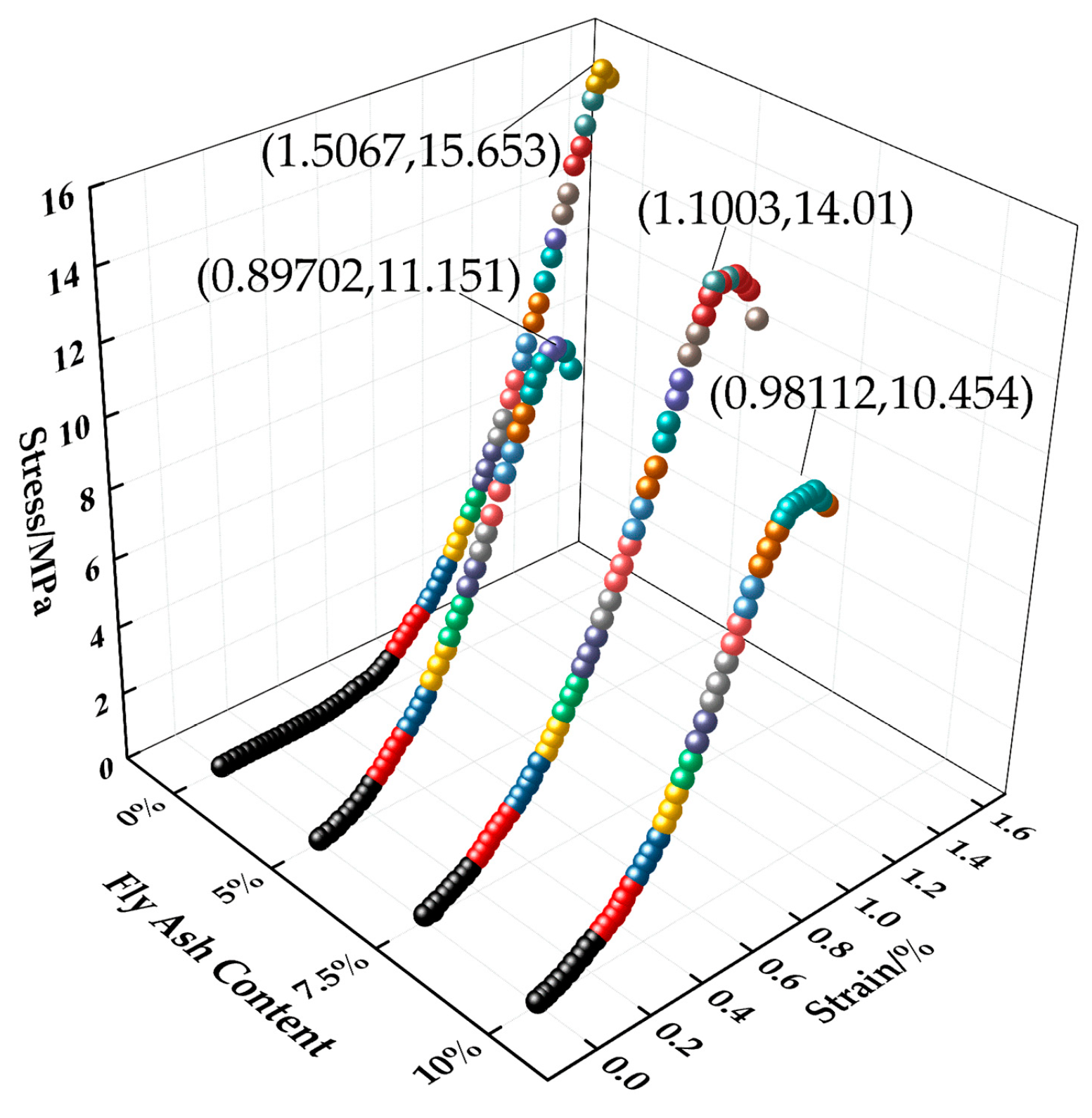

3.2. Influence of Fly Ash Content on Permeable Concrete Performance

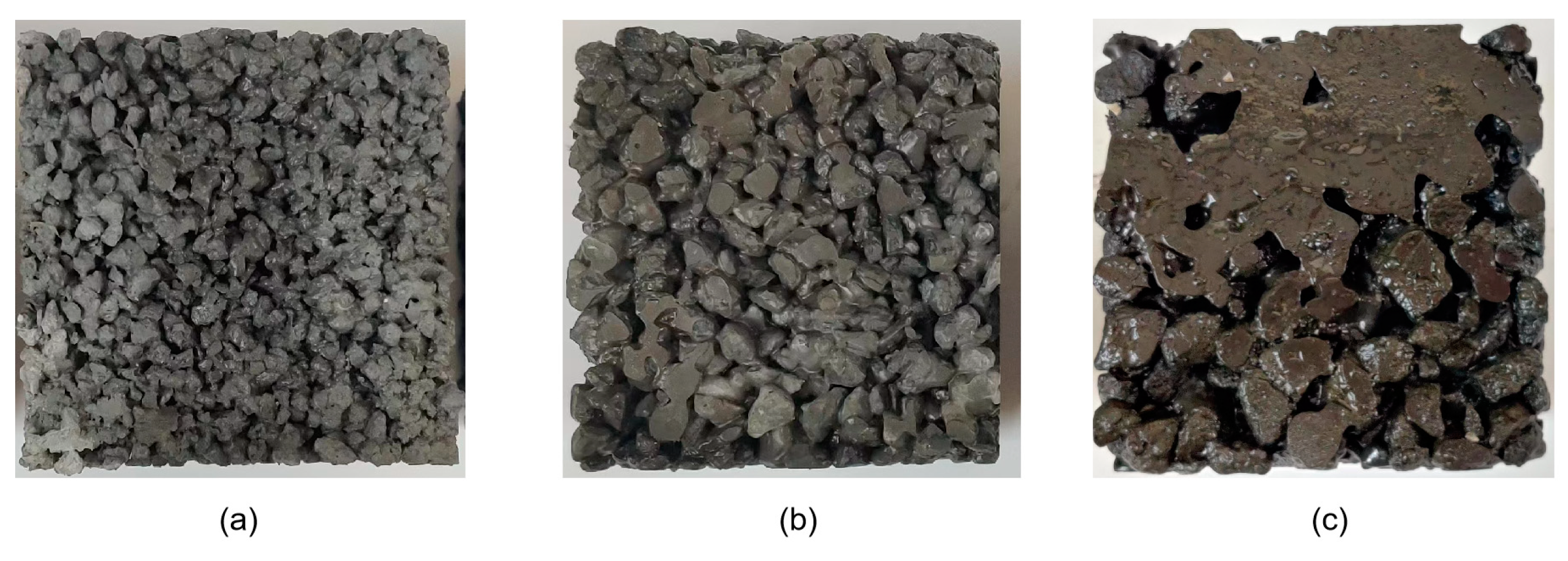

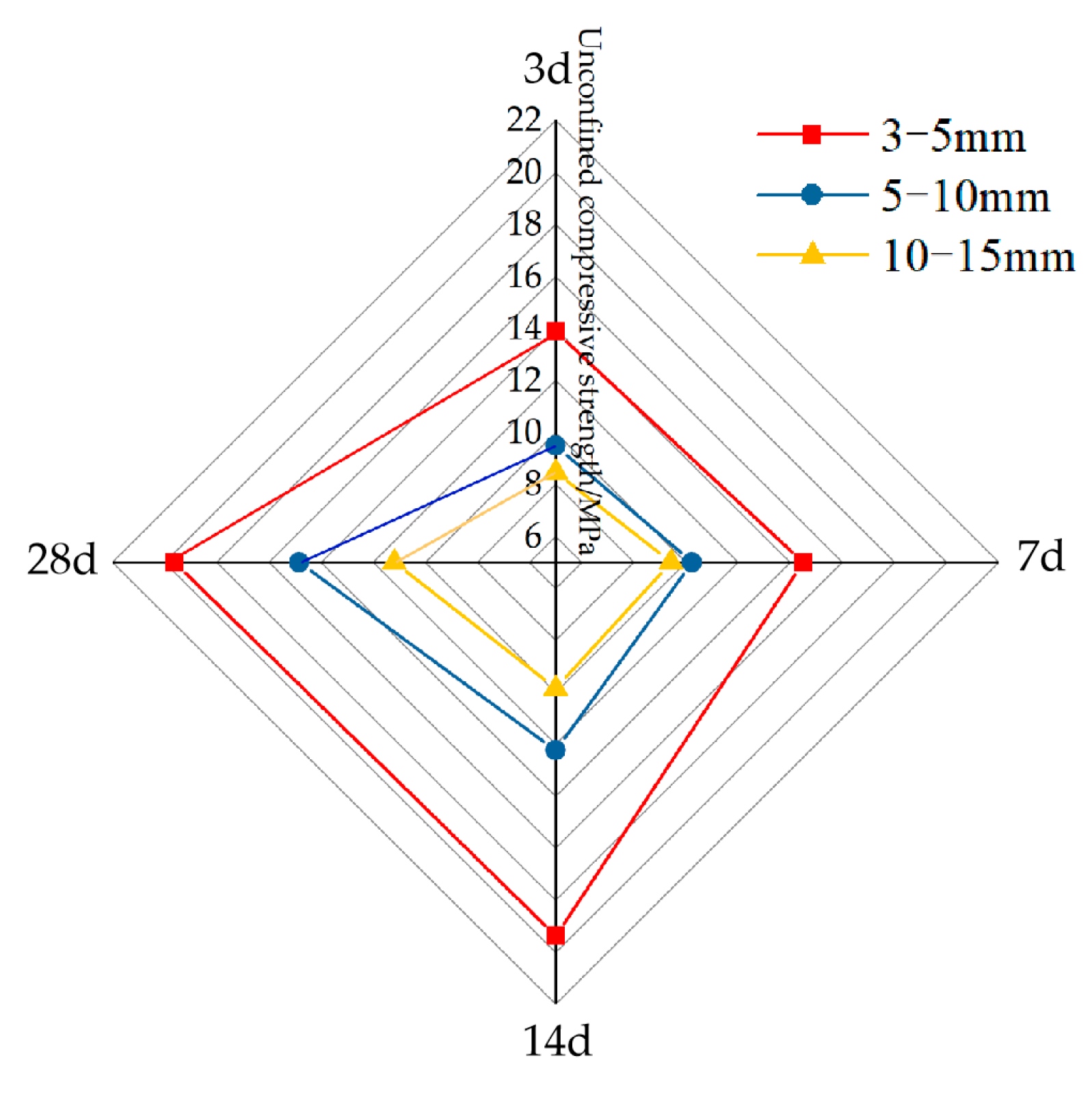

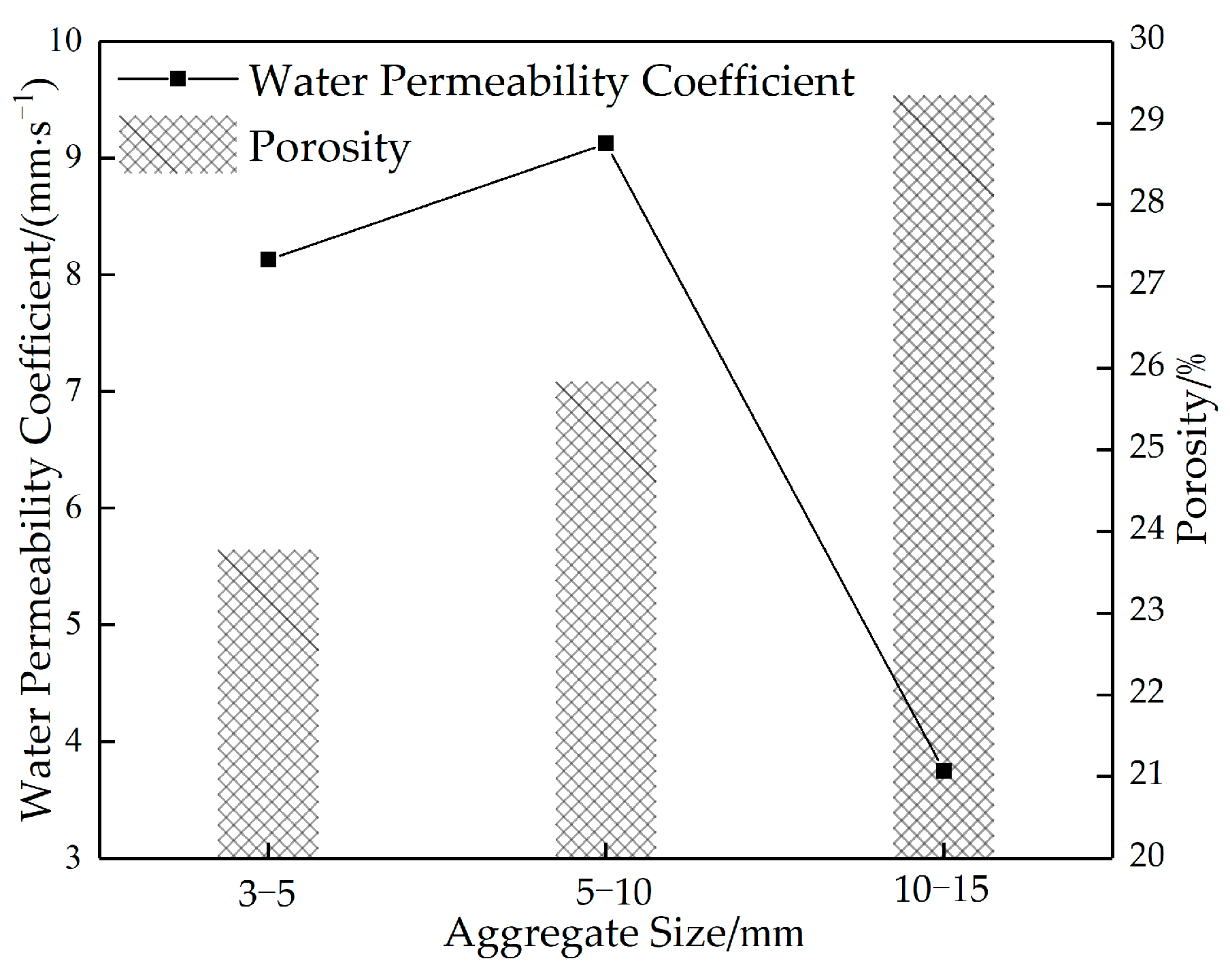

3.3. Influence of Aggregate Particle Grade on the Performance of Permeable Concrete

3.4. Influence of Cut Glass Fiber on Permeable Concrete Performance

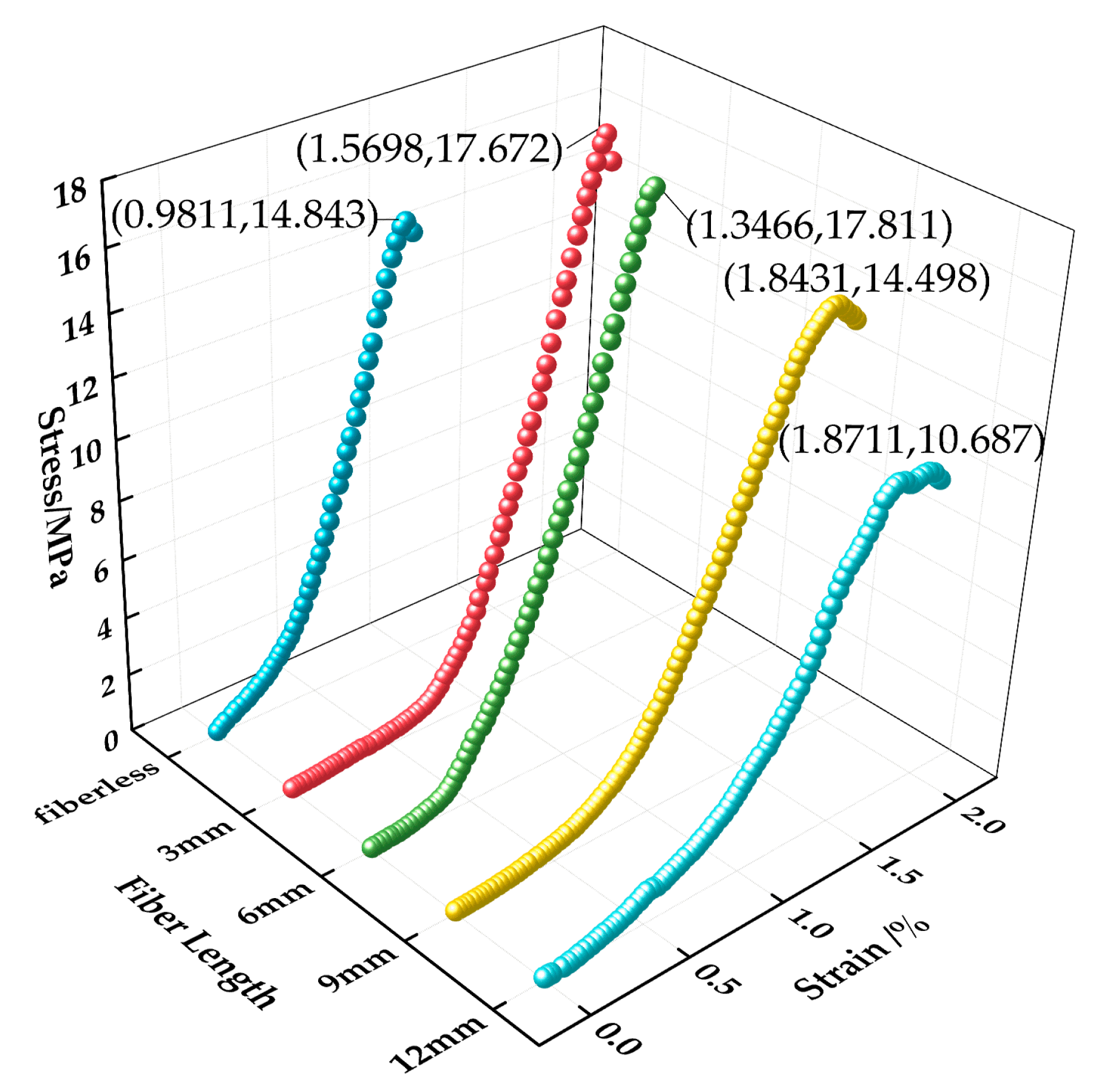

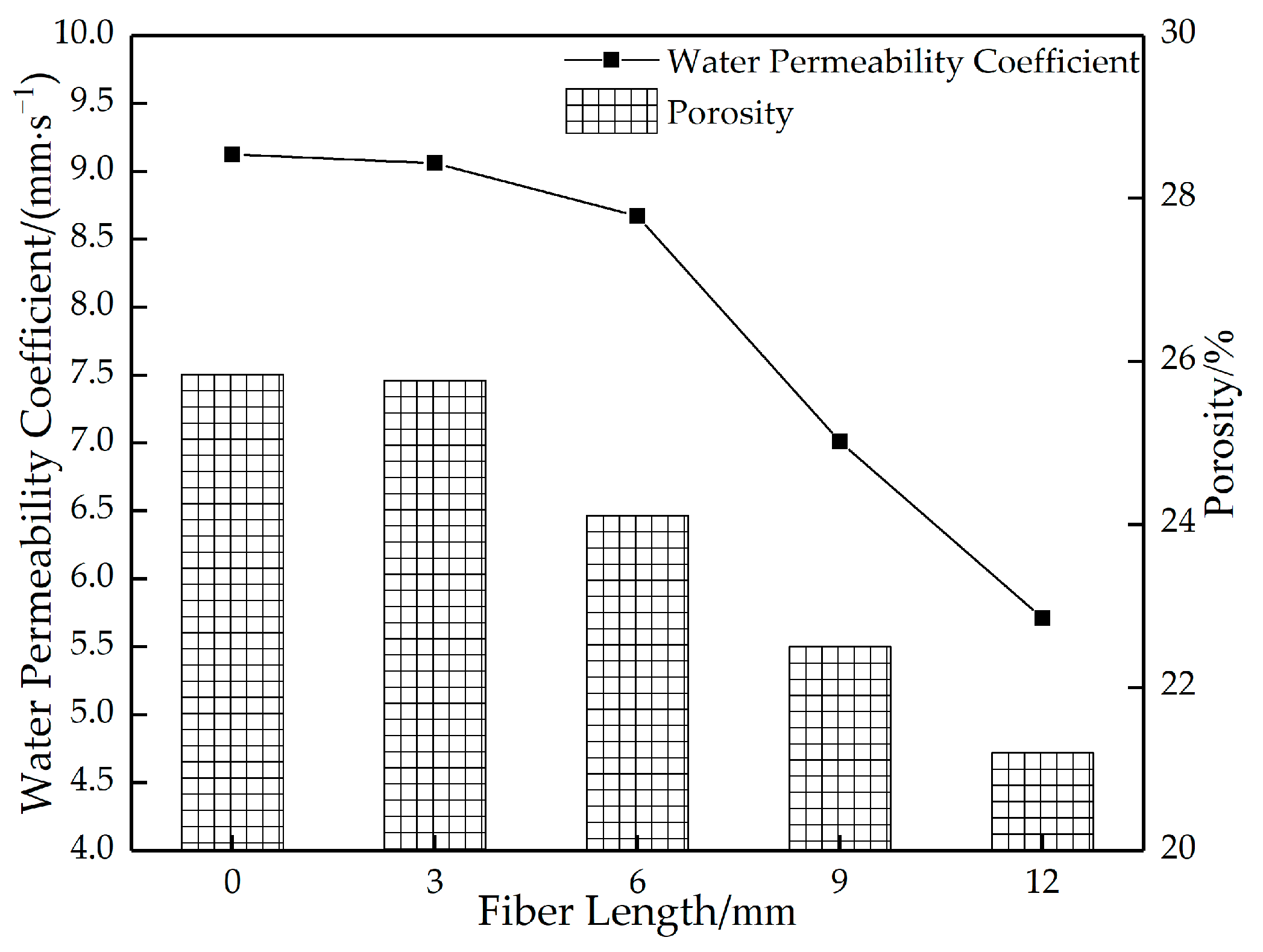

3.4.1. Influence of Fiber Length on the Mechanical Properties of Permeable Concrete

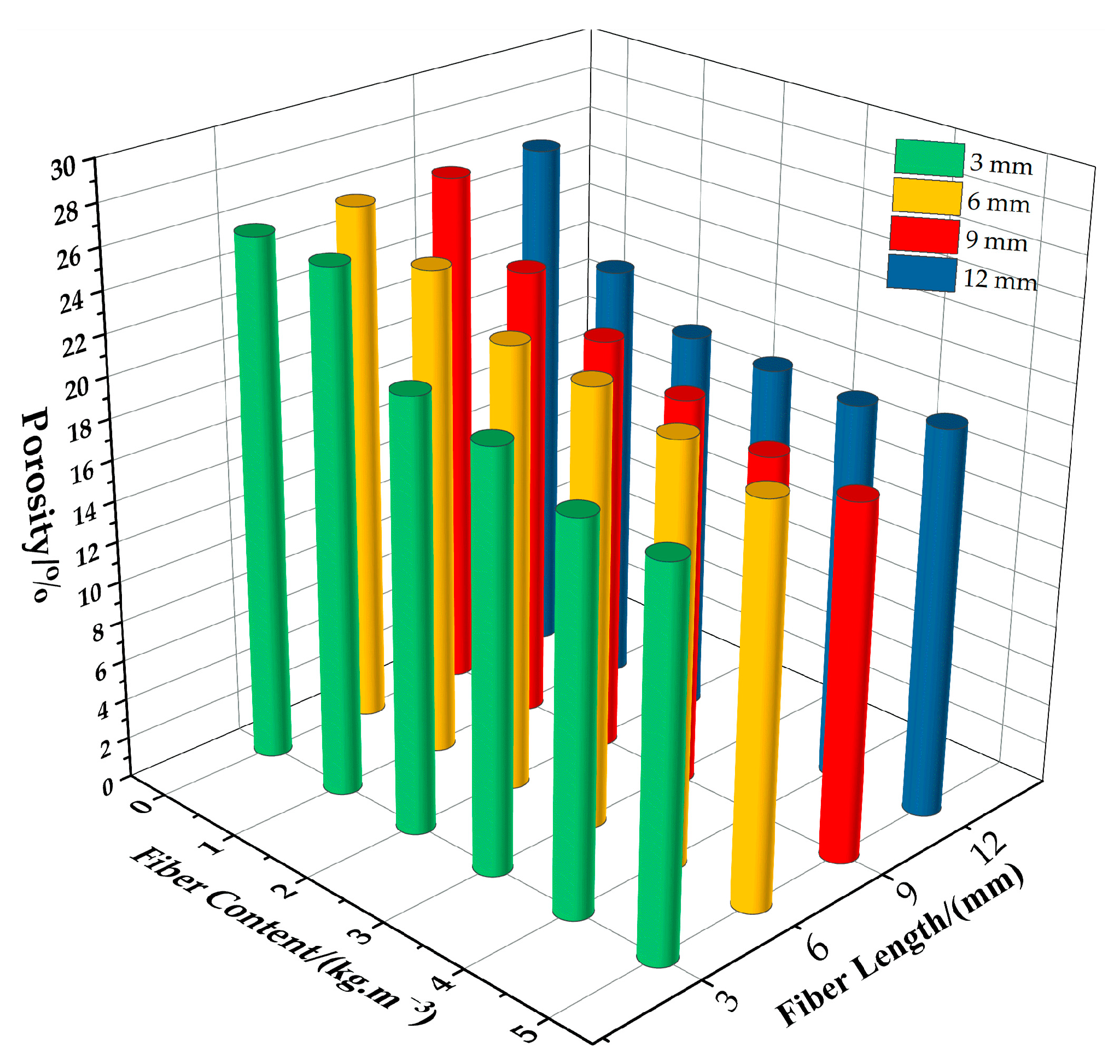

3.4.2. Influence of Fiber Length on the Permeable Performance of Permeable Concrete

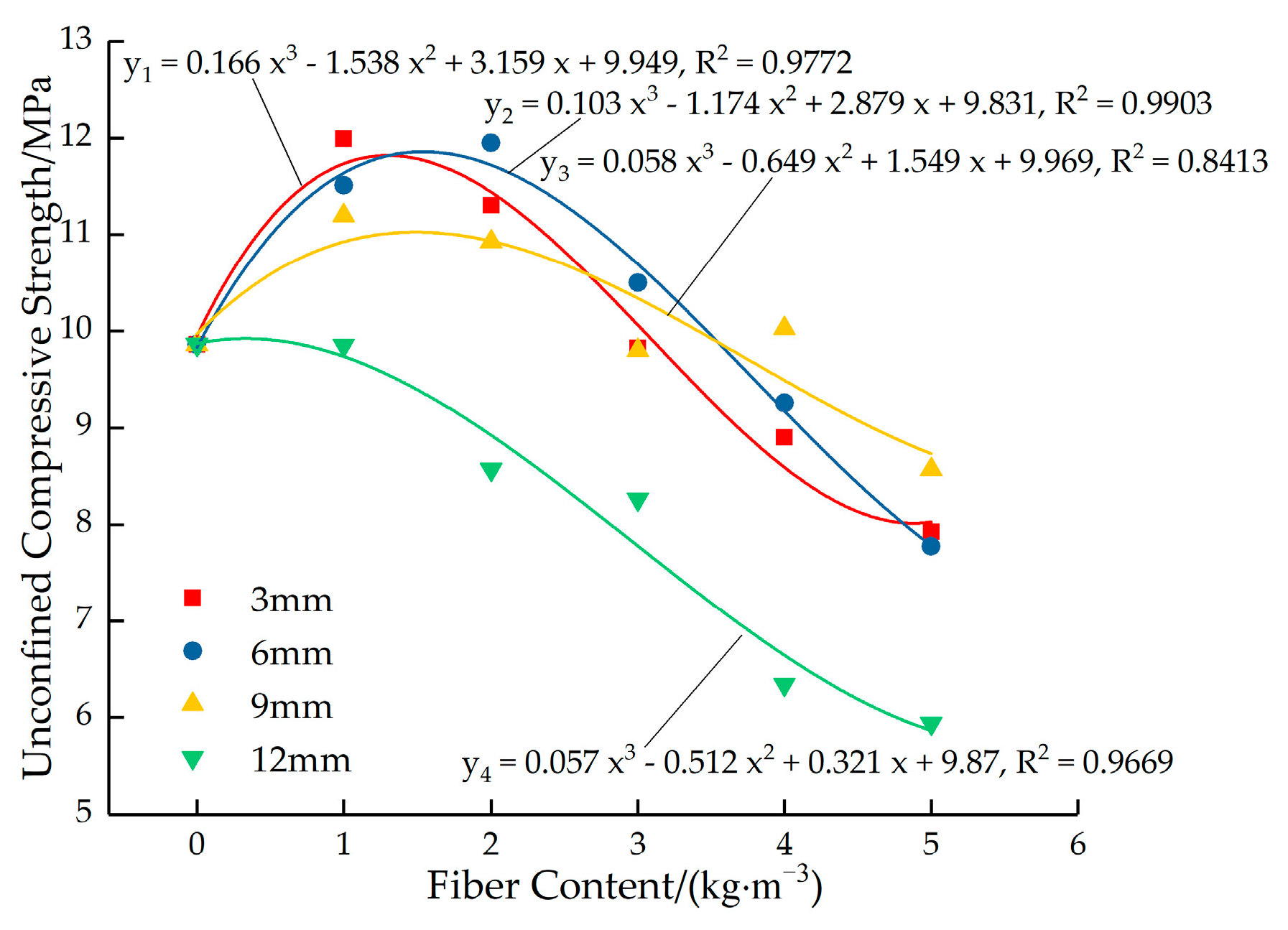

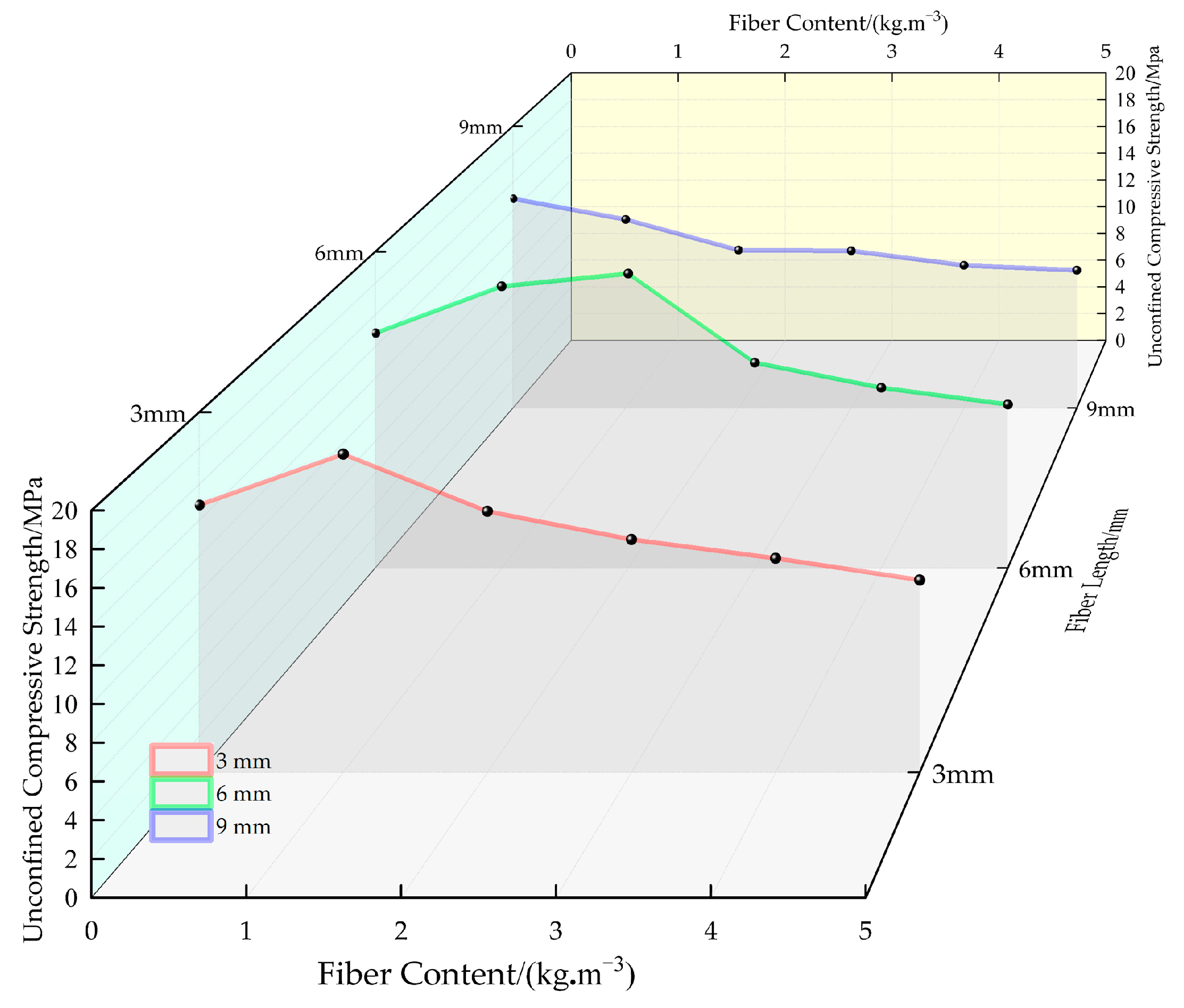

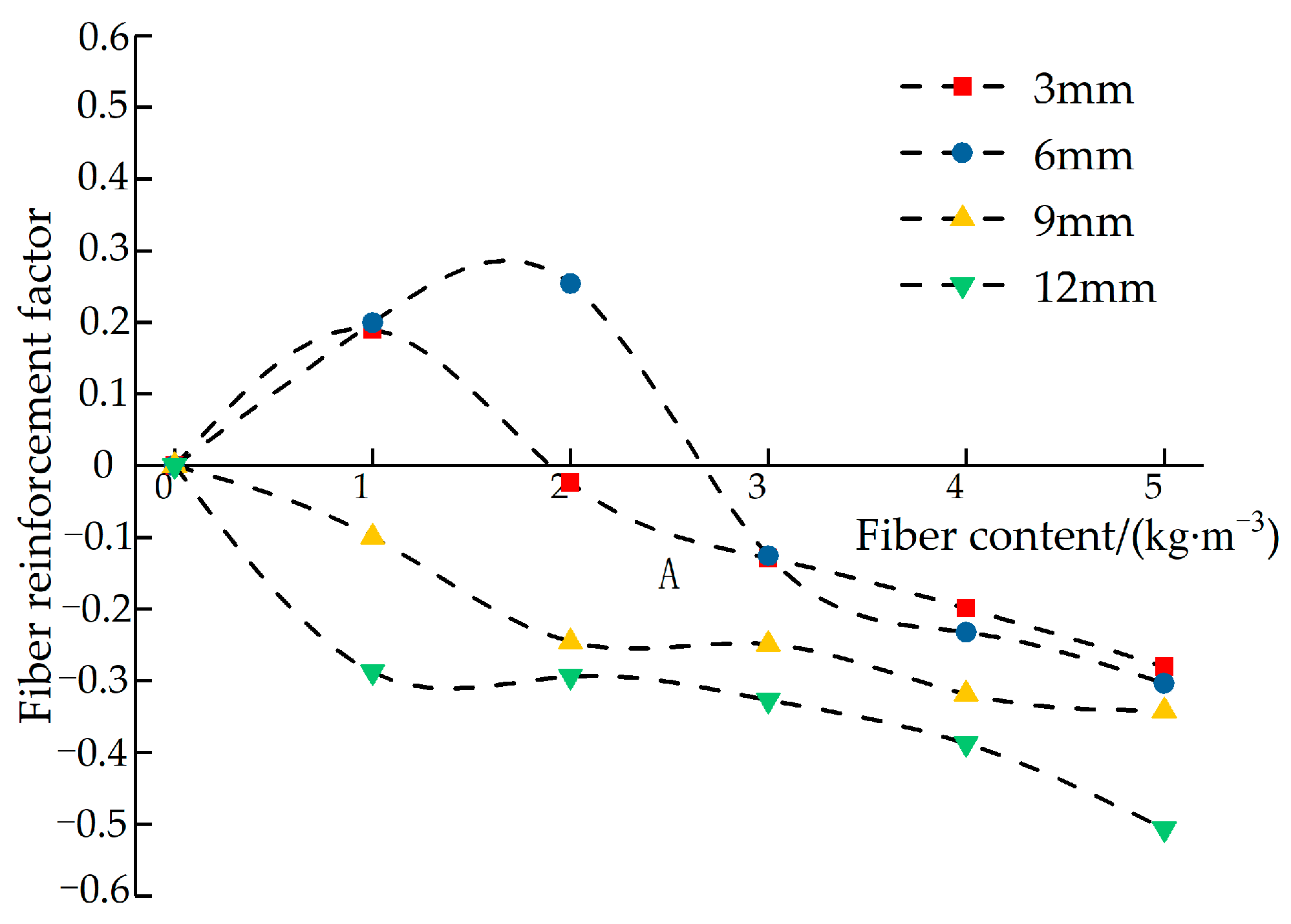

3.4.3. Influence of Fiber Content on the Mechanical Properties of Permeable Concrete

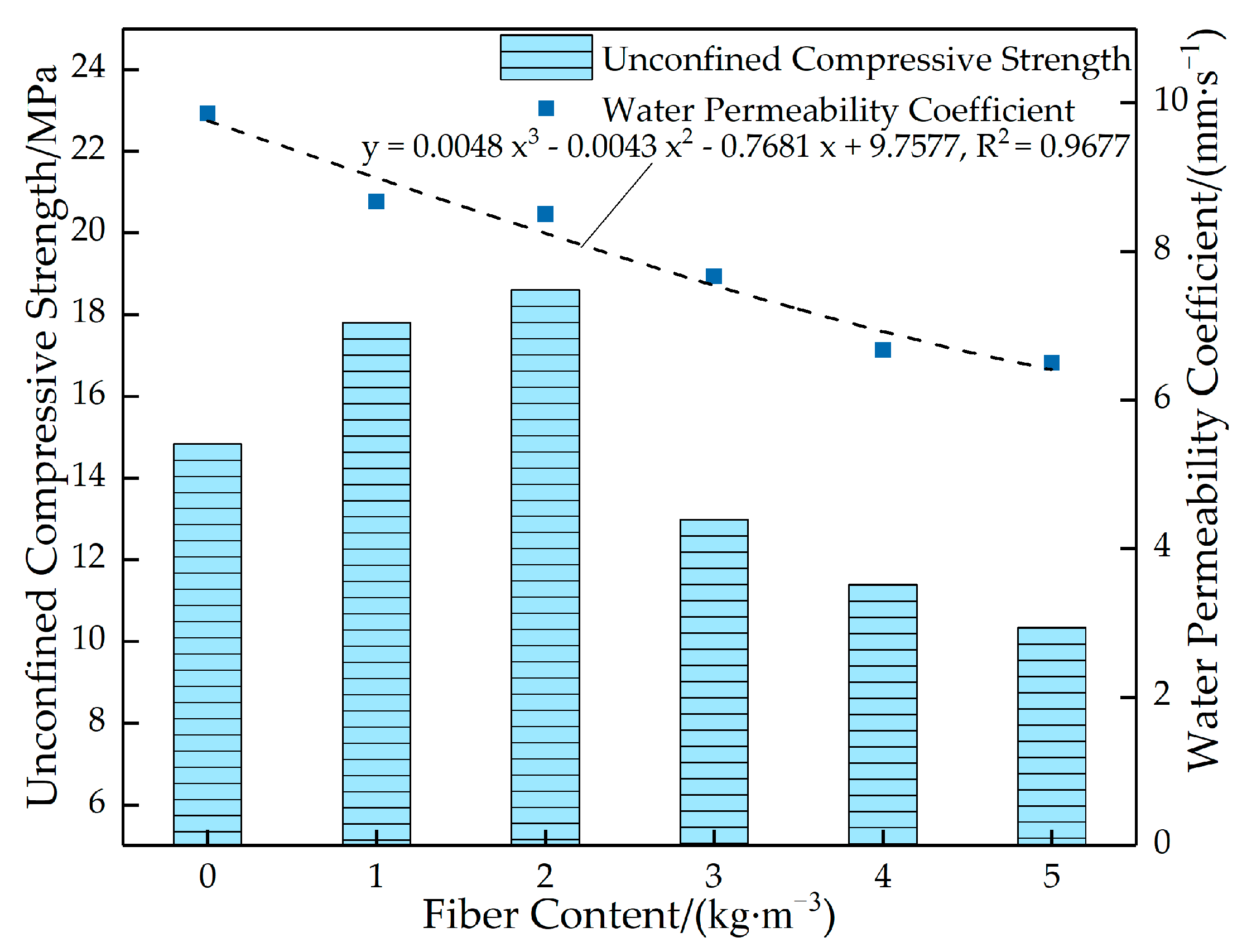

3.4.4. Influence of Fiber Content on the Permeable Performance of Permeable Concrete

3.5. Strain Cloud Image Analysis Based on Vic-3D Technology

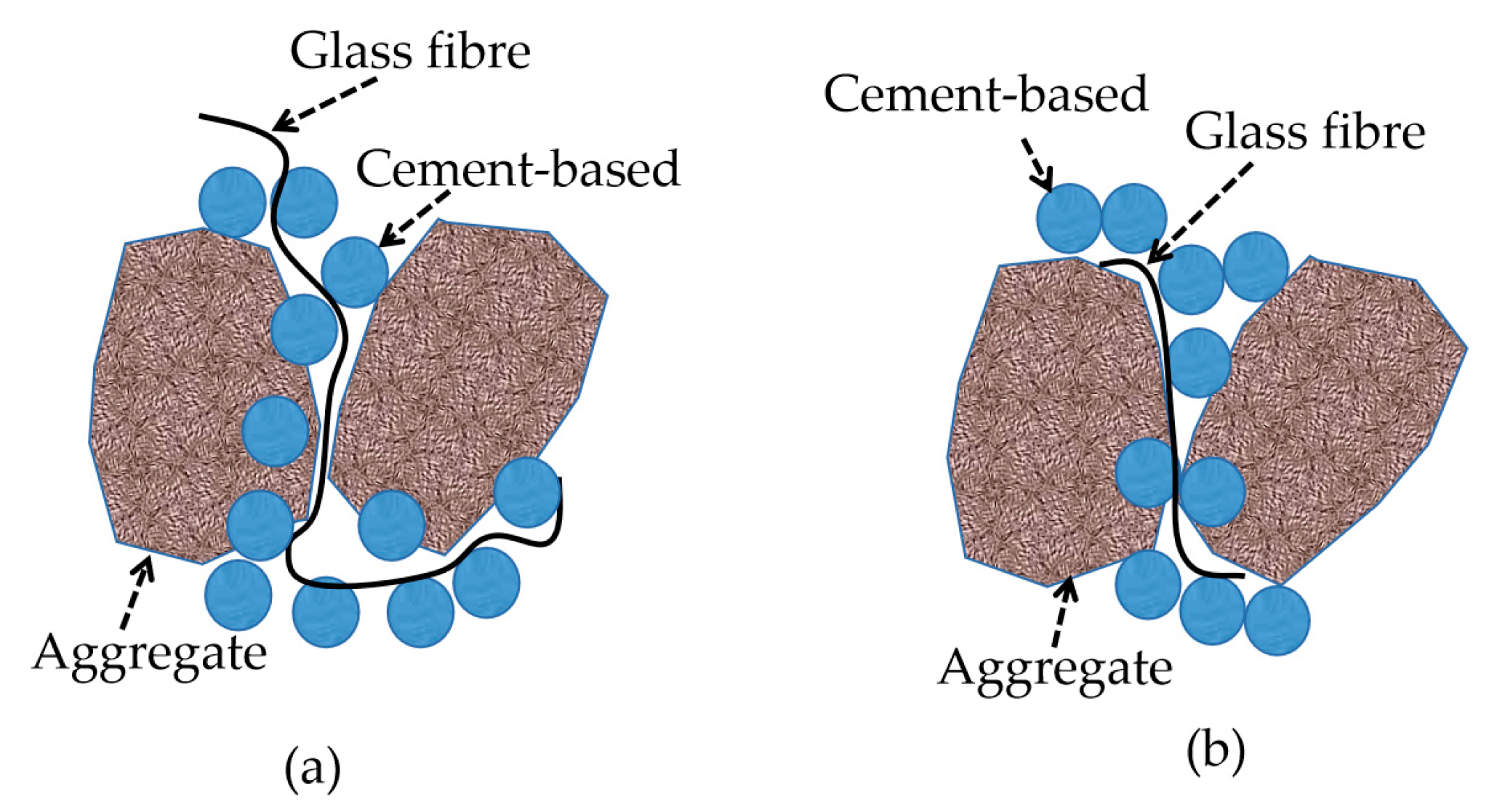

4. Analysis of Fiber Reinforcement Mechanism

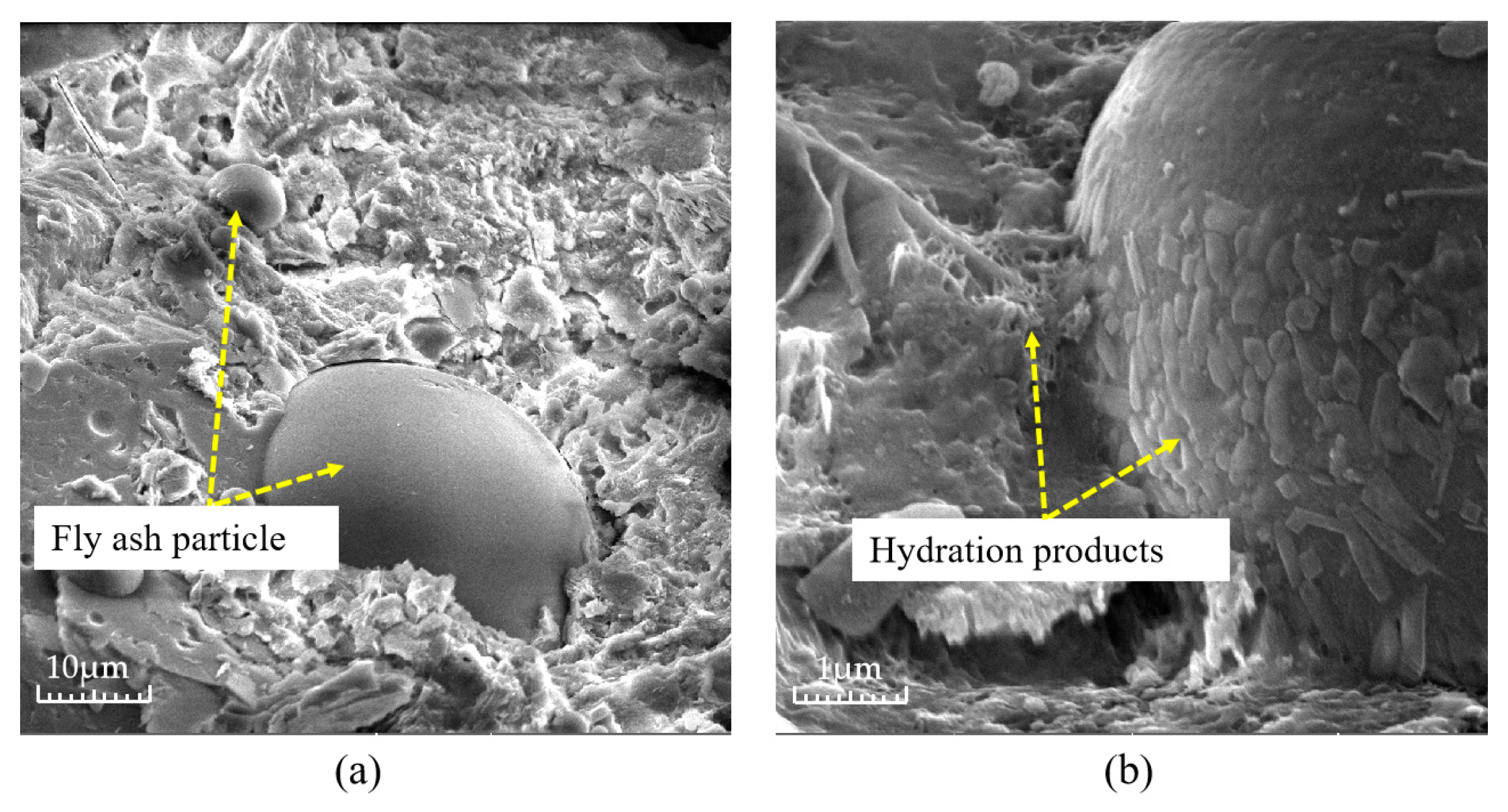

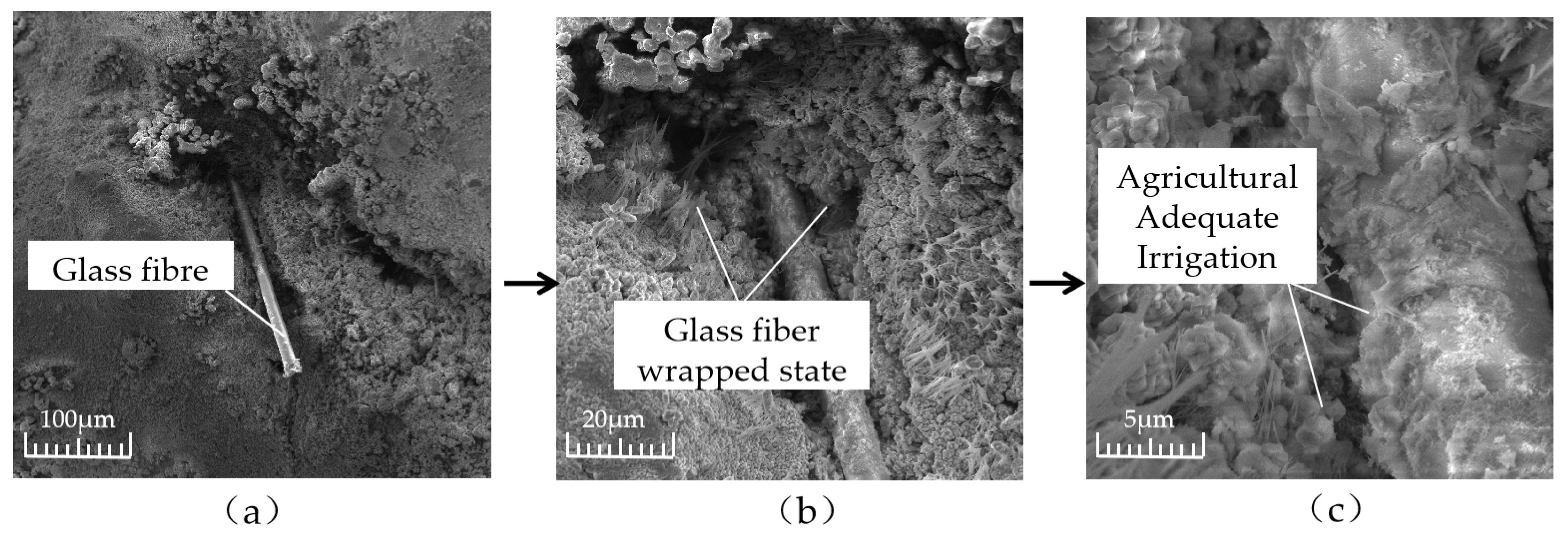

4.1. Microscopic Analysis of Glass Fiber in the Cement Matrix

4.2. Fiber Reinforcement Factor Theory

5. Conclusions

- (1)

- The shaking time has a significant influence on the strength and water permeability of permeable concrete. With the extension of shaking time, the strength of the test block gradually increases, and the water permeability coefficient gradually decreases. When the shaking time is 3 s, the performance of the test block is the most balanced; that is, it has high strength while satisfying good water permeability.

- (2)

- Fly ash can enhance structural compactness and improve slurry fluidity. When the fly ash content is 7.5%, the permeable concrete has high strength while ensuring good workability.

- (3)

- With the increase in aggregate particle composition, the porosity of permeable concrete showed an increasing trend, and the water permeability coefficient first increased and then decreased, and the strength relationship was 3–5 mm > 5–10 mm > 10–15 mm. The strength and water permeability of the test block can be maintained at a good level when the aggregate particle size is 5–10 mm.

- (4)

- The porosity and water permeability coefficient of permeable concrete is degraded when glass fiber of different lengths and dosages is added. With an increase in glass fiber length, the compressive strength of permeable concrete first increases and then decreases. With an increase in glass fiber content, the changing trend of the compressive strength of permeable concrete is closely related to the fiber length. Under the test conditions, the optimal fiber incorporation length is 6 mm, and the content is 2 kg/m3.

- (5)

- Glass fiber was mixed into the permeable concrete, and the fiber network was formed through the bonding effect of cement slurry so as to strengthen the reinforcement effect. The reasonable incorporation of fiber can not only have a better permeable effect but also improve strength and slow down the development of cracks, which has a certain value for the application of road engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petr, L.; Kristýna, H. Evaluation of degradation and mechanical parameters and sustainability indicators of zeolite concretes. Constr. Build. Mater. 2023, 371, 130791. [Google Scholar]

- Badarloo, B.; Lehner, P.; Koubová, L.; Pirizadeh, M. Correlation study of physical and mechanical properties of concretes with crushed LCD glass. J. Clean. Prod. 2023, 385, 135756. [Google Scholar] [CrossRef]

- Alalea, K.; Jasmine, M.; Hong, S.; Christopher, R. Structural and hydrological design of permeable concrete pavements. Case Stud. Constr. Mater. 2021, 15, e00564. [Google Scholar]

- Murugan, M.; Łukasz, S. Performance of permeable concrete mixes based on cement and geopolymer in aggressive aqueous environments. J. Build. Eng. 2023, 76, 107143. [Google Scholar]

- Wu, R.; Shi, S.; Shen, Y.; Hu, C.; Luo, M.; Gan, Z.; Xiao, B.; Wang, Z. Effects of Different Factors on the Performance of Recycled Aggregate Permeable Pavement Concrete. Materials 2022, 15, 4566. [Google Scholar] [CrossRef]

- Vinícius, C.; Felippe, B.; Luísa, A.; Rosa, C. The effect of granulometry of natural and recycled coarse aggregate on permeable concrete properties. Mater. Today Proc. 2022, 65, 1711–1718. [Google Scholar]

- Li, L.; Feng, J.; Zhu, J.; Chu, S.; Kwan, A. Pervious concrete: Effects of porosity on permeability and strength. Mag. Concr. Res. 2019, 71, 69–79. [Google Scholar] [CrossRef]

- He, S.; Jiao, C.; Li, S. Effect of Ultrafine Supplementary Cementitious Materials on the Performance of Pervious Concrete. J. Sci. Technol. Eng. 2020, 20, 14660–14667. [Google Scholar]

- Xu, C.; Gui, M.; Gong, M.; Liu, J.; Chen, Q. Impact of different molding methods on pervious concrete performance. Concrete 2011, 265, 129–131. [Google Scholar]

- Lei, B.; Xiong, Q.; Tang, Z.; Yao, Z.; Jiang, J. Effect of Recycled Aggregate Modification on the Properties of Permeable Asphalt Concrete. Sustainability 2022, 14, 10495. [Google Scholar] [CrossRef]

- Li, R.; Yu, Q.; Wei, J.; Zhong, Y.; Xu, Y. Research on the Model of Pore in the Porous Concrete. J. Wuhan Univ. Technol. 2009, 31, 11–15. [Google Scholar]

- Xu, Y.; Li, R.; Yu, Q.; Wei, J.; Wei, L.; Tan, X.; Xiao, P. Pore representation and the relationship between pore and permeability of the porous concrete. J. Concr. 2009, 31, 16–20. [Google Scholar]

- Carmichael, M.J.; Arulraj, G.P.; Meyyappan, P. Effect of partial replacement of cement with nano fly ash on permeable concrete: A strength study. Mater. Today Proc. 2021, 43, 2109–2116. [Google Scholar] [CrossRef]

- Wu, D.; Liu, X.; Wu, X.; Zhao, X. Impact of formation way and sand ratio to the pervious concrete performance. Concrete 2009, 235, 100–102. [Google Scholar]

- Xu, R.; Liu, J.; Zheng, C.; Cai, Z. Optimal design of pervious concrete proportion using Design-Expert software. N. Build. Mater. 2010, 37, 17–20. [Google Scholar]

- Cheng, J.; Guo, X. Effect of fly ash and mineral powder on the performance of pervious concrete. J. Build. Blocks Block Build. 2007, 2007, 27–30. [Google Scholar]

- Gong, P.; Xie, X.; Li, J. Effects study of molding method on properties of porous pervious concrete with recycled aggregates. J. Constr. Technol. 2015, 44, 65–68. [Google Scholar]

- Sheng, Y.; Chen, S.; Zheng, M. Comparison of road performance of porous concrete with different forming methods. J. Highw. 2008, 2008, 193–197. [Google Scholar]

- Chen, S.; Lu, P.; Li, B.; Wang, L.; Guo, L.; Zhang, J. Influence and Evaluation Analysis of Different Fibers on the Performance of Recycled Aggregate Pervious Concrete. J. Basic Sci. Eng. 2022, 30, 208–218. [Google Scholar]

- Xue, W. Experimental Study on Properties of Basalt Fiber Permeable Concrete. Ph.D. Thesis, Shanghai Jiaotong University, Shanghai, China, 2018. [Google Scholar]

- Hou, M.; Tao, Y.; Tao, Z.; Cai, D.; Chen, X. Basic mechanical properties and analysis of chopped carbon fiber reinforced concrete. Concrete 2020, 42, 74–77. [Google Scholar]

- Chen, X. Study on Freezing Resistance of Basalt Fiber Permeable Concrete. Ph.D. Thesis, Changchun Institute of Technology, Changchun, China, 2021. [Google Scholar]

- Meeju, L.; Kyeongjin, K.; Chul-Woo, C.; WooSeok, K.; Yoseok, J.; Jaeha, L. Mechanical characterization of recycled-PET fiber reinforced mortar composites treated with nano-SiO2 and mixed with seawater. Constr. Build. Mater. 2023, 392, 131882. [Google Scholar]

- Akand, L.; Yang, J.; Wang, X. Effectiveness of chemical treatment on polypropylene fibers as reinforcement in pervious concrete. Constr. Build. Mater. 2018, 163, 32–39. [Google Scholar] [CrossRef]

- Liu, X.; Lin, W.; Li, J. Durability performance research on permeable concrete with rigid polypropylene fiber. Concrete 2017, 2017, 133–136. [Google Scholar]

- Meng, X.; Chi, Y.; Jiang, Q.; Liu, R.; Wu, K.; Li, S. Experimental investigation on the flexural behavior of pervious concrete beams reinforced with geogrids. Constr. Build. Mater. 2019, 215, 275–284. [Google Scholar] [CrossRef]

- CJJ/T 135-2009; Technical Specification for Pervious Cement Concrete Pavement. China Architecture & Building Press: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Du, Y.; Wang, S.; Hao, W.; Shi, F.; Wang, H.; Xu, F.; Du, T. Investigations of the Mechanical Properties and Durability of Reactive Powder Concrete Containing Waste Fly Ash. Buildings 2022, 12, 560. [Google Scholar] [CrossRef]

- Farhan, N.; Sheikh, M.; Hadi, M. Engineering properties of ambient cured alkali-activated fly ash-slag concrete reinforced with different types of steel fiber. J. Mater. Civ. Eng. 2018, 30, 2333. [Google Scholar] [CrossRef]

- Dvorkin, L.; Zhitkovsky, V.; Sonebi, M.; Marchuk, V.; Stepasiuk, Y. Improving Concrete and Mortar Using Modified Ash and Slag Cements; CRC Press: Boca Raton, FL, USA; London, UK, 2020; p. 184. [Google Scholar]

- Zhao, J.; Yang, X.; Li, H.; Ma, Y. Effect of chopped fibers on the performance of pervious concrete. J. Build. Mater. 2019, 22, 266–271. [Google Scholar]

- Zhao, Z. Experimental research and application of polypropylene fiber enhancement water-permeable concrete. J. Exp. Technol. Manag. 2007, 24, 26–28. [Google Scholar]

- Kerekes, R.; Chell, C. Characterization of fiber flocculation regimes by a crowding factor. J. Pulp Pap. Sci. 1992, 18, 32–38. [Google Scholar]

| Specific Surface Area (m2/kg) | Setting Time (min) | Rupture Strength (MPa) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3d | 28d | 3d | 28d | |

| 351 | 168 | 258 | 5.5 | 9.1 | 23.9 | 50.1 |

| Density (g/cm3) | Burn Loss | Water Content | Activity Index | Stability |

|---|---|---|---|---|

| 2.85 | ≤4.5% | ≤1.0% | 80% | on test |

| Particle Size (mm) | Performance Density (kg/m3) | Bulk Density (kg/m3) | Void Volume Fraction |

|---|---|---|---|

| 3~5 | 1570 | 2780 | 43.52% |

| 5~10 | 1483 | 3026 | 50.99% |

| 10~15 | 1600 | 2810 | 43.06% |

| Particle Size (mm) | Aggregate Dosage (kg/m3) | Cement Content (kg/m3) | Fly ash Consumption (kg/m3) |

|---|---|---|---|

| 3~5 | 1453.56 | 482.38 | 25.38 |

| 5~10 | 1538.61 | 371.92 | 19.58 |

| 352.92 | 39.15 | ||

| 362.25 | 29.25 | ||

| 10~15 | 1568.01 | 365.17 | 19.22 |

| Particle Size (mm) | Cement Content (kg/m3) | Fly Ash Content (kg/m3) | Fiber Length (mm) | Fiber Content (kg/m3) |

|---|---|---|---|---|

| 5~10 | 362.25 | 29.25 | 3 mm | 1, 2, 3, 4, 5 |

| 5~10 | 362.25 | 29.25 | 6 mm | 1, 2, 3, 4, 5 |

| 5~10 | 362.25 | 29.25 | 9 mm | 1, 2, 3, 4, 5 |

| 5~10 | 362.25 | 29.25 | 12 mm | 1, 2, 3, 4, 5 |

| Fiber Length (mm) | σmax (MPa) | Rate of Increase | ε | Rate of Increase |

|---|---|---|---|---|

| 3 | 17.672 | 19.06% | 1.5689% | 59.91% |

| 6 | 17.811 | 20.00% | 1.3466% | 37.25% |

| 9 | 14.498 | −2.32% | 1.8431% | 87.86% |

| 12 | 10.687 | −28.00% | 1.8711% | 90.71% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Ding, X.; Niu, L.; Huang, Z.; Sun, S. Experimental Study on the Mechanical Properties and Influencing Factors of Glass Fiber-Reinforced Permeable Concrete. Materials 2023, 16, 5970. https://doi.org/10.3390/ma16175970

Xu L, Ding X, Niu L, Huang Z, Sun S. Experimental Study on the Mechanical Properties and Influencing Factors of Glass Fiber-Reinforced Permeable Concrete. Materials. 2023; 16(17):5970. https://doi.org/10.3390/ma16175970

Chicago/Turabian StyleXu, Lina, Xu Ding, Lei Niu, Zhanfang Huang, and Shuang Sun. 2023. "Experimental Study on the Mechanical Properties and Influencing Factors of Glass Fiber-Reinforced Permeable Concrete" Materials 16, no. 17: 5970. https://doi.org/10.3390/ma16175970

APA StyleXu, L., Ding, X., Niu, L., Huang, Z., & Sun, S. (2023). Experimental Study on the Mechanical Properties and Influencing Factors of Glass Fiber-Reinforced Permeable Concrete. Materials, 16(17), 5970. https://doi.org/10.3390/ma16175970