Grain Structure Evolution in 6013 Aluminum Alloy during High Heat-Input Friction-Stir Welding

Abstract

:1. Introduction

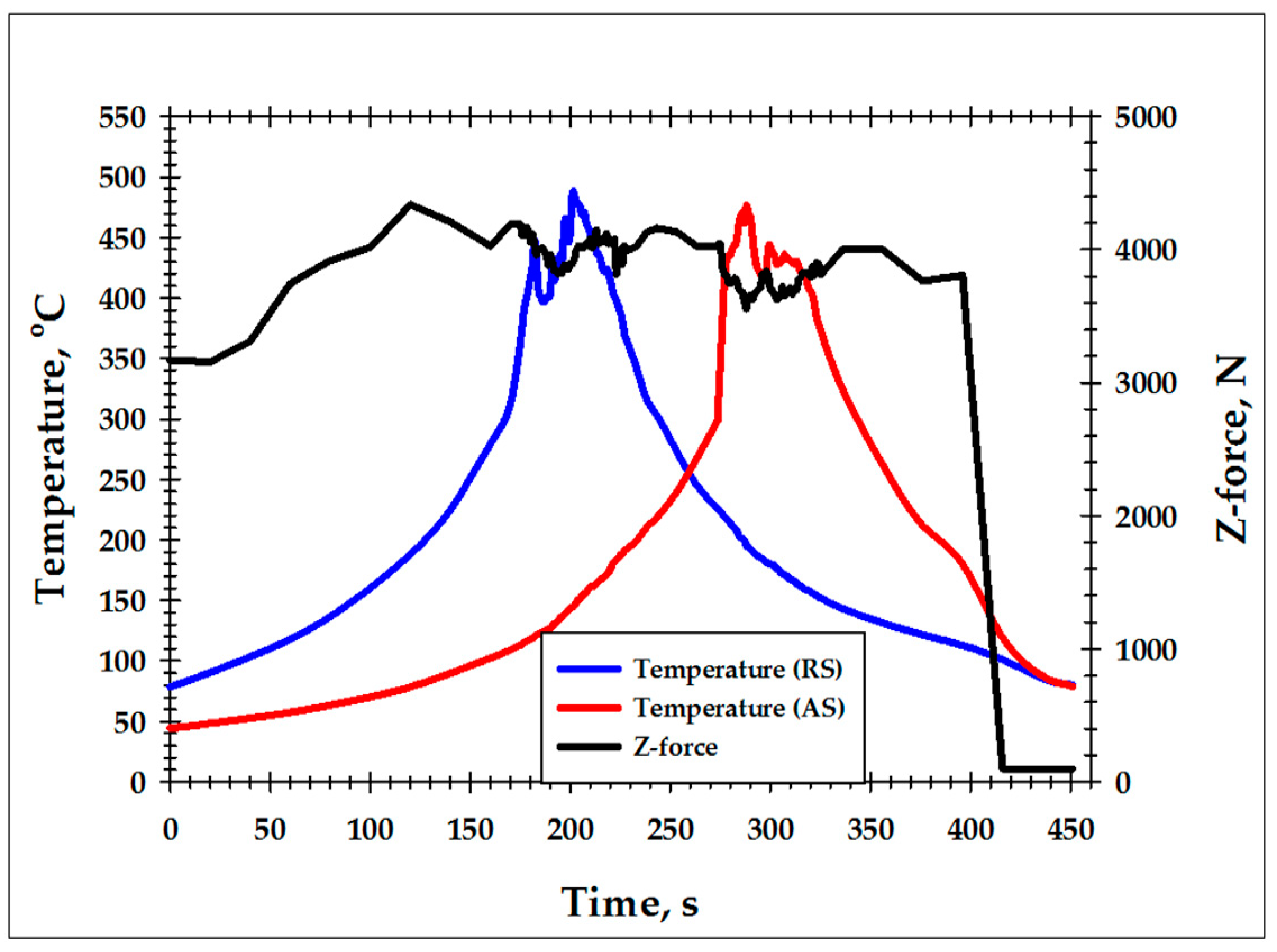

2. Materials and Methods

3. Results

3.1. Microhardness Distribution

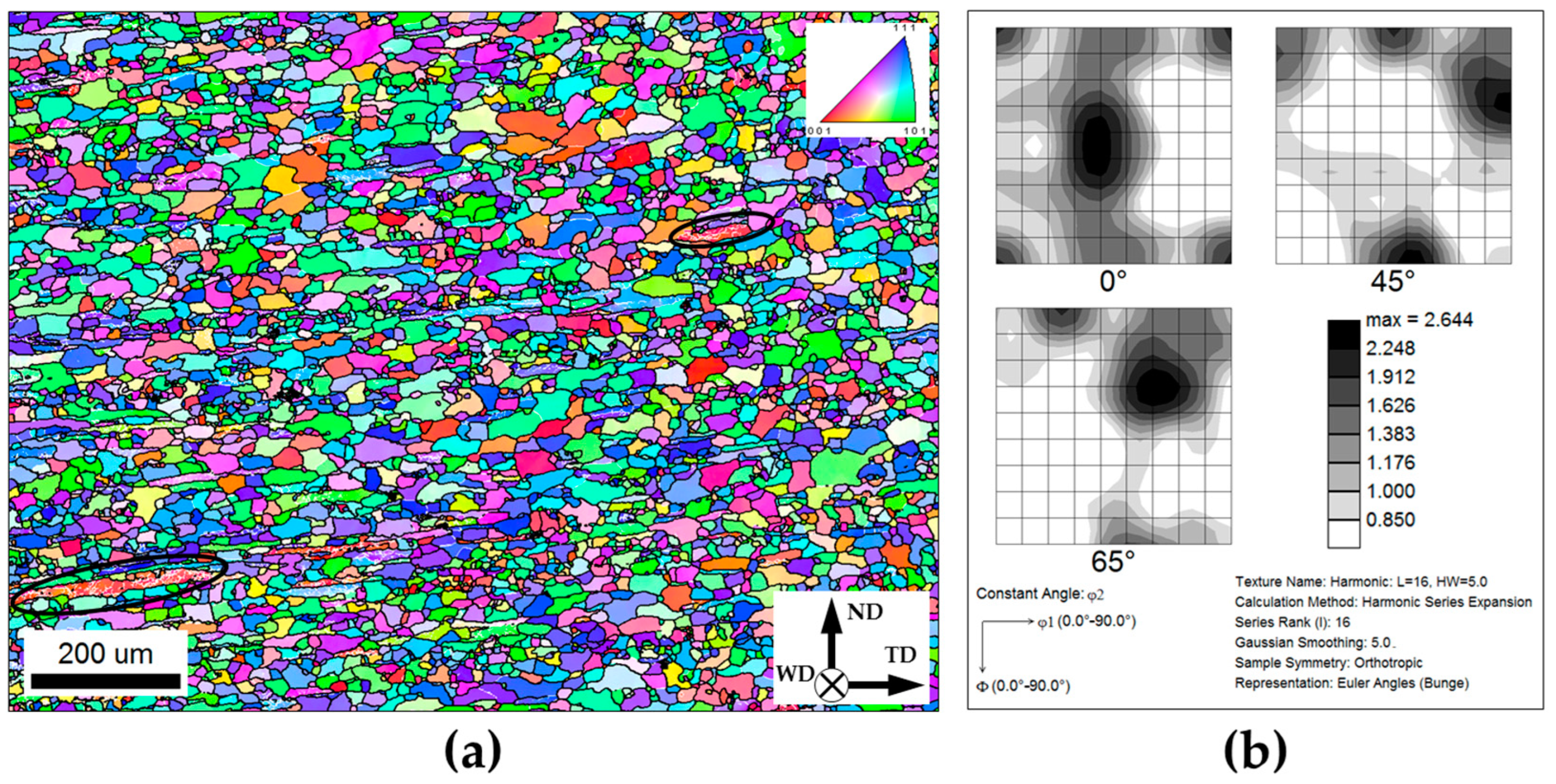

3.2. Heat-Affected Zone

3.3. Thermo-Mechanically Affected Zone

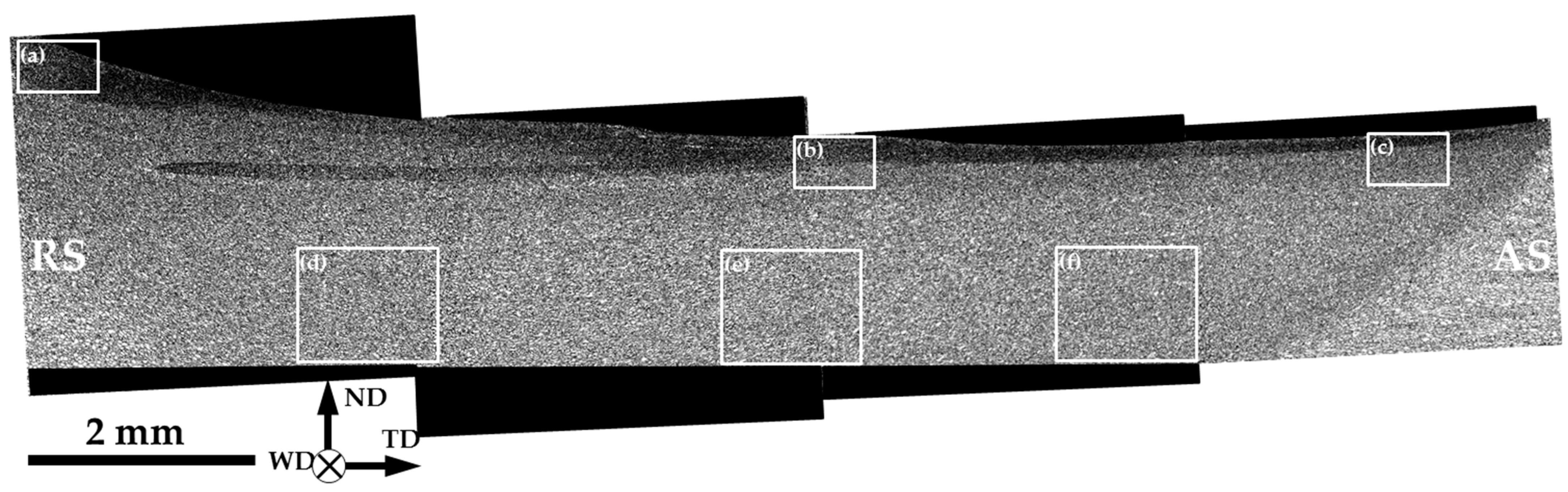

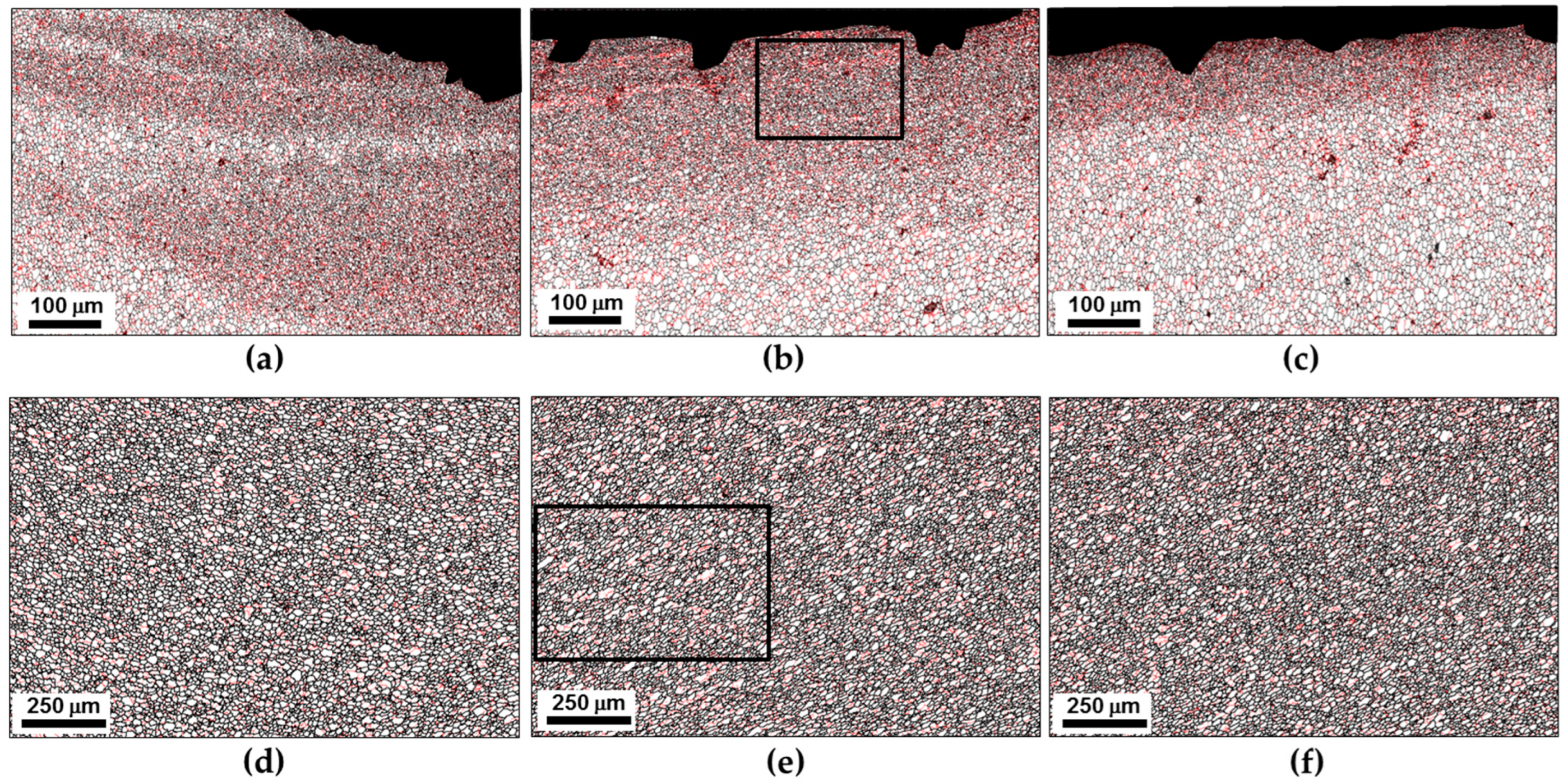

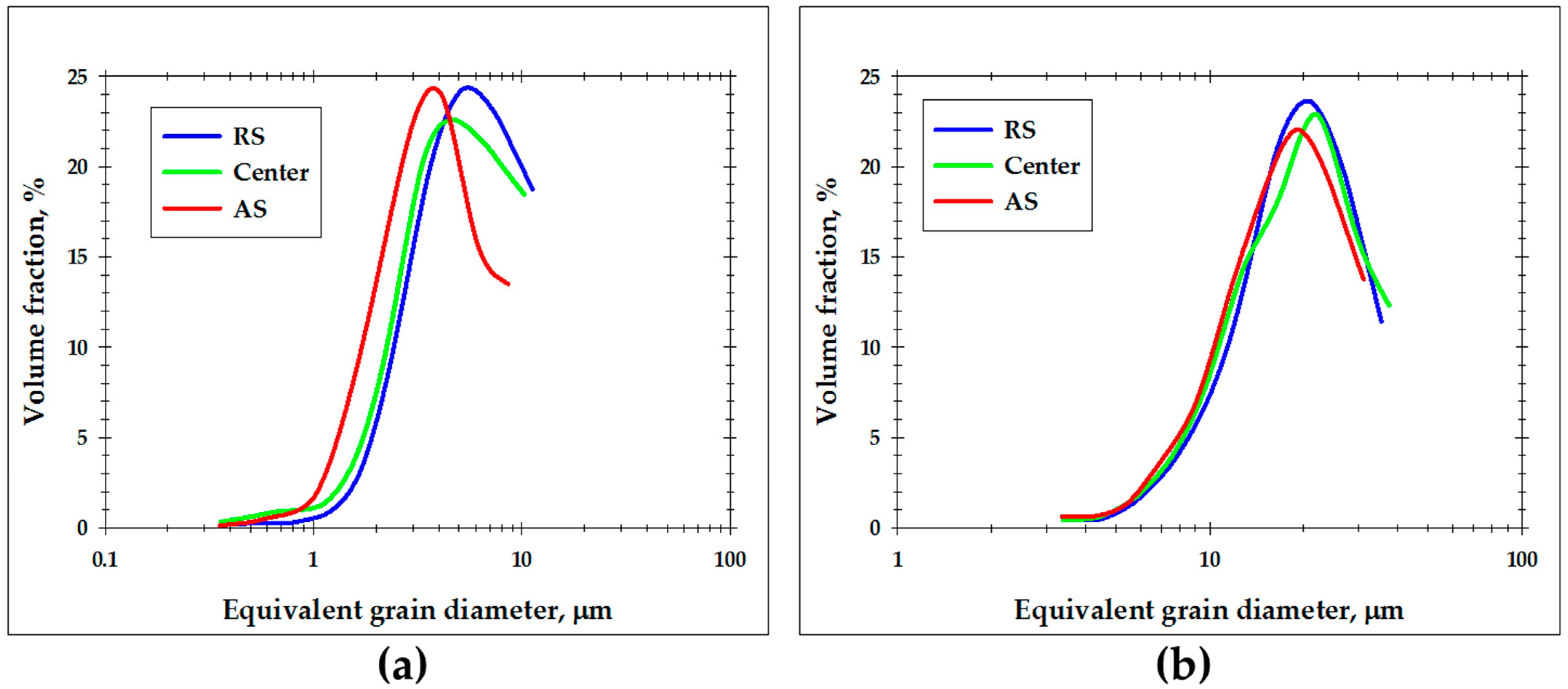

3.4. Microstructure Distribution within the Stir Zone

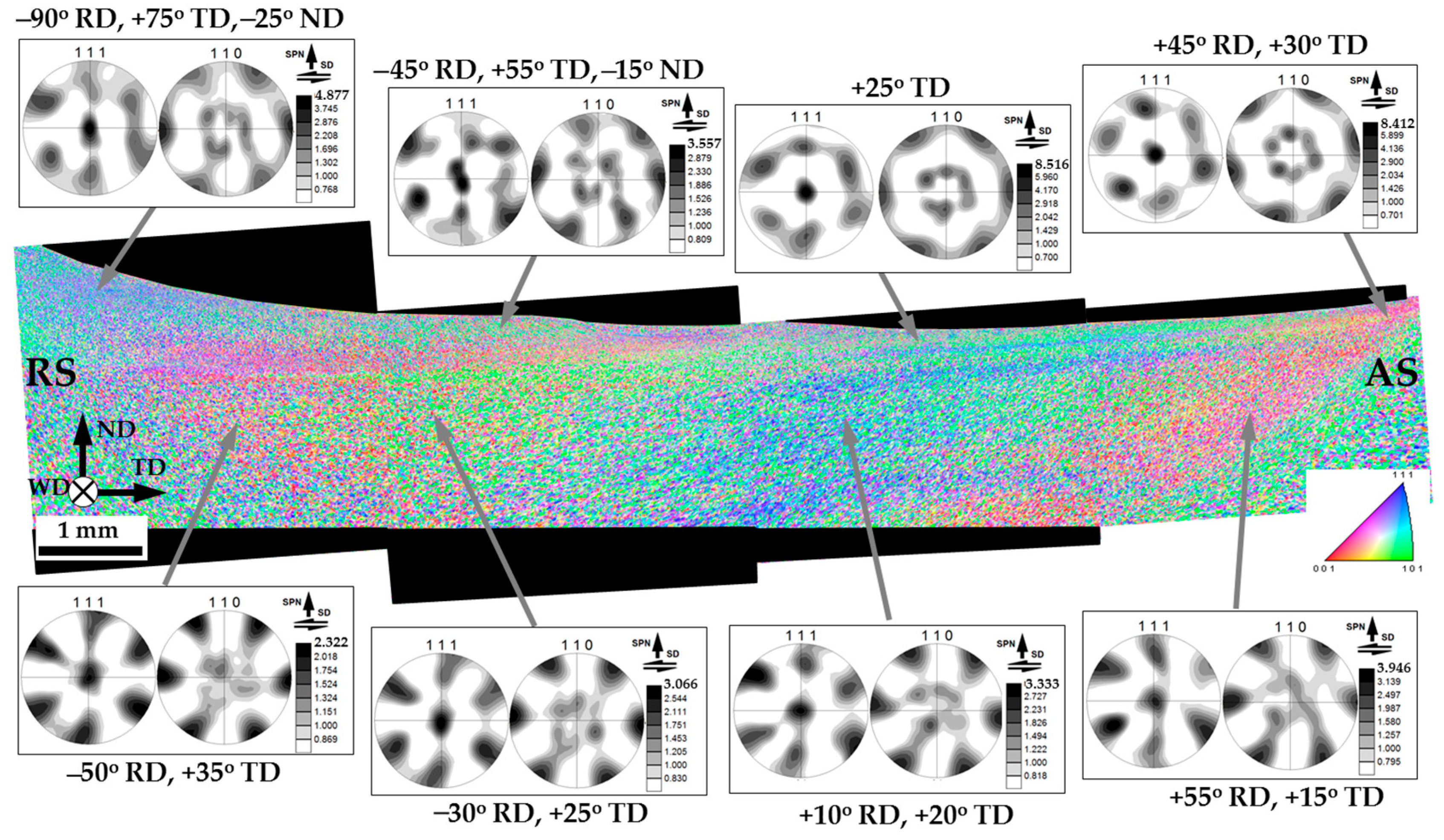

3.5. The Distribution of Crystallographic Texture within the Stir Zone

4. Discussion

4.1. Microstructural Evolution during FSW

- (i)

- The base material underwent almost complete static recrystallization in the heat-affected zone. Thus, the initial microstructure was fundamentally altered before its direct contact with the FSW tool.

- (ii)

- Material flow during FSW was primarily governed by the tool shoulder.

- (iii)

- FSW resulted in the formation of a pronounced layer of fine-grained microstructure at the upper surface of the stir zone.

- (iv)

- The microstructure within the stir zone contained a significant fraction of the survived remnants of coarse grains, i.e., the recrystallization process was far from being completed.

4.2. The Post-Weld Aging Behavior

5. Summary

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction Stir Welding of Aluminium Alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Heason, C.P. Grain Structure Formation during Friction Stir Welding Observed by the ‘Stop Action Technique’. Acta Mater. 2005, 53, 3179–3192. [Google Scholar] [CrossRef]

- Shen, J.; Lage, S.B.M.; Suhuddin, U.F.H.; Bolfarini, C.; dos Santos, J.F. Texture Development and Material Flow Behavior During Refill Friction Stir Spot Welding of AlMgSc. Metall. Mater. Trans. A. 2018, 49, 241–254. [Google Scholar] [CrossRef]

- Chu, Q.; Li, W.Y.; Wu, D.; Liu, X.C.; Hao, S.J.; Zou, F.; Yang, X.W.; Vairis, A. In-Depth Understanding of Material Flow Behavior and Refinement Mechanism during Bobbin Tool Friction Stir Welding. Int. J. Machin. Tool. Manuf. Volume 2021, 171, 103816. [Google Scholar] [CrossRef]

- Fonda, R.W.; Bingert, J.F.; Colligan, K.J. Development of Grain Structure during Friction Stir Welding. Scripta Mater. 2004, 51, 243–248. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous Dynamic Recrystallization during Friction Stir Welding of High Strength Aluminum Alloys. Scr. Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Liu, X.C.; Ye, T.; Li, Y.Z.; Pei, J.; Sun, Z. Quasi-in-Situ Characterization of Microstructure Evolution in Friction Stir Welding of Aluminum Alloy. J. Mater. Res. Technol. 2023, 25, 6380–6394. [Google Scholar] [CrossRef]

- Fonda, R.W.; Bingert, J.F. Precipitation and Grain Refinement in a 2195 Al Friction Stir Weld. Metall. Mater. Trans. A. 2006, 37, 3593–3604. [Google Scholar] [CrossRef]

- Fonda, R.W.; Knipling, K.E.; Bingert, J.F. Microstructural Evolution Ahead of the Tool in Aluminum Friction Stir Welds. Scr. Mater. 2008, 58, 343–348. [Google Scholar] [CrossRef]

- Ding, T.; Yan, H.; Chen, J.; Xia, W.; Su, B.; Zhu, H. Microstructure Evolution and Recrystallization Mechanisms of High Mg Alloyed Al-Mg Alloy during Friction Stir Welding with Different Cooling Media. J. Mater. Eng. Perform. 2023, 32, 3809–3820. [Google Scholar] [CrossRef]

- Li, D.; Liu, H.; Du, S.; Li, X.; Gao, Y.; Zuo, Y. Investigation on Material Flow and Microstructural Evolution Mechanism in Non-Thinning and Penetrating Friction Stir Welded Al–Cu Aluminum Alloy. Mater. Sci. Eng. A. 2023, 864, 144572. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Javidani, M.; Mofarrehi, M.; Motalleb-nejad, P.; Mohammadzadeh, R.; Jafarian, H.; Chen, X.-G. Grain Structure Formation and Texture Modification through Multi-Pass Friction Stir Processing in AlSi10Mg Alloy Produced by Laser Powder Bed Fusion. Materials 2023, 16, 944. [Google Scholar] [CrossRef] [PubMed]

- Gu, C.; Yang, X.; Tang, W.; Luo, T.; Wang, R. Softening Behavior of Stationary Shoulder Friction Stir Welded Joint for Thick-Plate Al–Li–Cu Alloy. J. Mater. Res. Technol. 2022, 20, 3008–3024. [Google Scholar] [CrossRef]

- Qiang, F.; Wang, W.; Qiao, K.; Peng, P.; Zhang, T.; Guan, X.-H.; Cai, J.; Meng, Q.; Zhao, H.-X.; Wang, K.-S. Microstructure and Mechanical Properties in Friction Stir Welded Thick Al–Zn–Mg–Cu Alloy Plate. Acta Metall. Sin. 2022, 35, 1329–1342. [Google Scholar] [CrossRef]

- Mishin, V.; Shishov, I.; Kalinenko, A.; Vysotskii, I.; Zuiko, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Numerical Simulation of the Thermo-Mechanical Behavior of 6061 Aluminum Alloy during Friction-Stir Welding. J. Manuf. Mater. Process. 2022, 6, 68. [Google Scholar] [CrossRef]

- Kalinenko, A.; Mishin, V.; Shishov, I.; Malopheyev, S.; Zuiko, I.; Novikov, V.; Mironov, S.; Kaibyshev, R.; Semiatin, S.L. Mechanisms of Abnormal Grain Growth in Friction-Stir-Welded Aluminum Alloy 6061-T6. Mater. Character. 2022, 194, 112473. [Google Scholar] [CrossRef]

- Liu, X.C.; Sun, Y.F.; Fujii, H. Clarification of Microstructure Evolution of Aluminum during Friction Stir Welding Using Liquid CO2 Rapid Cooling. Mater. Design. 2017, 129, 151–163. [Google Scholar] [CrossRef]

- Imam, M.; Sun, Y.; Fujii, H.; Ma, N.; Tsutsumi, S.; Ahmed, S.; Chintapenta, V.; Murakawa, H. Deformation Characteristics and Microstructural Evolution in Friction Stir Welding of Thick 5083 Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2018, 99, 663–681. [Google Scholar] [CrossRef]

- Nagira, T.; Liu, X.; Ushioda, K.; Fujii, H. Microstructural Evolutions of 2N Grade Pure Al and 4N Grade High-Purity Al during Friction Stir Welding. Materials 2021, 14, 3606. [Google Scholar] [CrossRef]

- Kalinenko, A.; Dolzhenko, P.; Borisova, Y.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Tailoring of Dissimilar Friction Stir Lap Welding of Aluminum and Titanium. Materials 2022, 15, 8418. [Google Scholar] [CrossRef] [PubMed]

- Humphreys, F.J. Quantitative Metallography by Electron Backscatter Diffraction. J. Micros. 1999, 195, 170–185. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Jiang, T.; Wang, J.; Liu, Q.; Wu, Z.; Yu, Y.; Skaret, P.C.; Roven, H.J. Aging Behavior and Mechanical Properties of 6013 Aluminum Alloy Processed by Severe Plastic Deformation. Trans. Nonfer. Metal. Soc. China 2014, 24, 3858–3865. [Google Scholar] [CrossRef]

- Fonda, R.W.; Knipling, K.E. Texture Development in Friction Stir Welds. Sci. Technol. Weld. Join. 2011, 16, 288–294. [Google Scholar] [CrossRef]

| Al | Mg | Si | Cu | Mn | Fe | Zn | Cr | Ti |

|---|---|---|---|---|---|---|---|---|

| Bal. | 0.8–1.2 | 0.6–1.0 | 0.6–1.1 | 0.2–0.8 | ≤0.5 | ≤0.25 | ≤0.1 | ≤0.1 |

| Texture Component | Volume Fraction, % | |

|---|---|---|

| Base Material | Heat-Affected Zone | |

| Copper {112}<111> | 7.7 | 6.7 |

| S {123}<634> | 20.3 | 13.2 |

| Brass {011}<211> | 9.4 | 7.5 |

| Cube {001}<100> | 3.3 | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalinenko, A.; Dolzhenko, P.; Malopheyev, S.; Yuzbekova, D.; Shishov, I.; Mishin, V.; Mironov, S.; Kaibyshev, R. Grain Structure Evolution in 6013 Aluminum Alloy during High Heat-Input Friction-Stir Welding. Materials 2023, 16, 5973. https://doi.org/10.3390/ma16175973

Kalinenko A, Dolzhenko P, Malopheyev S, Yuzbekova D, Shishov I, Mishin V, Mironov S, Kaibyshev R. Grain Structure Evolution in 6013 Aluminum Alloy during High Heat-Input Friction-Stir Welding. Materials. 2023; 16(17):5973. https://doi.org/10.3390/ma16175973

Chicago/Turabian StyleKalinenko, Alexander, Pavel Dolzhenko, Sergey Malopheyev, Diana Yuzbekova, Ivan Shishov, Vasiliy Mishin, Sergey Mironov, and Rustam Kaibyshev. 2023. "Grain Structure Evolution in 6013 Aluminum Alloy during High Heat-Input Friction-Stir Welding" Materials 16, no. 17: 5973. https://doi.org/10.3390/ma16175973

APA StyleKalinenko, A., Dolzhenko, P., Malopheyev, S., Yuzbekova, D., Shishov, I., Mishin, V., Mironov, S., & Kaibyshev, R. (2023). Grain Structure Evolution in 6013 Aluminum Alloy during High Heat-Input Friction-Stir Welding. Materials, 16(17), 5973. https://doi.org/10.3390/ma16175973