Investigation of Deformation Behavior of Additively Manufactured AISI 316L Stainless Steel with In Situ Micro-Compression Testing

Abstract

:1. Introduction

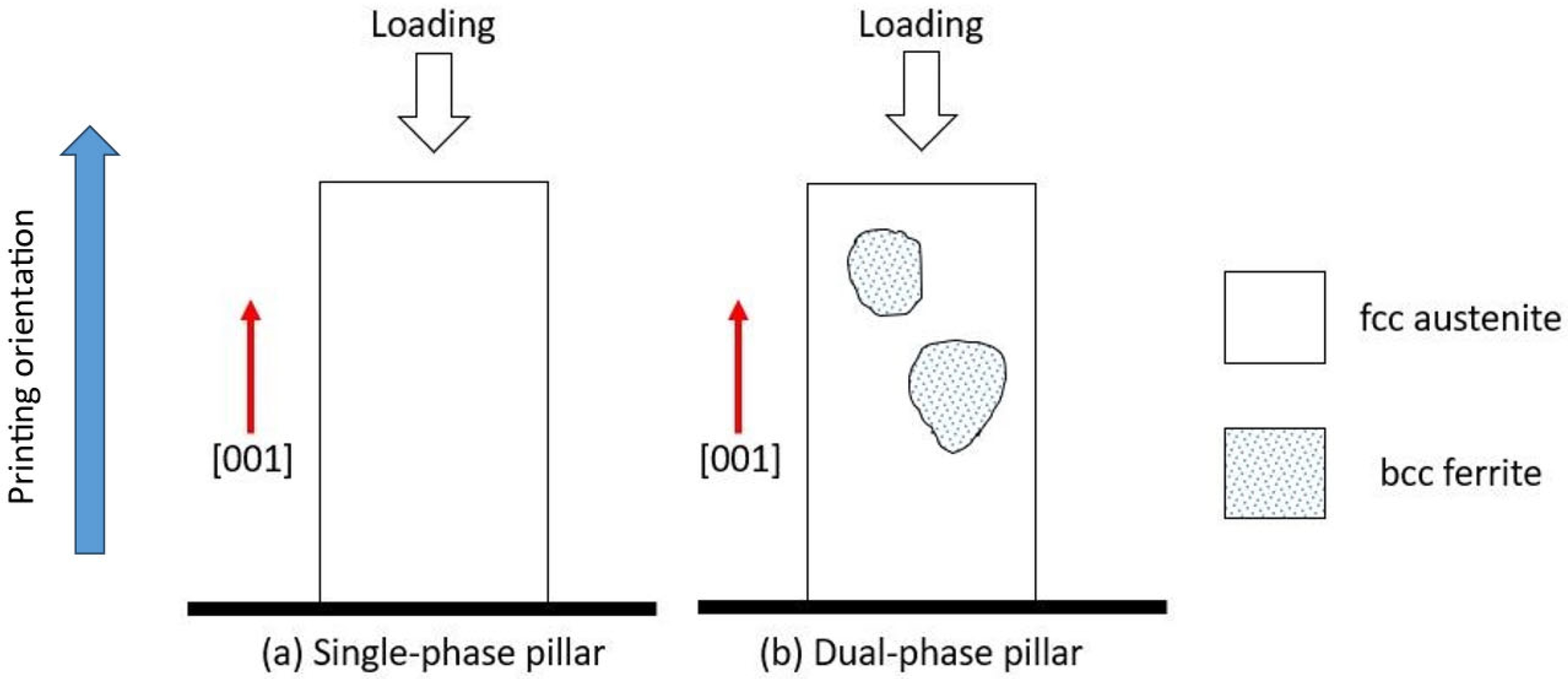

2. Experimental Methods

3. Results

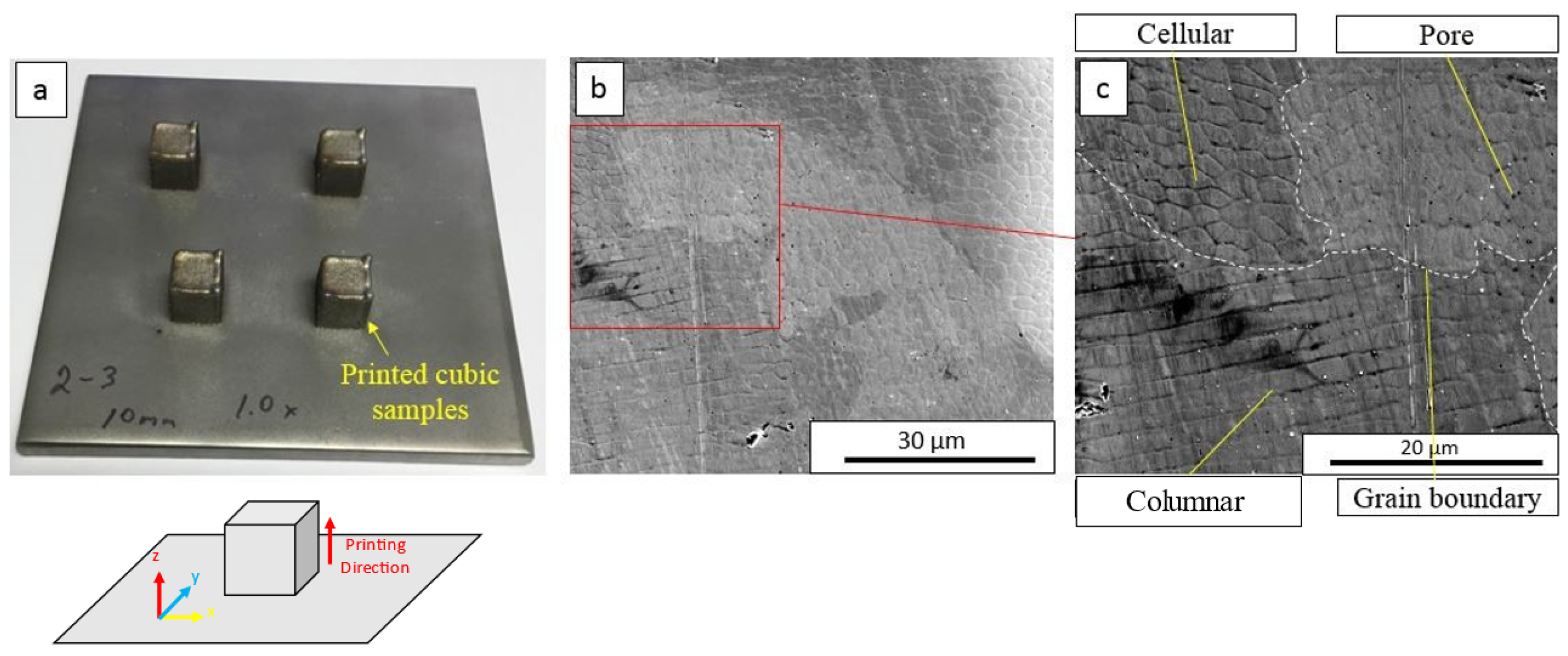

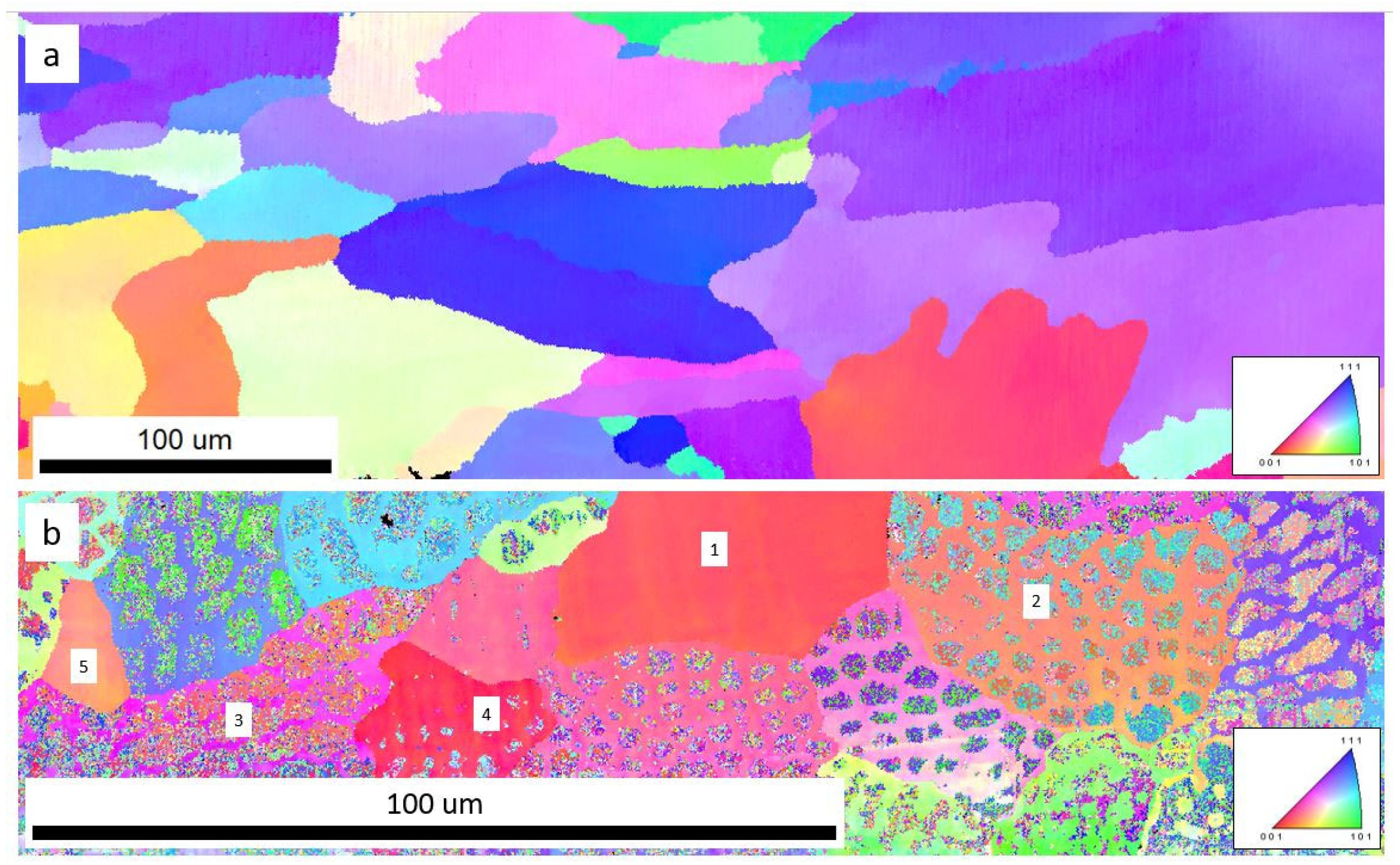

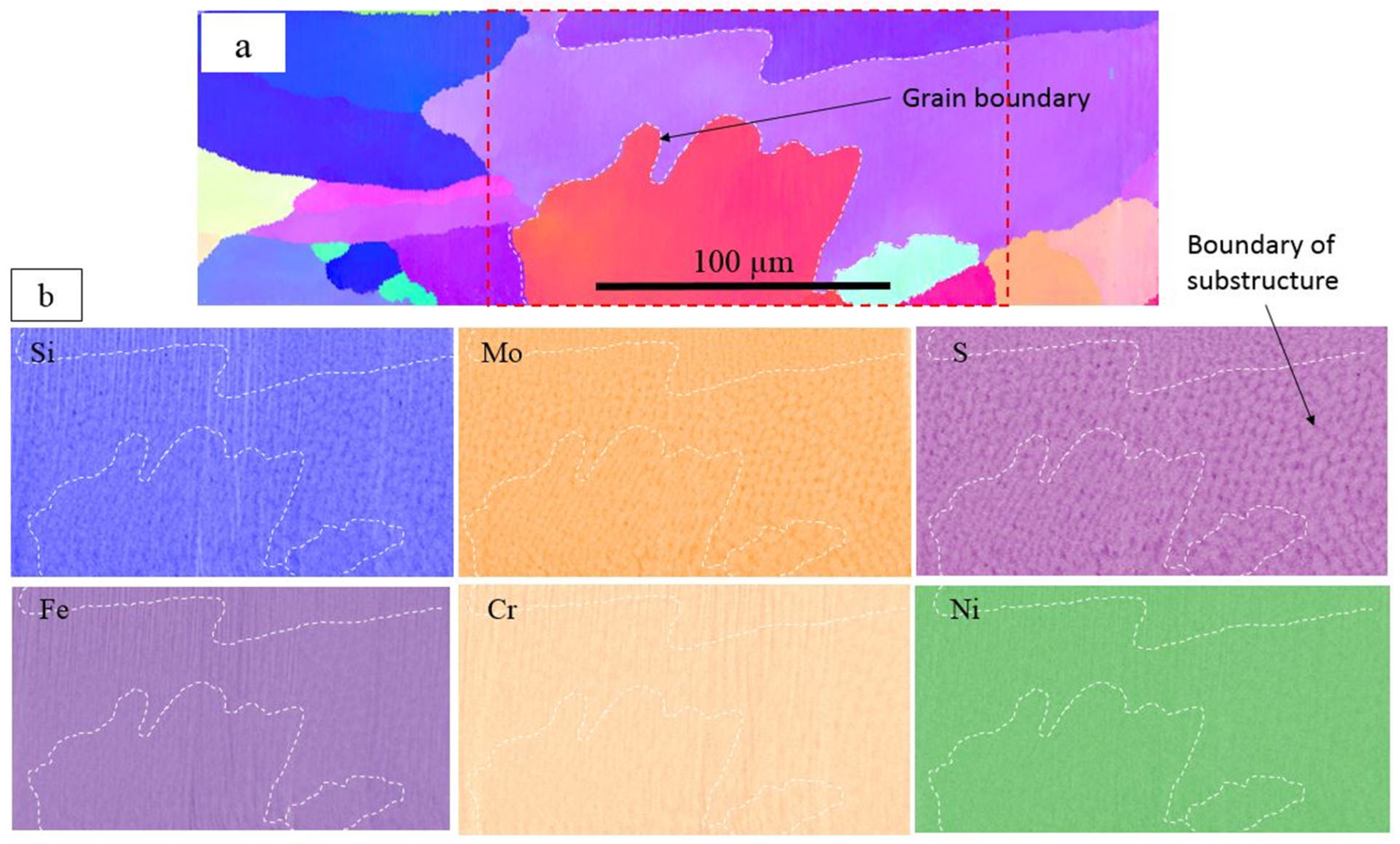

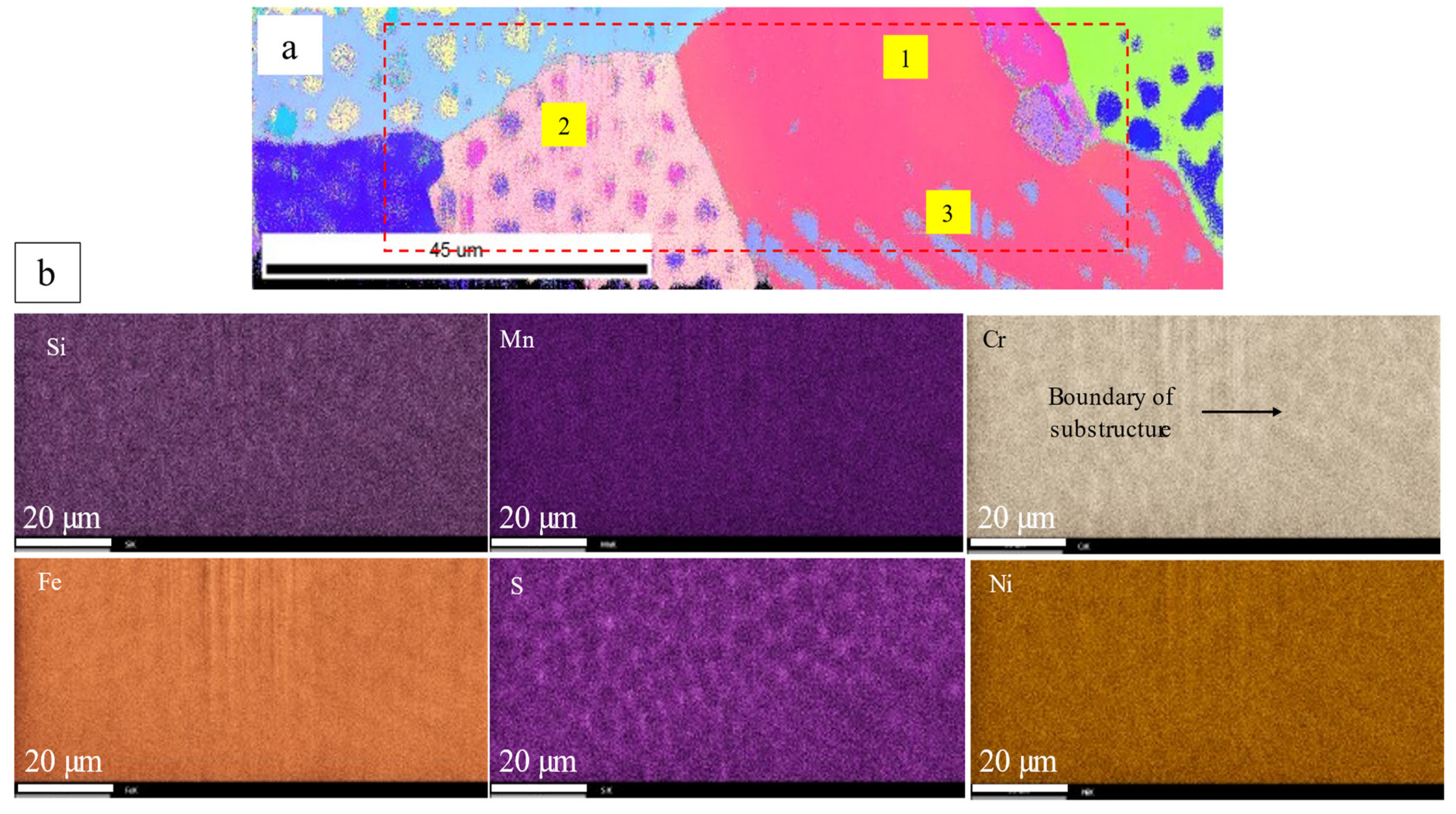

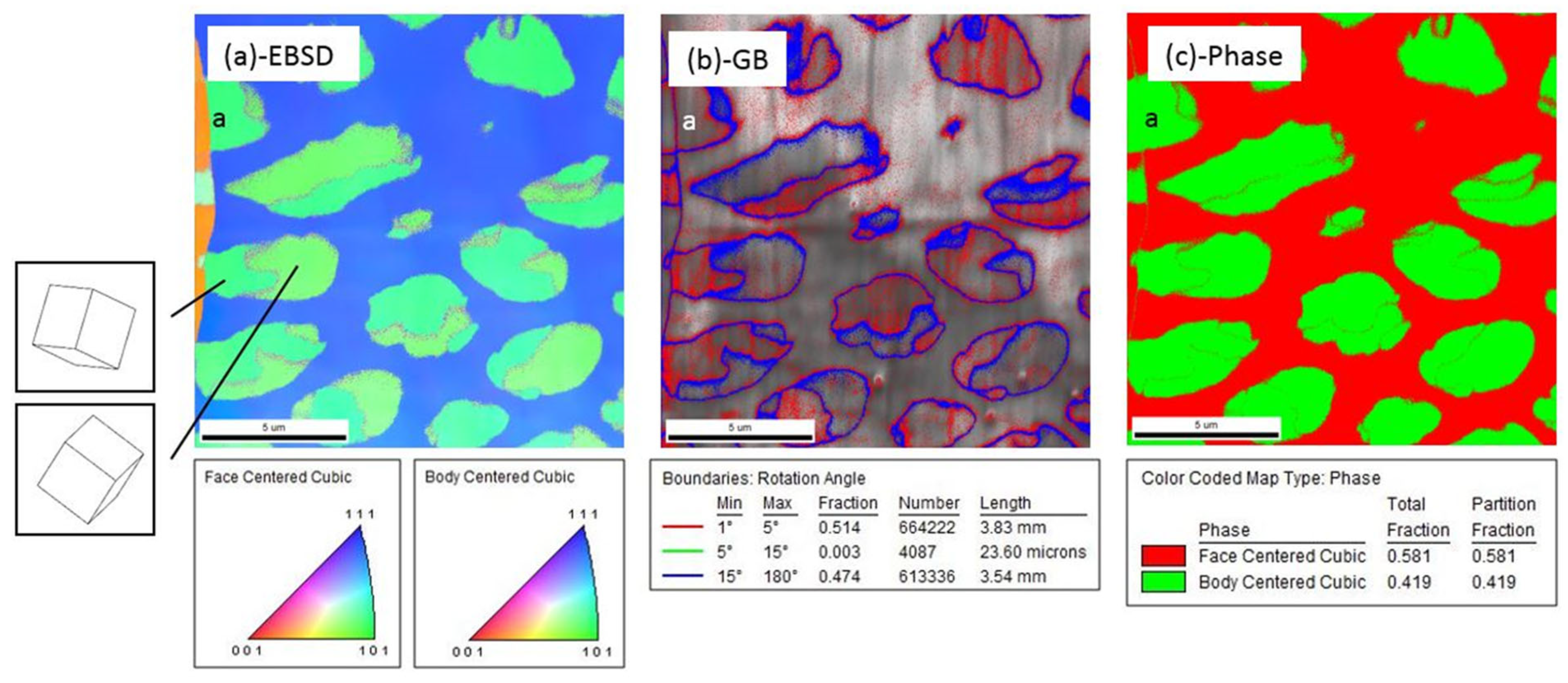

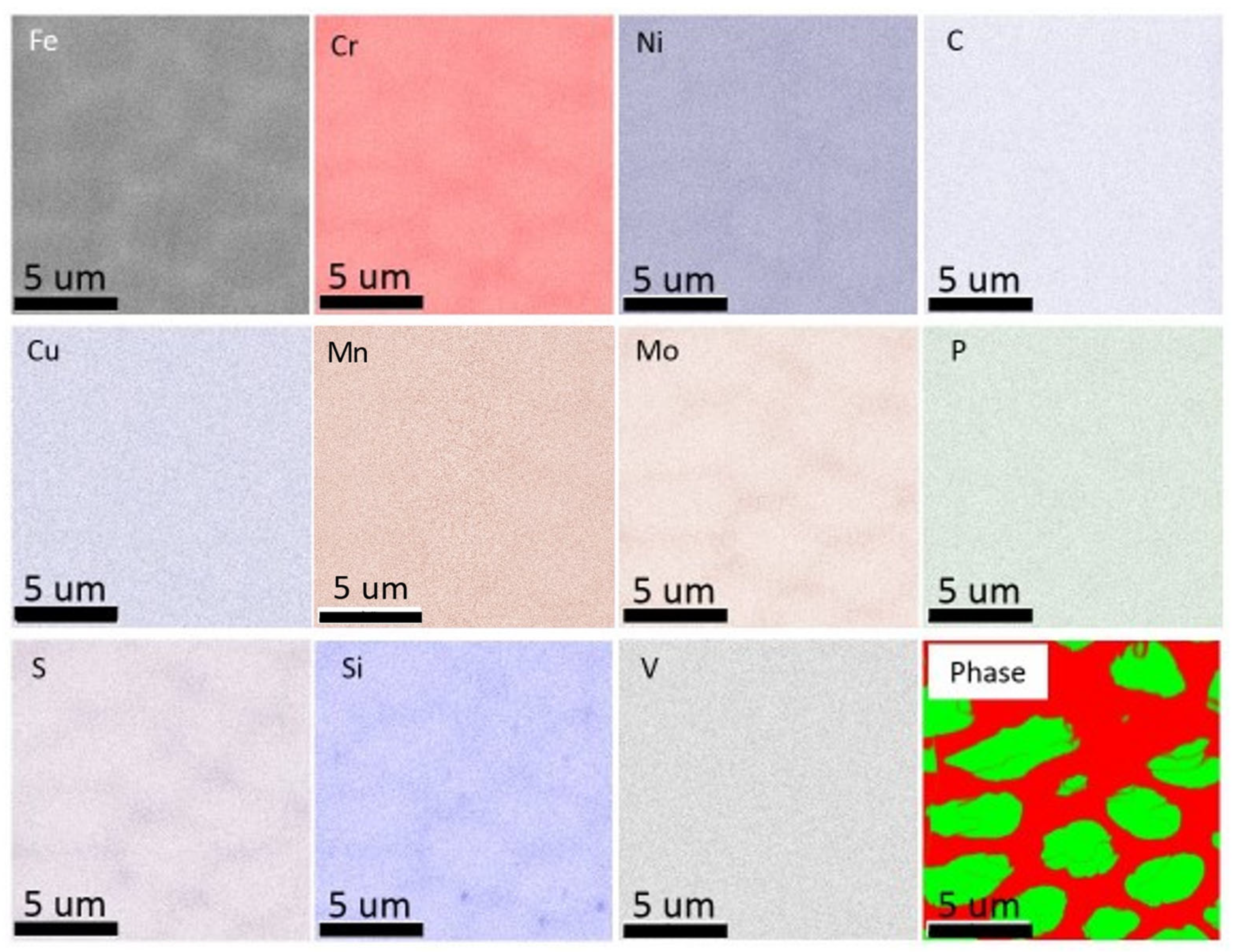

3.1. Microstructure and Microchemistry

3.2. In Situ Micro-Compression Tests

4. Discussion

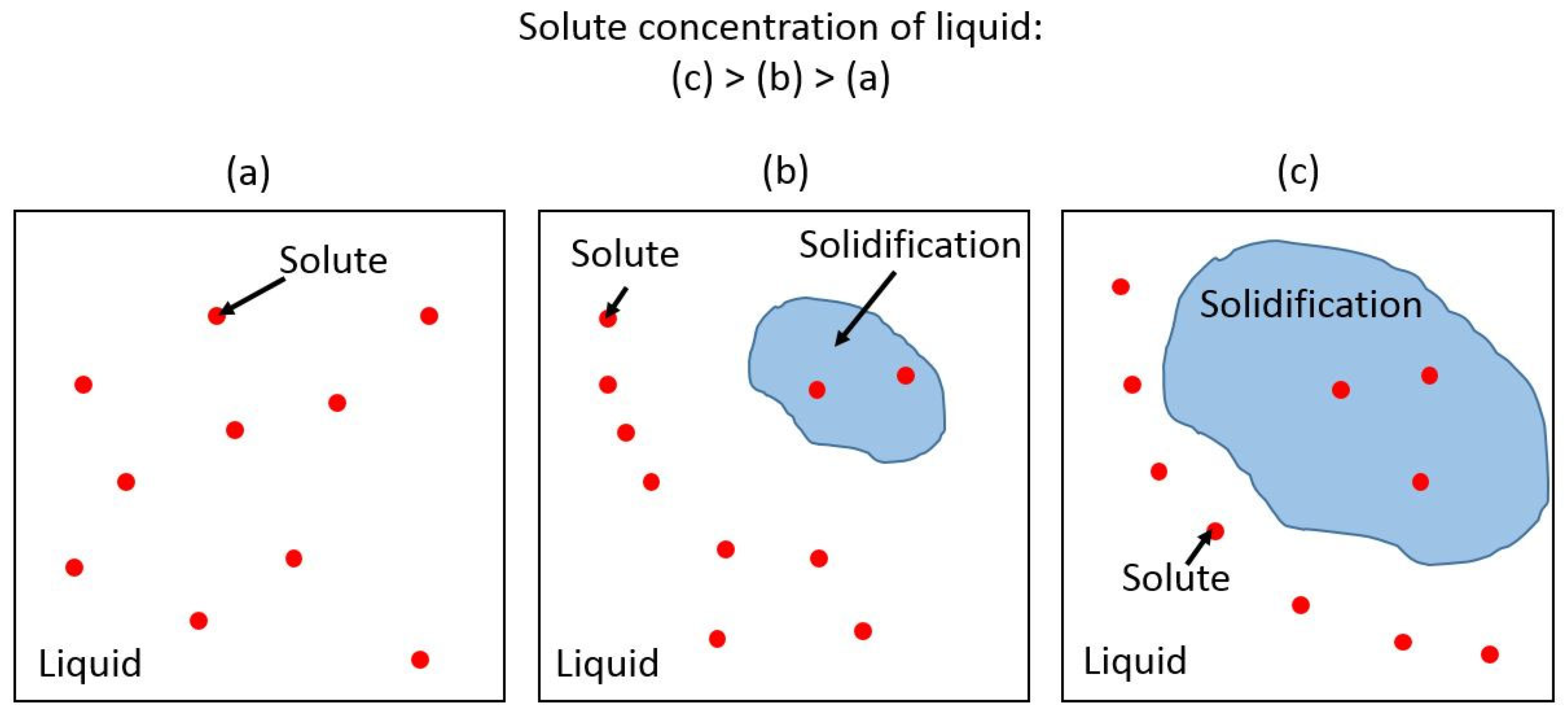

4.1. Microstructure Evolution in As-Printed AM316L

4.2. Effect of Dual-Phase Structures on Deformation Behavior in Additively Manufactured 316L

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Brandl, E.; Palm, F.; Michailov, V.; Viehweger, B.; Leyens, C. Mechanical properties of additive manufactured titanium (Ti–6Al–4V) blocks deposited by a solid-state laser and wire. Mater. Des. 2011, 32, 4665–4675. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Badrossamay, M.; Childs, T. Further studies in selective laser melting of stainless and tool steel powders. Int. J. Mach. Tools Manuf. 2007, 47, 779–784. [Google Scholar] [CrossRef]

- Carlton, H.D.; Haboub, A.; Gallegos, G.F.; Parkinson, D.Y.; MacDowell, A.A. Damage evolution and failure mechanisms in additively manufactured stainless steel. Mater. Sci. Eng. A 2016, 651, 406–414. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L.; Sewell, N. Effect of selective laser melting layout on the quality of stainless steel parts. Rapid Prototyp. J. 2012, 18, 241–249. [Google Scholar] [CrossRef]

- Jerrard, P.; Hao, L.; Evans, K. Experimental investigation into selective laser melting of austenitic and martensitic stainless steel powder mixtures. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 1409–1416. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Du, M.; Xie, Z. 316 L stainless steel with gradient porosity fabricated by selective laser melting. J. Mater. Eng. Perform. 2009, 19, 666–671. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wang, L.; Liu, J.; Wang, Z. The key metallurgical features of selective laser melting of stainless steel powder for building metallic part. Sov. Powder Met. Met. Ceram. 2011, 50, 141–150. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly anisotropic steel processed by selective laser melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Kempen, K.; Yasa, E.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Microstructure and mechanical properties of Selective Laser Melted 18Ni-300 steel. Phys. Procedia 2011, 12, 255–263. [Google Scholar] [CrossRef]

- Jägle, E.A.; Choi, P.-P.; Van Humbeeck, J.; Raabe, D. Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J. Mater. Res. 2014, 29, 2072–2079. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.; Contuzzi, N.; Ludovico, A. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Burkert, T.; Fischer, A. The effects of heat balance on the void formation within marage 300 processed by selective laser melting. In Proceedings of the 2015 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; pp. 745–757. [Google Scholar]

- Starr, T.L.; Rafi, K.; Stucker, B.; Scherzer, C.M. Controlling phase composition in selective laser melted stainless steels. Power 2012, 195, 195. [Google Scholar]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and properties of 17-4 PH stainless steel fabricated by selective laser melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsava, I.; Fredriksson, G.; Yadroitsev, I. In situ heat treatment in selective laser melted martensitic AISI 420 stainless steels. Mater. Des. 2015, 87, 380–385. [Google Scholar] [CrossRef]

- Zhao, X.; Song, B.; Zhang, Y.; Zhu, X.; Wei, Q.; Shi, Y. Decarburization of stainless steel during selective laser melting and its influence on Young’s modulus, hardness and tensile strength. Mater. Sci. Eng. A 2015, 647, 58–61. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Pinkerton, A.; Liu, Z.; Manna, I.; Li, L. Microstructure characterisation and process optimization of laser assisted rapid fabrication of 316L stainless steel. Appl. Surf. Sci. 2005, 247, 320–327. [Google Scholar] [CrossRef]

- Mahmood, K.; Pinkerton, A.J. Direct laser deposition with different types of 316L steel particle: A comparative study of final part properties. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 520–531. [Google Scholar] [CrossRef]

- Mazumder, J.; Choi, J.; Nagarathnam, K.; Koch, J.; Hetzner, D. The direct metal deposition of H13 tool steel for 3-D components. JOM 1997, 49, 55–60. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ceylan, A.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; et al. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

- Petroušek, P.; Kvačkaj, T.; Bidulská, J.; Bidulský, R.; Grande, M.A.; Manfredi, D.; Weiss, K.-P.; Kočiško, R.; Lupták, M.; Pokorný, I. Investigation of the Properties of 316L Stainless Steel after AM and Heat Treatment. Materials 2023, 16, 3935. [Google Scholar] [CrossRef]

- Kluczyński, J.; Jasik, K.; Łuszczek, J.; Sarzyński, B.; Grzelak, K.; Dražan, T.; Joska, Z.; Szachogłuchowicz, I.; Płatek, P.; Małek, M. A Comparative Investigation of Properties of Metallic Parts Additively Manufactured through MEX and PBF-LB/M Technologies. Materials 2023, 16, 5200. [Google Scholar] [CrossRef]

- Ostra, T.; Alonso, U.; Veiga, F.; Ortiz, M.; Ramiro, P.; Alberdi, A. Analysis of the Machining Process of Inconel 718 Parts Manufactured by Laser Metal Deposition. Materials 2019, 12, 2159. [Google Scholar] [CrossRef]

- Rombouts, M.; Maes, G.; Hendrix, W.; Delarbre, E.; Motmans, F. Surface Finish after Laser Metal Deposition. Phys. Procedia 2013, 41, 810–814. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010. [Google Scholar]

- Cherry, J.; Davies, H.; Mehmood, S.; Lavery, N.; Brown, S.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316 L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of stainless steel parts by Laser Metal Deposition Shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316 L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2016, 240, 12–22. [Google Scholar] [CrossRef]

- Shiau, C.-H.; McMurtrey, M.D.; O’Brien, R.C.; Jerred, N.D.; Scott, R.D.; Lu, J.; Zhang, X.; Wang, Y.; Shao, L.; Sun, C. Deformation behavior and irradiation tolerance of 316 L stainless steel fabricated by direct energy deposition. Mater. Des. 2021, 204, 109644. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Wang, D.; Song, C.; Yang, Y.; Bai, Y. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Des. 2016, 100, 291–299. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; Jersey, N., Ed.; Cambridge University Press: Cambridge, UK, 2003; pp. 431–446. [Google Scholar]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Elmer, J.W.; Allen, S.M.; Eagar, T.W. Microstructural development during solidification of stainless steel alloys. Met. Trans. A 1989, 20, 2117–2131. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V.A. The onset of twinning in metals: A constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Vöhringer, O. Einsatzspannung für die Bildung von Verformungszwillingen bei vielkristallinen α-Kupferlegierungen. Z. Naturforschung A 1969, 24, 478. [Google Scholar] [CrossRef]

- Mulford, R.; Kocks, U. New observations on the mechanisms of dynamic strain aging and of jerky flow. Acta Met. 1979, 27, 1125–1134. [Google Scholar] [CrossRef]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy fcc alloys that form deformation twins. Met. Mater. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Influence of grain size and stacking-fault energy on deformation twinning in fcc metals. Met. Mater. Trans. A 1999, 30, 1223–1233. [Google Scholar] [CrossRef]

- Venables, J.A. Deformation twinning in face-centred cubic metals. Philos. Mag. 1961, 6, 379–396. [Google Scholar] [CrossRef]

- Cohen, J.; Weertman, J. A dislocation model for twinning in fcc metals. Acta Met. 1963, 11, 996–998. [Google Scholar] [CrossRef]

- Lagerlöf, K.; Castaing, J.; Pirouz, P.; Heuer, A. Nucleation and growth of deformation twins: A perspective based on the double-cross-slip mechanism of deformation twinning. Philos. Mag. A 2002, 82, 2841–2854. [Google Scholar] [CrossRef]

- Hirth, J.; Lothe, J. Theory of dislocations. J. Appl. Mech. 1983, 50, 476–477. [Google Scholar] [CrossRef]

- Chen, M.; Ma, E.; Hemker, K.J.; Sheng, H.; Wang, Y.; Cheng, X. Deformation twinning in nanocrystalline aluminum. Science 2003, 300, 1275–1277. [Google Scholar] [CrossRef] [PubMed]

- Vitos, L.; Nilsson, J.O.; Johansson, B. Alloying effects on the stacking fault energy in austenitic stainless steels from first-principles theory. Acta Mater. 2006, 54, 3821–3826. [Google Scholar] [CrossRef]

| Element | Result wt% | Min wt% | Max wt% |

|---|---|---|---|

| Cr | 16.23 | 16.00 | 18.00 |

| Ni | 13.07 | 10.00 | 14.00 |

| C | 0.025 | 0.000 | 0.030 |

| Mn | 0.31 | 0.000 | 2.00 |

| P | <0.010 | 0.000 | 0.045 |

| S | 0.011 | 0.000 | 0.030 |

| Si | 0.73 | 0.000 | 1.00 |

| Mo | 2.09 | 2.00 | 3.00 |

| Fe | Balance | Balance | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, F.; Shiau, C.-H.; Sun, C.; O’Brien, R.C.; McMurtrey, M.D. Investigation of Deformation Behavior of Additively Manufactured AISI 316L Stainless Steel with In Situ Micro-Compression Testing. Materials 2023, 16, 5980. https://doi.org/10.3390/ma16175980

Teng F, Shiau C-H, Sun C, O’Brien RC, McMurtrey MD. Investigation of Deformation Behavior of Additively Manufactured AISI 316L Stainless Steel with In Situ Micro-Compression Testing. Materials. 2023; 16(17):5980. https://doi.org/10.3390/ma16175980

Chicago/Turabian StyleTeng, Fei, Ching-Heng Shiau, Cheng Sun, Robert C. O’Brien, and Michael D. McMurtrey. 2023. "Investigation of Deformation Behavior of Additively Manufactured AISI 316L Stainless Steel with In Situ Micro-Compression Testing" Materials 16, no. 17: 5980. https://doi.org/10.3390/ma16175980

APA StyleTeng, F., Shiau, C.-H., Sun, C., O’Brien, R. C., & McMurtrey, M. D. (2023). Investigation of Deformation Behavior of Additively Manufactured AISI 316L Stainless Steel with In Situ Micro-Compression Testing. Materials, 16(17), 5980. https://doi.org/10.3390/ma16175980