Analysis of the Synergistic Effect on the Strength Characteristics of Modified Red Mud-Based Stabilized Soil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

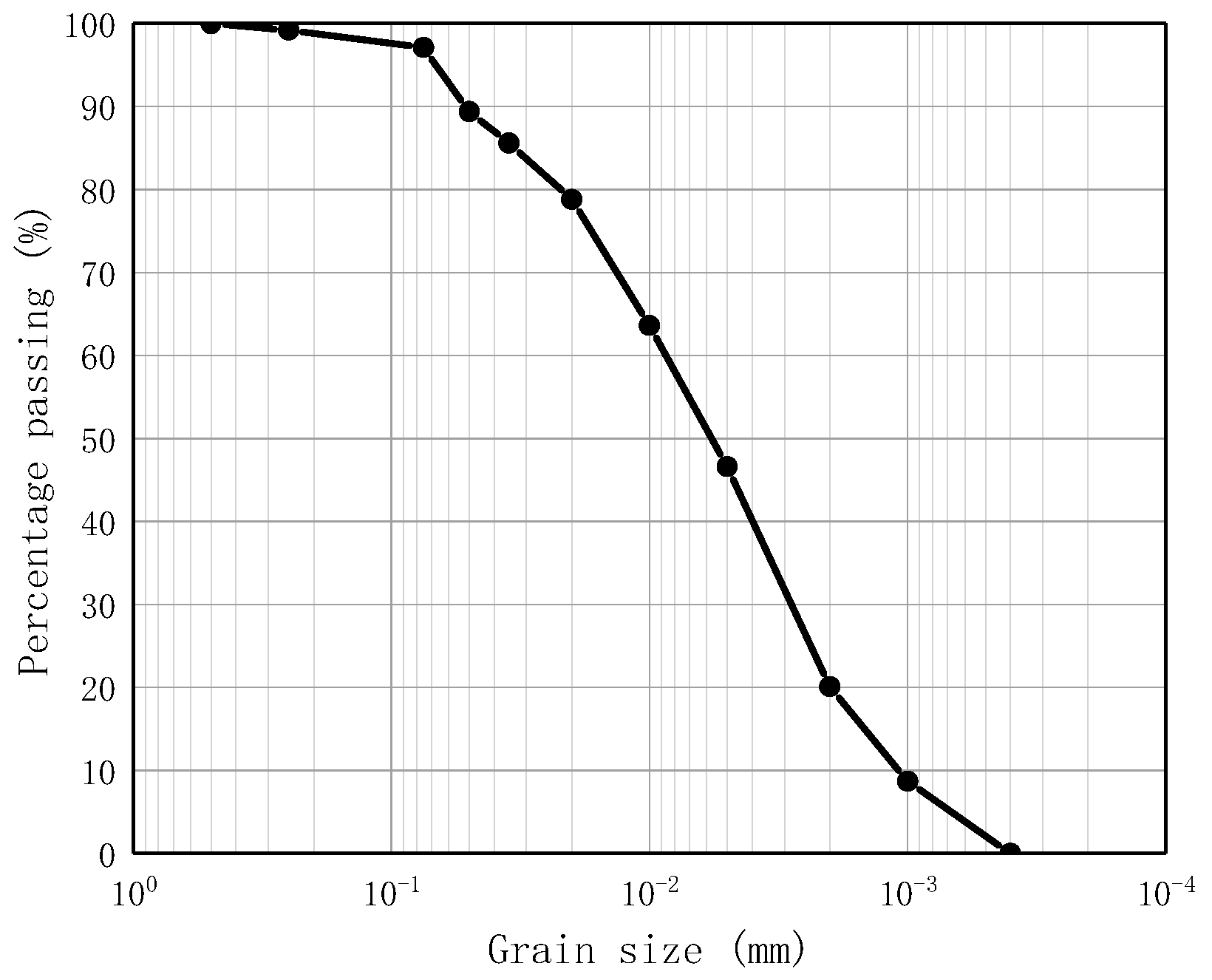

2.1.1. Red Mud

2.1.2. Nano-SiO2

2.1.3. Cement

2.1.4. Gypsum

2.2. Experimental Design

- Adding cement alone to dry red mud and testing the effect of the individual admixture of cement on the strength of the specimen;

- The nano-SiO2 dosing of 1% was selected to test the effect of different cement dosing on the unconfined compressive strength of specimens under the synergistic effect of nano-SiO2;

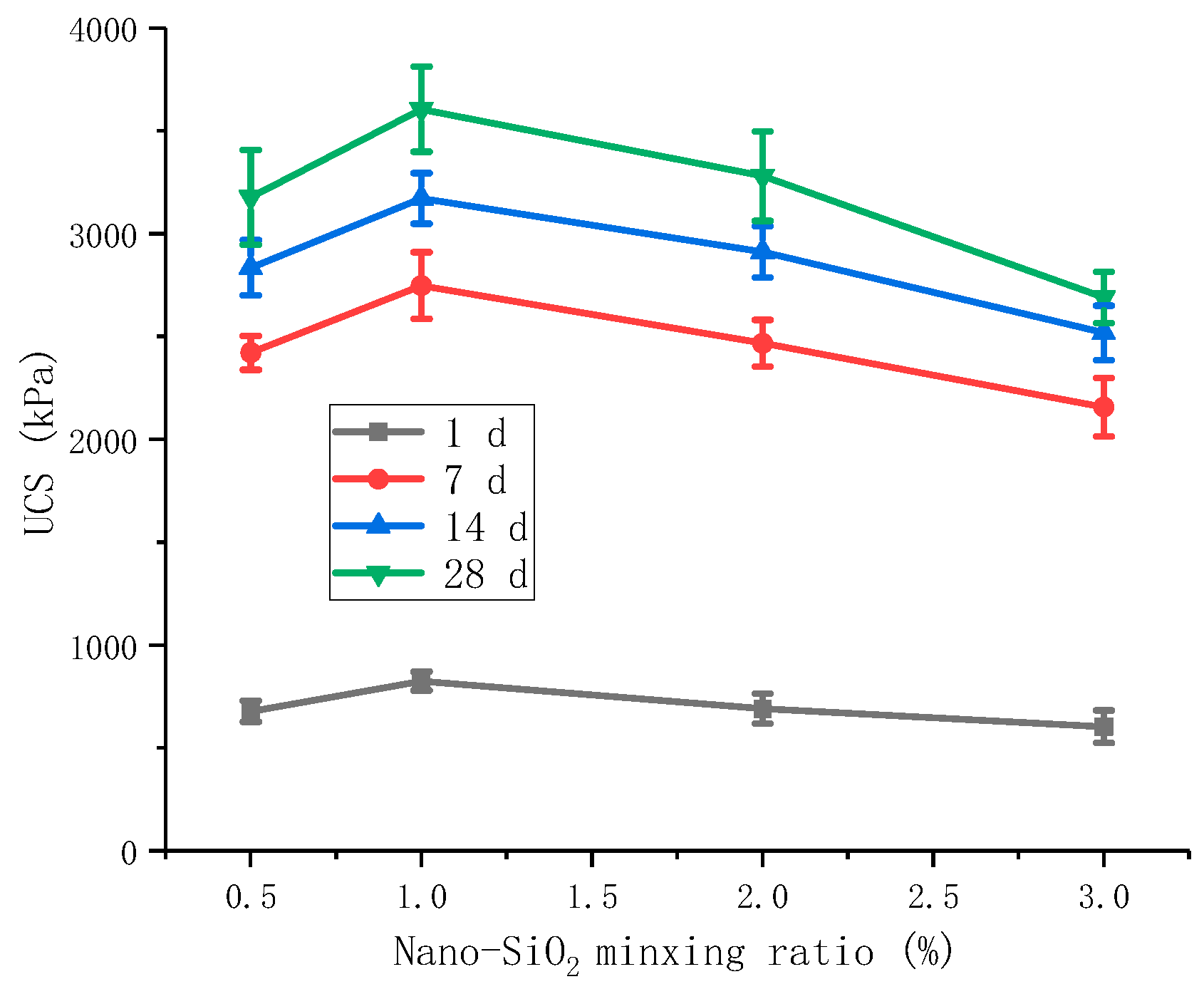

- The optimum dose of 3% cement and 6% gypsum was selected from both strength and economic considerations, and different mass ratios of nano-SiO2 were added on this basis to test the synergistic effects of the three modified materials on strength control and to determine the optimum nano-SiO2 dosage.

2.3. Specimen Preparation

- Firstly, the sampling red mud was dried at room temperature and crushed into powder with a plastic hammer; then, the crushed powder was sieved using a 0.5 mm steel sieve; the sieved red mud was oven-dried at 105 °C to further remove the moisture.

- In accordance with the optimal water content determined by the compaction test, the modified materials (stabilizers, all in powder form) and a certain mass of deionized water were added into the red mud according to the designed dosage and mixed thoroughly.

- The stabilized soil was compacted to a 5 mm × 5 mm cylindrical column. Note that the compaction should be done within 1 h after adding cement.

- The compacted specimens were sealed with plastic film and placed in an environmentally controlled chamber with a temperature of 20 °C and relative humidity of 95° for curing. After reaching different curing periods of 1, 7, 14, 28, 60, and 120 days, the specimens were taken out for unconfined compressive strength tests.

2.4. Unconfined Compressive Strength Test

3. Results and Analysis

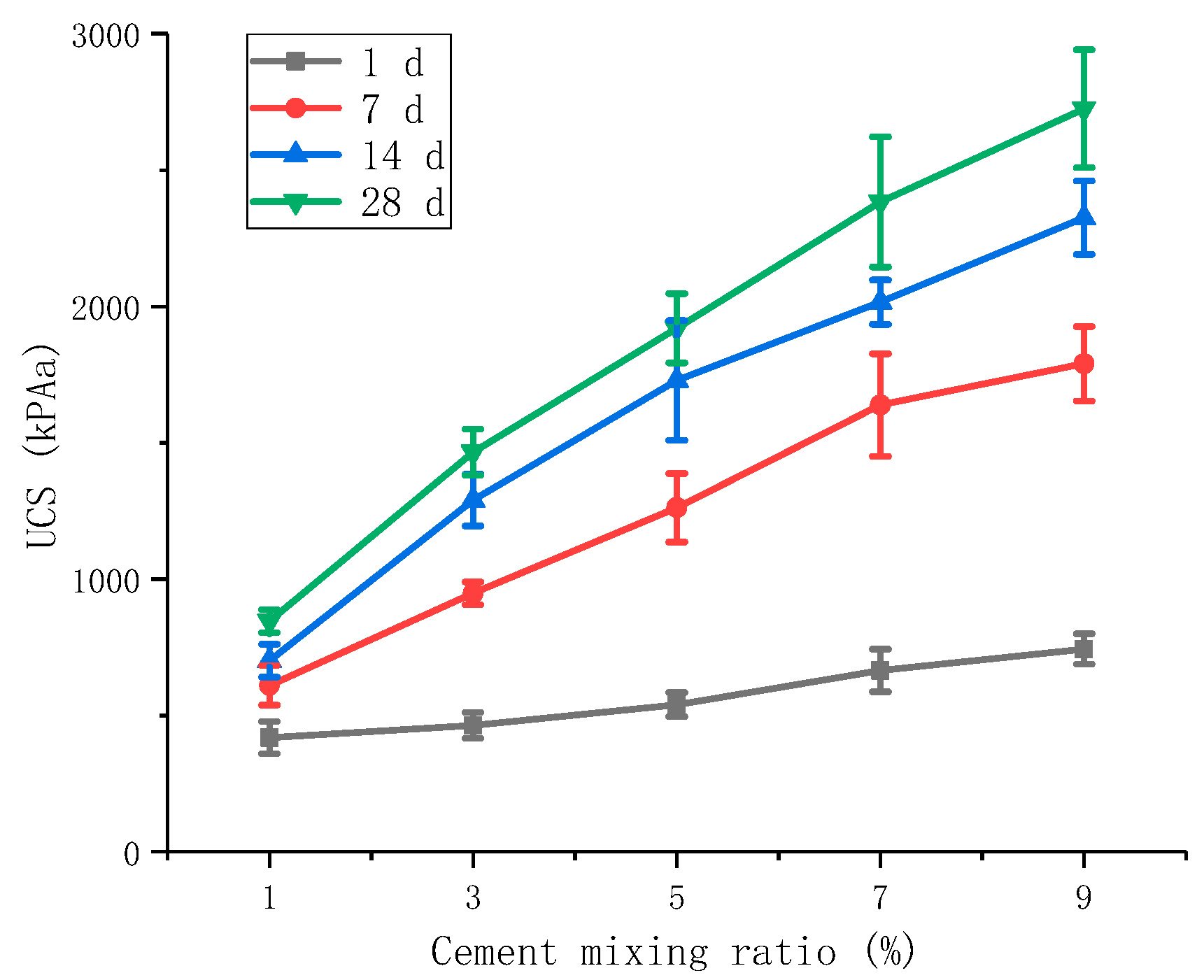

3.1. Effect of Cement

3.2. Effect of Synergistic Modification

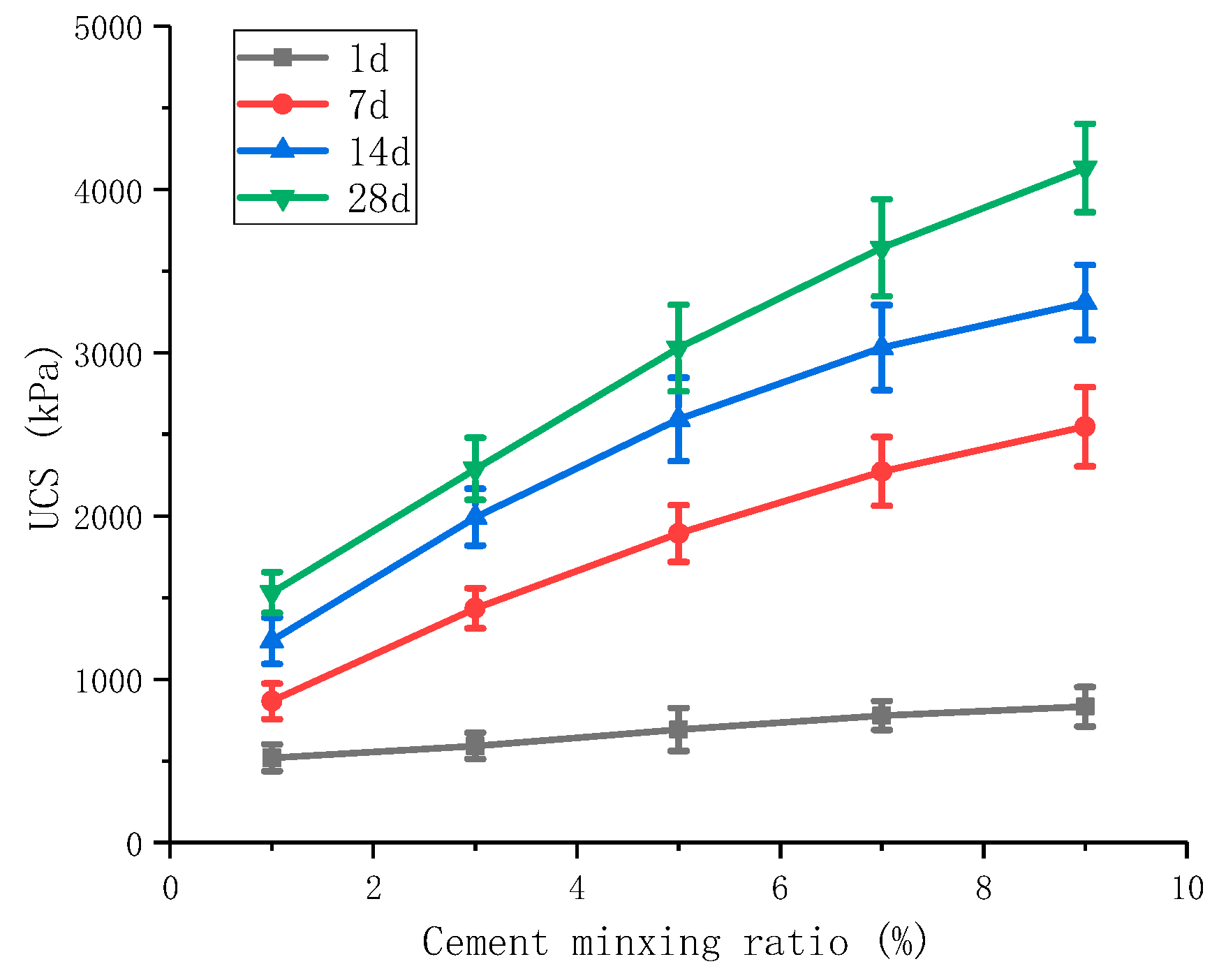

3.2.1. Effect of Nano-SiO2 and Cement Co-Modification

3.2.2. Effect of Nano-SiO2 Co-Modification with Cement and Gypsum

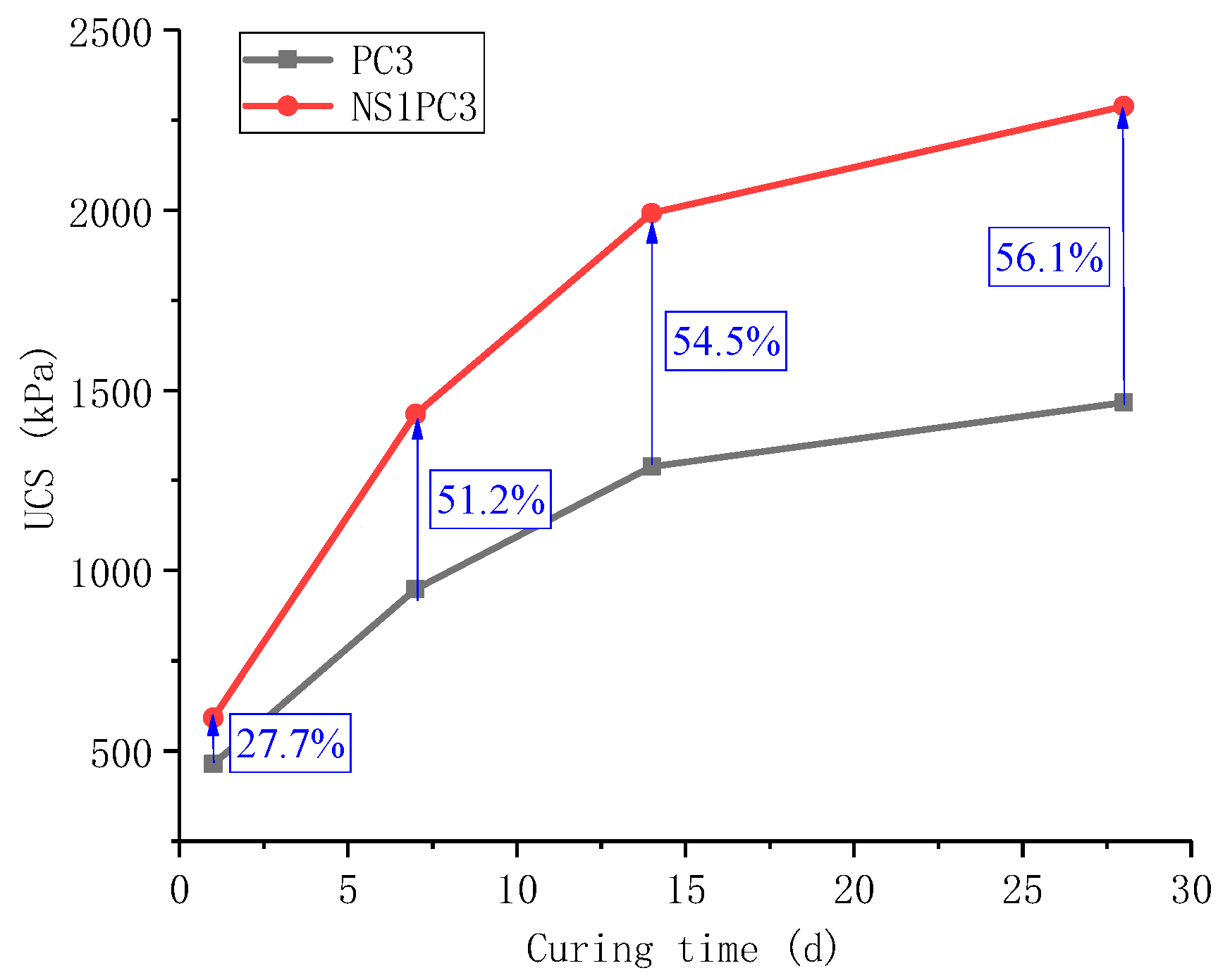

3.2.3. Analysis of the Synergistic Effect of Nano-SiO2

- (1)

- When the red mud is unmodified, the unconfined compressive strength of the specimens made under the conditions of 93% compaction, optimum moisture content, and maximum dry density is 388 kPa, which has a structural strength. However, because no modified material is added, the unconfined compressive strength cannot be enhanced with the increase in curing time. At the same time, the structure of the compacted specimens will be damaged if disturbed by external forces.

- (2)

- Cement modification alone can make the red mud-based stabilized soil obtain higher compressive strength than that of unmodified, and the 7 d unconfined compressive strength with 3% cement admixture is 948 kPa, which is about 2.5 times that of unmodified compressive specimens. When 1% nano-SiO2 was added, the compressive strength of the red mud-based stabilized soil reached 1434 kPa, which was 1.5 times that of the compressive strength of the red mud-based stabilized soil modified by PC3 alone. The synergistic effect of nano-SiO2 promoted the modification of the red mud-based stabilized soil and led to further growth of the lateral-free compressive strength.

- (3)

- When nano-SiO2 was modified with CS6 and PC3, the modified red mud-based stabilized soil obtained higher unconfined compressive strength. The 7 d unconfined compressive strength obtained at 1% nano-SiO2 was 2748 kPa, which was greater than the strength of 591 kPa of NS1 modified with CS6 and 1434 kPa of NS1 modified with PC3, and greater than the sum of 2025 kPa. This value is greater than the strength of NS1-modified soil with CS6 of 591 kPa and the strength of NS1-modified soil with PC3 of 1434 kPa and is greater than the sum of both of them of 2025 kPa. The synergistic effect of nano-SiO2 with CS and PC has obtained the effect of “1 + 1 > 2”.

- (4)

- The above series of unconfined compressive strength tests gradually revealed the optimal amount of the three modified materials while further revealing the superiority of the synergistic effect to enhance the compressive strength of the modified materials, and NS1CS6PC3 was the best modified solution for the test from both economic and strength considerations.

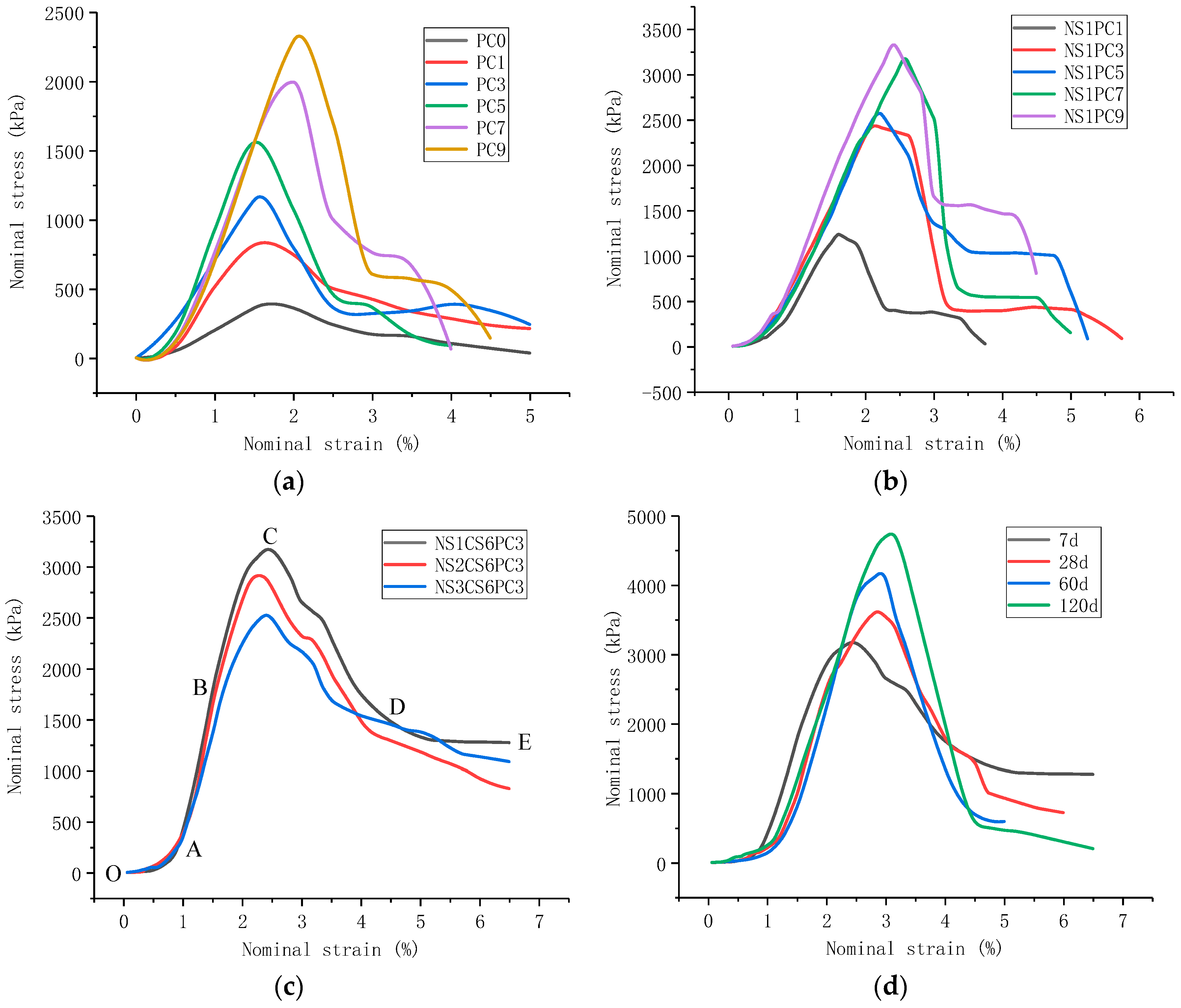

3.3. Compressive Damage Characteristics of Red Mud-Based Stabilized Soil

3.3.1. Typical Damage Characteristics

3.3.2. Nominal Stress–strain Relationship

4. Conclusions

- (1)

- Cement alone can improve the unconfined compressive strength of red mud-based stabilized soil; when nano-SiO2 is modified with cement, nano-SiO2 can significantly improve the early unconfined compressive strength of red mud-based stabilized soil; when nano-SiO2, gypsum, and cement are modified with 6% gypsum and 3% cement, under the synergistic effect of nano-SiO2 (1%, 2%, and 3%, respectively), the 7 d unconfined compressive strength of the red mud-based stabilized soil was greater than 2 MPa. The maximum was achieved at 1% nano-SiO2, satisfying the strength requirements of the roadbed material. The synergistic results of the addition of nano-SiO2, gypsum, and cement showed the superiority of synergy. Compared with other modification research results, the amount of red mud in the red mud-based stabilized soil is relatively high, accounting for 90%, so the application of the research results in roadbed filling can consume a large amount of red mud and has a good development prospect.

- (2)

- The compressive damage patterns of the specimens showed that most of the modified terracotta-based stabilized soils exhibited brittle damage, especially when the modified materials and the age of maintenance promoted conditions that increased the nominal stresses. Under the condition of increasing uniaxial pressure, vertical cracks appeared in the specimens first, and with the increase in cracks, slip appeared at the bottom. As the pressure increases, transverse cracks appear in the specimen, and the transverse cracks promote shear damage on one side of the specimen. When the other side without transverse shear damage also produces damage, the specimen is finally completely destroyed.

- (3)

- The compressive deformation of the red mud-based stabilized soil shows the characteristics of elastic-plastic deformation, and the nominal stress–strain curves of the red mud-based stabilized soil under each modified condition are divided into five stages: “compressive compacting stage”, “elastic deformation and plastic deformation stage”, “damage deformation and residual deformation stage”, and so on. Most of the specimens showed “damage platform”. Most of the specimens showed a ductile character with small changes in stress but with an increase in stress variation before the resistance to compression was completely lost, indicating that the red mud-based stabilized soil has good buffering performance. It is more suitable to be applied as road base material for general roads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shirdam, R.; Sadeghi, B.; Rad, M.R.; Bakhshi, N.; Mirzaei, H.A. Reusing red mud waste and low grade bauxite as raw materials for brick manufacturing by experimental design technique. Int. J. Environ. Waste Manag. 2021, 27, 46. [Google Scholar] [CrossRef]

- Piirainen, V.Y.; Barinkova, A.A.; Starovoytov, V.N.; Barinkov, V.M. Deactivation of Red Mud by Primary Aluminum Production Wastes. Mater. Sci. Forum 2021, 1040, 109–116. [Google Scholar] [CrossRef]

- Joseph, C.G.; Yap, Y.H.T.; Krishnan, V.; Puma, G.L. Application of modified red mud in environmentally-benign applications: A review. Environ. Eng. Res. 2019, 25, 795–806. [Google Scholar] [CrossRef]

- Singh, G.; Kumar, H.; Singh, S. Mechanical performance of red mud polymer concrete composites fabricated using recycled PET resin. Abstr. Int. Conf. Meet. 2021, 1, 21. [Google Scholar]

- Gupta, T.; Agrawal, Y.; Kanyal, K.S. Properties of Sustainable Concrete Containing Red Mud: A Review. J. Sci. Res. Rep. 2021, 27, 15–26. [Google Scholar]

- Bombik, E.; Bombik, A.; Rymuza, K. The influence of environmental pollution with fluorine compounds on the level of fluoride in soil, feed and eggs of laying hens in Central Pomerania, Poland. Environ. Monit. Assess. 2020, 192, 178. [Google Scholar] [CrossRef]

- Lockwood, C.L.; Stewart, D.I.; Mortimer, R.; Mayes, W.M.; Jarvis, A.P.; Gruiz, K.; Burke, I.T. Leaching of copper and nickel in soil-water systems contaminated by bauxite residue (red mud) from Ajka, Hungary: The importance of soil organic matter. Environ. Sci. Pollut. Res. 2015, 22, 10800–10810. [Google Scholar] [CrossRef]

- Chandra, S.; Krishnaiah, S.; Sahile, K. Utilization of Red Mud-Fly Ash Reinforced with Cement in Road Construction Applications. Adv. Mater. Sci. Eng. 2021, 2021, 3728652. [Google Scholar]

- Atan, E.; Sutcu, M.; Cam, A.S. Combined effects of bayer process bauxite waste (red mud) and agricultural waste on technological properties of fired clay bricks. J. Build. Eng. 2021, 43, 103194. [Google Scholar] [CrossRef]

- Putrevu, M.; Thiyagarajan, J.S.; Pasla, D.; Kabeer, K.S.A.; Bisht, K. State-of-the-Art Review Valorization of Red Mud Waste for Cleaner Production of Construction Materials. J. Hazard. Toxic Radioact. Waste 2021, 25, 03121002. [Google Scholar] [CrossRef]

- Beulah, M.; Sudhir, M.R.; Mohan, M.K.; Gayathri, G.; Jain, D. Mine Waste-Based Next Generation Bricks: A Case Study of Iron Ore Tailings, Red Mudand GGBS Utilization in Bricks. Adv. Mater. Sci. Eng. 2021, 2021, 9499613. [Google Scholar] [CrossRef]

- Ou, X.; Chen, S.; Jiang, J.; Qin, J.; Zhang, L. Reuse of Red Mud and Bauxite Tailings Mud as Subgrade Materials from the Perspective of Mechanical Properties. Materials 2022, 15, 1123. [Google Scholar] [CrossRef]

- Ma, Q.; Duan, W.; Liu, X.; Fang, P.; Chen, R.; Wang, T.; Hao, Z. Engineering Performance Evaluation of Recycled Red Mud Stabilized Loessial Silt as a Sustainable Subgrade Material. Materials 2022, 9, 3391. [Google Scholar] [CrossRef]

- Yadav, G.V. Experimental Investigation on Cement Replacement with Red Mud Sludge of M60 Grade Concrete. 2020. Available online: https://www.irjet.net/archives/V7/i12/IRJET-V7I1281.pdf (accessed on 1 August 2023).

- Sethy, K.; Sitha, R.K.; Barpanda, S.; Bhoi, B.R. Experimental investigation of strength properties of red mud concrete. AIP Conf. Proc. 2019, 2158, 020015. [Google Scholar]

- Huynh, T.P. Evaluation of Properties of Controlled Low-Strength Material Produced Using a Ternary Mixture of Waste Red Mud, Slag and Portland Cement. 2018. Available online: https://media.neliti.com/media/publications/452907-none-aaa6c3ab.pdf (accessed on 1 August 2023).

- Jothilingam, M.; Paul, P. Study on the strength characteristics of carbonated red mud concrete. Pollut. Res. 2018, 37, 424–429. [Google Scholar]

- Ou, X.; Chen, S.; Jiang, J.; Qin, J.; Tan, Z. Analysis of Engineering Characteristics and Microscopic Mechanism of Red Mud-Bauxite Tailings Mud Foam Light Soil. Materials 2022, 15, 1782. [Google Scholar] [CrossRef] [PubMed]

- Mukiza, E.; Zhang, L.; Liu, X.; Zhang, N. Utilization of red mud in road base and subgrade materials: A review. Resour. Conserv. Recycl. 2019, 141, 187–199. [Google Scholar] [CrossRef]

- Li, H.D.; Yue, H.Z.; Liu, J.C.; Li, Z.C.; Z, N. Review on prevention and control of red mud radioactivity. J. Shandong Univ. Technol. (Nat. Sci. Ed.) 2020, 34, 40–43+48. (In Chinese) [Google Scholar]

- Gayathiri, K.; Praveenkumar, S. Influence of Nano Silica on Fresh and Hardened Properties of Cement-based Materials—A Review. Silicon 2022, 14, 8327–8357. [Google Scholar] [CrossRef]

- Lin, R.S.; Oh, S.; Du, W.; Wang, X.Y. Strengthening the performance of limestone-calcined clay cement (LC3) using nano silic. Constr. Build. Mater. 2022, 340, 127723. [Google Scholar] [CrossRef]

- Kumar, D.P.; Amit, S.; Chand, M. Influence of various nano-size materials on fresh and hardened state of fast setting high early strength concrete [FSHESC]: A state-of-the-art review. Constr. Build. Mater. 2021, 277, 122299. [Google Scholar] [CrossRef]

- Nandhini, K.; Ponmalar, V. Effect of Blending Micro and Nano Silica on the Mechanical and Durability Properties of Self-Compacting Concrete. Silicon 2021, 13, 687–695. [Google Scholar] [CrossRef]

- Ahmed, S.; Meng, T.; Taha, M. Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening. Nanotechnol. Rev. 2020, 9, 396–409. [Google Scholar] [CrossRef]

- GB/T50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- HJ/T 300-2007; Solid Waste-Extraction Procedure for Leaching Toxicity-Acetic Acid Buffer Solution Method. PRC Environmental Protection Agency: Beijing, China, 2007.

- GB 16889-2008; Standard for Pollution Control on the Landfill Site of Municipal Solid Waste. Ministry of Environmental Protection: Beijing, China, 2008.

- ASTM C150/C150M-2021; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2021.

- Li, X.F.; Guo, Y.; Zhu, F.; Huang, L.B.; Hartley, W.; Li, Y.W.; Kong, X.F.; Xue, S.G. Alkalinity stabilization behavior of bauxite residue: Ca-driving regulation characteristics of gypsum. J. Cent. South Univ. 2019, 26, 383–392. [Google Scholar] [CrossRef]

- JTG E51-2009; Test Method of Materials Stabilized whit Inorganic Binders for Highway Engineering. People’s Traffic Publishing House: Beijing, China, 2009.

- Liu, S.; Li, Z.; Li, Y.; Cao, W. Strength properties of Bayer red mud stabilized by lime-fly ash using orthogonal experiments. Constr. Build. Mater. 2018, 166, 554–563. [Google Scholar] [CrossRef]

- Ansoff, H.I. The emerging paradigm of strategic behavior. Strateg. Manag. J. 2011, 8, 501–515. [Google Scholar] [CrossRef]

- JTG/T F20-2015; Technical Guidelines for Construction of Highway Roadbases. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

| Projects | Cu | Zn | Pb | Cd | Ni | As | Cr |

|---|---|---|---|---|---|---|---|

| leaching concentration (mg/L) | 0.27 | 0.02 | 0.01 | 0.10 | 0.12 | 0.17 | 0.09 |

| mass concentration limit (mg/L) | 40 | 100 | 0.25 | 0.15 | 0.50 | 0.30 | 4.5 |

| Projects | Synergistic Solution Portfolio | ||||

|---|---|---|---|---|---|

| Program 1 | Program 2 | Program 3 | Program 4 | Program 5 | |

| RM unmodified | RM | ||||

| PC individually modified | PC1 | PC3 | PC5 | PC7 | PC9 |

| NS + PC synergistic modification | NS1PC1 | NS1PC3 | NS1PC5 | NS1PC7 | NS1PC9 |

| NS + CS6 + PC3 synergistic modification | NS0.5CS6PC3 | NS1CS6PC3 | NS2CS6PC3 | NS3CS6PC3 | |

| Projects | NS Doping | Remarks | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 0.5% | 1% | 1.5% | 2% | 2.5% | 3% | ||

| RM unmodified | 388 | Control test | ||||||

| PC3 separately modified | 948 | |||||||

| NS1 + PC3 synergistic modification | 1434 | |||||||

| NS + CS6 + PC3 synergistic modification | 2421 | 2748 | 2467 | 2156 | ||||

| Curing Period (d) | 0 | 14 | 28 | 60 | 120 |

|---|---|---|---|---|---|

| Residual stress/peak stress | 0.53 | 0.44 | 0.24 | 0.16 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Jiang, J.; Ou, X.; Tan, Z. Analysis of the Synergistic Effect on the Strength Characteristics of Modified Red Mud-Based Stabilized Soil. Materials 2023, 16, 6104. https://doi.org/10.3390/ma16186104

Chen S, Jiang J, Ou X, Tan Z. Analysis of the Synergistic Effect on the Strength Characteristics of Modified Red Mud-Based Stabilized Soil. Materials. 2023; 16(18):6104. https://doi.org/10.3390/ma16186104

Chicago/Turabian StyleChen, Shengjin, Jie Jiang, Xiaoduo Ou, and Zhijie Tan. 2023. "Analysis of the Synergistic Effect on the Strength Characteristics of Modified Red Mud-Based Stabilized Soil" Materials 16, no. 18: 6104. https://doi.org/10.3390/ma16186104

APA StyleChen, S., Jiang, J., Ou, X., & Tan, Z. (2023). Analysis of the Synergistic Effect on the Strength Characteristics of Modified Red Mud-Based Stabilized Soil. Materials, 16(18), 6104. https://doi.org/10.3390/ma16186104