1. Introduction

Optical 3D scanners are used in a wide range of applications for their ability to digitize physical objects into the virtual environment. They are typically used for reverse engineering, geometric and dimensional inspection, medical purposes, etc. This work focused on active optical triangulation-based 3D scanners, specifically structured light scanners. The working principle of these scanners is described in the work of Sansoni [

1]. The scanner consists of a projector and camera/s. The projector projects a light pattern on the scanned object, which is deformed by the object geometry, and the cameras capture the scene. The orientation and position of the projector and cameras in the scanner body are known thanks to the calibration. It enables the reconstruction of the scanned objects by triangulation.

The advantages of structured light scanners are their scanning speed and the fact that they are non-contact. However, they have limitations when objects with problematic surfaces must be scanned, typically specular (reflective), translucent, transparent, or dark surfaces [

2]. It is coupled with the working principle of these scanners when the projected light is reflected from the scanned object. A proper reflection from the scanned surface is thus essential. Phenomena coupled with the scanning of the specular surface were described in the work of Wang and Feng [

3]. In this case, the most problematic is a specular reflection. In the work of Chen [

4], the effect of the translucent surface on the results of structured light 3D scanning was discussed. Projected light can penetrate the translucent surface, resulting in the wrong computation of a depth coordinate of the scanned point cloud, which can lead to a non-accurate 3D scan. In the case of transparent surfaces, conventional scanners fail completely. The problem with dark surfaces is that they absorb the projected light and thus reduce the amount of reflected light into the cameras of the scanner. The influence of the scanned surface color on the results of 3D scanning was investigated in the work of Zaimović-Uzunović and Lemeš [

5]. All problematic surfaces generally lead to 3D scans with errors or scans with insufficient information about the digitized surface.

There are two approaches for digitizing problematic objects using the 3D scanner. The first one is based on using special 3D scanning techniques. The main drawback of this approach is that each type of problematic surface requires a different scanning technique with specific hardware and software. This is reported in the work of Ihrke [

6]. The second approach is based on using a temporary matte coating. In this case, the scanned surface is covered by a matte coating, which improves its optical properties and enables its digitization. The main advantage of this approach is that it is usable for all conventional 3D scanners. The disadvantage of this approach is that the applied coating can change the geometry of the scanned object because it is an added material on the surface of the scanned body, as was stated in the work of Rukosuyev [

7]. For accurate 3D scanning, the coating thickness must be as thin as possible and at the same time must sufficiently improve the optical properties of the scanned surface. The topic of the fine even coating was also the scope of the work of Maeng and Lee [

8]. They explored the usability of electrostatic powder coating for 3D scanning purposes. In this study, both coating and removal process were investigated.

The work of Paloušek [

9] was focused on the effect of matte coating on the accuracy of optical 3D scanning. A chalk spray and titanium dioxide (TiO

2) deposited by an airbrush gun were used as the coating materials. The coating thickness of the chalk spray was around 44 µm, while the titanium-based coating was almost ten times thinner. The coating thickness values were obtained based on the 3D scanning of the coated gauges. Another paper dealing with TiO

2-based coatings and their effect on 3D scanning accuracy is the work of Franke [

10]. This work was focused on optimizing the process of matte coating deposition in terms of coating thickness and matting ability. The resulting coatings had a thickness below 1 µm and provided sufficient optical properties for accurate 3D scanning. The coating thickness in this study was measured by stylus profilometer. The work of Pereira [

2] is another study focusing on the effect of the coating material on 3D scanning accuracy. The gold, silver, platinum, and carbon deposited by sputtering were used as coating materials. All these materials were suitable for accurate 3D scanning and measurements with a tolerance of up to 0.01 mm, compared to the traditionally used developer. The effect of the matte coating on the 3D scanning accuracy in dental applications was discussed in the work of Burde [

11]. Aerosol sprays, such as Helling 3D Laser Scanning Anti-Glare and Digiscan-Spray, were used as matting agents. Both sprays had acceptable coating thickness for clinical use. The coating thickness was around 16.1 µm for the Helling spray and 13.6 µm for the Digiscan spray. The coating thickness values were obtained by comparing the 3D scans of the non-coated and coated part. The work of Yang [

12] studied the effect of the chalk spray coating on the 3D scanning results. In this case, the effects of spray condition and spray operator skills on the precision of 3D scanning were investigated.

From the nature of the previously mentioned coating materials, there is one more disadvantage of matte coatings. Cleaning must be performed to remove the coating from the surface of the scanned object. The cleaning is generally conducted by wiping with a cloth or with a brush or by washing. Sometimes, an ultrasonic cleaner must be used. However, in some cases, even an ultrasonic cleaner cannot completely remove the coating material from the surface. This is typical for TiO

2-based coatings and their application on rubber surfaces, rough surfaces, surfaces with complex geometry, etc. This disadvantage can be eliminated by using sublimation scanning sprays, which spontaneously vanish from the scanned surface after 3D scanning. Sublimation coatings were investigated in the work of Díaz-Marín [

13]. In this case, cyclododecane was used as a coating agent for the 3D scanning of archaeological objects. The sublimation rate measurement in this study was based on the scanning process. The effective time in which cyclododecane can be used as an opacifier for acquisition purposes was estimated. Nowadays, there are sublimation materials developed especially for 3D scanning on the market, which are listed as follows: Aesub (Scanningspray Vertriebs GmbH, Recklinghausen, Germany), Reflecon Type 1 (MR Chemie GmbH, Unna, Germany), and Attblime (Graichen Produktions- und Vertriebs GmbH, Bensheim, Germany) [

14,

15,

16]. Currently, the only information about these materials is stated in the datasheets provided by their manufacturers, i.e., currently, there is a knowledge gap in the investigation and verification of their properties in terms of matting efficiency, thickness, or sublimation time.

The main goal of this work is a comparison of a wide range of commercially available sublimation scanning sprays. This work verified the effect of the number of applied coating layers on the 3D scanning results and coating thickness. This study also investigated the overall one-layer coating sublimation time. The work considered constant conditions for all experiments and coating deposition to maximize objectivity when comparing individual materials.

2. Materials and Methods

Scanning sprays used in this work are stated in

Table 1. Currently available commercial sprays that were dedicated as sublimation scanning sprays were used for the purpose of this work. The abbreviations stated in

Table 1 are used further in this work for a distinction of the sprays. All tested materials were delivered as aerosol spray cans. In the right column, sublimation times declared by the manufacturers of the scanning sprays are also mentioned. The sprays RefT50, AtAB6, AtAB2, and AtAB0 are cyclododecane-based, while the other sprays are based on other materials. The exact composition of the products is not specified by the manufacturers.

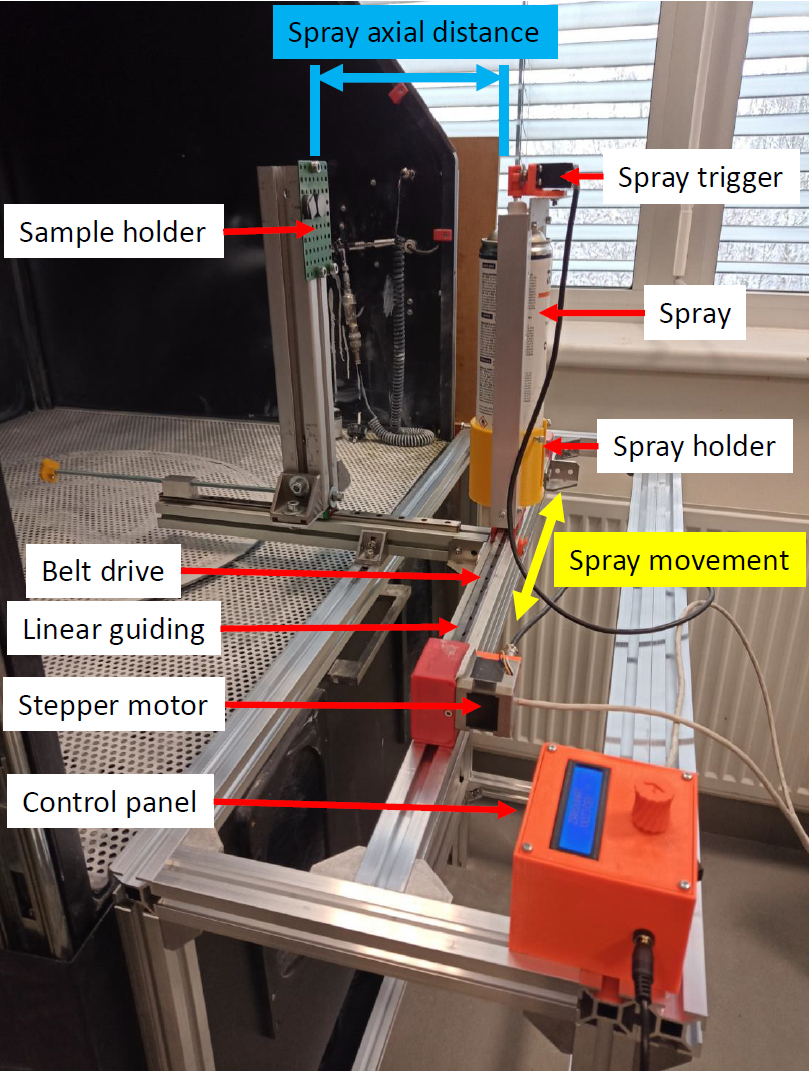

An automated coating deposition system was used to ensure uniform conditions for coating application (see

Figure 1).

Spray movement was ensured by a stepper motor with a belt drive and linear guiding. Coating deposition from the spray can was turned on using a servo motor with a trigger placed on the top of the spray holder (see

Figure 1). The trigger intensity was set the same for all used scanning sprays. Spray movement speed, number of deposited coating layers, and triggering of the spray were driven by a microcontroller Arduino placed in the control panel. The spray movement speed was set at a constant 800 mm/s for all performed experiments. The spray axial distance was also set as constant, and all coatings were deposited at a distance of 175 mm from the spray nozzle. The spray movement speed and deposition distance were set experimentally to avoid over-spraying after one spray pass. Coating deposition was conducted perpendicularly to the coated surfaces, and the spray axis was directed at the center of the sample. Four samples were created for each measurement. All experiments were performed under constant ambient conditions. The ambient temperature for all experiments was 21 ± 1 °C. All experiments were performed 2 min after the coating deposition to eliminate the effect of the ambient environment and the time-dependent behavior of the coatings.

2.1. Coated Objects

A highly reflective Si-wafer (15 × 15 × 0.5 mm) was used for the surface coverage analysis, the analysis of the matting efficiency, and the measurement of the sublimation time. The Si-wafer was chosen for its excellent flatness (<400 nm) and low roughness (Ra ≈ 1 nm). The flatness and roughness of the Si-wafer were measured by the stylus profiler Bruker DektakXT (Bruker, Billerica, MA, USA), with a stylus radius of 12.5 μm, a stylus force of 3 mg, and a scan duration of 160 s. The surface of the Si-wafer is impossible to scan without a matte coating, which was necessary for matting efficiency analysis. Excellent flatness and low roughness were necessary to determine the effect of matte coating on the 3D scan quality.

A white ceramic gauge block with a nominal dimension of 30 mm (30 × 35 × 9 mm) was used for the measurement of the coating thickness. It was used because its surface is possible to scan without matte coating and for its precise geometry.

Objects used for the coating deposition were not pretreated before the matting process. Wiping with the cloth was performed before testing to remove the dust and other impurities from the test surface. This corresponds to a common workflow during the 3D scanning process.

2.2. 3D Scanning

Atos III Triple Scan (Carl Zeiss GOM Metrology GmbH, Braunschweig, Germany) was used for 3D scanning. The 3D scanner was used for the verification of the effect of the coating on the 3D scan quality and the coating thickness measurement. The process of 3D scanning was automated using an assembly with the lift and rotation table to ensure uniform conditions during measurements, and each sample was scanned in one shot. Scanning details are mentioned in

Table 2. A 3D scanning setup differed for the Si-wafer and ceramic gauge block measurement.

2.2.1. 3D Scanning of the Si-Wafer

The Si-wafer was scanned by a measuring volume MV60, with perpendicular scanning orientation between the scanner and wafer. MV60 offered the best possible measuring point distance. Perpendicular orientation offered the worst scanning scenario when the light was reflected directly on the cameras of the scanner. This measurement was made to investigate the effect of matte coating on the 3D scan quality and its ability to improve the 3D scanning of the highly reflective surface. The analysis of the 3D scans was performed in the software GOM Inspect (Carl Zeiss GOM Metrology GmbH, Braunschweig, Germany). The coating ability to improve 3D scanning was evaluated by measuring the area captured by the scanner and the number of holes in the scanned mesh. The size of the evaluated area was 12 × 12 mm. The 3D scan quality was evaluated by the standard deviation (Sigma) of the captured point cloud against the fitted plane. The fitted plane was created using the Gaussian Best-fit method, with a selection of points in the range of 3σ.

2.2.2. 3D Scanning of the Ceramic Gauge Block

The gauge block was scanned by measuring volume MV170 due to its larger dimensions. In this case, the scanning orientation was set as 45° to eliminate problematic direct reflections during 3D scanning. This measurement was conducted to investigate the coating thickness. The use of 3D scanner for the coating thickness measurement was motivated by the following statements: Firstly, 3D scanning results can show the effect of the coating on the 3D scanning accuracy, i.e., 3D scanning results can show if the coating is detectable by the scanner. Secondly, the 3D scanner can capture the entire coated surface in one shot. It was necessary to eliminate the time-dependent behavior of deposited coatings. The gauge block was coated in the middle of the surface, defining its nominal dimension (see

Figure 2). The width of the coated area was 15 mm. The rest of the surface remained uncoated, which defined a zero reference plane. This was achieved using a clamping mask during the coating deposition.

The coating thickness was measured in the software GOM Inspect. The distance between the coated area and the zero reference plane was measured using the Projected Point Distance function. The measurement was conducted for 9 measuring points. The first measuring point was in the center of the coated area. The rest of the measuring points were offset from the center point by ±1.5 mm in the Y direction and by ±5 mm in the Z direction.

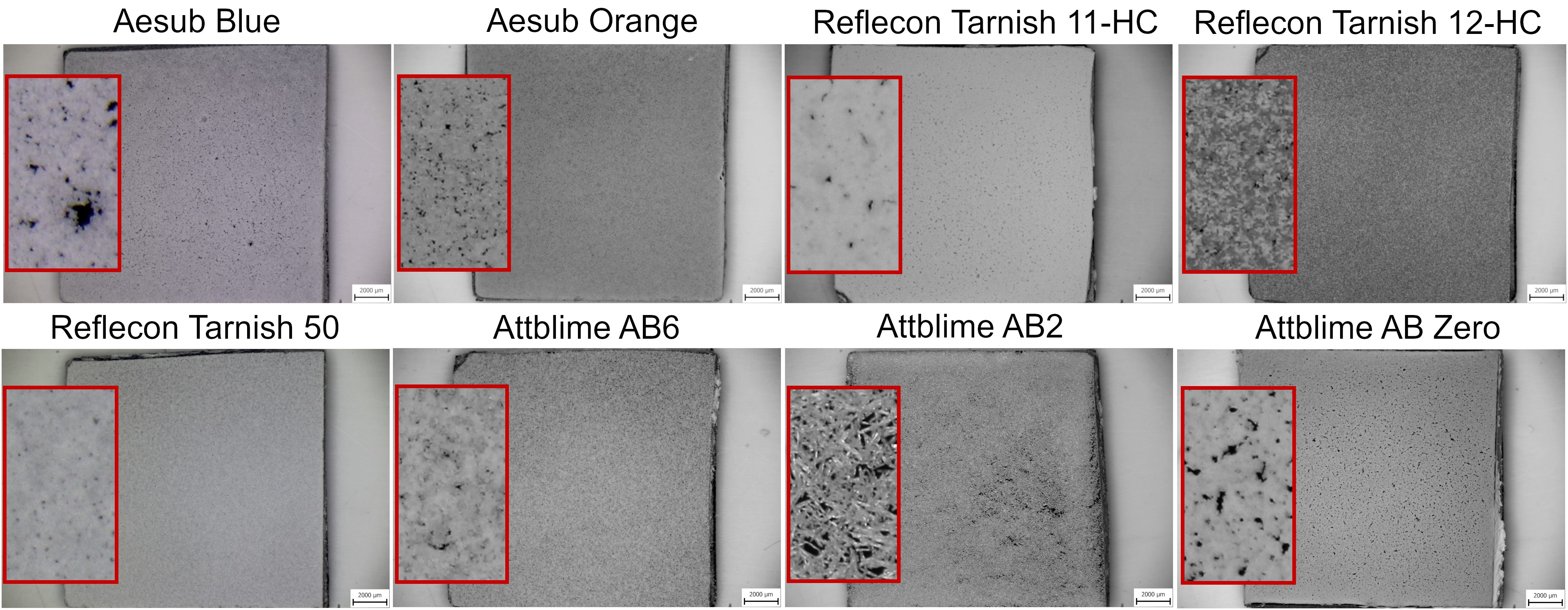

2.3. Coverage of the Si-Wafer by the Coating

The analysis of the coverage of the Si-wafer by the coating was performed to determine the amount of deposited coating material. Coatings were captured by an optical microscope Olympus SZX7 (Olympus, Tokyo, Japan). Magnification was set as 1. The percentage overlap of the wafer surface by the coating was measured in the software ImageJ, Version 1.53t (NIH, Bethesda, MD, USA and LOCI, University of Wisconsin-Madison, Madison, WI, USA) using the Measure function. For this analysis, captured images were converted into a binary image by thresholding (see

Figure 3). White spots in

Figure 3 represent the coating. The thresholding was also performed in the ImageJ software, Version 1.53t, where the threshold was set using the Yen algorithm [

17].

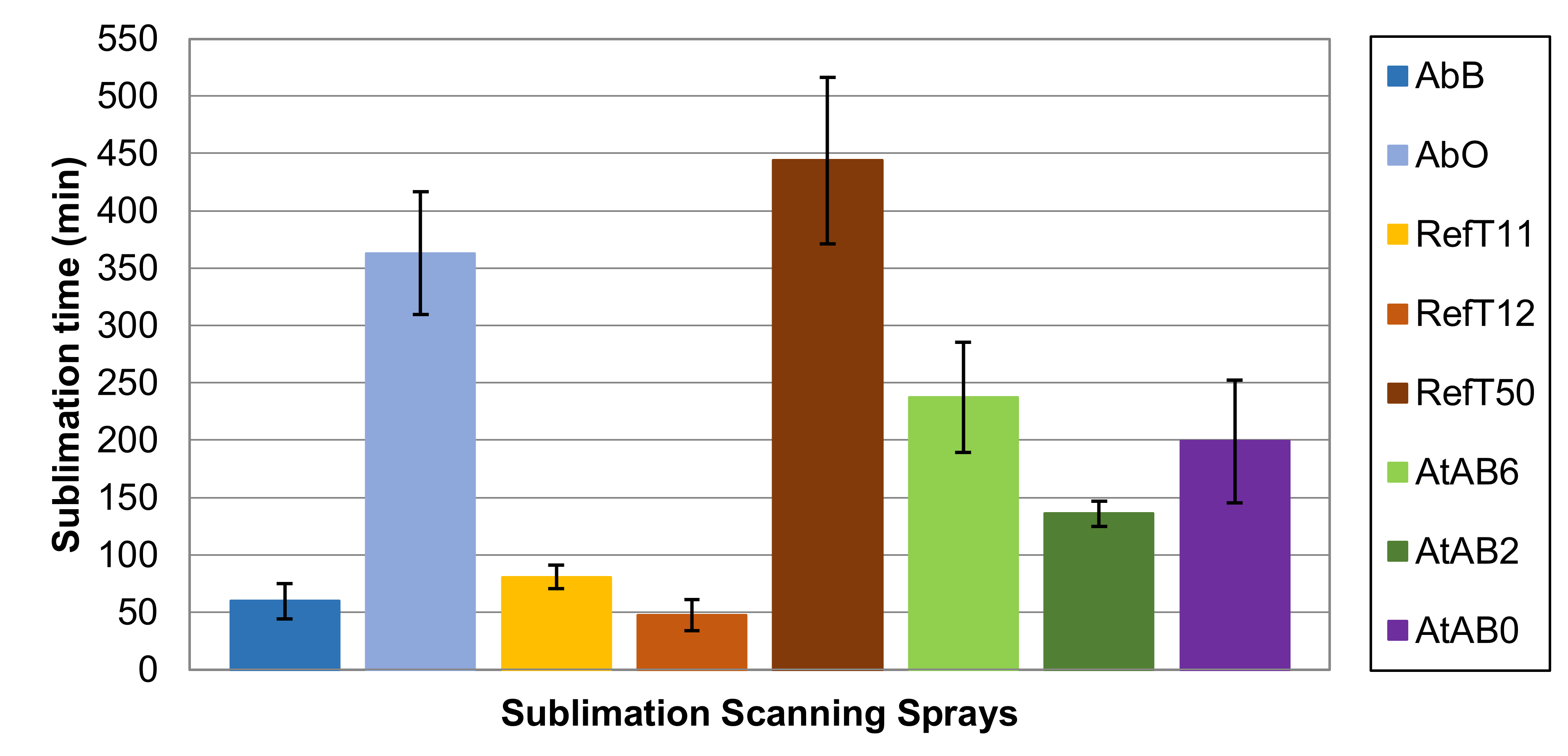

2.4. Sublimation Time Measurement

The sublimation time measurement was performed in the closed box (180 × 120 × 130 mm), which eliminated the effect of the ambient environment. Sublimation time was measured based on the images taken by the camera Imaging Source DMK 23U618 (The Imaging Source, LLC, Charlotte, NC, USA) with the lens Computar T0812FICS-3 (CBC Group, Tokyo, Japan). Samples were photographed every 60 s, and the sublimation time was computed from the time stamps of the taken photos. Measurements were automated using Python script and microcontroller Arduino. The sublimation time represents the moment when the coating completely disappeared from the surface of the Si-wafer after its deposition.

4. Conclusions

This study focused on the comparison of eight sublimation scanning sprays in terms of their effect on the 3D scanning results, coating thickness, and sublimation time. All coatings were applied by the automated system, and all experiments were performed under constant ambient conditions, two minutes after their deposition. The ability of the sublimation coating to improve 3D scanning was investigated on the highly reflective surface of the Si-wafer. The coated surface was reconstructed by the structured light 3D scanner. This study proved that all used materials were able to improve the optical properties of the Si-wafer surface. The results also showed that sublimation scanning sprays can be a suitable alternative for scanning problematical surfaces when the cleaning process must be eliminated or excluded from the scanning process. However, the differences between some sprays were significant. The general results of this study are as follows:

All tested sprays created coatings with a thickness in the order of tens of micrometers. This means that they are suitable for 3D scanning when a lower accuracy is required.

All tested materials vanished from the surface of the Si-wafer completely. However, all coatings left traces on the smooth mirror-like surface of the Si-wafer after their sublimation.

Tested sprays were divided into three categories according to their sublimation time. Short-time sublimation sprays (AbB, RefT11, and RefT12): sublimation time did not exceed 90 min. Middle-time sublimation sprays (AtAB6, AtAB2, and AtAB0): sublimation times were in the range of 130–300 min. Long-time sublimation sprays (AbO and RefT50): sublimation times were in the range of 300–500 min. The values correspond to the one-layer coatings.

The best 3D scanning results were obtained with the six-layer coating applied by the spray AbO. The standard deviation of the point cloud (Sigma) of 0.75 µm was the lowest, the Si-wafer surface was reconstructed completely without holes, and the coating thickness was, in the case of six-layer coating, around 24 µm.

The lowest ability to improve the highly reflexive surface for 3D scanning was provided by the spray AtAB2. Although this spray created one of the thinnest coatings, its coatings led to the scanning results with the lowest quality. The scans contained holes, and the Sigma values were around 9 µm.

The future direction for this research topic can be seen in the investigation of the time-dependent behavior of the sublimation coatings and its effect on the 3D scanning results. Another direction can be the investigation of how the ambient environment and the type of coated object affect deposited coatings, their sublimation time, and the associated 3D scanning results. There is also a space for investigating sublimation scanning liquids that can be applied by spray guns. Spray gun can provide more stable deposition conditions and may allow the optimization of the coating deposition process for specific requirements of the resulting coating.