Field and Laboratory Wear Tests of Machine Components Used for Renovation of Dirt Roads—A Case Study

Abstract

:1. Introduction

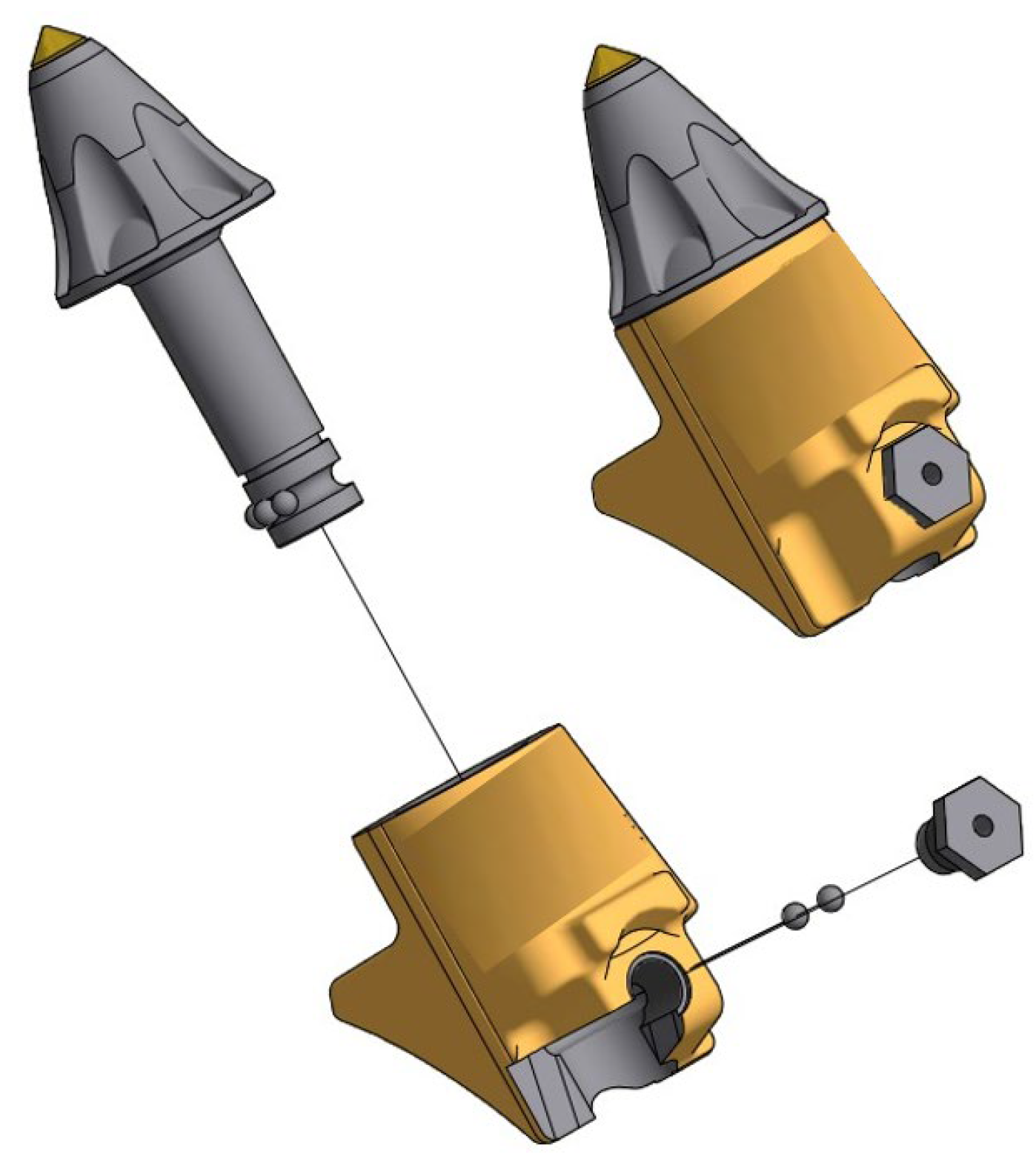

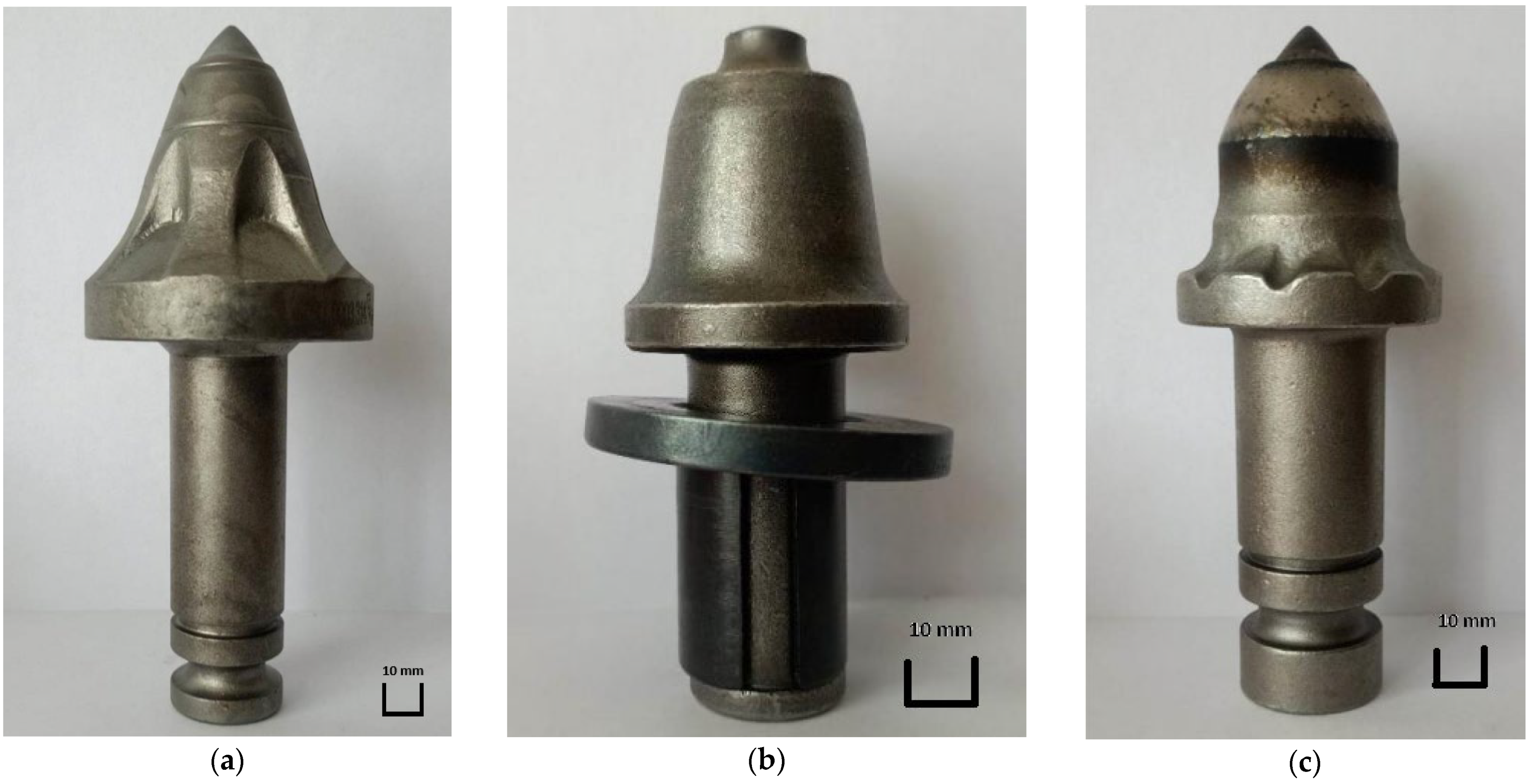

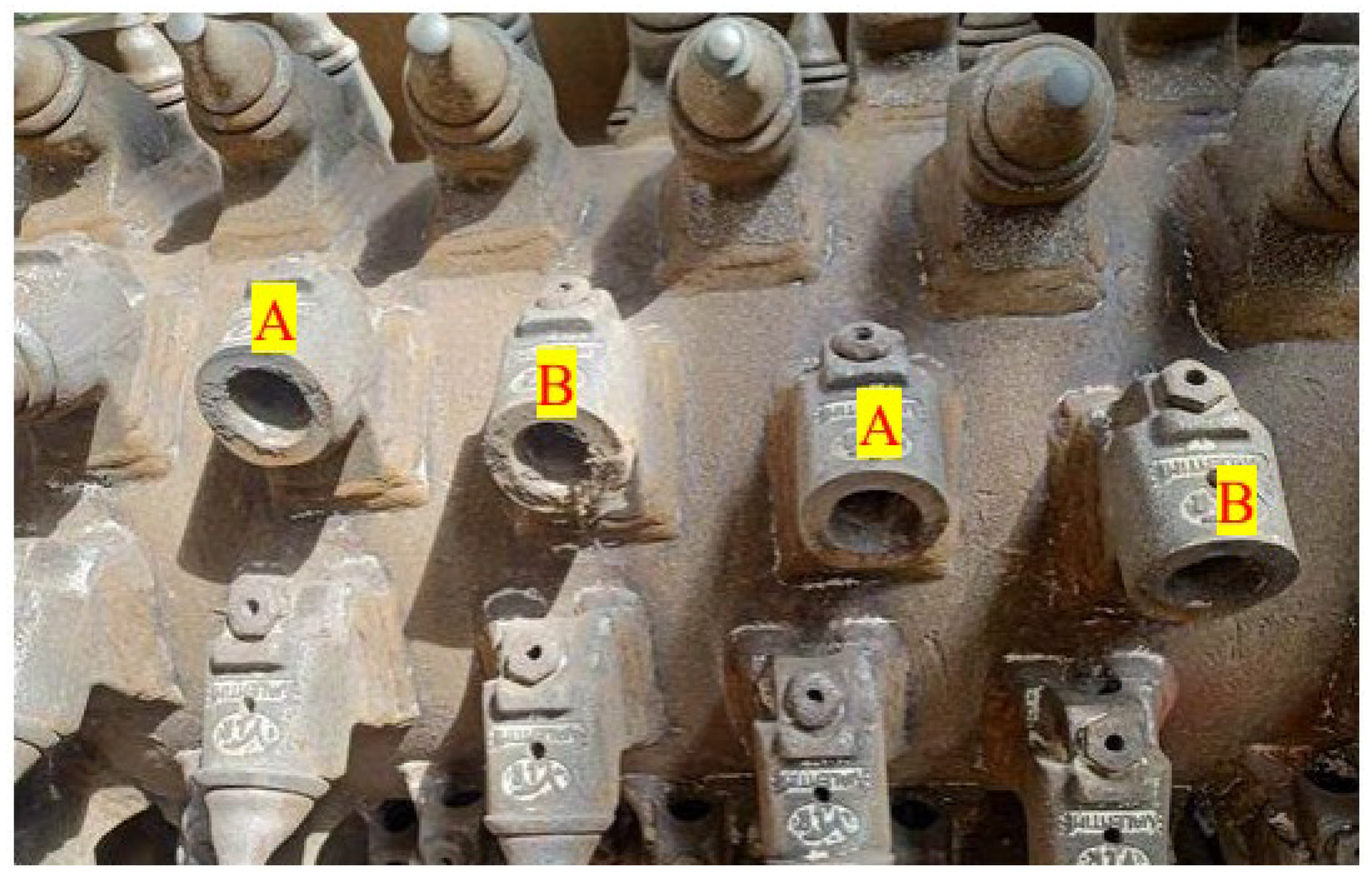

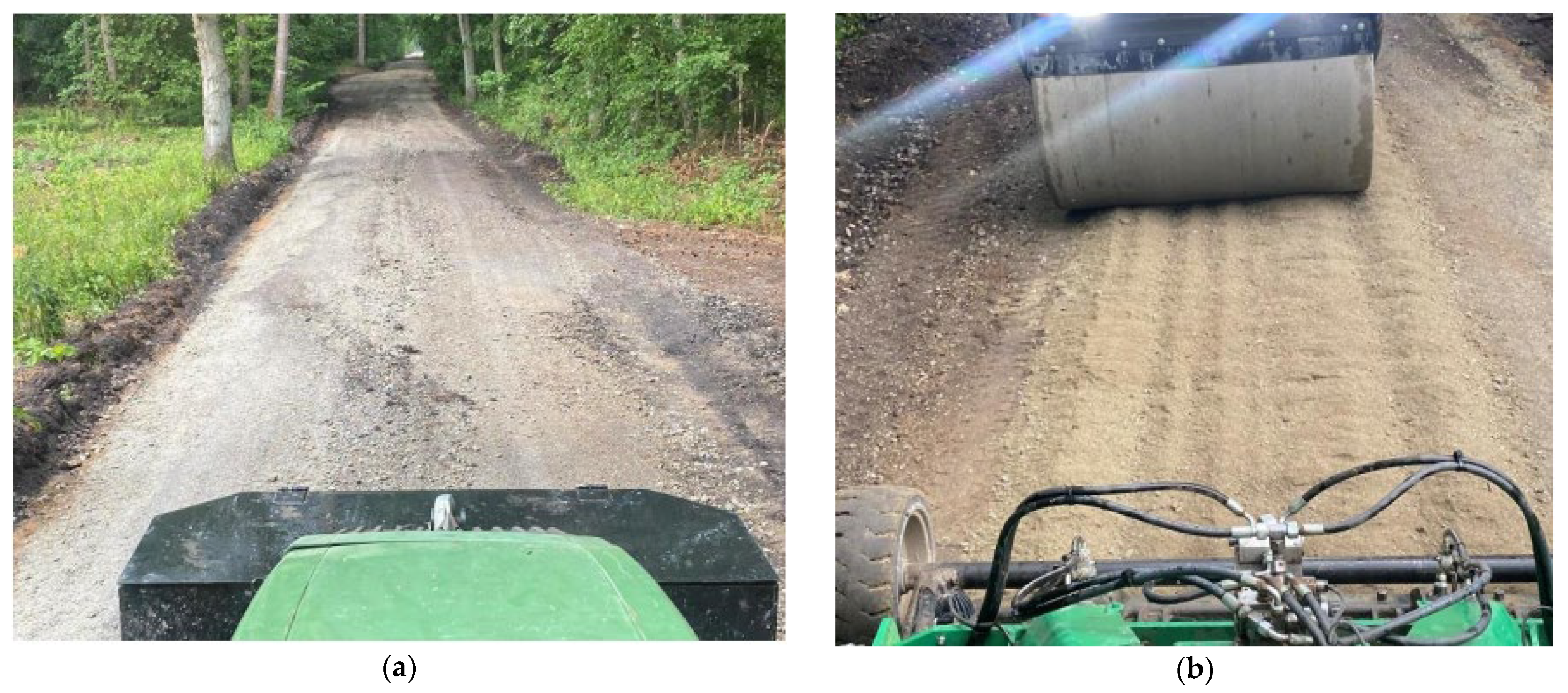

2. Materials and Methods

- Milling cutter Ø25 mm mounted on bearing balls (Ø25 mm balls);

- Milling cutter Ø25 mm mounted on expansion sleeve (Ø25 mm sleeve);

- Milling cutter Ø35 mm mounted on bearing balls (Ø35 mm balls).

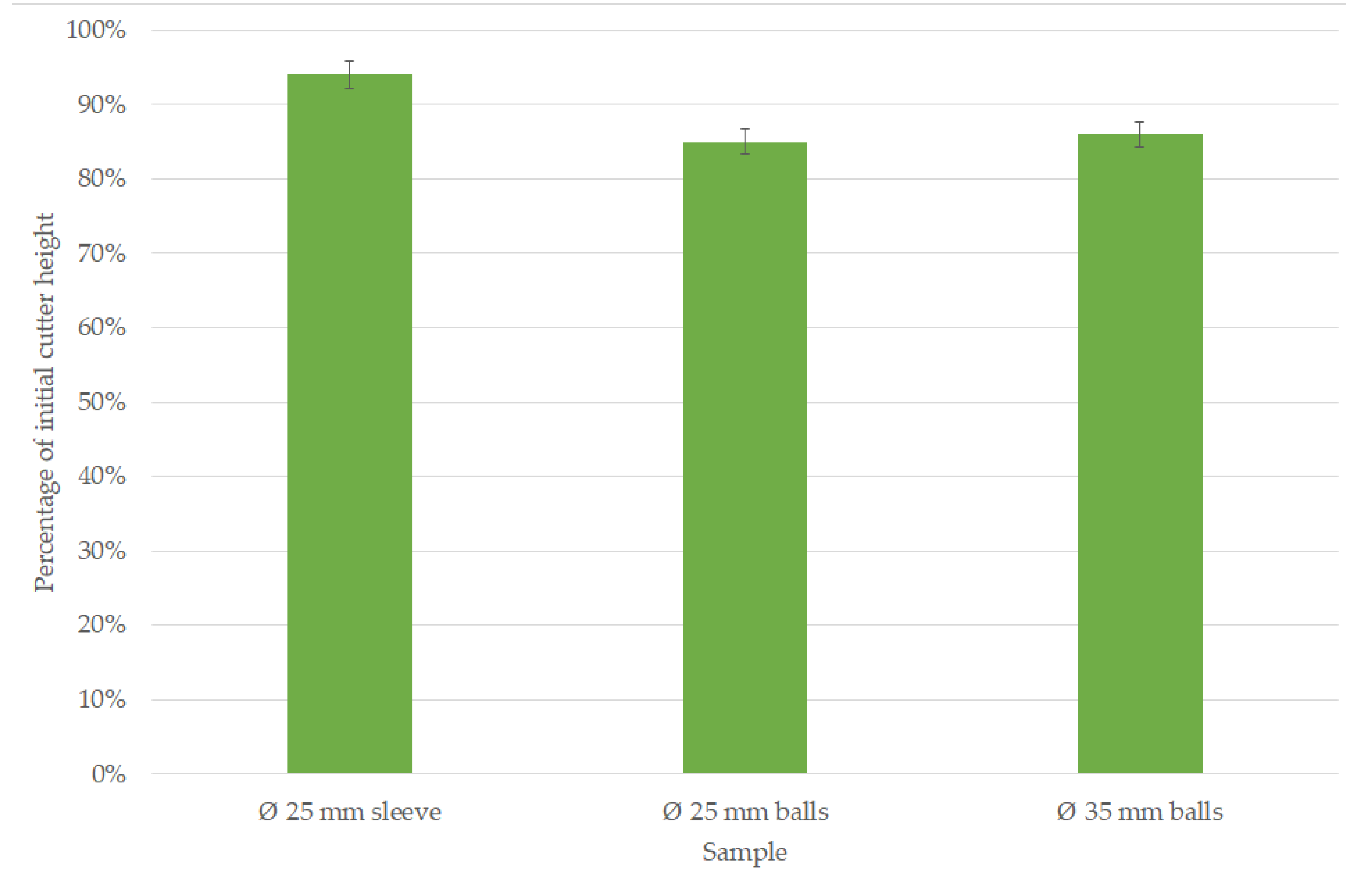

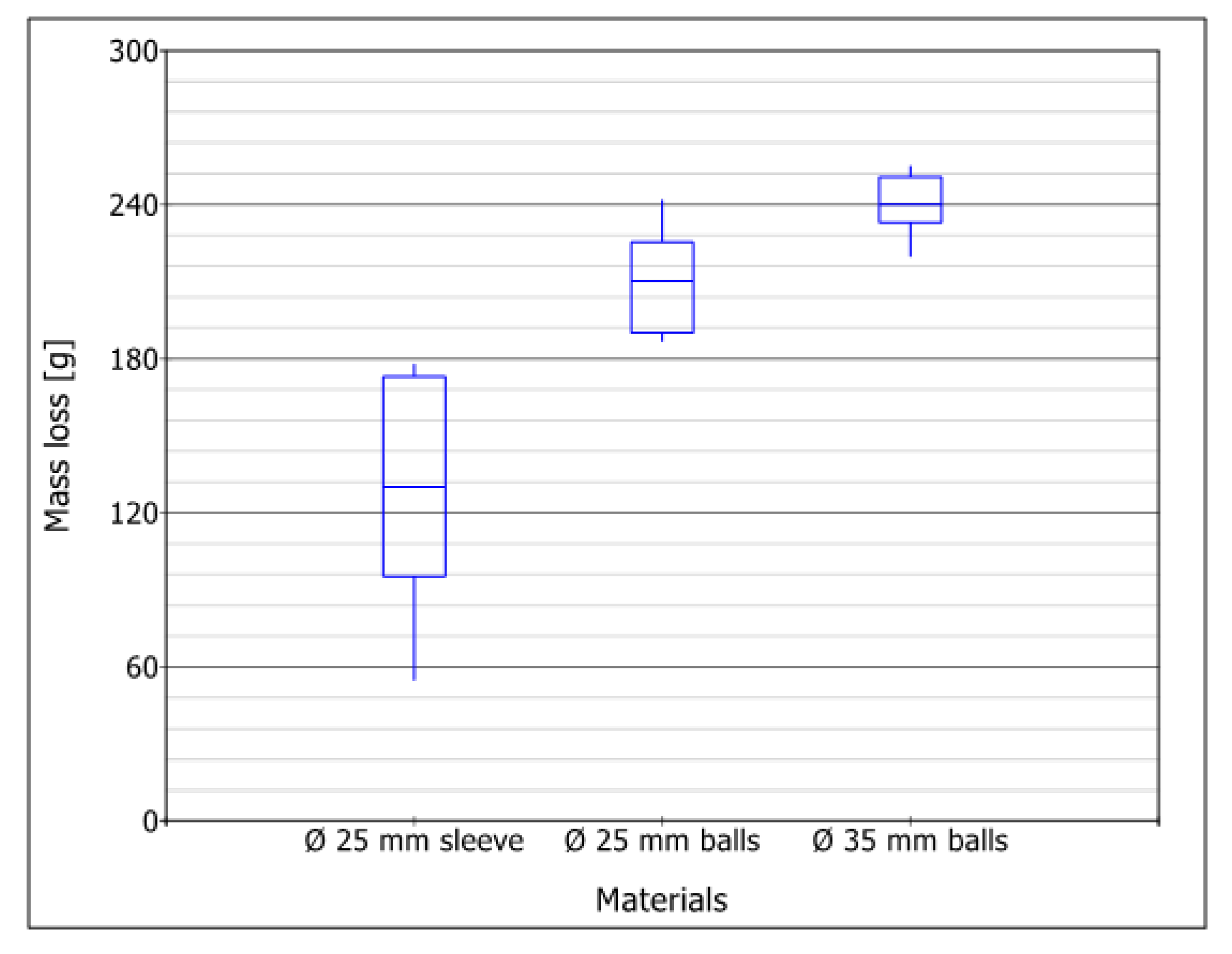

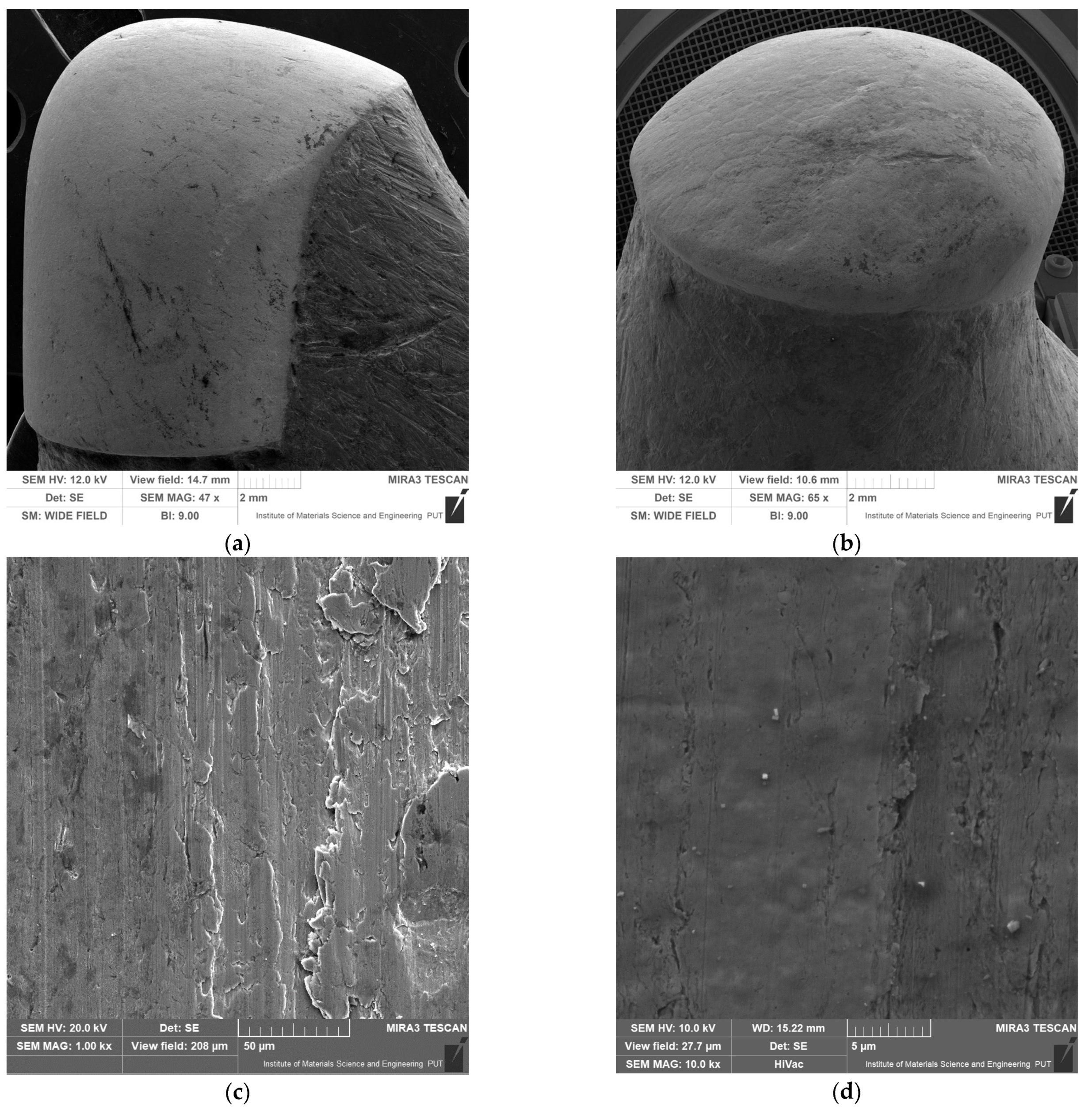

3. Results and Discussion

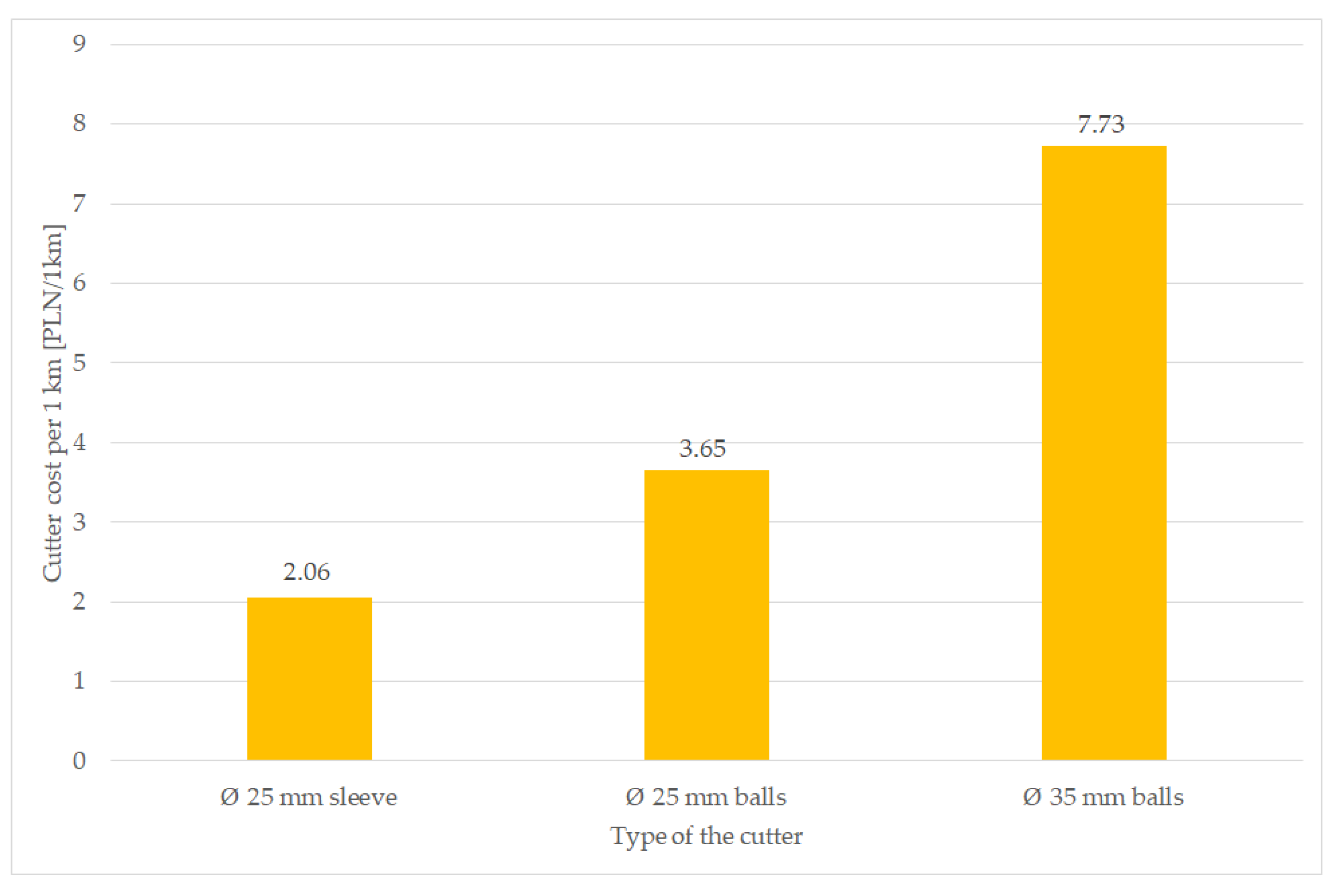

4. Cost and Efficiency Analysis

- P—cost of regeneration of 1 km of road with a given cutter [PLN/km];

- Cf—price of the cutter [PLN];

- h—number of working hours required to replace the worn tool [h];

- Ch—cost of an hour of downtime [PLN/h];

- d—the distance that the replacement cutter is able to work [km].

- Milling cutter Ø25 mm mounted on bearing balls (Ø25 mm balls)—PLN 50;

- Milling cutter Ø25 mm mounted on expansion sleeve (Ø25 mm sleeve)—PLN 40;

- Milling cutter Ø35 mm mounted on bearing balls (Ø35 mm balls)—PLN 160.

- Milling cutter Ø25 mm mounted on bearing balls (Ø25 mm balls)—PLN 3.65;

- Milling cutter Ø25 mm mounted on expansion sleeve (Ø25 mm sleeve)—PLN 2.06;

- Milling cutter Ø35 mm mounted on bearing balls (Ø35 mm balls)—PLN 7.73.

- Milling cutter Ø25 mm mounted on bearing balls (Ø25 mm balls)—PLN 1.04;

- Milling cutter Ø25 mm mounted on expansion sleeve (Ø25 mm sleeve)—PLN 0.23;

- Milling cutter Ø35 mm mounted on bearing balls (Ø35 mm balls)—PLN 0.86.

5. Conclusions

- The mass loss and shape-dimensional change depends mainly on the shape of the cutter and the parameters of the abrasive compound; the lowest mass loss was obtained in the Ø25 cutter mounted on an expanding sleeve during testing of the renovation of a dirt road.

- Immobilizing the specimen in one position during the implementation of the laboratory tests resulted in achieving intensive wear in one area of the cutter and smaller wear elsewhere—where the abrasive mass was not pushing on the working element.

- The difference in operating costs for the whole machine between the cheapest and the most expensive variant is about four-fold; therefore, choosing a cutter with a diameter of 25 mm fixed with an expansion sleeve, instead of a cutter with a diameter of 35 mm, saves PLN 750 for each kilometer of dirt road renovated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Devaraju, A. A critical review on different types of wear of materials. Int. J. Mech. Eng. Technol. 2015, 6, 77–83. [Google Scholar]

- Rani, A.; Singh, T.P.; Singh, J.; Patel, V.; Choudhary, M.K. Abrasive wear behavior of EN42 steel used in agricultural discs in field conditions. Eng. Fail. Anal. 2022, 142, 106789. [Google Scholar] [CrossRef]

- Tan, N.; Qiao, J.; Wang, Q. Tribocorrosion performance of medium-manganese austenitic wear-resistant steel in simulated mine water. Corros. Sci. 2023, 219, 111225. [Google Scholar] [CrossRef]

- Hwang, I.-S.; So, T.-Y.; Lee, D.-H.; Shin, C.-S. Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding. Materials 2023, 16, 2144. [Google Scholar] [CrossRef] [PubMed]

- Kalácska, Á.; Székely, L.; Keresztes, R.Z.; Gábora, A.; Mankovits, T.; De Baets, P. Abrasive Sensitivity of Martensitic and a Multi-Phase Steels under Different Abrasive Conditions. Materials 2021, 14, 1343. [Google Scholar] [CrossRef]

- Malvajerdi, A.S. Wear and coating of tillage tools: A review. Heliyon 2023, 9, e116669. [Google Scholar] [CrossRef]

- Asea del Sol, D.; Sanchez Iznaga, A.L.; Herrera Suarez, M.; Socarras Armenteros, Y. Theoretical aspects on the abrasive wear of farming tools. Rev. Científica Agroecosistemas 2018, 6, 74–83. [Google Scholar]

- Barge, M.; Kermouche, G.; Gilles, P.; Bergheau, J.M. Experimental and numerical study of the ploughing part of abrasive wear. Wear 2003, 255, 30–37. [Google Scholar] [CrossRef]

- Kostencki, P.; Stawicki, T.; Królicka, A. Wear of the working parts of agricultural tools in the context of the mass of chemical elements introduced into soil during its cultivation. Int. J. Water Conserv. Res. 2021, 9, 229–240. [Google Scholar] [CrossRef]

- Zemlik, M.; Konat, Ł.; Napiórkowski, J. Comparative Analysis of the Influence of Chemical Composition and Microstructure on the Abrasive Wear of High-Strength Steels. Materials 2022, 15, 5083. [Google Scholar] [CrossRef]

- He, T.; Liu, N.; Xia, H.; Wu, L.; Zhang, Y.; Li, D.; Chen, Y. Progress and trend of minimum quantity lubrication (MQL): A comprehensive review. J. Clean. Prod. 2023, 386, 135809. [Google Scholar] [CrossRef]

- Lu, X.; Gu, X.; Shi, Y. A review on the synthesis of MXenes and their lubrication performance and mechanisms. Tribol. Int. 2023, 179, 108170. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Z.; Chen, J.; Zhou, X.; Zong, Y. Microstructure, Wear and Corrosion Behaviors of Electrodeposited Ni-Diamond Micro-Composite Coatings. Coatings 2022, 12, 1391. [Google Scholar] [CrossRef]

- Maltanava, H.; Shiman, D.; Ovodok, E.; Svito, I.; Makarevich, M.; Kostjuk, S.; Poznyak, S.; Aniskevich, A. Polymer Coatings Based on Polyisobutylene, Polystyrene and Poly(styrene-block-isobutylene-block-styrene) for Effective Protection of MXenes. Coatings 2022, 12, 1477. [Google Scholar] [CrossRef]

- Gou, R.; Park, J.-H.; Yamashita, S.; Hagio, T.; Ichino, R.; Kita, H. Aluminum Electrodeposition on the Surface of Boron Carbide Ceramics by Use EMIC–AlCl3 Ions Liquid. Coatings 2022, 12, 1535. [Google Scholar] [CrossRef]

- Osintsev, K.; Konovalov, S.; Ivanov, Y.; Gromov, V.; Vorobyev, S.; Panchenko, I. Characterization of Al-Co-Cr-Fe-Mn-Ni High-Entropy Alloy Coating Fabricated onto AA5083 Using Wire-Arc Additive Manufacturing. Metals 2022, 12, 1612. [Google Scholar] [CrossRef]

- Ndumia, J.N.; Kang, M.; Lin, J.; Liu, J.; Li, H. Influence of Heat Treatment on the Microstructure and Wear Properties of Arc-Sprayed FeCrAl/Al Coating. Coatings 2022, 12, 374. [Google Scholar] [CrossRef]

- Baharare, O.S.; Sarve, S.A.; Gengane, V.V.; Sahane, A.S.; Jikar, P.C. Effect of various surface heat treatment methods and its parametric variation on the hardness properties of different steels grades. Mater. Proc. 2023, in press. [Google Scholar] [CrossRef]

- Pavan, P.; Talari, M.K.; Babu, N.K.; Rehman, A.U.; Srirangam, P. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Rotary Friction Welded Dissimilar IN718 to SS304L Alloys. Appl. Sci. 2023, 13, 3584. [Google Scholar] [CrossRef]

- Vargova, M.; Tavodova, M.; Monkova, K.; Dzupon, M. Research of Resistance of Selected Materials to Abrasive Wear to Increase the Ploughshare Lifetime. Metals 2022, 12, 940. [Google Scholar] [CrossRef]

- Jankauskas, V.; Katinas, E.; Pusvaškis, M.; Leišys, R. A Study of the Durability of Hardened Plough Point. J. Frict. Wear 2020, 41, 78–84. [Google Scholar] [CrossRef]

- Romek, D.; Selech, J.; Ulbrich, D.; Felusiak, A.; Kieruj, P.; Janeba-Bartoszewicz, E.; Pieniak, D. The impact of padding weld shape of agricultural machinery tools on their abrasive wear. Tribologia 2020, 2, 55–62. [Google Scholar] [CrossRef]

- Ataya, S.; El-Sayed Seleman, M.M.; Latief, F.H.; Ahmed, M.M.Z.; Hajlaoui, K.; Soliman, A.M.; Alsaleh, N.A.; Habba, M.I.A. Wear Characteristics of Mg Alloy AZ91 Reinforced with Oriented Short Carbon Fibers. Materials 2022, 15, 4841. [Google Scholar] [CrossRef]

- El-Sayed Seleman, M.M.; Ahmed, M.M.Z.; Ataya, S. Microstructure and mechanical properties of hot extruded 6016 aluminum alloy/graphite composites. J. Mater. Sci. Technol. 2018, 34, 1580–1591. [Google Scholar] [CrossRef]

- Kaushik, J.; Khan, H.A.; Tiwari, A.; Nafees, K.; Varshney, S.; Singh, S.P. A review on application and optimization processes used for wear testing machine (pin on disc apparatus). Mater. Proc. 2022, 64, 1440–1444. [Google Scholar] [CrossRef]

- Romek, D.; Ulbrich, D.; Selech, J.; Kowalczyk, J.; Wlad, R. Assessment of Padding Elements Wear of Belt Conveyors Working in Combination of Rubber–Quartz–Metal Condition. Materials 2021, 14, 4323. [Google Scholar] [CrossRef]

- Selech, J.; Ulbrich, D.; Romek, D.; Kowalczyk, J.; Wlodarczyk, K.; Nadolny, K. Experimental Study of Abrasive, Mechanical and Corrosion Effects in Ring-on-Ring Sliding Contact. Materials 2020, 13, 4950. [Google Scholar] [CrossRef]

- Kostencki, P.; Stawicki, T.; Królicka, A.; Sędłak, P. Wear of cultivator coulters reinforced with cemented-carbide plates and hardfacing. Wear 2019, 438–439, 203063. [Google Scholar] [CrossRef]

- Bayhan, Y. Reduction of wear via hardfacing of chisel ploughshare. Tribol. Int. 2006, 39, 570–574. [Google Scholar] [CrossRef]

- Su, Z.; Li, J.; Zhang, Z.; Ren, S.; Shi, Y.; Wang, X. Analysis of the mechanical properties and wear characteristics of nail teeth based on sowing layer residual film recovery machine. Eng. Fail. Anal. 2023, 143, 106869. [Google Scholar] [CrossRef]

- Duchnowska, M.; Strzałkowski, P.; Bakalarz, A.; Kaźmierczak, U.; Köken, E.; Karwowski, P.; Wolny, M.; Stępień, T. Influence of Basalt Aggregate Crushing Technology on Its Geometrical Properties—Preliminary Studies. Materials 2023, 16, 602. [Google Scholar] [CrossRef] [PubMed]

- Forsberg, C. Low-cost crushed-rock heat storage with oil or salt heat transfer. Appl. Energy 2023, 335, 120753. [Google Scholar] [CrossRef]

- Choteborsky, R.; Linda, M.; Hromasova, M. Wear and stress analysis of chisel. Agron. Res. 2017, 15, 971–980. [Google Scholar]

- Katinas, E.; Choteborsky, R. Volume/shear work ratio influence on wear and stress of soil chisel tine modelled by DEM. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 236, 1985–1992. [Google Scholar] [CrossRef]

- Guan, C.; Fu, J.; Cui, Z.; Wang, S.; Gao, Q.; Yang, Y. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Tillage Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Available online: https://www.valentini-group.com/en/cat/construction/frutti-stone-crusher/ (accessed on 10 June 2023).

- Available online: https://www.valentini-group.com/en/cat/construction/fi-ivan-2/ (accessed on 10 June 2023).

- ASTM G65-16; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- Rabinowicz, E.; Dunn, L.A.; Russell, P.G. A study of abrasive wear under three-body conditions. Wear 1961, 4, 345–355. [Google Scholar] [CrossRef]

- Kalacska, A.; De Baets, P.; Fauconnier, D.; Schramm, F.; Frerichs, L.; Sukumara, J. Abrasive wear behaviour of 27MnB5 steel used in agricultural tines. Wear 2020, 442–443, 203107. [Google Scholar] [CrossRef]

- Kostencki, P.; Stawicki, T.; Białobrzeska, B. Durability and wear geometry of subsoiler shanks provided with sintered carbide plates. Tribol. Int. 2016, 104, 19–35. [Google Scholar] [CrossRef]

- Coronado, J.J.; Sinatora, A. Effect of abrasive size on wear of metallic materials and its relationship with microchips morphology and wear micromechanisms: Part 1. Wear 2011, 271, 1794–1803. [Google Scholar] [CrossRef]

| Content (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Mo | Cu |

| 0.38–0.45 | 0.50–0.80 | 0.17–0.37 | ≤0.035 | ≤0.035 | 0.90–1.20 | ≤0.030 | 0.15–0.25 | ≤0.030 |

| Cutter Type | Ø 25 mm Sleeve | Ø 25 mm Balls | Ø 35 mm Balls | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension mm | Weight g | Dimension mm | Weight g | Dimension mm | Weight g | |||||||

| Before | After | Before | After | Before | After | Before | After | Before | After | Before | After | |

| 1 | 104.38 | 97.52 | 648.945 | 480.616 | 142.33 | 118.59 | 905.345 | 688.681 | 151.2 | 125.01 | 1293 | 1053 |

| 2 | 104.29 | 102.01 | 649.234 | 555.338 | 142.1 | 134.67 | 906.04 | 706.002 | 151.492 | 123.53 | 1293 | 1053 |

| 3 | 104.67 | 96.14 | 650.245 | 475.594 | 142.67 | 124.82 | 906.569 | 702.927 | 151.401 | 125.13 | 1294 | 1044 |

| 4 | 104.58 | 100.34 | 650.693 | 551.1 | 142.79 | 116.63 | 906.221 | 681.556 | 151.594 | 139.31 | 1293 | 1042 |

| 5 | 104.44 | 103.55 | 650.329 | 595.32 | 142.42 | 115.15 | 905.893 | 680.176 | 151.603 | 140.63 | 1295 | 1056 |

| 6 | 104.31 | 100.63 | 649.998 | 542.317 | 142.6 | 122.06 | 905.934 | 664.084 | 151.382 | 140.33 | 1293 | 1062 |

| 7 | 104.61 | 97.69 | 650.801 | 498.39 | 142.25 | 116.69 | 905.873 | 719.025 | 151.499 | 125.8 | 1294 | 1074 |

| 8 | 104.87 | 86.30 | 648.988 | 471.14 | 142.11 | 116.03 | 906.29 | 766.304 | 151.508 | 125.83 | 1295 | 1040 |

| Standard Deviation | 0.187 | 4.999 | 0.702 | 45.655 | 0.241 | 6.160 | 0.338 | 31.379 | 0.123 | 7.314 | 0.829 | 11.486 |

| Cutter Type | Ø 25 mm Sleeve | Ø 25 mm Balls | ||

|---|---|---|---|---|

| Weight g | Weight g | |||

| Before | After | Before | After | |

| 1 | 650.414 | 650.353 | 905.339 | 905.242 |

| 2 | 648.915 | 648.859 | 906.978 | 906.814 |

| 3 | 649.672 | 649.547 | 905.446 | 905.382 |

| 4 | 647.068 | 646.947 | 905.684 | 905.577 |

| 5 | 652.994 | 652.881 | 906.024 | 905.886 |

| 6 | 648.271 | 648.082 | 905.981 | 905.871 |

| Standard Deviation | 1.863 | 0.049 | 0.045 | 0.034 |

| Contrast | Mean Difference | Pooled Standard Error | p Value |

|---|---|---|---|

| Ø 25 mm sleeve–Ø 25 mm balls | −76.249 | 16.3323 | 0.000132 |

| Ø 25 mm sleeve–Ø 35 mm balls | −112.07275 | 16.3323 | 8.785396 × 10−7 |

| Ø 25 mm balls–Ø 35 mm balls | −35.82375 | 16.3323 | 0.039672 |

| Contrast | Mean Difference | Pooled Standard Error | p Value |

|---|---|---|---|

| Ø 25 mm sleeve–Ø 25 mm balls | −0.0025 | 0.024383 | 0.920363 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selech, J.; Majchrzycki, W.; Ulbrich, D. Field and Laboratory Wear Tests of Machine Components Used for Renovation of Dirt Roads—A Case Study. Materials 2023, 16, 6180. https://doi.org/10.3390/ma16186180

Selech J, Majchrzycki W, Ulbrich D. Field and Laboratory Wear Tests of Machine Components Used for Renovation of Dirt Roads—A Case Study. Materials. 2023; 16(18):6180. https://doi.org/10.3390/ma16186180

Chicago/Turabian StyleSelech, Jarosław, Wiktor Majchrzycki, and Dariusz Ulbrich. 2023. "Field and Laboratory Wear Tests of Machine Components Used for Renovation of Dirt Roads—A Case Study" Materials 16, no. 18: 6180. https://doi.org/10.3390/ma16186180

APA StyleSelech, J., Majchrzycki, W., & Ulbrich, D. (2023). Field and Laboratory Wear Tests of Machine Components Used for Renovation of Dirt Roads—A Case Study. Materials, 16(18), 6180. https://doi.org/10.3390/ma16186180