Characteristics and Functionality of Cantilevers and Scanners in Atomic Force Microscopy

Abstract

:1. Introduction

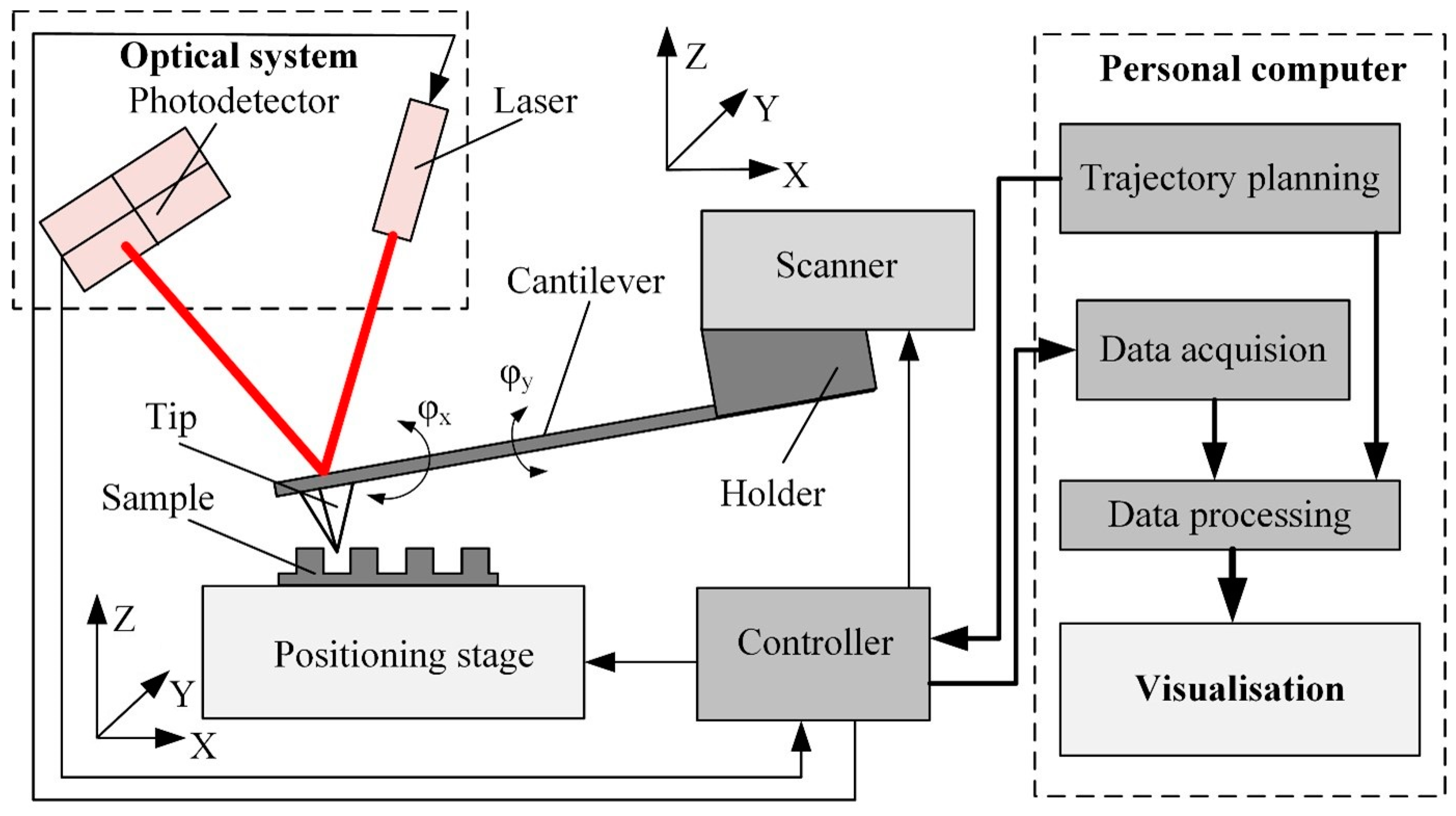

2. Background of the Atomic Force Microscope

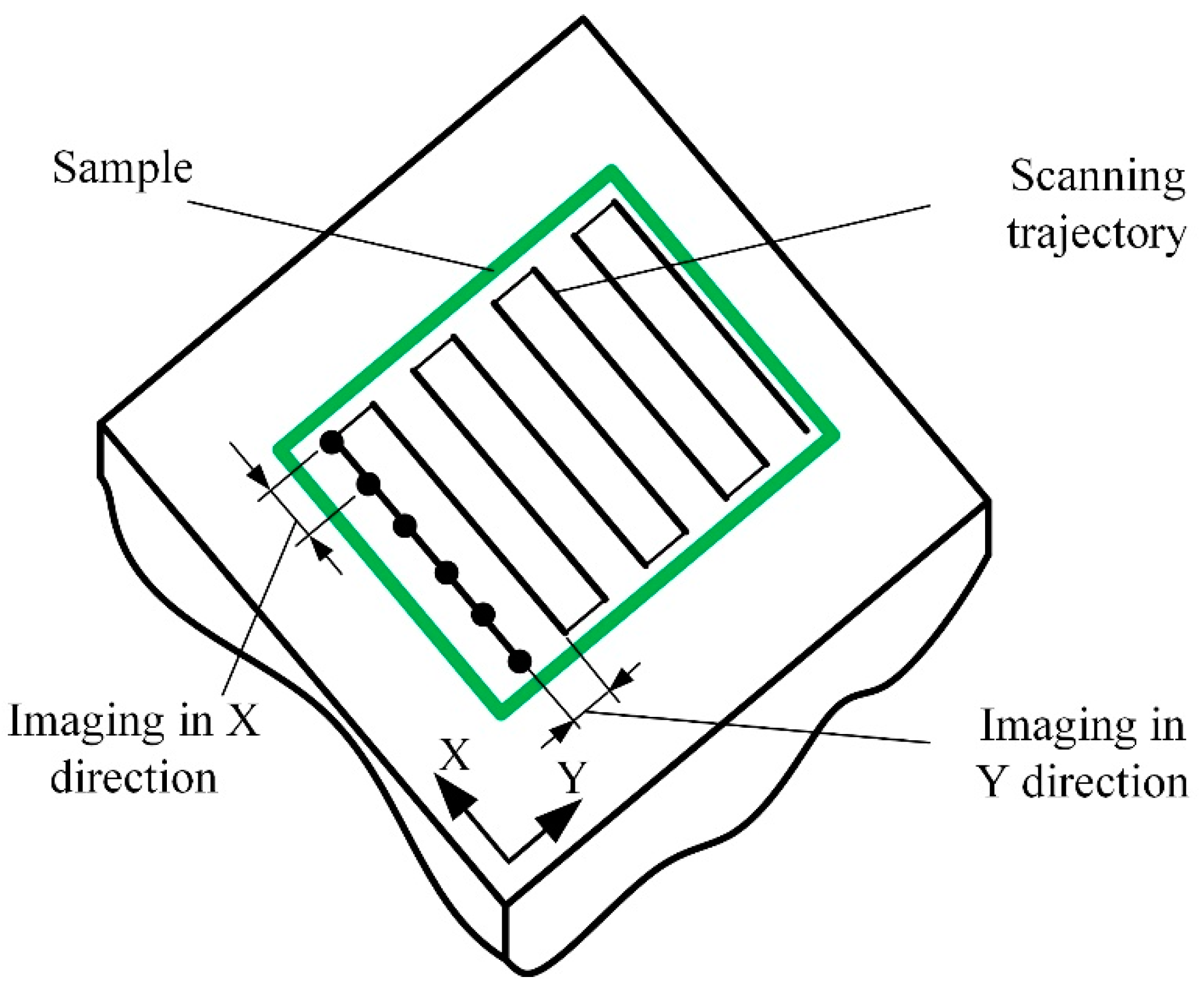

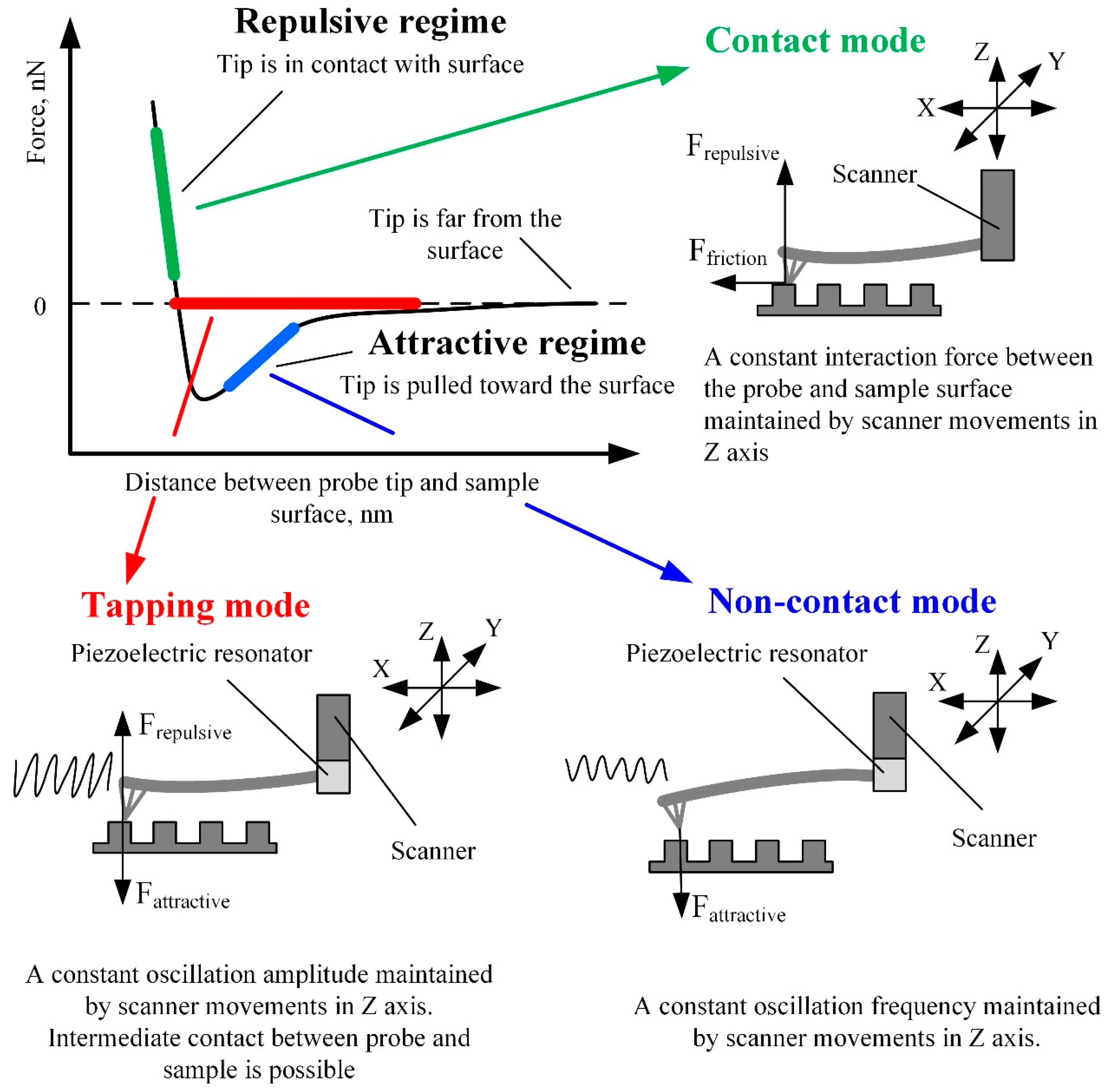

2.1. AFM Operating Modes

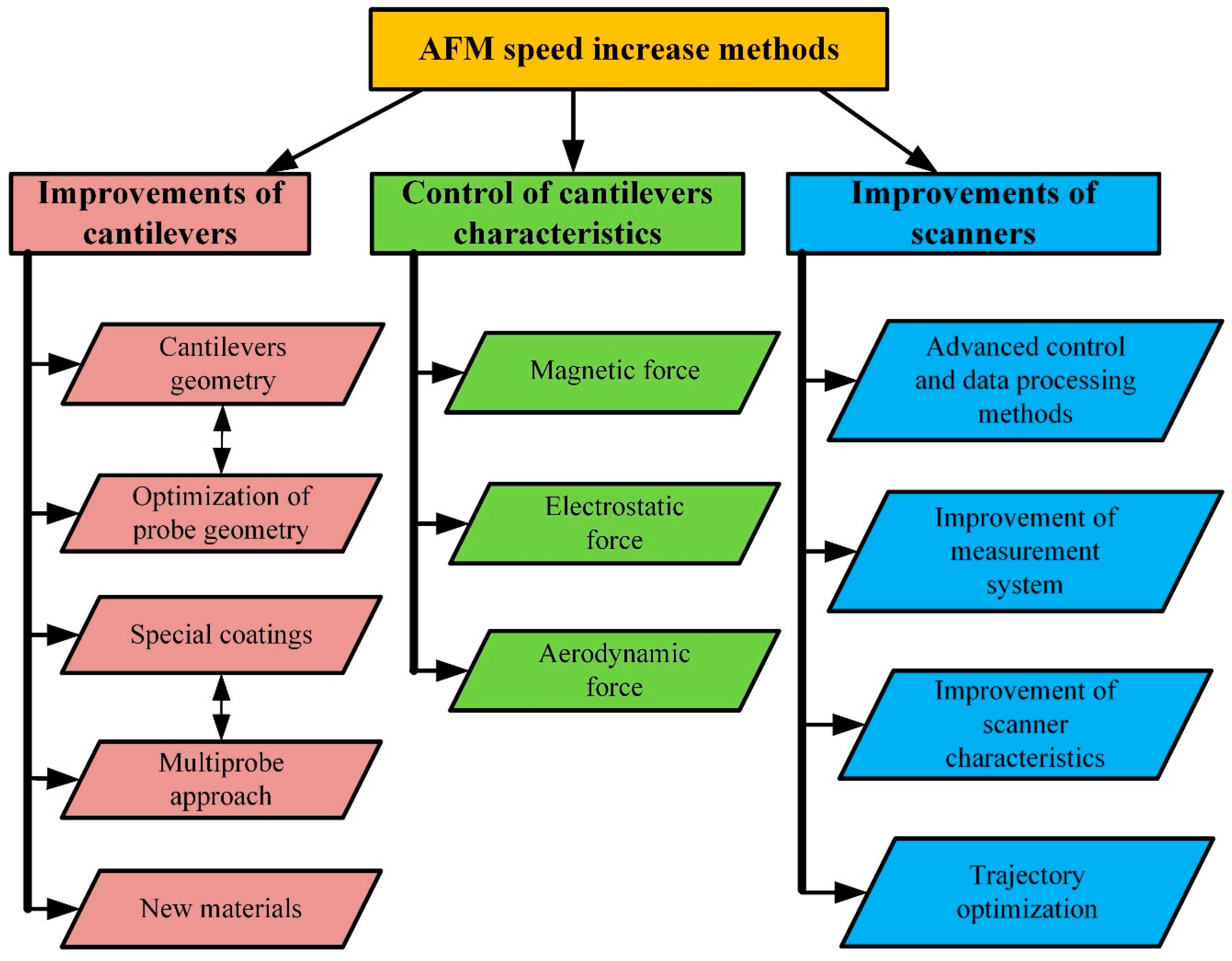

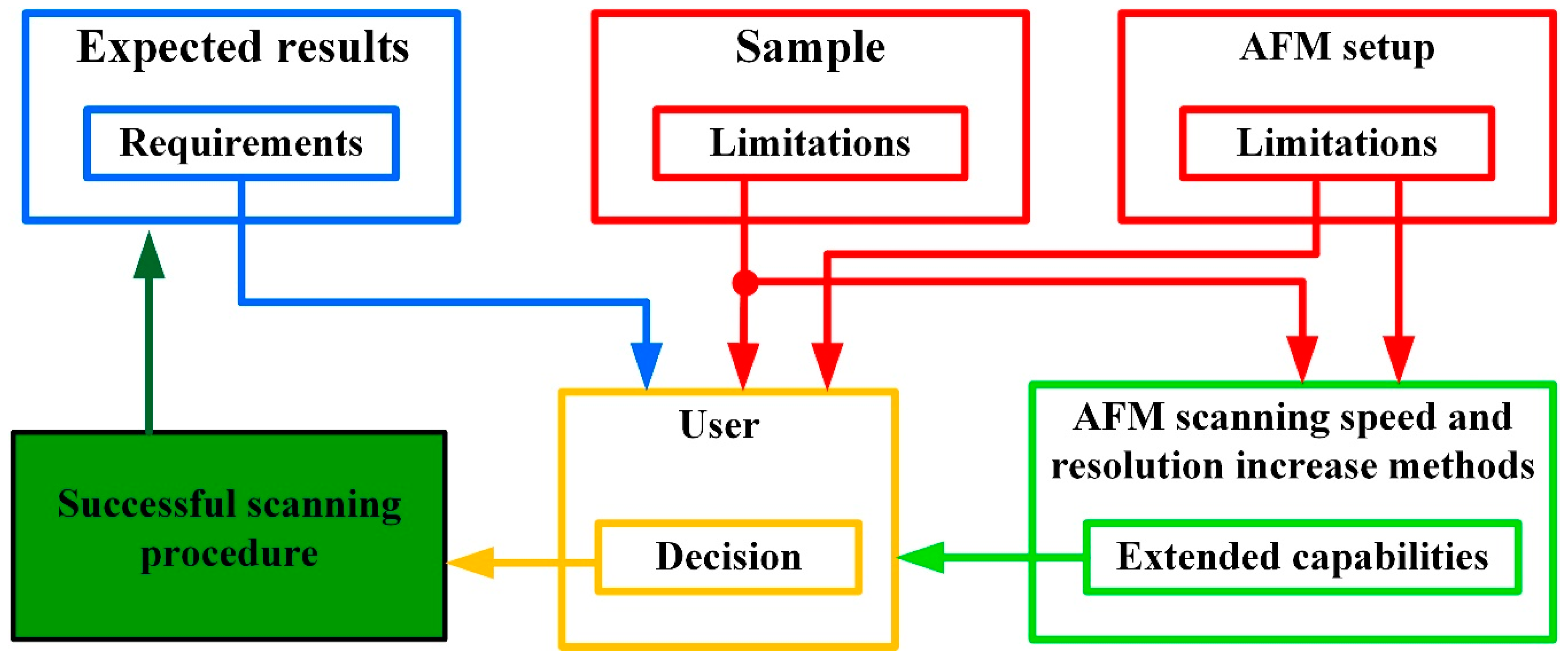

2.2. AFM Imaging Speed Optimization and Performance Increase Methods

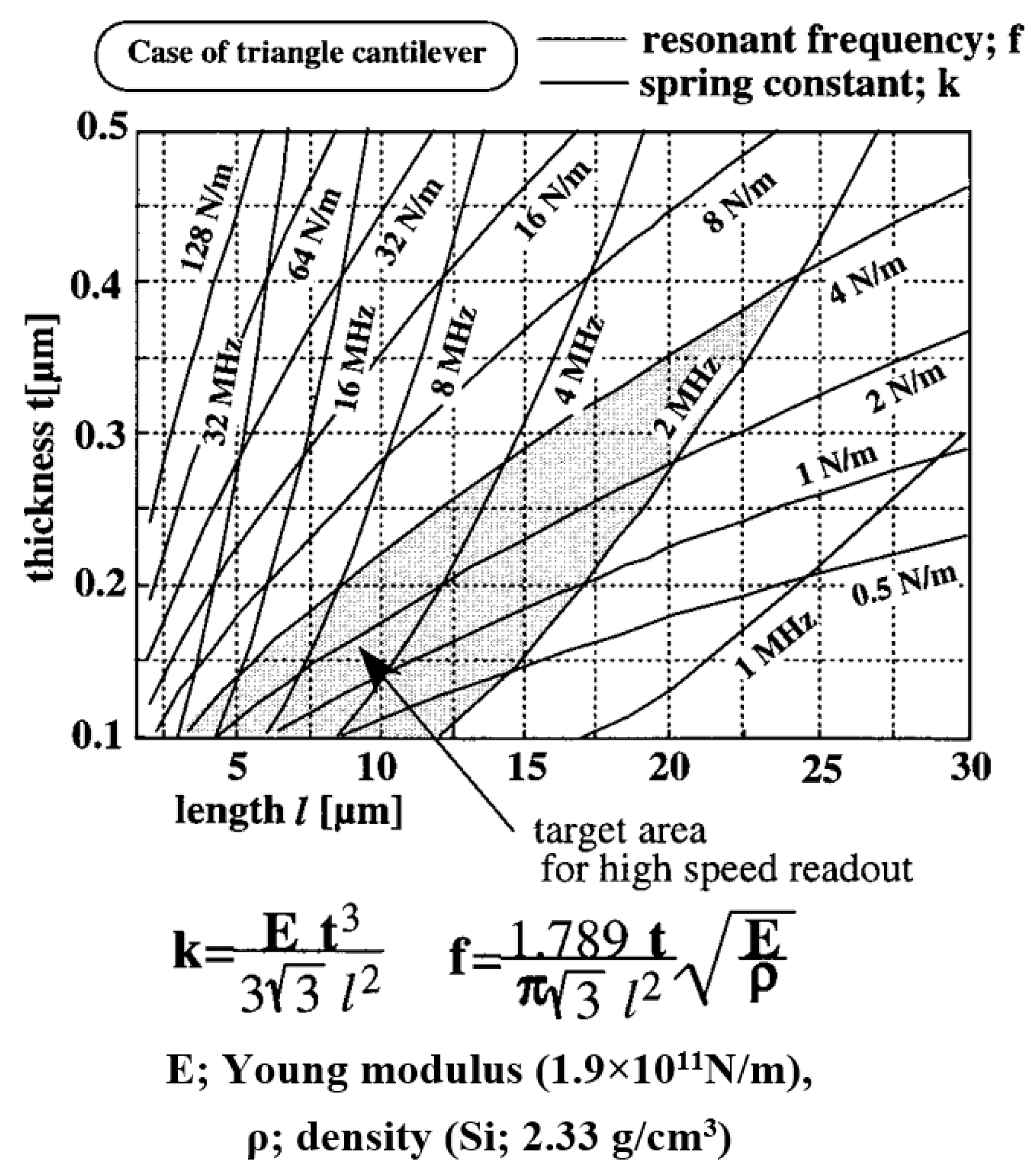

3. Cantilevers

- Select the probe with the appropriate stiffness, resonance frequency, and resonance quality.

- Adjust the cantilever working conditions to increase damping and shift the resonance frequency away from the selected regime.

- Select scanning parameters (scanning speed and resolution) to operate above the resonance frequency.

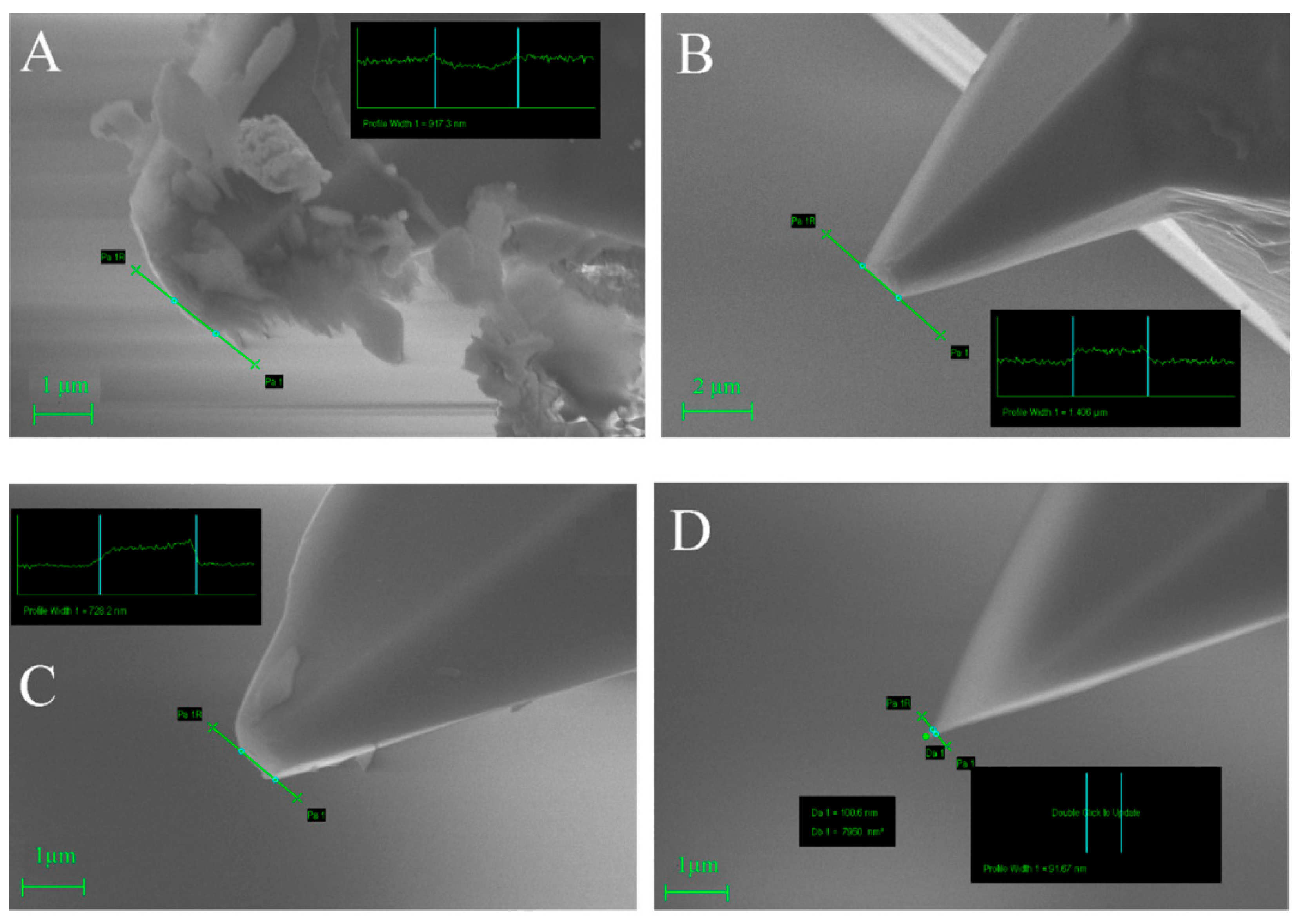

3.1. Geometry of Cantilevers and Tips

3.2. Special Coatings and New Materials

3.3. Adjustment and In Situ Control of Cantilever Dynamic Characteristics

4. Scanners

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vorburger, T.V.; Dagata, J.A.; Wilkening, G.; Iizuka, K.; Thwaite, E.G.; Lonardo, P. Industrial Uses of STM and AFM. CIRP Ann.-Manuf. Technol. 1997, 46, 597–620. [Google Scholar] [CrossRef]

- Andriukonis, E.; Stirke, A.; Garbaras, A.; Mikoliunaite, L.; Ramanaviciene, A.; Remeikis, V.; Thornton, B.; Ramanavicius, A. Yeast-Assisted Synthesis of Polypyrrole: Quantification and Influence on the Mechanical Properties of the Cell Wall. Colloids Surfaces B Biointerfaces 2018, 164, 224–231. [Google Scholar] [CrossRef]

- Tolenis, T.; Grinevičiūtė, L.; Kičas, S.; Buzelis, R. Enhancement of Optical Resistance in High Reflectivity Coatings Using Oblique Angle Deposition Method. In Proceedings of the Nanostructured Thin Films XI; International Society for Optics and Photonics, San Diego, CA, USA, 19–23 August 2018; Volume 10731, p. 107310. [Google Scholar]

- Gruskiene, R.; Krivorotova, T.; Staneviciene, R.; Ratautas, D.; Serviene, E.; Sereikaite, J. Preparation and Characterization of Iron Oxide Magnetic Nanoparticles Functionalized by Nisin. Colloids Surfaces B Biointerfaces 2018, 169, 126–134. [Google Scholar] [CrossRef]

- Batiuskaite, D.; Bruzaite, I.; Snitka, V.; Ramanavicius, A. Assessment of TiO2 Nanoparticle Impact on Surface Morphology of Chinese Hamster Ovary Cells. Materials 2022, 15, 4570. [Google Scholar] [CrossRef]

- Enrriques, A.E.; Howard, S.; Timsina, R.; Khadka, N.K.; Hoover, A.N.; Ray, A.E.; Ding, L.; Onwumelu, C.; Nordeng, S.; Mainali, L.; et al. Atomic Force Microscopy Cantilever-Based Nanoindentation: Mechanical Property Measurements at the Nanoscale in Air and Fluid. J. Vis. Exp. 2022, 190, e64497. [Google Scholar] [CrossRef] [PubMed]

- el Rifai, K.; el Rifai, O.; Youcef-Toumi, K. Modeling and Control of AFM-Based Nano-Manipulation Systems. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; IEEE: New York, NY, USA, 2005; Volume 2005, pp. 157–162. [Google Scholar]

- Wang, Y.; Wang, J. Friction Determination by Atomic Force Microscopy in Field of Biochemical Science. Micromachines 2018, 9, 313. [Google Scholar] [CrossRef] [PubMed]

- Hosaka, S.; Etoh, K.; Kikukawa, a.; Koyanagi, H. Megahertz Silicon Atomic Force Microscopy (AFM) Cantilever and High-Speed Readout in AFM-Based Recording. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2000, 18, 94. [Google Scholar] [CrossRef]

- Peña, B.; Adbel-Hafiz, M.; Cavasin, M.; Mestroni, L.; Sbaizero, O. Atomic Force Microscopy (AFM) Applications in Arrhythmogenic Cardiomyopathy. Int. J. Mol. Sci. 2022, 23, 3700. [Google Scholar] [CrossRef]

- Russell-Pavier, F.S.; Picco, L.; Day, J.C.C.; Shatil, N.R.; Yacoot, A.; Payton, O.D. “Hi-Fi AFM”: High-Speed Contact Mode Atomic Force Microscopy with Optical Pickups. Meas. Sci. Technol. 2018, 29, 105902. [Google Scholar] [CrossRef]

- Nishida, S.; Kobayashi, D.; Sakurada, T.; Nakazawa, T.; Hoshi, Y.; Kawakatsu, H. Photothermal Excitation and Laser Doppler Velocimetry of Higher Cantilever Vibration Modes for Dynamic Atomic Force Microscopy in Liquid. Rev. Sci. Instrum. 2008, 79, 123703. [Google Scholar] [CrossRef]

- Rugar, D.; Mamin, H.J.; Guethner, P. Improved Fiber-Optic Interferometer for Atomic Force Microscopy. Appl. Phys. Lett. 1989, 55, 2588–2590. [Google Scholar] [CrossRef]

- Göddenhenrich, T.; Lemke, H.; Hartmann, U.; Heiden, C. Force Microscope with Capacitive Displacement Detection. J. Vac. Sci. Technol. A Vac. Surf. Film. 1990, 8, 383–387. [Google Scholar] [CrossRef]

- Giessibl, F.J.; Trafas, B.M. Piezoresistive Cantilevers Utilized for Scanning Tunneling and Scanning Force Microscope in Ultrahigh Vacuum. Rev. Sci. Instrum. 1994, 65, 1923–1929. [Google Scholar] [CrossRef]

- Alunda, B.O.; Lee, Y.J. Review: Cantilever-Based Sensors for High Speed Atomic Force Microscopy. Sensors 2020, 20, 4784. [Google Scholar] [CrossRef]

- Han, G.; Lv, L.; Yang, G.; Niu, Y. Super-Resolution AFM Imaging Based on Compressive Sensing. Appl. Surf. Sci. 2020, 508, 145231. [Google Scholar] [CrossRef]

- Amyot, R.; Marchesi, A.; Franz, C.M.; Casuso, I.; Flechsig, H. Simulation Atomic Force Microscopy for Atomic Reconstruction of Biomolecular Structures from Resolution-Limited Experimental Images. PLoS Comput. Biol. 2022, 18, e1009970. [Google Scholar] [CrossRef] [PubMed]

- Nan, R.; Sun, G.; Wang, Z.; Ren, X. Research on Image Reconstruction of Compressed Sensing Based on a Multi-Feature Residual Network. Sensors 2020, 20, 4202. [Google Scholar] [CrossRef]

- Sajjadi, M.; Chahari, M.; Nejat Pishkenari, H. Imaging Performance of Trolling Mode Atomic Force Microscopy: Investigation of Effective Parameters. Arch. Appl. Mech. 2022, 92, 1551–1570. [Google Scholar] [CrossRef]

- Carracedo-Cosme, J.; Romero-Muñiz, C.; Pou, P.; Pérez, R. QUAM-AFM: A Free Database for Molecular Identification by Atomic Force Microscopy. J. Chem. Inf. Model. 2022, 62, 1214–1223. [Google Scholar] [CrossRef] [PubMed]

- Morkvenaite-Vilkonciene, I.; Virzonis, D.; Dzedzickis, A.; Bucinskas, V.; Rozene, J.; Vilkoncius, R.; Vaiciulis, D.; Ramanaviciene, A.; Ramanavicius, A. The Improvement of the Accuracy of Electromagnetic Actuator Based Atomic Force Microscope Operating in Contact Mode and the Development of a New Methodology for the Estimation of Control Parameters and the Achievement of Superior Image Quality. Sens. Actuators A Phys. 2019, 287, 168–176. [Google Scholar] [CrossRef]

- Yang, C.W.; Hwang, I.S.; Chen, Y.F.; Chang, C.S.; Tsai, D.P. Imaging of Soft Matter with Tapping-Mode Atomic Force Microscopy and Non-Contact-Mode Atomic Force Microscopy. Nanotechnology 2007, 18, 084009. [Google Scholar] [CrossRef]

- Tello, M.; García, R. Nano-Oxidation of Silicon Surfaces: Comparison of Noncontact and Contact Atomic-Force Microscopy Methods. Appl. Phys. Lett. 2001, 79, 424–426. [Google Scholar] [CrossRef]

- Butt, H.-J.; Cappella, B.; Kappl, M. Force Measurements with the Atomic Force Microscope: Technique, Interpretation and Applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef]

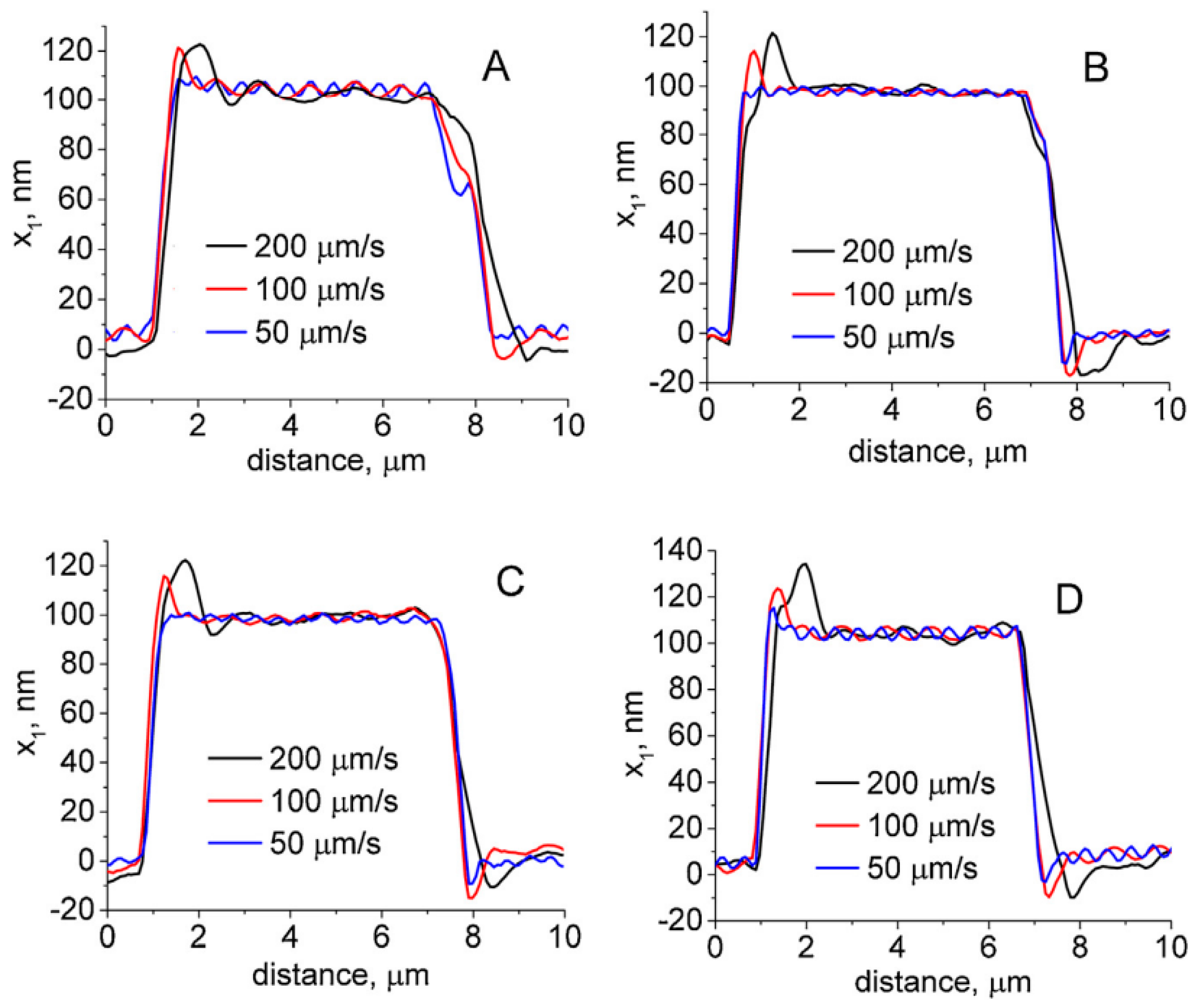

- Dzedzickis, A.; Bucinskas, V.; Viržonis, D.; Sesok, N.; Ulcinas, A.; Iljin, I.; Sutinys, E.; Petkevicius, S.; Gargasas, J.; Morkvenaite-Vilkonciene, I.; et al. Modification of the AFM Sensor by a Precisely Regulated Air Stream to Increase Imaging Speed and Accuracy in the Contact Mode. Sensors 2018, 18, 2694. [Google Scholar] [CrossRef] [PubMed]

- Magonov, S.N.; Whangbo, M. Surface Analysis with STM and AFM; Wiley: Hoboken, NJ, USA, 1995; ISBN 9783527293131. [Google Scholar]

- Zakaria, N.S.; Aziz, A.A. Effect of Medium on Interaction Forces between Atomic Force Microscopy (AFM) Tip and Gold Nanoparticle. J. Phys. Conf. Ser. 2018, 1083, 012035. [Google Scholar] [CrossRef]

- Lei, H.; Cheng, N.; Zhao, J. Interaction between Membrane and Organic Compounds Studied by Atomic Force Microscopy with a Tip Modification. J. Memb. Sci. 2018, 556, 178–184. [Google Scholar] [CrossRef]

- Agmon, L.; Shahar, I.; Yosufov, D.; Pimentel, C.; Pina, C.M.; Gnecco, E.; Berkovich, R. Estimation of Interaction Energy and Contact Stiffness in Atomic-Scale Sliding on a Model Sodium Chloride Surface in Ethanol. Sci. Rep. 2018, 8, 4681. [Google Scholar] [CrossRef]

- Zhong, Q.; Inniss, D.; Kjoller, K.; Elings, V.B. Fractured Polymer/Silica Fiber Surface Studied by Tapping Mode Atomic Force Microscopy. Surf. Sci. 1993, 290, L688–L692. [Google Scholar] [CrossRef]

- Gross, L.; Mohn, F.; Moll, N.; Liljeroth, P.; Meyer, G. The Chemical Structure of a Molecule Resolved by Atomic Force Microscopy. Science 2009, 325, 1110–1114. [Google Scholar] [CrossRef]

- Xu, K.; Sun, W.; Shao, Y.; Wei, F.; Zhang, X.; Wang, W.; Li, P. Recent Development of PeakForce Tapping Mode Atomic Force Microscopy and Its Applications on Nanoscience. Nanotechnol. Rev. 2018, 7, 605–621. [Google Scholar] [CrossRef]

- García, R. Dynamic Atomic Force Microscopy Methods. Surf. Sci. Rep. 2002, 47, 197–301. [Google Scholar] [CrossRef]

- PhaseImaging Mode—Imaging Modes of AFM; Bruker: Billerica, MA, USA.

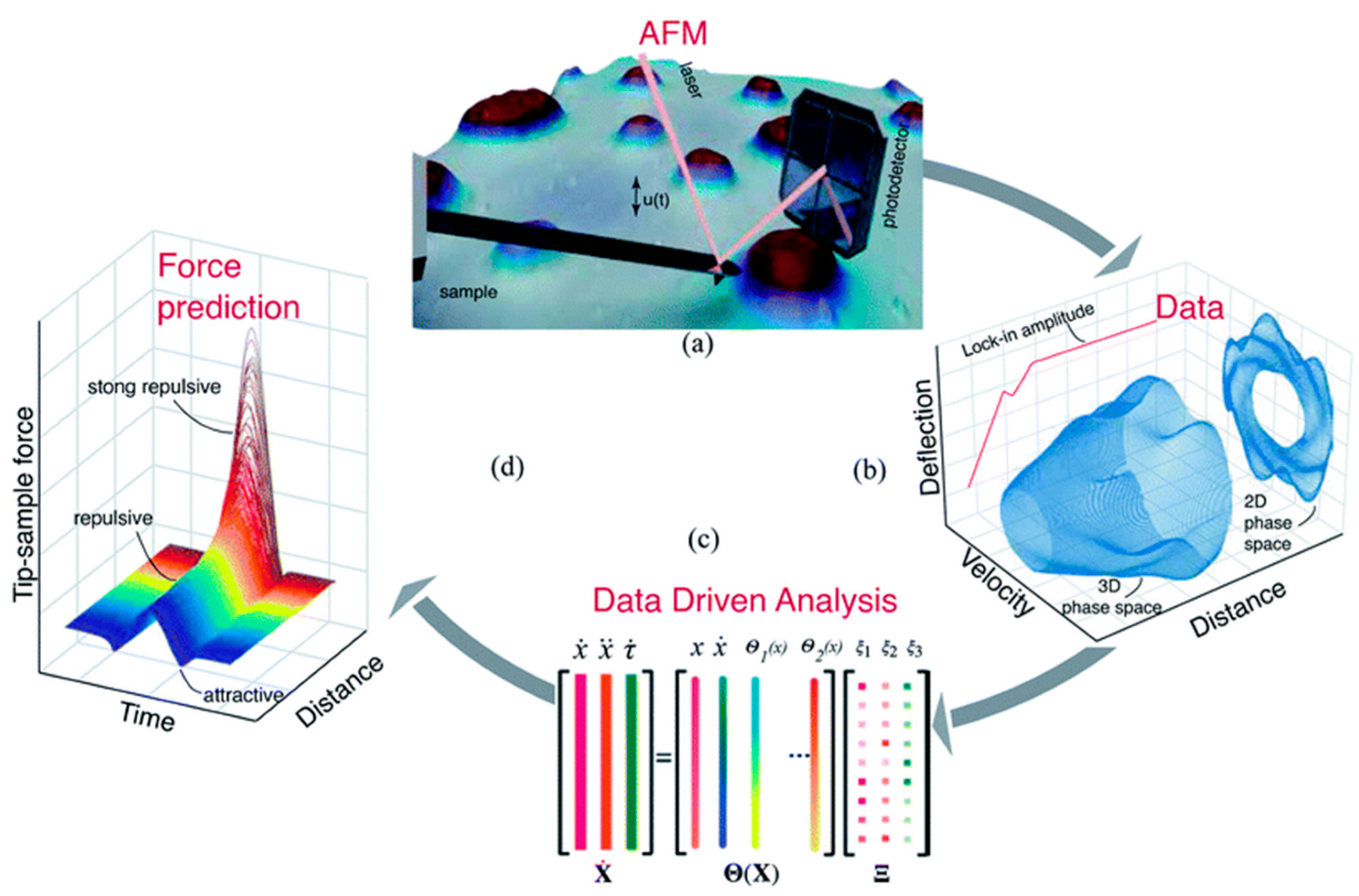

- Chandrashekar, A.; Belardinelli, P.; Bessa, M.A.; Staufer, U.; Alijani, F. Quantifying Nanoscale Forces Using Machine Learning in Dynamic Atomic Force Microscopy. Nanoscale Adv. 2022, 4, 2134–2143. [Google Scholar] [CrossRef]

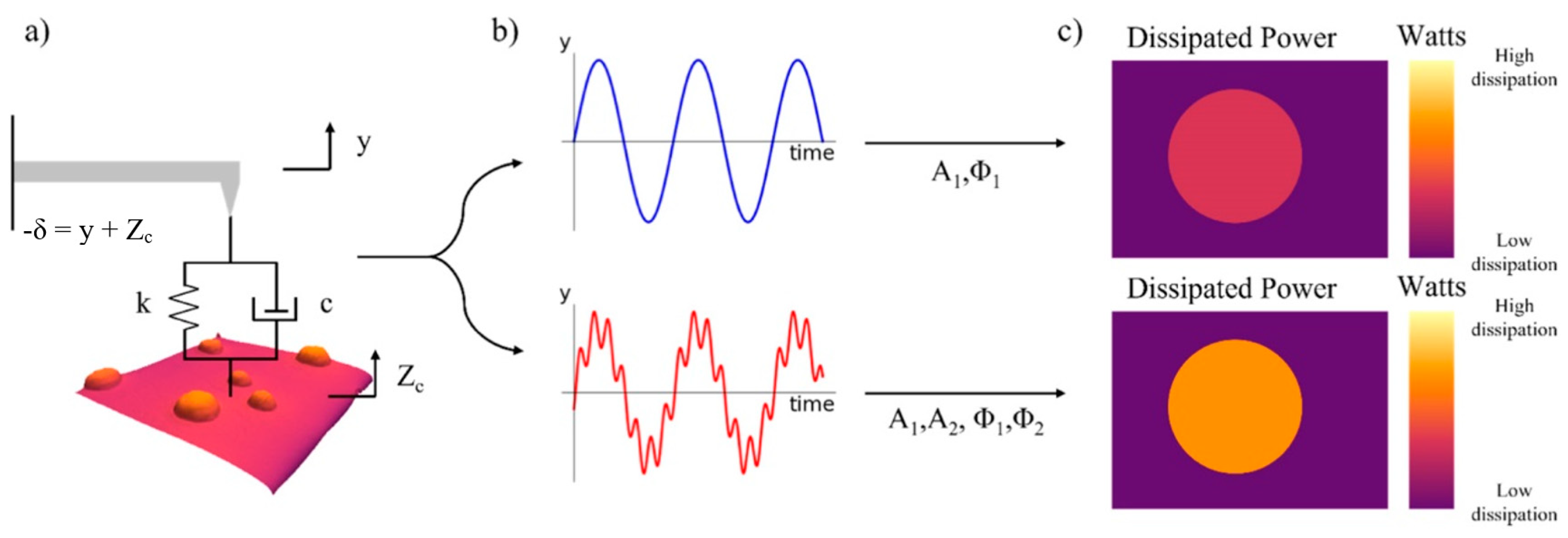

- Kiracofe, D.; Raman, A.; Yablon, D. Multiple Regimes of Operation in Bimodal AFM: Understanding the Energy of Cantilever Eigenmodes. Beilstein J. Nanotechnol. 2013, 4, 385–393. [Google Scholar] [CrossRef]

- Damircheli, M.; Jung, U.; Wagner, R. The Effect of Sample Viscoelastic Properties and Cantilever Amplitudes on Maximum Repulsive Force, Indentation, and Energy Dissipation in Bimodal AFM. Phys. Scr. 2023, 98, 035708. [Google Scholar] [CrossRef]

- Solares, S.D.; Chawla, G. Frequency Response of Higher Cantilever Eigenmodes in Bimodal and Trimodal Tapping Mode Atomic Force Microscopy. Meas. Sci. Technol. 2010, 21, 125502. [Google Scholar] [CrossRef]

- Ando, T. High-Speed AFM Imaging. Curr. Opin. Struct. Biol. 2014, 28, 63–68. [Google Scholar] [CrossRef]

- Manalis, S.R.; Minne, S.C.; Quate, C.F. Atomic Force Microscopy for High Speed Imaging Using Cantilevers with an Integrated Actuator and Sensor. Appl. Phys. Lett. 1996, 68, 871–873. [Google Scholar] [CrossRef]

- Minne, S.C.; Yaralioglu, G.; Manalis, S.R.; Adams, J.D.; Zesch, J.; Atalar, A.; Quate, C.F. Automated Parallel High-Speed Atomic Force Microscopy. Appl. Phys. Lett. 1998, 72, 2340–2342. [Google Scholar] [CrossRef]

- Cao, W.; Alsharif, N.; Huang, Z.; White, A.E.; Wang, Y.; Brown, K.A. Massively Parallel Cantilever-Free Atomic Force Microscopy. Nat. Commun. 2021, 12, 393. [Google Scholar] [CrossRef] [PubMed]

- Boisen, A.; Hansen, O.; Bouwstra, S. AFM Probes with Directly Fabricated Tips. J. Micromech. Microeng. 1996, 6, 58–62. [Google Scholar] [CrossRef]

- Farooqui, M.M.; Evans, A.G.R.; Stedman, M.; Haycocks, J. Micromachined Silicon Sensors for Atomic Force Microscopy. Nanotechnology 1992, 3, 91–97. [Google Scholar] [CrossRef]

- Lindley, D. Landmarks—Atomic Force Microscope Makes Angstrom-Scale Images. Phys. College Park. Md. 2012, 5, 106. [Google Scholar] [CrossRef]

- Cumpson, P.J.; Zhdan, P.; Hedley, J. Calibration of AFM Cantilever Stiffness: A Microfabricated Array of Reflective Springs. Ultramicroscopy 2004, 100, 241–251. [Google Scholar] [CrossRef]

- Boccaccio, A.; Lamberti, L.; Papi, M.; De Spirito, M.; Pappalettere, C. Effect of AFM Probe Geometry on Visco-Hyperelastic Characterization of Soft Materials. Nanotechnology 2015, 26, 325701. [Google Scholar] [CrossRef] [PubMed]

- Burt, D.P.; Wilson, N.R.; Janus, U.; Macpherson, J.V.; Unwin, P.R. In-Situ Atomic Force Microscopy (AFM) Imaging: Influence of AFM Probe Geometry on Diffusion to Microscopic Surfaces. Langmuir 2008, 24, 12867–12876. [Google Scholar] [CrossRef]

- Shibata, T.; Furukawa, H.; Ito, Y.; Nagahama, M.; Hayashi, T.; Ishii-Teshima, M.; Nagai, M. Photocatalytic Nanofabrication and Intracellular Raman Imaging of Living Cells with Functionalized AFM Probes. Micromachines 2020, 11, 495. [Google Scholar] [CrossRef]

- Meirovitch, L.; Parker, R. Fundamentals of Vibrations. Appl. Mech. Rev. 2001, 54, B100–B101. [Google Scholar] [CrossRef]

- Glover, C.C.; Killgore, J.P.; Tung, R.C. Scanning Speed Phenomenon in Contact-Resonance Atomic Force Microscopy. Beilstein J. Nanotechnol. 2018, 9, 945–952. [Google Scholar] [CrossRef]

- Yang, Q.; Ma, Q.; Herum, K.M.; Wang, C.; Patel, N.; Lee, J.; Wang, S.; Yen, T.M.; Wang, J.; Tang, H.; et al. Array Atomic Force Microscopy for Real-Time Multiparametric Analysis. Proc. Natl. Acad. Sci. USA 2019, 116, 5872–5877. [Google Scholar] [CrossRef]

- Wu, T.S.; Chang, W.J.; Hsu, J.C. Effect of Tip Length and Normal and Lateral Contact Stiffness on the Flexural Vibration Responses of Atomic Force Microscope Cantilevers. Microelectron. Eng. 2004, 71, 15–20. [Google Scholar] [CrossRef]

- Hoh, J.H. AFM Cantilevers and Methods for Making and Using Same. U.S. Patent 7,441,444 B2, 28 October 2008. [Google Scholar]

- Rasmussen, J.P.; Tang, P.T.; Sander, C.; Hansen, O.; Berger, R.; Delamarche, E.; Lang, H.P.; Gerber, C.; Gimzewski, J.K.; Meyer, E. Microfabrication of Cantilevers Using Sacrificial Templates. U.S. Patent 6,016,693, 25 January 2000. [Google Scholar]

- Viani, M.B.; Schäffer, T.E.; Chand, A.; Rief, M.; Gaub, H.E.; Hansma, P.K. Small Cantilevers for Force Spectroscopy of Single Molecules. J. Appl. Phys. 1999, 86, 2258–2262. [Google Scholar] [CrossRef]

- Walters, D.A.; Cleveland, J.P.; Thomson, N.H.; Hansma, P.K.; Wendman, M.A.; Gurley, G.; Elings, V. Short Cantilevers for Atomic Force Microscopy. Rev. Sci. Instrum. 1996, 67, 3583–3590. [Google Scholar] [CrossRef]

- Butt, H.J. Electrostatic Interaction in Atomic Force Microscopy. Biophys. J. 1991, 60, 777–785. [Google Scholar] [CrossRef] [PubMed]

- Stowe, T.D.; Yasumura, K.; Kenny, T.W.; Botkin, D.; Wago, K.; Rugar, D. Attonewton Force Detection Using Ultrathin Silicon Cantilevers. Appl. Phys. Lett. 1997, 71, 288–290. [Google Scholar] [CrossRef]

- Viani, M.B.; Schäffer, T.E.; Paloczi, G.T.; Pietrasanta, L.I.; Smith, B.L.; Thompson, J.B.; Richter, M.; Rief, M.; Gaub, H.E.; Plaxco, K.W.; et al. Fast Imaging and Fast Force Spectroscopy of Single Biopolymers with a New Atomic Force Microscope Designed for Small Cantilevers. Rev. Sci. Instrum. 1999, 70, 4300–4303. [Google Scholar] [CrossRef]

- Minne, S.C. Method of Performing Lithography Using Cantilever Array. U.S. Patent 5,666,190, 9 September 1997. [Google Scholar]

- Neumeister, J.M.; Ducker, W.A. Lateral, Normal, and Longitudinal Spring Constants of Atomic Force Microscopy Cantilevers. Rev. Sci. Instrum. 1994, 65, 2527–2531. [Google Scholar] [CrossRef]

- Clifford, C.A.; Seah, M.P. The Determination of Atomic Force Microscope Cantilever Spring Constants via Dimensional Methods for Nanomechanical Analysis Related Content. Nanotechnology 2005, 16, 1666. [Google Scholar] [CrossRef]

- Pedersen, N.L. Design of Cantilever Probes for Atomic Force Microscopy (AFM). Eng. Optim. 2000, 32, 373–392. [Google Scholar] [CrossRef]

- Hodges, A.R.; Bussmann, K.M.; Hoh, J.H. Improved Atomic Force Microscope Cantilever Performance by Ion Beam Modification. Rev. Sci. Instrum. 2001, 72, 3880–3883. [Google Scholar] [CrossRef]

- Sadewasser, S.; Villanueva, G.; Plaza, J.A. Special Cantilever Geometry for the Access of Higher Oscillation Modes in Atomic Force Microscopy. Appl. Phys. Lett. 2006, 89, 033106. [Google Scholar] [CrossRef]

- Cai, J.; Xia, Q.; Luo, Y.; Wang, M.Y.; Zhang, L. Optimal Design and Evaluation of Cantilever Probe for Multifrequency Atomic Force Microscopy. In Proceedings of the 11th World Congress on Structural and Multidisciplinary Optimisation, Sydney, Australia, 7–12 June 2015; pp. 6–10. [Google Scholar]

- Odin, C.; Aimé, J.; El Kaakour, Z.; Bouhacina, T. Tip’s Finite Size Effects on Atomic Force Microscopy in the Contact Mode: Simple Geometrical Considerations for Rapid Estimation of Apex Radius and Tip Angle Based on the Study of Polystyrene Latex Balls. Surf. Sci. 1994, 317, 321–340. [Google Scholar] [CrossRef]

- Orji, N.G.; Itoh, H.; Wang, C.; Dixson, R.G.; Walecki, P.S.; Schmidt, S.W.; Irmer, B. Tip Characterization Method Using Multi-Feature Characterizer for CD-AFM. Ultramicroscopy 2016, 162, 25–34. [Google Scholar] [CrossRef]

- Stirling, J.; Shaw, G.A. Calculation of the Effect of Tip Geometry on Noncontact Atomic Force Microscopy Using a QPlus Sensor. Beilstein J. Nanotechnol. 2013, 4, 10–19. [Google Scholar] [CrossRef] [PubMed]

- Dai, G.; Xu, L.; Hahm, K. Accurate Tip Characterization in Critical Dimension Atomic Force Microscopy. Meas. Sci. Technol. 2020, 31, 074011. [Google Scholar] [CrossRef]

- Lee, S.I.; Lee, J.M.; Hong, S.H. Dynamics and Control of Tapping Tip in Atomic Force Microscope for Surface Measurement Applications. CIRP Ann.-Manuf. Technol. 2005, 54, 527–530. [Google Scholar] [CrossRef]

- Bloo, M.L.; Haitjema, H.; Pril, W.O. Deformation and Wear of Pyramidal, Silicon-Nitride AFM Tips Scanning Micrometre-Size Features in Contact Mode. Meas. J. Int. Meas. Confed. 1999, 25, 203–211. [Google Scholar] [CrossRef]

- Stevens, R.M. New Carbon Nanotube AFM Probe Technology. Mater. Today 2009, 12, 42–45. [Google Scholar] [CrossRef]

- Weber, J.C.; Blanchard, P.T.; Sanders, A.W.; Imtiaz, A.; Wallis, T.M.; Coakley, K.J.; Bertness, K.A.; Kabos, P.; Sanford, N.A.; Bright, V.M. Gallium Nitride Nanowire Probe for Near-Field Scanning Microwave Microscopy. Appl. Phys. Lett. 2014, 104, 023113. [Google Scholar] [CrossRef]

- Hosoi, A.; Koto, H.; Ju, Y. Fabrication of AFM Probe with CuO Nanowire Formed by Stress-Induced Method. Microsyst. Technol. 2014, 20, 2221–2229. [Google Scholar] [CrossRef]

- Ercolano, G.; van Nisselroy, C.; Merle, T.; Vörös, J.; Momotenko, D.; Koelmans, W.; Zambelli, T. Additive Manufacturing of Sub-Micron to Sub-Mm Metal Structures with Hollow AFM Cantilevers. Micromachines 2019, 11, 6. [Google Scholar] [CrossRef]

- Yao, Z.; Xia, X.; Hou, Y.; Zhang, P.; Zhai, X.; Chen, Y. Metasurface-Enhanced Optical Lever Sensitivity for Atomic Force Microscopy. Nanotechnology 2019, 30, 365501. [Google Scholar] [CrossRef]

- Fischeneder, M.; Oposich, M.; Schneider, M.; Schmid, U. Tuneable Q-Factor of MEMS Cantilevers with Integrated Piezoelectric Thin Films. Sensors 2018, 18, 3842. [Google Scholar] [CrossRef] [PubMed]

- Adams, J.D.; Erickson, B.W.; Grossenbacher, J.; Brugger, J.; Nievergelt, A.; Fantner, G.E. Harnessing the Damping Properties of Materials for High-Speed Atomic Force Microscopy. Nat. Nanotechnol. 2016, 11, 147–151. [Google Scholar] [CrossRef]

- Fairbairn, M.W.; Moheimani, S.O.R.; Fleming, A.J. Improving the Scan Rate and Image Quality in Tapping Mode Atomic Force Microscopy with Piezoelectric Shunt Control. In Proceedings of the Proceedings of the 2011 Australian Control Conference, AUCC 2011, Melbourne, Australia, 10–11 November 2011; IEEE: New York, NY, USA, 2011; pp. 26–31. [Google Scholar]

- McCarty, R.; Nima Mahmoodi, S. Parameter Sensitivity Analysis of Nonlinear Piezoelectric Probe in Tapping Mode Atomic Force Microscopy for Measurement Improvement. J. Appl. Phys. 2014, 115, 74501. [Google Scholar] [CrossRef]

- Korayem, M.H.; Nahavandi, A. Modeling and Simulation of AFM Cantilever with Two Piezoelectric Layers Submerged in Liquid over Rough Surfaces. Precis. Eng. 2015, 42, 261–275. [Google Scholar] [CrossRef]

- Satoh, N.; Kobayashi, K.; Watanabe, S.; Fujii, T.; Matsushige, K.; Yamada, H. Scanning Near-Field Optical Microscopy System Based on Frequency-Modulation Atomic Force Microscopy Using a Piezoelectric Cantilever. Jpn. J. Appl. Phys. 2014, 53, 125201. [Google Scholar] [CrossRef]

- Satoh, N.; Tsunemi, E.; Kobayashi, K.; Matsushige, K.; Yamada, H. Multi-Probe Atomic Force Microscopy Using Piezo-Resistive Cantilevers and Interaction between Probes. e-J. Surf. Sci. Nanotechnol. 2013, 11, 13–17. [Google Scholar] [CrossRef]

- Rogers, B.; Sulchek, T.; Murray, K.; York, D.; Jones, M.; Manning, L.; Malekos, S.; Beneschott, B.; Adams, J.D.; Cavazos, H.; et al. High Speed Tapping Mode Atomic Force Microscopy in Liquid Using an Insulated Piezoelectric Cantilever. Rev. Sci. Instrum. 2003, 74, 4683–4686. [Google Scholar] [CrossRef]

- Peng, J.; Guo, J.; Ma, R.; Jiang, Y. Water-Solid Interfaces Probed by High-Resolution Atomic Force Microscopy. Surf. Sci. Rep. 2022, 77, 100549. [Google Scholar] [CrossRef]

- Rogers, B.; Manning, L.; Sulchek, T.; Adams, J. Improving Tapping Mode Atomic Force Microscopy with Piezoelectric Cantilevers. Ultramicroscopy 2004, 100, 267–276. [Google Scholar] [CrossRef]

- Ried, R.P.; Mamin, H.J.; Terris, B.D.; Fan, L.S.; Rugar, D. 6-MHz 2-N/m Piezoresistive Atomic-Force-Microscope Cantilevers with INCISIVE Tips. J. Microelectromech. Syst. 1997, 6, 294–302. [Google Scholar] [CrossRef]

- Rugar, D.; Züger, O.; Hoen, S.; Yannoni, C.S.; Vieth, H.M.; Kendrick, R.D. Force Detection of Nuclear Magnetic Resonance. Science 1994, 264, 1560–1563. [Google Scholar] [CrossRef]

- Florin, E.; Radmacher, M.; Fleck, B.; Gaub, H.E. Atomic Force Microscope with Magnetic Force Modulation. Rev. Sci. Instrum. 1994, 65, 639–643. [Google Scholar] [CrossRef]

- Karatay, D.U.; Harrison, J.S.; Glaz, M.S.; Giridharagopal, R.; Ginger, D.S. Fast Time-Resolved Electrostatic Force Microscopy: Achieving Sub-Cycle Time Resolution. Rev. Sci. Instrum. 2016, 87, 053702. [Google Scholar] [CrossRef] [PubMed]

- Liebig, A.; Peronio, A.; Meuer, D.; Weymouth, A.J.; Giessibl, F.J. High-Precision Atomic Force Microscopy with Atomically-Characterized Tips. New J. Phys. 2020, 22, 063040. [Google Scholar] [CrossRef]

- Mineta, T.; Kawashima, K.; Taguchi, R. Fabrication and Characterization of Dual AFM Probe with Narrow-Gapped Silicon Tips and Switchable Cantilevers with Magneto-Strictive FePd Film Actuator. Microelectron. Eng. 2017, 168, 45–49. [Google Scholar] [CrossRef]

- Bucinskas, V.; Dzedzickis, A.; Sutinys, E.; Lenkutis, T.; Bučinskas, V.; Dzedzickis, A.; Šutinys, E.; Lenkutis, T. Implementation of Different Gas Influence for Operation of Modified Atomic Force Microscope Sensor. Solid State Phenom. 2017, 260, 99–104. [Google Scholar] [CrossRef]

- Dzedzickis, A.; Bučinskas, V.; Lenkutis, T.; Morkvėnaitė-Vilkončienė, I.; Kovalevskyi, V. Increasing Imaging Speed and Accuracy in Contact Mode AFM. In Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2020; Volume 920, pp. 599–607. ISBN 9783030132729. [Google Scholar]

- Degertekin, F.L.; Hadimioglu, B.; Sulchek, T.; Quate, C.F. Actuation and Characterization of Atomic Force Microscope Cantilevers in Fluids by Acoustic Radiation Pressure. Appl. Phys. Lett. 2001, 78, 1628–1630. [Google Scholar] [CrossRef]

- Kwon, J.; Hong, J.; Kim, Y.-S.; Lee, D.-Y.; Lee, K.; Lee, S.; Park, S. Atomic Force Microscope with Improved Scan Accuracy, Scan Speed, and Optical Vision. Rev. Sci. Instrum. 2003, 74, 4378–4383. [Google Scholar] [CrossRef]

- Cai, K.; He, X.; Tian, Y.; Liu, X.; Zhang, D.; Shirinzadeh, B. Design of a XYZ Scanner for Home-Made High-Speed Atomic Force Microscopy. Microsyst. Technol. 2018, 24, 3123–3132. [Google Scholar] [CrossRef]

- Soltani Bozchalooi, I.; Careaga Houck, A.; AlGhamdi, J.M.; Youcef-Toumi, K. Design and Control of Multi-Actuated Atomic Force Microscope for Large-Range and High-Speed Imaging. Ultramicroscopy 2016, 160, 213–224. [Google Scholar] [CrossRef]

- Ulčinas, A.; Vaitekonis, Š. Rotational Scanning Atomic Force Microscopy. Nanotechnology 2017, 28, 10LT02. [Google Scholar] [CrossRef] [PubMed]

- Nievergelt, A.P.; Andany, S.H.; Adams, J.D.; Hannebelle, M.T.; Fantner, G.E. Components for High-Speed Atomic Force Microscopy Optimized for Low Phase-Lag. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Munich, Germany, 3–7 July 2017; IEEE: New York, NY, USA, 2017; pp. 731–736. [Google Scholar]

- Heaps, E.; Yacoot, A.; Dongmo, H.; Picco, L.; Payton, O.D.; Russell-Pavier, F.; Klapetek, P. Bringing Real-Time Traceability to High-Speed Atomic Force Microscopy. Meas. Sci. Technol. 2020, 31, 74005–74016. [Google Scholar] [CrossRef]

- Fleming, A.J.; Kenton, B.J.; Leang, K.K. Bridging the Gap between Conventional and Video-Speed Scanning Probe Microscopes. Ultramicroscopy 2010, 110, 1205–1214. [Google Scholar] [CrossRef] [PubMed]

- Fairbairn, M.W.; Moheimani, S.O.R. Control Techniques for Increasing the Scan Speed and Minimizing Image Artifacts in Tapping-Mode Atomic Force Microscopy: Toward Video-Rate Nanoscale Imaging. IEEE Control Syst. 2013, 33, 46–67. [Google Scholar] [CrossRef]

- Schitter, G.; Fantner, G.E.; Thurner, P.J.; Adams, J.; Hansma, P.K. Design and Characterization of a Novel Scanner for High-Speed Atomic Force Microscopy. IFAC Proc. Vol. 2006, 39, 819–824. [Google Scholar] [CrossRef]

- Schitter, G.; Stemmer, A.; Allgower, F. Robust Two-Degree-of-Freedom Control of an Atomic Force Microscope. Asian J. Control 2004, 6, 156–163. [Google Scholar] [CrossRef]

- López-Guerra, E.A.; Somnath, S.; Solares, S.D.; Jesse, S.; Ferrini, G. Few-Cycle Regime Atomic Force Microscopy. Sci. Rep. 2019, 9, 12721. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-Y.; Mullin, N.; Hobbs, J.K. High-Speed Large Area Atomic Force Microscopy Using a Quartz Resonator. Nanotechnology 2018, 29, 335502. [Google Scholar] [CrossRef] [PubMed]

| Dimensions 1 | Spring Constant, N/m | Resonant Frequency, kHz | Working Environment | Ref. | ||

|---|---|---|---|---|---|---|

| l, μm | w, μm | t, nm | ||||

| 100–450 | 50 | 2000 | - | - | Air | [79] |

| 750 | 160 | - | - | 48.5 | Air | [80] |

| 200 20 85 | 20 0.75 18 | 600 | (0.1–10) −6 | (0.1–100) × 103 | Liquid | [55] |

| 5 | 2 | 50 | 0.1 | 2.8 × 103 | - | [56] |

| 23–203 | - | - | 1.3 | - | Air and liquid | [58] |

| 20–400 | 4–6 | 600 | 6.5 × 10−6 | 1.7 | - | [60] |

| 10–14 | 3–5 | 100 | 0.1–0.2 | 100–200 | Liquid | [61] |

| - | - | - | 1.7 ± 0.2 | 61.85 ± 0.1 | Liquid | [52] |

| ∼200 ∼388 | - | - | 0.02–0.03 | 0–100 | Air and liquid | [53] |

| 10–100 | - | - | 0.01–100 | 30–190 | - | [54] |

| - | - | - | 0.06 | - | - | [69] |

| 21 200 | 0.75 20 | - 600 | 0.5 | 7–62 35–136 | Liquid Air | [66] |

| 200 | 10–50 | 1000 | - | 40–140 | Air | [67] |

| 225 | 27 | 2700 | 1.6 | 61 | - | [68] |

| 100 25 | 30 10 | 10 2.5 | 6 74 | 1690 337 | Air and liquid | [81] |

| Scanning Mode | Improvement | Scanning Area, µm2 | Achieved Velocities, mm/s | Ref. |

|---|---|---|---|---|

| Contact mode | Increased scanner stiffness, designed piezoelectric scanner based on the parallel mechanism with flexible links | 8 × 7 | 2 | [100] |

| - | Multiple drives connected in series | 120 × 120 | 3 | [101] |

| Contact mode | Implementation of a resonance-based drive into the scanner x-axis | 170 × 170 | 200–440 | [110] |

| Contact mode | Implementation of rotational scanning trajectory | ∅ 141.9 | 45 | [102] |

| Tapping mode | Photothermal cantilever drive and imaging algorithm which considers the delay of system components | 1.6 × 1.6 | 3.2 | [103] |

| Contact mode | Cantilever deflection measurement system based on the optical pickup unit | 14 × 14 | 10 | [11] |

| Contact mode | Implementation of high-speed vertical positioning sinusoidal scanning and high-speed image acquisition | 20 × 20 | 4 | [105] |

| Tapping mode | Analyzed and implemented control techniques based on a modification of z-axis feedback and active control of the cantilever quality factor to increase scanning speed and minimize image artifacts | - | - | [106] |

| - | Increased scanner stiffness and implemented a mechanism with flexible links, enabling the decoupling of separate axes. Implemented the scanner dynamic compensation function into the control algorithm | 13 × 13 | 101.5 | [107] |

| - | Designed a controller for a two-degrees-of-freedom system in which a model-based control method was realized instead of the traditional proportional–integral method | 15 × 15 | 0.15 | [108] |

| - | Designed scanner with optical position measuring system based on interferometers | 500 × 80 | 8 | [104] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzedzickis, A.; Rožėnė, J.; Bučinskas, V.; Viržonis, D.; Morkvėnaitė-Vilkončienė, I. Characteristics and Functionality of Cantilevers and Scanners in Atomic Force Microscopy. Materials 2023, 16, 6379. https://doi.org/10.3390/ma16196379

Dzedzickis A, Rožėnė J, Bučinskas V, Viržonis D, Morkvėnaitė-Vilkončienė I. Characteristics and Functionality of Cantilevers and Scanners in Atomic Force Microscopy. Materials. 2023; 16(19):6379. https://doi.org/10.3390/ma16196379

Chicago/Turabian StyleDzedzickis, Andrius, Justė Rožėnė, Vytautas Bučinskas, Darius Viržonis, and Inga Morkvėnaitė-Vilkončienė. 2023. "Characteristics and Functionality of Cantilevers and Scanners in Atomic Force Microscopy" Materials 16, no. 19: 6379. https://doi.org/10.3390/ma16196379