Mechanisms of Serrated Flow and Microstructural Evolution in MarBN Steel

Abstract

:1. Introduction

2. Experimental Procedure

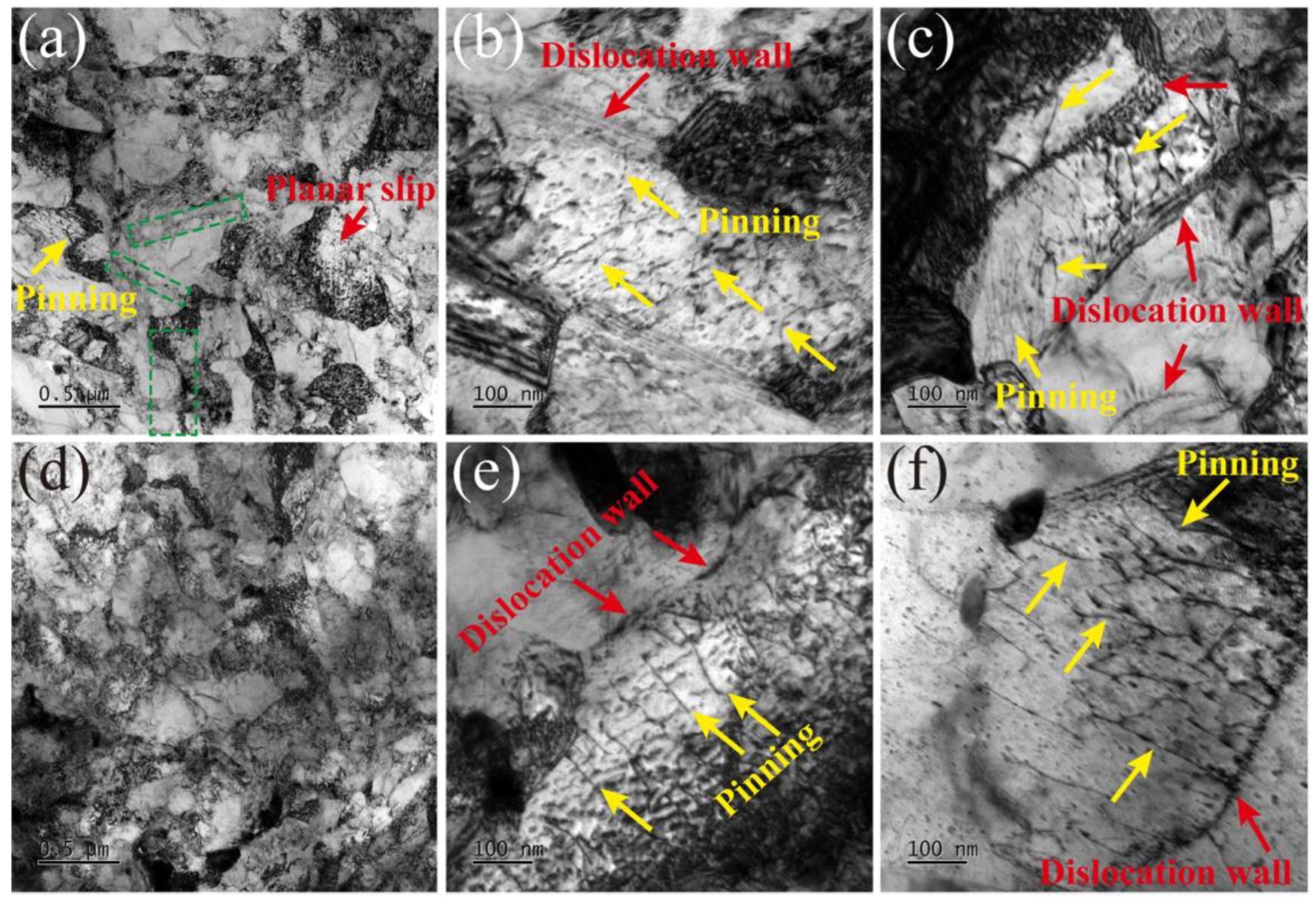

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Cottrell, A.H. LXXXVI. A note on the Portevin-Le Chatelier effect. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1953, 44, 829–832. [Google Scholar] [CrossRef]

- Ilić, N.; Drobnjak, D.; Radmilović, V.; Jovanović, M.T.; Marković, D. Serrated yielding in Al-Li base alloys. Scr. Mater. 1996, 34, 1123–1130. [Google Scholar] [CrossRef]

- Kumar, S.; Król, J.; Pink, E. Mechanism of serrated flow in binary Al-Li alloys. Scr. Mater. 1996, 35, 775–780. [Google Scholar] [CrossRef]

- Nalawade, S.A.; Sundararaman, M.; Kishore, R.; Shah, J.G. The influence of aging on the serrated yielding phenomena in a nickel-base superalloy. Scr. Mater. 2008, 59, 991–994. [Google Scholar] [CrossRef]

- Rai, R.K.; Sahu, J.K. Mechanism of serrated flow in a cast nickel base superalloy. Mater. Lett. 2018, 210, 298–300. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.; Li, K.; Song, Y.; Liu, D.; Yuan, R.; Wang, J.; Tang, B.; Kou, H.; Li, J. Serrated flow behavior and microstructure evolution of Inconel 625 superalloy during plane-strain compression with different strain rates. J. Alloys Compd. 2021, 881, 160648. [Google Scholar] [CrossRef]

- Zhu, S.M.; Nie, J.F. Serrated flow and tensile properties of a Mg–Y–Nd alloy. Scr. Mater. 2004, 50, 51–55. [Google Scholar] [CrossRef]

- Wang, W.H.; Wu, D.; Shah, S.S.A.; Chen, R.S.; Lou, C.S. The mechanism of critical strain and serration type of the serrated flow in Mg–Nd–Zn alloy. Mater. Sci. Eng. A 2016, 649, 214–221. [Google Scholar] [CrossRef]

- Pozuelo, M.; Chang, Y.W.; Marian, J.; Yang, J.M. Serrated flow in nanostructured binary Mg-Al alloys. Scr. Mater. 2017, 127, 178–181. [Google Scholar] [CrossRef]

- Chandravathi, K.S.; Laha, K.; Parameswaran, P.; Mathew, M.D. Effect of microstructure on the critical strain to onset of serrated flow in modified 9Cr–1Mo steel. Int. J. Press. Vessels Pip. 2012, 89, 162–169. [Google Scholar] [CrossRef]

- Choudhary, B.K. Influence of strain rate and temperature on serrated flow in 9Cr–1Mo ferritic steel. Mater. Sci. Eng. A 2013, 564, 303–309. [Google Scholar] [CrossRef]

- Qian, L.; Guo, P.; Zhang, F.; Meng, J.; Zhang, M. Abnormal room temperature serrated flow and strain rate dependence of critical strain of a Fe–Mn–C twin-induced plasticity steel. Mater. Sci. Eng. A 2013, 561, 266–269. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, P.; Wang, G.; Liu, S. Serrated flow and failure behaviors of a Hadfield steel at various strain rates under extensometer-measured strain control tensile load. J. Mater. Res. Technol. 2020, 9, 1500–1508. [Google Scholar] [CrossRef]

- Oh, S.-K.; Kwon, H.-J.; Lee, Y.-K. Inverse PLC behavior of type A serration in Fe–18Mn-0.55C steel. J. Mater. Res. Technol. 2023, 26, 984–989. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, X.; Zhang, B.; Cen, Q.; Dong, H. Plasticity enhancement mechanism: Effect of the annealing temperature on strain-induced segmented martensitic transformations and Portevin–Le Chatelier bands in 7Mn steel after deep cryogenic treatment. Mater. Charact. 2022, 194, 112475. [Google Scholar] [CrossRef]

- McCormigk, P.G. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, B.; Xie, X.; Ren, Y.; Venable, J.D.; Liaw, P.K.; Zinkle, S.J. Entropy modeling on serrated flows in carburized steels. Mater. Sci. Eng. A 2019, 753, 135–145. [Google Scholar] [CrossRef]

- Abe, F. Research and Development of Heat-Resistant Materials for Advanced USC Power Plants with Steam Temperatures of 700 °C and Above. Engineering 2015, 1, 211–224. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Gong, X.; Li, Q.; Liu, Y.; Wang, Q.; Zhang, H.; Wang, Q. Low cycle fatigue properties, damage mechanism, life prediction and microstructure of MarBN steel: Influence of temperature. Int. J. Fatigue 2021, 144, 106070. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Q.; Gong, X.; Wang, T.; Pei, Y.; Zhang, W.; Liu, Y.; Wang, C.; Wang, Q. Comparisons of low cycle fatigue response, damage mechanism, and life prediction of MarBN steel under stress and strain-controlled modes. Int. J. Fatigue 2021, 149, 106291. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Q.; Gong, X.; Wang, T.; Zhang, W.; Chen, K.; Wang, C.; Liu, Y.; Wang, Q. Dependence on temperature of compression behavior and deformation mechanisms of nickel-based single crystal CMSX-4. J. Alloys Compd. 2021, 866, 158878. [Google Scholar] [CrossRef]

- Gong, X.; Wang, T.; Li, Q.; Liu, Y.; Zhang, H.; Zhang, W.; Wang, Q.; Wang, Q. Cyclic responses and microstructure sensitivity of Cr-based turbine steel under different strain ratios in low cycle fatigue regime. Mater. Des. 2021, 201, 109529. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Q.; Chen, X.; Chen, Z.; Jiang, Z.; Wu, X.; Fan, J. Three types of Portevin–Le Chatelier effects: Experiment and modelling. Acta Mater. 2007, 55, 2219–2228. [Google Scholar] [CrossRef]

- Chihab, K.; Estrin, Y.; Kubin, L.P.; Vergnol, J. The kinetics of the Portevin-Le Chatelier bands in an Al-5at%Mg alloy. Scr. Met. Mater. 1987, 21, 203–208. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Van Den Beukel, A.; Kocks, U.F. The strain dependence of static and dynamic strain-aging. Acta Metall. 1982, 30, 1027–1034. [Google Scholar] [CrossRef]

- Fu, S.; Cheng, T.; Zhang, Q.; Hu, Q.; Cao, P. Two mechanisms for the normal and inverse behaviors of the critical strain for the Portevin–Le Chatelier effect. Acta Mater. 2012, 60, 6650–6656. [Google Scholar] [CrossRef]

- Huang, A.; Wang, Z.; Liu, X.; Yuan, Q.; Ye, J.; Zhang, Y. Dynamic strain aging and serrated flow behavior of Cr-Ti-B low carbon steel during warm deformation. Mater. Charact. 2021, 172, 110828. [Google Scholar] [CrossRef]

- Chaenock, W. The initiation of serrated yielding at elevated temperatures. Philos. Mag. A J. Theor. Exp. Appl. Phys. 1969, 20, 427–432. [Google Scholar] [CrossRef]

- Kubin, L.P.; Estrin, Y. Evolution of dislocation densities and the critical conditions for the Portevin-Le Châtelier effect. Acta Met. Mater. 1990, 38, 697–708. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials; Wiley-Interscience: Hoboken, NJ, USA, 1994. [Google Scholar]

- Zhang, J.-S. High Temperature Deformation and Fracture of Materials; Woodhead Publishing: Cambridge, UK, 2010; p. 384. [Google Scholar]

- Hirth, J.P.; Lothe, J. Theory of Dislocations, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1982; pp. 476–477. [Google Scholar]

- Palaparti, D.P.R.; Choudhary, B.K.; Isaac Samuel, E.; Srinivasan, V.S.; Mathew, M.D. Influence of strain rate and temperature on tensile stress–strain and work hardening behaviour of 9Cr–1Mo ferritic steel. Mater. Sci. Eng. A 2012, 538, 110–117. [Google Scholar] [CrossRef]

- Nicho, R.V.V. Symposium on Internal Stresses in Metals and Alloys. Nature 1949, 164, 296. [Google Scholar] [CrossRef]

- Zhou, H.; Bai, F.; Yang, L.; Wei, H.; Chen, Y.; Peng, G.; He, Y. Mechanism of Dynamic Strain Aging in a Niobium-Stabilized Austenitic Stainless Steel. Metall. Mater. Trans. A 2018, 49, 1202–1210. [Google Scholar] [CrossRef]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, T.; Wang, Q.; Pei, Y.; Mei, T.; Zhang, H. Mechanisms of Serrated Flow and Microstructural Evolution in MarBN Steel. Materials 2023, 16, 6411. https://doi.org/10.3390/ma16196411

Zou T, Wang Q, Pei Y, Mei T, Zhang H. Mechanisms of Serrated Flow and Microstructural Evolution in MarBN Steel. Materials. 2023; 16(19):6411. https://doi.org/10.3390/ma16196411

Chicago/Turabian StyleZou, Tongfei, Quanyi Wang, Yubing Pei, Ting Mei, and Hong Zhang. 2023. "Mechanisms of Serrated Flow and Microstructural Evolution in MarBN Steel" Materials 16, no. 19: 6411. https://doi.org/10.3390/ma16196411