Translucency of Lithium-Based Silicate Glass–Ceramics Blocks for CAD/CAM Procedures: A Narrative Review

Abstract

:1. Introduction

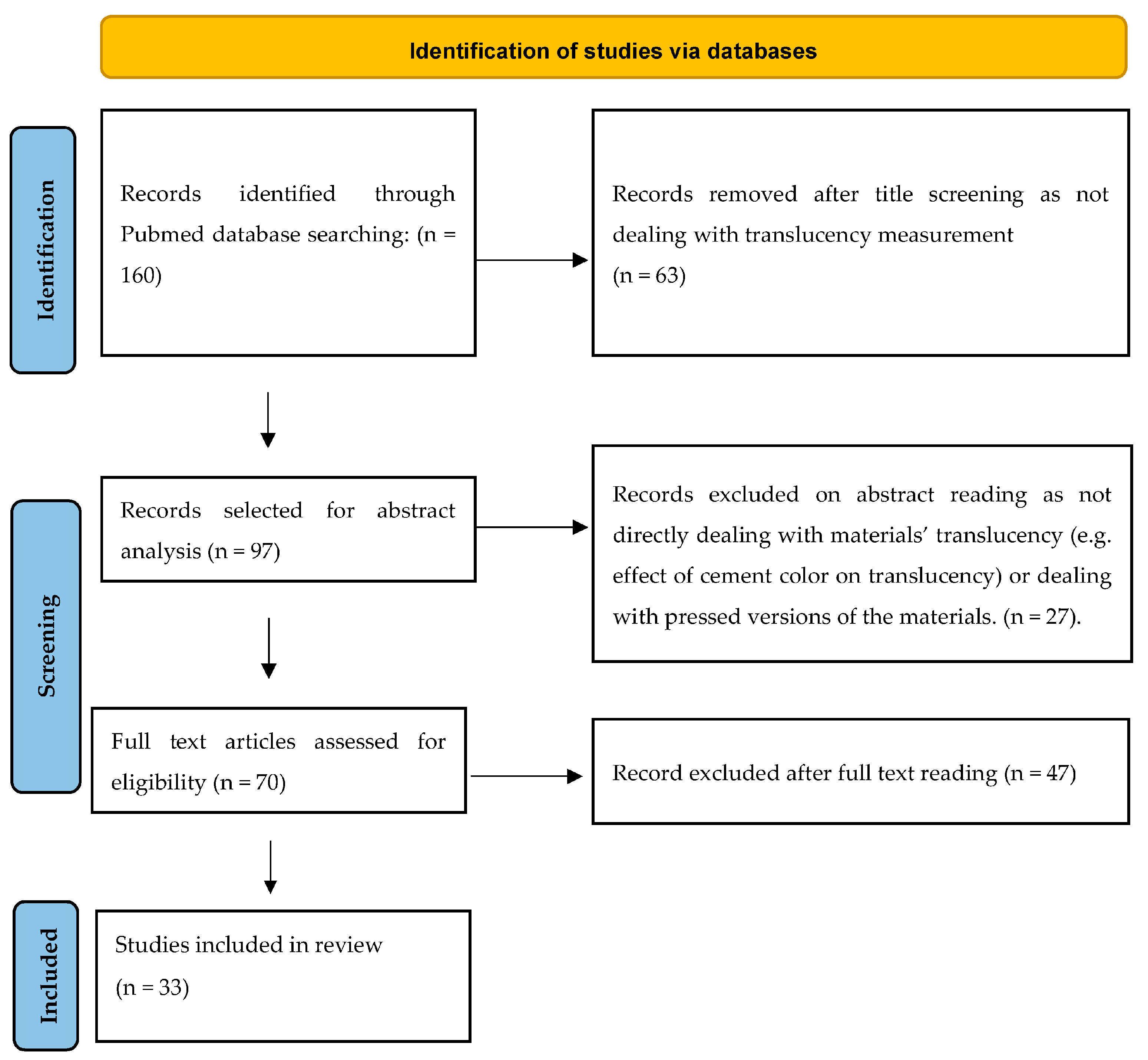

2. Materials and Methods

2.1. Search Strategy

2.2. Inclusion Criteria

2.3. Exclusion Criteria

2.4. Data Extraction

3. Results

4. Discussion

5. Conclusions

- TP is the most used method for evaluating the translucency of LSGC;

- Most of the studies used a 1 mm specimen thickness;

- HT and LT (T) formulations were equally investigated; A2 was the most investigated color, followed by A1 and A3;

- Data are sufficiently available for e.max lithium disilicate but scarce for ZLS VITA Suprinity PC and Celtra Duo and not available for the other searched LDGCs (N!ce, LiSi CAD, Amber Mill, and Tessera);

- TP was prevalently measured in the range of 16–18 for LT and in the range of 18–19 for HT;

- CR was prevalently measured in the range of 0.56–0.63 for LT and in the range of 0.48–0.58 for HT.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fathy, S.M.; Al-Zordk, W.; Grawish, M.; Swain, M.V. Flexural Strength and Translucency Characterization of Aesthetic Monolithic Zirconia and Relevance to Clinical Indications: A Systematic Review. Dent. Mater. 2021, 37, 711–730. [Google Scholar] [CrossRef] [PubMed]

- Della Bona, A.; Kelly, J.R. The Clinical Success of All-Ceramic Restorations. J. Am. Dent. Assoc. 2008, 139, S8–S13. [Google Scholar] [CrossRef] [PubMed]

- Vichi, A.; Sedda, M.; Del Siena, F.; Louca, C.; Ferrari, M. Flexural resistance of Cerec CAD/CAM System Ceramic Blocks. Part I: Chairside materials. Am. J. Dent. 2013, 26, 255–259. [Google Scholar] [PubMed]

- Sedda, M.; Vichi, A.; Del Siena, F.; Louca, C.; Ferrari, M. Flexural resistance of Cerec CAD/CAM System Ceramic Blocks. Part II: Outsourcing materials. Am. J. Dent. 2014, 27, 17–22. [Google Scholar] [PubMed]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Güth, J.F. Evaluation of Mechanical and Optical Behavior of Current Esthetic Dental Restorative CAD/Cam Composites. J. Mech. Behav. Biomed. Mater. 2015, 55, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Tezulas, E.; Yildiz, C.; Evren, B.; Ozkan, Y. Clinical Procedures, Designs, and Survival Rates of All-Ceramic Resin-Bonded Fixed Dental Prostheses in the Anterior Region: A Systematic Review. J. Esthet. Restor. Dent. 2018, 30, 307–318. [Google Scholar] [CrossRef]

- Chen, J.; Cai, H.; Ren, X.; Suo, L.; Pei, X.; Wan, Q. A Systematic Review of the Survival and Complication Rates of All-Ceramic Resin-Bonded Fixed Dental Prostheses. J. Prosthodont. 2017, 27, 535–543. [Google Scholar] [CrossRef]

- Vichi, A.; Goracci, C.; Carrabba, M.; Tozzi, G.; Louca, C. Flexural resistance of CAD/CAM blocks. Part 3: Polymer-based restorative materials for permanent restorations. Am. J. Dent. 2020, 33, 243–247. [Google Scholar]

- Saravi, B.; Vollmer, A.; Hartmann, M.; Lang, G.; Kohal, R.-J.; Boeker, M.; Patzelt, S.B. Clinical Performance of CAD/CAM All-Ceramic Tooth-Supported Fixed Dental Prostheses: A Systematic Review and Meta-Analysis. Materials 2021, 14, 2672. [Google Scholar] [CrossRef]

- Vichi, A.; Zhao, Z.; Paolone, G.; Scotti, N.; Mutahar, M.; Goracci, C.; Louca, C. Factory crystallized silicates for monolithic metal-free restorations: A flexural strength and translucency comparison test. Materials 2022, 15, 7834. [Google Scholar] [CrossRef]

- Sen, N.; Us, Y.O. Mechanical and Optical Properties of Monolithic CAD-Cam Restorative Materials. J. Prosthet. Dent. 2018, 119, 593–599. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Ahn, J.S.; Lee, Y.K. Measurement of Translucency of Tooth Enamel and Dentin. Acta Odontol. Scand. 2009, 67, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Skyllouriotis, A.L.; Yamamoto, H.L.; Nathanson, D. Masking Properties of Ceramics for Veneer Restorations. J. Prosthet. Dent. 2017, 118, 517–523. [Google Scholar] [CrossRef] [PubMed]

- Basegio, M.; Pecho, O.; Ghinea, R.; Perez, M.; Della Bona, A. Masking ability of indirect restorative systems on tooth-colored resin substrates. Dent. Mater. 2019, 35, e122–e130. [Google Scholar] [CrossRef] [PubMed]

- Gunal, B.; Ulusoy, M.M. Optical Properties of Contemporary Monolithic CAD-Cam Restorative Materials at Different Thicknesses. J. Esthet. Restor. Dent. 2018, 30, 434–441. [Google Scholar] [CrossRef]

- Lubauer, J.; Belli, R.; Peterlik, H.; Hurle, K.; Lohbauer, U. Grasping the Lithium Hype: Insights into Modern Dental Lithium Silicate Glass-Ceramics. Dent. Mater. 2022, 38, 318–332. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Mandl, A.; Liebermann, A. Modern CAD/CAM Silicate Ceramics, Their Translucency Level and Impact of Hydrothermal Aging on Translucency, Martens Hardness, Biaxial Flexural Strength and Their Reliability. J. Mech. Behav. Biomed. Mater. 2021, 118, 104456. [Google Scholar] [CrossRef]

- Johnston, W.M.; Ma, T.; Kienle, B.H. Translucency parameter of colorants for maxillofacial prostheses. Int. J. Prosthodont. 1995, 8, 79–86. [Google Scholar]

- Shirani, M.; Savabi, O.; Mosharraf, R.; Akhavankhaleghi, M.; Hebibkhodaei, M.; Isler, S. Comparison of Translucency and Opalescence among Different Dental Monolithic Ceramics. J. Prosthet. Dent. 2021, 126, 446.e1–446.e6. [Google Scholar] [CrossRef]

- Carrabba, M.; Keeling, A.J.; Aziz, A.; Vichi, A.; Fabian Fonzar, R.; Wood, D.; Ferrari, M. Translucent Zirconia in the Ceramic Scenario for Monolithic Restorations: A Flexural Strength and Translucency Comparison Test. J. Dent. 2017, 60, 70–76. [Google Scholar] [CrossRef]

- Alayad, A.S.; Alqhatani, A.; Alkatheeri, M.S.; Alshehri, M.; AlQahtani, M.A.; Osseil, A.E.; Almusallam, R.A. Effects of CAD/CAM Ceramics and Thicknesses on Translucency and Color Masking of Substrates. Saudi Dent. J. 2021, 33, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Bagis, B.; Turgut, S. Optical Properties of Current Ceramics Systems for Laminate Veneers. J. Dent. 2013, 41, e24–e30. [Google Scholar] [CrossRef] [PubMed]

- Baldissara, P.; Wandscher, V.F.; Marchionatti, A.M.; Parisi, C.; Monaco, C.; Ciocca, L. Translucency of IPS E.max and Cubic Zirconia Monolithic Crowns. J. Prosthet. Dent. 2018, 120, 269–275. [Google Scholar] [CrossRef]

- Barizon, K.T.L.; Bergeron, C.; Vargas, M.A.; Qian, F.; Cobb, D.S.; Gratton, D.G.; Geraldeli, S. Ceramic Materials for Porcelain Veneers. Part I: Correlation between Translucency Parameters and Contrast Ratio. J. Prosthet. Dent. 2013, 110, 397–401. [Google Scholar] [CrossRef] [PubMed]

- Barizon, K.T.L.; Bergeron, C.; Vargas, M.A.; Qian, F.; Cobb, D.S.; Gratton, D.G.; Geraldeli, S. Ceramic Materials for Porcelain Veneers: Part II. Effect of Material, Shade, and Thickness on Translucency. J. Prosthet. Dent. 2014, 112, 864–870. [Google Scholar] [CrossRef]

- Basso, G.R.; Kodama, A.B.; Pimentel, A.H.; Kaizer, M.R.; Della Bona, A.; Moraes, R.R.; Boscato, N. Masking Colored Substrates Using Monolithic and Bilayer CAD-Cam Ceramic Structures. Oper. Dent. 2017, 42, 387–395. [Google Scholar] [CrossRef] [PubMed]

- Brescansin, F.N.; Prochnow, C.; Guilardi, L.F.; Kleverlaan, C.J.; Bacchi, A.; Valandro, L.F.; Pereira, G.K. Effect of Different Surface Treatments on Optical, Colorimetric, and Surface Characteristics of a Lithium Disilicate Glass–Ceramic. J. Esthet. Restor. Dent. 2021, 33, 1017–1028. [Google Scholar] [CrossRef]

- Campanelli de Morais, D.; Oliveira Abuizze, F.; Rivoli Rossi, N.; Gallo Oliani, M.; Assunção de Souza, R.O.; Siqueira Anzolini Saavedra, G.; Bottino, M.A.; Marques de Melo Marinho, R. Effect of Consecutive Firings on the Optical and Mechanical Properties of Silicate and Lithium Disilicate Based Glass-Ceramics. J. Prosthodont. 2021, 30, 776–782. [Google Scholar] [CrossRef]

- Caprak, Y.O.; Turkoglu, P.; Akgungor, G. Does the Translucency of Novel Monolithic CAD/CAM Materials Affect Resin Cement Polymerization with Different Curing Modes? J. Prosthodont. 2018, 28, e572–e579. [Google Scholar] [CrossRef]

- Della Bona, A.; Nogueira, A.D.; Pecho, O.E. Optical Properties of CAD–Cam Ceramic Systems. J. Dent. 2014, 42, 1202–1209. [Google Scholar] [CrossRef]

- Gasparik, C.; Culic, B.; Varvara, M.A.; Grecu, A.; Burde, A.; Dudea, D. Effect of Accelerated Staining and Bleaching on Chairside CAD/CAM Materials with High and Low Translucency. Dent. Mater. J. 2019, 38, 987–993. [Google Scholar] [CrossRef] [PubMed]

- Juntavee, N.; Uasuwan, P. Influence of Thermal Tempering Processes on Color Characteristics of Different Monolithic Computer-Assisted Design and Computer-Assisted Manufacturing Ceramic Materials. J. Clin. Exp. Dent. 2019, 11, 614–624. [Google Scholar] [CrossRef] [PubMed]

- Kanpalta, B.; Burduroğlu, D.; Kara, Ö. Effect of Artificial Aging on the Translucency of Monolithic Zirconia Materials Sintered at Different Temperatures. J. Prosthet. Dent. 2022, 128, 91.e1–91.e6. [Google Scholar] [CrossRef] [PubMed]

- Karci, M.; Demir, N. Effect of Home Bleaching on the Translucency of CAD/CAM Systems. J. Prosthodont. 2017, 28, 310–314. [Google Scholar] [CrossRef]

- Kulkarni, A.; Rothrock, J.; Thompson, J. Impact of Gastric Acid Induced Surface Changes on Mechanical Behavior and Optical Characteristics of Dental Ceramics. J. Prosthodont. 2018, 29, 207–221. [Google Scholar] [CrossRef]

- Kurt, M.; Bankoğlu Güngör, M.; Karakoca Nemli, S.; Turhan Bal, B. Effects of Glazing Methods on the Optical and Surface Properties of Silicate Ceramics. J. Prosthodont. 2020, 64, 202–209. [Google Scholar] [CrossRef]

- Kurtulmus-Yilmaz, S.; Cengiz, E.; Ongun, S.; Karakaya, I. The Effect of Surface Treatments on the Mechanical and Optical Behaviors of CAD/CAM Restorative Materials. J. Prosthodont. 2018, 28, 496–503. [Google Scholar] [CrossRef]

- Kwon, S.J.; Lawson, N.C.; McLaren, E.E.; Nejat, A.H.; Burgess, J.O. Comparison of the Mechanical Properties of Translucent Zirconia and Lithium Disilicate. J. Prosthet. Dent. 2018, 120, 132–137. [Google Scholar] [CrossRef]

- Lawson, N.C.; Maharishi, A. Strength and Translucency of Zirconia after High-Speed Sintering. J. Esthet. Restor. Dent. 2019, 32, 219–225. [Google Scholar] [CrossRef]

- Ledić, K.; Majnarić, I.; Milardović Ortolan, S.; Špalj, S.; Štefančić, S.; Mehulić, K. Analysis of Translucency Parameter of Glass-Ceramics Fabricated by Different Techniques. Acta Stomatol. Croat. 2015, 49, 27–35. [Google Scholar] [CrossRef]

- Monaco, C.; Arena, A.; Scheda, L.; Di Fiore, A.; Zucchelli, G. In Vitro 2D and 3D Roughness and Spectrophotometric and Gloss Analyses of Ceramic Materials after Polishing with Different Prophylactic Pastes. J. Prosthet. Dent. 2020, 124, 787.e1–787.e8. [Google Scholar] [CrossRef] [PubMed]

- Nogueira, A.D.; Della Bona, A. The Effect of a Coupling Medium on Color and Translucency of CAD–Cam Ceramics. J. Dent. 2013, 41, 18–23. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Shin, S.M.; Kim, H.J.; Paek, J.; Kim, S.J.; Yoon, T.H.; Kim, S.Y. Influence of Glass-Based Dental Ceramic Type and Thickness with Identical Shade on the Light Transmittance and the Degree of Conversion of Resin Cement. Int. J. Oral Sci. 2018, 10, 5. [Google Scholar] [CrossRef] [PubMed]

- Sen, N.; Isler, S. Microstructural, Physical, and Optical Characterization of High-Translucency Zirconia Ceramics. J. Prosthet. Dent. 2020, 123, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Supornpun, N.; Oster, M.; Phasuk, K.; Chu, T.M.G. Effects of Shade and Thickness on the Translucency Parameter of Anatomic-Contour Zirconia, Transmitted Light Intensity, and Degree of Conversion of the Resin Cement. J. Prosthet. Dent. 2021, 8, 3913. [Google Scholar] [CrossRef]

- Turgut, S.; Kılınç, H.; Bağış, B. Effect of UV Aging on Translucency of Currently Used Esthetic Cad-Cam Materials. J. Esthet. Restor. Dent. 2019, 31, 147–152. [Google Scholar] [CrossRef]

- Vichi, A.; Carrabba, M.; Paravina, R.; Ferrari, M. Translucency of Ceramic Materials for Cerec CAD/CAM System. J. Esthet. Restor. Dent. 2014, 26, 224–231. [Google Scholar] [CrossRef]

- Wang, F.; Yu, T.; Chen, J. Biaxial Flexural Strength and Translucent Characteristics of Dental Lithium Disilicate Glass Ceramics with Different Translucencies. J. Prosthodont. 2020, 64, 71–77. [Google Scholar] [CrossRef]

- Heffernan, M. Relative Translucency of Six All-Ceramic Systems. Part I: Core Materials. J. Prosthet. Dent. 2002, 88, 4–9. [Google Scholar] [CrossRef]

- Ziyad, T.A.; Abu-Naba’a, L.A.; Almohammed, S.N. Optical Properties of CAD-CAM monolithic systems compared; three multi-layerd zirconia and on lithium disilicate system. Heliyon 2021, 10, e08151. [Google Scholar] [CrossRef]

- Lee, Y.K. Influence of Scattering/Absorption Characteristics on the Color of Resin Composites. Dent. Mater. 2007, 23, 124–131. [Google Scholar] [CrossRef] [PubMed]

- Della Bona, A. Bonding to Ceramics: Scientific Evidences for Clinical Dentistry; Artes Medicas: Sao Paulo, Brazil, 2009. [Google Scholar]

- Baldissara, P.; Llukacej, A.; Ciocca, L.; Valandro, F.L.; Scotti, R. Translucency of Zirconia Copings Made with Different CAD/CAM Systems. J. Prosthet. Dent. 2010, 104, 6–12. [Google Scholar] [CrossRef] [PubMed]

- Powers, J.M.; Dennison, J.B.; Lepeak, P.J. Parameters That Affect the Color of Direct Restorative Resins. J. Dent. Res. 1978, 57, 876–880. [Google Scholar] [CrossRef] [PubMed]

- Shono, N.N.; Al Nahedh, H.N. Contrast Ratio and Masking Ability of Three Ceramic Veneering Materials. Oper. Dent. 2012, 37, 406–416. [Google Scholar] [CrossRef] [PubMed]

- Pecho, O.E.; Ghinea, R.; Ionescu, A.M.; de Cardona, J.; Paravina, R.D.; Pérez, M.M. Color and Translucency of Zirconia Ceramics, Human Dentine and Bovine Dentine. J. Dent. 2012, 40, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Pérez, M.M.; Ghinea, R.; Ugarte-Alván, L.I.; Pulgar, R.; Paravina, R.D. Color and Translucency in Silorane-Based Resin Composite Compared to Universal and Nanofilled Composites. J. Dent. 2010, 38, 110–116. [Google Scholar] [CrossRef]

- Miyagawa, Y.; Powers, J.M.; O’Brien, W.J. Optical Properties of Direct Restorative Materials. J. Dent. Res. 1981, 60, 890–894. [Google Scholar] [CrossRef]

- Spink, L.S.; Rungruanganut, P.; Megremis, S.; Kelly, J.R. Comparison of an Absolute and Surrogate Measure of Relative Translucency in Dental Ceramics. Dent. Mater. 2013, 29, 702–707. [Google Scholar] [CrossRef]

- Vichi, A.; Sedda, M.; Fabian Fonzar, R.; Carrabba, M.; Ferrari, M. Comparison of Contrast Ratio, Translucency Parameter, and Flexural Strength of Traditional and “Augmented Translucency” Zirconia for Cerec CAD/CAM System. J. Esthet. Restor. Dent. 2016, 2, 32–39. [Google Scholar] [CrossRef]

- Sakaguchi, R.L.; Powers, J.M. Fundamentals of materials science. In Craig’s Restorative Dental Mater; Elsevier: Philadelphia, PA, USA, 2012; pp. 33–81. [Google Scholar]

- Nejatidanesh, F.; Azadbakht, K.; Savabi, O.; Sharifi, M.; Shirani, M. Effect of Repeated Firing on the Translucency of CAD-Cam Monolithic Glass-Ceramics. J. Prosthet. Dent. 2020, 123, 530.e1–530.e6. [Google Scholar] [CrossRef]

- Li, S.; Pang, L.; Yao, J. The effects of firing numbers on the opening total pore volume, translucency parameter and color of dental all-ceramic systems. Hua Xi Kou Qiang Yi Xue Za Zhi 2012, 30, 417–420. [Google Scholar] [PubMed]

- Bayindir, F.; Ozbayram, O. Effect of Number of Firings on the Color and Translucency of Ceramic Core Materials with Veneer Ceramic of Different Thicknesses. J. Prosthet. Dent. 2018, 119, 152–158. [Google Scholar] [CrossRef] [PubMed]

- Fathi, A.; Farzin, M.; Giti, R.; Kalantari, M.H. Effects of Number of Firings and Veneer Thickness on the Color and Translucency of 2 Different Zirconia-Based Ceramic Systems. J. Prosthet. Dent. 2019, 122, 565.e1–565.e7. [Google Scholar] [CrossRef] [PubMed]

- Heffernan, M. Relative Translucency of Six All-Ceramic Systems. Part II: Core and Veneer Materials. J. Prosthet. Dent. 2002, 88, 10–15. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, S.H. Effect of Hydrothermal Aging on the Optical Properties of Precolored Dental Monolithic Zirconia Ceramics. J. Prosthet. Dent. 2019, 121, 676–682. [Google Scholar] [CrossRef]

- Awad, D.; Stawarczyk, B.; Liebermann, A.; Ilie, N. Translucency of Esthetic Dental Restorative CAD/Cam Materials and Composite Resins with Respect to Thickness and Surface Roughness. J. Prosthet. Dent. 2015, 113, 534–540. [Google Scholar] [CrossRef]

- Wang, F.; Takahashi, H.; Iwasaki, N. Translucency of Dental Ceramics with Different Thicknesses. J. Prosthet. Dent. 2013, 110, 14–20. [Google Scholar] [CrossRef]

- Antonson, S.A.; Anusavice, K.J. Contrast ratio of veneering and core ceramics as a function of thickness. Int. J. Prosthodont. 2001, 14, 316–320. [Google Scholar]

- Pop-Ciutrila, I.S.; Ghinea, R.; Dudea, D.; Ruiz-Lopez, J.; Perez, M.; Colosi, H. The effect of thickness and shade on translucency parameters of contemporary, esthetic dental ceramics. J Esthet. Restor. Dent. 2021, 33, 795–806. [Google Scholar] [CrossRef]

- Paradowska-Stolarz, A.; Wieckiewicz, M.; Kozakiewicz, M.; Jurczyszyn, K. Mechanical Properties, Fractal Dimension, and Texture Analysis of selected 3D-Printed resins used in dentistry that underwent the Compression Test. Polymers 2023, 15, 1772. [Google Scholar] [CrossRef]

- Grzebieluch, W.; Kowalewski, P.; Grygier, D.; Rutkowska-Gorczyca, M.; Kozakiewicz, M.; Jurczyszyn, K. Printable and Machinable dental restorative composites for CAD/CAM application—Comparison of Mechanical Properties, Fractographic, Texture and Fractal Dimension Analysis. Materials 2021, 14, 4919. [Google Scholar] [CrossRef] [PubMed]

- Jurado, C.A.; Afrashtehfar, K.I.; Hyer, J.; Alhotan, A. Effect of sintering on the translucency of CAD-ACM lithium disilicate restoration: A comparative in vitro study. J. Prosthodont. 2023. [Google Scholar] [CrossRef] [PubMed]

- Jurado, C.A.; Amarillas-Gastelum, C.; Tsujimoto, A.; Alresayes, S.; French, K.; Nurrohman, H. Light Transmission for a novel chairside CAD/CAM lithium disilicate ceramic. J. Contemp. Dent. Pract. 2021, 22, 1366. [Google Scholar] [CrossRef]

- Dietschi, D.; Ardu, S.; Krejci, I. A new shading concept based on natural tooth color applied to direct composite restorations. Quintessence Int. 2006, 37, 91–102. [Google Scholar] [PubMed]

- Paravina, R.; Perez, M.; Ghinea, R. Acceptability and perceptibility thresholds in dentistry: A comprehensive review of clinical and research applications. J. Esthet. Restor. Dent. 2019, 31, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.C.; Aquilino, S.A.; Lund, P.S.; Vargas, M.A.; Diaz-Arnold, A.M.; Gratton, D.G.; Qian, F. Human perception of dental porcelain translucency correlated to spectrophotometric measurements. J. Prosthodont. 2010, 19, 187–193. [Google Scholar] [CrossRef]

| Material | Manufacturer | Definition | Chemical Composition | Thermal Treatment | Translucency Availability |

|---|---|---|---|---|---|

| Celtra DUO | Dentsply Sirona, Charlotte, NC, USA | Lithium silicate, zirconia reinforced | 58% SiO2; 18.5% Li2O; 5% P2O5; 10.1% ZrO; 1.9% Al2O3; 2% CeO2; 1% Tb4O7 | Optional | HT LT |

| Initial LiSi Block | GC, Tokyo, Japan | Lithium disilicate | 55–80% SiO2, 10–30% Li2O; 5–20% other oxides; pigments: trace ** | No | HT LT |

| N!ce | Straumann, Basel, Switzerland | Lithium fluorosilicate | 64–70% SiO2; 10.5–12.5% Li2O; 0–3% K2O; 3–8% P2O5; 0–0.5% ZrO2; 10.5–11.5% Al2O3; 1–2% CaO; 0–9% pigments; 1–3% Na2O | No | HT LT |

| IPS e.max CAD | Ivoclar Vivadent, Schaan, Liechtenstein | Lithium disilicate | 57–80% SiO2; 11–19% Li2O; 0–13% K2O; 0–11% P2O5; 0–8% ZrO2, 0–8% ZnO; 0–12% others + coloring oxides | Yes | HT MT LT MO |

| Tessera | Dentsply Sirona, Charlotte, NC, USA | Lithium disilicate based | Li2Si2O5: 90% Li3PO4: 5% Li0.5Al0.5Si2.5O6 (LAS, lithium alumino silicate—virgilite): 5% | Yes | HT MT |

| Suprinity PC | VITA Zahnfabrik, Bad Sackingen, Germany | Lithium silicate, zirconia reinforced | SiO2: 56–64% Li2O: 15–21% ZrO2: 8–12% P2O5: 3–8% K2O: 1–4% Al2O3: 1–4% CeO2: 0–4% pigments: 0–4% | Yes | HT T |

| Amber Mill | Hass, Gangwon-do, Korea | Lithium disilicate | SiO2, Li2O, K2O, MgO, Al2O3,P2O5, other oxides | Yes | HT * MT * LT * MO * |

| Article | LSGC Type | Shade | Translucency | Thickness (mm) | TP | CR |

|---|---|---|---|---|---|---|

| Alayad et al. (2021) [21] | IPS e.max CAD | n.r. | n.r. | 0.5; 1; 1.5 | 0.5 mm: 21.33 ± 1.73 1 mm: 13.34 ± 0.59 1.5 mm: 10.28 ± 0.42 | |

| Suprinity PC | n.r. | n.r. | 0.5; 1; 1.5 | 0.5 mm: 42.49 ± 4.26 1 mm: 42.28 ± 2.79 1.5 mm: 43.25 ± 4.47 | ||

| Celtra Duo | n.r. | n.r. | 0.5; 1; 1.5 | 0.5 mm: 23.94 ± 1.79 1 mm: 14.81 ± 0.53 1.5 mm: 10.39 ± 0.48 | ||

| Bagis and Turgut (2013) [22] | IPS e.max CAD | A1 | n.r. | 0.5 | 14.49 ± 0.83 | |

| Baldissara et al. (2018) [23] | IPS e.max CAD | A2 | LT | 1.5 | 0.84 ± 0.02 | |

| Barizon et al. (2013) [24] | IPS e.max CAD | A1 | HT | 0.7 | 33.02 ± 0.07 | 0.25 ± 0.00 |

| Barizon et al. (2014) [25] | IPS e.max CAD | A1 | HT | 0.7 | 33.02 ± 0.07 | |

| Basso et al. (2017) [26] | IPS e.max CAD | A1 | HT; LT | 0.5; 1; 1.5; 2 | TP mean (95% confidence interval) values: HT0.7: 44.9 (44.2–45.6) HT1.0: 37.3 (36.8–37.8) HT1.5: 29.4 (28.8–30.0) HT2.0: 22.9 (22.6–23.2) LT0.7: 34.4 (33.9–34.9) LT1.0: 27.3 (26.7–27.9) LT1.5: 22.2 (21.7–22.7) LT2.0: 15.5 (15.2–15.8) | |

| Brescansin et al. (2021) [27] | IPS e.max CAD | A2 | HT | 1.5 | * Data retrieved from graph: 14.1 | |

| Carrabba et al. (2017) [20] | IPS e.max CAD | n.r. | LT | 1 | 0.56 | |

| Campanelli et al. (2021) [28] | IPS e.max CAD | n.r. | n.r. | 1.2 | 29.16–30.32 (depending on firings) | |

| Suprinity PC | n.r. | n.r. | 26.89–29.17 (depending on firings) | |||

| Caprak et al. (2019) [29] | IPS e.max CAD | A2 | HT | 2 | 10.16 ± 0.50 | |

| Suprinity PC | 2M2 | HT | 2 | 11.92 ± 0.78 | ||

| Della Bona et al. (2014) [30] | IPS e.max CAD | A1; A2; A3 | LT; HT | 1 | LT A1: 16.79 ± 0.35 HT A1: 18.51 ± 0.59 LT A2: 17.35 ± 0.81 HT A2: 18.97 ± 0.16 LT A3: 18.62 ± 1.06 HT A3: 18.98 ± 0.28 | LT A1: 0.64 ± 0.01 HT A1: 0.59 ± 0.01 LT A2: 0.62 ± 0.01 HT A2: 0.58 ± 0.01 LT A3: 0.60 ± 0.02 HT A3: 0.57 ± 0.01 |

| Gasparik et al. (2019) [31] | IPS e.max CAD | A3 | HT; LT | 1 | HT 18.87 (0.32) LT 17.79 (0.24) | |

| Gunal and Ulusoy (2018) [15] | IPS e.max CAD | A2 | LT | 0.5; 1.0 | 0.5 mm: 27.51 ± 0.94 1 mm: 16.13 ± 0.33 | |

| Suprinity PC | A2 | T | 0.5 mm: 23.30 ± 0.71 1 mm: 14.26 ± 0.52 | |||

| Juvantee and Uasuwan (2019) [32] | IPS e.max CAD | A2 | n.r. | 1.2 | Depending on thermal tempering speed: (S)low, (N)ormal, (S)low S:5.53 ± 0.17 N:5.49 ± 0.17 F:5.36 ± 0.06 | Depending on thermal tempering speed: (S)low, (N)ormal, (S)low S:0.821 ± 0.006 N: 0.822 ± 0.006 F:0.826 ± 0.002 |

| Suprinity PC | A2 | n.r. | S: 2.44 ± 0.24 N: 4.05 ± 0.3 F: 3.79 ± 0.17 | S: 0.958 ± 0.006 N: 0.911 ± 0.010 F: 0.919 ± 0.006 | ||

| Kanpalta et al. (2022) [33] | IPS e.max CAD | A2 | LT | 1 | 18.93 ± 0.52 | |

| Karci and Demir (2019) [34] | IPS e.max CAD | A2 | LT | 1 | 18.11 ± 1.46 | 0.56 ± 0.02 |

| Kulkarni et al. (2020) [35] | IPS e.max CAD | n.r. | n.r. | 1 | 8.49 ± 1.01 | |

| Kurt et al. (2020) [36] | IPS e.max CAD | A2 | HT | 1 | Before crystallization: 18.53 ± 0.64 After crystallization: 18.25 ± 0.41 | |

| Suprinity PC | A2 | HT | Before crystallization: 16.16 ± 0.70 After crystallization: 16.44 ± 0.53 | |||

| Kurtulmus-Yilmaz et al. (2019) [37] | IPS e.max CAD | A2 | HT | 1 | 20.1 ± 0.5 | |

| Kwon et al. (2018) [38] | IPS e.max CAD | A1 | HT; LT | 1 | HT: 12.64 ± 0.48 LT: 9.28 ± 0.36 | |

| Lawson and Maharishi (2020) [39] | IPS e.max CAD | BL1 | LT | 1 | 9.33 ± 0.56 | |

| Ledić et al. (2015) [40] | IPS e.max CAD | A2; C2; B3 | HT | 0.8 | A2: 14.17 ± 0.85 C2: 13.87 ± 1.17 B3: 14.27 ± 0.50 | |

| Monaco et al. (2020) [41] | IPS e.max CAD | A2 | LT | 2 | 14.54 ± 1.64 | |

| Nogueira and Della Bona (2013) [42] | IPS e.max CAD | A2 | LT; HT | 1 | LT: 17.3 ± 0.81 HT: 19.0 ± 0.16 | LT: 0.63 ± 0.02 HT: 0.58 ± 0.00 |

| Oh et al. (2018) [43] | IPS e.max CAD | A2 | HT;LT | 0.5; 1; 2; 4 | HT: 0.5 mm: 20.79 ± 0.10 1 mm: 13.39 ± 0.04 2 mm: 5.27 ± 0.18 4 mm: 1.21 ± 0.20 LT: 0.5 mm: 17.64 ± 0.05 1 mm: 9.74 ± 0.10 2 mm: 1.93 ± 0.03 4 mm: 0.58 ± 0.10 | |

| Şen and Us (2017) [44] | IPS e.max CAD | A2 | HT | 1.2 | 26.0 ± 0.6 | |

| Suprinity PC | 2M2 | HT | 31.0 ± 1.0 | |||

| Sen and Isler (2020) [44] | IPS e.max CAD | A1 | LT | 0.5; 1; 1.5 | * Data retrieved from graph: 0.5 mm: 32 1 mm: 25 1.5 mm: 18 | * Data retrieved from graph: 0.5 mm: 0.28 1 mm: 0.34 1.5 mm: 0.53 |

| Skyllouriotis et al. (2017) [13] | IPS e.max CAD | A2 | LT; HT | 0.5 | LT: 40.24 HT: 52.85 | LT: 0.25 HT: 0.17 |

| Supornpun et al. (2021) [45] | IPS e.max CAD | A2 | HT | 1; 1.25; 1.5; 1.75; 2 | 1 mm: 12.44 ± 0.06 1.25 mm: 11.24 ± 0.53 1.5 mm: 9.72 ± 0.08 1.75 mm: 8.67 ± 0.02 2.00 mm: 7.85 ± 0.26 | |

| Turgut et al. (2019) [46] | IPS e.max CAD | A1 | LT | 1 | 20.6 ± 0.5 | |

| Suprinity PC | A1 | T | 22.5 ± 0.7 | |||

| Vichi et al. (2014) [47] | IPS e.max CAD | A2 | LT; HT; MO | 0.5; 1.0 | HT 0.5 mm: 0.35 ± 0.01 HT 1.0 mm: 0.48 ± 0.01 LT 0.5 mm: 0.43 ± 0.02 LT 1.0 mm: 0.56 ± 0.02 MO 0.5 mm: 0.50 ± 0.03 MO 1.0 mm: 0.71 ± 0.02 | |

| Wang et al. (2020) [48] | IPS e.max CAD | A2 | HT; MO | 0.5; 1 | * Data retrieved from graph: 0.5 mm: 24 1.0 mm: 17 | |

| Ziyad et al. (2021) [50] | IPS e.max CAD | A2 | LT | 1 | 20.439 ± 0.86 | 0.592 ± 0.016 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vichi, A.; Zhao, Z.; Mutahar, M.; Paolone, G.; Louca, C. Translucency of Lithium-Based Silicate Glass–Ceramics Blocks for CAD/CAM Procedures: A Narrative Review. Materials 2023, 16, 6441. https://doi.org/10.3390/ma16196441

Vichi A, Zhao Z, Mutahar M, Paolone G, Louca C. Translucency of Lithium-Based Silicate Glass–Ceramics Blocks for CAD/CAM Procedures: A Narrative Review. Materials. 2023; 16(19):6441. https://doi.org/10.3390/ma16196441

Chicago/Turabian StyleVichi, Alessandro, Zejiao Zhao, Mahdi Mutahar, Gaetano Paolone, and Chris Louca. 2023. "Translucency of Lithium-Based Silicate Glass–Ceramics Blocks for CAD/CAM Procedures: A Narrative Review" Materials 16, no. 19: 6441. https://doi.org/10.3390/ma16196441

APA StyleVichi, A., Zhao, Z., Mutahar, M., Paolone, G., & Louca, C. (2023). Translucency of Lithium-Based Silicate Glass–Ceramics Blocks for CAD/CAM Procedures: A Narrative Review. Materials, 16(19), 6441. https://doi.org/10.3390/ma16196441