Experimental Validation of the Cementation Mechanism of Wood Pellet Fly Ash Blended Binder in Weathered Granite Soil

Abstract

:1. Introduction

2. Previous Work

3. Objectives of This Study

4. Materials and Methods

5. Results

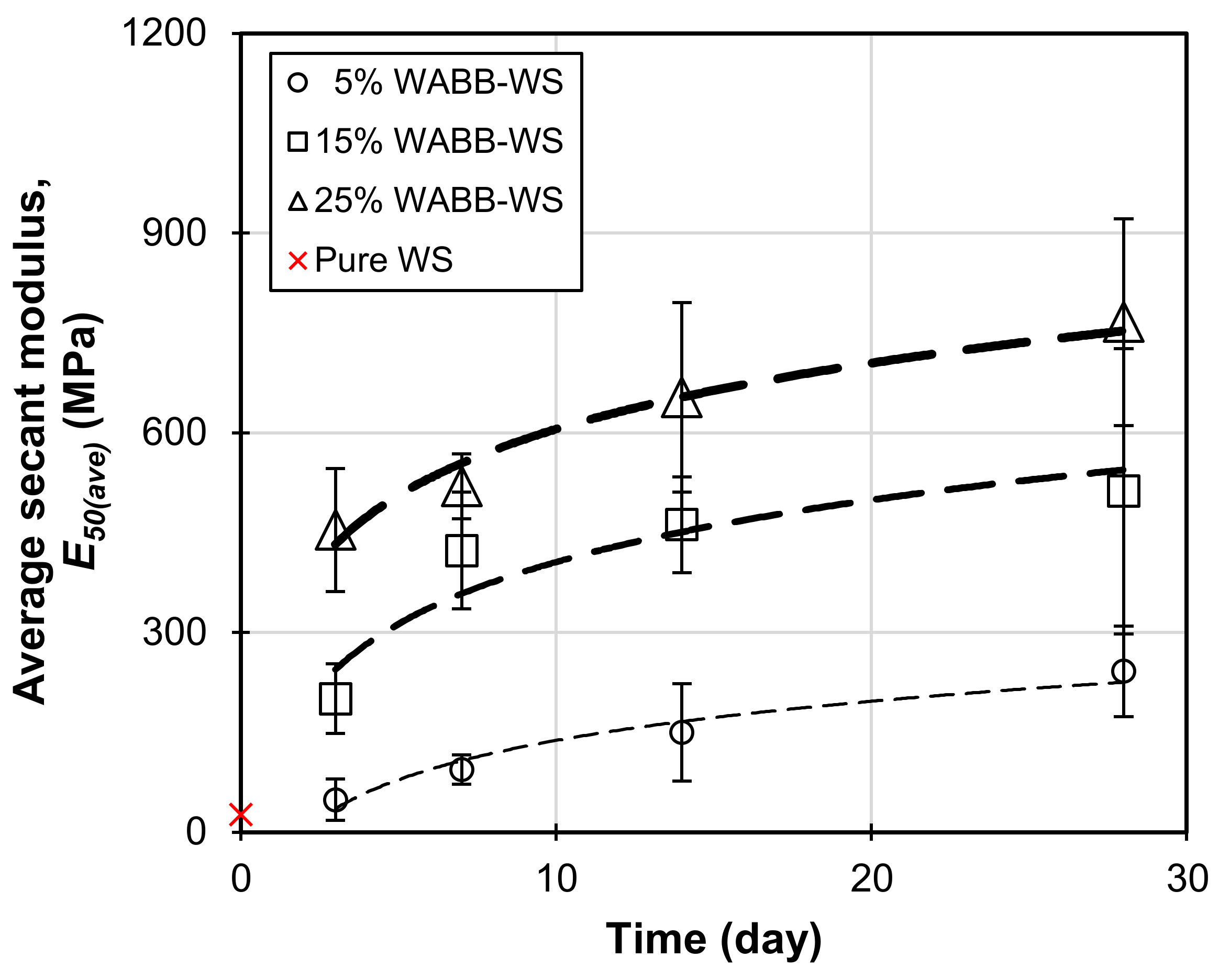

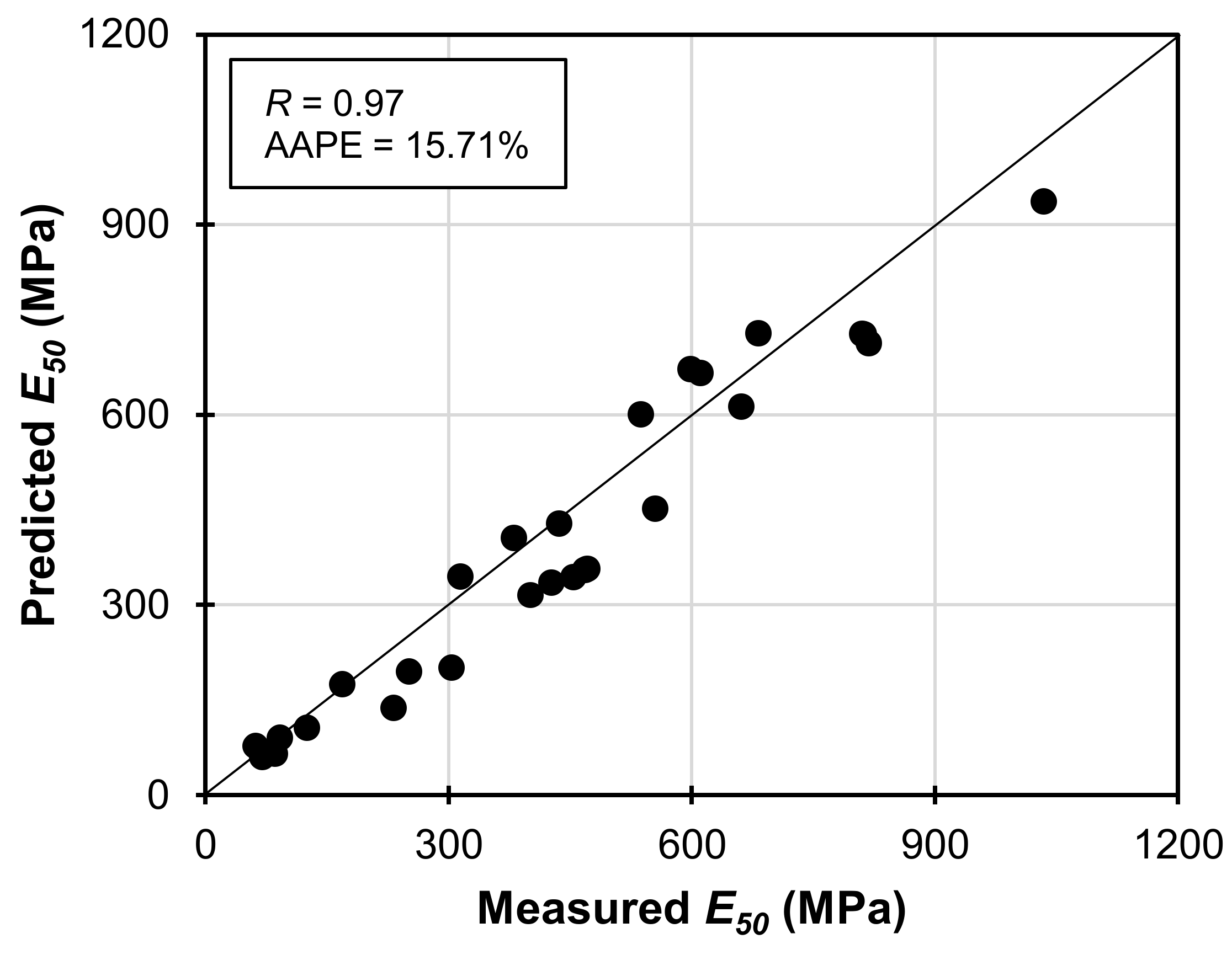

5.1. Unconfined Compressive Strength and Secant Modulus

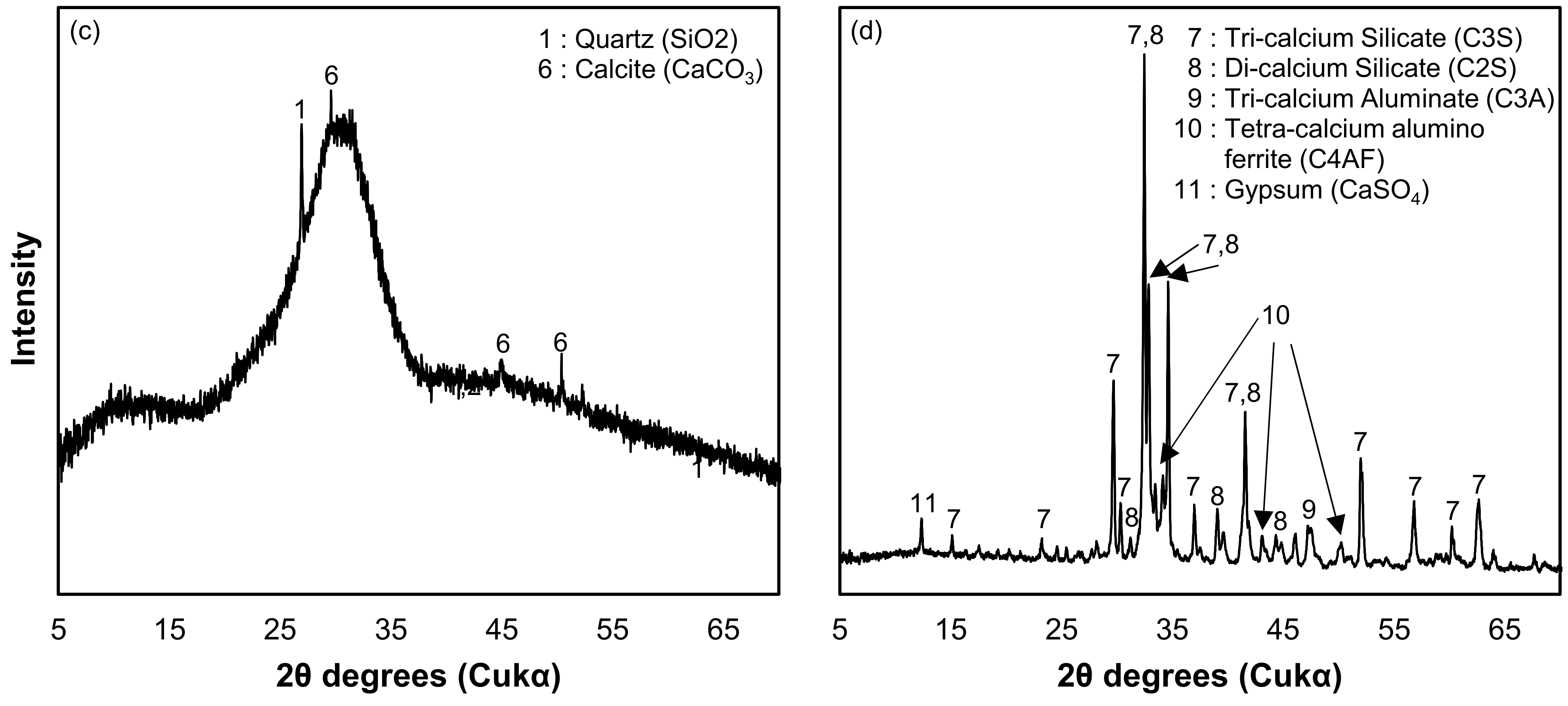

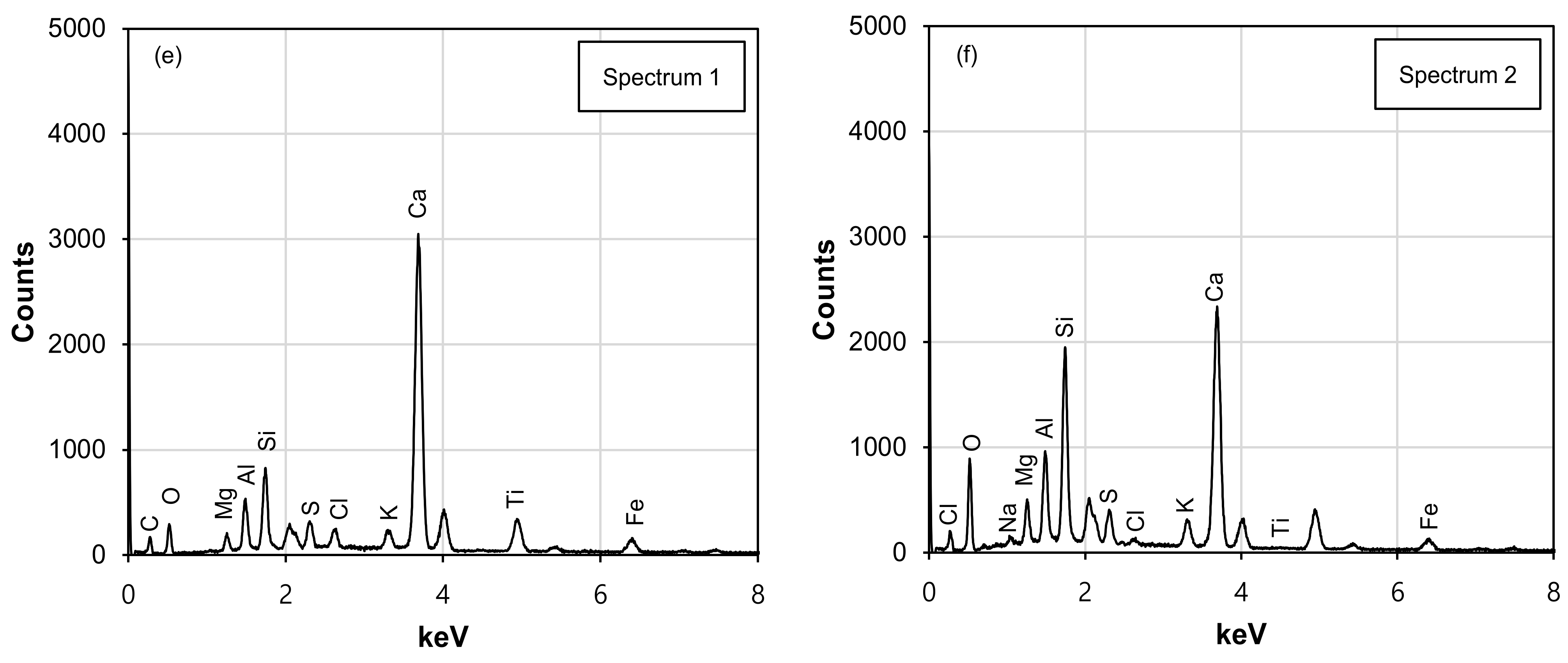

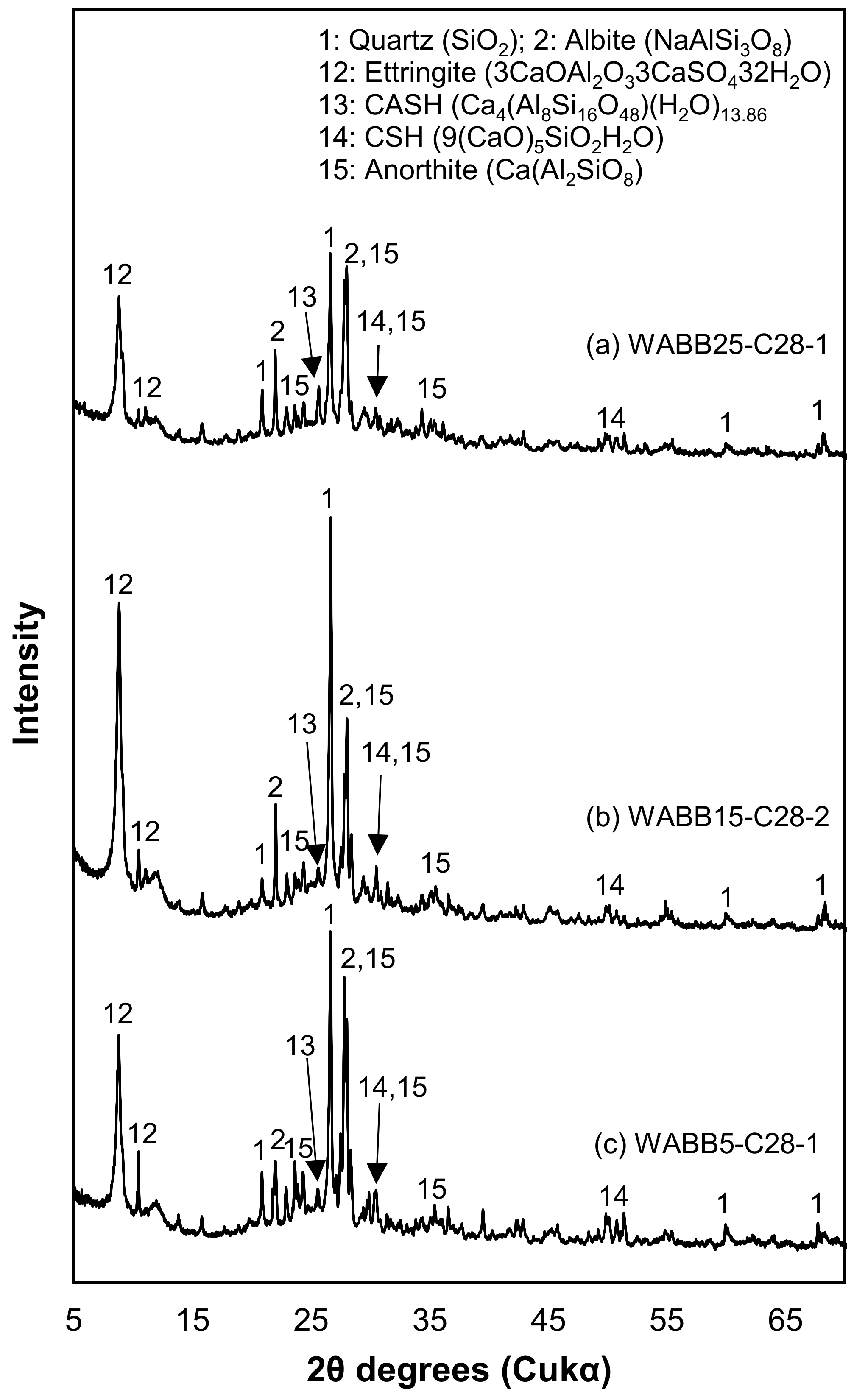

5.2. Microstructural Analysis

5.3. pH Tests

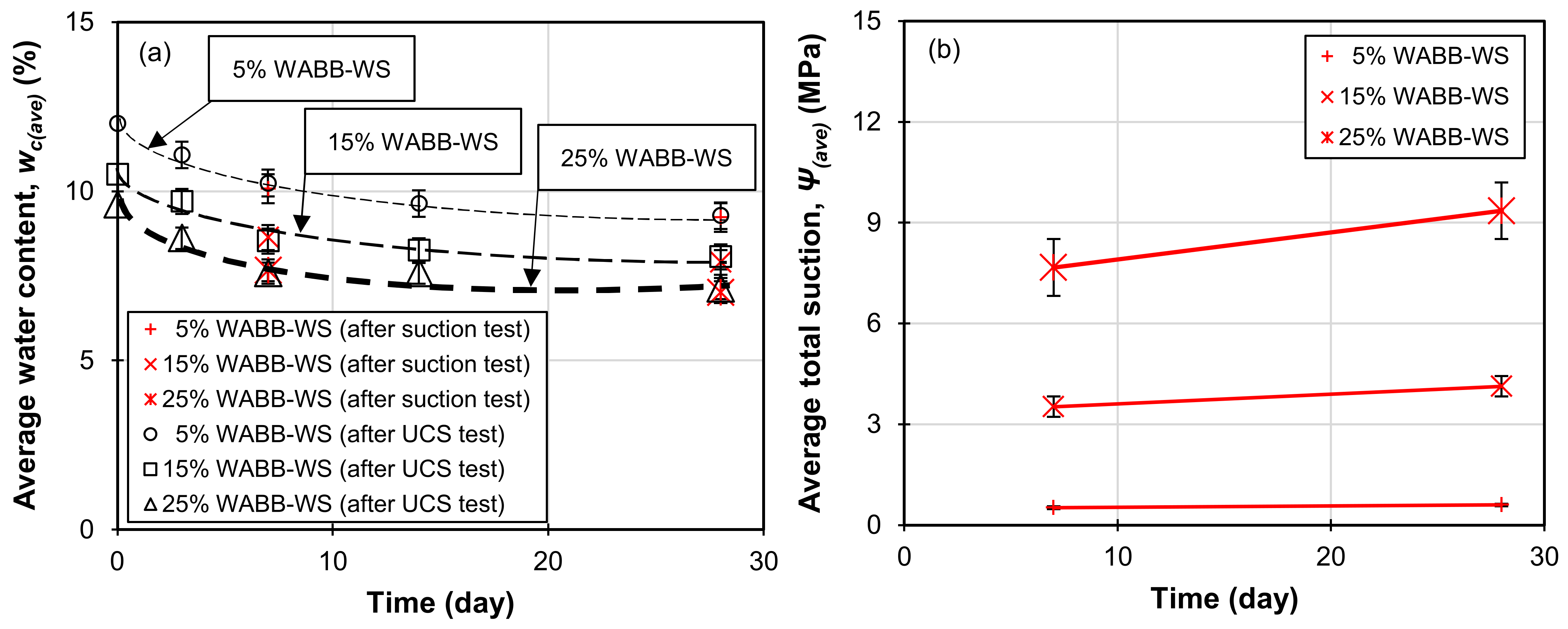

5.4. Total Suction Measurement

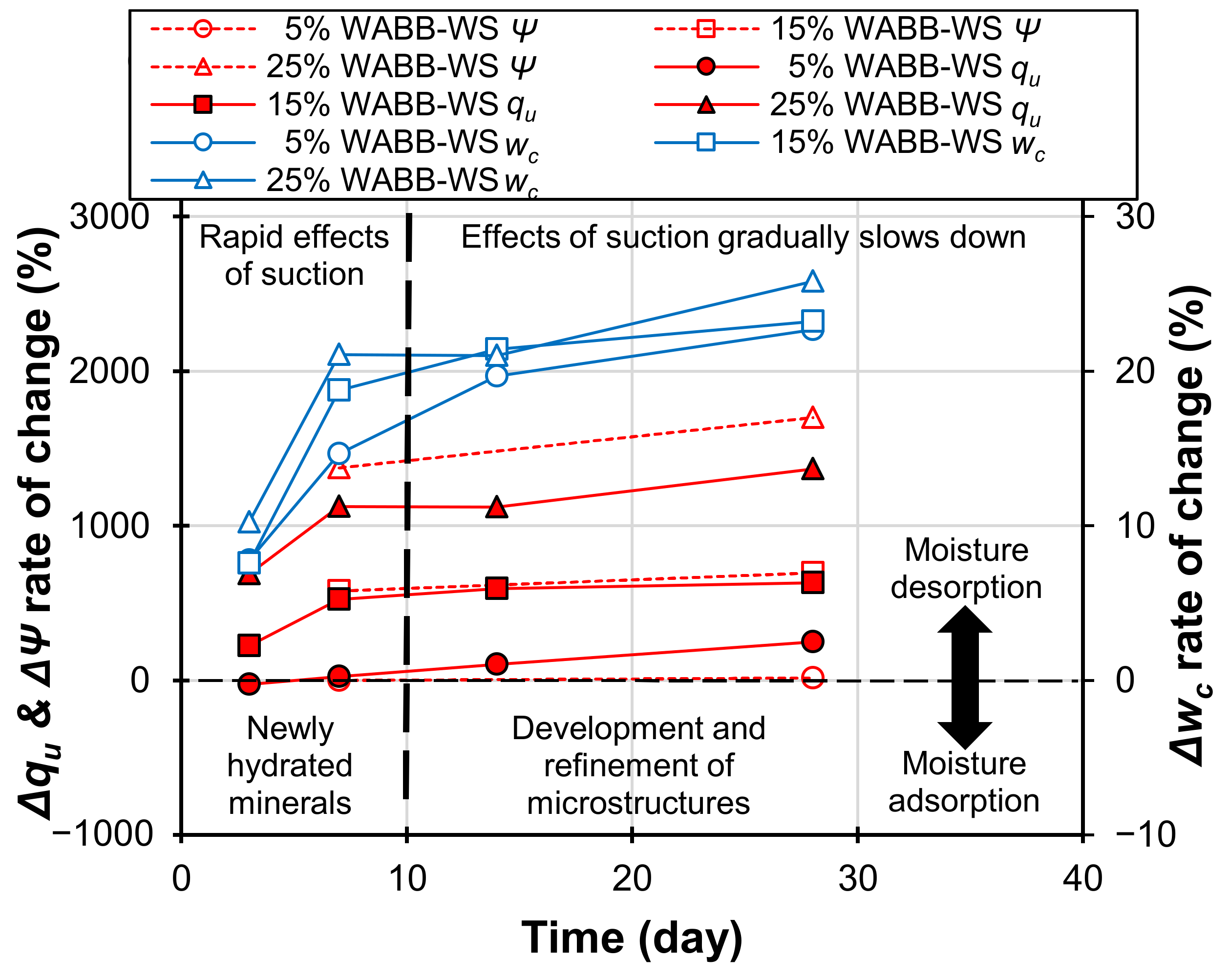

6. Discussion: Cementation and Suction Development

7. Conclusions

- This study provides the first observation of the clear cementation mechanism of WABB with natural soil, an albite-based weathered soil commonly found in inland areas, especially in Korea and Eastern Asia.

- The unconfined compressive strength (qu) and secant modulus (E50) increased with the increase in WABB content and curing days. These findings are attributed to the cement hydration and its influence on rapid early strength gain, GGBS latent hydraulic capacity, and the alkali stimulation of WA, leading to the combined hydration of the WABB with the WS SiO2 (through quartz) and Al2O3 (through albite) constituents.

- The hydration of the WABB in WS was verified to significantly alter the soil microstructure, as confirmed via XRD and SEM-EDS investigations. These analyses revealed the partially converted WS and the presence of newly formed cementitious minerals: ettringite, C-S-H, C-A-S-H, and anorthite.

- The strength development of the WABB–WS specimen is influenced by the total suction and cementation contributed by the increasing of the quantity of wood pellet fly ash blended binder at the early stage. After 7 days, the strength gain of WABB–WS was regulated with the WABB’s cementation, leading to a positive increase in the strength and moduli. These results corroborate the unique cementation effect of a three-component binder consisting of WABB with WS.

- Empirical equations were derived to estimate the mechanical properties qu(7 to 28) and E50(7 to 28) from the WABB dosage rate and curing days. The proposed model equation may have the potential to be applied in the design of the strength gain of WABB-stabilized weathered granite soil for ground improvement projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khabbaz, H.; Fatahi, B. Stabilisation of Closed Landfill Sites by Fly Ash Using Deep Mixing Method. In Proceedings of the Fourth International Conference on Grouting and Deep Mixing, New Orleans, LA, USA, 19 December 2012; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 417–426. [Google Scholar]

- Mohammadinia, A.; Disfani, M.M.; Conomy, D.; Arulrajah, A.; Horpibulsuk, S.; Darmawan, S. Utilization of Alkali-Activated Fly Ash for Construction of Deep Mixed Columns in Loose Sands. J. Mater. Civ. Eng. 2019, 31, 04019233. [Google Scholar] [CrossRef]

- Ali, F.H.; Adnan, A.; Choy, C.K. Use of Rice Husk Ash to Enhance Lime Treatment of Soil. Can. Geotech. J. 1992, 29, 843–852. [Google Scholar] [CrossRef]

- Farnsworth, C.B.; Bartlett, S.F.; Negussey, D.; Stuedlein, A.W. Rapid Construction and Settlement Behavior of Embankment Systems on Soft Foundation Soils. J. Geotech. Geoenvironmental Eng. 2008, 134, 289–301. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2022, 15, 209. [Google Scholar] [CrossRef]

- Kumar, S.; Skariah Thomas, B.; Gupta, V.; Basu, P.; Shrivastava, S. Sandstone Wastes as Aggregate and Its Usefulness in Cement Concrete—A Comprehensive Review. Renew. Sustain. Energy Rev. 2018, 81, 1147–1153. [Google Scholar] [CrossRef]

- Pasupathy, K.; Sanjayan, J.; Rajeev, P. Evaluation of Alkalinity Changes and Carbonation of Geopolymer Concrete Exposed to Wetting and Drying. J. Build. Eng. 2021, 35, 102029. [Google Scholar] [CrossRef]

- Lu, S.; Koopialipoor, M.; Asteris, P.G.; Bahri, M.; Armaghani, D.J. A Novel Feature Selection Approach Based on Tree Models for Evaluating the Punching Shear Capacity of Steel Fiber-Reinforced Concrete Flat Slabs. Materials 2020, 13, 3902. [Google Scholar] [CrossRef] [PubMed]

- Cardinale, T.; D’Amato, M.; Sulla, R.; Cardinale, N. Mechanical and Physical Characterization of Papercrete as New Eco-Friendly Construction Material. Appl. Sci. 2021, 11, 1011. [Google Scholar] [CrossRef]

- Jura, J.; Ulewicz, M. Assessment of the Possibility of Using Fly Ash from Biomass Combustion for Concrete. Materials 2021, 14, 6708. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Iglesias-Godino, F.J.; Corpas-Iglesias, F.A. Development of Geopolymers as Substitutes for Traditional Ceramics for Bricks with Chamotte and Biomass Bottom Ash. Materials 2021, 14, 199. [Google Scholar] [CrossRef]

- Barišić, I.; Netinger Grubeša, I.; Hackenberger, D.K.; Palijan, G.; Glavić, S.; Trkmić, M. Multidisciplinary Approach to Agricultural Biomass Ash Usage for Earthworks in Road Construction. Materials 2022, 15, 4529. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Deng, P.; Zhang, Z. Application of Silica-Rich Biomass Ash Solid Waste in Geopolymer Preparation: A Review. Constr. Build. Mater. 2022, 356, 129142. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Nalanda, Y. Performance of Industrial By-Products in Controlled Low-Strength Materials (CLSM). Waste Manag. 2008, 28, 1168–1181. [Google Scholar] [CrossRef]

- Winogard, I.J. Radioactive Waste Disposal in Thick Unsaturated Zones. Science 1981, 212, 1457–1464. [Google Scholar] [CrossRef]

- Šķēls, P.; Bondars, K.; Plonis, R.; Haritonovs, V.; Paeglītis, A. Usage of Wood Fly Ash in Stabilization of Unbound Pavement Layers and Soils. In Proceedings of the 13th Baltic Sea Geotechnical Conference, Vilnius, Lithuania, 22–24 September 2016; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2016; pp. 122–125. [Google Scholar]

- Ayininuola, G.M.; Oyedemi, O.P. Impact of Hardwood and Softwood Ashes on Soil Geotechnical Properties. Transnatl. J. Sci. Technol. 2013, 3, 1–7. [Google Scholar]

- Okagbue, C.O. Stabilization of Clay Using Woodash. J. Mater. Civ. Eng. 2007, 19, 14–18. [Google Scholar] [CrossRef]

- Grau, F.; Choo, H.; Hu, J.; Jung, J. Engineering Behavior and Characteristics of Wood Ash and Sugarcane Bagasse Ash. Materials 2015, 8, 6962–6977. [Google Scholar] [CrossRef]

- Ale, T.O. Improving the Geotechnical Properties of a Nigerian Termite Reworked Soil Using Pretest Drying Conditions and Sawdust Ash. Int. J. Geo-Eng. 2023, 14, 1. [Google Scholar] [CrossRef]

- Barišić, I.; Netinger Grubeša, I.; Dokšanović, T.; Marković, B. Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials 2019, 12, 1375. [Google Scholar] [CrossRef]

- Kumar Yadav, A.; Gaurav, K.; Kishor, R.; Suman, S.K. Stabilization of Alluvial Soil for Subgrade Using Rice Husk Ash, Sugarcane Bagasse Ash and Cow Dung Ash for Rural Roads. Int. J. Pavement Res. Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Butt, W.A.; Gupta, K.; Jha, J.N. Strength Behavior of Clayey Soil Stabilized with Saw Dust Ash. Int. J. Geo-Eng. 2016, 7, 18. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Castro, J.; Ureña, C.G.; Azañón, J.M. Stabilisation of Clayey and Marly Soils Using Industrial Wastes: PH and Laser Granulometry Indicators. Eng. Geol. 2016, 200, 10–17. [Google Scholar] [CrossRef]

- Pushpakumara, B.H.J.; Mendis, W.S.W. Suitability of Rice Husk Ash (RHA) with Lime as a Soil Stabilizer in Geotechnical Applications. Int. J. Geo-Eng. 2022, 13, 4. [Google Scholar] [CrossRef]

- Kim, J.-M.; Choo, Y.-W.; Kim, H.-S.; Kang, I.-G.; Kim, G.-W.; Kim, B.-S.; Balagosa, J.; Bae, G.-H.; Yun, J.-S.; Lee, M.-J.; et al. Development of Non-Cement Based Soil Stabilizer Using Wood Pellet Fly Ash. Final Research Report (Project No. 2020-Field-01); Korea South-East Power Co.: Jinju-si, Republic of Korea, 2021. (In Korean) [Google Scholar]

- ISO 17225-1:2021; Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements. International Organization for Standardization (ISO): Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/76087.html (accessed on 18 April 2023).

- Ministry of Trade, Industry and Energy (MOTIE) Korea Renewable Energy 3020 Plan—Policies. Available online: https://www.iea.org/policies/6569-korea-renewable-energy-3020-plan (accessed on 18 April 2023).

- Ministry of Trade, Industry and Energy (MOTIE) 8th Basic Plan for Long-Term Electricity Supply and Demand (BPLE) (2017–2031) | ESCAP Policy Documents Management. Available online: https://policy.asiapacificenergy.org/node/3844 (accessed on 18 April 2023).

- Oh, J.-H.; Hwang, J.-S.; Cha, D.-S. Fuel Properties of Woody Pellets in Domestic Markets of Korea. J. For. Environ. Sci. 2014, 30, 362–369. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon Dioxide Emissions from the Global Cement Industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Yoon, S.; Nadvi, K. Industrial Clusters and Industrial Ecology: Building ‘Eco-Collective Efficiency’ in a South Korean Cluster. Geoforum 2018, 90, 159–173. [Google Scholar] [CrossRef]

- Hawkins Wright 2017 Wood Pellet Market Outlook. Available online: https://www.hawkinswright.com/news-and-events/blog/post/hawkins-wright-blog/2017/01/20/2017-wood-pellet-market-outlook (accessed on 18 April 2023).

- Kim, H.S.; Kim, K.S.; Kim, Y.W. Characteristics of Solidification Using Wood Pellets Fly Ash. In Proceedings of the Korean Recycled Construction Resource Institute 2022 Fall Conference, 2022; pp. 225–226. (In Korean). Available online: https://rcr.or.kr/publication/publication03_list.asp (accessed on 18 June 2023).

- Kim, H.S.; Park, J.H.; Shin, S.C.; Kim, J.M. Properties of Non-cement Matrix Using Wood Pellets Fly Ash. In Proceedings of the Korean Institute of Building Construction Conference, In Proceedings of the Korean Recycled Construction Resource Institute 2021 Spring Conference. 2021; Volume 21, pp. 3–4. (In Korean). Available online: https://www.auric.or.kr/User/Rdoc/DocRdoc.aspx?returnVal=RD_R&dn=405500 (accessed on 18 June 2023).

- Kim, H.S.; Kang, I.K.; Shin, S.C.; Kim, J.M. Properties of CLSM Using Wood Pellets Fly Ash. In Proceedings of the Korean Recycled Construction Resource Institute 2021 Fall Conference, 2021; pp. 7–8. (In Korean). Available online: https://rcr.or.kr/publication/publication03_list.asp (accessed on 18 June 2023).

- Nordmark, D.; Vestin, J.; Lagerkvist, A.; Lind, B.B.; Arm, M.; Hallgren, P. Geochemical Behavior of a Gravel Road Upgraded with Wood Fly Ash. J. Environ. Eng. 2014, 140, 05014002. [Google Scholar] [CrossRef]

- Leong, H.Y.; Ong, D.E.L.; Sanjayan, J.G.; Nazari, A. The Effect of Different Na2O and K2O Ratios of Alkali Activator on Compressive Strength of Fly Ash Based-Geopolymer. Constr. Build. Mater. 2016, 106, 500–511. [Google Scholar] [CrossRef]

- Balagosa, J.; Lee, M.J.; Choo, Y.W.; Kim, H.S.; Kim, J.M. Stabilization Mechanism of Wood Pellet Fly Ash for Weathered Granite Soils: Mechanical Property and Microstructure. Soils Found. 2023. under review. [Google Scholar]

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil, D 2166, Section 4, Volume 04.08, Soil and Rock (I). ASTM: West Conshohocken, PA, USA, 2016.

- KS L ISO 679; Methods of Testing Cements-Determination of Strength. Korean Standard Association: Seoul, Republic of Korea, 2011. (In Korean)

- KS F 2594; Method of Test for Slump Flow of Fresh Concrete. Korean Standard Association: Seoul, Republic of Korea, 2009. (In Korean)

- KS F 2436; Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance. Korean Standard Association: Seoul, Republic of Korea, 2007. (In Korean)

- KS L 5105; Testing Method for Compressive Strength of Hydraulic Cement Mortar. Korean Standard Association: Seoul, Republic of Korea, 2007. (In Korean)

- KS F 2408; Method of Test for Flexural Strength of Concrete. Seoul: Korean Standard Association: Seoul, Republic of Korea, 2000. (In Korean)

- Wei, X.; Liu, H.; Choo, H.; Ku, T. Correlating Failure Strength with Wave Velocities for Cemented Sands from the Particle-Level Analysis. Soil Dyn. Earthq. Eng. 2022, 152, 107062. [Google Scholar] [CrossRef]

- ASTM D6913-04; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2004.

- AASHTO Transportation Officials. AASHTO Guide for Design of Pavement Structures, 1993; AASHTO: Washington, DC, USA, 1993; Volume 1, ISBN 978-1-56051-055-0. [Google Scholar]

- Anupam, A.K.; Kumar, P.; Ransinchung, G.D. Use of Various Agricultural and Industrial Waste Materials in Road Construction. Procedia Soc. Behav. Sci. 2013, 104, 264–273. [Google Scholar] [CrossRef]

- Maeda, N.; Katakura, T.; Fukasawa, T.; Huang, A.-N.; Kawano, T.; Fukui, K. Morphology of Woody Biomass Combustion Ash and Enrichment of Potassium Components by Particle Size Classification. Fuel Process. Technol. 2017, 156, 1–8. [Google Scholar] [CrossRef]

- Wang, G.; Shen, L.; Sheng, C. Characterization of Biomass Ashes from Power Plants Firing Agricultural Residues. Energy Fuels 2012, 26, 102–111. [Google Scholar] [CrossRef]

- Medina, J.M.; Sáez del Bosque, I.F.; Frías, M.; Sánchez de Rojas, M.I.; Medina, C. Durability of New Blended Cements Additioned with Recycled Biomass Bottom ASH from Electric Power Plants. Constr. Build. Mater. 2019, 225, 429–440. [Google Scholar] [CrossRef]

- Fořt, J.; Šál, J.; Ševčík, R.; Doleželová, M.; Keppert, M.; Jerman, M.; Záleská, M.; Stehel, V.; Černý, R. Biomass Fly Ash as an Alternative to Coal Fly Ash in Blended Cements: Functional Aspects. Constr. Build. Mater. 2021, 271, 121544. [Google Scholar] [CrossRef]

- Sarkkinen, M.; Kujala, K.; Kemppainen, K.; Gehör, S. Effect of Biomass Fly Ashes as Road Stabilisation Binder. Road Mater. Pavement Des. 2018, 19, 239–251. [Google Scholar] [CrossRef]

- Kusuma, R.T.; Hiremath, R.B.; Rajesh, P.; Kumar, B.; Renukappa, S. Sustainable Transition towards Biomass-Based Cement Industry: A Review. Renew. Sustain. Energy Rev. 2022, 163, 112503. [Google Scholar] [CrossRef]

- Pu, S.; Zhu, Z.; Huo, W. Evaluation of Engineering Properties and Environmental Effect of Recycled Gypsum Stabilized Soil in Geotechnical Engineering: A Comprehensive Review. Resour. Conserv. Recycl. 2021, 174, 105780. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Candamano, S.; Crea, F.; Gazzaniga, G.; Pastore, T. The Combined Use of Admixtures for Shrinkage Reduction in One-Part Alkali Activated Slag-Based Mortars and Pastes. Constr. Build. Mater. 2020, 248, 118682. [Google Scholar] [CrossRef]

- ASTM D1557-12e1; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000ft-Lbf/Ft3(2,700 KN-m/M3)), D 1557, Section 4, Volume 04.08, Soil and Rock (I). ASTM: West Conshohocken, PA, USA, 2012.

- Wang, F.; Li, K.; Liu, Y. Optimal Water-Cement Ratio of Cement-Stabilized Soil. Constr. Build. Mater. 2022, 320, 126211. [Google Scholar] [CrossRef]

- Timoney, M.J.; McCabe, B.A.; Bell, A.L. Experiences of Dry Soil Mixing in Highly Organic Soils. Proc. Inst. Civ. Eng. Ground Improv. 2012, 165, 3–14. [Google Scholar] [CrossRef]

- Yoo, N.-J.; Park, B.-S.; Hong, Y.-G. A Study on Correlations between Compaction Properties and Soil Constants of Granite Soil in the Kangwon Province. J. Ind. Technol. 1998, 18, 77–86. [Google Scholar]

- ASTM D4972-01; Standard Test Method for PH of Soils. ASTM: West Conshohocken, PA, USA, 2001.

- Padilla-Encinas, P.; Palomo, A.; Blanco-Varela, M.T.; Fernández-Carrasco, L.; Fernández-Jiménez, A. Monitoring Early Hydration of Calcium Sulfoaluminate Clinker. Constr. Build. Mater. 2021, 295, 123578. [Google Scholar] [CrossRef]

- Ferrari, A.; Favero, V.; Laloui, L. Experimental Analysis of the Retention Behavior of Shales. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013. [Google Scholar]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Mechanical Properties of Biopolymer-Stabilised Soil-Based Construction Materials. Géotechnique Lett. 2017, 7, 309–314. [Google Scholar] [CrossRef]

- Murray, I.; Tarantino, A. Mechanisms of Failure in Saturated and Unsaturated Clayey Geomaterials Subjected to (Total) Tensile Stress. Géotechnique 2019, 69, 701–712. [Google Scholar] [CrossRef]

- Das, G.; Razakamanantsoa, A.; Herrier, G.; Deneele, D. Influence of Wetting Fluids on the Compressive Strength, Physicochemical, and Pore-Structure Evolution in Lime-Treated Silty Soil Subjected to Wetting and Drying Cycles. Transp. Geotech. 2022, 35, 100798. [Google Scholar] [CrossRef]

- Ponzoni, E.; Nocilla, A.; Jommi, C. Determination of Water Retention Properties of Silty Sands by Means of Combined Commercial Techniques. Geosciences 2021, 11, 315. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, X.; Buzzi, O. A Microstructural Perspective on Soil Collapse. Géotechnique 2021, 71, 132–140. [Google Scholar] [CrossRef]

- Almajed, A.; Dafalla, M.; Shaker, A.A. The Combined Effect of Calcium Chloride and Cement on Expansive Soil Materials. Appl. Sci. 2023, 13, 4811. [Google Scholar] [CrossRef]

- Wang, D.; Korkiala-Tanttu, L. 1-D Compressibility Behaviour of Cement-Lime Stabilized Soft Clays. Eur. J. Environ. Civ. Eng. 2020, 24, 1013–1031. [Google Scholar] [CrossRef]

- Anysz, H.; Brzozowski, Ł.; Kretowicz, W.; Narloch, P. Feature Importance of Stabilised Rammed Earth Components Affecting the Compressive Strength Calculated with Explainable Artificial Intelligence Tools. Materials 2020, 13, 2317. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.A.; Zaman, M. Field and Laboratory Evaluation of Cement Kiln Dust as a Soil Stabilizer. Transp. Res. Rec. 2000, 1714, 25–32. [Google Scholar] [CrossRef]

- Yi, Y.; Liska, M.; Al-Tabbaa, A. Properties of Two Model Soils Stabilized with Different Blends and Contents of GGBS, MgO, Lime, and PC. J. Mater. Civ. Eng. 2014, 26, 267–274. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Li, N. Utilization of Lime/Carbide Slag-Activated Ground Granulated Blast-Furnace Slag for Dredged Sludge Stabilization. Mar. Georesources Geotechnol. 2021, 39, 659–669. [Google Scholar] [CrossRef]

- Abdila, S.R.; Abdullah, M.M.A.B.; Ahmad, R.; Rahim, S.Z.A.; Rychta, M.; Wnuk, I.; Nabiałek, M.; Muskalski, K.; Tahir, M.F.M.; Syafwandi; et al. Evaluation on the Mechanical Properties of Ground Granulated Blast Slag (GGBS) and Fly Ash Stabilized Soil via Geopolymer Process. Materials 2021, 14, 2833. [Google Scholar] [CrossRef]

- ACI (American Concrete Institute). Report on Soil Cement. ACI230.1R-09, Committee Report; ACI: Farmington Hills, MI, USA, 2009. [Google Scholar]

- Bruce, M.E.C.; Berg, R.R.; Filz, G.M.; Terashi, M.; Yang, D.S. Federal Highway Administration Design Manual: Deep Mixing for Embankment and Foundation Support; Office of Transportation Management Federal Highway Administration: Washington, DC, USA, 2013. [Google Scholar]

- Abdul-Hussain, N.; Fall, M. Unsaturated Hydraulic Properties of Cemented Tailings Backfill That Contains Sodium Silicate. Eng. Geol. 2011, 123, 288–301. [Google Scholar] [CrossRef]

- Phan, N.B.; Hayano, K.; Mochizuki, Y.; Yamauchi, H. Mixture Design Concept and Mechanical Characteristics of PS Ash–Cement-Treated Clay Based on the Water Absorption and Retention Performance of PS Ash. Soils Found. 2021, 61, 692–707. [Google Scholar] [CrossRef]

- Mehta, P.K. Mechanism of Sulfate Attack on Portland Cement Concrete—Another Look. Cem. Concr. Res. 1983, 13, 401–406. [Google Scholar] [CrossRef]

- Myers, R.J.; Bernal, S.A.; San Nicolas, R.; Provis, J.L. Generalized Structural Description of Calcium–Sodium Aluminosilicate Hydrate Gels: The Cross-Linked Substituted Tobermorite Model. Langmuir 2013, 29, 5294–5306. [Google Scholar] [CrossRef]

- Ho, L.S.; Nakarai, K.; Ogawa, Y.; Sasaki, T.; Morioka, M. Strength Development of Cement-Treated Soils: Effects of Water Content, Carbonation, and Pozzolanic Reaction under Drying Curing Condition. Constr. Build. Mater. 2017, 134, 703–712. [Google Scholar] [CrossRef]

- Malhotra, V.M. Fly Ash, Slag, Silica Fume, and Rice Husk Ash in Concrete: A Review. Concr. Int. 1993, 15, 23–28. [Google Scholar]

- Chen, J.J.; Thomas, J.J.; Taylor, H.F.W.; Jennings, H.M. Solubility and Structure of Calcium Silicate Hydrate. Cem. Concr. Res. 2004, 34, 1499–1519. [Google Scholar] [CrossRef]

- Wongkeo, W.; Thongsanitgarn, P.; Chaipanich, A. Compressive Strength of Binary and Ternary Blended Cement Mortars Containing Fly Ash and Silica Fume under Autoclaved Curing. Adv. Mater. Res. 2012, 343–344, 316–321. [Google Scholar] [CrossRef]

- Dadsetan, S.; Bai, J. Mechanical and Microstructural Properties of Self-Compacting Concrete Blended with Metakaolin, Ground Granulated Blast-Furnace Slag and Fly Ash. Constr. Build. Mater. 2017, 146, 658–667. [Google Scholar] [CrossRef]

- Sutan, N.M.; Yakub, I.; Jaafar, M.S.; Matori, K.A.; Sahari, S.K. Sustainable Nanopozzolan Modified Cement: Characterizations and Morphology of Calcium Silicate Hydrate during Hydration. J. Nanomater. 2015, 2015, 7. [Google Scholar] [CrossRef]

- Sumesh, M.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.; Singh, R.; Nayaka, R.R.; Srinivas, K. Chemo-Physico-Mechanical Characteristics of High-Strength Alkali-Activated Mortar Containing Non-Traditional Supplementary Cementitious Materials. J. Build. Eng. 2021, 44, 103368. [Google Scholar] [CrossRef]

- Tang, W.C.; Wang, Z.; Liu, Y.; Cui, H.Z. Influence of Red Mud on Fresh and Hardened Properties of Self-Compacting Concrete. Constr. Build. Mater. 2018, 178, 288–300. [Google Scholar] [CrossRef]

- Little, D.N.; Nair, S.; Herbert, B. Addressing Sulfate-Induced Heave in Lime Treated Soils. J. Geotech. Geoenvironmental Eng. 2010, 136, 110–118. [Google Scholar] [CrossRef]

- Jain, A.; Chaudhary, S.; Gupta, R. Mechanical and Microstructural Characterization of Fly Ash Blended Self-Compacting Concrete Containing Granite Waste. Constr. Build. Mater. 2022, 314, 125480. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.R. Effect of Calcination Temperature on the Pozzolanic Activity of Sugar Cane Bagasse Ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- Barbosa, F.L.; Cordeiro, G.C. Partial Cement Replacement by Different Sugar Cane Bagasse Ashes: Hydration-Related Properties, Compressive Strength and Autogenous Shrinkage. Constr. Build. Mater. 2021, 272, 121625. [Google Scholar] [CrossRef]

- Cuenca, J.; Rodríguez, J.; Martín-Morales, M.; Sánchez-Roldán, Z.; Zamorano, M. Effects of Olive Residue Biomass Fly Ash as Filler in Self-Compacting Concrete. Constr. Build. Mater. 2013, 40, 702–709. [Google Scholar] [CrossRef]

- Dimter, S.; Šimun, M.; Zagvozda, M.; Rukavina, T. Laboratory Evaluation of the Properties of Asphalt Mixture with Wood Ash Filler. Materials 2021, 14, 575. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R. Utilization of Waste Materials and By-Products in Producing Controlled Low-Strength Materials. Resour. Conserv. Recycl. 2009, 54, 1–8. [Google Scholar] [CrossRef]

- Kahle, M.; Kleber, M.; Jahn, R. Review of XRD-Based Quantitative Analyses of Clay Minerals in Soils: The Suitability of Mineral Intensity Factors. Geoderma 2002, 109, 191–205. [Google Scholar] [CrossRef]

- Dermatas, D. Ettringite-Induced Swelling in Soils: State-of-the-Art. Appl. Mech. Rev. 1995, 48, 659–673. [Google Scholar] [CrossRef]

- Puppala, A.J.; Intharasombat, N.; Vempati, R.K. Experimental Studies on Ettringite-Induced Heaving in Soils. J. Geotech. Geoenvironmental Eng. 2005, 131, 325–337. [Google Scholar] [CrossRef]

- Iler, K.R. The Chemistry of Silica. Solubility, Polymerization, Colloid and Surface Properties and Biochemistry of Silica; Wiley: Hoboken, NJ, USA, 1979. [Google Scholar]

- Keller, W.D. The Principles of Chemical Weathering: Soil Science; Lucas Brothers: Baltimore, MD, USA, 1955. [Google Scholar]

- Jing, P.; Song, X.; Zhang, J.; Nowamooz, H. A Review of Hydro-Mechanical Coupling Behaviour of Cement-Treated Materials. Constr. Build. Mater. 2022, 322, 126446. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, W. Quantitative Analysis of Generalized Suction on the Shear Strength of Unsaturated Soils. IOP Conf. Ser. Earth Environ. Sci. 2021, 651, 032001. [Google Scholar] [CrossRef]

- Min, C.; Shi, Y.; Liu, Z. Properties of Cemented Phosphogypsum (PG) Backfill in Case of Partially Substitution of Composite Portland Cement by Ground Granulated Blast Furnace Slag. Constr. Build. Mater. 2021, 305, 124786. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, A.; Wang, S.; Wang, H.; Yang, L.; Wang, Y.; Ruan, Z. Correlative Mechanism of Hydraulic-Mechanical Property in Cemented Paste Backfill. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2017, 32, 579–585. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Routledge: New York, NY, USA, 1988; ISBN 978-0-203-77158-7. [Google Scholar]

- Kim, S.; Kim, H. A New Metric of Absolute Percentage Error for Intermittent Demand Forecasts. Int. J. Forecast. 2016, 32, 669–679. [Google Scholar] [CrossRef]

- Gowida, A.; Elkatatny, S.; Gamal, H. Unconfined Compressive Strength (UCS) Prediction in Real-Time While Drilling Using Artificial Intelligence Tools. Neural Comput. Appl. 2021, 33, 8043–8054. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of Woody Biomass Fly Ash in Cement-Based Materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

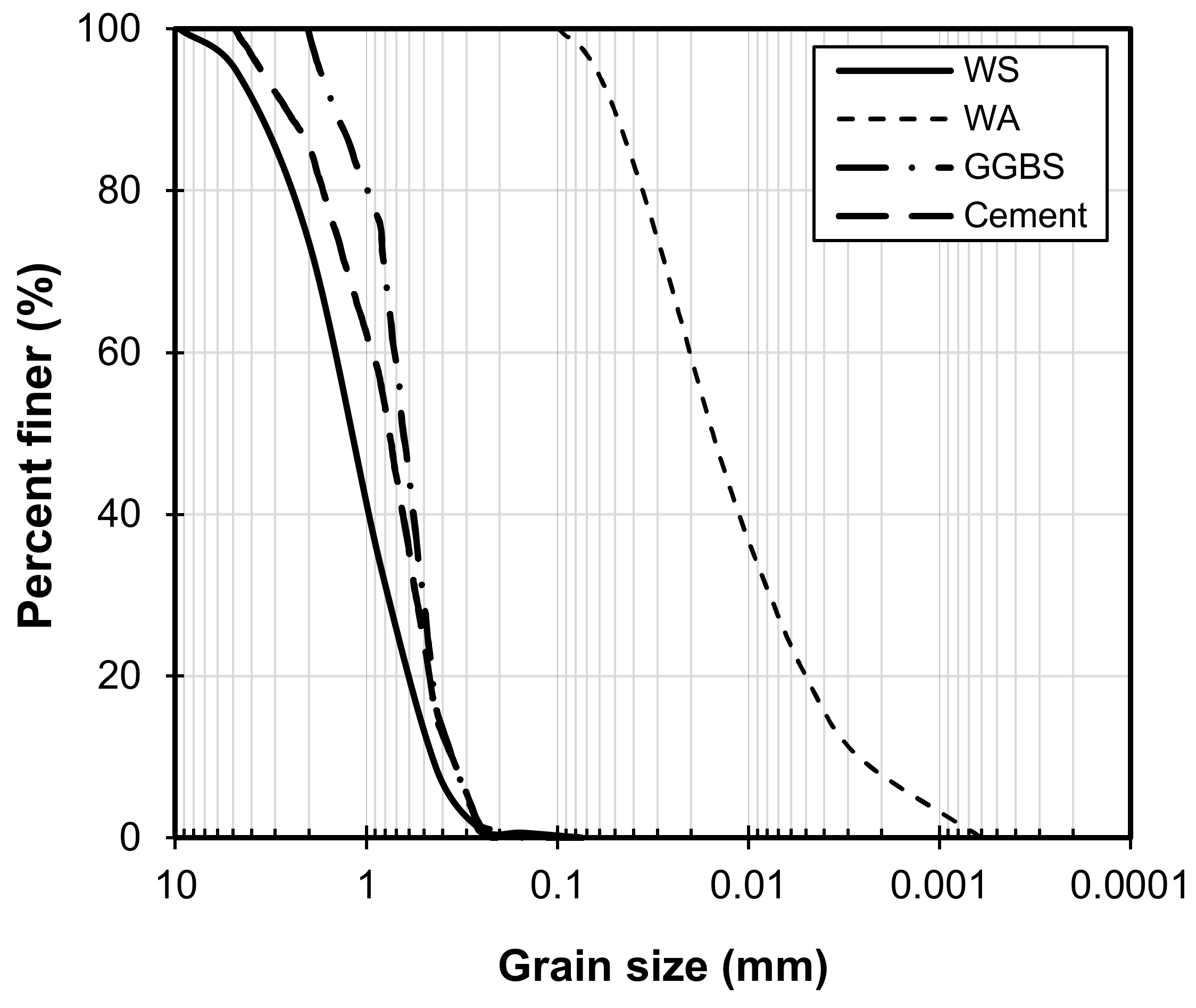

| Properties | WS | WA | CEMENT | GGBS |

|---|---|---|---|---|

| Specific gravity, Gs | 2.67 | 2.31 | 3.15 | 2.85 |

| Fine content passing #200 (%) | 0.01 | - | - | - |

| Maximum void ratio, emax | 1.021 | - | - | - |

| Minimum void ratio, emin | 0.554 | - | - | - |

| Grain size (mm) | d10 = 0.447 | d10 = 2.636 × 10−3 | d10 = 0.362 | d10 = 0.354 |

| d50 = 1.207 | d50 = 15.347 × 10−3 | d50 = 0.768 | d50 = 0.644 | |

| d60 = 1.490 | d60 = 20.233 × 10−3 | d60 = 0.9513 | d60 = 0.712 | |

| Soil classification, USCS | SP | - | - | - |

| Coefficient of uniformity, cu | 3.333 | - | - | - |

| Plastic index, PI (%) | NP | - | - | - |

| Optimum moisture content * (%) | 11 | - | - | - |

| Maximum dry density * (g/cm3) | ||||

| LOI | 6.82 | 0.35 | 0.3 | |

| LSF | 1.984 | 0 | 90.4 | 1 |

| Components | WA (%) | Cement (%) | GGBS (%) |

|---|---|---|---|

| Na2O | 3.47 | ||

| MgO | 3.21 | 2.01 | 5.3 |

| Al2O3 | 6.6 | 5.02 | 15.8 |

| SiO2 | 23.25 | 21.88 | 33.4 |

| P2O5 | 2.28 | ||

| SO3 | 8.4 | 1.83 | 0.3 |

| Cl | 2.8 | ||

| K2O | 16.64 | 0.92 | 1.5 |

| CaO | 27.8 | 64.18 | 41.8 |

| TiO2 | 0.43 | ||

| MnO | 0.5 | ||

| Fe2O3 | 3.81 | 3.66 | 0.6 |

| ZnO | 0.14 | ||

| SiO | 0.16 | ||

| etc. | 0.50 |

| Specimen ID | UCS | ST | pH | MA | Specimen ID | UCS | ST | pH | MA | Specimen ID | UCS | ST | pH | MA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WABB5-C3-1 | ✓ | WABB15-C3-1 | ✓ | WABB25-C3-1 | ✓ | |||||||||

| WABB5-C3-2 | ✓ | WABB15-C3-2 | ✓ | WABB25-C3-2 | ✓ | |||||||||

| WABB5-C3-3 | ✓ | ✓ | WABB15-C3-3 | ✓ | ✓ | WABB25-C3-3 | ✓ | ✓ | ||||||

| WABB5-C7-1 | ✓ | WABB15-C7-1 | ✓ | WABB25-C7-1 | ✓ | |||||||||

| WABB5-C7-2 | ✓ | WABB15-C7-2 | ✓ | WABB25-C7-2 | ✓ | |||||||||

| WABB5-C7-3 | ✓ | WABB15-C7-3 | ✓ | WABB25-C7-3 | ✓ | |||||||||

| WABB5-C7-4 | ✓ | ✓ | WABB15-C7-4 | ✓ | ✓ | WABB25-C7-4 | ✓ | ✓ | ||||||

| WABB5-C14-1 | ✓ | WABB15-C14-1 | ✓ | WABB25-C14-1 | ✓ | |||||||||

| WABB5-C14-2 | ✓ | WABB15-C14-2 | ✓ | WABB25-C14-2 | ✓ | |||||||||

| WABB5-C14-3 | ✓ | ✓ | WABB15-C14-3 | ✓ | ✓ | WABB25-C14-3 | ✓ | ✓ | ||||||

| WABB5-C28-1 | ✓ | ✓ | WABB15-C28-1 | ✓ | WABB25-C28-1 | ✓ | ✓ | |||||||

| WABB5-C28-2 | ✓ | WABB15-C28-2 | ✓ | ✓ | WABB25-C28-2 | ✓ | ||||||||

| WABB5-C28-3 | ✓ | WABB15-C28-3 | ✓ | WABB25-C28-3 | ✓ | |||||||||

| WABB5-C28-4 | ✓ | ✓ | WABB15-C28-4 | ✓ | ✓ | WABB25-C28-4 | ✓ | ✓ | ||||||

| WS-1 | ✓ | ✓ | ✓ | WS-2 | ✓ | WS-3 | ✓ |

| Mixtures | wc(m) | 3 Days | 7 Days | 14 Days | 28 Days |

|---|---|---|---|---|---|

| WS + 5% WABB | 12.00 | 11.07 | 10.24 | 9.64 | 9.28 |

| WS + 15% WABB | 10.50 | 9.70 | 8.53 | 8.25 | 8.06 |

| WS + 25% WABB | 9.60 | 8.62 | 7.58 | 7.57 | 7.12 |

| Element | 5% WABB | 15% WABB | 25% WABB | |||

|---|---|---|---|---|---|---|

| S1 (%) | S2 (%) | S1 (%) | S2 (%) | S1 (%) | S2 (%) | |

| Oxygen (O) | 43.58 | 29.15 | 39.91 | 34.70 | 48.11 | 26.25 |

| Aluminum (Al) | 10.92 | 16.28 | 5.95 | 6.13 | 4.76 | 5.93 |

| Sulfur (S) | 0.75 | - | 2.17 | 0.56 | 1.58 | 1.16 |

| Sodium (Na) | 2.61 | 1.31 | 0.84 | 0.41 | 0.40 | 0.35 |

| Silicon (Si) | 18.53 | 25.89 | 9.29 | 16.73 | 7.68 | 18.86 |

| Calcium (Ca) | 9.03 | 7.36 | 22.85 | 7.68 | 29.02 | 38.73 |

| Ca:Si | 0.49 | 0.28 | 2.46 | 0.45 | 3.78 | 2.05 |

| Al:Ca | 1.21 | 2.21 | 0.26 | 0.79 | 0.16 | 0.15 |

| Si:Al | 1.70 | 1.59 | 1.56 | 2.73 | 1.61 | 3.18 |

| Suspected minerals | C-S-H, C-A-S-H | Ett | C-S-H, C-A-S-H | Ett | C-S-H, C-A-S-H | Ett |

| Minerals | 5% WABB | 15% WABB | 25% WABB | Norm. 15% WABB | Norm. 25% WABB | |

|---|---|---|---|---|---|---|

| 2θ (Cuka) | Int. | Int. | Int. | Norm. Int. | Norm. Int. | |

| Quartz | 20.71 | 7556.84 | 5206.40 | 6844.66 | 0.69 | 0.91 |

| Quartz | 26.50 | 30,171.54 | 39,293.70 | 19,697.65 | 1.30 | 0.65 |

| Quartz | 59.97 | 2519.38 | 2026.42 | 2051.53 | 0.80 | 0.81 |

| Quartz | 67.70 | 2693.04 | 3101.29 | 2873.15 | 1.15 | 1.07 |

| Albite | 21.81 | 8487.33 | 12,198.67 | 10,731.32 | 1.44 | 1.26 |

| Anorthite | 22.76 | 6061.73 | 5709.27 | 5404.96 | 0.94 | 0.89 |

| Anorthite | 36.47 | 4174.35 | 4481.96 | 5163.72 | 1.07 | 1.24 |

| Ettringite | 8.66 | 20,442.82 | 31,212.72 | 15,734.26 | 1.53 | 0.77 |

| Ettringite | 10.38 | 9438.60 | 7872.78 | 5018.26 | 0.83 | 0.53 |

| C-A-S-H | 25.44 | 5932.98 | 6710.39 | 7224.77 | 1.13 | 1.22 |

| Albite, anorthite | 27.76 | 25,880.79 | 20,197.73 | 18,570.71 | 0.78 | 0.72 |

| C-S-H, anorthite | 30.40 | 5738.28 | 6346.06 | 5223.20 | 1.11 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balagosa, J.; Lee, M.-J.; Choo, Y.-W.; Kim, H.-S.; Kim, J.-M. Experimental Validation of the Cementation Mechanism of Wood Pellet Fly Ash Blended Binder in Weathered Granite Soil. Materials 2023, 16, 6543. https://doi.org/10.3390/ma16196543

Balagosa J, Lee M-J, Choo Y-W, Kim H-S, Kim J-M. Experimental Validation of the Cementation Mechanism of Wood Pellet Fly Ash Blended Binder in Weathered Granite Soil. Materials. 2023; 16(19):6543. https://doi.org/10.3390/ma16196543

Chicago/Turabian StyleBalagosa, Jebie, Min-Jy Lee, Yun-Wook Choo, Ha-Seog Kim, and Jin-Man Kim. 2023. "Experimental Validation of the Cementation Mechanism of Wood Pellet Fly Ash Blended Binder in Weathered Granite Soil" Materials 16, no. 19: 6543. https://doi.org/10.3390/ma16196543

APA StyleBalagosa, J., Lee, M.-J., Choo, Y.-W., Kim, H.-S., & Kim, J.-M. (2023). Experimental Validation of the Cementation Mechanism of Wood Pellet Fly Ash Blended Binder in Weathered Granite Soil. Materials, 16(19), 6543. https://doi.org/10.3390/ma16196543