Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Metal Active Gas Arc Welded and Narrow Gap Submerged Arc Welded Q235A Low Carbon Steel

Abstract

:1. Introduction

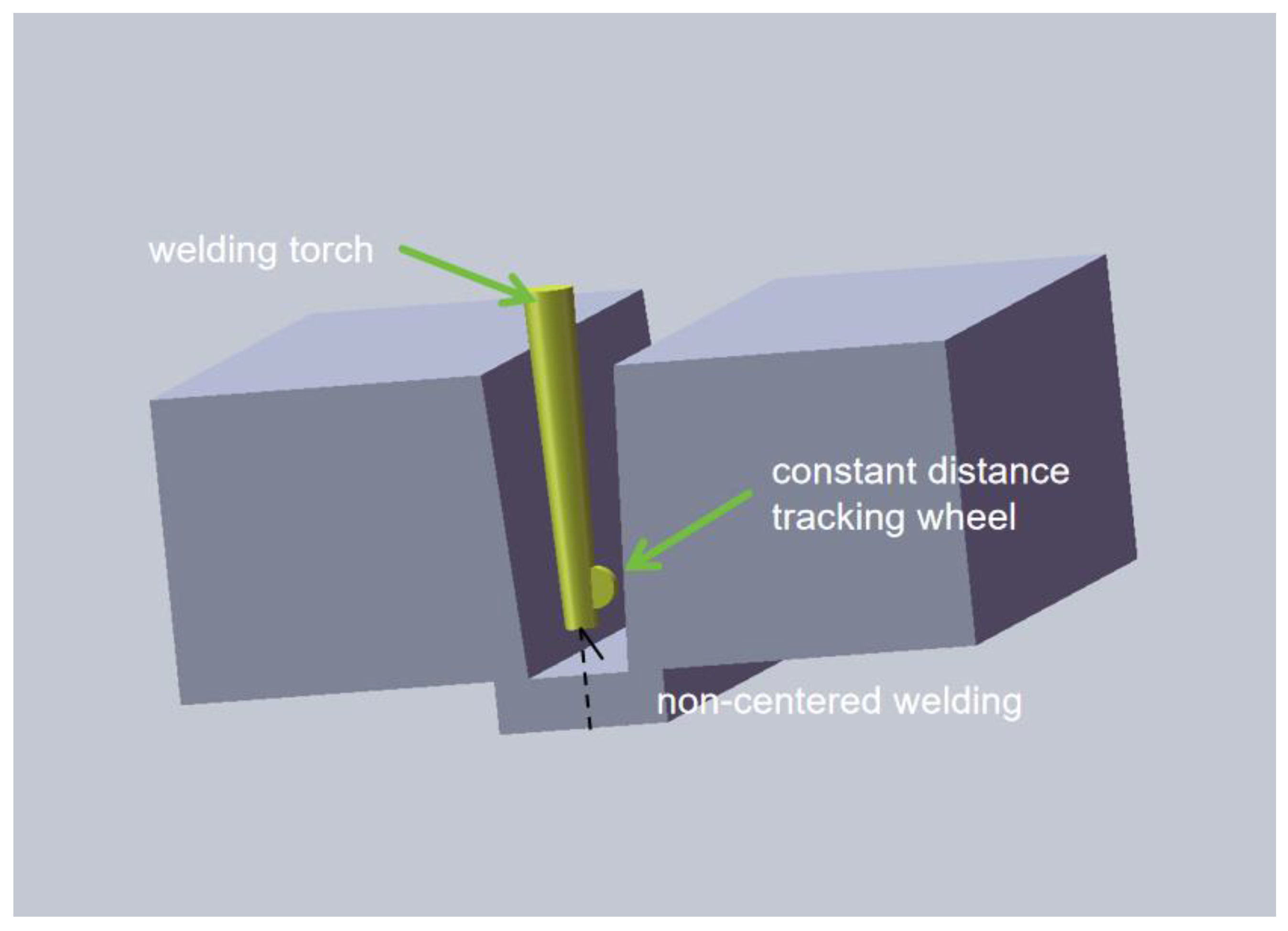

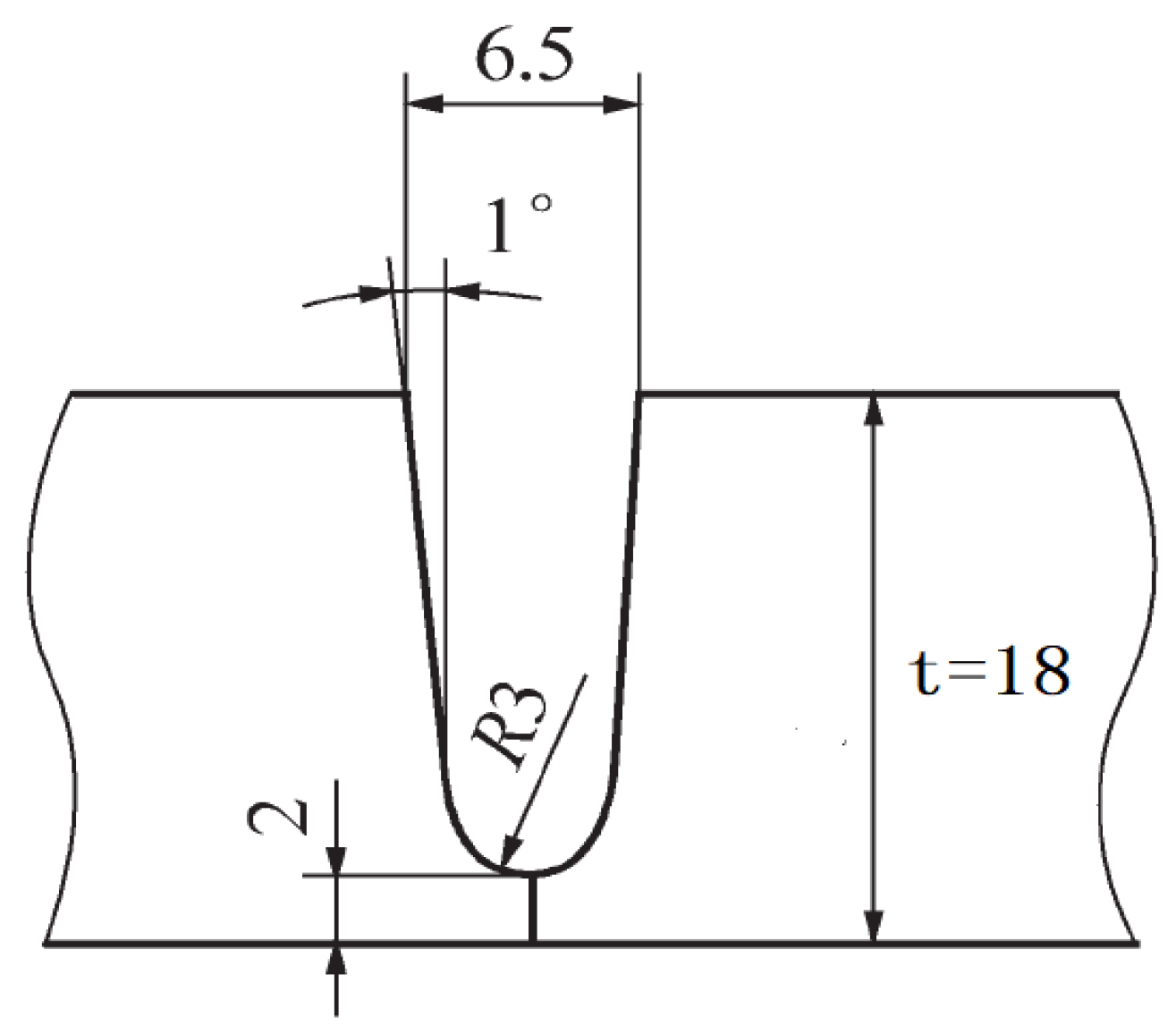

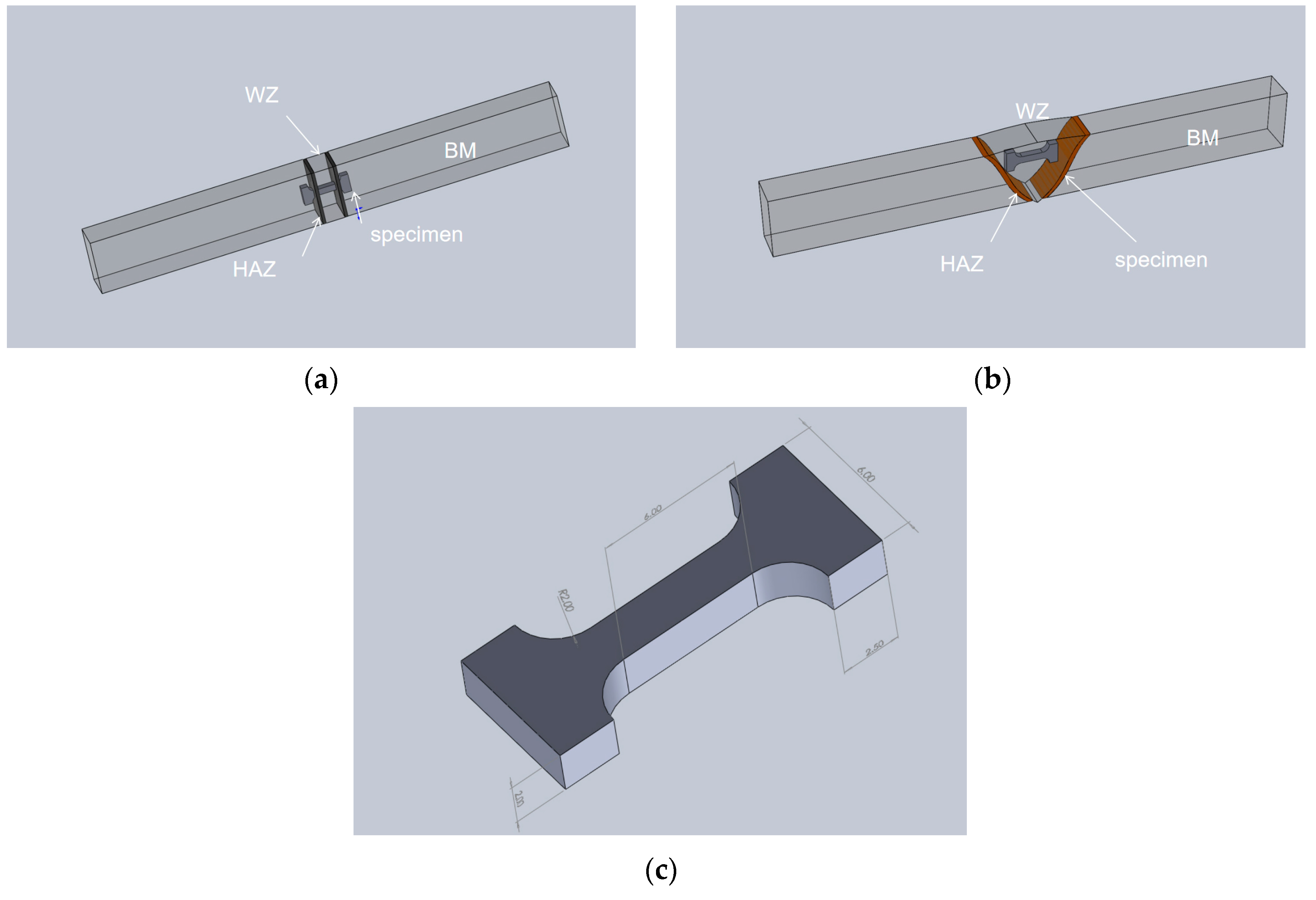

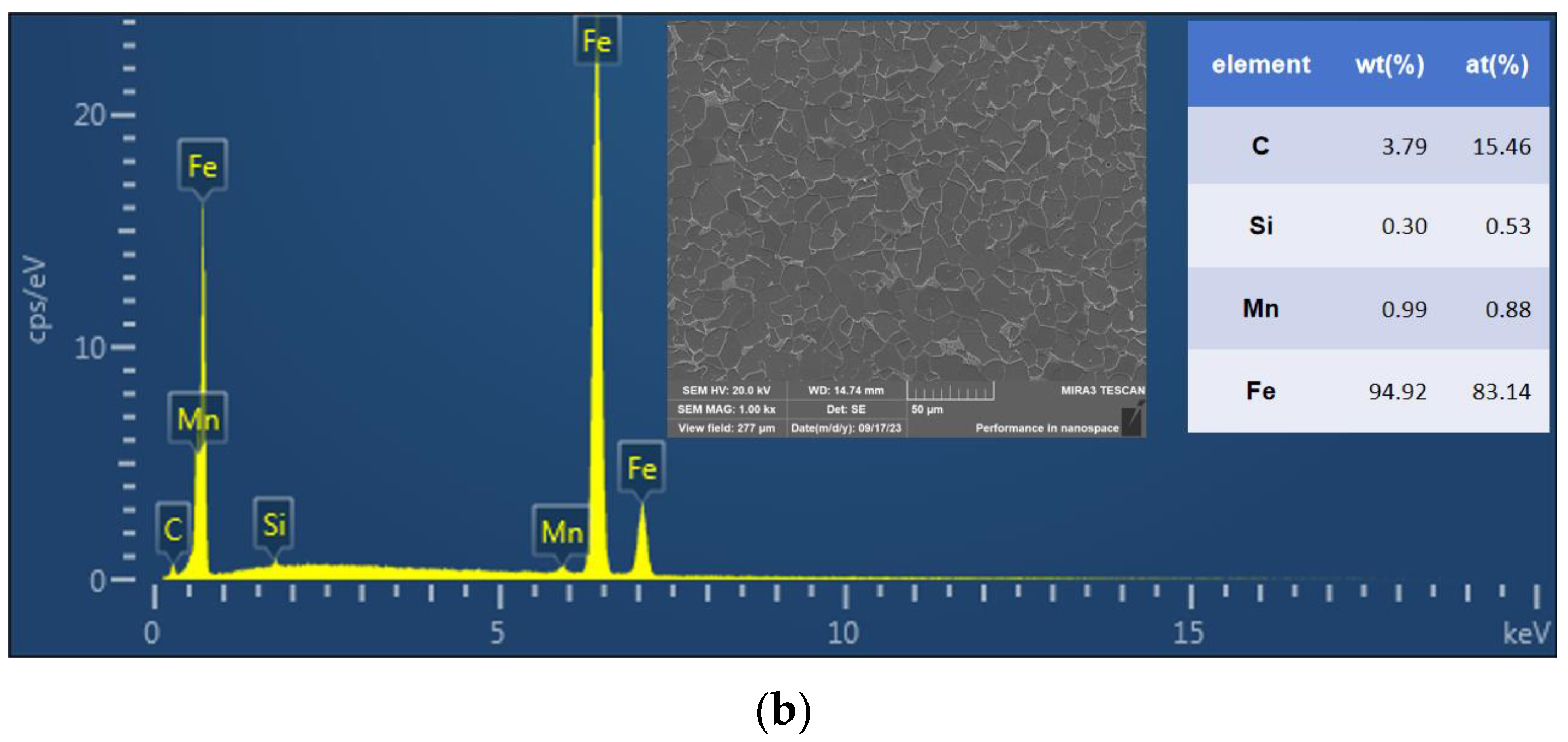

2. Materials and Methods

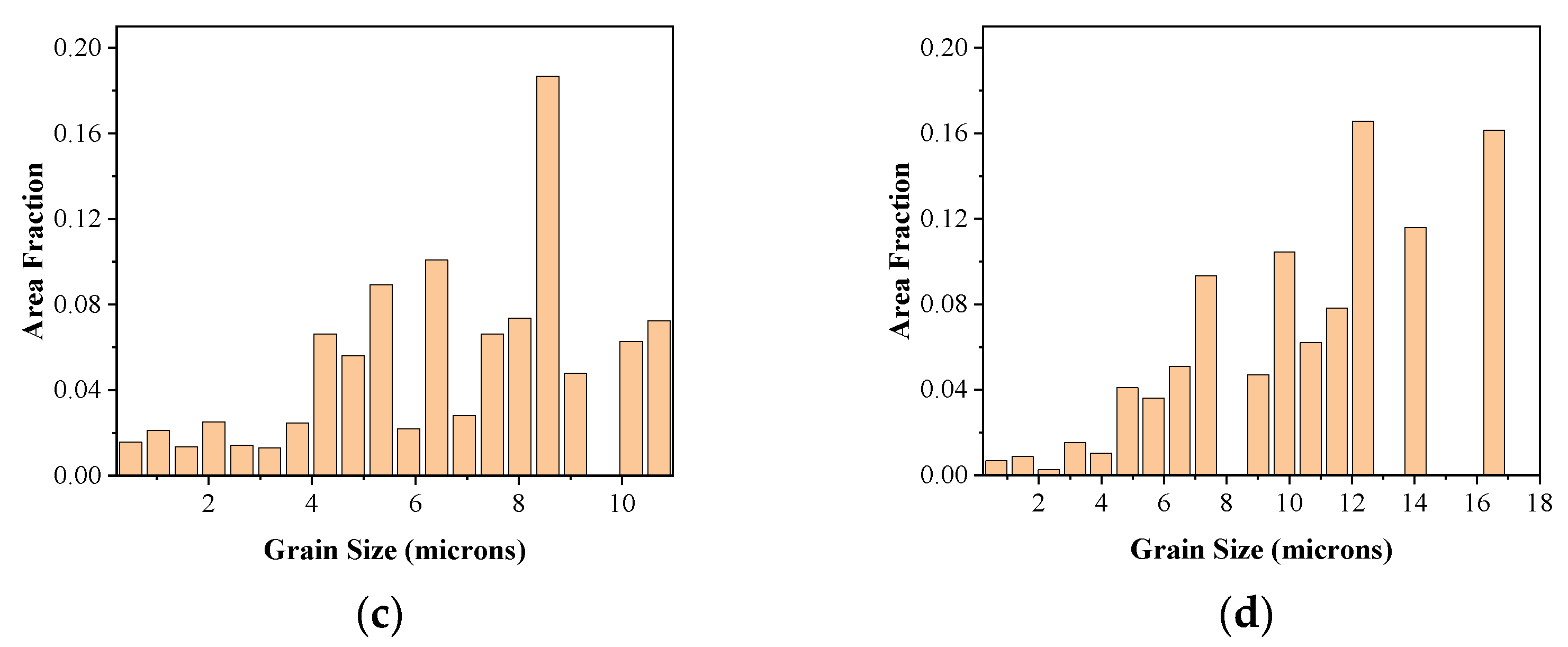

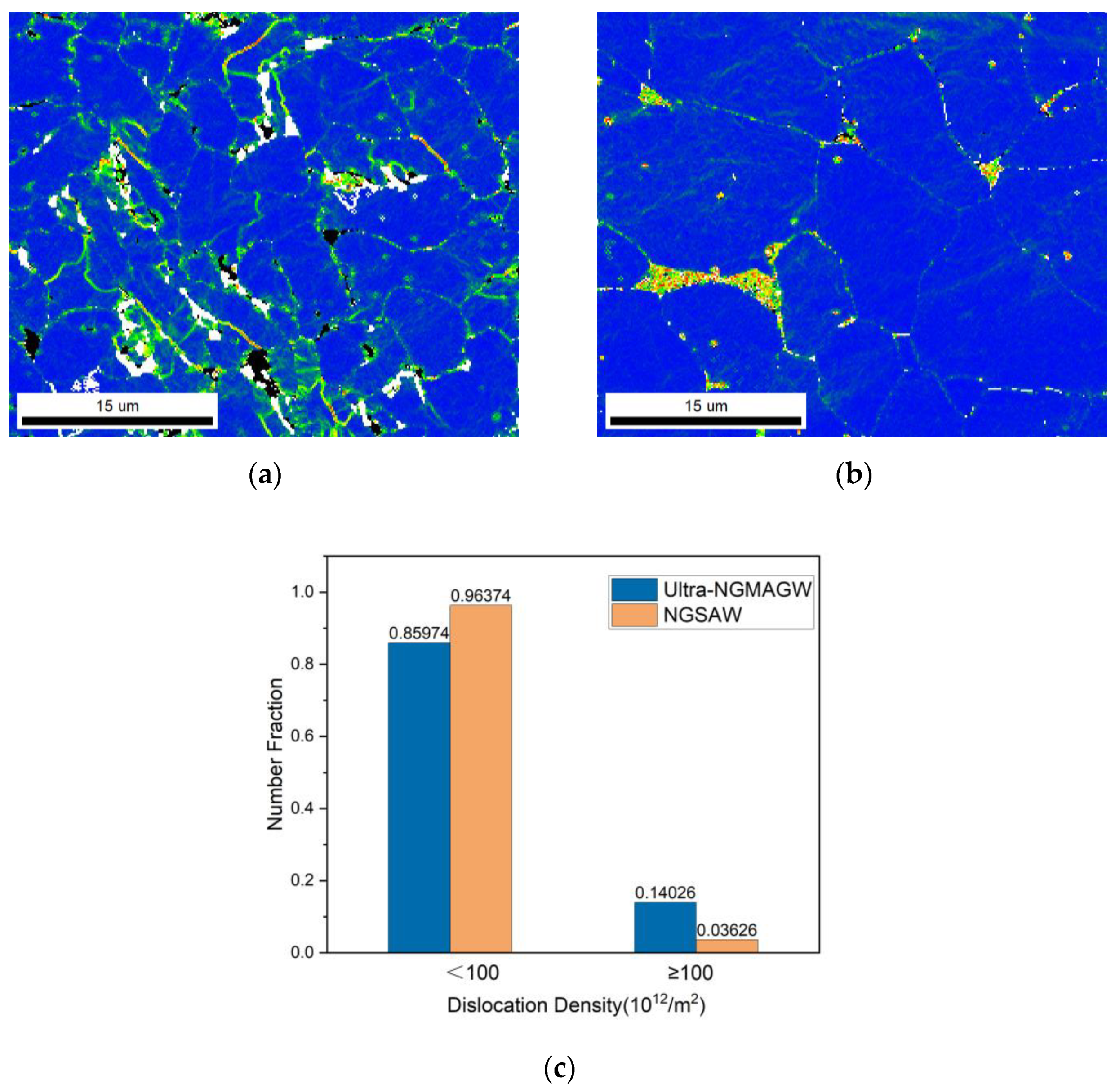

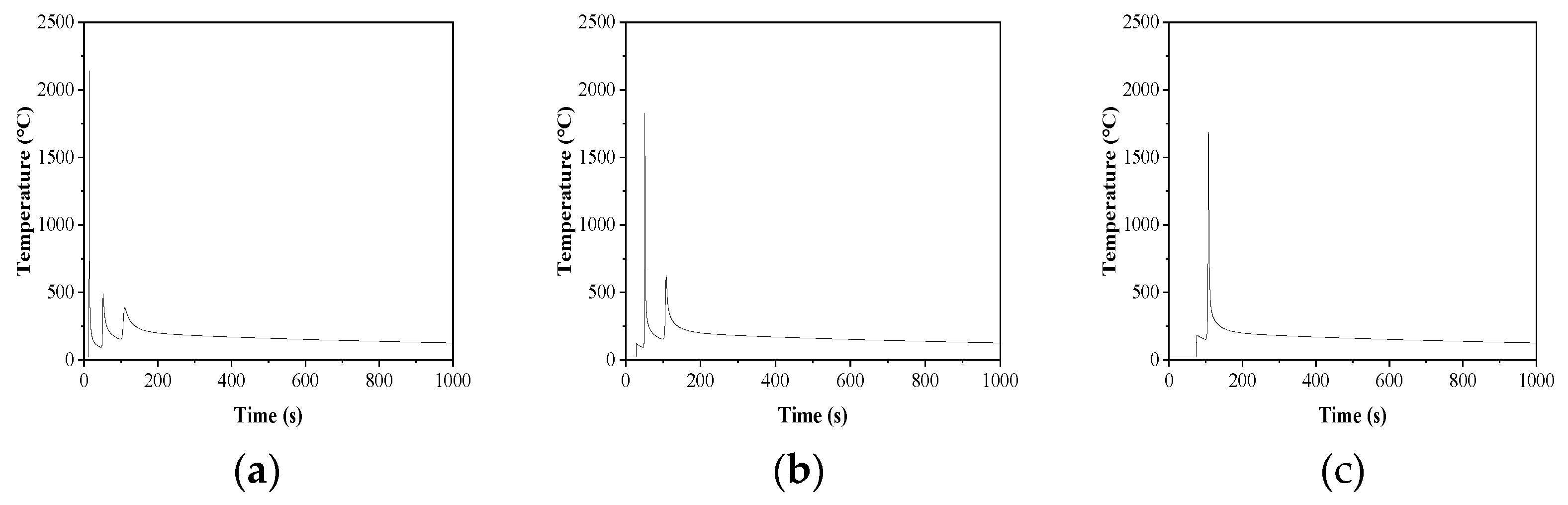

3. Results

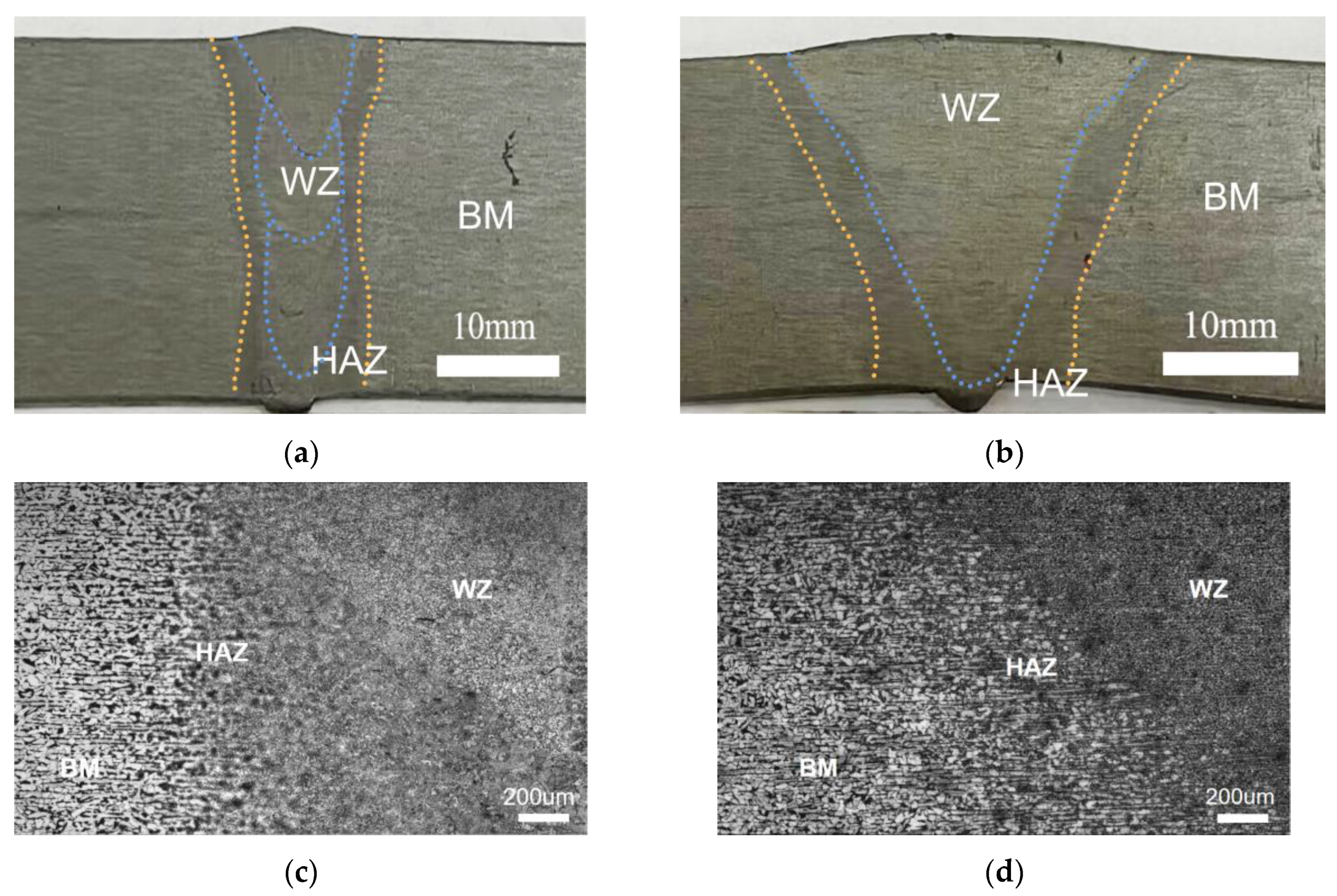

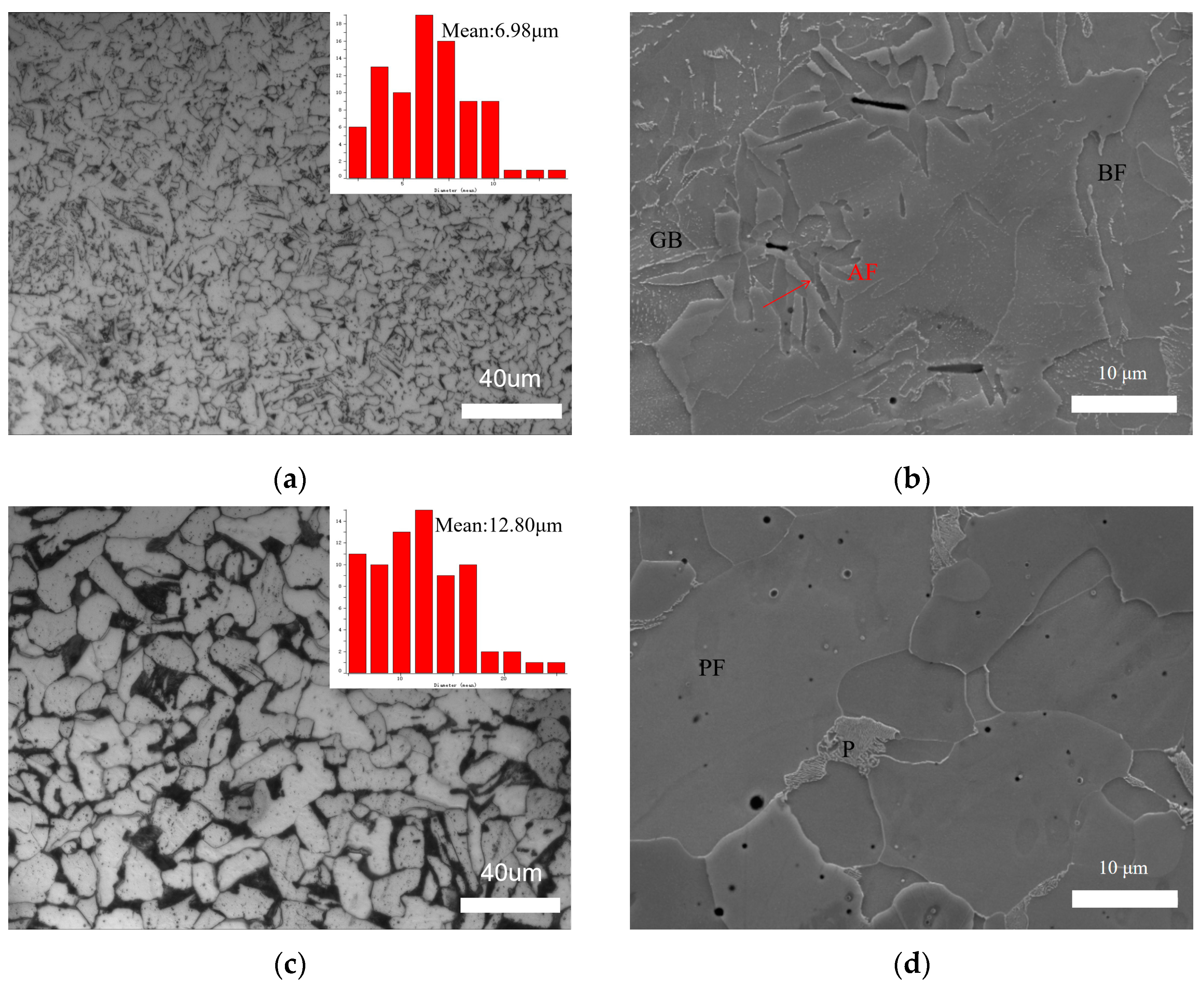

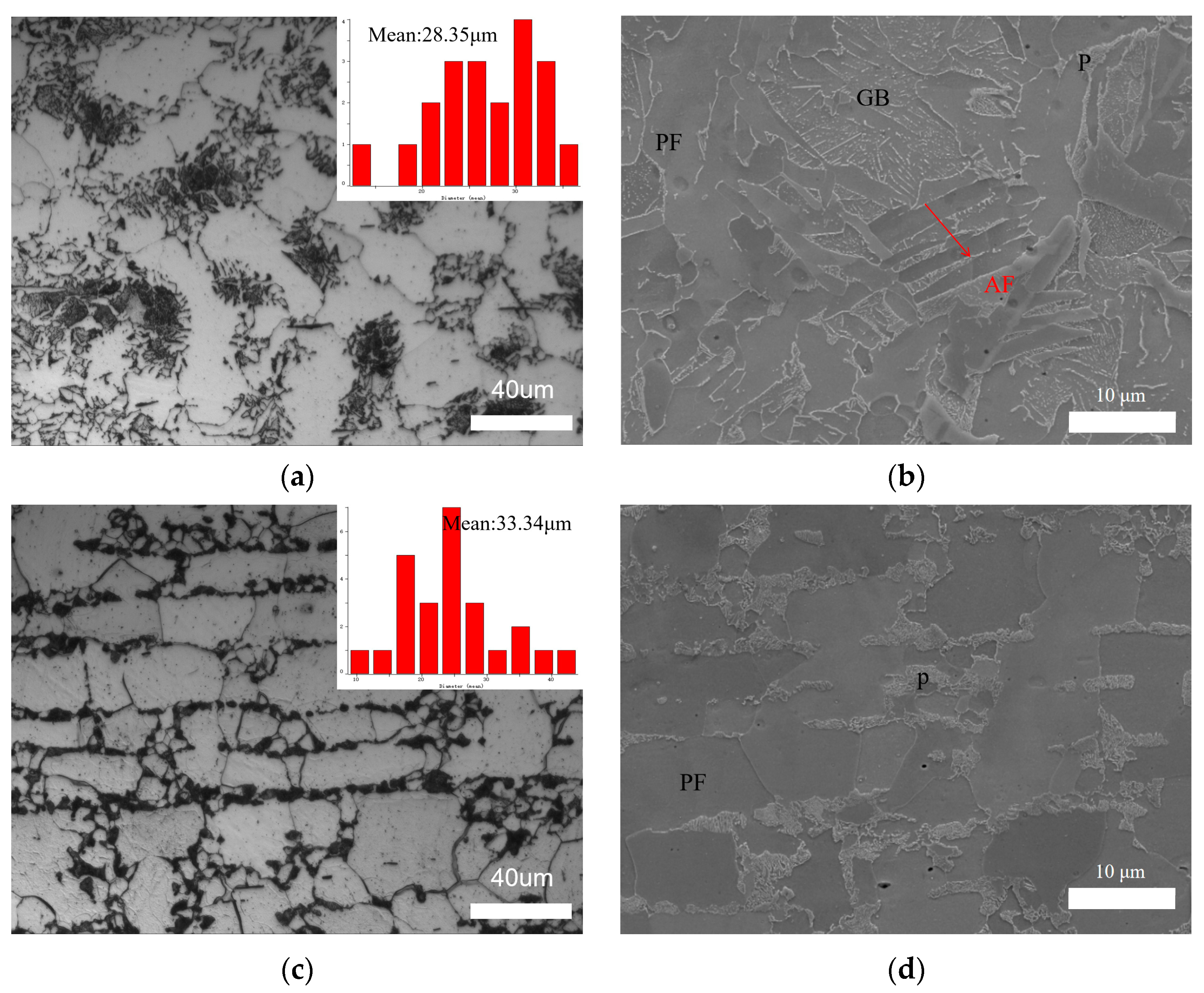

3.1. Structure and Morphology of Welded Joints

3.2. Mechanical Properties

3.2.1. Microhardness

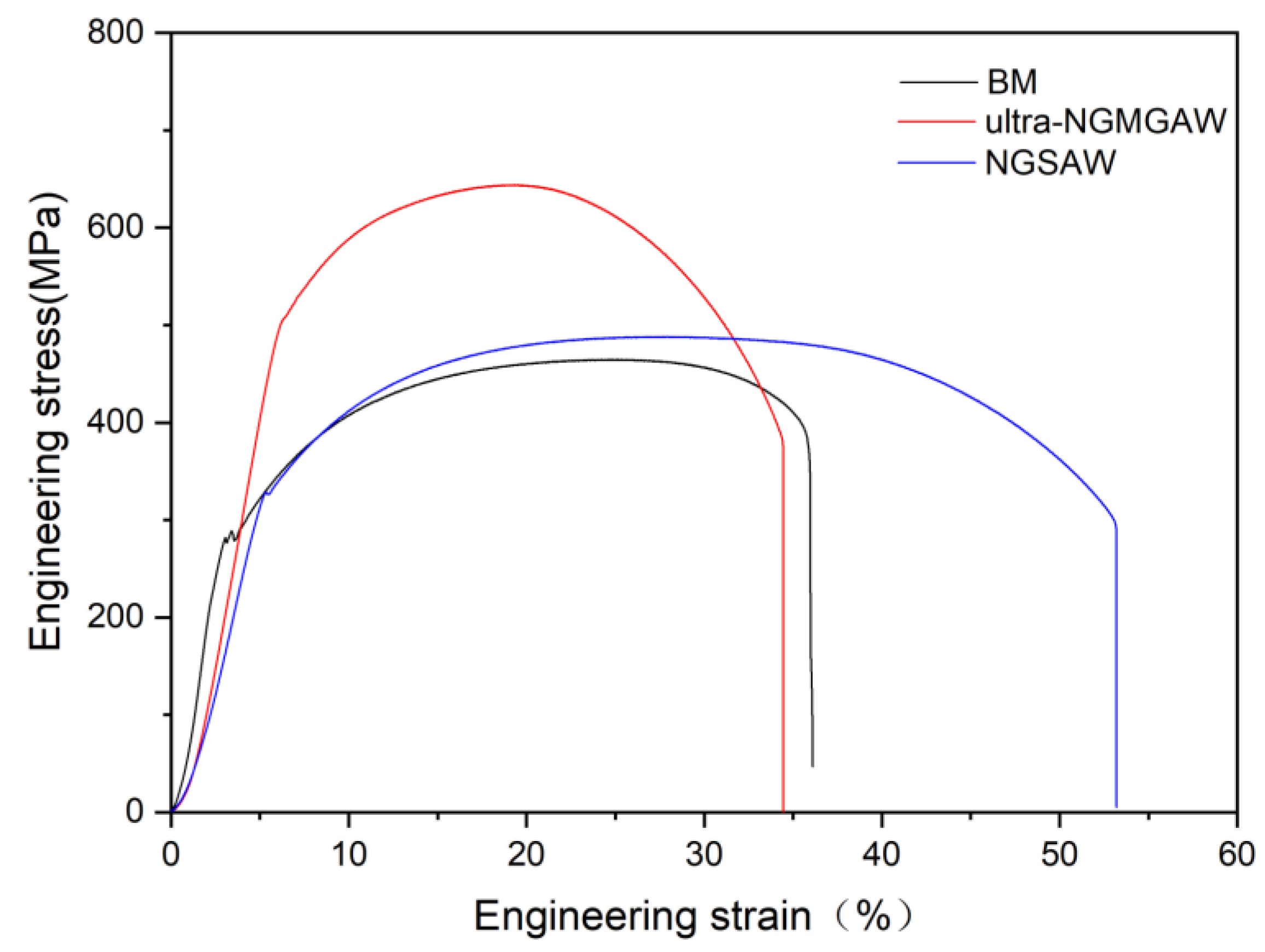

3.2.2. Tensile Property

4. Discussion

4.1. Reinforcement Mechanism

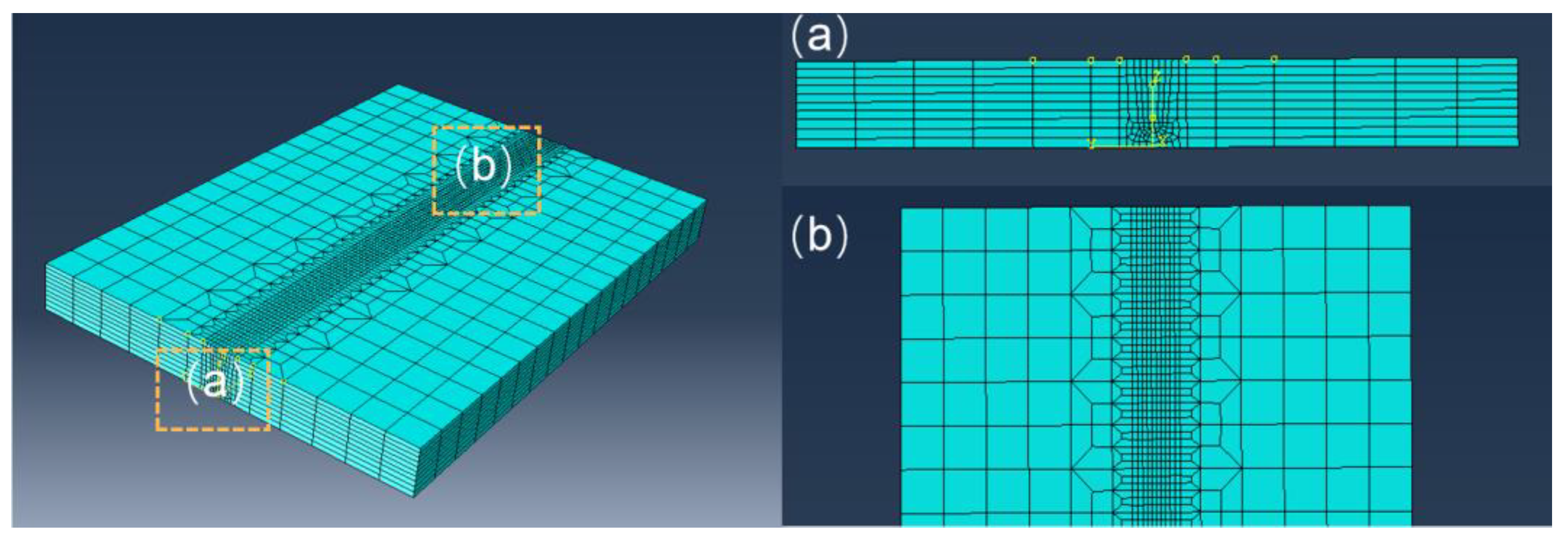

4.2. Numerical Simulation and Microstructure Evolution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.D.; Ma, X.P.; Subramanian, S.V.; Misra, R.D.K.; Shang, C.J. Structure–Property–Fracture Mechanism Correlation in Heat-Affected Zone of X100 Ferrite−Bainite Pipeline Steel. Metall. Mater. Trans.E. 2015, 2, 1. [Google Scholar] [CrossRef]

- Sun, Q.J.; Hu, H.F.; Yuan, X.; Feng, J.C. Research Status and Development Trend of Narrow-gap TIG Welding. Adv. Des. Technol. 2011, 308, 1170–1176. [Google Scholar] [CrossRef]

- Zhang, F.; Guo, J.; Zhang, G.; Wang, Y. Narrow Gap/Ultra Narrow Gap Welding Technology (IV) Ultra Narrow Gap MAG/MIG Welding Technology. Electr. Weld. Mach. 2017, 47, 25–29. [Google Scholar]

- Guo, J.; Zhang, F.; Pang, H.; Zhang, G. Analysis of microstructure and properties of ultra narrow gap MAG welded joints between 34Cr2Ni2Mo and 35CrMoV steel thick plates. Electr. Weld. Mach. 2018, 48, 51–54+60. [Google Scholar]

- Guo, J.; Wan, W.; Zhang, F.; Zhang, G. Microstructure analysis of ultra-narrow gap MAG welding joints in 35CrMo quenched and tempered steel. Electr. Weld. Mach. 2017, 47, 24–27. [Google Scholar]

- Zhao, M.-C.; Ke, Y.; Shan, Y.-Y. Comparison on Strength and Toughness Behaviors of Pipeline Steels with AF and Ultrafine Ferrite. Mater. Lett. 2003, 57, 1496–1500. [Google Scholar] [CrossRef]

- Byun, J.-S.; Shim, J.-H.; Suh, J.-Y.; Oh, Y.-J.; Cho, Y.W.; Shim, J.-D.; Lee, D.N. Inoculated AF Microstructure and Mechanical Properties. Mater. Sci. En. A Struct. Mater. Prop. Microstruct. Process. 2001, 319, 326–331. [Google Scholar] [CrossRef]

- Zhao, M.; Xiao, F.; Shan, Y.; Li, Y.; Yang, K. Microstructural Characteristic and Toughening of an Ultralow Carbon AF Pipeline Steel. Chin Shu Hsüeh Pao 2002, 38, 283–287. [Google Scholar]

- Lan, L.; Qiu, C.; Zhao, D. The Formation of AF and Mechanical Properties Behaviors in a Low Welding Crack Susceptibility Steel. Adv. Mater. Res. 2011, 163–167, 337–341. [Google Scholar]

- Zhao, L.; Zhao, X. Microstructure and Mechanical Properties of Weld in High Strength Low Alloy Steel by Ultra-narrow Gap Welding. Adv. Mater. Res. 2011, 154–155, 1792–1795. [Google Scholar] [CrossRef]

- Song, M.; Song, B.; Zhang, S.; Xue, Z.; Yang, Z.; Xu, R. Role of Lanthanum Addition on AF Transformation in C-Mn Steel. ISIJ Int. 2017, 57, 1261–1267. [Google Scholar] [CrossRef]

- Cui, Z.M.; Zhu, L.G.; Li, Y.L.; Zhang, Q.J.; Yan, C.L.; Mo, W.L. Relationship between Crystal Structure of Inclusions and Formation of AFs. J. Iron Steel Res. Int. 2016, 23, 586–592. [Google Scholar] [CrossRef]

- Xiao, F.R.; Zhao, M.C.; Shan, Y.Y.; Liao, B.; Yang, K. Processing of Ultralow Carbon Pipline Steels with AF. J. Mater. Sci. Technol. 2004, 20, 779–781. [Google Scholar]

- Wu, K.M. Three-dimensional Analysis of AF in a Low-carbon Steel Containing Titanium. Scr. Mater. 2006, 54, 569–574. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M. Tensile and Impact Behaviour of Thermo Mechanically Treated and Micro-alloyed Medium Carbon Steel Bar. Constr. Build. Mater. 2018, 192, 657–670. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M.; Gudimetla, K.; Kalsar, R.; Kestens, L.A.I.; Kondaveeti, C.S.; Pugazhendhi, B.S.; Ravisankar, B. Development of Ultrafine Grained Al–Zn–Mg–Cu Alloy by Equal Channel Angular Pressing: Microstructure, Texture and Mechanical Properties. Arch. Civ. Mech. Eng. 2020, 20, 7. [Google Scholar] [CrossRef]

- Chokshi, A.H.; Rosen, A.; Karch, J.; Gleiter, H. On the validity of the Hall-Petch relationship in nanocrystalline materials. Scr. Met. 1989, 23, 1679–1684. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M.; Shankar, G. On the Role of Precipitates in Controlling Microstructure and Mechanical Properties of Ag and Sn Added 7075 Alloys during Artificial Ageing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 738, 399–411. [Google Scholar] [CrossRef]

- Chen, J.; Tang, S.; Liu, Z.Y.; Wang, G.D. Microstructural characteristics with various cooling paths and the mechanism of embrittlement and toughening in low-carbon high performance bridge steel. Mater. Sci. Eng. A 2013, 559, 241–249. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.-Y.; Gianetto, J. Thermal and microstructure simulation of high strength pipeline girth welds. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6–11 July 2008. [Google Scholar]

- Lampman, S.R. Weld Integrity and Performance, ASM International Technology& Engineering; Material Park: Novelty, OH, USA, 1997. [Google Scholar]

- Vezzù, S.; Scappin, M.; Boaretto, D.; Timelli, G. On the Effect of Slight Variations of Si, Mn, and Ti on Inclusions Properties, Microstructure, and Mechanical Properties of YS460 C-Mn Steel Welds. Metallogr. Microstruct. Anal. 2019, 8, 292–306. [Google Scholar] [CrossRef]

- Shang, C.; Hu, L.; Yang, S.; Wang, X.; Zhao, Y.; He, X. Forming and Controlling of the AF in Low Carbon Steel. Chin Shu Hsüeh Pao 2005, 41, 471–476. [Google Scholar]

- Zhao, M.; Shan, Y.; Qu, J.; Xiao, F.; Zhong, Y.; Yang, K. AF Formation in a Pipeline Steel with Thermo-mechanical Control Process. Chin Shu Hsüeh Pao 2001, 37, 820–824. [Google Scholar]

- Kim, Y.M.; Lee, H.; Kim, N.J. Transformation Behavior and Microstructural Characteristics of AF in Linepipe Steels. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 478, 361–370. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P | Nb | Fe |

|---|---|---|---|---|---|---|

| 0.14–0.22 | 0.30 | 0.3–0.65 | 0.05 | 0.04 | 0.15–0.16 | Bal. |

| C | Si | Mn | S | Cr | Ni | Mo | V | W | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.06 | 0.40 | 0.78 | 0.001 | 2.68 | 0.06 | 0.01 | 0.21 | 1.69 | 0.04 | Bal. |

| Arc Voltage | Welding Current | Welding Speed | Protective Gas | Gas Flow |

|---|---|---|---|---|

| 26.4 V | 195 A | 4.64 mm/s | 80% (Ar) + 20% (CO2) | 20 L/min |

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | |

|---|---|---|---|

| BM | 281 | 464 | 36.1 |

| ultra-NGMAGW | 504 | 643 | 34.5 |

| NGSAW | 327 | 487 | 53.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Xiao, W.; Gong, L.; Zhang, F. Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Metal Active Gas Arc Welded and Narrow Gap Submerged Arc Welded Q235A Low Carbon Steel. Materials 2023, 16, 6601. https://doi.org/10.3390/ma16196601

Wu S, Xiao W, Gong L, Zhang F. Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Metal Active Gas Arc Welded and Narrow Gap Submerged Arc Welded Q235A Low Carbon Steel. Materials. 2023; 16(19):6601. https://doi.org/10.3390/ma16196601

Chicago/Turabian StyleWu, Shang, Wenkai Xiao, Lingfei Gong, and Fuju Zhang. 2023. "Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Metal Active Gas Arc Welded and Narrow Gap Submerged Arc Welded Q235A Low Carbon Steel" Materials 16, no. 19: 6601. https://doi.org/10.3390/ma16196601

APA StyleWu, S., Xiao, W., Gong, L., & Zhang, F. (2023). Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Metal Active Gas Arc Welded and Narrow Gap Submerged Arc Welded Q235A Low Carbon Steel. Materials, 16(19), 6601. https://doi.org/10.3390/ma16196601