Eco-Friendly Sustainable Concrete and Mortar Using Coal Dust Waste

Abstract

:1. Introduction

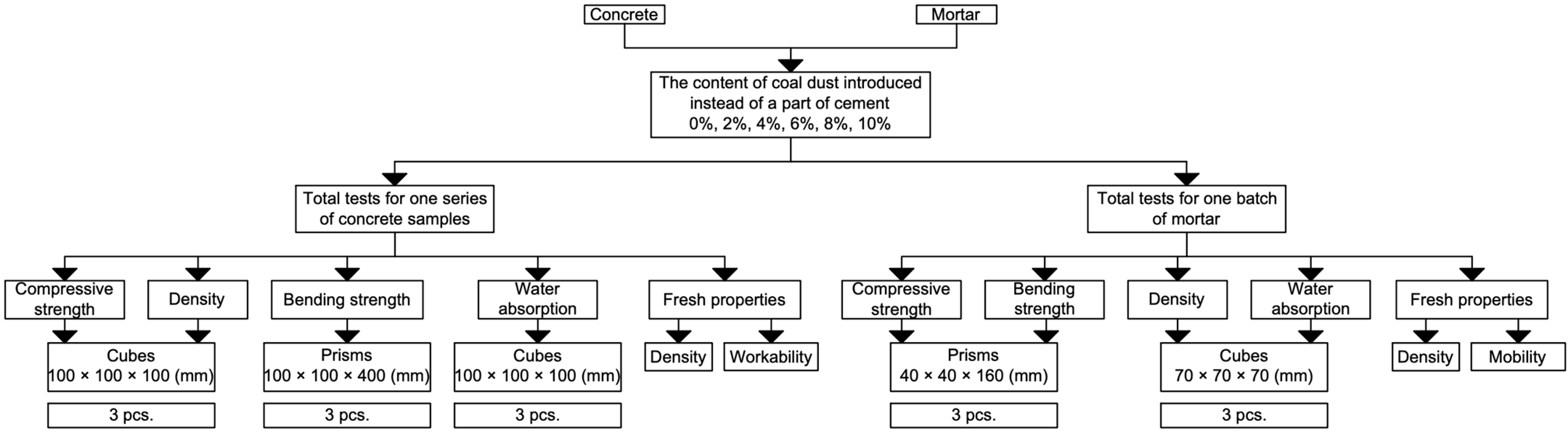

2. Materials and Methods

2.1. Materials

- -

- Portland cement CEM I 52.5N (C) (CEMROS, Stary Oskol, Russia) [41];

- -

- Crushed sandstone (CS) (RostMed, Kamensk, Russia);

- -

- Quartz sand (S) (RostStroyMix, Rostov-on-Don, Russia);

- -

- Coal dust (CD) (IMPEX-GROUP, Krasny Sulin, Russia).

2.2. Methods

- -

- Laboratory concrete mixer BL-10 (ZZBO, Zlatoust, Russia);

- -

- Forms 2FK-100, 3FK-70, FB-400, 3FB40 (RNPO RusPribor, St. Petersburg, Russia);

- -

- Normal curing chamber KNT-1 (RNPO RusPribor, St. Petersburg, Russia);

- -

- Laboratory vibration platform (IMash, Armavir, Russia).

3. Results

4. Conclusions

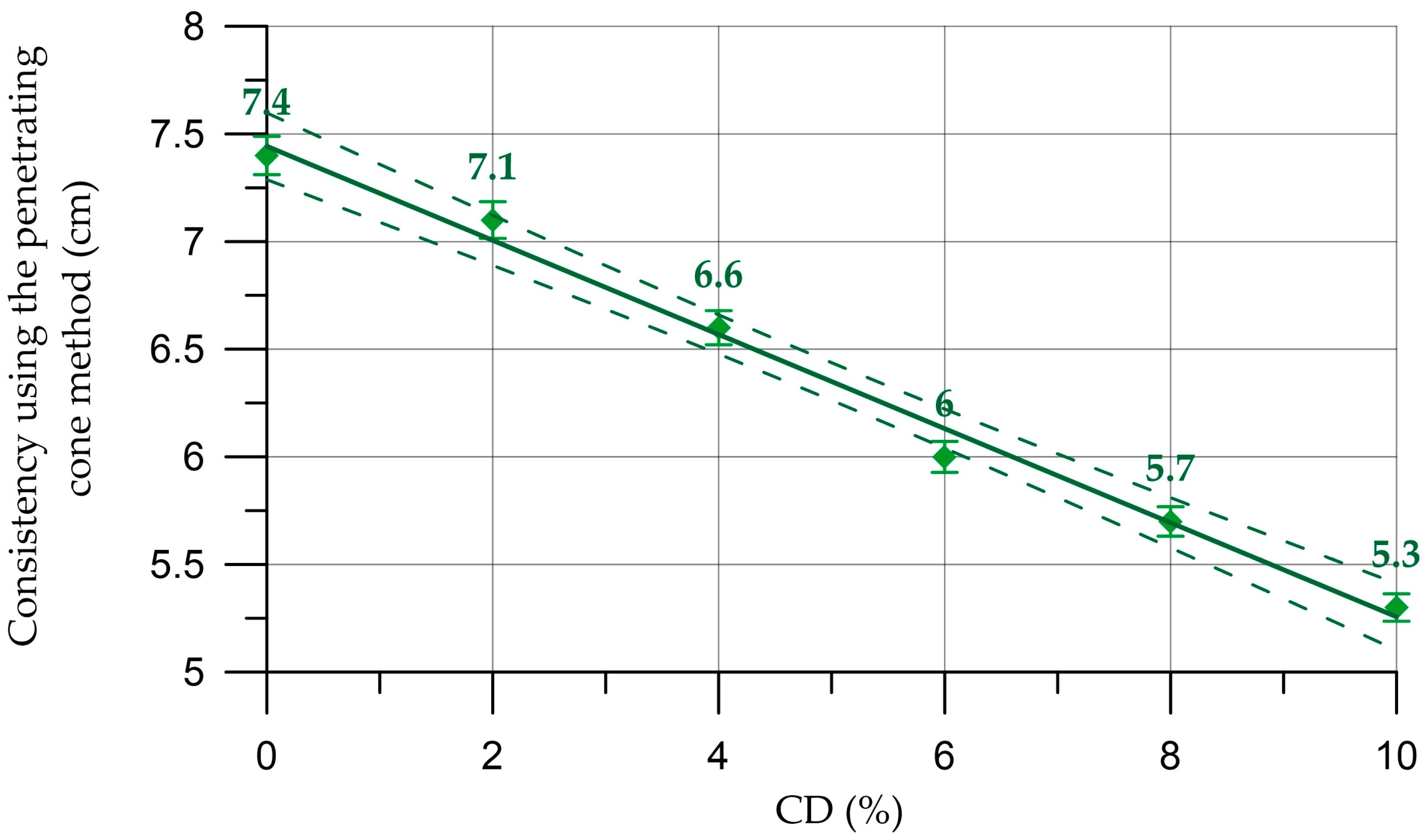

- (1)

- It was established that coal dust, introduced to replace part of the cement, negatively affects the mobility of concrete and mortar mixtures. However, the introduction of a plasticizing additive allows one to adjust the mobility value of concrete and mortar mixtures and maintain it within the same brand.

- (2)

- Replacing part of the cement with coal dust by up to 10% does not have a significant effect on the change in the density of concrete and mortar mixtures or in hardened composites.

- (3)

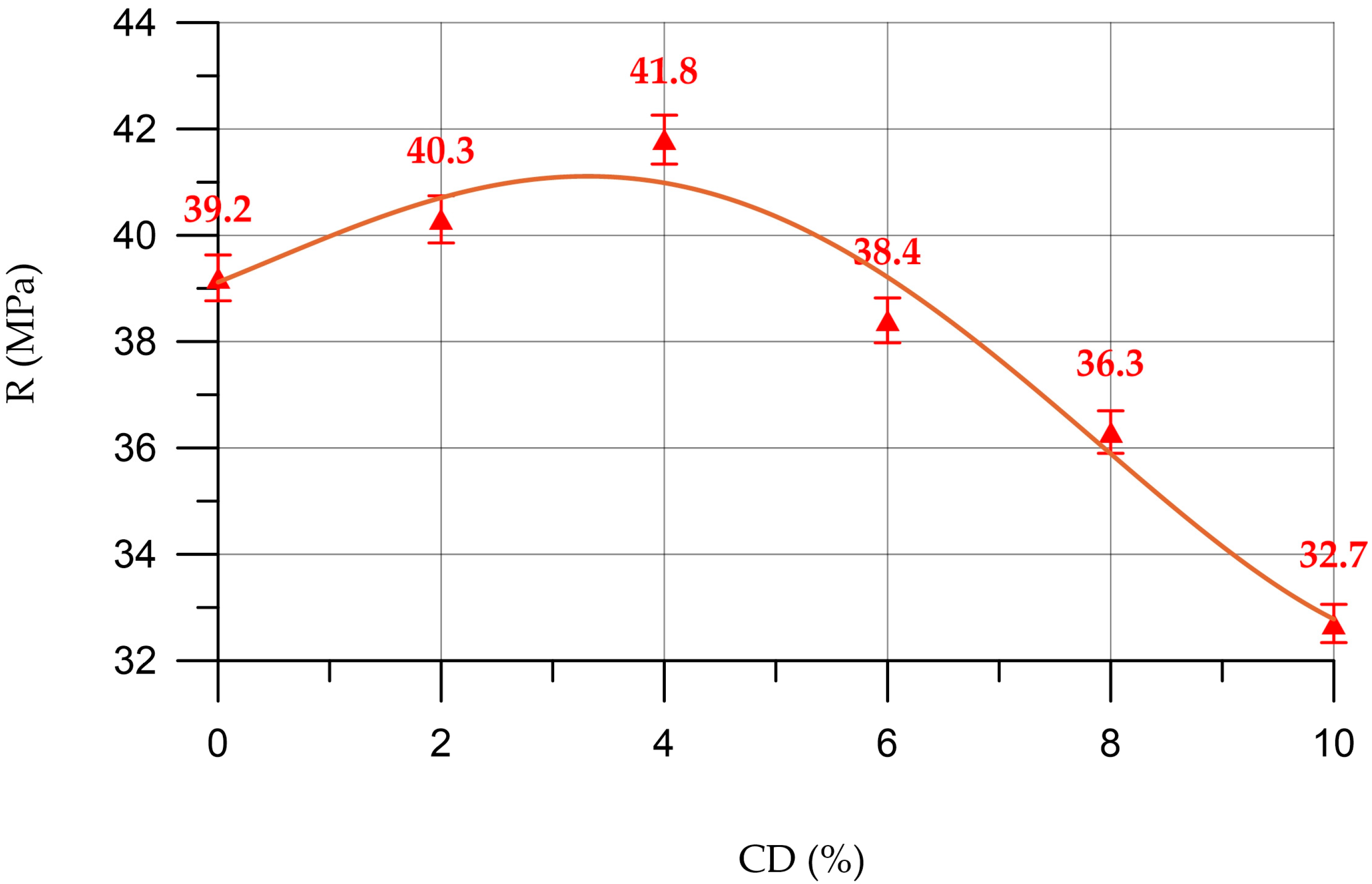

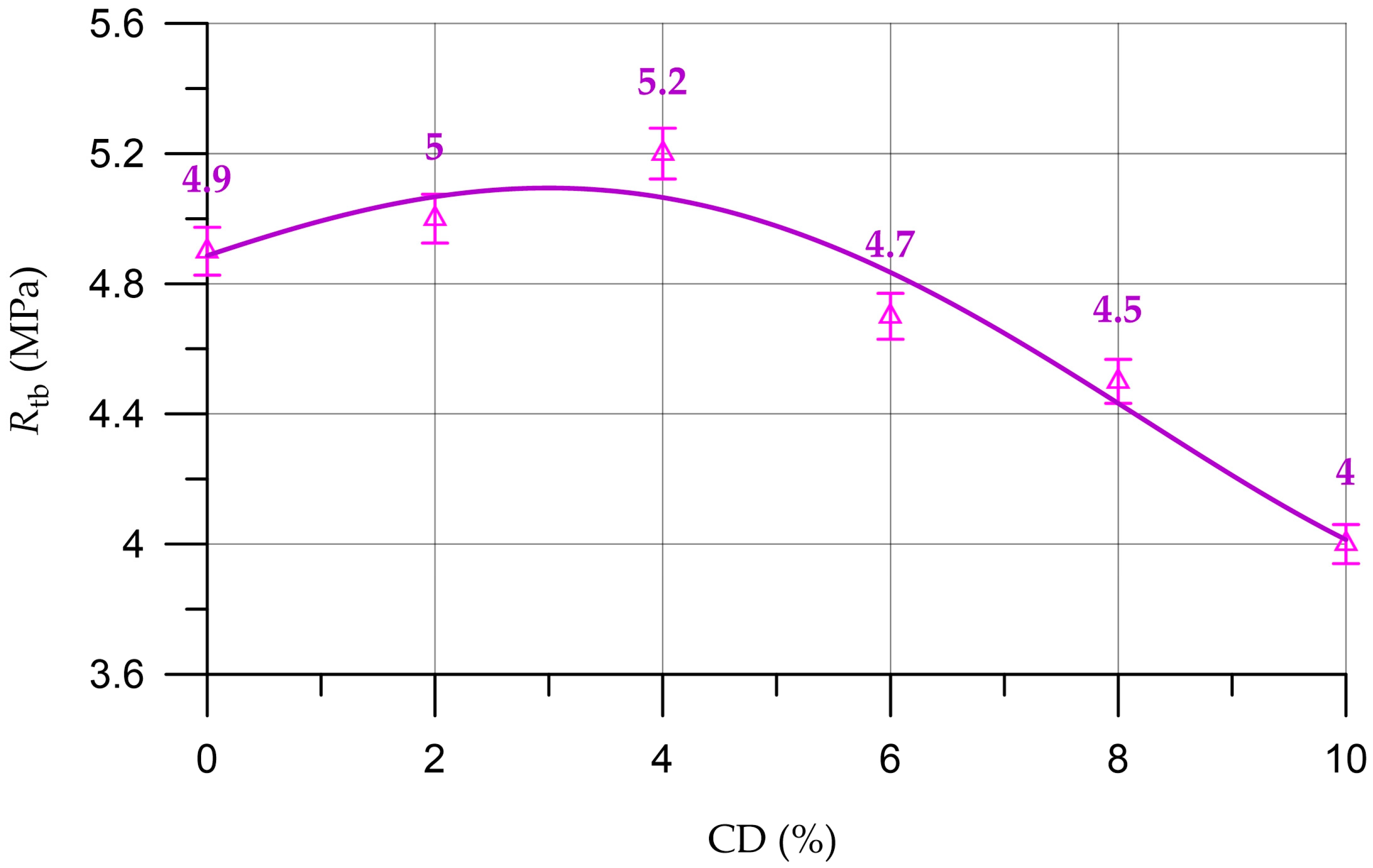

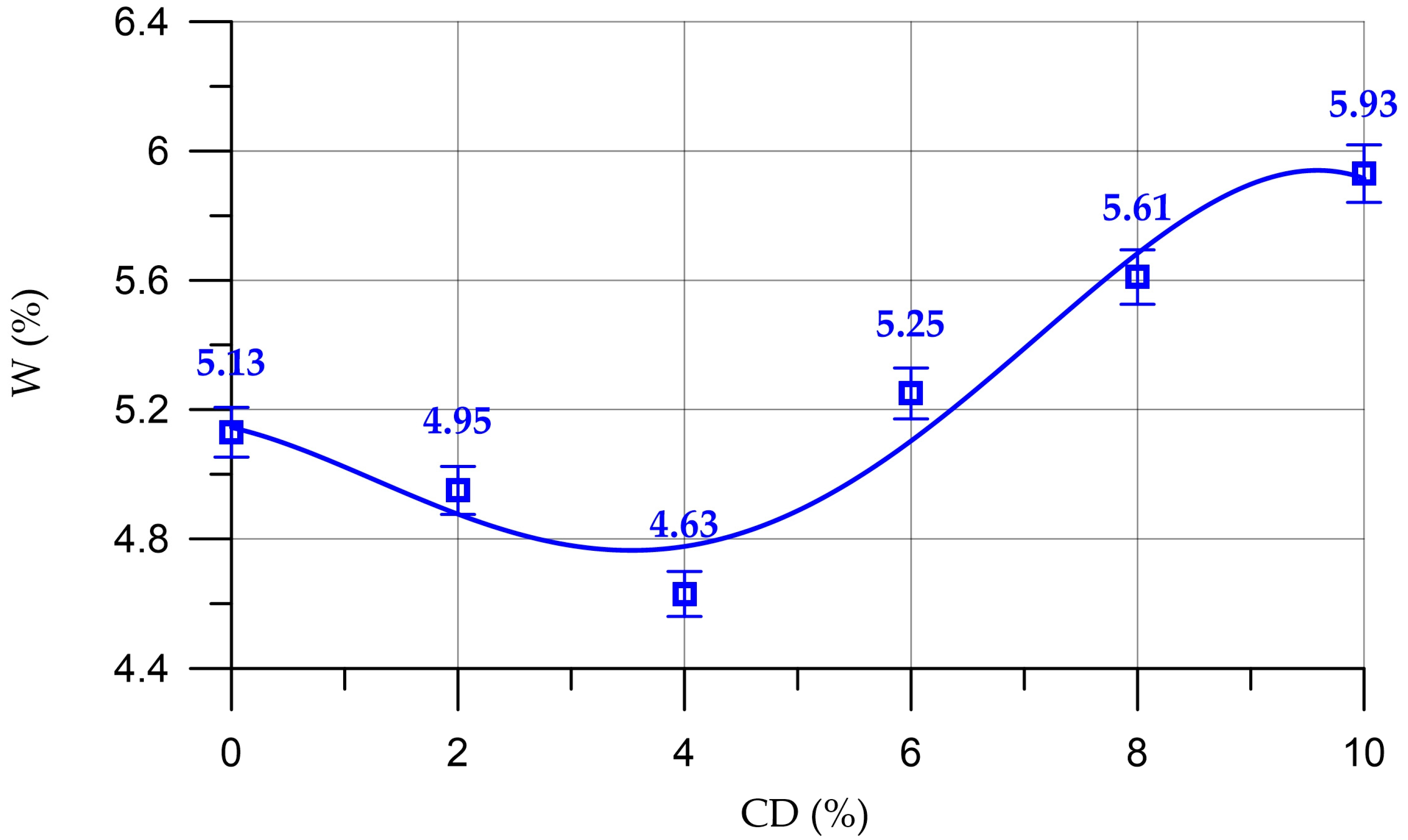

- Compared to the control composition, concrete samples with 4% coal dust showed greater efficiency: increases in compressive and flexural strength were 6.6% and 6.1%, and water absorption decreased by 9.7%.

- (4)

- The increases in compressive and flexural strength of the mortar with 4% coal dust content compared to control samples were 5.7% and 5.6%, and water absorption decreased by 9.3%.

- (5)

- The most effective amount of coal dust, introduced instead of part of the cement, was 4%. It was possible to use coal dust in an amount of 6% without a significant loss of strength characteristics for both concrete and mortars.

- (6)

- The use of coal industry waste is potentially effective in the construction sector due to its mineral activity and geographical accessibility. The prospect of effective use of coal dust in appropriate, rationally selected quantities in concrete production was confirmed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, R.; Srivastava, A.; Lakhani, R. Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review. Sustainability 2022, 14, 331. [Google Scholar] [CrossRef]

- Li, J. Municipal Solid Waste Incineration Ash-Incorporated Concrete: One Step towards Environmental Justice. Buildings 2021, 11, 495. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Fiúza, A.; Ferreira, A.; Dinis, M.D.L.; Meira Castro, A.C.; Meixedo, J.P.; Alvim, M.R. Recycling Approach towards Sustainability Advance of Composite Materials’ Industry. Recycling 2016, 1, 178–193. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Evtushenko, A.; Chernil’nik, A.; El’shaeva, D.; Karalar, M.; et al. Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash. J. Compos. Sci. 2023, 7, 356. [Google Scholar] [CrossRef]

- Meskhi, B.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Shilov, A.A.; El’shaeva, D.; Shilova, K.; Karalar, M.; Aksoylu, C.; et al. Analytical Review of Geopolymer Concrete: Retrospective and Current Issues. Materials 2023, 16, 3792. [Google Scholar] [CrossRef]

- Du, J.; Ma, A.; Wang, X.; Zheng, X. Review of the Preparation and Application of Porous Materials for Typical Coal-Based Solid Waste. Materials 2023, 16, 5434. [Google Scholar] [CrossRef]

- Liu, Z.; Ao, Z.; Zhou, W.; Zhang, B.; Niu, J.; Wang, Z.; Liu, L.; Yang, Z.; Xu, K.; Lu, W.; et al. Research on the Physical and Chemical Characteristics of Dust in Open Pit Coal Mine Crushing Stations and Closed Dust Reduction Methods. Sustainability 2023, 15, 12202. [Google Scholar] [CrossRef]

- Pokorný, J.; Ševčík, R.; Zárybnická, L.; Podolka, L. The Role of High Carbon Additives on Physical–Mechanical Characteristics and Microstructure of Cement-Based Composites. Buildings 2023, 13, 1585. [Google Scholar] [CrossRef]

- Caneda-Martínez, L.; Kunther, W.; Medina, C.; Sánchez de Rojas, M.I.; Frías, M. Exploring sulphate resistance of coal mining waste blended cements through experiments and thermodynamic modelling. Cem. Concr. Compos. 2021, 121, 104086. [Google Scholar] [CrossRef]

- Simão, L.; Faraco, M.N.S.; Borgert, C.H.; Olivo, E.; Montedo, O.R.K.; Raupp-Pereira, F. Waste valorization of coal mining waste from a circular economy perspective: A Brazilian case study based on environmental and physicochemical features. Resour. Policy 2023, 80, 103243. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Beskopylny, N.; El’shaeva, D. A Study on the Cement Gel Formation Process during the Creation of Nanomodified High-Performance Concrete Based on Nanosilica. Gels 2022, 8, 346. [Google Scholar] [CrossRef] [PubMed]

- Korovkin, M.O.; Grintsov, D.M.; Eroshkina, N.A. Rational Use of Inert Mineral Additives In Concrete Technology. Eng. Bull. Don 2017, 3, 115. Available online: ivdon.ru/ru/magazine/archive/n3y2017/4361 (accessed on 6 October 2023).

- Muhammad, A.; Thienel, K.-C. Properties of Self-Compacting Concrete Produced with Optimized Volumes of Calcined Clay and Rice Husk Ash—Emphasis on Rheology, Flowability Retention and Durability. Materials 2023, 16, 5513. [Google Scholar] [CrossRef] [PubMed]

- Kavithaa, O.R.; Shanthib, V.M.; Prince Arulraja, G.; Sivakumar, V.R. Microstructural studies on eco-friendly and durable Self-compacting concrete blended with metakaolin. Appl. Clay Sci. 2016, 124–125, 143–149. [Google Scholar] [CrossRef]

- Gill, A.S.; Siddique, R. Durability properties of self-compacting concrete incorporating metakaolin and rice husk ash. Constr. Build. Mater. 2018, 176, 323–332. [Google Scholar] [CrossRef]

- Abdul Sahib, M.Q.; Farzam, M.; Sukkar, K.A. Development and Performance Evaluation of UHPC and HPC Using Eco-Friendly Additions as Substitute Cementitious Materials with Low Cost. Buildings 2023, 13, 2078. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Shaurdho, N.M.N.; Sobuz, M.H.R.; Meraz, M.M.; Islam, M.S.; Miah, M.J. Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement. Sustainability 2023, 15, 11254. [Google Scholar] [CrossRef]

- Elkerany, A.M.; Keshta, M.M.; Elshikh, M.M.Y.; Elshami, A.A.; Youssf, O. Characteristics of Sustainable Concrete Containing Metakaolin and Magnetized Water. Buildings 2023, 13, 1430. [Google Scholar] [CrossRef]

- Selvaraj, T.; Kaliyavaradhan, S.K.; Kakria, K.; Malladi, R.C. Use of E-Waste in Metakaolin Blended Cement Concrete for Sustainable Construction. Sustainability 2022, 14, 16661. [Google Scholar] [CrossRef]

- Saeb, S.; Capitán, J.A.; Cobo, A. The Effect of Electric Arc Furnace Dust (EAFD) on Improving Characteristics of Conventional Concrete. Buildings 2023, 13, 1526. [Google Scholar] [CrossRef]

- Fares, G.; Al-Negheimish, A.I.; Al-Mutlaq, F.M.; Alhozaimy, A.M.; Iqbal Khan, M. Effect of freshly produced electric arc-furnace dust and chloride-free chemical accelerators on concrete performance. Construct. Build. Mater. 2021, 274, 121832. [Google Scholar] [CrossRef]

- Fares, G.; Al-Zaid, R.Z.; Fauzi, A.; Alhozaimy, A.M.; Al-Negheimish, A.I.; Iqbal Khan, M. Performance of optimized electric arc furnace dust-based cementitious matrix compared to conventional supplementary cementitious materials. Constr. Build. Mater. 2016, 112, 210–221. [Google Scholar] [CrossRef]

- Singh, P.; Yee, N.C.; Mohammed, B.S. Utilizing Stearic-Acid-Coated Marble Dust for the Production of Eco-Friendly Self-Cleaning Concrete: RSM Modeling and Optimization. Sustainability 2023, 15, 8635. [Google Scholar] [CrossRef]

- Vardhan, K.; Goyal, S.; Siddique, R.; Singh, M. Mechanical properties and microstructural analysis of cement mortar incorporating marble powder as partial replacement of cement. Constr. Build. Mater. 2015, 96, 615–621. [Google Scholar] [CrossRef]

- Ansari, Y.; Husain, D.; Das, U.K.; Haloi, J.; Khan, N.A.; Prakash, R.; Husain, M. Ecological Footprint Assessment of Concrete: Partial Replacement of Cement by Water Treatment Sludge and Stone Dust. Sustainability 2023, 15, 7512. [Google Scholar] [CrossRef]

- Zamir Hashmi, S.R.; Khan, M.I.; Khahro, S.H.; Zaid, O.; Shahid Siddique, M.; Md Yusoff, N.I. Prediction of Strength Properties of Concrete Containing Waste Marble Aggregate and Stone Dust—Modeling and Optimization Using RSM. Materials 2022, 15, 8024. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Csetenyi, L.J. Sustainable use of marble slurry in concrete. J. Clean. Prod. 2015, 94, 304–311. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Beskopylny, A.N.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Pimenova, E.; El’shaeva, D. Combined Effect of Ceramic Waste Powder Additives and PVA on the Structure and Properties of Geopolymer Concrete Used for Finishing Facades of Buildings. Materials 2023, 16, 3259. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, S.M.; Yang, B.J.; Jang, J.G. Calcined Oyster Shell Powder as an Expansive Additive in Cement Mortar. Materials 2019, 12, 1322. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Nworg, A.T.; Odetoyan, A.O.; Kareem, M.; Enabulele, D.O.; Bassey, D.E. Sustainable use of seashells as binder in concrete production: Prospect and challenges. J. Build. Eng. 2021, 34, 101864. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Nanomodified Concrete with Enhanced Characteristics Based on River Snail Shell Powder. Appl. Sci. 2022, 12, 7839. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Tashpulatov, S.S.; Chernil’nik, A.; Shcherban’, N.; Tyutina, A. Composition, Technological, and Microstructural Aspects of Concrete Modified with Finely Ground Mussel Shell Powder. Materials 2023, 16, 82. [Google Scholar] [CrossRef] [PubMed]

- Shetty, P.P.; Rao, A.U.; Pai, B.H.V.; Kamath, M.V. Performance of High-Strength Concrete with the Effects of Seashell Powder as Binder Replacement and Waste Glass Powder as Fine Aggregate. J. Compos. Sci. 2023, 7, 92. [Google Scholar] [CrossRef]

- Zhang, H.; Liao, W.; Chen, G.; Ma, H. Development and Characterization of Coal-Based Thermoplastic Composite Material for Sustainable Construction. Sustainability 2023, 15, 12446. [Google Scholar] [CrossRef]

- Arogundade, S.; Dulaimi, M.; Ajayi, S. Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach. Buildings 2023, 13, 1780. [Google Scholar] [CrossRef]

- Mostafaei, H.; Badarloo, B.; Chamasemani, N.F.; Rostampour, M.A.; Lehner, P. Investigating the Effects of Concrete Mix Design on the Environmental Impacts of Reinforced Concrete Structures. Buildings 2023, 13, 1313. [Google Scholar] [CrossRef]

- Digulla, F.-E.; Bringezu, S. Comparative Life Cycle Assessment of Carbon Dioxide Mineralization Using Industrial Waste as Feedstock to Produce Cement Substitutes. Energies 2023, 16, 4118. [Google Scholar] [CrossRef]

- Gurvich, A.; Creamer, G.G. Overallocation and Correction of Carbon Emissions in the Evaluation of Carbon Footprint. Sustainability 2021, 13, 13613. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Mačiūnas, D.; Nosewicz, S.; Kačianauskas, R.; Boris, R.; Stonys, R. Numerical Simulation of Thermal Conductivity and Thermal Stress in Lightweight Refractory Concrete with Cenospheres. Materials 2023, 16, 190. [Google Scholar] [CrossRef]

- GOST 31108-2020; Common Cements. Specifications. Available online: https://docs.cntd.ru/document/1200174658 (accessed on 25 September 2023).

- GOST R 57813-2017/EN 12350-6:2009; Testing Fresh Concrete. Part 6. Density. Available online: https://docs.cntd.ru/document/1200157335 (accessed on 15 September 2023).

- GOST R 57809-2017/EN 12350-2:2009; Testing Fresh Concrete. Part 2. Slump Test. Available online: https://docs.cntd.ru/document/1200157288 (accessed on 15 September 2023).

- GOST 10180-2012; Concretes. Methods for Strength Determination Using Reference Specimens. Gost Standard: Moscow, Russia, 2012. Available online: http://docs.cntd.ru/document/1200100908 (accessed on 15 September 2023).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 15 September 2023).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 15 September 2023).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 15 September 2023).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 15 September 2023).

- EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/5653c2c7-55a9-4bcb-8e13-5b1dfb0e3baf/en-12390-5-2019 (accessed on 15 September 2023).

- GOST 12730.1-2020; Concretes. Methods of Determination of Density. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177299 (accessed on 15 September 2023).

- EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/811a0cf3-55e3-495a-b06e-5c302d5f2806/en-12390-7-2019 (accessed on 15 September 2023).

- GOST 12730.3-2020; Concretes. Method of Determination of Water Absorption. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177301 (accessed on 15 September 2023).

- BS 1881-122:2011+A1:2020; Testing Concrete Method for Determination of Water Absorption. European Standards: Plzen, Czech Republic, 2020. Available online: https://www.en-standard.eu/bs-1881-122-2011-a1-2020-testing-concrete-method-for-determination-of-water-absorption/ (accessed on 15 September 2023).

- GOST 5802-86; Mortars. Test Methods. Gost Standard: Moscow, Russia, 1986. Available online: https://docs.cntd.ru/document/901710699 (accessed on 15 September 2023).

- ISO 13765-1:2004; Refractory Mortars—Part 1: Determination of Consistency Using the Penetrating cone Method. International Standard: Geneva, Switzerland, 2004. Available online: https://www.iso.org/standard/35314.html (accessed on 15 September 2023).

- GOST 7473-2010; Fresh Concrete. Specifications. Gost Standard: Moscow, Russia, 2010. Available online: https://docs.cntd.ru/document/1200085075 (accessed on 15 September 2023).

- GOST 28013-98; Mortars. General Specifications. Gost Standard: Moscow, Russia, 1998. Available online: https://docs.cntd.ru/document/1200003926 (accessed on 15 September 2023).

- Babkov, V.V.; Gabitov, A.I.; Sakhibgareev, R.R.; Sakhibgareev, R.R. Amorphous microsilica in structurization and hardening of a cement stone processes. Bashkir Chem. J. 2010, 17, 206–210. [Google Scholar]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Beskopylny, N.; El’shaeva, D. Enhanced Eco-Friendly Concrete Nano-Change with Eggshell Powder. Appl. Sci. 2022, 12, 6606. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; Varavka, V.; Beskopylny, N. Nano-Modified Vibrocentrifuged Concrete with Granulated Blast Slag: The Relationship between Mechanical Properties and Micro-Structural Analysis. Materials 2022, 15, 4254. [Google Scholar] [CrossRef] [PubMed]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Butko, D.; Smolyanichenko, A.S. Influence of Composition and Technological Factors on Variatropic Efficiency and Constructive Quality Coefficients of Lightweight Vibro-Centrifuged Concrete with Alkalized Mixing Water. Appl. Sci. 2021, 11, 9293. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Varavka, V. Quantitative and Qualitative Aspects of Composite Action of Concrete and Dispersion-Reinforcing Fiber. Polymers 2022, 14, 682. [Google Scholar] [CrossRef] [PubMed]

| Property | Value | |||||

|---|---|---|---|---|---|---|

| Portland cement CEM I 52.5N | ||||||

| Specific surface area (m2/kg) | 339 | |||||

| Soundness (mm) | 0.5 | |||||

| Fineness, passage through sieve No. 008 (%) | 97.5 | |||||

| Setting times (min): - Start - End | 170 240 | |||||

| Compressive strength (MPa): - 2 days - 28 days | 25.7 58.5 | |||||

| Crushed sandstone | ||||||

| Particle size (mm) | 5–20 | |||||

| Bulk density (kg/m3) | 1429 | |||||

| Apparent density (kg/m3) | 2553 | |||||

| Resistance to fragmentation (wt %) | 11.8 | |||||

| Content of lamellar and acicular grains (wt %) | 9.7 | |||||

| Quartz sand | ||||||

| Sieve diameter (mm) | Content (% by weight) of grains with a particle size of less than 0.16 mm | Fineness modulus | ||||

| Partial residues on sieves (%) | ||||||

| Total residues on sieves (%) | ||||||

| 2.5 | 1.25 | 0.63 | 0.315 | 0.16 | ||

| 3.2 | 10.1 | 14.3 | 16.6 | 54.7 | 1.0 | 1.87 |

| 3.2 | 13.3 | 27.6 | 44.2 | 99.0 | ||

| Bulk density (kg/m3) | 1255 | |||||

| The content of dust and clay particles (%) | 0.09 | |||||

| Content of clay in lumps (%) | 0.12 | |||||

| Organic and contaminant content (%) | No | |||||

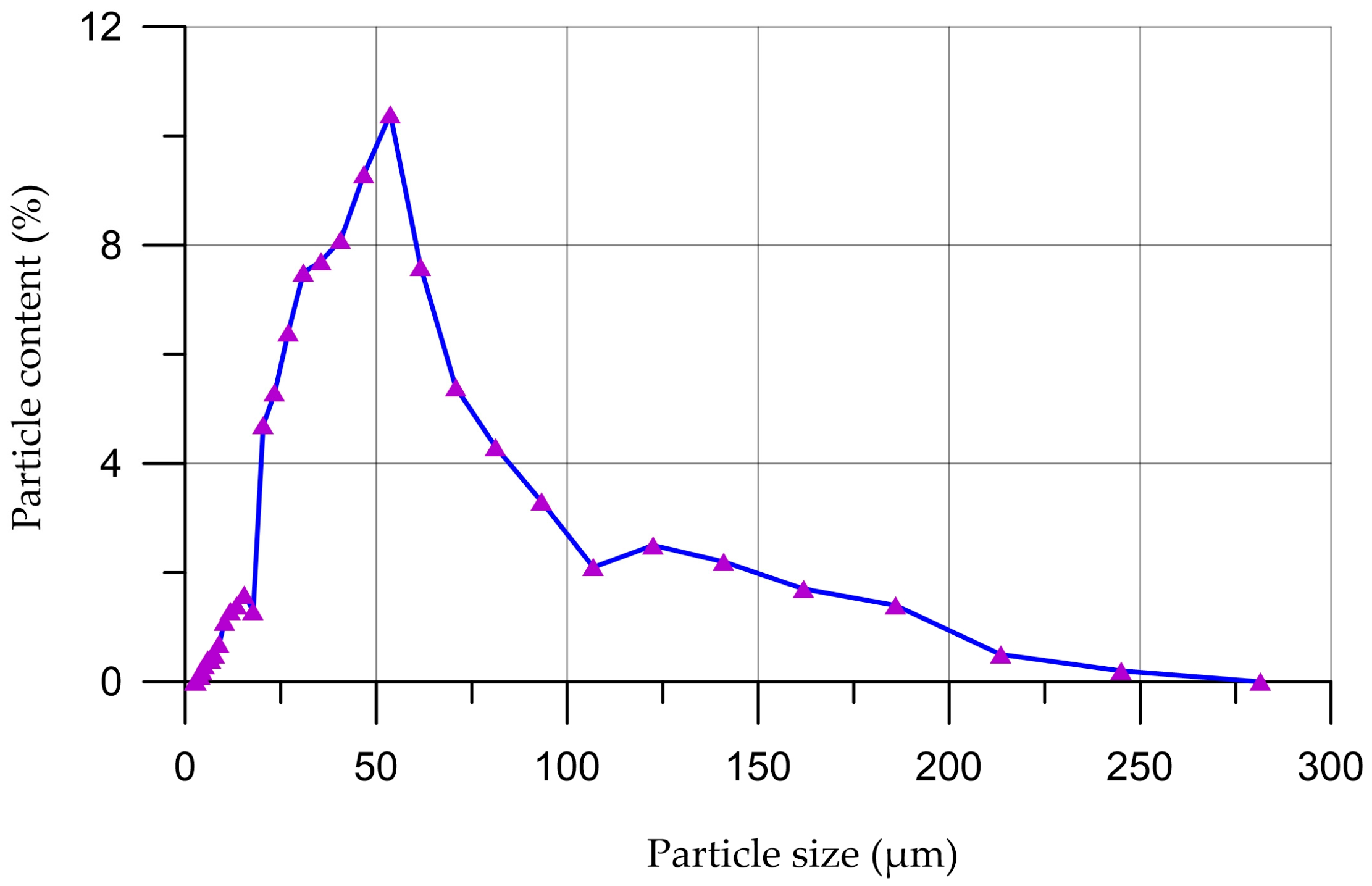

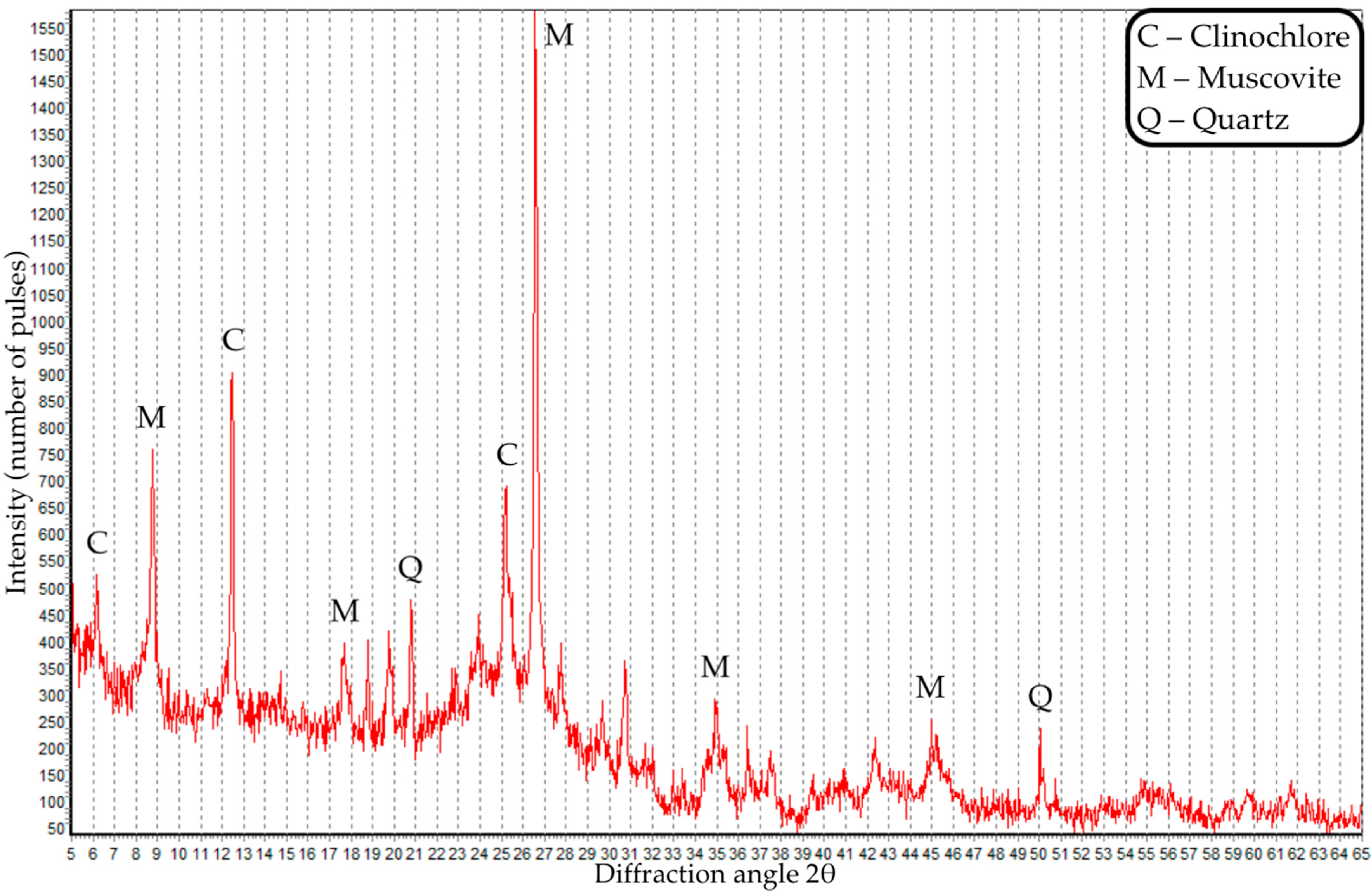

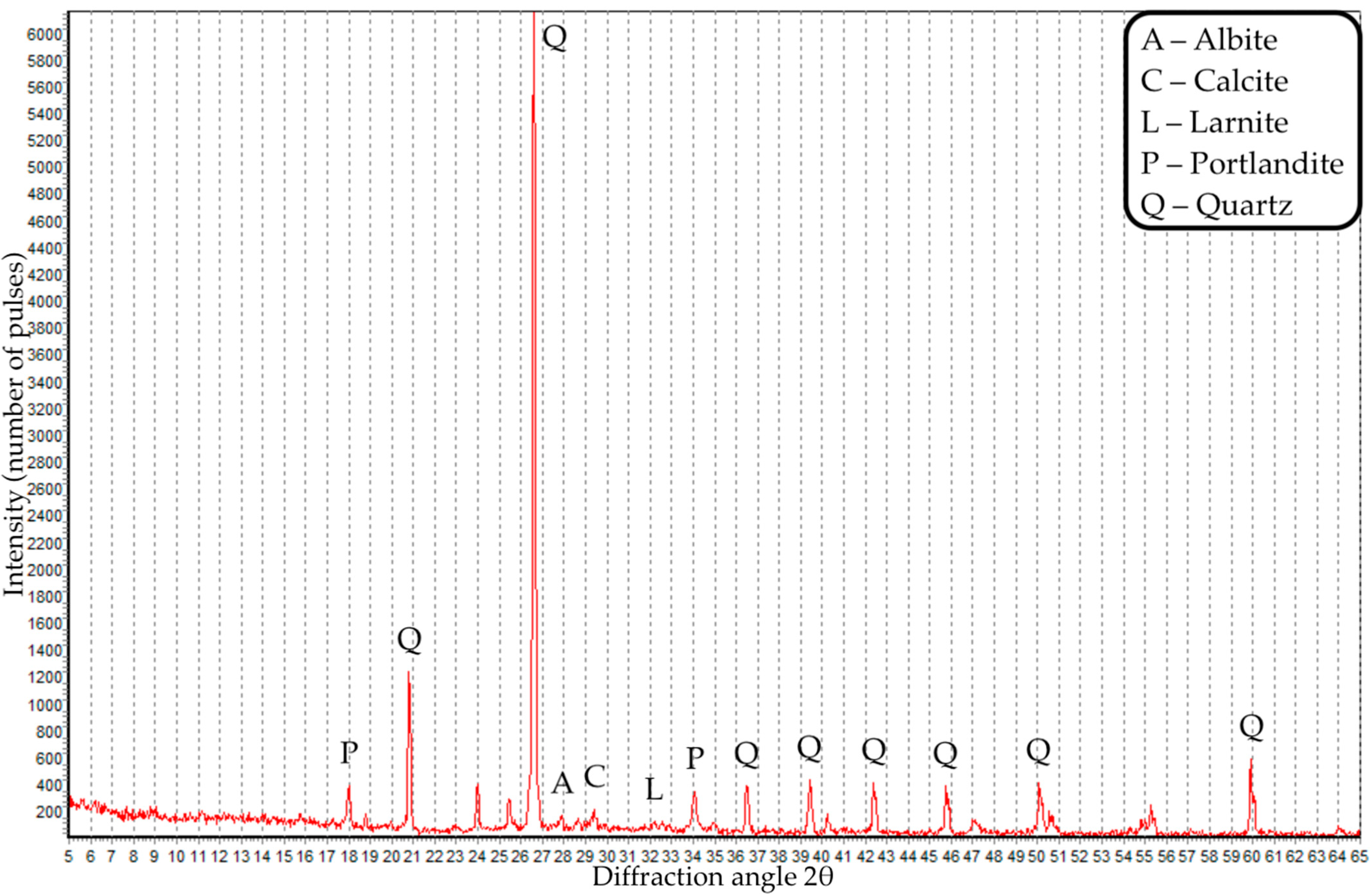

| Coal dust (CD) | ||||||

| Bulk density (kg/m3) | 345 | |||||

| Loss on ignition (%) | 37.34 | |||||

| Silicon oxide SiO2 (%) | 30.83 | |||||

| Aluminum oxide Al2O3 (%) | 15.74 | |||||

| Iron oxide Fe2O3 total (%) | 6.22 | |||||

| Calcium oxide CaO (%) | 2.92 | |||||

| Magnesium oxide MgO (%) | 3.43 | |||||

| Titanium oxide TiO2 (%) | 0.64 | |||||

| Phosphorus oxide P2O5 (%) | 0.07 | |||||

| Total sulfur oxide SO3 (%) | 2.81 | |||||

| Mixture Type | Concrete Mixture Proportion per 1 m3 | |||||

|---|---|---|---|---|---|---|

| C (kg/m3) | W (L/m3) | CS (kg/m3) | S (kg/m3) | CD (kg/m3) | P (% by Weight of Cement) | |

| 0CD/C | 353 | 199 | 936 | 711 | 0 | 0 |

| 2CD/C | 345.9 | 199 | 936 | 711 | 7.1 | 1.0 |

| 4CD/C | 338.9 | 199 | 936 | 711 | 14.1 | 1.5 |

| 6CD/C | 331.8 | 199 | 936 | 711 | 21.2 | 1.5 |

| 8CD/C | 324.8 | 199 | 936 | 711 | 28.2 | 2.0 |

| 10CD/C | 317.7 | 199 | 936 | 711 | 35.3 | 2.5 |

| Mixture Type | Mortar Mixture Proportion per 1 m3 | ||||

|---|---|---|---|---|---|

| C (kg/m3) | W (L/m3) | S (kg/m3) | CD (kg/m3) | P (% by Weight of Cement) | |

| 0CD/M | 346 | 214 | 1481 | 0 | 0 |

| 2CD/M | 339.1 | 214 | 1481 | 6.9 | 1.0 |

| 4CD/M | 332.2 | 214 | 1481 | 13.8 | 1.5 |

| 6CD/M | 325.2 | 214 | 1481 | 20.8 | 1.5 |

| 8CD/M | 318.3 | 214 | 1481 | 27.7 | 2.0 |

| 10CD/M | 311.4 | 214 | 1481 | 34.6 | 2.0 |

| Characteristics | ∆ (%) with CD Content Introduced Instead of Part of the Cement (%) | |||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | 10 | |

| Concrete | ||||||

| Density (kg/m3) | 0 | −0.2 | −0.4 | −0.5 | −0.7 | −0.8 |

| R (MPa) | 0 | 2.8 | 6.6 | −2.0 | −7.4 | −16.6 |

| Rtb (MPa) | 0 | 2.0 | 6.1 | −4.1 | −8.2 | −18.4 |

| W (%) | 0 | −3.5 | −9.7 | 2.3 | 9.4 | 15.6 |

| Mortar | ||||||

| Density (kg/m3) | 0 | −0.1 | −0.2 | −0.4 | −0.6 | −0.7 |

| R (MPa) | 0 | 1.6 | 5.7 | −2.4 | −8.9 | −17.9 |

| Rtb (MPa) | 0 | 1.7 | 5.6 | −4.4 | −9.4 | −19.4 |

| W (%) | 0 | −3.2 | −9.3 | 3.0 | 10.4 | 16.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Elshaeva, D.; Chernil’nik, A.; Mailyan, A.L.; Ananova, O. Eco-Friendly Sustainable Concrete and Mortar Using Coal Dust Waste. Materials 2023, 16, 6604. https://doi.org/10.3390/ma16196604

Shcherban’ EM, Stel’makh SA, Beskopylny AN, Mailyan LR, Meskhi B, Elshaeva D, Chernil’nik A, Mailyan AL, Ananova O. Eco-Friendly Sustainable Concrete and Mortar Using Coal Dust Waste. Materials. 2023; 16(19):6604. https://doi.org/10.3390/ma16196604

Chicago/Turabian StyleShcherban’, Evgenii M., Sergey A. Stel’makh, Alexey N. Beskopylny, Levon R. Mailyan, Besarion Meskhi, Diana Elshaeva, Andrei Chernil’nik, Alexander L. Mailyan, and Oxana Ananova. 2023. "Eco-Friendly Sustainable Concrete and Mortar Using Coal Dust Waste" Materials 16, no. 19: 6604. https://doi.org/10.3390/ma16196604

APA StyleShcherban’, E. M., Stel’makh, S. A., Beskopylny, A. N., Mailyan, L. R., Meskhi, B., Elshaeva, D., Chernil’nik, A., Mailyan, A. L., & Ananova, O. (2023). Eco-Friendly Sustainable Concrete and Mortar Using Coal Dust Waste. Materials, 16(19), 6604. https://doi.org/10.3390/ma16196604