FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of AlMgSi and AlZnMg Alloys

2.2. FEM Numerical Modeling of Extrusion Process

2.3. Extrusion Trials of Round Tubes

2.4. 3D Optical Scanning of Extruded Tubes and Dies

2.5. Statistical Analysis of Results for Extruded Tubes and Extrusion Dies

3. Results

3.1. FEM Numerical Calculations

3.2. Extrusion Trials

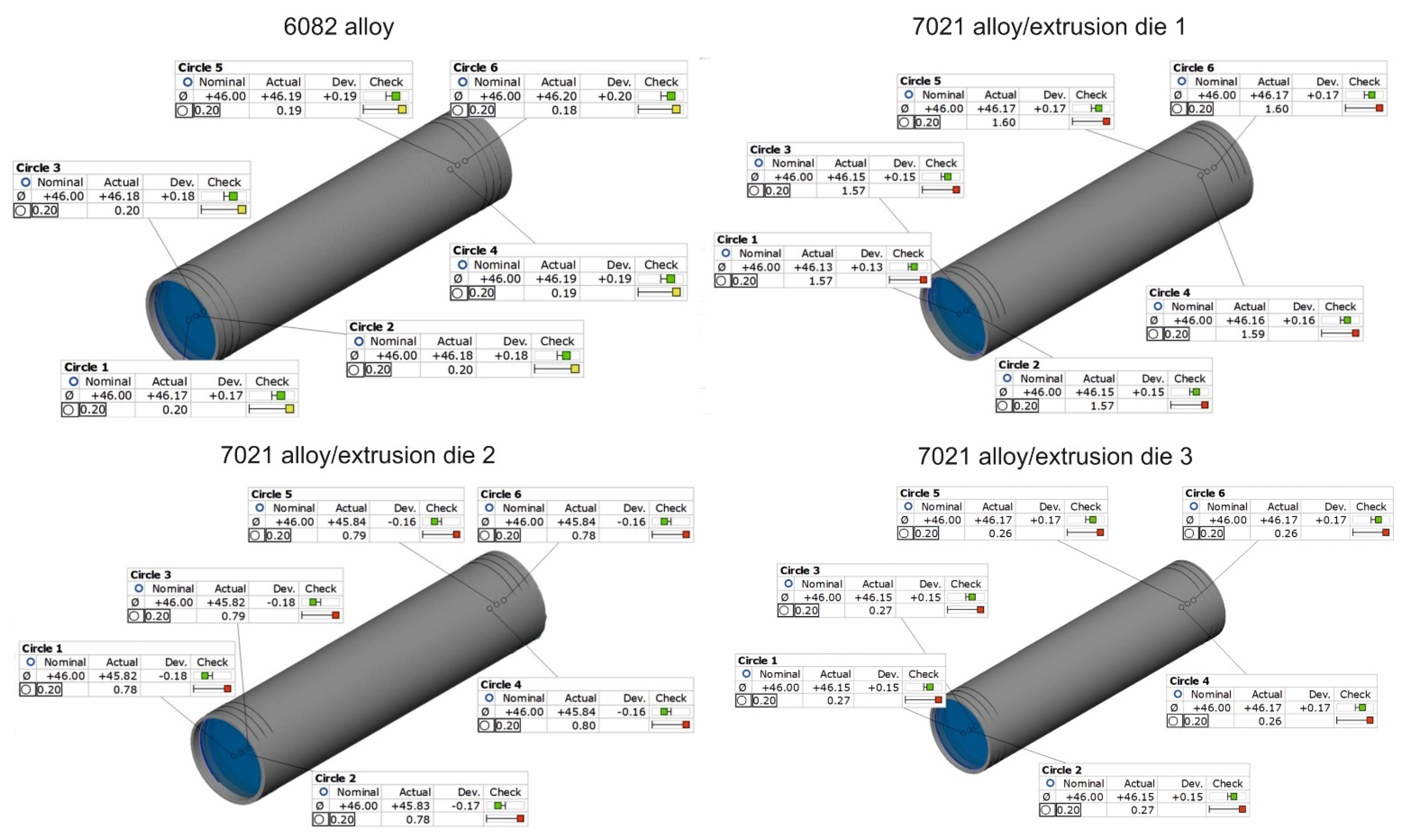

3.3. 3D Optical Scanning of Extruded Tubes

3.4. Corelation Statistical Analysis of Extruded Tubes

3.5. 3D Optical Scanning of Extrusion Porthole Dies

3.6. ANOVA Statistical Analysis of Extrusion Porthole Dies

4. Discussion

5. Conclusions

- The extrusion of tubes of Ø50 × 2 mm from the 7021 alloy with the use of the porthole dies is connected with high deformation resistance and high frictional resistance in comparison to the extrusion of analogical tubes from the 6082 alloy, which translates to higher extrusion pressures and lower metal exit speeds.

- High unit pressures during extrusion tubes of Ø50 × 2 leads to high thermo-mechanical loads of dies connected with permanent deflection of bridges and mandrels, which leads to significant dimensional deviations of circularity and eccentricity, exceeding standard’s limits.

- Strong plus correlation between extrusion speed and tube circularity, strong minus correlation of extrusion speed and the wall thickness, inner and outer diameter of tubes, and moderate minus correlations between billet heating temperature and circularity of tubes exist. This means that maximal permissible extrusion speed cannot be applied, but high billet heating temperatures should possibly be advised.

- The application of the modified die 3 resulted in successful control of the metal flow, which consisted in the effective facilitating of the inflow of metal to the sub-bridge areas, thus minimizing the side deviation of mandrels.

- The design of the porthole dies for the extrusion of the 7xxxx series aluminium alloys needs new assumptions in relation to classic dies for the extrusion of the 6xxxx series alloys. In the extrusion of tubes from a 7021 alloy, we recommend: slightly thicker and considerably elongated bridges, special central die compartment, higher welding chambers, shaped pocket dies, geometrically modified mandrels and smooth entries to the die cavity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomesani, L. Numerical Assessment of the Influence of Process and Geometric Parameters on Extrusion Welds and Die Deformation after Multiple-cycles. Mater. Today Proc. 2015, 2, 4856–4865. [Google Scholar]

- Kang, C.K. Effects of chamber shapes of porthole die on elastic deformation and extrusion process in condenser tube extrusion. Mater. Des. 2005. [Google Scholar]

- Liu, Z.; Li, L.; Li, S.; Yi, J.; Wang, G. Simulation analysis of porthole die extrusion process and die structure modifications for an aluminium profile with high length–width ratio and small cavity. Materials 2018, 11, 1517. [Google Scholar] [CrossRef] [Green Version]

- Xue, X.; Vincze, G.; Pereira, A.B.; Pan, J.; Liao, J. Assessment of Metal Flow Balance in Multi-Output Porthole Hot Extrusion of AA6060 Thin-Walled Profile. Metals 2018, 8, 462. [Google Scholar] [CrossRef] [Green Version]

- Selvaggio, A.T.; Kloppenborg, T.; Schwane, M.; Hölker, R.; Jäger, A.; Donati, L.; Tomesani, L.; Tekkaya, A.E. Experimental Analysis of Mandrel Deflection, Local Temperature and Pressure in Extrusion Dies. Key Eng. Mater. 2014, 585, 13–22. [Google Scholar] [CrossRef]

- Biba, N.; Rezwych, R.; Kniazkin, I. Quality prediction and improvement of extruded profiles by means of simulation. Alum. Extrus. Finish. 2019, 2, 13–17. [Google Scholar]

- Biba, N.; Stebunov, S.; Lishny, A. Simulation of material flow coupled with die analysis in complex shape extrusion. Key Eng. Mater. 2013, 585, 85–92. [Google Scholar] [CrossRef]

- Chathuranga, P. Case study of extrusion die optimization using innovative cartridge type die. Light Met. Age 2019, 77, 20–24. [Google Scholar]

- Li, P. Design of a Multihole Porthole Die for Aluminum Tube Extrusion. Mater. Manuf. Process. 2012, 27, 147–153. [Google Scholar]

- Pietzka, D.; Ben Khalifa, N.; Donati, L.; Tomesani, L.; Tekkaya, A.E. Extrusion Benchmark 2009 Experimental analysis of deflection in extrusion dies. Key Eng. Mater. 2010, 424, 19–26. [Google Scholar] [CrossRef]

- Yi, J.; Wang, Z.; Liu, Z.; Zhang, J.; Xin He, X. FE analysis of extrusion defect and optimization of metal flow in porthole die for complex hollow aluminium profile. Trans. Nonferr. Met. Soc. China 2018, 28, 2094–2101. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, G.Q.; Zhang, C.S.; Guan, Y.J.; Liu, H.; Kou, F.J. Numerical simulation of extrusion process and die structure optimization for a complex aluminium multicavity wallboard of high-speed train. Mater. Manuf. Process. 2011, 26, 1530–1538. [Google Scholar] [CrossRef]

- Hsu, Q.C.; Chen, Y.L.; Lee, T.H. Non-symmetric hollow extrusion of high strength 7075 aluminium alloy. Sci. Direct Procedia Eng. 2014, 81, 622–627. [Google Scholar] [CrossRef] [Green Version]

- Lou, S.; Wanga, Y.; Lub, S.; Sua, C. Die structure optimization for hollow aluminium profile. Sci. Direct Procedia Manuf. 2018, 15, 249–256. [Google Scholar]

- Cheng, L. Die structure optimization for a large, multi-cavity aluminium profile using numerical simulation and experiments. Mater. Des. 2012, 36, 152–160. [Google Scholar]

- Lee, X. Virtual try-out and optimization of the extrusion die for an aluminium profile with complex cross-sections. Int. J. Adv. Manuf. Technol. 2015, 78, 927–937. [Google Scholar]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W.; Wu, T. Analysis and porthole die design for a multi-hole extrusion process of a hollow, thin-walled aluminium profile. Int. J. Adv. Manuf. Technol. 2014, 74, 383–392. [Google Scholar] [CrossRef]

- Esund, J. Extrusion of 7075 aluminium alloy through double-pocket dies to manufacture a complex profile. J. Mater. Process. Technol. 2009, 209, 3050–3059. [Google Scholar]

- Truong, T.T.; Hsu, C.C.; Tong, V.C.; Sheu, J.J. A Design Approach of Porthole Die for Flow Balance in Extrusion of Complex Solid Aluminum Heatsink Profile with Large Variable Wall Thickness. Metals 2020, 10, 553. [Google Scholar] [CrossRef]

- Jo, H.H.; Jeong, S.C.; Lee, S.K.; Kim, B.M. Determination of welding pressure in the non-steady-state porthole die extrusion of improved Al7003 hollow section tubes. J. Mater. Process. Technol. 2003, 139, 428–433. [Google Scholar] [CrossRef]

- Zhou, W.; Yu, J.; Lin, J.; Dean, T.A. Effects of die land length and geometry on curvature and effective strain of profiles produced by a novel sideways extrusion process. J. Mater. Process. Technol. 2020, 282, 116682. [Google Scholar] [CrossRef]

- Woźnicki, A.; Leszczyńska-Madej, B.; Włoch, G.; Grzyb, J.; Madura, J.; Leśniak, D. Homogenization of 7075 and 7049 aluminium alloys intended for extrusion welding. Metals 2021, 11, 338. [Google Scholar] [CrossRef]

| Alloy Denotation | Si | Fe | Cu | Mg | Cr | Zn | Ti | Zr |

|---|---|---|---|---|---|---|---|---|

| 6082 | 1.3 | 0.21 | 0.03 | 0.59 | 0.00 | 0.4 | 0.2 | 0.1 |

| Alloy Denotation | Si | Fe | Cu | Mg | Cr | Zn | Ti | Zr |

|---|---|---|---|---|---|---|---|---|

| 7021 | 0.08 | 0.21 | 0.00 | 2.12 | 0.00 | 5.47 | 0.01 | 0.15 |

| Alloy | Solidus Temperature, °C | Incipient Melting Heat, J/g |

|---|---|---|

| 7021 alloy | 572.1 | 0.29 |

| Alloy | 7021 |

| Billet dimensions | Ø178 × 800 mm |

| Billet temperature | 480, 500, 510, 520 °C |

| Container/Die temperature | 450 °C |

| Extrusion ratio | 42 |

| Stem velocity | 1.5–4 mm/s |

| Metal exit speed | 2.5–10 m/min |

| Friction coefficient | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leśniak, D.; Zasadziński, J.; Libura, W.; Żaba, K.; Puchlerska, S.; Madura, J.; Balcerzak, M.; Płonka, B.; Jurczak, H. FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys. Materials 2023, 16, 556. https://doi.org/10.3390/ma16020556

Leśniak D, Zasadziński J, Libura W, Żaba K, Puchlerska S, Madura J, Balcerzak M, Płonka B, Jurczak H. FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys. Materials. 2023; 16(2):556. https://doi.org/10.3390/ma16020556

Chicago/Turabian StyleLeśniak, Dariusz, Józef Zasadziński, Wojciech Libura, Krzysztof Żaba, Sandra Puchlerska, Jacek Madura, Maciej Balcerzak, Bartłomiej Płonka, and Henryk Jurczak. 2023. "FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys" Materials 16, no. 2: 556. https://doi.org/10.3390/ma16020556

APA StyleLeśniak, D., Zasadziński, J., Libura, W., Żaba, K., Puchlerska, S., Madura, J., Balcerzak, M., Płonka, B., & Jurczak, H. (2023). FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys. Materials, 16(2), 556. https://doi.org/10.3390/ma16020556