Research on Explosive Hardening of Titanium Grade 2

Abstract

1. Introduction

2. Materials and Methods

2.1. Tested Materials

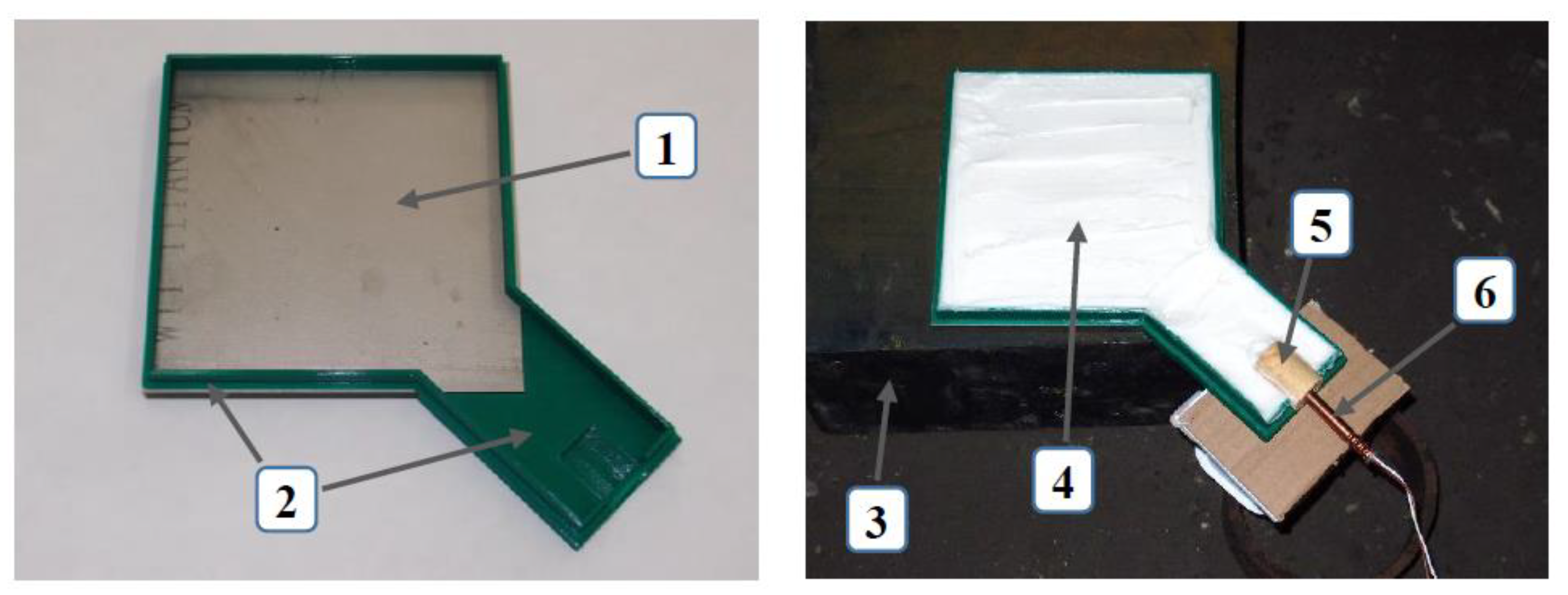

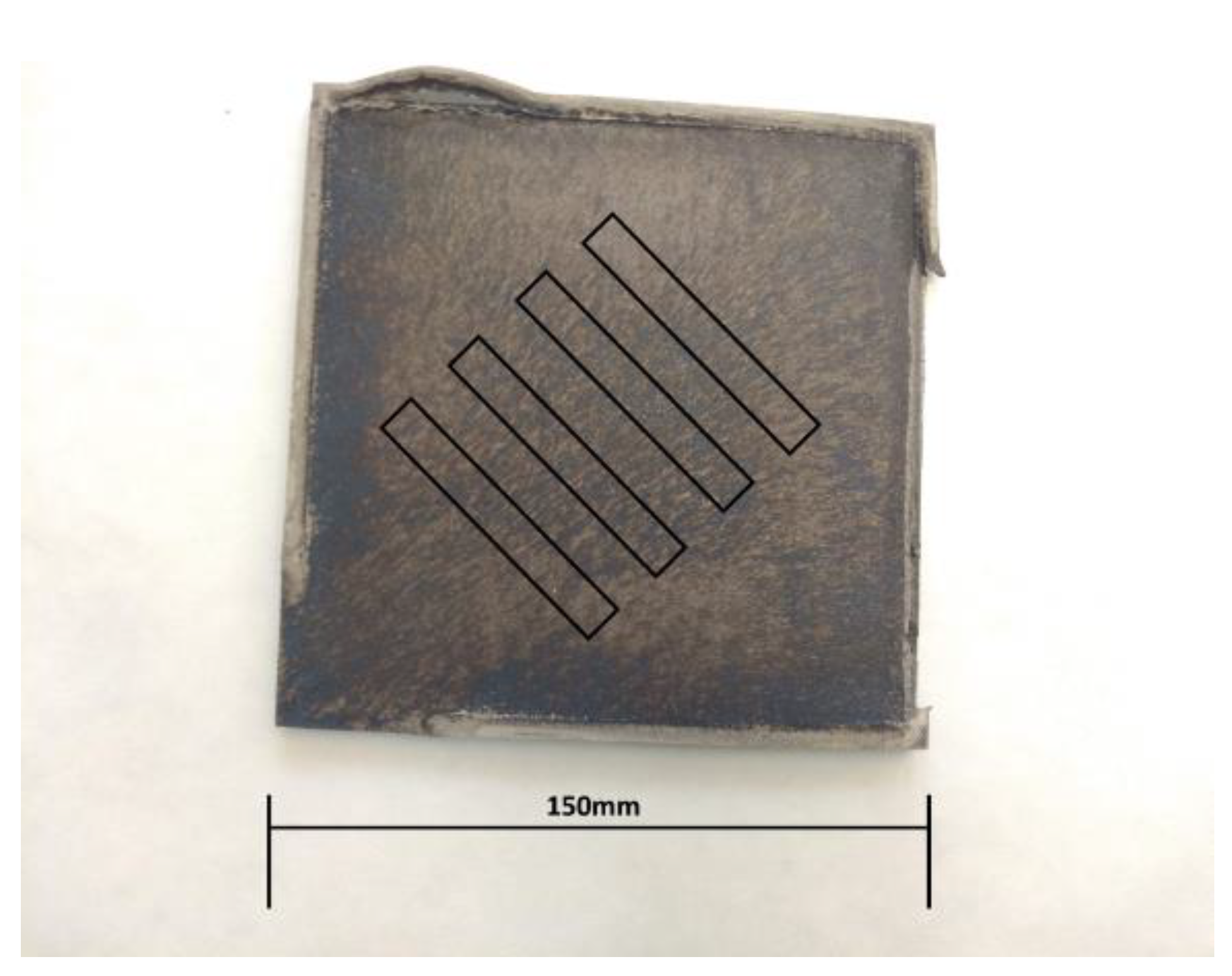

2.2. Explosive Strengthening System

2.3. Strength Tests

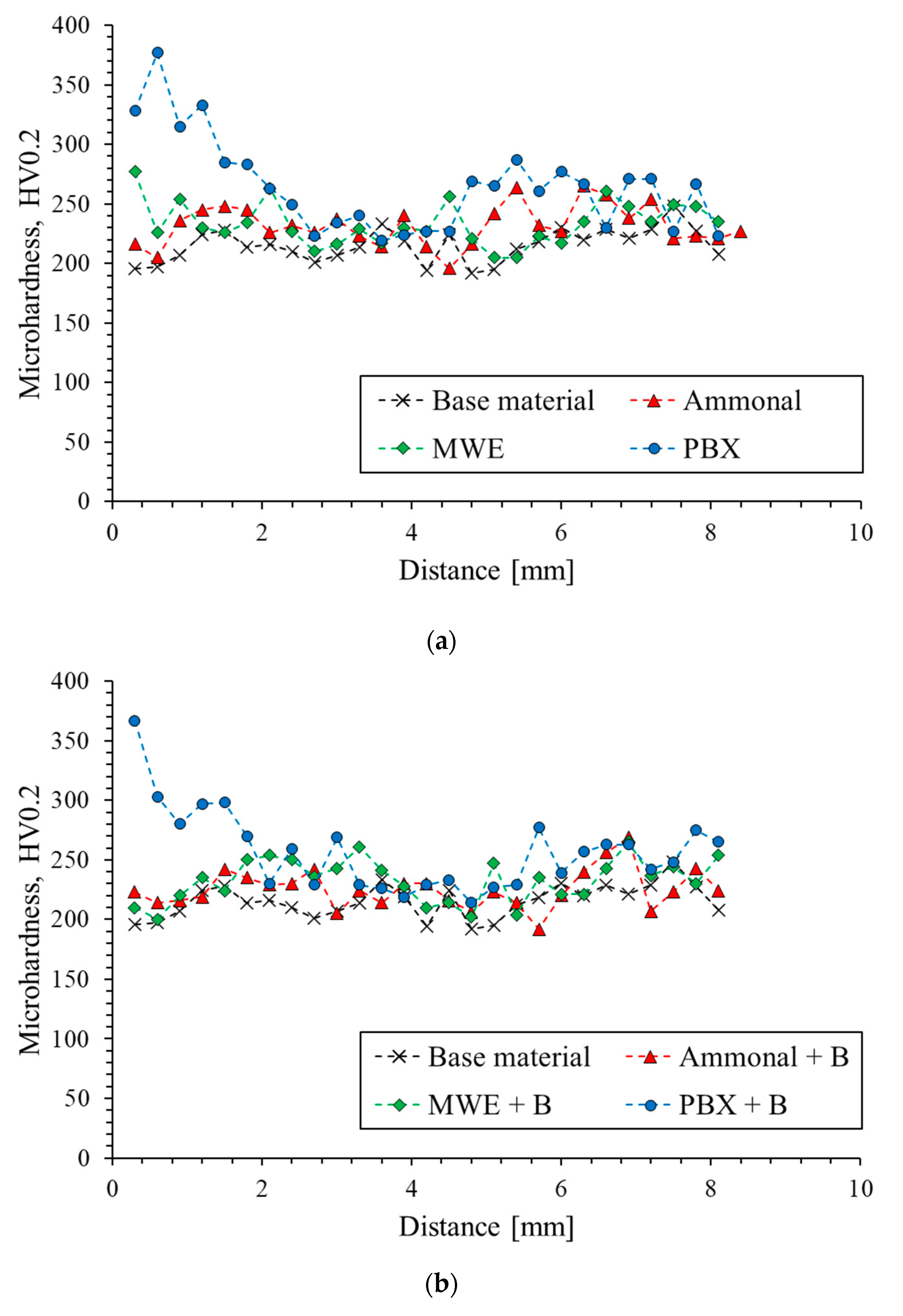

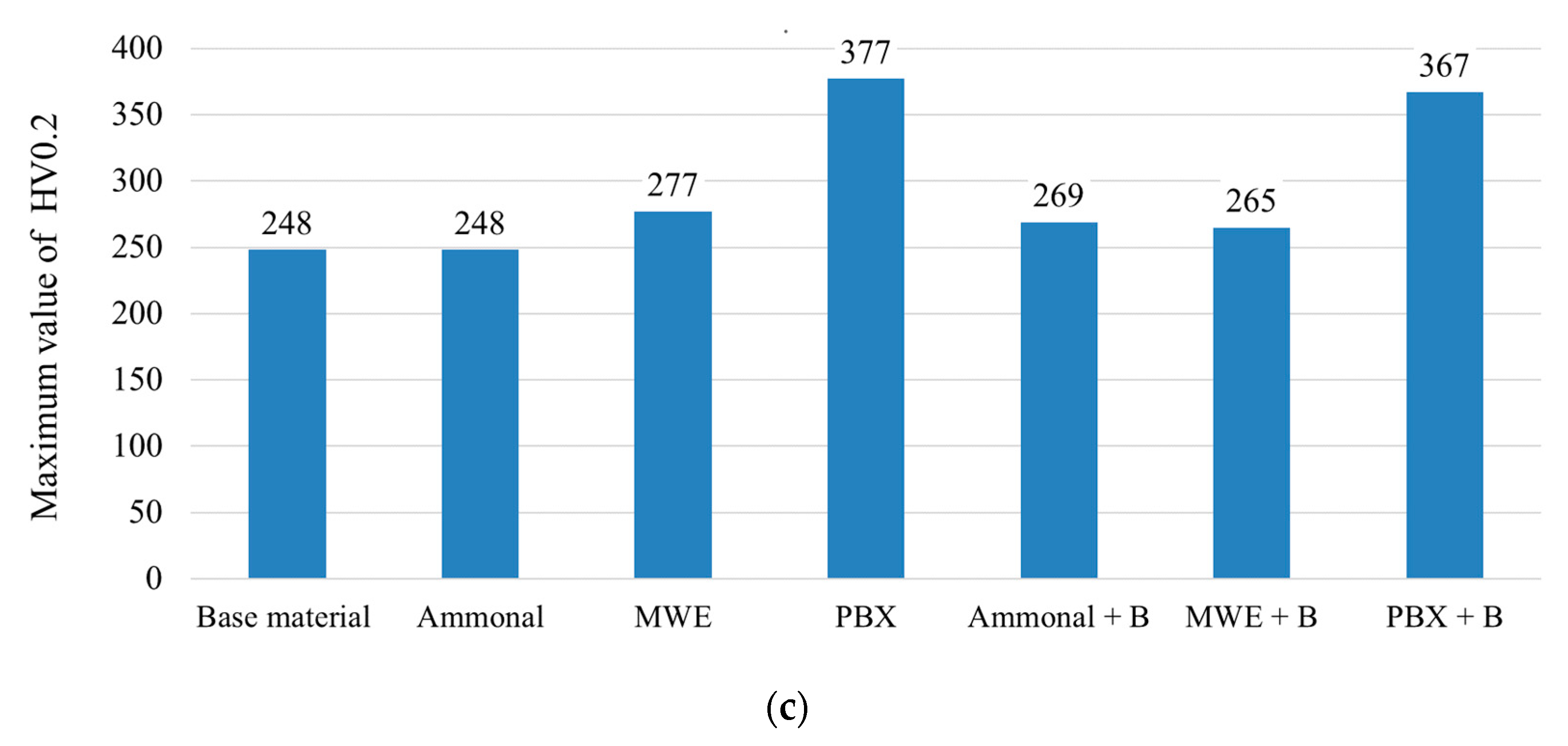

2.4. Microhardness Tests

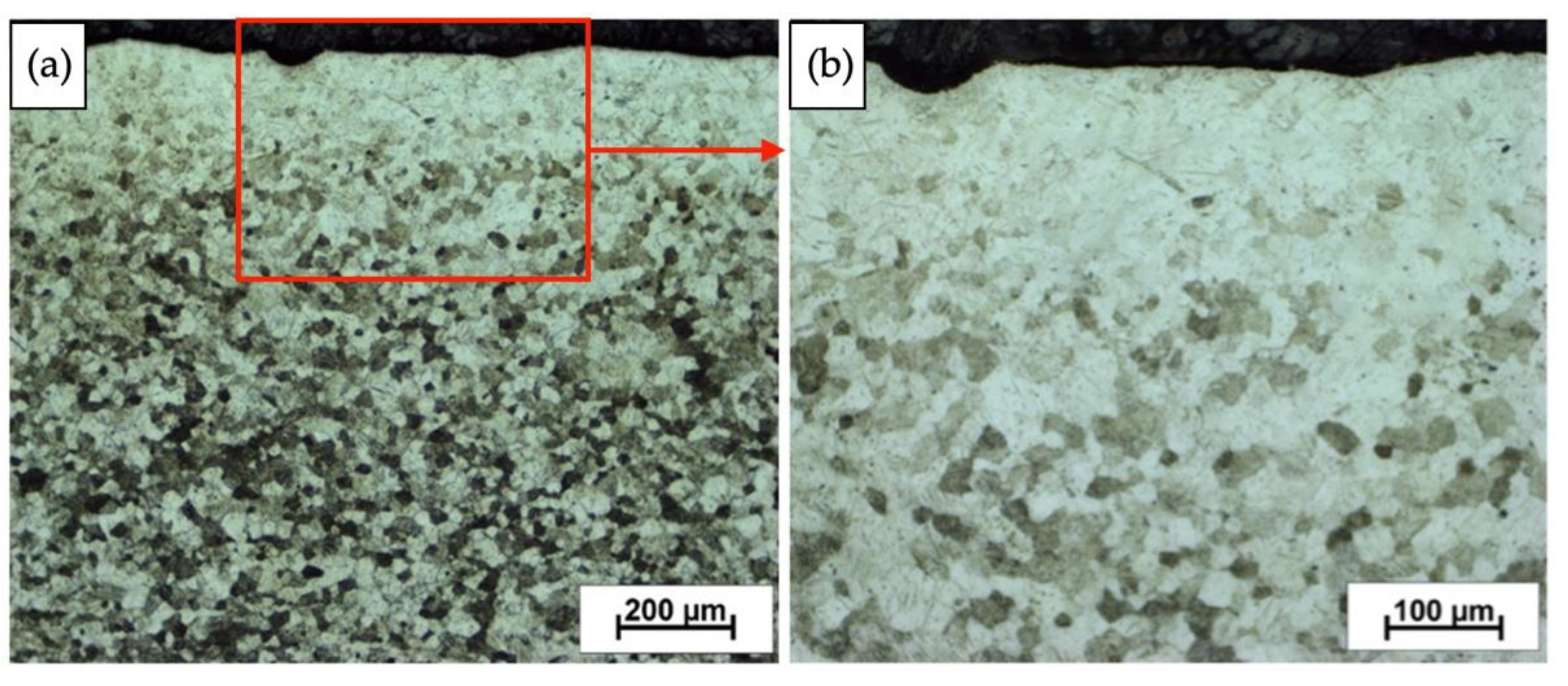

2.5. Microstructural Tests

2.6. Quantitative Analysis of the Microstructure

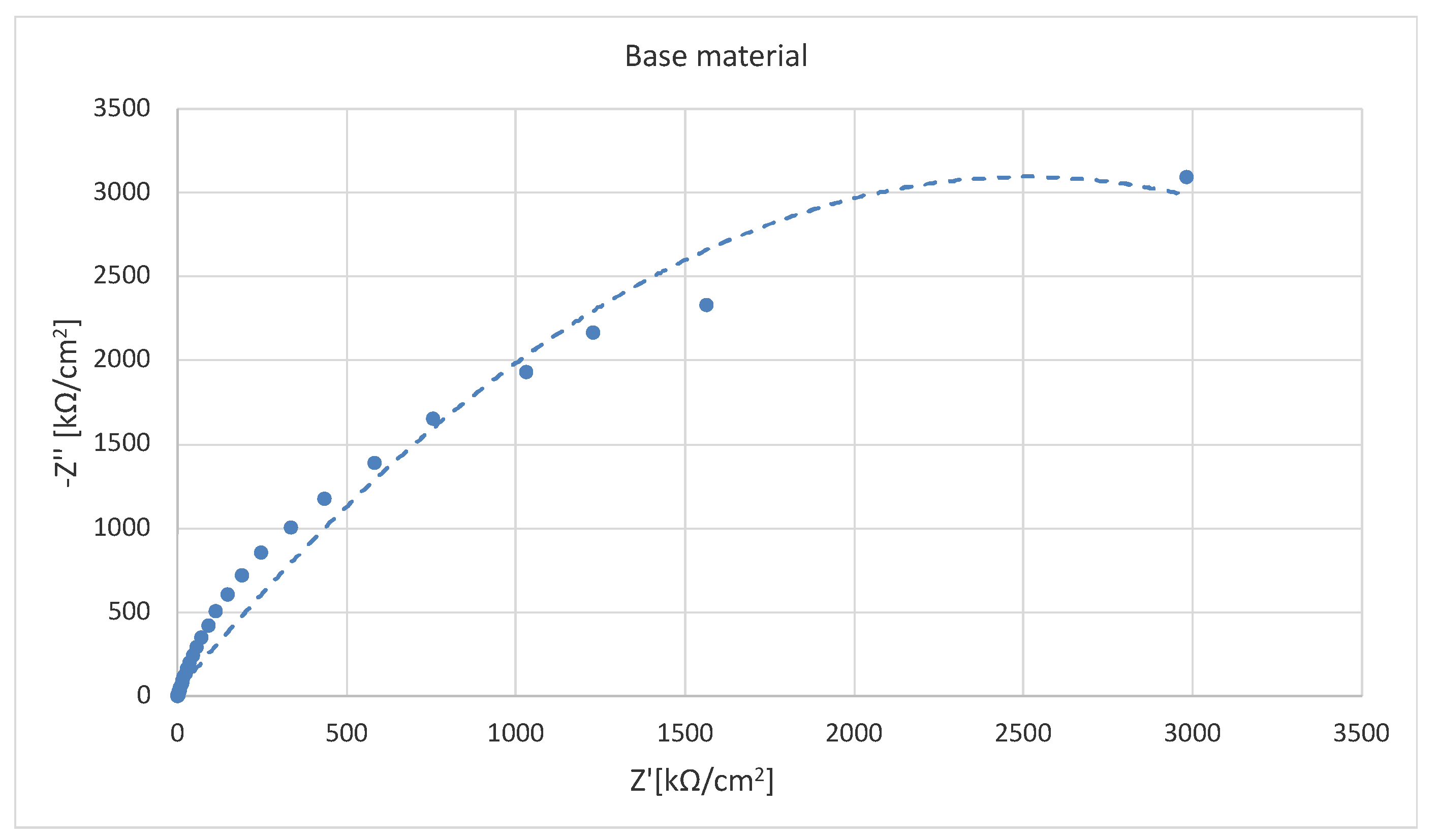

2.7. Corrosion Tests

3. Results and Discussion

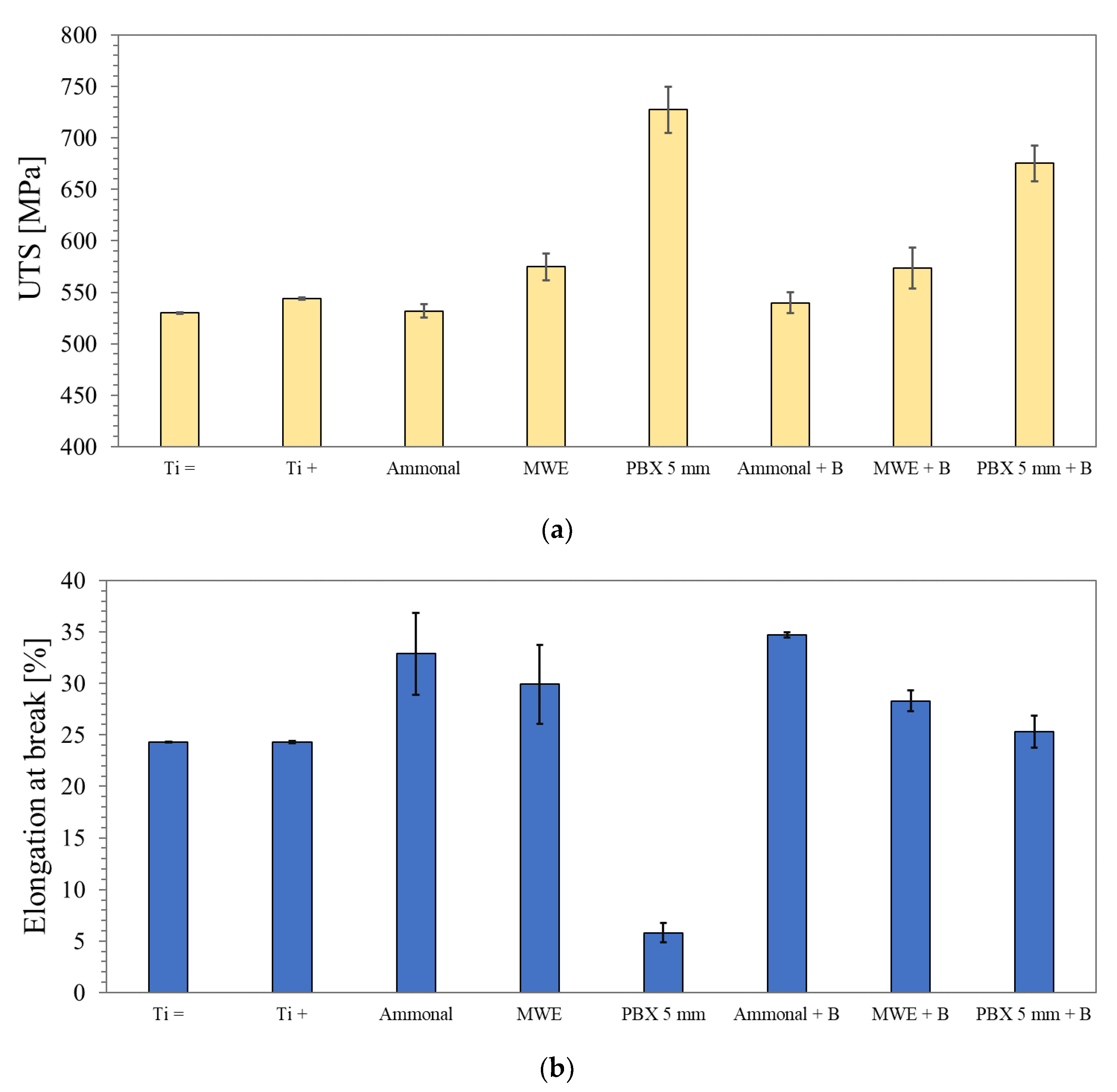

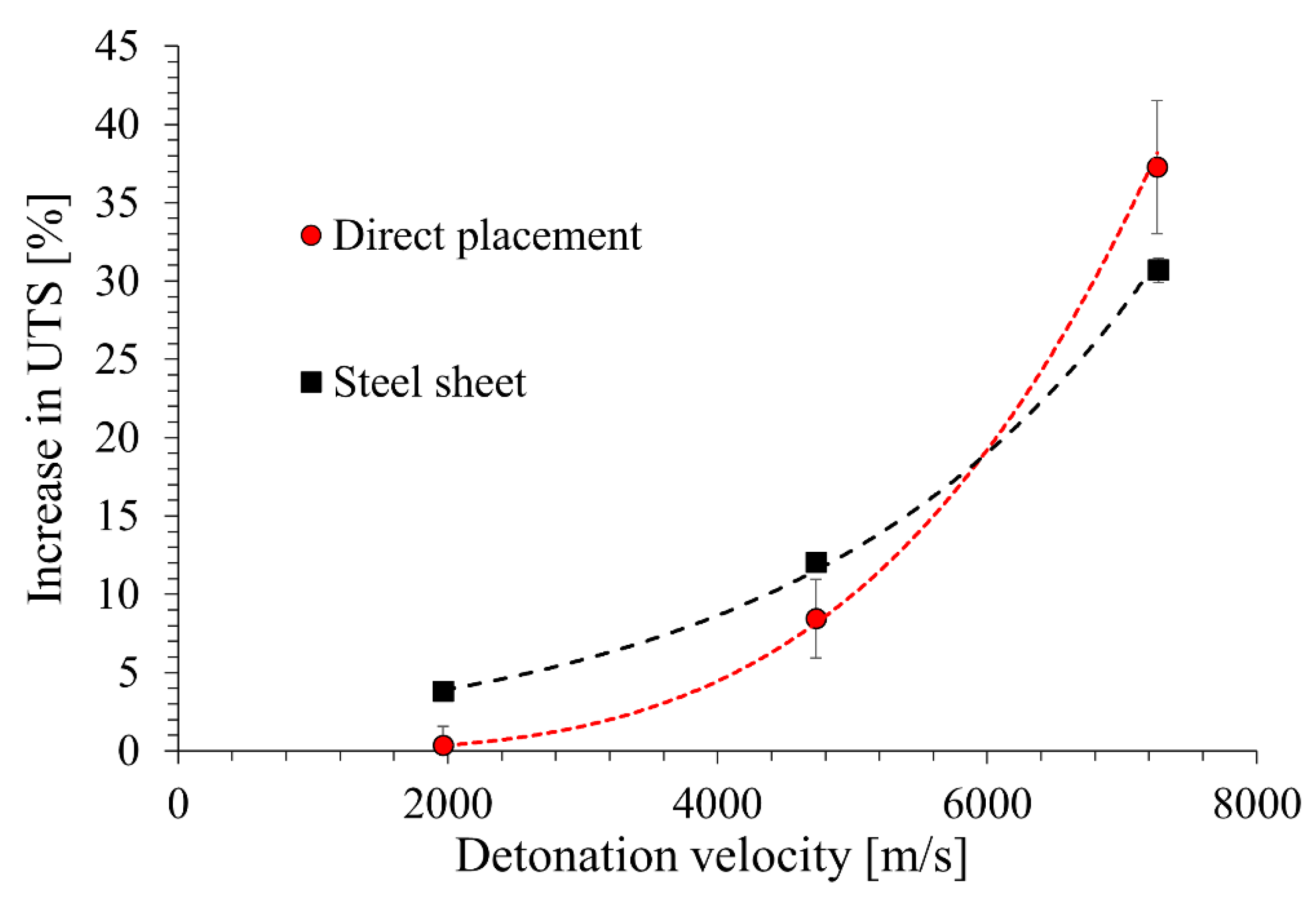

3.1. Strength Tests

3.2. Microhardness Tests

3.3. Microstructure—Initial State

3.4. Microstructure—Explosively Hardened Titanium with PBX

3.5. Quantitative Analysis of the Microstructure

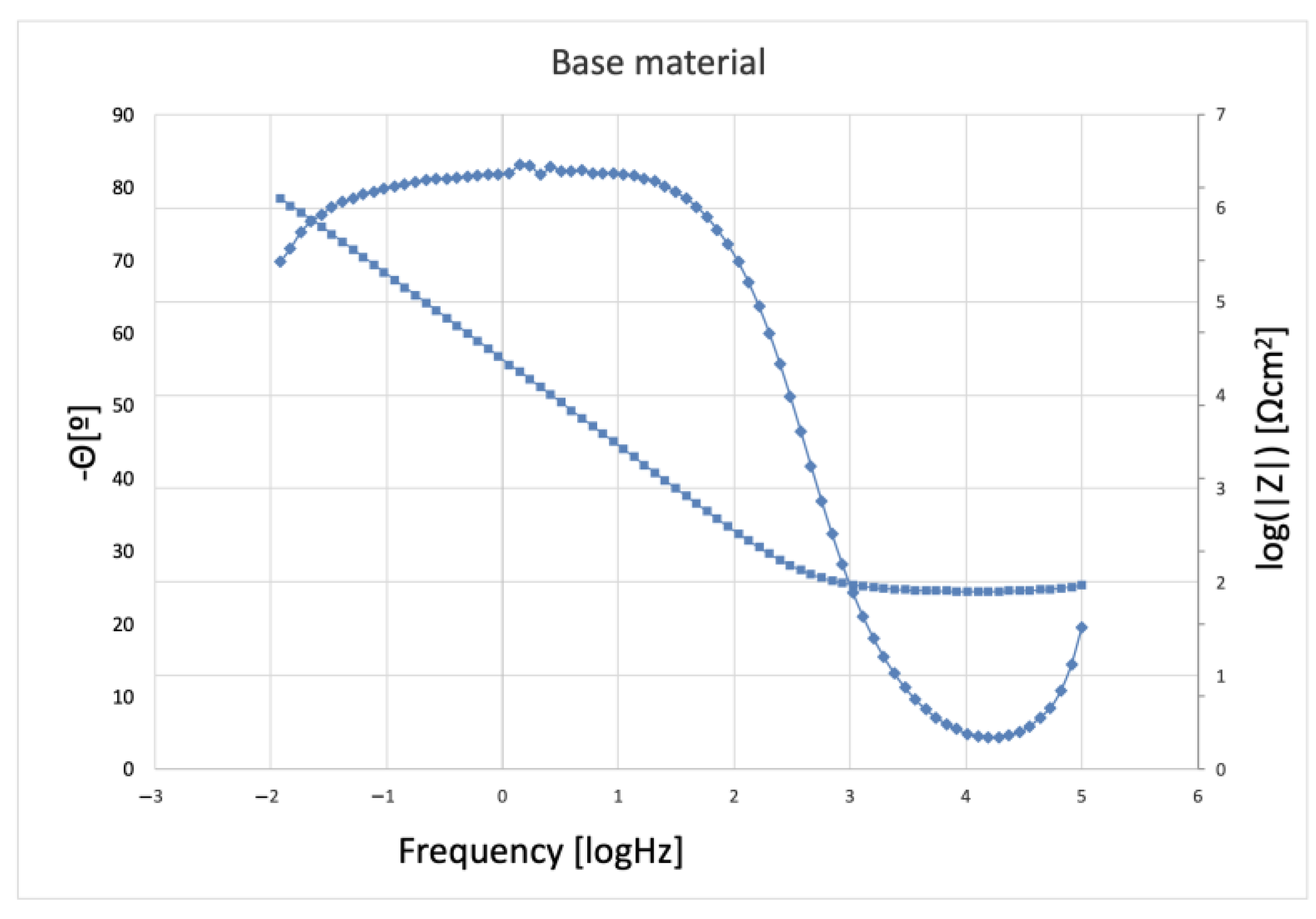

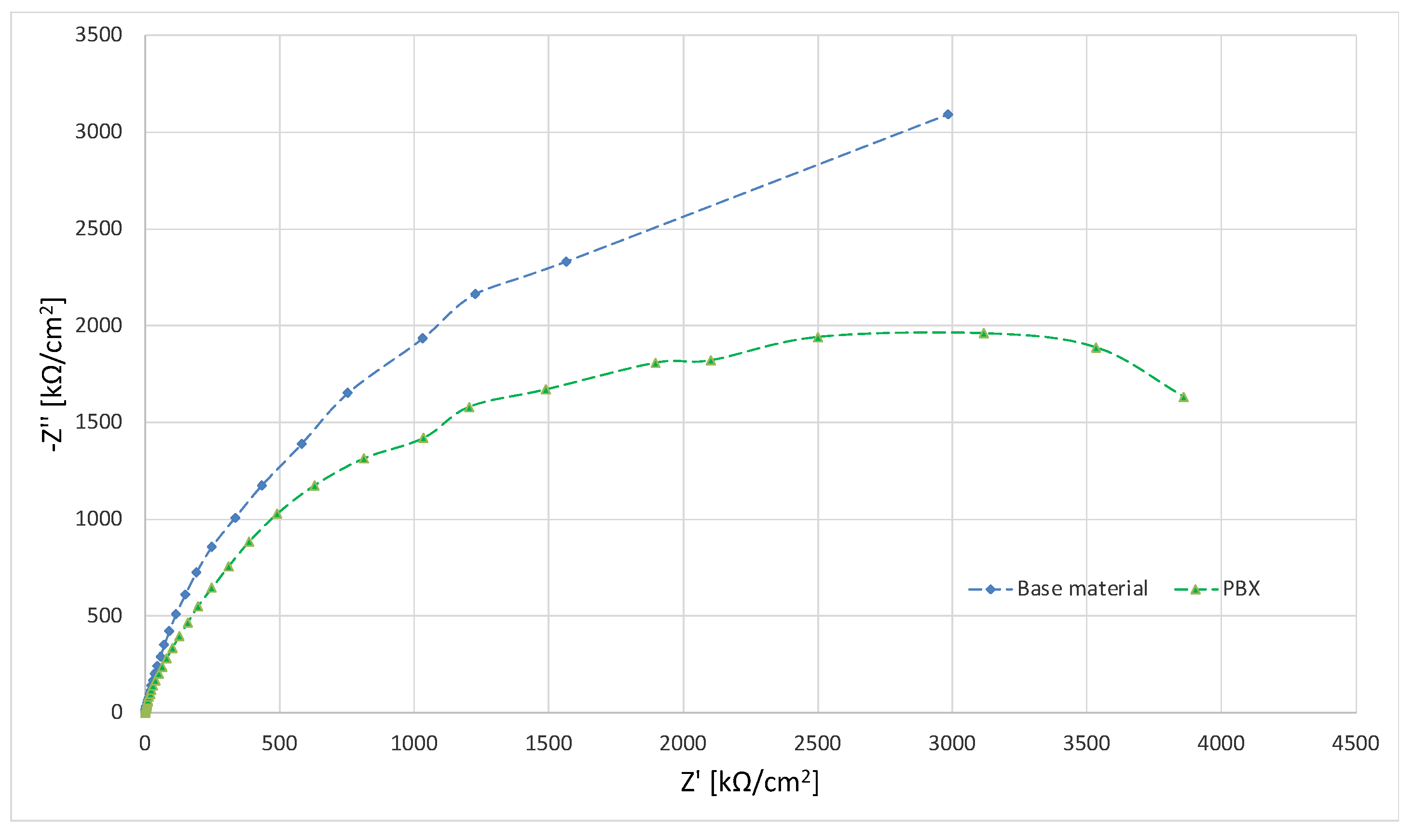

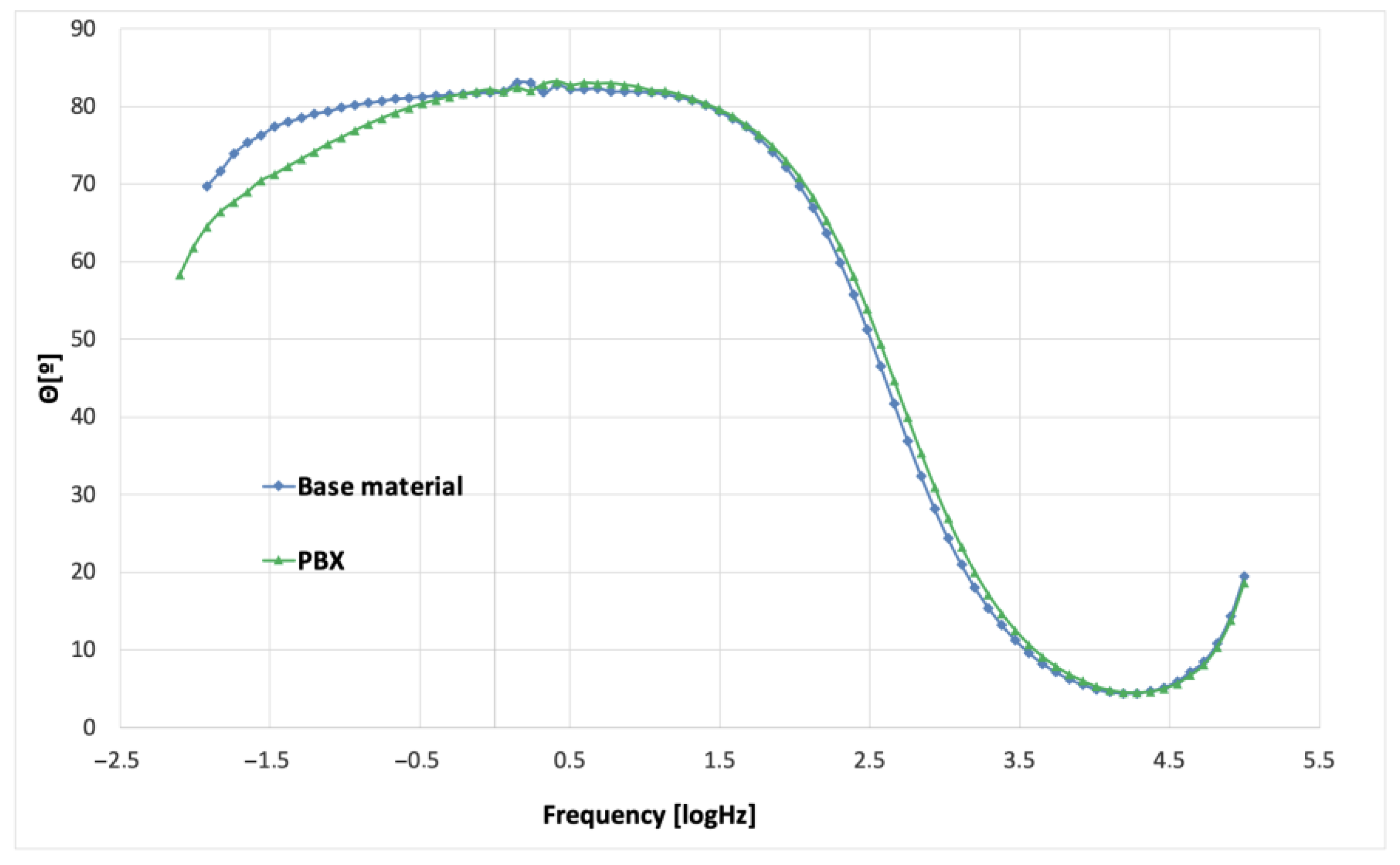

3.6. Corrosion Tests—Electrochemical Impedance Spectroscopy

3.7. Corrosion Tests—DC Electrochemical Research

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Veiga, C.; Davim, J.; Loureiro, A. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 133–148. [Google Scholar]

- Elias, C.; Lima, J.; Valiev, R. Biomedical applications of titanium and its alloys. JOM—US 2008, 60, 46–49. [Google Scholar] [CrossRef]

- Dziubińska, A.; Majerski, K.; Winiarski, G. Investigation of the Effect of Forging Temperature on the Microstructure of Grade 5 Titanium ELI. Adv. Sci. Tech. 2017, 11, 147–158. [Google Scholar] [CrossRef][Green Version]

- Haydar, H.; Jamal Al-Deen, H.; Abidali, A.; Mahmoud, A. Improved performance of Ti6Al4V alloy in Biomedical applications—Review. J. Phys. Conf. Ser. 2021, 1973, 012146. [Google Scholar] [CrossRef]

- Kikuchi, S.; Takemura, K.; Hayami, Y.; Ueno, A.; Ameyama, K. Evaluation of the Fatigue Properties of Ti-6Al-4V Alloy with Harmonic Structure in 4-Points Bending. J. Soc. Mater. Sci. 2015, 64, 880–886. [Google Scholar] [CrossRef]

- Haase, F.; Siemers, C.; Klinge, L.; Lu, C.; Lang, P.; Lederer, S.; König, T.; Rösler, J. Aluminum-and Vanadium-free Titanium Alloys for Medical Applications. In Proceedings of the MATEC Web of Conferences, Nantes, France, 10–14 June 2020; Volume 321. [Google Scholar] [CrossRef]

- Nikolova, M.; Yankov, E.; Petrov, P.; Nikolov, D.; Valkov, S.; Zaharieva, V.; Ormanova, M. Phase and Mechanical Changes of Ti5Al4V Alloy after Heat Treatment in Vacuum. In Proceedings of the MMETAL 2017—26th International Conference on Metallurgy and Materials, Brno, Czech Republic, 24–26 May 2017. [Google Scholar]

- Yang, H.; Fan, X.; Sun, Z.; Guo, L.; Zhan, M. Recent developments in plastic forming technology of titanium alloys. Sci. China Technol. Sci. 2011, 54, 490–501. [Google Scholar] [CrossRef]

- Topolski, K.; Halina, G. Manufacturing of Nanostructured Titanium Grade2 Using Caliber Rolling. Mater. Sci. Eng. A 2018, 739, 277–288. [Google Scholar] [CrossRef]

- Ravisankar, B.; Park, J. ECAP of commercially pure titanium: A review. T. Indian I. Met. 2012, 61, 51–62. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, J.; Liu, H.; Sun, J.; Gu, Y.; Tang, R.; Zhao, X.; Ma, A. Fabrication of an Ultra-Fine Grained Pure Titanium with High Strength and Good Ductility via ECAP plus Cold Rolling. Metals 2017, 7, 563. [Google Scholar] [CrossRef]

- Agarwal, K.; Tyagi, R.K.; Singhal, A.; Bhatia, D. Effect of ECAP on the mechanical properties of titanium and its alloys for biomedical applications. Mater. Sci. Energy Technol. 2020, 3, 921–927. [Google Scholar] [CrossRef]

- Guskov, A.; Zubashevskii, K.; Milevskii, K.; Samoilenko, V. Effect of Explosion on the Mechanical Properties of 110G13L Steel. Combust. Explo. Shock. 2019, 55, 744–749. [Google Scholar] [CrossRef]

- Kosturek, R.; Śnieżek, L.; Maranda, A.; Wachowski, M.; Mierzyński, J.; Grzelak, K. The influence of the post-weld heat treatment on the microstructure of Mangalloy—Carbon steel clad-plate obtained by explosive welding. Kov. Mater. 2020, 58, 33–39. [Google Scholar] [CrossRef]

- Zhang, M.; Lv, B.; Zhang, F.; Feng, X. Explosion Deformation and Hardening Behaviours of Hadfield Steel Crossing. ISIJ Int. 2012, 52, 2093–2095. [Google Scholar] [CrossRef][Green Version]

- Kosturek, R.; Wachowski, M.; Śnieżek, L.; Kruk, A.; Torzewski, J.; Grzelak, K.; Mierzyński, J. Research on the microstructure of a Ti6Al4V-AA1050 explosive-welded bimetallic joint. Mater. Tehnol. 2019, 53, 109–113. [Google Scholar] [CrossRef]

- Ba, Q.; Song, R.; Feng, Y.; Li, L. Microstructural Properties and Hardening Mechanism of Explosion Hardening of Mn13Cr2 Steel Surface. In CMC 2017: Advances in Materials Processing; Lecture Notes in Mechanical, Engineering; Han, Y., Ed.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Kovacs-Coskun, T. Explosive Surface Hardening of Austenitic Stainless Steel. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Miskolc-Lillafüred, Hungary, 6–10 October 2016; Volume 123, p. 012010. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, Q.; Ran, C.; Liu, R.; Arab, A.; Ren, Y.; Chen, P. Shock-induced large-depth gradient microstructure in commercial pure titanium subjected to explosive hardening. Mater. Des. 2022, 213, 110309. [Google Scholar] [CrossRef]

- Garcia-Falcon, C.M.; Gil-Lopez, T.; Verdu-Vazquez, A.; Mirza-Rosca, J.C. Corrosion behavior in Ringer solution of several commercially used metal alloys. Anti-Corros. Methods Mater. 2021, 68, 324–330. [Google Scholar] [CrossRef]

- Akpan, E.D.; Isaac, I.O.; Olasunkanmi, L.O.; Ebenso, E.E.; Sherif, E.S.M. Acridine-based thiosemicarbazones as novel inhibitors of mild steel corrosion in 1 M HCl: Synthesis, electrochemical, DFT and Monte Carlo simulation studies. RSC Adv. 2019, 9, 29590–29599. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, D.V.; Abrantes, J.C.C. Application of electrochemical impedance spectroscopy (EIS) to monitor the corrosion of reinforced concrete: A new approach. Constr. Build. Mater. 2016, 111, 98–104. [Google Scholar] [CrossRef]

- Choi, W.; Shin, H.C.; Kim, J.M.; Choi, J.Y.; Yoon, W.S. Modeling and Applications of Electrochemical Impedance Spectroscopy (EIS) for Lithium-ion Batteries. J. Electrochem. Sci. Technol. 2020, 11, 1–13. [Google Scholar] [CrossRef]

- Prakashaiah, B.G.; Vinaya Kumara, D.; Anup Pandith, A.; Nityananda Shetty, A.; Amitha Rani, B.E. Corrosion inhibition of 2024-T3 aluminum alloy in 3.5% NaCl by thiosemicarbazone derivatives. Corros. Sci. 2018, 136, 326–338. [Google Scholar] [CrossRef]

- Bhandari, H.; Anoop Kumar, S.; Dhawan S., K. Conducting Polymer Nanocomposites for Anticorrosive and Antistatic Applications. Nanocomposites-New Trends Dev. 2012, 73–96. [Google Scholar] [CrossRef]

| Designation | Description of the Samples |

|---|---|

| Base material | Sheet in the initial state provided by the manufacturer |

| Ammonal | Sheet deformed with an explosive—ammonal explosive |

| MWE | Sheet deformed with an explosive—emulsion explosive |

| PBX | Sheet deformed with an explosive—plastic bonded explosive |

| Ammonal + B | Sheet deformed with ammonal explosive with an additional technological spacer in the form of a 1 mm thick steel sheet |

| MWE + B | Sheet deformed with emulsion explosive with an additional technological spacer in the form of a 1 mm thick steel sheet |

| PBX + B | Sheet deformed with plastic bonded explosive with an additional technological spacer in the form of a 1 mm thick steel sheet |

| Designation | Composition | Layer Thickness [mm] | Density [g/cm3] | Velocity of Detonation [m/s] |

|---|---|---|---|---|

| Ammonal | 10.0% Al, 86.5% ammonium nitrate(V), and 3.5% dolomite | 10 | 0.72 | 2000 |

| Emulsion explosive | 97% emulsion matrix and 3% glass microspheres | 10 | 1.11 | 4700 |

| Plastic bonded explosive | 85% hexogen and 15% matrix (binder, plasticizer, and oil) | 5 | 1.48 | 7300 |

| Ingredient | Content g/dm3 |

|---|---|

| NaCl | 6.0 |

| KCl | 0.075 |

| CaCl2 | 0.1 |

| NaHCO3 | 0.1 |

| State | Grain Quantity | Equivalent Diameter [µm] | Variance | Standard Deviation | CV |

|---|---|---|---|---|---|

| Base material | 171 | 23.3 | 128.36 | 11.33 | 0.49 |

| PBX | 183 | 18.1 | 53.4 | 7.31 | 0.40 |

| State | U [mV] | I [nA/cm2] | CR [mm/Year] |

|---|---|---|---|

| Baseline | −469 | 4.6 | 0.00008 |

| PBX | −490 | 5.5 | 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gloc, M.; Przybysz-Gloc, S.; Wachowski, M.; Kosturek, R.; Lewczuk, R.; Szachogłuchowicz, I.; Paziewska, P.; Maranda, A.; Ciupiński, Ł. Research on Explosive Hardening of Titanium Grade 2. Materials 2023, 16, 847. https://doi.org/10.3390/ma16020847

Gloc M, Przybysz-Gloc S, Wachowski M, Kosturek R, Lewczuk R, Szachogłuchowicz I, Paziewska P, Maranda A, Ciupiński Ł. Research on Explosive Hardening of Titanium Grade 2. Materials. 2023; 16(2):847. https://doi.org/10.3390/ma16020847

Chicago/Turabian StyleGloc, Michał, Sylwia Przybysz-Gloc, Marcin Wachowski, Robert Kosturek, Rafał Lewczuk, Ireneusz Szachogłuchowicz, Paulina Paziewska, Andrzej Maranda, and Łukasz Ciupiński. 2023. "Research on Explosive Hardening of Titanium Grade 2" Materials 16, no. 2: 847. https://doi.org/10.3390/ma16020847

APA StyleGloc, M., Przybysz-Gloc, S., Wachowski, M., Kosturek, R., Lewczuk, R., Szachogłuchowicz, I., Paziewska, P., Maranda, A., & Ciupiński, Ł. (2023). Research on Explosive Hardening of Titanium Grade 2. Materials, 16(2), 847. https://doi.org/10.3390/ma16020847