Improvement of Mechanical Properties of Composites with Surface Modified B4C for Precision Machining

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization and Testing

3. Results and Discussion

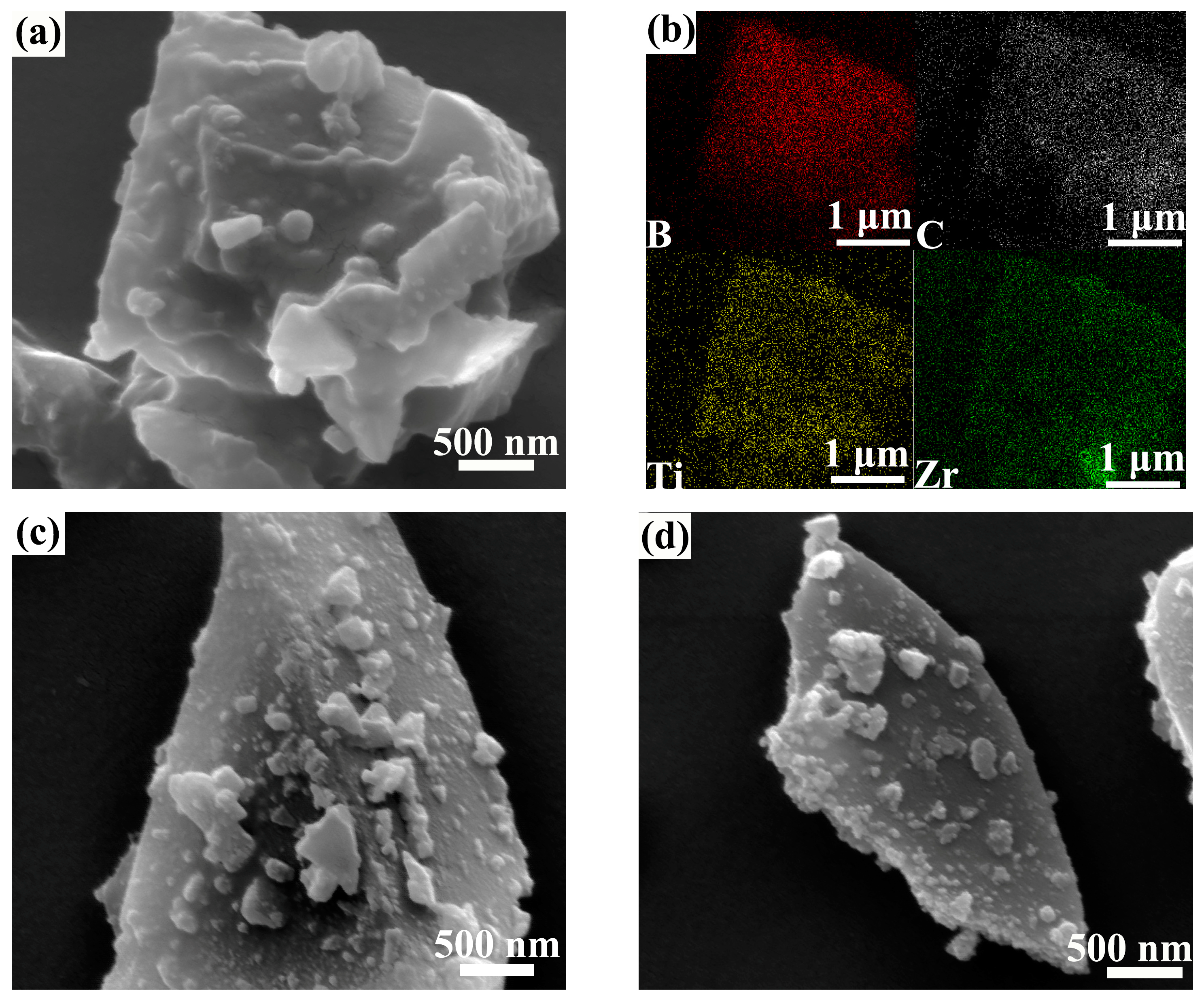

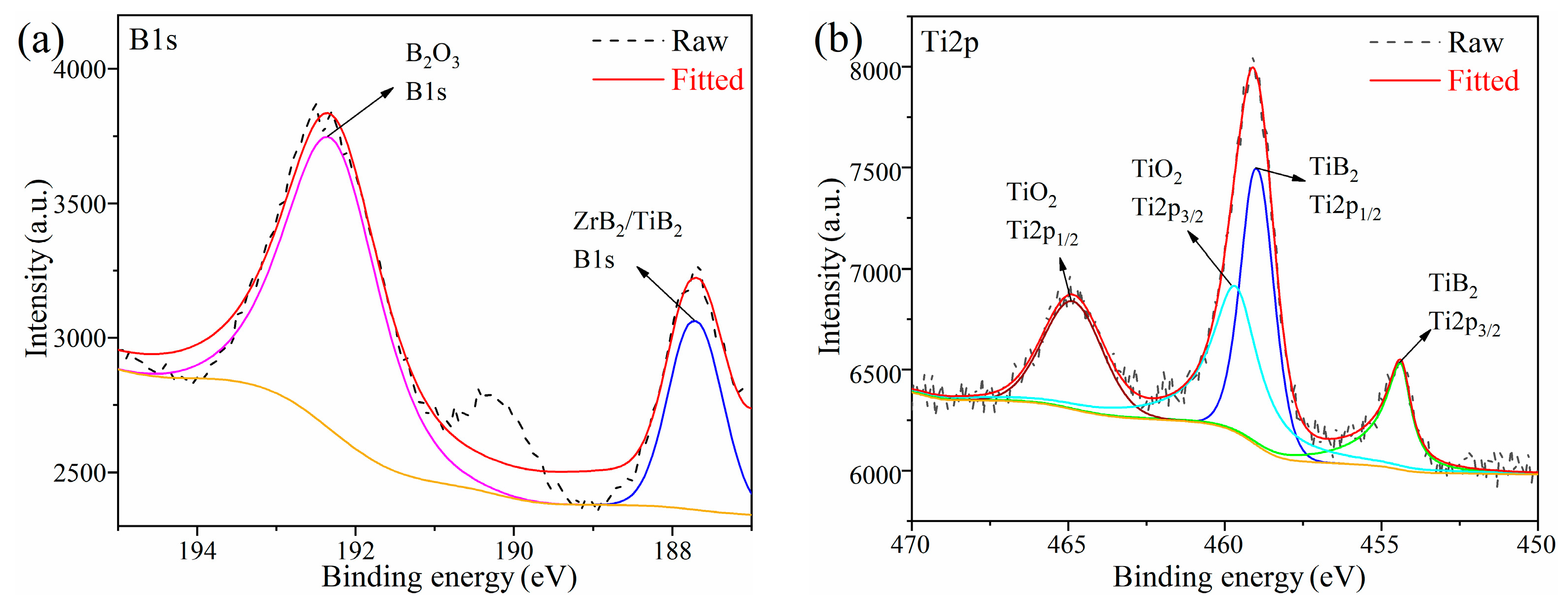

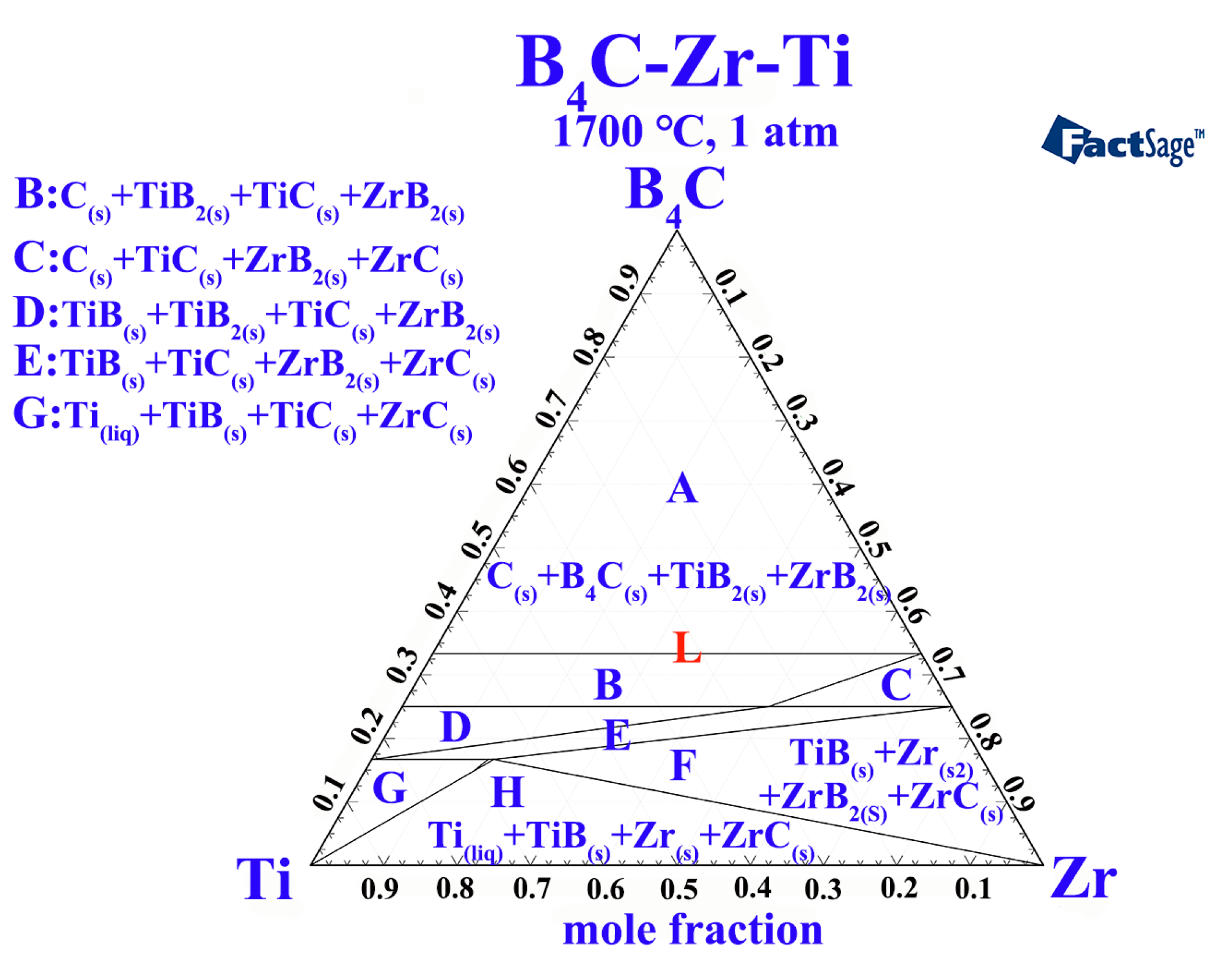

3.1. B4C@ZrB2–TiB2 Composite Powder

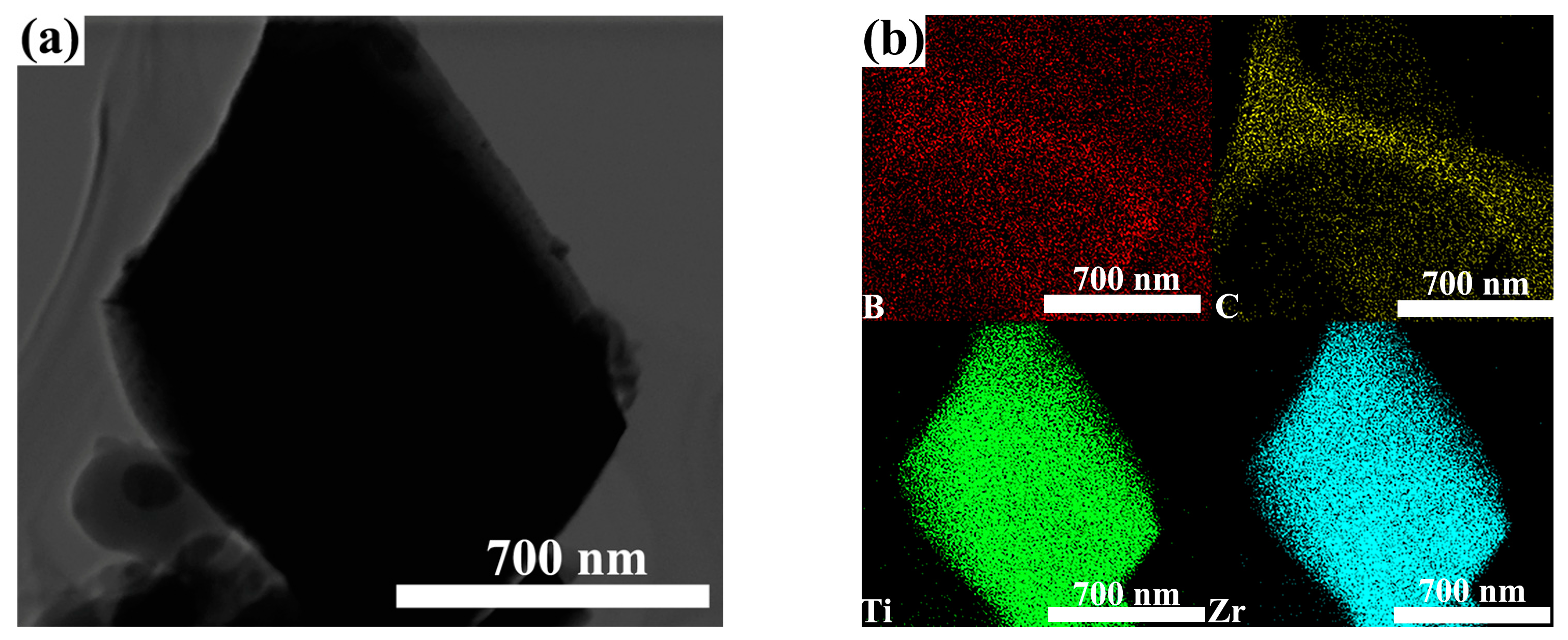

3.2. B4C–(Zr, Ti)B2 Composite Ceramics

4. Conclusions

- (1)

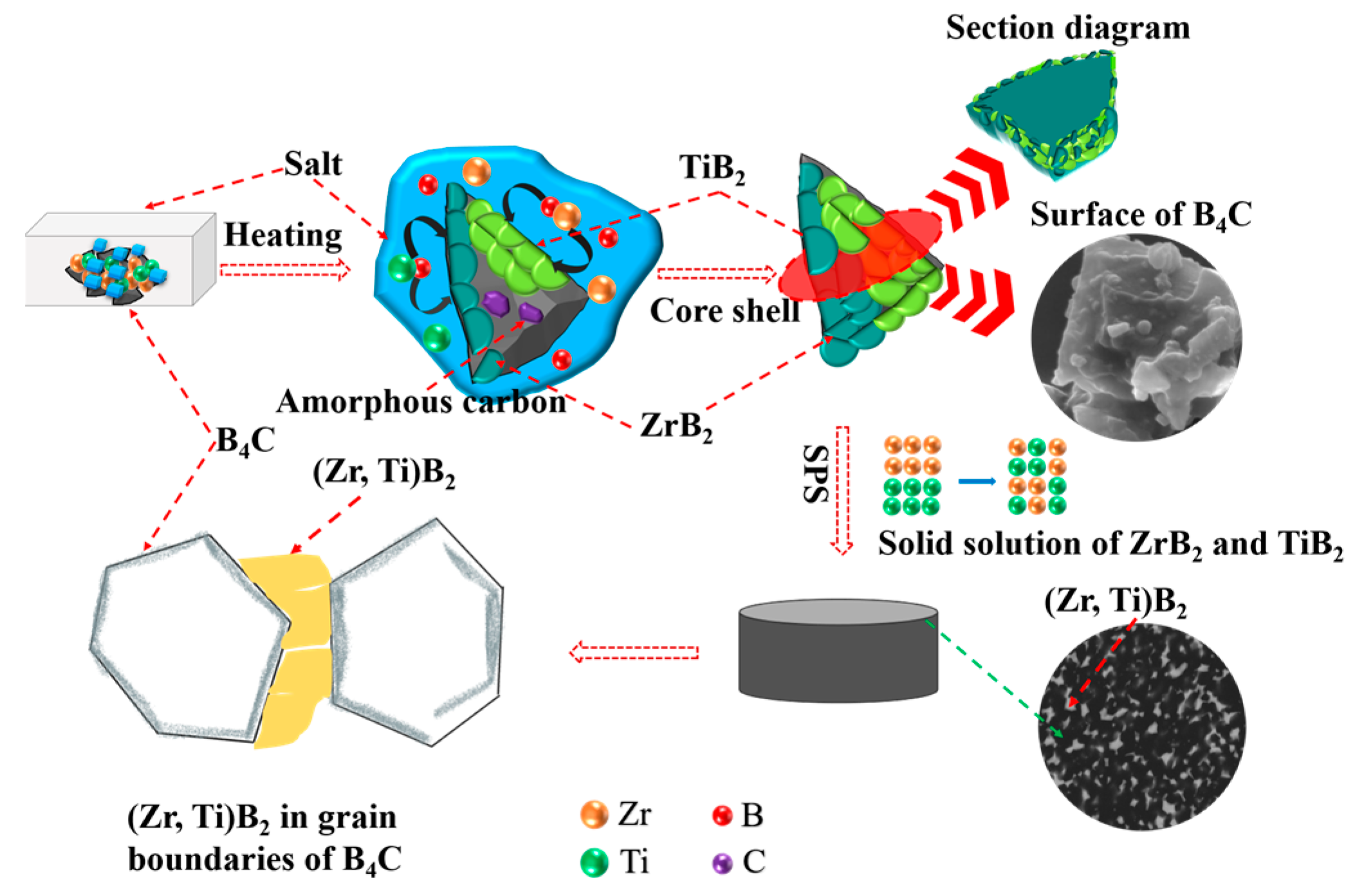

- Thermodynamic calculation and phase analysis revealed that Zr and Ti reacted with B4C to form ZrB2 and TiB2 in a B4C-rich environment. Thanks to the heat and mass transfer of molten salt medium, the product is uniformly coated on the surface of B4C particles.

- (2)

- When the powder is sintered by SPS at 1700 ℃, ZrB2 and TiB2 form solid solution (Zr, Ti)B2 at high temperature, the primary phases of composite ceramics are B4C, (Zr, Ti)B2, and C.

- (3)

- Due to the synergistic effect of solid solution strengthening and particle toughening, better comprehensive properties can be obtained. When n(B4C):n(Zr):n(Ti) = 12:1:1, the Vickers hardness reach 41.2 GPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Johnson, W.B.; Claar, T.D.; Schiroky, G.H. Preparation and processing of platelet-reinforced ceramics by the directed reaction of zirconium with boron carbide. Ceram. Eng. Sci. Proc. 1989, 10, 588–598. [Google Scholar]

- Johnson, W.B.; Claar, T.D.; Schiroky, G.H. Microstructure and properties of platelet-reinforced ceramics by the directed reaction of zirconium with boron carbide. Ceram. Eng. Sci. Proc. 1989, 10, 599–609. [Google Scholar]

- Johnson, W.B.; Nagelberg, A.S.; Breval, E. Kinetics of formation of a platelet-reinforced ceramic composite prepared by the directed reaction of zirconium with boron carbide. J. Am. Ceram. Soc. 2010, 74, 2093–2101. [Google Scholar] [CrossRef]

- Guo, W.M.; Wu, L.X.; You, Y.; Lin, H.T.; Zhang, G.J. Three-step reactive hot pressing of B4C-ZrB2 ceramics. J. Eur. Ceram. Soc. 2016, 36, 951–957. [Google Scholar] [CrossRef]

- Rehman, S.S.; Ji, W.; Fu, Z.Y.; Wang, W.M.; Wang, H.; Asif, M.; Zhang, J.Y. In situ synthesis and sintering of B4C/ZrB2 composites from B4C and ZrH2 mixtures by spark plasma sintering. J. Eur. Ceram. Soc. 2015, 35, 1139–1145. [Google Scholar] [CrossRef]

- Zamora, V.; Guiberteau, F.; Borrero-López, O.; Ortiz, A.L. Ultra-low temperature spark plasma sintering of super wear-resistant hard B4C composites. Scripta Mater. 2022, 211, 114516. [Google Scholar] [CrossRef]

- Zhang, W.K.; Gao, L.Z.; Lei, Y.; Yang, B.J.; Li, J.; Xiao, L.; Yin, Y.S. TiAl/B4C composite fabricated by high energy ball milling and hot press sintering processes and its mechanical properties. Mater. Sci. Eng. 2010, 527, 7436–7441. [Google Scholar] [CrossRef]

- Sun, J.L.; Liu, C.X.; Wang, R.G. Low pressure hot pressing of B4C matrix ceramic composites improved by Al2O3 and TiC additives. Mater. Sci. Eng. A 2009, 519, 27–31. [Google Scholar] [CrossRef]

- Guo, W.C.; He, Q.L.; Wang, A.Y.; Tian, T.; Liu, C.; Hu, L.X.; Wang, W.M.; Wang, H.; Fu, Z.Y. Effect of TiB2 particles on microstructure and mechanical properties of B4C–TiB2 ceramics prepared by hot pressing. Ceram. Int. 2022, 48, 25637–25641. [Google Scholar] [CrossRef]

- Feng, B.; Martin, H.-P.; Michaelis, A. Preparation and Characterization of B4C-HfB2 Composites as Material for High-Temperature Thermocouples. Crystals 2022, 12, 621. [Google Scholar] [CrossRef]

- Liu, G.; Chen, S.; Zhao, Y.; Fu, Y.; Wang, Y. The Effects of Transition Metal Oxides (Me = Ti, Zr, Nb, and Ta) on the Mechanical Properties and Interfaces of B4C Ceramics Fabricated via Pressureless Sintering. Coatings 2020, 10, 1253. [Google Scholar] [CrossRef]

- Chen, H.; Zeng, F.H.; Li, W.J.; Liu, J.A.; Gu, Y.; Zhang, F.Q. Densification behavior and mechanical properties of spark plasma reaction sintered ZrB2-ZrC-B4C ceramics from B4C–Zr system. Ceram. Int. 2019, 45, 12122–12129. [Google Scholar] [CrossRef]

- Sha, W.H.; Liu, Y.Y.; Zhou, Y.B.; Huang, Y.H.; Huang, Z.R. Effect of Carbon Content on Mechanical Properties of Boron Carbide Ceramics Composites Prepared by Reaction Sintering. Materials 2022, 15, 6028. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Cheng, H.W.; Wang, Y.W.; An, R. Effects of carbon and silicon on microstructure and mechanical properties of pressureless sintered B4C/TiB2 composites. J. Alloys Compd. 2019, 772, 537–545. [Google Scholar] [CrossRef]

- Yan, X.H.; Zhou, X.G.; Wang, H.L. Effect of Additive Ti3SiC2 Content on the Mechanical Properties of B4C–TiB2 Composites Ceramics Sintered by Spark Plasma Sintering. Materials 2020, 13, 4616. [Google Scholar] [CrossRef]

- Ren, D.L.; Deng, Q.H.; Wang, J.; Li, Y.B.; Li, M.; Ran, S.L.; Du, S.Y.; Huang, Q. Densification and mechanical properties of pulsed electric current sintered B4C with in situ synthesized Al3BC obtained by the molten–salt method. J. Eur. Ceram. Soc. 2017, 37, 4524–4531. [Google Scholar] [CrossRef]

- Wang, J.; Ren, D.L.; Chen, L.L.; Man, G.A.; Zhang, H.Y.; Zhang, H.P.; Luo, L.H.; Li, W.P.; Pan, Y.B.; Gao, P.F.; et al. Initial investigation of B4C–TiB2 composites as neutron absorption material for nuclear reactors. J. Nucl. Mater. 2020, 539, 152275. [Google Scholar] [CrossRef]

- Zamora, V.; Nygren, M.; Guiberteau, F.; Ortiz, A.L. Effect of graphite addition on the spark-plasma sinterability of ZrB2 and ZrB2-SiC ultra-high-temperature ceramics. Ceram. Int. 2014, 40, 11457–11464. [Google Scholar] [CrossRef]

- Wang, S.; Gao, S.B.; Xing, P.F.; Nie, D.; Yan, S.; Zhuang, Y.X. Pressureless liquid-phase sintering of B4C with MoSi2 as a sintering aid. Ceram. Int. 2019, 45, 13502–13508. [Google Scholar] [CrossRef]

- Wang, S.; Deng, Y.Y.; Yang, M.S.; Wang, L.Y.; Li, H.Q.; Xing, P.F. Microstructure and mechanical property of B4C-SiC-CrB2 composites fabricated via reactive hot pressing. Ceram. Int. 2020, 46, 29261–29270. [Google Scholar] [CrossRef]

- Song, Q.; Zhang, Z.H.; Hu, Z.Y.; Yin, S.P.; Wang, H.; Ma, Z.W. Microstructure and mechanical properties of super-hard B4C ceramic fabricated by spark plasma sintering with (Ti3SiC2+Si) as sintering aid. Ceram. Int. 2019, 45, 8790–8797. [Google Scholar] [CrossRef]

- Yavas, B.; Sahin, F.; Yucel, O.; Goller, G. Effect of particle size, heating rate and CNT addition on densification, microstructure and mechanical properties of B4C ceramics. Ceram. Int. 2015, 41, 8936–8944. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Cumbrera, F.L.; Ortiz, A.L.; Casitllo-Rodriguez, M.; Gomez-Garcia, D. Additive-free superhard B4C with ultrafine-grained dense microstructures. J. Eur. Ceram. Soc. 2014, 34, 841–848. [Google Scholar] [CrossRef] [Green Version]

- Moshtaghioun, B.M.; Ortiz, A.L.; Gomez-Garcia, D.; Dominguez-Rodriguez, A. Densification of B4C nanopowder with nanograin retention by spark-plasma sintering. J. Eur. Ceram. Soc. 2015, 35, 1991–1998. [Google Scholar] [CrossRef]

- Zeppelin, F.; Hirscher, M.; Stanzick, H.; Banhart, J. Desorption of hydrogen from blowing agents used for foaming metals. Compos. Sci. Technol. 2003, 63, 2293–2300. [Google Scholar]

- Namini, A.S.; Delbari, S.A.; Asl, M.S.; Le, Q.V.; Shokouhimehr, M. Characterization of reactive spark plasma sintered (Zr, Ti)B2–ZrC–SiC composites. J. Taiwan Inst. Chem. Eng. 2021, 119, 187–195. [Google Scholar] [CrossRef]

- Akarsu, M.K.; Akin, I. Mechanical properties and oxidation behavior of spark plasma sintered (Zr, Ti)B2 ceramics with graphene nanoplatelets. Ceram. Int. 2020, 46, 26109–26120. [Google Scholar] [CrossRef]

- Jin, H.; Meng, S.H.; Zhang, X.H.; Zeng, Q.X.; Niu, J.H. Effects of oxygen partial pressure on the oxidation of ZrB2–SiC–graphite composites at 1800 °C. Ceram. Int. 2016, 42, 6480–6486. [Google Scholar] [CrossRef]

- Ga, X.H.; Qiu, X.L.; Li, X.T.; Theiss, W.; Chen, B.H.; Guo, H.X.; Zhao, T.H.; Liu, G. Structure, thermal stability and optical simulation of ZrB2 based spectrally selective solar absorber coatings. Sol. Energy Mater. Sol. Cells 2019, 193, 178–183. [Google Scholar] [CrossRef]

- Ding, J.C.; Lee, D.; Mei, H.J.; Zhang, T.F.; Kang, M.C.; Wang, Q.M.; Kim, K.H. Influence of Si addition on structure and properties of TiB2–Si nanocomposite coatings deposited by high–power impulse magnetron sputtering. Ceram. Int. 2019, 45, 6363–6372. [Google Scholar] [CrossRef]

- Yuan, J.Y.; Zhang, Z.Z.; Yang, M.M.; Guo, F.; Men, X.H.; Liu, W.M. TiB2 reinforced hybrid–fabric composites with enhanced thermal and mechanical properties for high–temperature tribological applications. Tribol. Int. 2017, 115, 8–17. [Google Scholar] [CrossRef]

- Xia, M.; Feng, Y.; Tian, P.; Song, Z.K.; Zhao, L.; Cai, C.Y. Quantitative Analysis of TiB2 Particles and Properties of Cu-TiB2 Composite Prepared by in Situ Reaction. Rare Metal Mat. Eng. 2017, 46, 3260–3266. [Google Scholar]

- Bakhit, B.; Palisaitis, J.; Thörnberg, J.; Rosen, J.; .Persson, P.Å.; Hultman, L.; Petrov, L.; .Greene, J.E.; Greczynski, G. Improving the high-temperature oxidation resistance of TiB2 thin films by alloying with Al. Acta Mater. 2020, 196, 677–689. [Google Scholar] [CrossRef]

- Shestakov, V.A.; Gudyma, T.S.; Krutskii, Y.L.; Uvarov, N.F. Determination of the optimal temperature range for synthesis of B4C–TiB2 and B4C–ZrB2 powder composite materials. Mater. Today 2020, 31, 506–508. [Google Scholar] [CrossRef]

- Asl, M.S.; Kakroudi, M.G.; Nayebi, B. A fractographical approach to the sintering process in porous ZrB2–B4C binary composites. Ceram. Int. 2015, 41, 379–387. [Google Scholar]

- Niu, H.; Zhu, Y.; You, N.; Wang, Y.; Cheng, H.; Luo, D.; Tang, M.; Zhang, J. Effects of TiB2 Particles on the Microstructure Evolution and Mechanical Properties of B4C/TiB2 Ceramic Composite. Materials 2021, 14, 5227. [Google Scholar] [CrossRef]

- Lin, X.; Ai, S.H.; Feng, Y.R.; Gao, D.Z.; Guo, X.; Liu, Y.; Xie, B.Y.; Gong, H.Y.; Zhang, Y.J. Fabrication and properties of in–situ pressureless–sintered ZrB2/B4C composites. Ceram. Int. 2017, 43, 15593–15596. [Google Scholar] [CrossRef]

- He, R.J.; Jing, L.; Qu, Z.L.; Zhou, Z.L.; Ai, S.G.; Kai, W. Effects of ZrB2 contents on the mechanical properties and thermal shock resistance of B4C–ZrB2 ceramics. Mater. Des. 2015, 71, 56–61. [Google Scholar] [CrossRef]

- He, R.J.; Zhou, Z.L.; Qu, Z.L.; Cheng, X.M. High temperature flexural strength and oxidation be-havior of hot–pressed B4C–ZrB2 ceramics with various ZrB2 contents at 1000–1600 °C in air. Int. Refract. Met. H 2016, 57, 125–133. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.G.; Vanmeensel, K.; Vleugels, J. Powder synthesis and densification of ultrafine B4C–ZrB2 composite by pulsed electrical current sintering. J. Eur. Ceram. Soc. 2014, 34, 1923–1933. [Google Scholar] [CrossRef]

| Sintering Process | Vickers Hardness (GPa) | References |

|---|---|---|

| Pressureless–sintered, 2100 °C, 60 min | 30.2 | [36] |

| Pressureless–sintered, 2100 °C, 60 min | 34.2 | [37] |

| Pressureless–sintered, 2150 °C, 60 min | 33.2 | [12] |

| HP, 1950 °C, 30 MPa, 60 min | 34.6 | [38] |

| HP, 1950 °C, 30 MPa, 60 min | – | [39] |

| HP, 1950 °C, 30 MPa, 30 min | 35.22 | [9] |

| HP, 2000 °C, 30 MPa, 60 min | 33 | [4] |

| SPS, 1700 °C, 32 MPa, 10 min | 31.28 | [5] |

| SPS, 2000 °C, 30 MPa, 3 min | 32.33 | [40] |

| SPS, 1700 °C, 50 MPa, 6 min | 41.2 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, J.; Wang, J.; Yang, H.; Liu, Z.; Yu, C.; Li, X.; Deng, C.; Zhu, H. Improvement of Mechanical Properties of Composites with Surface Modified B4C for Precision Machining. Materials 2023, 16, 882. https://doi.org/10.3390/ma16020882

Ding J, Wang J, Yang H, Liu Z, Yu C, Li X, Deng C, Zhu H. Improvement of Mechanical Properties of Composites with Surface Modified B4C for Precision Machining. Materials. 2023; 16(2):882. https://doi.org/10.3390/ma16020882

Chicago/Turabian StyleDing, Jun, Jintao Wang, Hao Yang, Zhenglong Liu, Chao Yu, Xiangcheng Li, Chengji Deng, and Hongxi Zhu. 2023. "Improvement of Mechanical Properties of Composites with Surface Modified B4C for Precision Machining" Materials 16, no. 2: 882. https://doi.org/10.3390/ma16020882

APA StyleDing, J., Wang, J., Yang, H., Liu, Z., Yu, C., Li, X., Deng, C., & Zhu, H. (2023). Improvement of Mechanical Properties of Composites with Surface Modified B4C for Precision Machining. Materials, 16(2), 882. https://doi.org/10.3390/ma16020882