3.2. Performance of the HTC Process

The

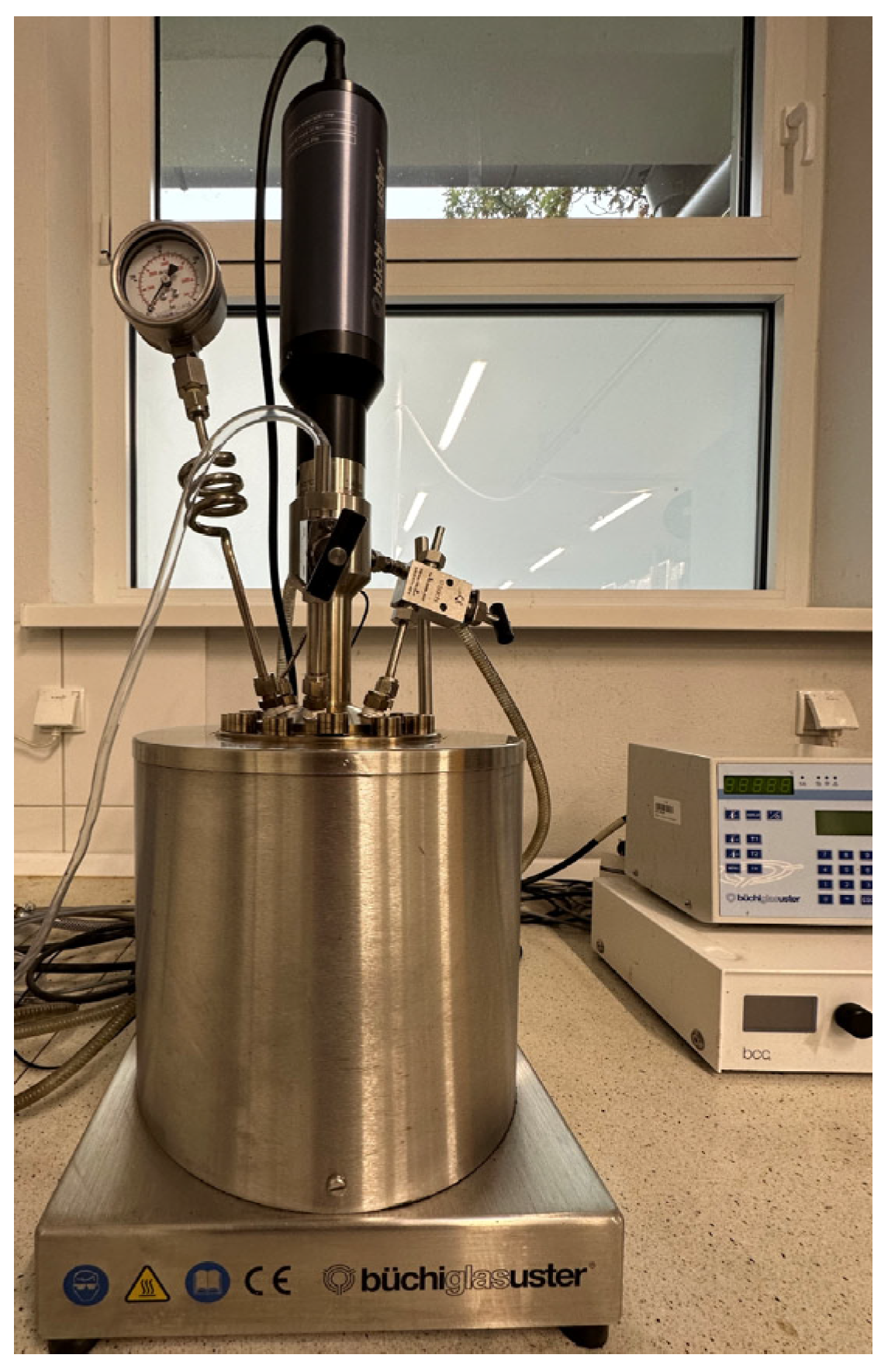

SS was processed in the reactor with a total volume of 600 mL. The material inside the reactor was heated to specific temperatures with the same power, and the heating rates varied from 3.98 to 5.46 °C × min

−1. The heating rate differed depending on the setpoint temperature, and obtained differences might have been the result of the used PID controller characteristics and possible occurrence of endo/exothermal reactions during material decomposition. After the end of the process, the reactor was cooled down to temperatures of around 45 °C, with heating rates varying from 1.82 to 3.24 °C × min

−1 (

Table 2).

For each process, 220 g of wet

SS was used. Due to the moisture content of

SS being 82.2%, the mass of total solids in the reactor was 39.16 g. As a result of the HTC process, the process slurry and process gas were obtained. The slurry consisted of solids particles (

HC) and liquids (process water). In

Table 2, the mass yields (

MY) of each product are summarized. The mass yields refer to the initial mass of wet

SS used for the HTC. Results show that with increasing temperature and process time, solids

MY decreased from 11.45% to 3.97% in favor of liquid fraction, for which an increase in

MY was observed from 64.73% to 73.57% for 180 °C, 30 min, and 300 °C, 180 min, respectively (

Table 2). The change in

MY of produced gas did not show any specific trend; therefore, it can be assumed that an increase in temperature and process time results in the conversion of solid matter to liquid more than to gas. Also, the pressure of the process increased with higher temperatures, reaching the average of 89 bars for 300 °C, 180 min (

Table 2). The obtained pressure values correspond well with the information given by Nizamuddin et al. [

49], according to whom pressure during the HTC ranges from 20 to 100 bars.

Figure 2 presents an example of the process development regarding changes in the temperatures of the heating jacket inside the reactor and the pressure.

The average heating rate was 4.85, 5.23, and 3.89 °C × min−1 for 180, 240, and 300 °C, respectively. The cooling rate increased with both temperature and time, reaching the average of 2.04, 2.83, and 3.14 °C × min−1 for 180, 240, and 300 °C, respectively.

Graphs visualizing the average patterns of temperature and pressure during the process of HTC for different parameters are summarized in

Appendix B (

Figure A1,

Figure A2,

Figure A3,

Figure A4,

Figure A5,

Figure A6,

Figure A7 and

Figure A8). According to the graphs, pressure depended on the set temperature, which confirms the reports given in the literature [

50]. The increase in pressure was related to temperature, headspace in the reactor, and the amount of gas being produced during HTC, hence the process of material decomposition.

3.3. Fuel Properties of Hydrochars

Generally, the temperature of the HTC process has a more considerable influence on

HC’s fuel properties and pressure generated during the process than retention time [

36]. Conducted research showed that in the case of

SS, the effect was not significant in the case of time variations (

Table 3) (

Table A1,

Table A2,

Table A3 and

Table A4).

The

VM content decreased significantly (

p < 0.05) from both raw

SS and

HC derived at 180 °C in 30 min to

HC derived at 300 °C in 180 min, reaching the lowest value of 56% (

Table 3,

Table A1). The lower the

VM content, the higher quality of the fuel, because

VM leads to tar production; hence, problems within combustion systems occur [

51]. A decrease in

VM content was also observed by other researchers. For example,

VM content of

HCs derived from waste straw decreased with both temperature and residence time [

52], at the same time being higher than results obtained from

SS in this study. Results obtained by Sobek et al. [

52] were also lower than

VM content in

HC obtained from

SS in 30 min 180 and 240 °C, reaching 70.50 and 63.25%, respectively. When compared to coal, which contains up to 44% of

VM, the results are still not satisfying [

53,

54].

The

FC content decreased in comparison with raw

SS and was the highest (4.20%) for

HC derived at 300 °C in 180 min, and the upward trend can be observed as well (

Table 3). The increase in the

FC content is due to the temperature increase, which causes the devolatilization process of

VM, hence the increase in the amount of remaining solid carbon [

55]. Received results are very low when compared with lignite coarse coke (69.90% of

FC), and high levels of

FC are in favor [

56,

57]. Furthermore, in the research conducted by Lee et al. [

53], the

FC in

HCs derived from

SS was 11.43% and 13.52% for temperatures of 180 °C and 240 °C, respectively.

SS contains a lot of cellulose, hemicellulose, and lignin (87% on average) due to the high quantity of toilet paper, which is the paramount organic component of municipal sewage, and it is assumed that toilet paper contains approximately 85% cellulose [

58]. Research conducted by Demirbaş [

59] suggests that the hemicellulose, cellulose, and lignin ratio influence the FC content, with cellulose being the component that decreases the

FC parameter. Therefore, it may be concluded that

SS used for this research contains even more cellulose than the approximate values.

FR of all obtained

HCs was <2.5 (

Table 3), which indicates that the material can be satisfactorily used in pulverized fuel-burning systems [

60]. It can be also observed that the

FR increased with temperature rise. No statistically significant differences were observed for time changes (

p > 0.05) (

Table A3).

The presence of alkali metals in ash may cause damage in combustion installations [

60]. Furthermore, the higher the

AC, the more waste is generated during combustion. Therefore, the

AC is an important indicator of fuel quality. The highest

AC was noted for the

HC derived at 300 °C in 180 min (~40%) (

Table 3), which implies that the process of HTC and temperature increase result in higher

AC values. Even higher results for hydrothermally treated

SS were obtained by Wilk et al. [

61], with

AC of 52.04% for

HC derived at 200 °C in 120 min. The change in

AC is the result of two reasons, namely, extracting inorganics from the matrix of biomass into the water, hence removing it from the solid fraction, and organic matter breaking down into the liquid phase, resulting in decreased

MY, hence densifying the ash in the

HC [

62]. For comparison,

HC derived from dead leaves at a temperature of 240 °C in 30 min contained 19.19% of ash, and

HC derived from watermelon peel at 260 °C in 60 min contained 5.33% of ash [

63,

64]. This proves the statement posed by Syed-Hassan et al. [

16] that

SS, on average, is characterized by a much higher

AC than coal and other types of biomasses.

The

C content increased after hydrothermal treatment, as well as due to the increased temperature of the process, reaching the maximum of almost 49% for

HC derived at 300 °C in 90 min with an increase of 5.20 percent points concerning raw

SS (

Table 1,

Table 4). The increase in

C content is caused by decaying carbon bonds on the surface of biomass and volatilization or degradation of

H and

O-reach compounds [

53].

No significant differences were observed for

H content values (

p > 0.05) (

Table A6); values decreased with temperature and duration time increase. The lowest

H value was noted for

HC derived at 300 °C in 30 min (

Table 4). Noticeably, the

O content intensely decreased, reaching the minimum of 0.51% for

HC derived at 300 °C in 90 min (

Table 4). Similar tendencies for

C,

H, and

O contents are commonly observed for

HC derived from different materials, such as chicken manure, dairy manure, swine manure, and food waste [

36,

60,

65]. The statistically significant effects of temperature and time on the change in elemental composition are given in

Appendix A in

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9.

During the thermochemical process of biomass decomposition, many reactions take place. Among others, general reactions like decarbonization, dehydrogenation, and deoxygenation result in mass loss of

C,

H, and

O [

66]. Therefore, though the elemental composition of

HCs changes, the content of particular elements is relative, and the relative increase or decrease in specific elements’ percentage share depends on processed material and courses of particular reactions taking place during HTC. The fact that some reactions took place during the HTC process can be found using the van Krevelen diagram (

Figure 3).

The diagram was introduced in 1950 by D.W. van Krevelen to help understand coal thermochemical processes, where reactions like dehydration, dehydrogenation, decarboxylation [

67], decarbonylation, demethylation, and demethanation take place [

68]. Those reactions result in the production of liquid and gas products (respectively, H

2O, H

2, CO

2, CO, CH

3, and CH

4) shifting molecular ratios in specific directions [

68]. It is well known that HTC leads to a decrease in

H/

C and

O/

C ratios, which is mainly due to reactions of dehydration and decarboxylation [

69]. Though separate reaction mechanisms are well known, the reaction network during HTC is not fully understood. The relative significance and the course of particular reactions primarily depend on the type of processed material and process conditions [

70]. In

Figure 3, the molecular ratios for obtained

HCs are presented with a visualization of ratios expected for common solid biofuels [

71] and general vectors of chemical reactions [

68]. In general, the lower the ratios of

H/

C and

O/

C, the better the fuel quality of the material [

69].

For studied

SS, the molar ratios of

H/

C and

O/

C were 1.77 and 0.25, while for obtained

HCs, these values varied from 1.61 to 1.50 and from 0.16 to 0.01. As a result, they did not fit into any common solid biofuel group (

Figure 2). It can be seen that with increasing temperature and retention time, both molar ratios decreased as a result of carbonization. The

H/

C ratios were similar to the initial value; however, the significant decrease in the

O/

C ratio may indicate the intensive deoxygenation processes mostly caused by the decarboxylation and dehydration—a loss of two atoms of oxygen in each molecule. Similarly to the result of Jellali et al. [

72], the main reaction responsible for the carbonization (the increase in

C content) with increasing temperature was dehydration (-H

2O). The higher degree of

O/

C ratio decrease than in the case of

H/C may indicate that the HTC process may be pretreatment before the gasification with a high yield of H

2, and CO in the syngas, but it requires further investigation. The obtained results are partly in agreement with other studies. In the work of Mendoza Martinez et al. [

73], the primary sludge was hydrothermally carbonized at temperatures of 180–240 °C for 3 h and pressure of 10–35 bar. The atomic ratios of

SS (

H/

C and

O/

C) were 1.84 and 0.78, while for

HCs, atomics ratio decreased to 1.62 and 0.67 (a smaller degree of the

O/

C ratio decrease than in the present research). Mendoza Martinez et al. [

73] also found that the main reaction pathways with increasing temperature of HTC were dehydration (-H

2O) and demethylation (-CH

3), while the role of decarboxylation (−CO

2) was relatively small, which is opposite in the present research. In the work of Wang et al. [

69], organic sludge was hydrothermally carbonized at temperatures of 180–240 °C and retention times of 60–240 min. Though the sludge was characterized by high initial values of atomic ratios

H/

C and

O/

C, respectively, 2.08 and 0.58, a similar decreasing trend with increasing temperature and retention time of the HTC process was found. Wang et al. [

69] also found that the dominant effect on the organic sludge dehydration was the temperature, while the retention time effect was negligible.

The

N content decreased with the temperature increase, significantly (

p < 0.05) falling from about 3.80% for raw

SS (

Table 1) to about 2.50% for

HC derived at 300 °C in 180 min (

Table 4). Those values are lower than the results obtained by Lee et al. [

53], where

HC derived from

SS at 180 °C and 240 °C in 30 min contained 6.78% and 7.15% of

N, respectively. However, the

N content in

HC obtained from sweet potato waste and fruit waste was lower [

66,

74].

As for the S content, there were no significant changes (

p > 0.05) (

Table A8) with temperature and time increase, and the average value was 2.76% (

Table 4). Generally, the amounts of N and S in

SS are considerably higher in comparison with other biomass materials, in which the average share of N reaches 0.94% and S 0.24% [

16]. The high contents of those elements pose challenges and threats related to SOx and NOx emissions [

51,

55]. According to Yao et al. [

75], the S content in solid fuel obtained during HTC is one of the limiting factors for its energy use. Additionally, it has been observed that the S content in soils tends to decrease [

76]. While this is an essential component, its deficiencies result in, among others, delayed plant growth, discoloration, and smaller leaves [

77]. Furthermore, S availability improves N uptake by plants. High amounts of S and N in obtained

HC may suggest further use in soil fertilization. This could also refer to the liquid fraction obtained during the HTC process, as it was proved that some valuable nutrients, such as phosphorus and nitrogen, are solubilized into the liquid phase, which creates a possibility for the recovery of these compounds [

78].

HHV is described as the highest possible energy being released through the process of one fuel unit’s full oxidation [

79]. As shown in

Figure 4, an increase in both temperature and HTC duration time had a positive influence on the HHV.

The lowest

HHV was noted for

HC derived at the lowest HTC parameters (180 °C, 30 min), reaching less than 22 MJ × kg

−1, whereas

HC obtained at the highest parameters of 300 °C and 180 min was characterized by the highest result (~24.02 MJ × kg

−1). The difference between the highest

HHV result and the

HHV of raw

SS was 3.07 MJ × kg

−1. A similar phenomenon was observed by Volpe et al. [

50], who treated

SS with HTC at 190 °C and 210 °C in 60 min and 180 min.

HHV for

SS and all treated samples remained stable, reaching ~16.50 MJ × kg

−1. The reason for such behavior may be the increase in the content of inorganic material. The

HHV value of obtained

HCs may be considered high. For comparison,

HHV of

HC derived from yard waste at temperatures of 160–200 °C in a retention time of 120–1440 min was 15.72–24.59 MJ × kg

−1 [

80].

LHV is useful when determining the real energy potential of biomass and refers to the amount of heat being released during complete combustion, including vaporization heat of the water that remains in the product [

55,

81]. The same tendency for the

HHV was observed for the

LHV (

Figure 4). The highest

LHV (dry basis) was noted for

HC derived at 300 °C in 180 min, with the result of 22.71 ± 0.07 MJ × kg

−1. For comparison, the average

LHV of food/yard waste and textiles is 14.60 MJ × kg

−1 and 19.09 MJ × kg

−1, respectively [

81].

LHV, as received, ranged from 0.82 MJ × kg

−1 for

HC derived at 300 °C in 180 min to 2.69 MJ × kg

−1 for

HC derived at 180 °C in 30 min. Differences between particular values were significant, especially for higher temperatures (

p < 0.05) (

Figure 4,

Table A11).

3.4. Hydrochar and HTC Energy Yields

Higher pressure of the processes led to lower

HC yield, which can be seen in

Figure 5.

MY was the highest (~63%) for

HCs derived at the lowest temperature (180 °C), and the lowest (less than 21%) for the highest temperature (300 °C). The described decrease in

MY may be caused by the process of decarboxylation, which is in accordance with the significant

O/

C ratio decrease, forming organic matter, which is soluble in water. Decomposition and depolymerization of cellulose and hemicellulose present in

SS lead to enhanced generation of the liquid and gaseous products of HTC [

58,

82].

The same tendency and very similar results were obtained in the case of the

EY, which describes the amount of energy remaining in

HC. A decrease in the

EY occurs due to the decomposition and conversion of material into liquid and gas products [

83]. The boundary values were ~67% and ~25%. This dependence has also been observed in the literature. For instance, Lee et al. (2019) [

53] noted that a temperature increase from 180 °C to 270 °C led to a decrease in

MY from 93.13% to 40.78%. The same phenomenon was observed for

HC derived from beet pulp [

61]. However, in both cases,

MY was higher compared to results obtained during this research, and the decrease was not so considerable. Li et al. (2022) [

65] observed a decrease in both

MY and

EY for

HC obtained from animal manures, with the lowest values reaching ~20%, hence similar to those obtained in this study. These results suggest that, in terms of

MY and

EY, HTC of

SS is not the most optimal route for its conversion, and that the temperature of the process should be lower to prevent the release of organic matter into a liquid fraction.

EDr describes the changes in the energy content of

HC concerning the raw material. As shown in

Table 5,

EDr increased with both time and temperature.

The lowest value was obtained for HC derived at 180 °C in 30 min (~104%), and the highest value for

HC was derived at 300 °C in 180 min (~114%). This tendency was also observed for

HC derived at 180, 200, and 220 °C in 60, 120, 180, and 240 min from beet pulp. The highest

EDr was seen for the highest process parameters and reached 147% [

61]. Those values suggest that the results of

EDr obtained in this study are relatively low.

In general,

EG tends to increase with increasing time and temperature of the process [

43]. However, here, the highest

EG was obtained for

HC derived at 240 °C in 180 min (almost 22%), and the lowest for

HC derived at 300 °C in 30 min (~8%) (

Table 5).

HC derived from eucalyptus tree residues at temperatures 250–300 °C in time of 20–60 min had

EG in the range of 51–63%. Previously conducted research on chicken manure in the same process parameters showed that

EG can reach up to 97.60% [

36]. Therefore, it may be concluded that the results obtained in this research are not satisfactory in the case of both

EDr and

EG.

As presented in

Figure 6, the energy usage (

Eu) increased with both temperature and time, reaching over 1300 kJ × g

−1.

However, the most considerable increase was observed for processes conducted at 300 °C. The highest result was over nine times higher than the lowest result obtained for the

HC derived at 180 °C in 30 min. Energy usage of the HTC process relative to the unit of energy available in the unit of dry

HC obtained after the process (

Eue) was also calculated (

Figure 7). The same tendency for energy usage relative to the mass of dry

HC was observed, with the highest result of over 50 J × J

h−1.

Statistically significant differences were mainly noted for energy usage by processes conducted at 300 °C (

Table A16 and

Table A17). The difference between 300 °C and lower temperatures can also be seen in

Figure 6 and

Figure 7. This suggests that the HTC process of

SS should be conducted at lower temperatures to provide profitability. For comparison, the chicken manure processed using the same reactor, sample size, and operating conditions (temperature, time) was characterized by much smaller energy consumption concerning the produced

HC [

36]. To produce 1 g of

HC from chicken manure, from 75 to 425 kJ is needed for 180–30 and 300–180 variants, respectively, while to produce 1 J of energy in

HC requires from 5 to 18 J [

36]. This shows that feedstock properties are an important factor affecting the energy efficiency of the HTC process.

However, it has to be noted that this research, as well as [

36], was conducted at a laboratory scale; thus, the heat loss was high, especially for the 300 °C variant. At the industrial scale, the HTC process would be less energy-demanding due to better isolations and the presence of heat exchangers between input feedstock and output slurry. In addition, the review works of [

84,

85,

86] showed that it can be cost-effective to combine HTC with the anaerobic digestion (AD) of

SS, which is usually implemented in the wastewater treatment plant. The SS is converted into biogas for electricity and heat production, while digestate is future-processed in HTC to produce solid fuel using residual heat from the combined heat and power unit (CHP). Moreover, the HTC process water can be reversed to the AD process, increasing methane production [

84,

85,

86]. Though more research is needed on the economic aspects of the combined HTC and AD, the work of Merzari et al. [

84] showed that a positive energy balance of HTC–AD can be found for 180–200 °C and 15–30 min. At higher temperatures and longer times, the process water can become toxic and hard to biodegrade in AD [

84]. This, and the fact that in this research the highest

MY and

EY with the lowest energy demands were found at 180 °C, indicates a need for further optimization research in a temperature range of 160–200 °C combined with parallel AD of HTC process waters and its effect on methane production.