Rapid Spheroidization Process of S Phase (Al2CuMg) in the As-Cast 2024 Al Alloy Induced by High-Energy Electropulsing

Abstract

:1. Introduction

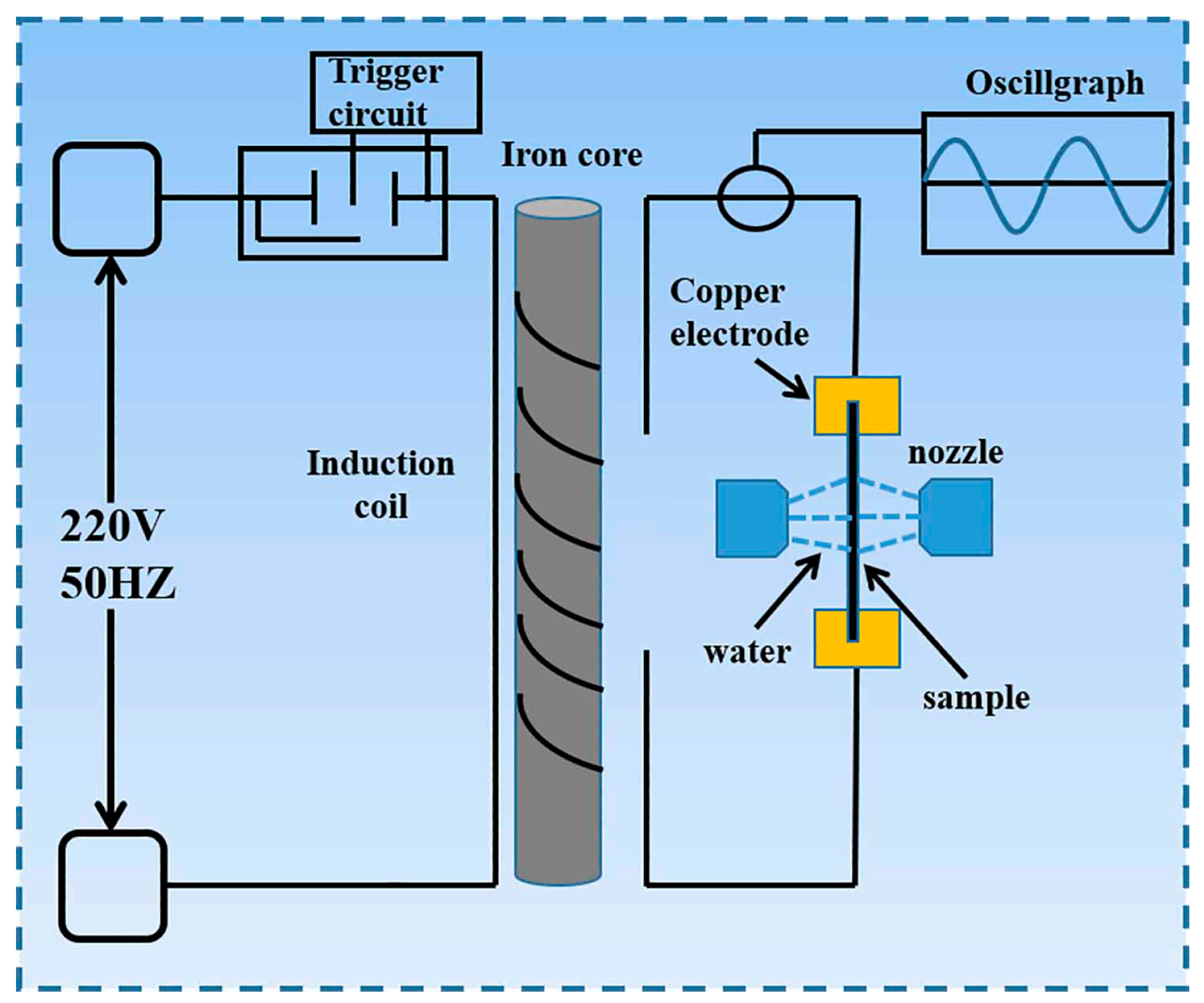

2. Materials and Methods

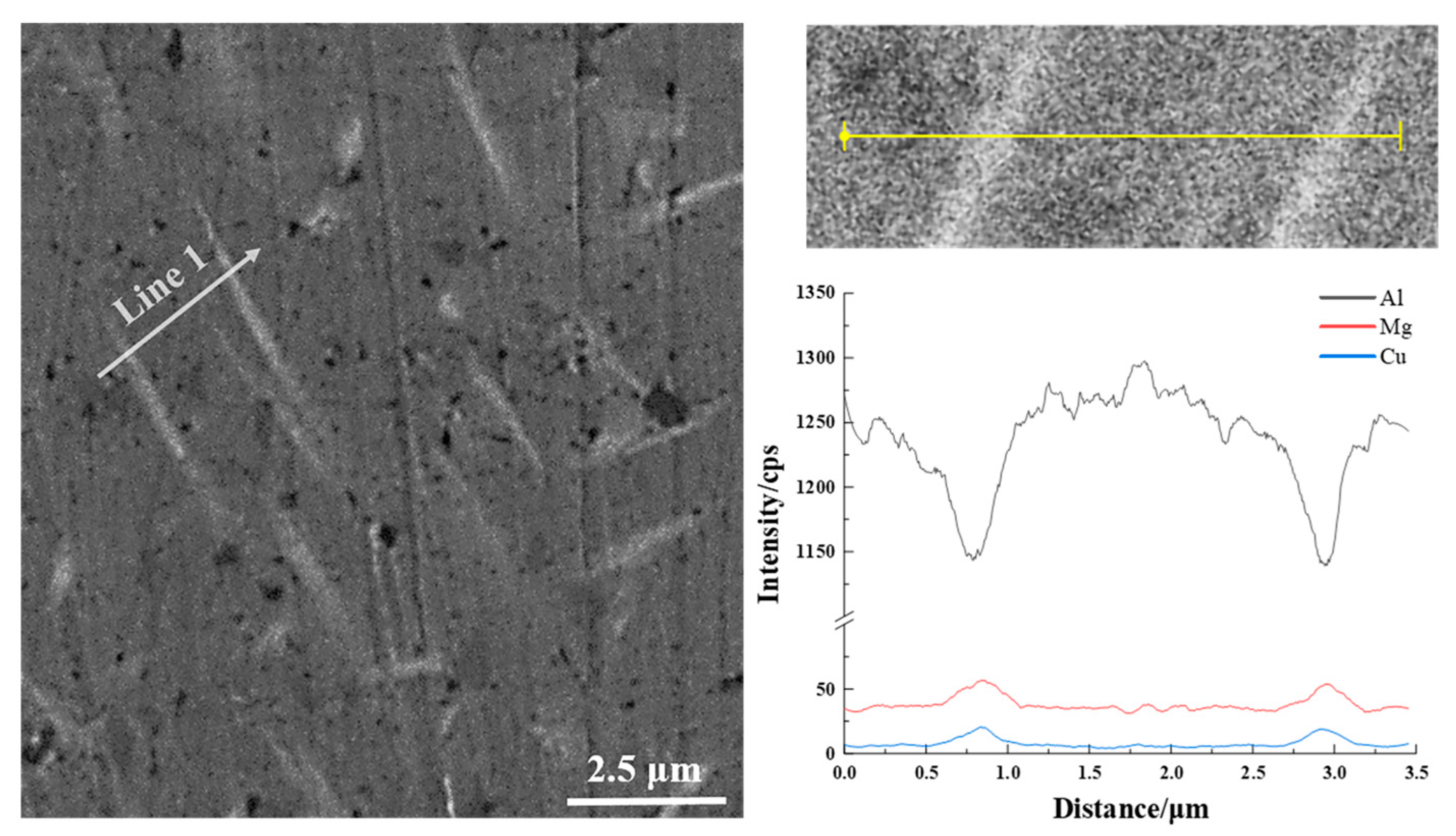

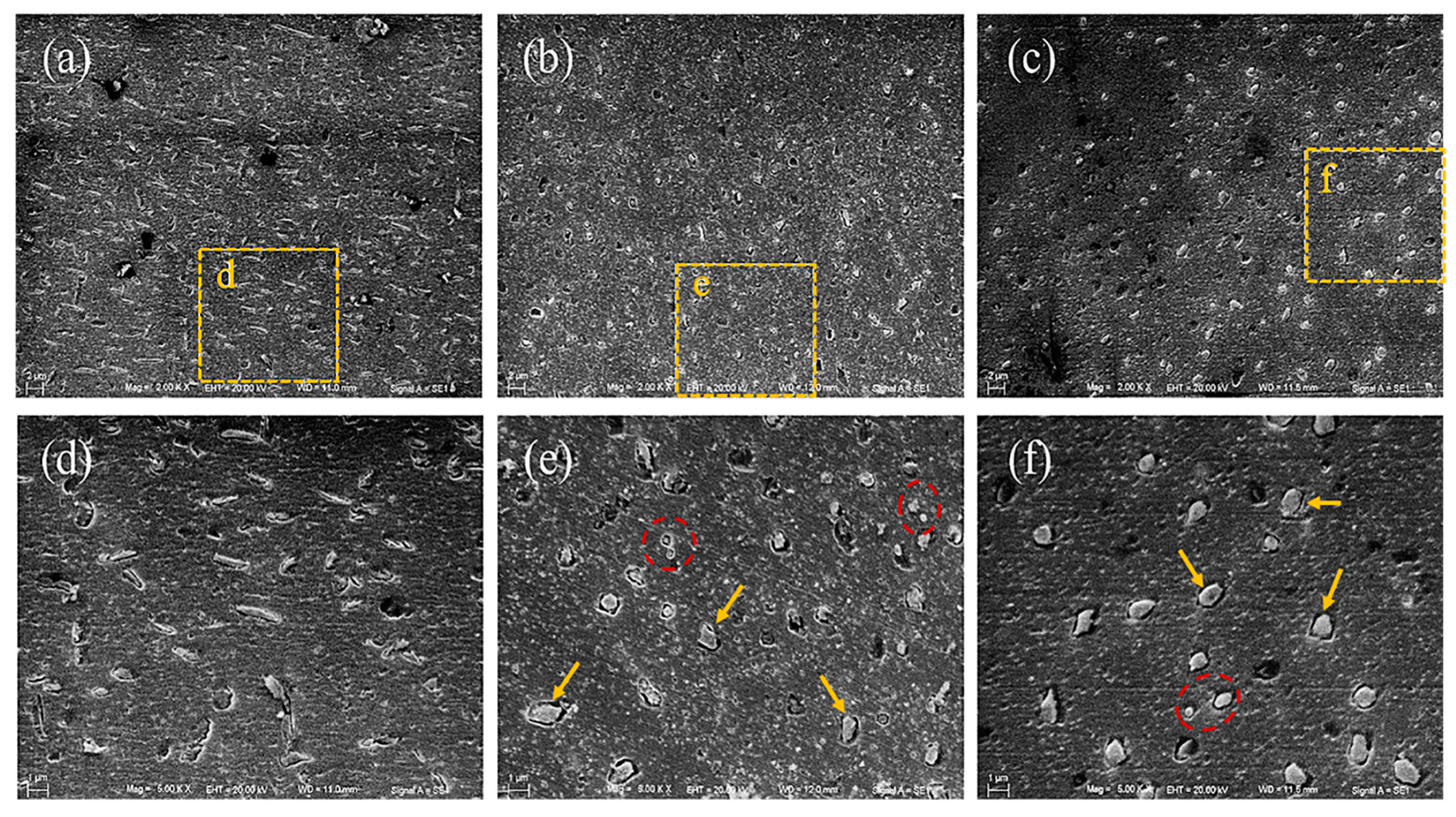

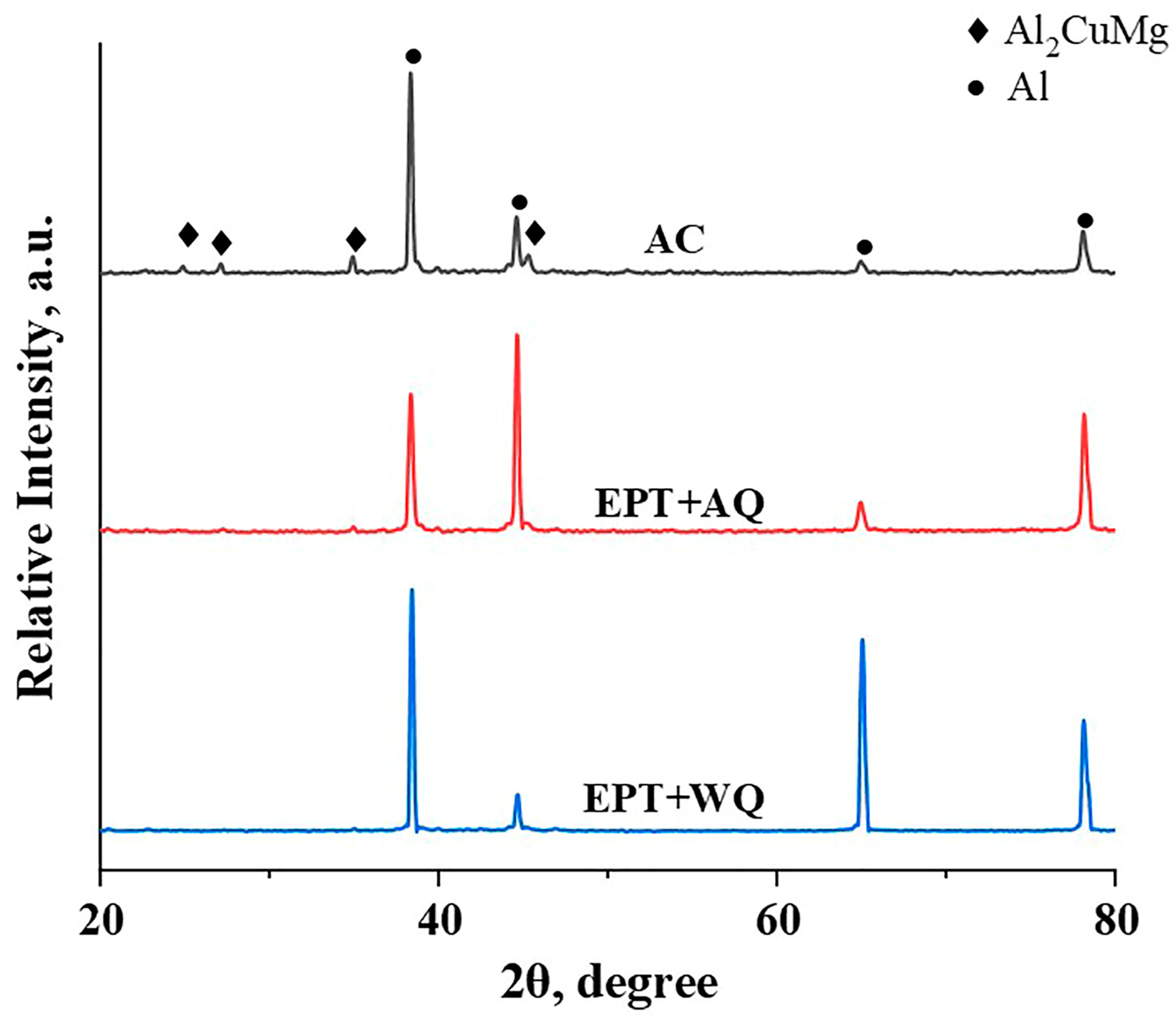

3. Results and Discussion

4. Conclusions

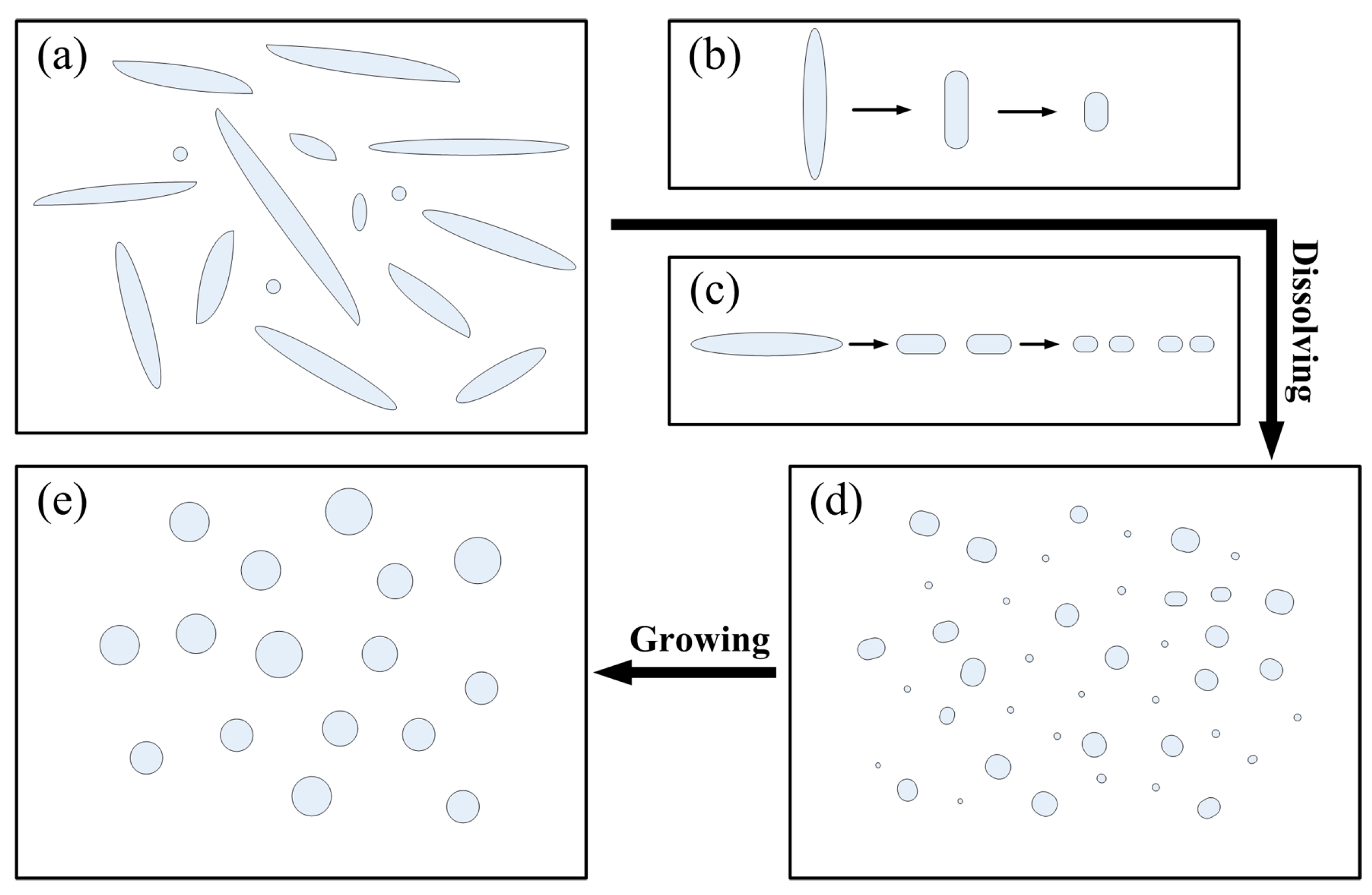

- The second-phase (Al2CuMg) dissolution could be precisely controlled by EPT, and the morphology of the second phase was transformed from a rod-like shape to a spherical shape. For the different cooling methods, the EPT + AQ sample has a more regular shape than the EPT + WQ sample.

- The athermal effect of the electropulsing treatment reduces the solid solution temperature of the second phase and promotes the diffusion of the alloying elements, thereby enabling the second phase to dissolve rapidly at a lower temperature.

- The dissolution behavior of the second phase with two different orientations during electropulsing treatment was simulated using ANSYS software (2021 R1). For the second phase oriented perpendicular to the current, the current dissolves the tip of the second phase rapidly. In contrast, the second phase parallel to the current direction will start to dissolve from the middle, thus splitting the rod-like grains into dispersions with lower aspect ratios. The second phase of other orientations proceeds on the basis of the combined action of these two mechanisms.

- The sphericity of the second phase in the EPT + AQ sample is higher than that of the EPT + WQ sample, which is a result from the spheroidization and growth of the second-phase grains due to the residual thermal and compression fields during the air cooling, which leads to a higher sphericity of the second phase in the samples of EPT + AQ.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, M.; Yang, W.; Tian, X.; Chen, L.; Hou, H.; Zhao, Y. Precipitation and refining of Al2Cu in graphene nanoplatelets reinforced 2024 Al composites. Mater. Charact. 2023, 200, 112854. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, H.; Liu, J.; Dan, C.; Ma, S.; Wang, H.; Chen, Z. Enhancing mechanical properties and improving mechanical anisotropy of rolled 2024 Al sheet by TiB2 nanoparticles. Mater. Sci. Eng. A 2023, 874, 145077. [Google Scholar] [CrossRef]

- Gairola, S.; Jayaganthan, R. Influence of heat treatment, microstructure evolution, and damage mechanism on high cycle fatigue behaviour of additively manufactured Ti-modified Al 2024 alloy. Mater. Charact. 2023, 203, 113047. [Google Scholar] [CrossRef]

- Mondou, E.; Proietti, A.; Charvillat, C.; Berziou, C.; Feaugas, X.; Sinopoli, D.; Blanc, C. Understanding the mechanisms of intergranular corrosion in 2024 Al alloy at the polycrystal scale. Corros. Sci. 2023, 221, 111338. [Google Scholar] [CrossRef]

- Zhu, C.; Zhao, Z.; Zhu, Q.; Wang, G.; Zuo, Y.; Li, Q.; Qin, G. Hot-top direct chill casting assisted by a twin-cooling field: Improving the ingot quality of a large-size 2024 Al alloy. J. Mater. Sci. Technol. 2022, 112, 114–122. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, M.; Liu, C.; Wang, L.; Chen, H.; Dan, C.; Ma, S.; Chen, Z.; Wang, H. Enhancing mechanical properties of uniformly distributed nano TiB2/2024 Al composite rolling sheet by pre-stretch aging. J. Alloys Compd. 2022, 913, 165172. [Google Scholar] [CrossRef]

- Hillert, M. Inhibition of grain growth by second-phase particles. Acta Metall. 1988, 36, 3177–3181. [Google Scholar] [CrossRef]

- Chang, K.; Feng, W.; Chen, L.Q. Effect of second-phase particle morphology on grain growth kinetics—ScienceDirect. Acta Mater. 2009, 57, 5229–5236. [Google Scholar] [CrossRef]

- Bate, P. The effect of deformation on grain growth in Zener pinned systems. Acta Materialia 2001, 49, 1453–1461. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, G.J.; Wang, R.H.; Hu, W.; Sun, J.; Chen, K.H. Heat treatment-modulated coupling effect of multi-scale second-phase particles on the ductile fracture of aged aluminum alloys. Acta Mater. 2007, 55, 273–284. [Google Scholar] [CrossRef]

- Tayanc, M.; Aytac, A.; Bayram, A. The effect of carbon content on fatigue strength of dual-phase steels. Mater. Des. 2007, 28, 1827–1835. [Google Scholar] [CrossRef]

- Zhao, M.C.; Liu, M.; Song, G.; Atrens, A. Influence of the β-phase morphology on the corrosion of the Mg alloy AZ91. Corros. Sci. 2008, 50, 1939–1953. [Google Scholar] [CrossRef]

- Liu, C.; Xin, Y.; Tang, G.; Chu, P.K. Influence of heat treatment on degradation behavior of bio-degradable die-cast AZ63 magnesium alloy in simulated body fluid. Mater. Sci. Eng. A 2007, 456, 350–357. [Google Scholar] [CrossRef]

- Sun, G.Y.; Chen, G.; Chen, G.L. Comparison of microstructures and properties of Zr-based bulk metallic glass composites with dendritic and spherical bcc phase precipitates. Intermetallics 2007, 15, 632–634. [Google Scholar] [CrossRef]

- Jiang, Y.; Tang, G.; Shek, C.; Zhu, Y.; Xu, Z. On the thermodynamics and kinetics of electropulsing induced dissolution of β-Mg17Al12 phase in an aged Mg–9Al–1Zn alloy—ScienceDirect. Acta Mater. 2009, 57, 4797–4808. [Google Scholar] [CrossRef]

- Jiang, Y.; Guan, L.; Tang, G.; Shek, C.; Zhang, Z. Influence of electropulsing treatment on microstructure and mechanical properties of cold-rolled Mg–9Al–1Zn alloy strip. Mater. Sci. Eng. A 2011, 528, 5627–5635. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, B.; Guo, H.; Ma, J.; Yang, Q.; Song, J.S. Electropulsing strengthened 2GPa boron steel with good ductility. Mater. Des. 2013, 43, 195–199. [Google Scholar] [CrossRef]

- Xu, Q.; Guan, L.; Jiang, Y.; Tang, G.; Wang, S. Improved plasticity of Mg–Al–Zn alloy by electropulsing tension. Mater. Lett. 2010, 64, 1085–1087. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, W.; Fu, B.; Xu, H.; Luo, G.; Tang, G.; Jiang, Y. The effects of electropulsing on the recrystallization behavior of rolled pure tungsten. J. Mater. Res. 2012, 27, 2630–2638. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Zhang, Y.; Wang, Y.; Hou, H. Fast recrystallization and phase transformation in ECAP deformed Ti–6Al–4V alloy induced by pulsed electric current. J. Alloys Compd. 2019, 786, 733–741. [Google Scholar] [CrossRef]

- Zeng, W.; Shen, Y.; Zhang, N.; Huang, X.; Wang, J.; Tang, G.; Shan, A. Rapid hardening induced by electric pulse annealing in nanostructured pure aluminum. Scr. Mater. 2012, 66, 147–150. [Google Scholar] [CrossRef]

- Waryoba, D.; Islam, Z.; Reutzel, T.; Haque, A. Electro-strengthening of the additively manufactured Ti–6Al–4V alloy. Mater. Sci. Eng. A 2020, 798, 140062. [Google Scholar] [CrossRef]

- Gao, J.B.; Ben, D.D.; Yang, H.J.; Meng, L.X.; Ji, H.B.; Lian, D.L.; Chen, J.; Yi, J.L.; Wang, L.; Li, P.; et al. Effects of electropulsing on the microstructure and microhardness of a selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2021, 875, 160044. [Google Scholar] [CrossRef]

- Jiang, Y.; Tang, G.; Shek, C.; Zhu, Y. Effect of electropulsing treatment on microstructure and tensile fracture behavior of aged Mg-9Al-1Zn alloy strip. Appl. Phys. A Mater. Sci. Process. 2009, 97, 607–615. [Google Scholar] [CrossRef]

- Xu, Z.; Tang, G.; Tian, S.; He, J. Research on the engineering application of multiple pulses treatment for recrystallization of fine copper wire. Mater. Sci. Eng. A 2006, 424, 300–306. [Google Scholar] [CrossRef]

- Wei, L.; Xu, X.; Zhao, Y.; Zhou, Y.; Yan, X.; Wu, Z.; Yu, Y.; Wu, C. A shortened process of tri-modal microstructure developing in Ti-6Al-4V alloy via electropulsing-induces grain spheroidization. Mater. Charact. 2023, 205, 300–306. [Google Scholar] [CrossRef]

- Xiao, A.; Huang, C.; Cui, X.; Yan, Z.; Yu, Z. Impact of the pulse induced current on the microstructure and mechanical properties of the 7075-T6 aluminum alloy. J. Alloys Compd. 2022, 911, 165021. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys; Chapman & Hall: London, UK, 1992. [Google Scholar]

- Jiang, Y.B.; Tang, G.Y.; Shek, C.H.; Liu, W. Microstructure and texture evolution of the cold-rolled AZ91 magnesium alloy strip under electropulsing treatment. J. Alloys Compd. 2011, 509, 4308–4313. [Google Scholar] [CrossRef]

- Callister, W.D., Jr. Fundamentals of Materials Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2001; Volume 34, p. 824. [Google Scholar]

- Zhang, M.; Tian, Y.; Zheng, X.; Zhang, Y.; Chen, L.; Wang, J. Research Progress on Multi-Component Alloying and Heat Treatment of High Strength and Toughness Al-Si-Cu-Mg Cast Aluminum Alloys. Materials 2023, 16, 1065. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.; Zhang, J.; Wang, H.; Cheng, W.; Li, B.; Bai, Y. Spheroidization behavior of W phase and transformation process of LPSO phase during solid-solution treatment in Mg–Zn–Y–Mn–Ti alloy. J. Mater. Res. Technol. 2022, 21, 4940–4949. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Ma, L.; Yi, J. Effects of Solution Treatment on Microstructure and High-Cycle Fatigue Properties of 7075 Aluminum Alloy. Metals 2017, 7, 193. [Google Scholar] [CrossRef]

- Staszczyk, A.; Sawicki, J.; Adamczyk-Cieslak, B. A Study of Second-Phase Precipitates and Dispersoid Particles in 2024 Aluminum Alloy after Different Aging Treatments. Materials 2019, 12, 4168. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.F.; Liu, J.N.; Tang, G.Y.; Shi, S.Q.; Fu, M.W. Properties, microstructure and texture evolution of cold rolled Cu strips under electropulsing treatment. J. Alloys Compd. 2012, 544, 203–208. [Google Scholar] [CrossRef]

- Conrad, H. Effects of electric current on solid state phase transformations in metals. Mater. Sci. Eng. A 2000, 287, 227–237. [Google Scholar] [CrossRef]

- Jiang, Y.; Tang, G.; Shek, C.; Zhu, Y.; Guan, L.; Wang, S.; Xu, Z. Improved ductility of aged Mg-9Al-1Zn alloy strip by electropulsing treatment. J. Mater Res. 2009, 24, 1810–1814. [Google Scholar] [CrossRef]

- Sharma, G.; Ramanujan, R.V.; Tiwari, G.P. Instability mechanisms in lamellar microstructures. Acta Mater. 2000, 48, 875–889. [Google Scholar] [CrossRef]

- Sabban, R.; Bahl, S.; Chatterjee, K.; Suwas, S. Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 2019, 162, 239–254. [Google Scholar] [CrossRef]

- Kampe, J.C.M.; Courtney, T.H.; Leng, Y. Shape instabilities of plate-like structures—I. Experimental observations in heavily cold worked in situ composites. Acta Metall. 1989, 37, 1735–1745. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Ma, H.; Zhou, D. Static globularization mechanism of Ti-17 alloy during heat treatment. J. Alloys Compd. 2018, 736, 99–107. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Xu, X.; Zhao, Y.; Yan, X.; Zhou, Y.; Yu, Y.; Wu, Z. Rapid Spheroidization Process of S Phase (Al2CuMg) in the As-Cast 2024 Al Alloy Induced by High-Energy Electropulsing. Materials 2023, 16, 6939. https://doi.org/10.3390/ma16216939

Wei L, Xu X, Zhao Y, Yan X, Zhou Y, Yu Y, Wu Z. Rapid Spheroidization Process of S Phase (Al2CuMg) in the As-Cast 2024 Al Alloy Induced by High-Energy Electropulsing. Materials. 2023; 16(21):6939. https://doi.org/10.3390/ma16216939

Chicago/Turabian StyleWei, Lai, Xiaofeng Xu, Yang Zhao, Xudong Yan, Yachong Zhou, Yongqiang Yu, and Zhicheng Wu. 2023. "Rapid Spheroidization Process of S Phase (Al2CuMg) in the As-Cast 2024 Al Alloy Induced by High-Energy Electropulsing" Materials 16, no. 21: 6939. https://doi.org/10.3390/ma16216939

APA StyleWei, L., Xu, X., Zhao, Y., Yan, X., Zhou, Y., Yu, Y., & Wu, Z. (2023). Rapid Spheroidization Process of S Phase (Al2CuMg) in the As-Cast 2024 Al Alloy Induced by High-Energy Electropulsing. Materials, 16(21), 6939. https://doi.org/10.3390/ma16216939