Study on Frost Resistance and Interface Bonding Performance through the Integration of Recycled Brick Powder in Ultra-High-Performance Concrete for Structural Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

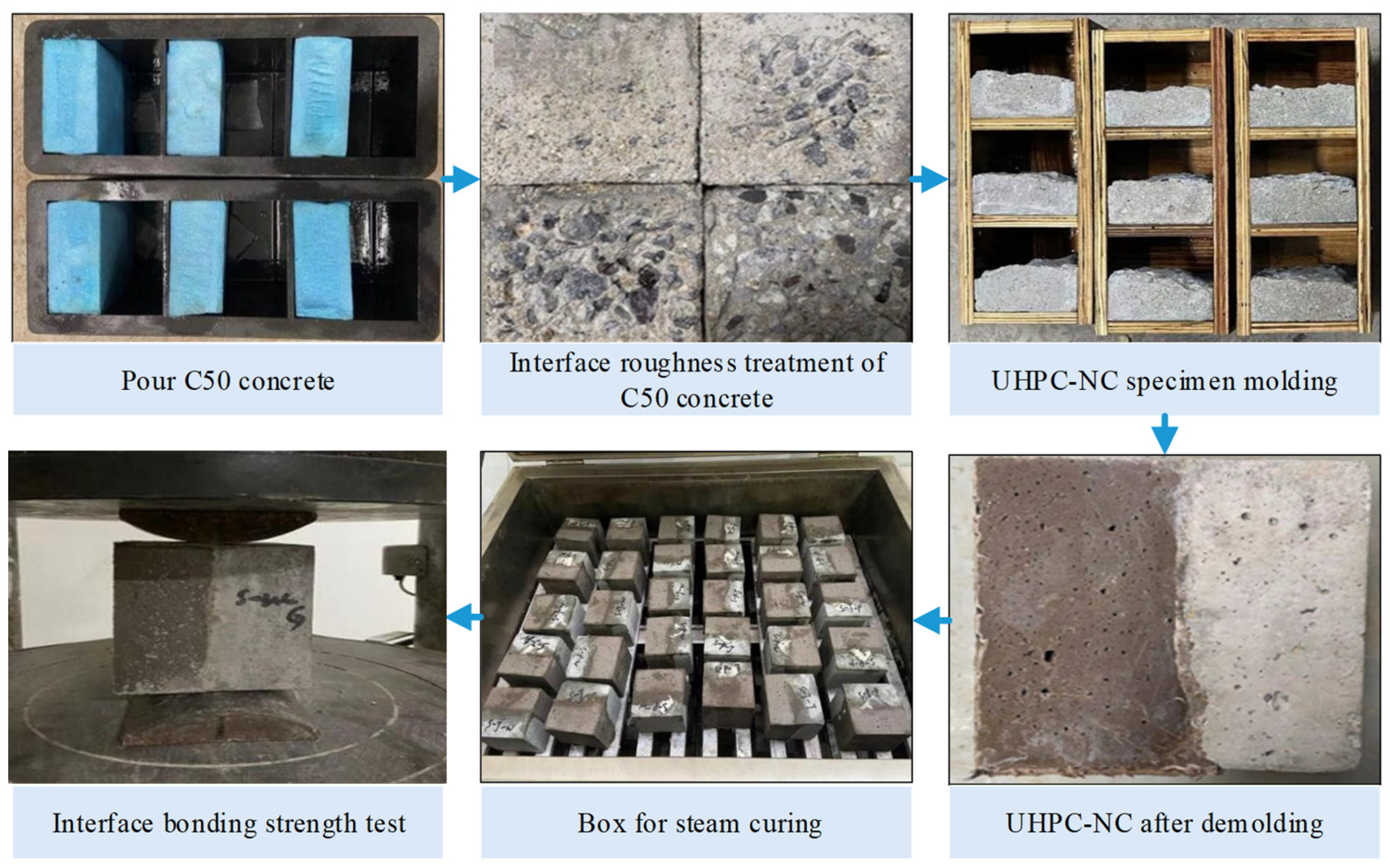

2.3. Specimens Preparing

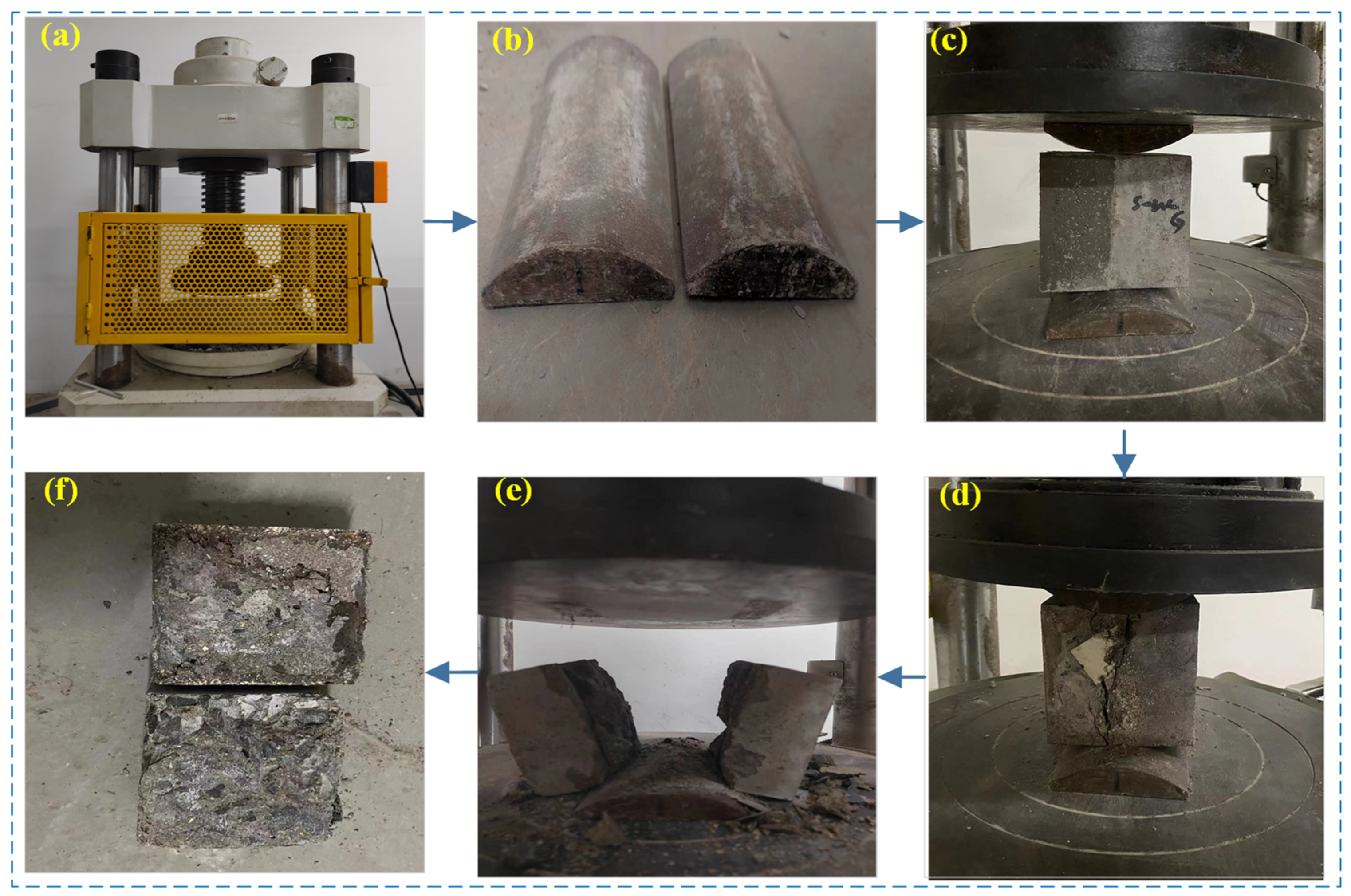

2.4. Experiment Method

2.5. Test Phenomena

3. Test Results and Analysis

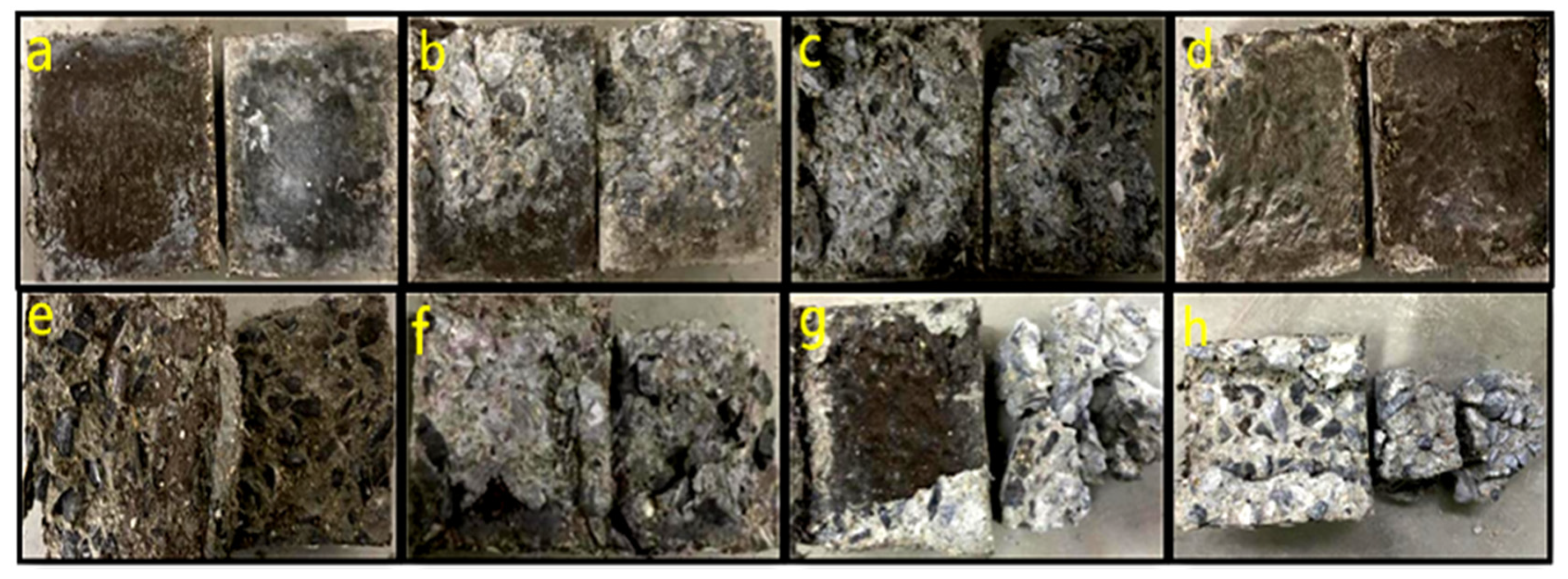

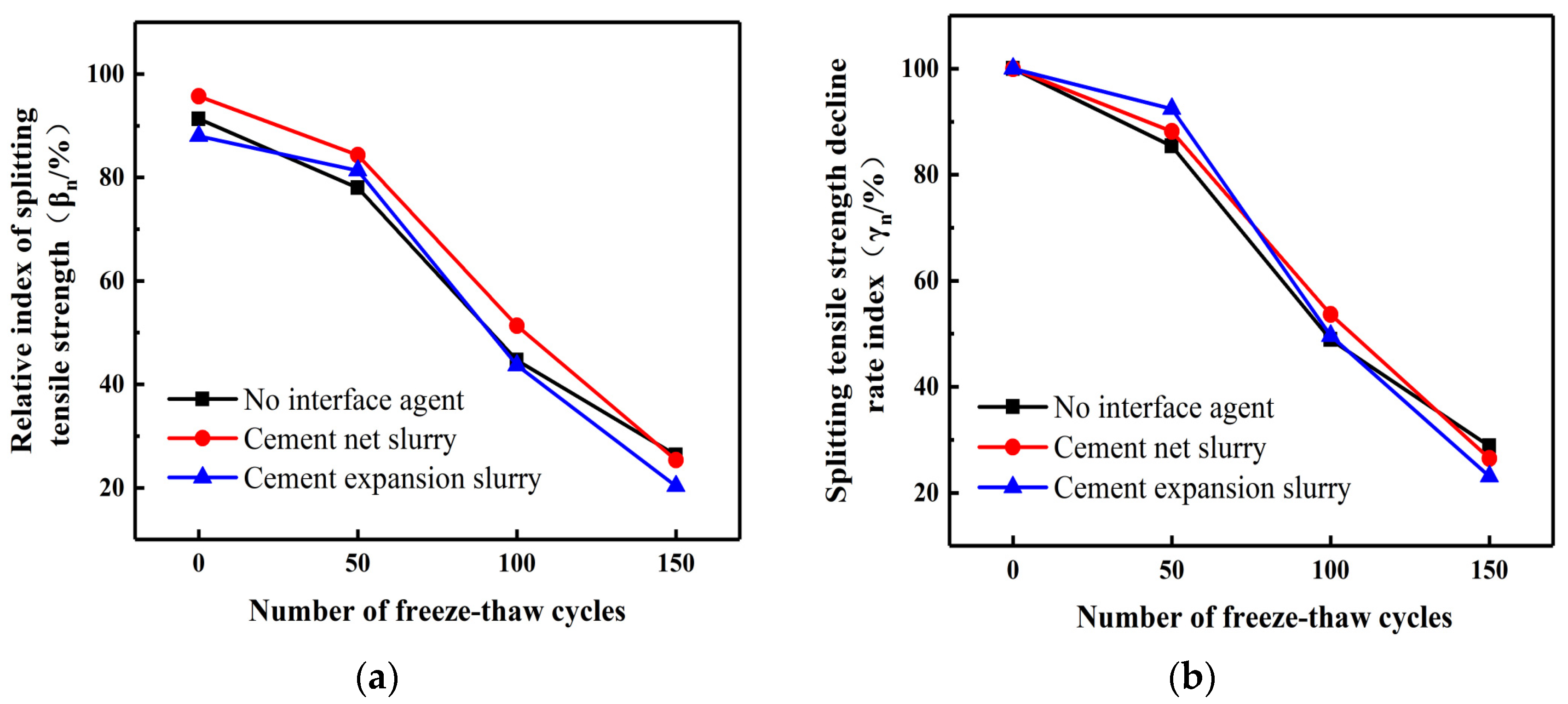

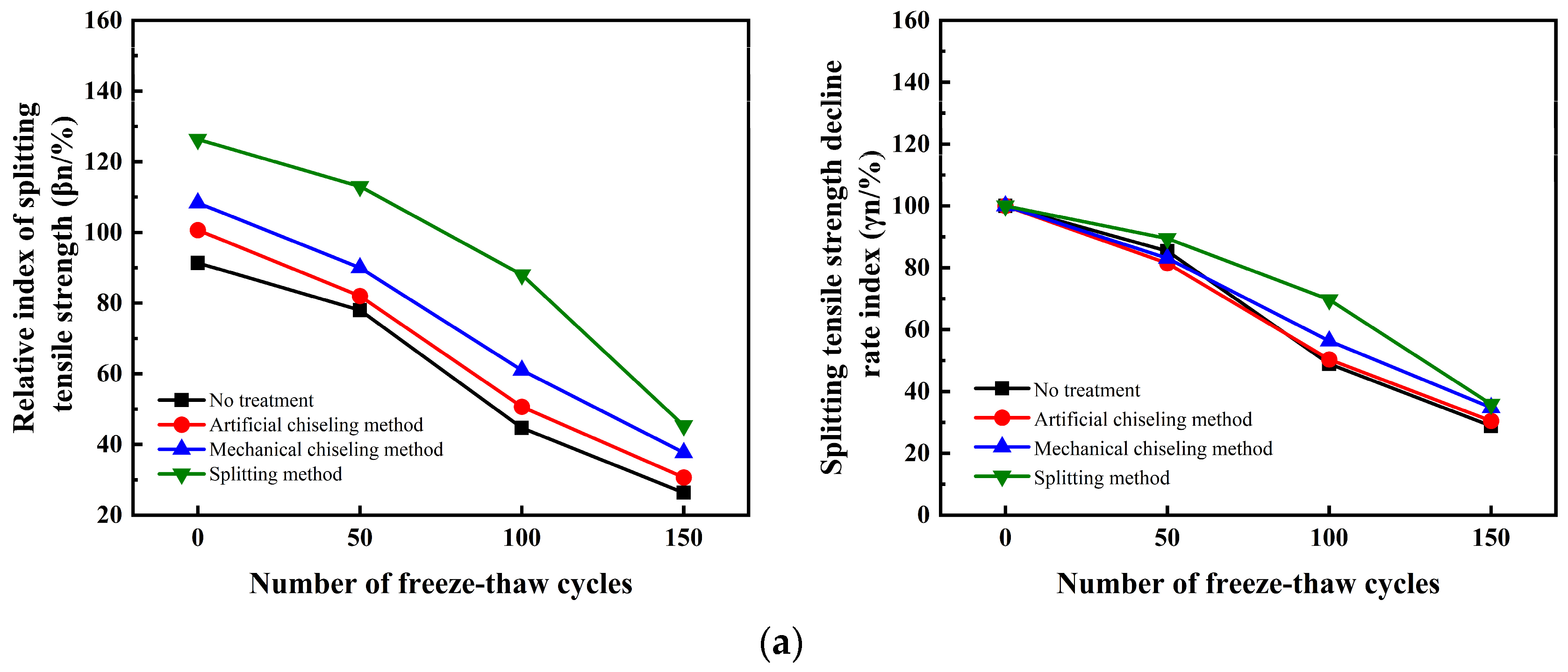

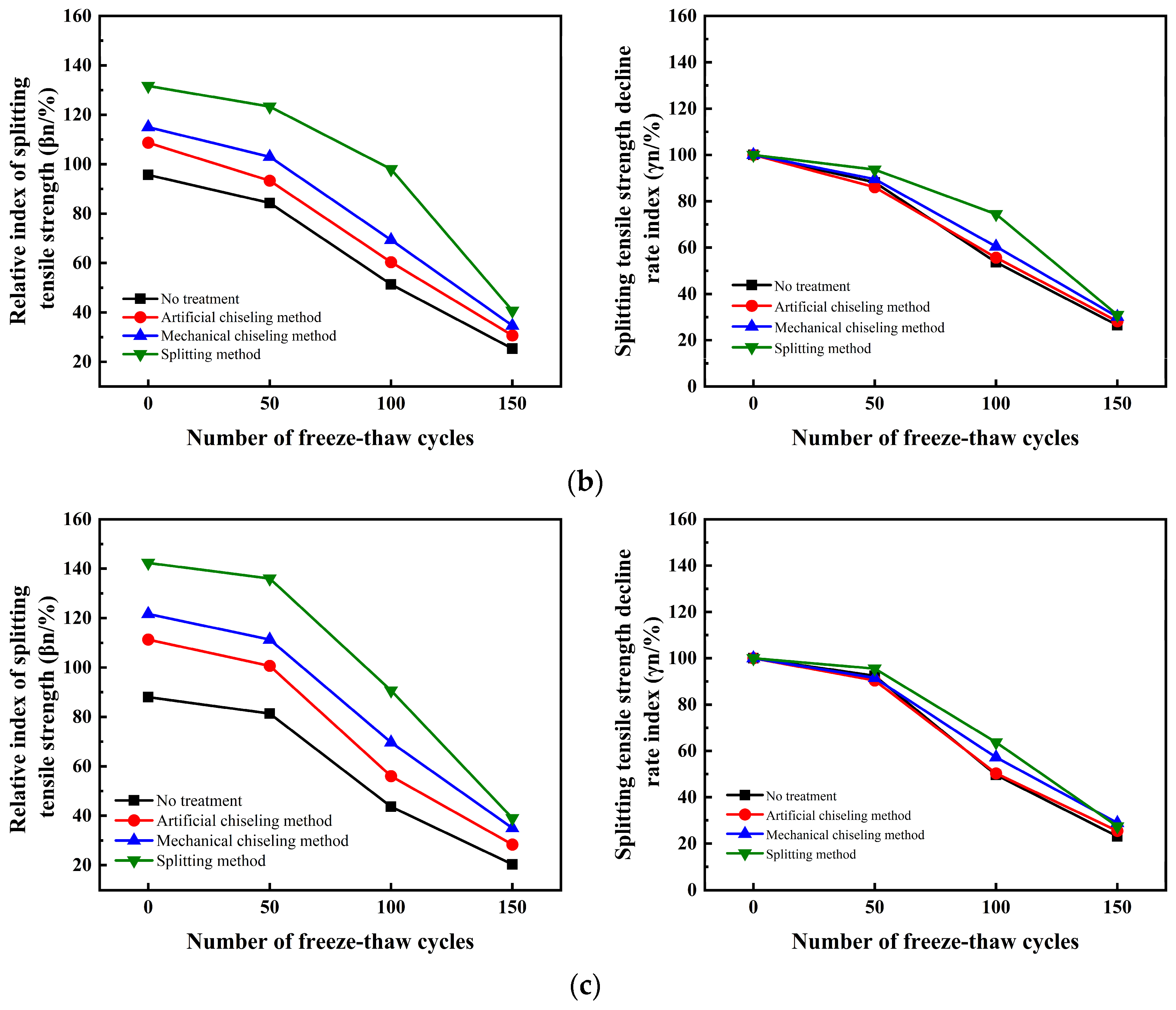

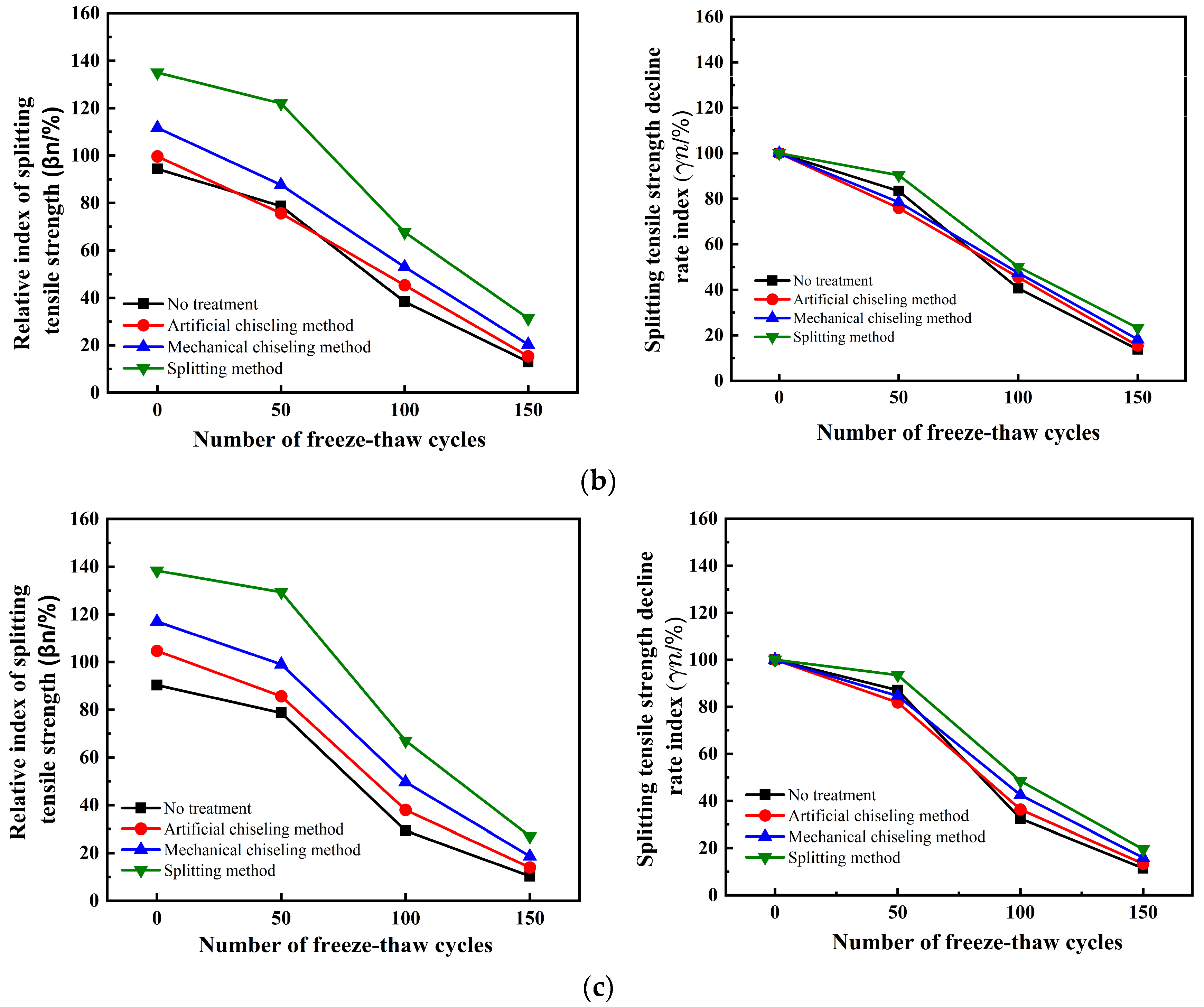

3.1. Interface Bonding Properties of RBP-UHPC-Reinforced Frost-Damaged Concrete under Water Freezing Conditions

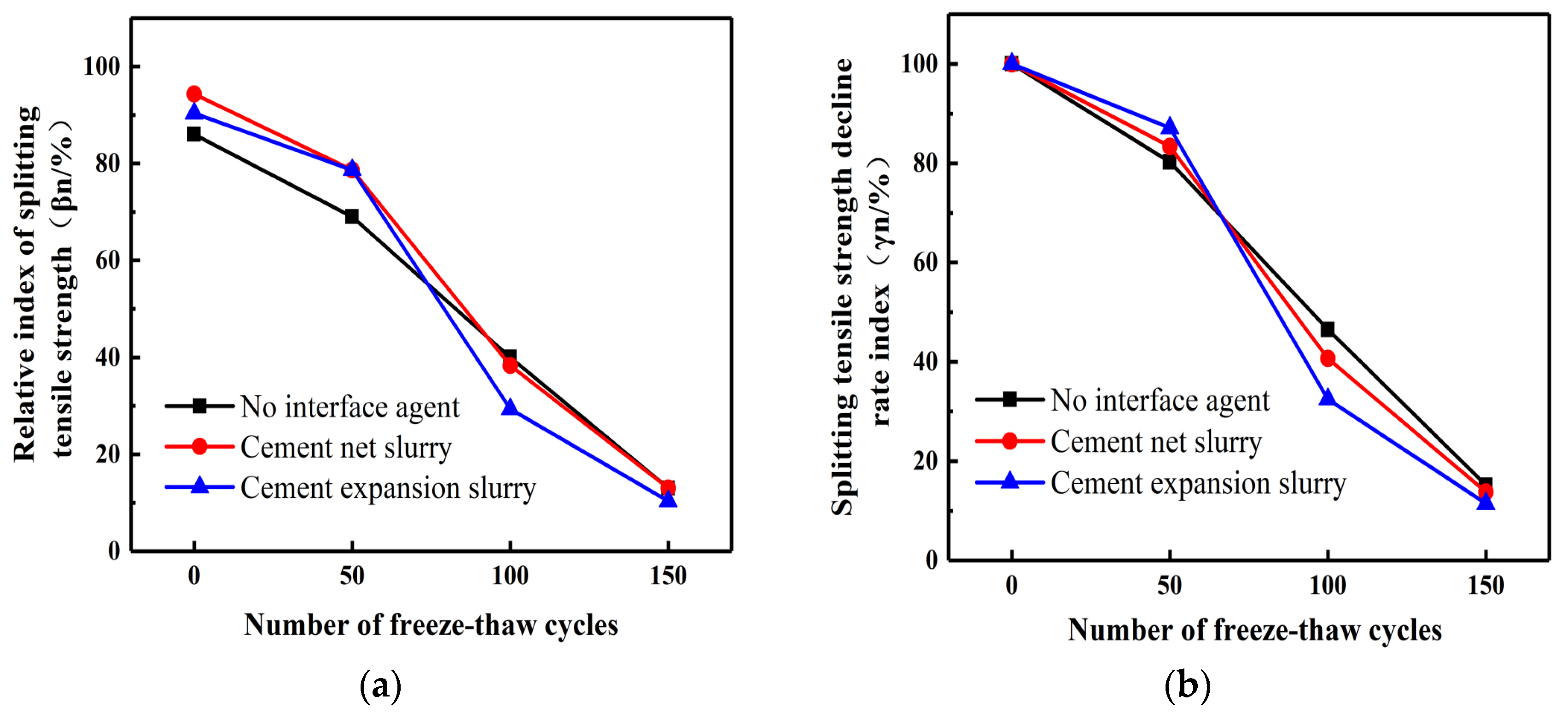

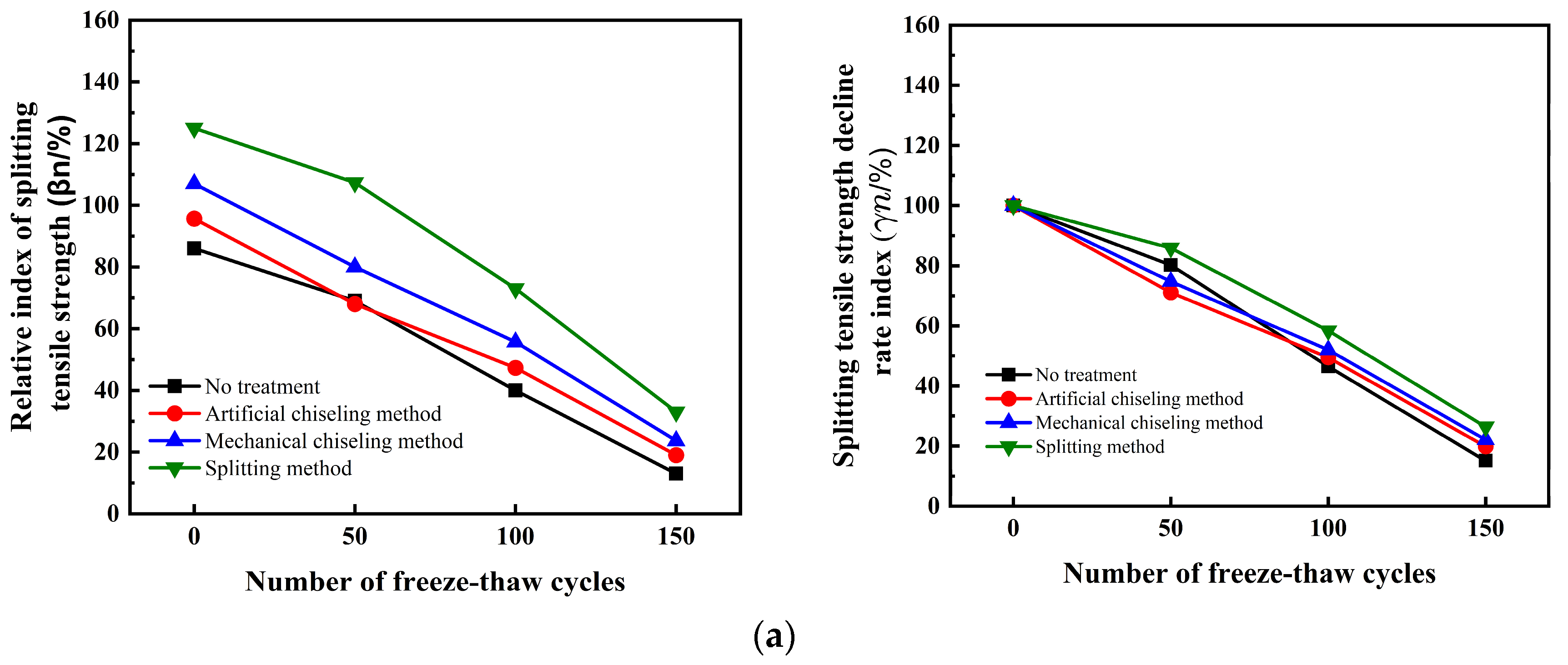

3.2. Interface Bonding Properties of RBP-UHPC-Reinforced Frost-Damaged Concrete under Salt Freezing Conditions

4. UHPC-NC Interface Bonding Strength Calculation Method

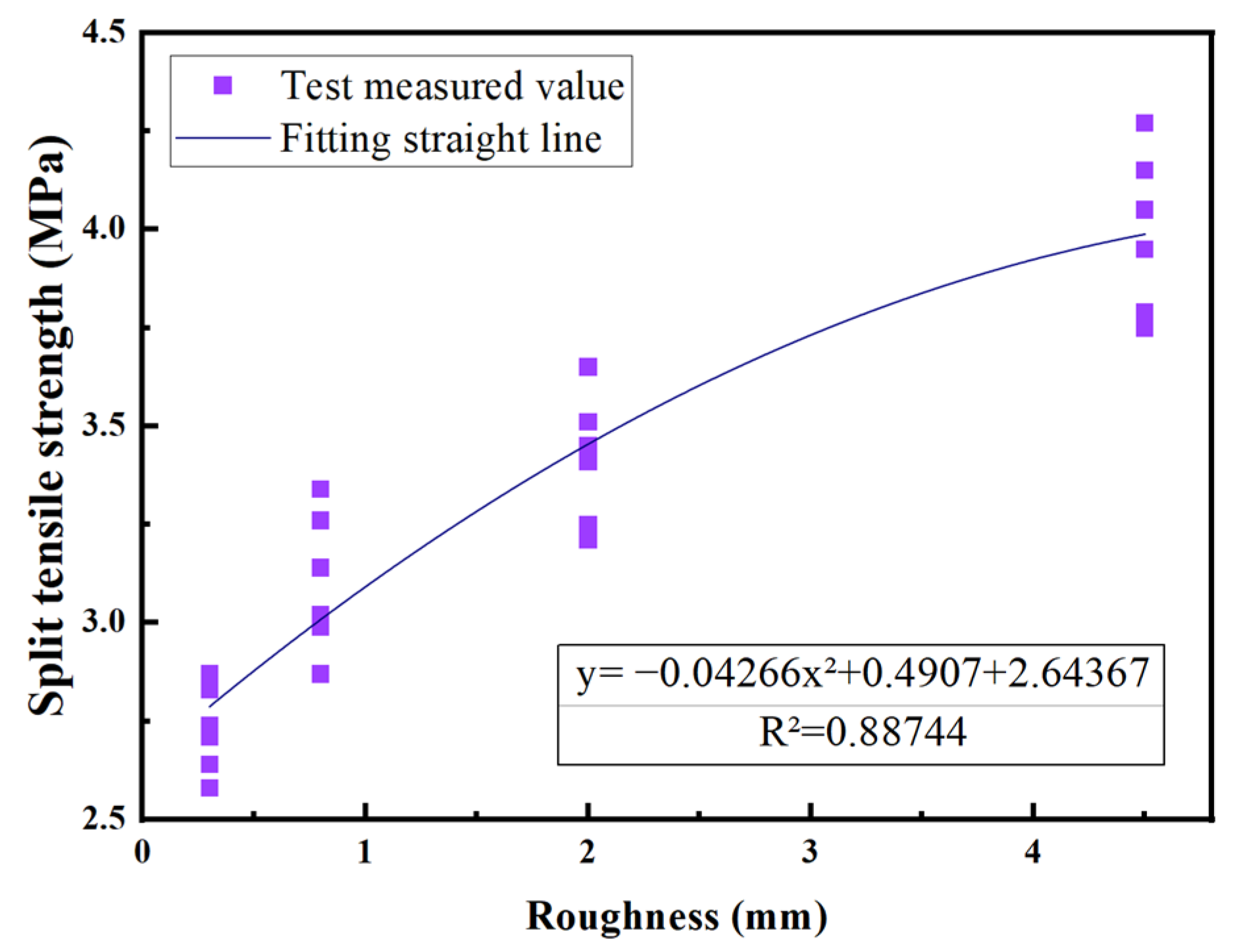

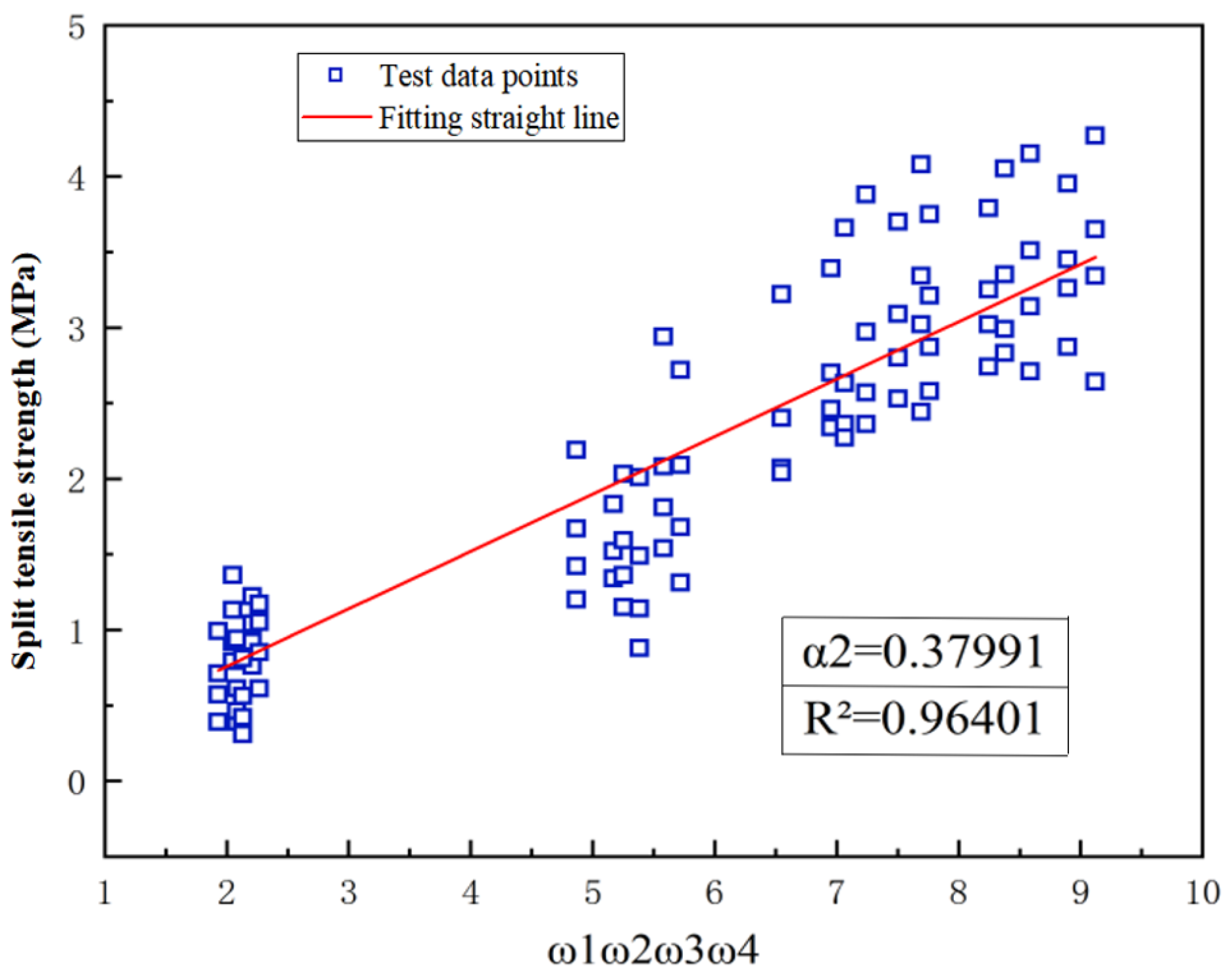

4.1. Calculation Formula of UHPC-NC Interface Bonding Splitting Strength at Room Temperature

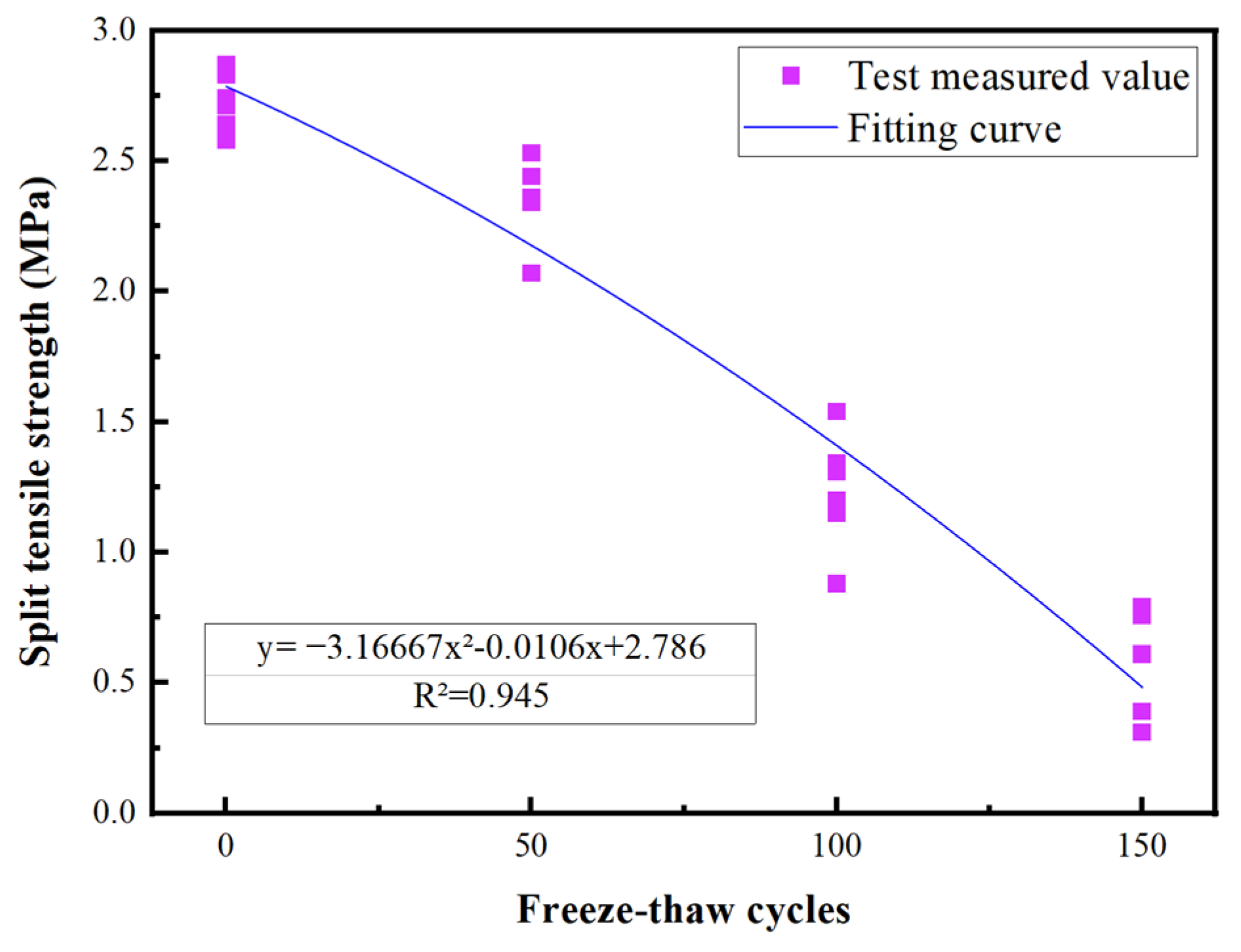

4.2. Formula for Evaluating Interface Bond Strength of UHPC-NC during Freeze–Thaw Cycling

5. Bonding Mechanism and Model Analysis

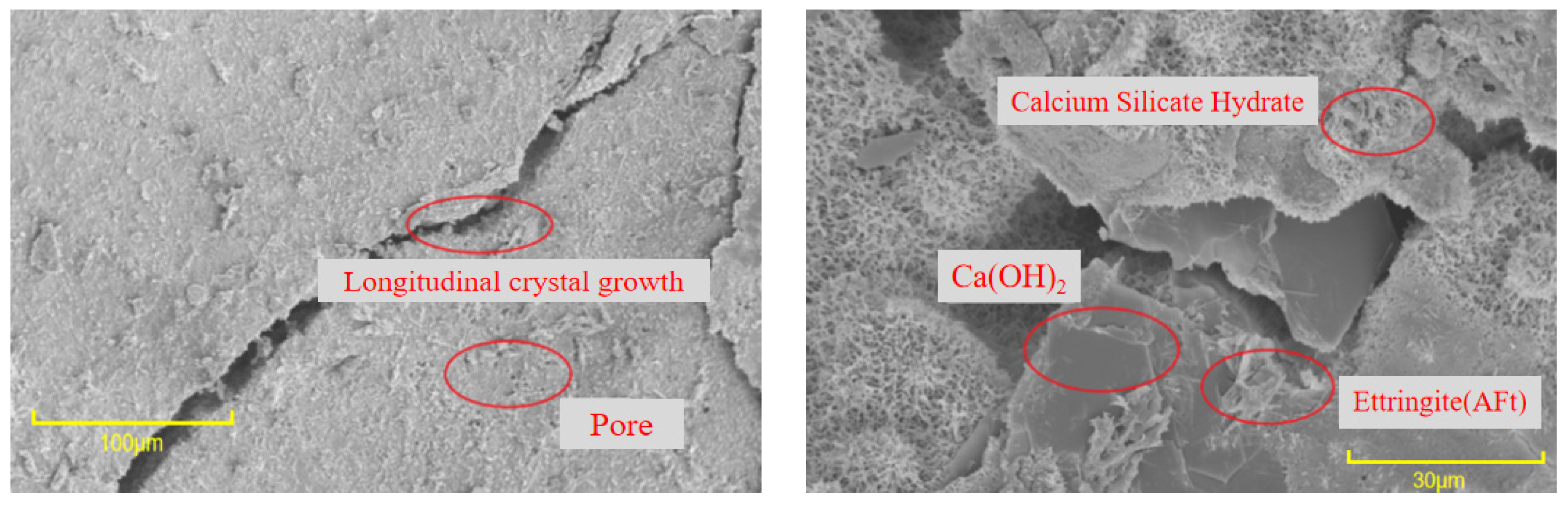

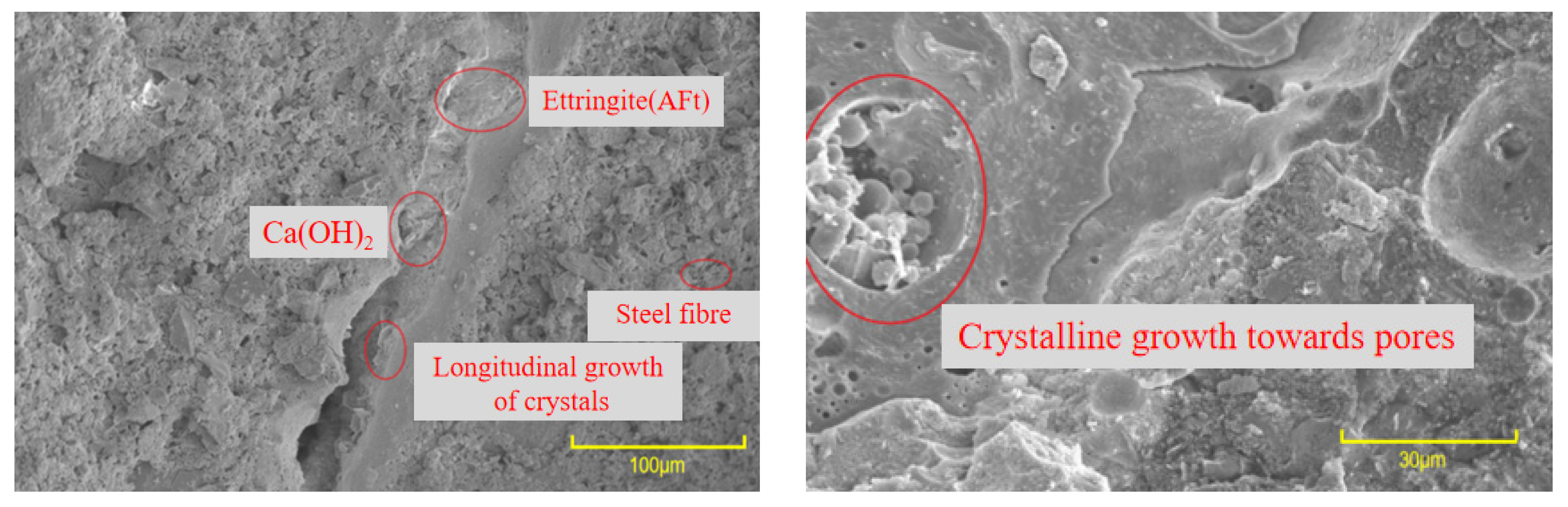

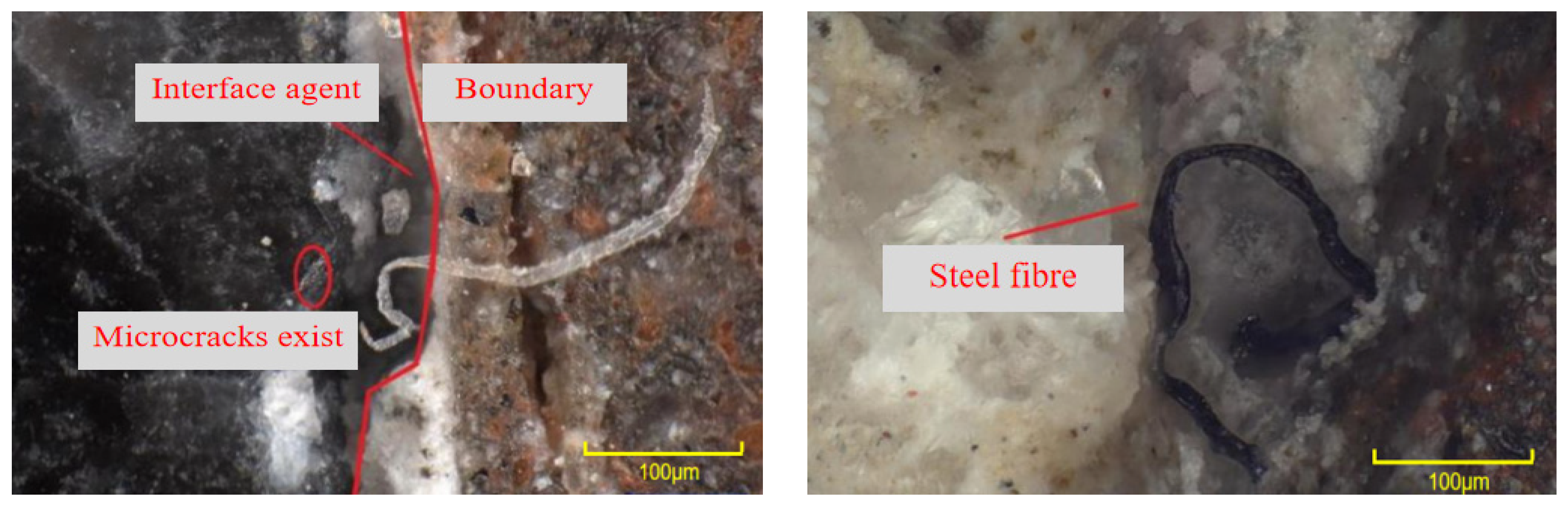

5.1. SEM Test

5.2. Bonding Model Analysis

6. Conclusions

- (1)

- Based on the findings of this study, the 30% recycled brick powder replacement rate into UHPC shows significant improvement in durability and frost resistance. The strength and relative dynamic elasticity modulus remained unchanged even after 150 freeze–thaw cycles. Therefore, the recycled brick powder UHPC can form a good adhesion with ordinary concrete, making it a valuable option for reinforcing existing frost-damaged concrete in cold areas.

- (2)

- During the initial phase of the freeze–thaw cycle, the specimens treated with the interface agent show stronger bonding at the interface as compared to specimens without the agent. However, as the number of freeze–thaw cycles increased, the beneficial impact of the interface agent on the specimens diminished gradually.

- (3)

- The bonding strength at the interface of the UHPC-NC specimens is weaker during salt freezing cycles compared to water freezing cycles. Additionally, the rate of decline in bonding strength is faster in the salt freezing environment, indicating more severe damage to the UHPC-NC specimens.

- (4)

- This study used a multi-factor formula and linear regression equation to accurately predict interface bonding strength in the UHPC-NC specimens based on factors like the interface agents used, the roughness, and the freeze–thaw conditions, aligning well with experimental results showing its accuracy.

- (5)

- Microscopic analysis of the bonding interface revealed that the bonding interface was not coated with the interface agent and showed poor bonding, due to the absence of the interface agent, large cracks, and insufficient cement hydration in the UHPC-NC. A three-zone–three-layer bonding model provides valuable insights into the intricate bonding mechanism between UHPC and NC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, X.; Chen, X.; Bai, Y.; Ning, Y.; Zhang, W. Evaluation of fracture behavior of high-strength hydraulic concrete damaged by freeze-thaw cycle test. Constr. Build. Mater. 2022, 321, 126346. [Google Scholar] [CrossRef]

- Chen, T.; Luan, Y.; Ma, T.; Zhu, J.; Huang, X.; Ma, S. Mechanical and microstructural characteristics of different interfaces in cold recycled mixture containing cement and asphalt emulsion. J. Clean. Prod. 2020, 258, 120674. [Google Scholar] [CrossRef]

- Tian, J.; Wu, X.; Zheng, Y.; Hu, S.; Ren, W.; Du, Y.; Wang, W.; Sun, C.; Ma, J.; Ye, Y. Investigation of damage behaviors of ECC-to-concrete interface and damage prediction model under salt freeze-thaw cycles. Constr. Build. Mater. 2019, 226, 238–249. [Google Scholar] [CrossRef]

- Li, X.; Xiao, S.; Gao, R.; Harries, K.A.; Wang, Z.; Xu, Q. Effects of grout sleeve defects and their repair on the seismic performance of precast concrete frame structures. Eng. Struct. 2021, 242, 112619. [Google Scholar] [CrossRef]

- Pessiki, S.; Harries, K.A.; Kestner, J.T.; Sause, R.; Ricles, J.M. Axial Behavior of Reinforced Concrete Columns Confined with FRP Jackets. J. Compos. Constr. 2001, 5, 237–245. [Google Scholar] [CrossRef]

- Alwash, D.; Kalfat, R.; Al-Mahaidi, R.; Du, H. Shear strengthening of RC beams using NSM CFRP bonded using cement-based adhesive. Constr. Build. Mater. 2021, 301, 124365. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental Tests and Reliability Analysis of the Cracking Impact Resistance of UHPFRC. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Ju, Y.; Shen, T.; Wang, D. Bonding behavior between reactive powder concrete and normal strength concrete. Constr. Build. Mater. 2020, 242, 118024. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, L.; Zhang, C.; Bangi, T. Influence of eco-friendly fine aggregate on macroscopic properties, microstructure and dura-bility of ultra-high performance concrete: A review. J. Build. Eng. 2022, 65, 105783. [Google Scholar] [CrossRef]

- Elsayed, M.; Badawy, S.; Tayeh, B.A.; Elymany, M.; Salem, M.; ElGawady, M. Shear behaviour of ultra-high performance concrete beams with openings. Structures 2022, 43, 546–558. [Google Scholar] [CrossRef]

- Nodehi, M.; Nodehi, S.E. Ultra high performance concrete (UHPC): Reactive powder concrete, slurry infiltrated fiber concrete and superabsorbent polymer concrete. Innov. Infrastruct. Solut. 2021, 7, 39. [Google Scholar] [CrossRef]

- Dobias, D.; Pernicova, R.; Mandlik, T. Water Transport Properties and Depth of Chloride Penetration in Ultra High Performance Concrete. Key Eng. Mater. 2016, 711, 137–142. [Google Scholar] [CrossRef]

- Xie, J.; Fu, Q.; Yan, J.-B. Compressive Behaviors of Concrete Stub Columns with SFRCC Jacket under Cold-Region Marine Environments. J. Cold Reg. Eng. 2020, 34, 04020021. [Google Scholar] [CrossRef]

- Wang, Y.; An, M.-Z.; Yu, Z.-R.; Han, S.; Ji, W.-Y. Durability of reactive powder concrete under chloride-salt freeze–thaw cycling. Mater. Struct. 2016, 50, 18. [Google Scholar] [CrossRef]

- Medina, C.; Banfill, P.; de Rojas, M.S.; Frías, M. Rheological and calorimetric behaviour of cements blended with containing ceramic sanitary ware and construction/demolition waste. Constr. Build. Mater. 2012, 40, 822–831. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Pastor, J.L.; Ortega, J.M.; Flor, M.; López, M.P.; Sánchez, I.; Climent, M.A. Microstructure and durability of fly ash cement grouts for micropiles. Constr. Build. Mater. 2016, 117, 47–57. [Google Scholar] [CrossRef]

- Álvarez, J.M.O.; Pérez, M.D.E.; Escribano, R.R.R.; Navarro, J.L.P.; Martín, I.S. Microstructural Effects of Sulphate Attack in Sustainable Grouts for Micropiles. Materials 2016, 9, 905. [Google Scholar] [CrossRef] [PubMed]

- Hamada, H.M.; Shi, J.; Abed, F.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T. Recycling solid waste to produce eco-friendly ultra-high performance concrete: A review of durability, microstructure and environment characteristics. Sci. Total Environ. 2023, 876, 162804. [Google Scholar] [CrossRef] [PubMed]

- Naceri, A.; Hamina, M.C. Use of waste brick as a partial replacement of cement in mortar. Waste Manag. 2009, 29, 2378–2384. [Google Scholar] [CrossRef]

- He, Z.-H.; Zhu, H.-N.; Zhang, M.-Y.; Shi, J.-Y.; Du, S.-G.; Liu, B. Autogenous shrinkage and nano-mechanical properties of UHPC containing waste brick powder derived from construction and demolition waste. Constr. Build. Mater. 2021, 306, 124869. [Google Scholar] [CrossRef]

- Yuan, C.; Fu, W.; Raza, A.; Li, H. Study on Mechanical Properties and Mechanism of Recycled Brick Powder UHPC. Buildings 2022, 12, 1622. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Liu, C.; Chen, X.; Xu, Z. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Xu, Z.; Li, S.; Luo, X.; Chen, G. Long-term hydration and microstructure evolution of blended cement containing ground granulated blast furnace slag and waste clay brick. Cem. Concr. Compos. 2021, 118, 103982. [Google Scholar] [CrossRef]

- Lin, K.-L.; Chen, B.-Y.; Chiou, C.-S.; Cheng, A. Waste brick’s potential for use as a pozzolan in blended Portland cement. Waste Manag. Res. J. A Sustain. Circ. Econ. 2010, 28, 647–652. [Google Scholar] [CrossRef]

- Xue, C.Z.; Shen, A.Q.; Chang, Y.T.; Liang, D. The Study of the Construction Waste Brick Powder’s Activity. Adv. Mater. Res. 2014, 1079, 309–311. [Google Scholar] [CrossRef]

- Gonçalves, J.; Tavares, L.; Filho, R.T.; Fairbairn, E. Performance evaluation of cement mortars modified with metakaolin or ground brick. Constr. Build. Mater. 2009, 23, 1971–1979. [Google Scholar] [CrossRef]

- Muñoz, M.A.C.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond Performance between Ultrahigh-Performance Concrete and Normal-Strength Concrete. J. Mater. Civ. Eng. 2014, 26, 04014031. [Google Scholar] [CrossRef]

- Harris, D.K.; Sarkar, J.; Ahlborn, T.M. Characterization of Interface Bond of Ultra-High-Performance Concrete Bridge Deck Overlays. Transp. Res. Rec. J. Transp. Res. Board 2011, 2240, 40–49. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and numerical study on mechanical properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Hussein, H.H.; Walsh, K.K.; Sargand, S.M.; Steinberg, E.P. Interfacial Properties of Ultrahigh-Performance Concrete and High-Strength Concrete Bridge Connections. J. Mater. Civ. Eng. 2016, 28, 04015208. [Google Scholar] [CrossRef]

- Liang, G.; Yao, W.; Wei, Y. A green ultra-high performance geopolymer concrete containing recycled fine aggregate: Mechanical properties, freeze-thaw resistance and microstructure. Sci. Total Environ. 2023, 895, 165090. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Hooton, R.; Zhang, X. Effects of interface roughness and interface adhesion on new-to-old concrete bonding. Constr. Build. Mater. 2017, 151, 582–590. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, J.; Chen, W.; Liu, H.; Li, H.; Guo, H. Experimental Study on Bond Performance of NC-UHPC Interfaces with Different Roughness and Substrate Strength. Materials 2023, 16, 2708. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, X.; Li, K.; Qiang, J. Experimental study of interfacial adhesion performance of prefabricated UHPC-NC diagonal shear groove. Case Stud. Constr. Mater. 2023, 19, e02343. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Luo, Y.; Wang, L. Effects of Interface Orientations on Bond Strength between Old Conventional Concrete and New Self-Consolidating Concrete. ACI Struct. J. 2020, 117, 191–201. [Google Scholar]

- Dagenais, M.-A.; Massicotte, B.; Boucher-Proulx, G. Seismic Retrofitting of Rectangular Bridge Piers with Deficient Lap Splices Using Ultrahigh-Performance Fiber-Reinforced Concrete. J. Bridg. Eng. 2018, 23. [Google Scholar] [CrossRef]

- Moon, J.; Taha, M.M.R.; Kim, J.J. Flexural Strengthening of RC Slabs Using a Hybrid FRP-UHPC System Including Shear Connector. Adv. Mater. Sci. Eng. 2017, 2017, 4387545. [Google Scholar] [CrossRef]

- GB/T 5101-2017; Sintered Ordinary Bricks. General Administration of Quality Supervision, Inspection and Quarantine of the China. Standardization Administration of China, China Standards Publishing House: Beijing, China, 2017.

- JGJ 55-2011; Specification for Mix Design of Ordinary Concrete. Ministry of Housing and Urban Rural Development of the Ministry of Housing and Urban-Rural Development, China Construction Industry Press: Beijing, China, 2011.

- Tayeh, B.A.; Abu Bakar, B.; Johari, M.M.; Voo, Y.L. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay. Constr. Build. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban Rural Development of the Ministry of Housing and Urban-Rural Development, China Construction Industry Press: Beijing, China, 2019.

- T/CECS 10107-2020; Technical Requirements for Ultra High Performance Concrete. China Engineering Construction Standardization Association: Beijing, China, 2020.

- GB/T 50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Ministry of Housing and Urban Rural Development of the Ministry of Housing and Urban-Rural Development, China Construction Industry Press: Beijing, China, 2019.

- Xu, X.; Cui, S.; Cao, Z.; Zhang, S.; Ju, J.-W.W.; Liu, P.; Wang, X. Study on the interfacial bonding performance of basalt ultra-high performance concrete repair and reinforcement materials under severe service environment. Constr. Build. Mater. 2023, 400, 132624. [Google Scholar] [CrossRef]

- Daneshvar, D.; Behnood, A.; Robisson, A. Interfacial bond in concrete-to-concrete composites: A review. Constr. Build. Mater. 2022, 359, 129195. [Google Scholar] [CrossRef]

- Tahmureszadeh, K.; Shehata, M.H.; Gong, B. Durability of Repairs under Freezing and Thawing and Alkali-Aggregate Reaction. ACI Mater. J. 2022, 119, 197–208. [Google Scholar] [CrossRef]

- Mengwei, W. Study on Influencing Factors of Bonding Performance between ECC and Existing Concrete; Southeast University: Nanjing, China, 2018. [Google Scholar]

- Zichen, G. Study on Interface Adhesion between Light Aggregate Concrete and Ordinary Concrete; Chang’an University: Xi’an, China, 2018. [Google Scholar]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Emmons, P.; Vayasburd, A.; McDonald, J. Concrete Repair in the Future Turn of the Century—Any Problems? Concr. Int. 1994, 16, 42–49. [Google Scholar]

- Qi, J.; Gao, Y.; Wang, Q. Microstructures of lightweight concrete with mixed fine aggregates. J. Tongji Univ. 2002, 30, 959–963. [Google Scholar]

| Specific Surface Area (m2·kg−1 ) | Stability | SO3 (%) | Cl− (%) | Admixture (%) | Ignition Loss (%) | Setting Time (min) | 28-Day Strength /MPa | ||

|---|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | Flexural Strength | Compressive Strength | ||||||

| 386 | Qualification | 2.33 | 0.036 | 6.0 | 2.30 | 170 | 222 | 7.5 | 55.6 |

| Grain Size (mm) | <0.075 | 0.075–0.17 | 0.17–0.315 | 0.315–0.63 | 0.63–1.25 | >1.25 |

|---|---|---|---|---|---|---|

| Content/% | 0.67 | 3.37 | 10.00 | 36.12 | 45.35 | 4.49 |

| Specific Surface Area (m2·kg−1) | Moisture Content (%) | Major Contents of Components (%) | ||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | ||

| 600 | ≤0.50 | 67.83 | 16.20 | 7.55 | 1.67 | 0.94 |

| Length/mm | Diameter/mm | Density/g·cm−3 | Form | Tensile Strength/MPa |

|---|---|---|---|---|

| 12.0 | 0.2 | 7.8 | Formed straight and smooth | >2000.0 |

| Constituencies | Substitution Rate/% | Recycled Brick Powder | Water | Fly Ash | Steel Fiber | Cement | Silica Ash | River Sand | Water Reducer |

|---|---|---|---|---|---|---|---|---|---|

| R0 | 0 | 0 | 160 | 100 | 156 | 700 | 200 | 1000 | 30 |

| R1 | 30 | 210 | 160 | 100 | 156 | 490 | 200 | 1000 | 30 |

| Constituencies | Sand | Cement | Macadam | Water |

|---|---|---|---|---|

| NC | 556 | 476 | 1183 | 195 |

| Constituencies | Interface Agent Name | Material Ratio | Water-to-Adhesive Ratio |

|---|---|---|---|

| A1 | No interface agent | - | - |

| A2 | Cement net slurry | Cement: water = 1:0.4 | 0.04 |

| A3 | Cement expansion slurry | Cement: Water: Bulking Agent = 1:0.29:0.11 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Raza, A.; Umar, M.; Chen, Y.; Yuan, C. Study on Frost Resistance and Interface Bonding Performance through the Integration of Recycled Brick Powder in Ultra-High-Performance Concrete for Structural Reinforcement. Materials 2023, 16, 6999. https://doi.org/10.3390/ma16216999

Zhang Y, Raza A, Umar M, Chen Y, Yuan C. Study on Frost Resistance and Interface Bonding Performance through the Integration of Recycled Brick Powder in Ultra-High-Performance Concrete for Structural Reinforcement. Materials. 2023; 16(21):6999. https://doi.org/10.3390/ma16216999

Chicago/Turabian StyleZhang, Yike, Ali Raza, Muhammad Umar, Yang Chen, and Chengfang Yuan. 2023. "Study on Frost Resistance and Interface Bonding Performance through the Integration of Recycled Brick Powder in Ultra-High-Performance Concrete for Structural Reinforcement" Materials 16, no. 21: 6999. https://doi.org/10.3390/ma16216999