Characterization of Densified Pine Wood and a Zero-Thickness Bio-Based Adhesive for Eco-Friendly Structural Applications

Abstract

:1. Introduction

2. Materials

2.1. Wood

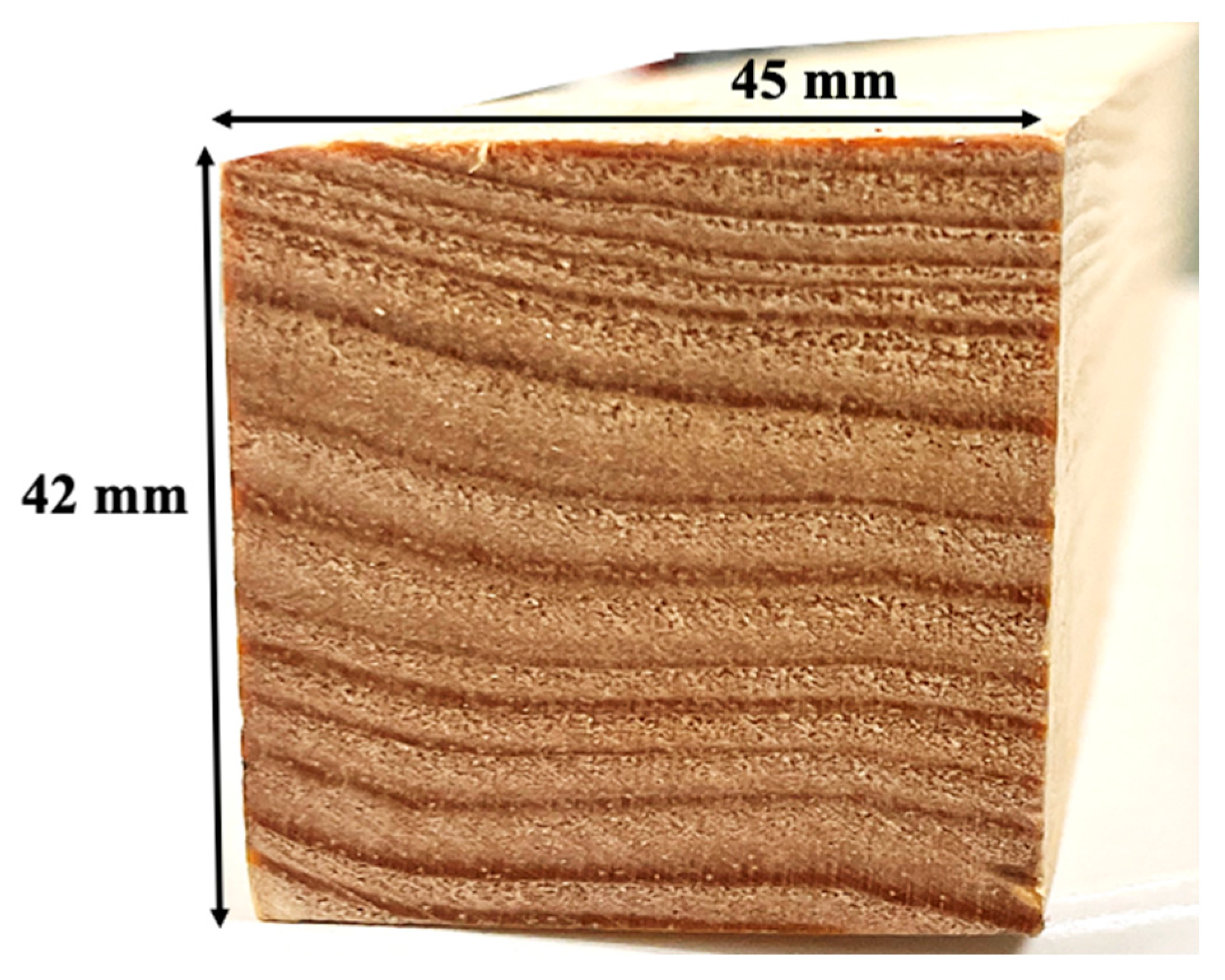

2.1.1. Natural Pine Wood

2.1.2. Densified Pine Wood

2.2. Bio-Based Adhesive

3. Experimental Details

3.1. Characterization of the Natural Pine Wood and Densified Pine Wood

3.1.1. Density Measurement

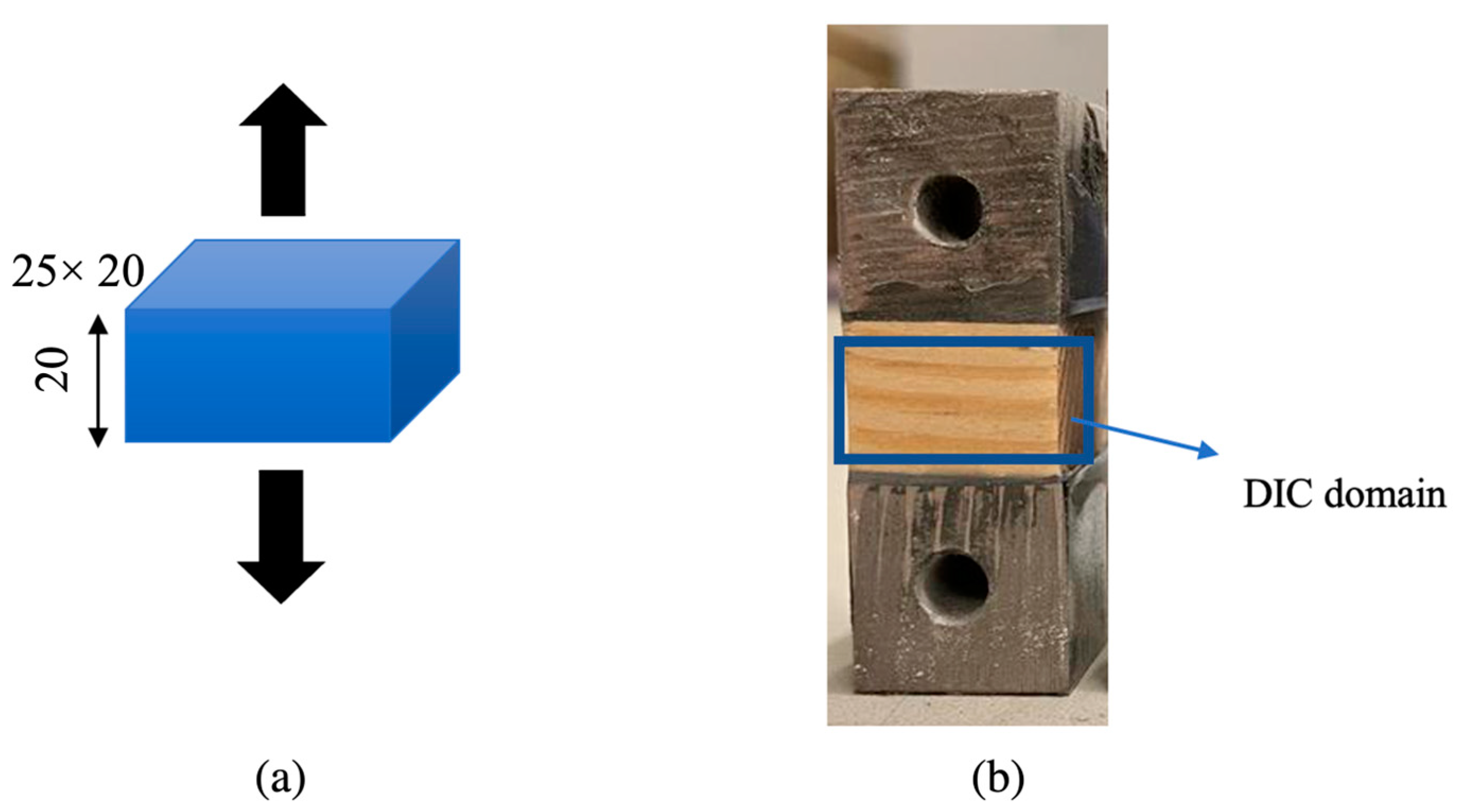

3.1.2. Strength Tests

3.1.3. Fracture Tests

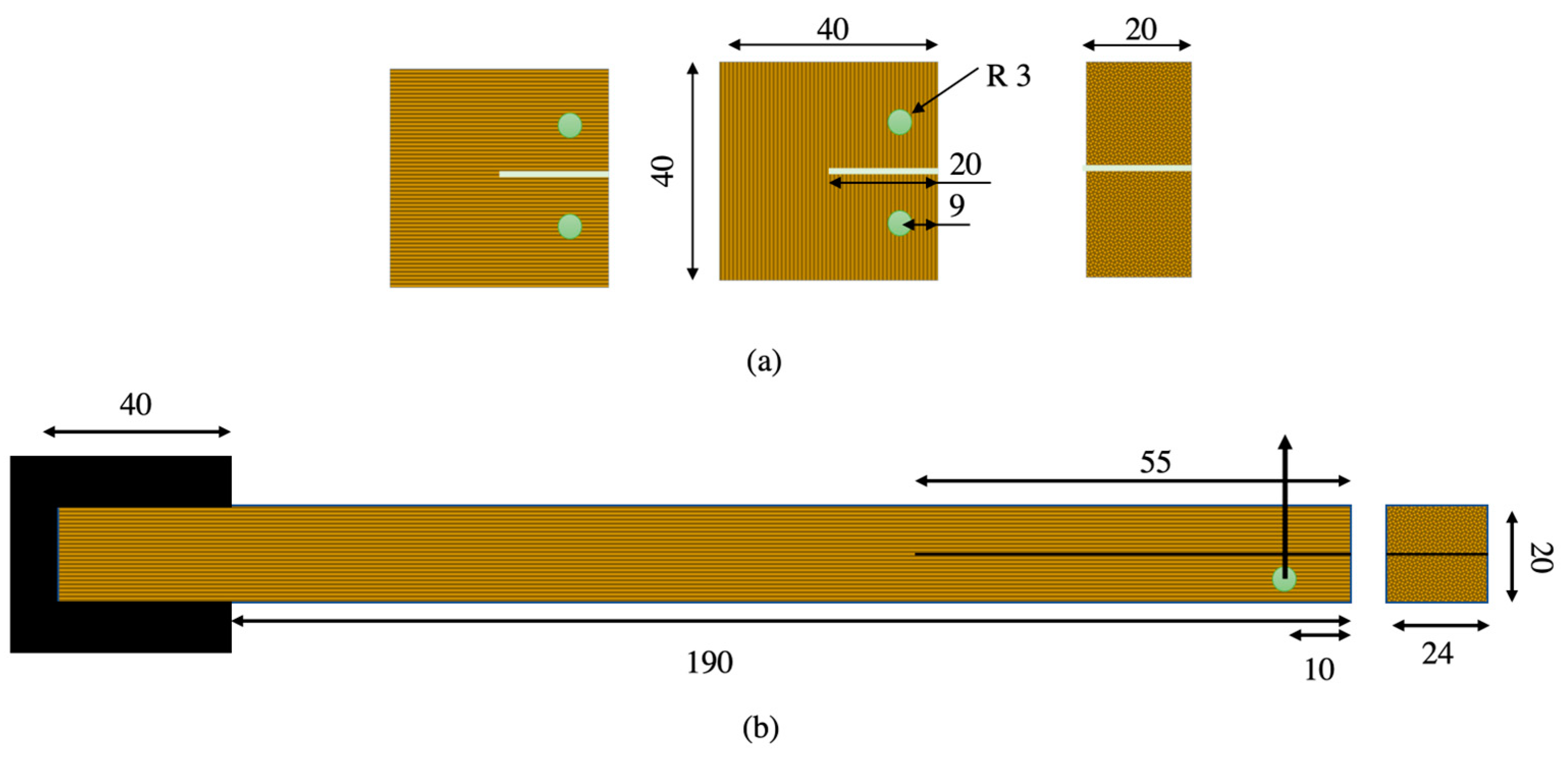

3.2. Characterization of Bio-Based Adhesive

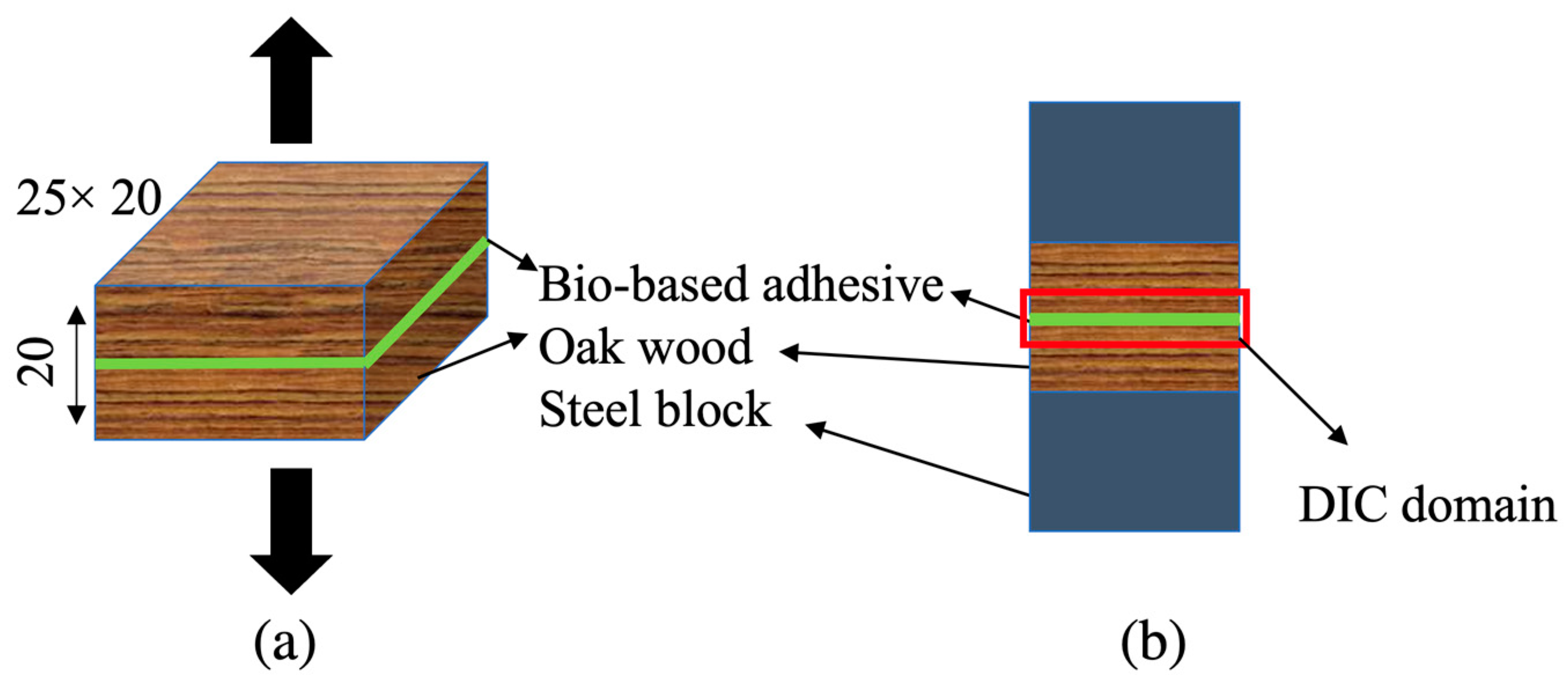

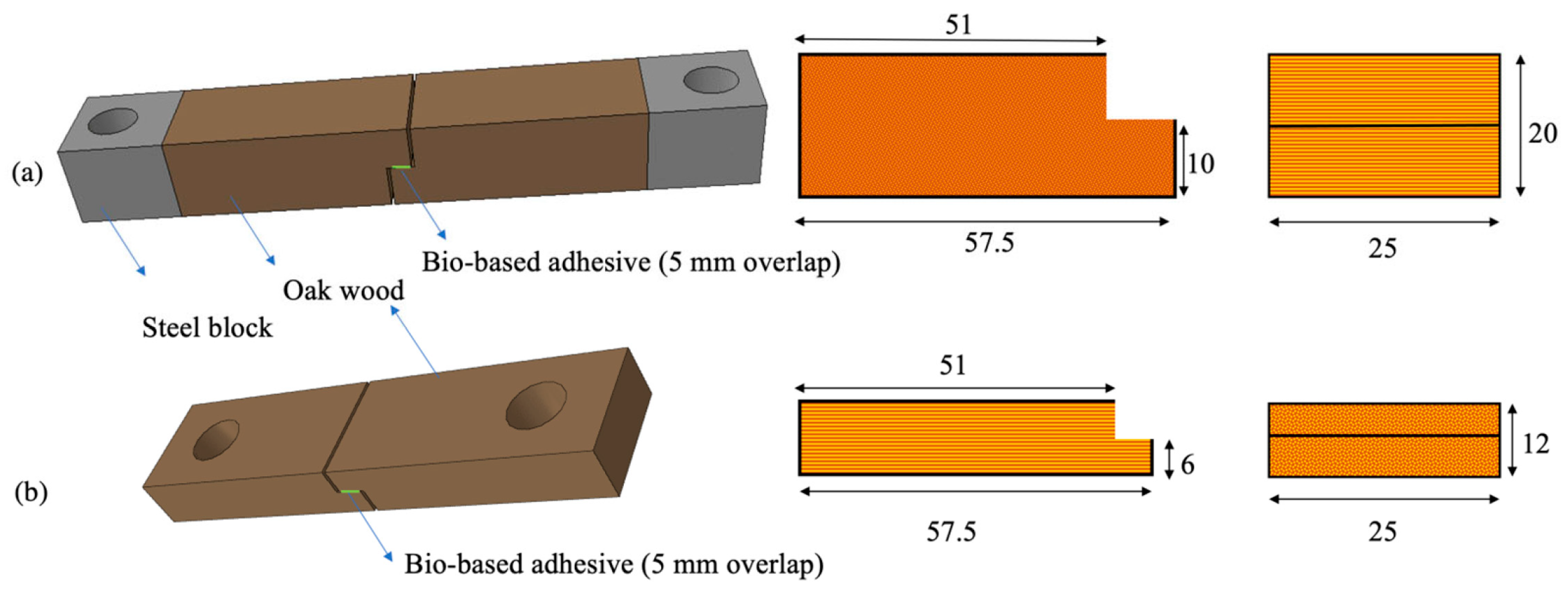

3.2.1. Strength Tests

3.2.2. Fracture Tests

4. Results and Discussion

4.1. Characterization of the Wood and Densified Wood

4.1.1. Density Measurement

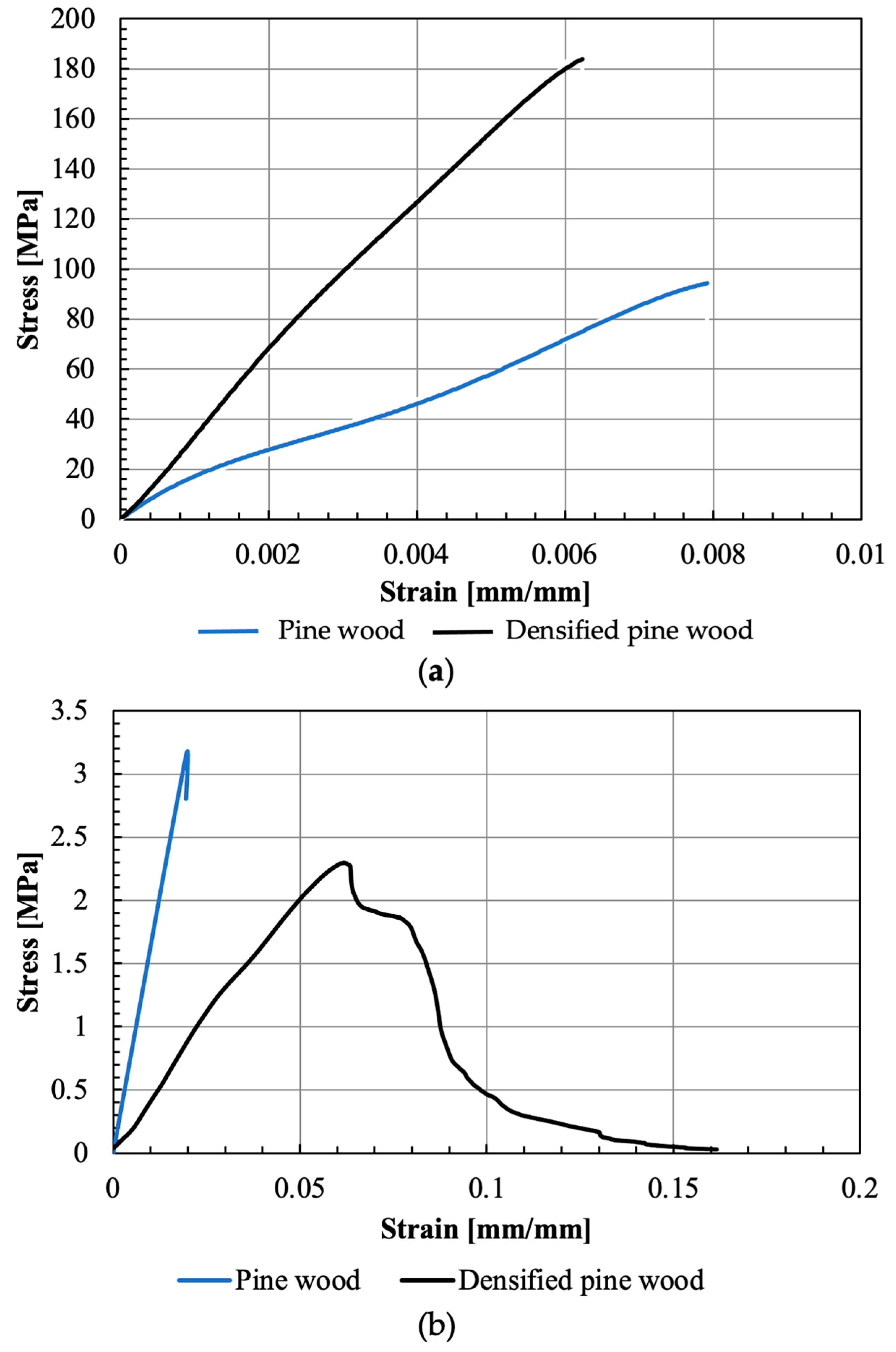

4.1.2. Strength Tests

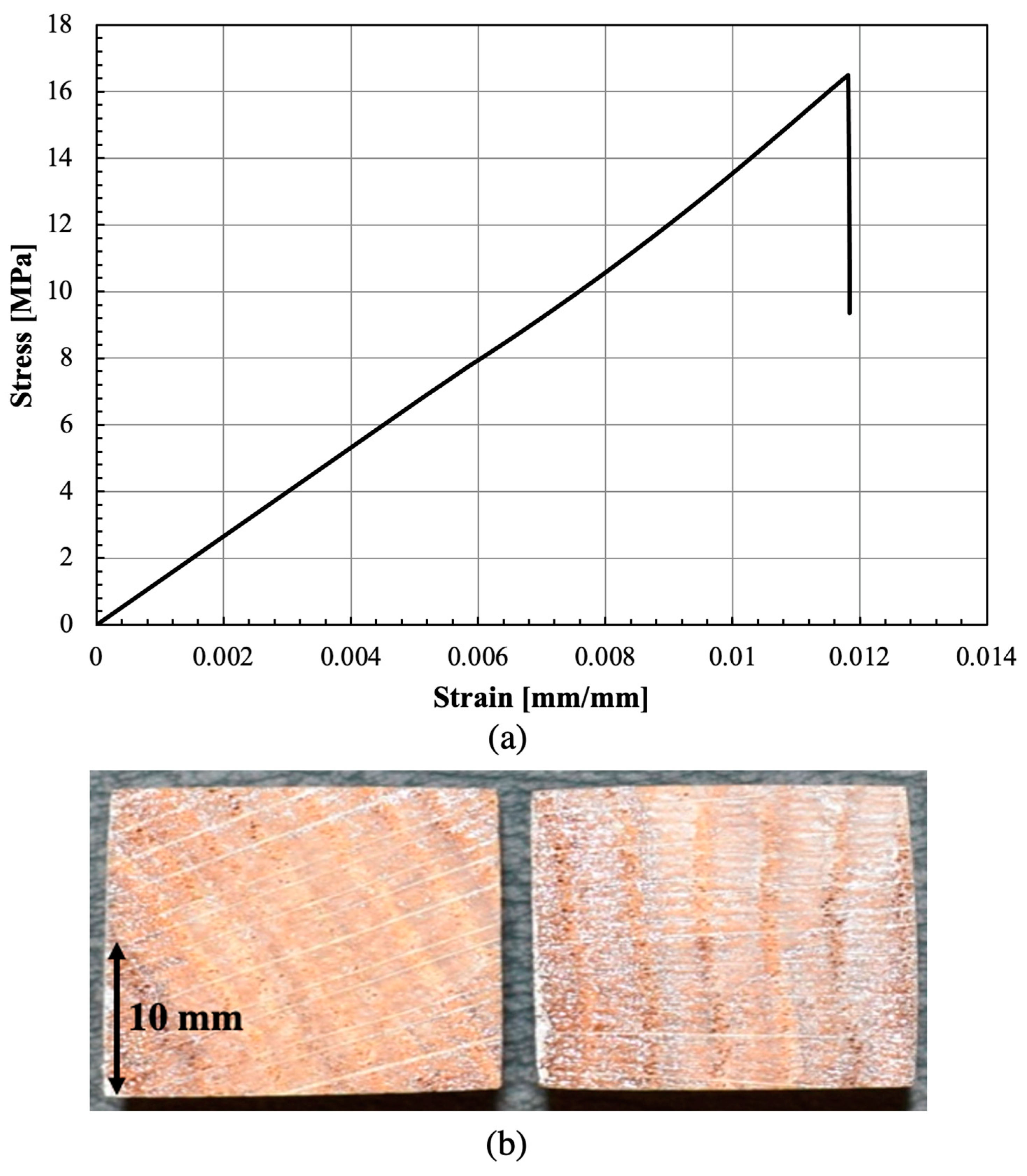

4.1.3. Fracture Tests

4.2. Characterization of Bio-Based Adhesive

4.2.1. Strength Tests

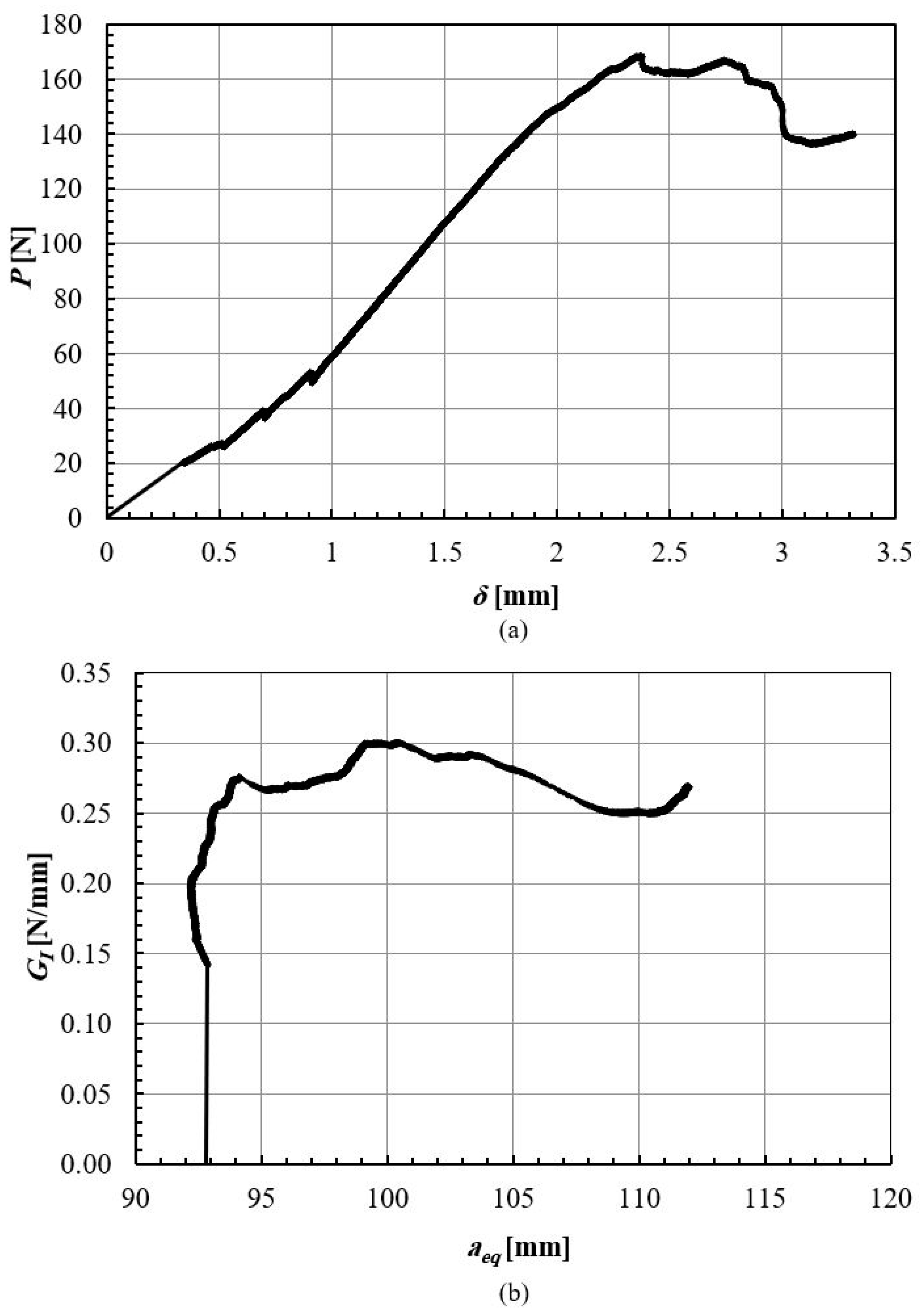

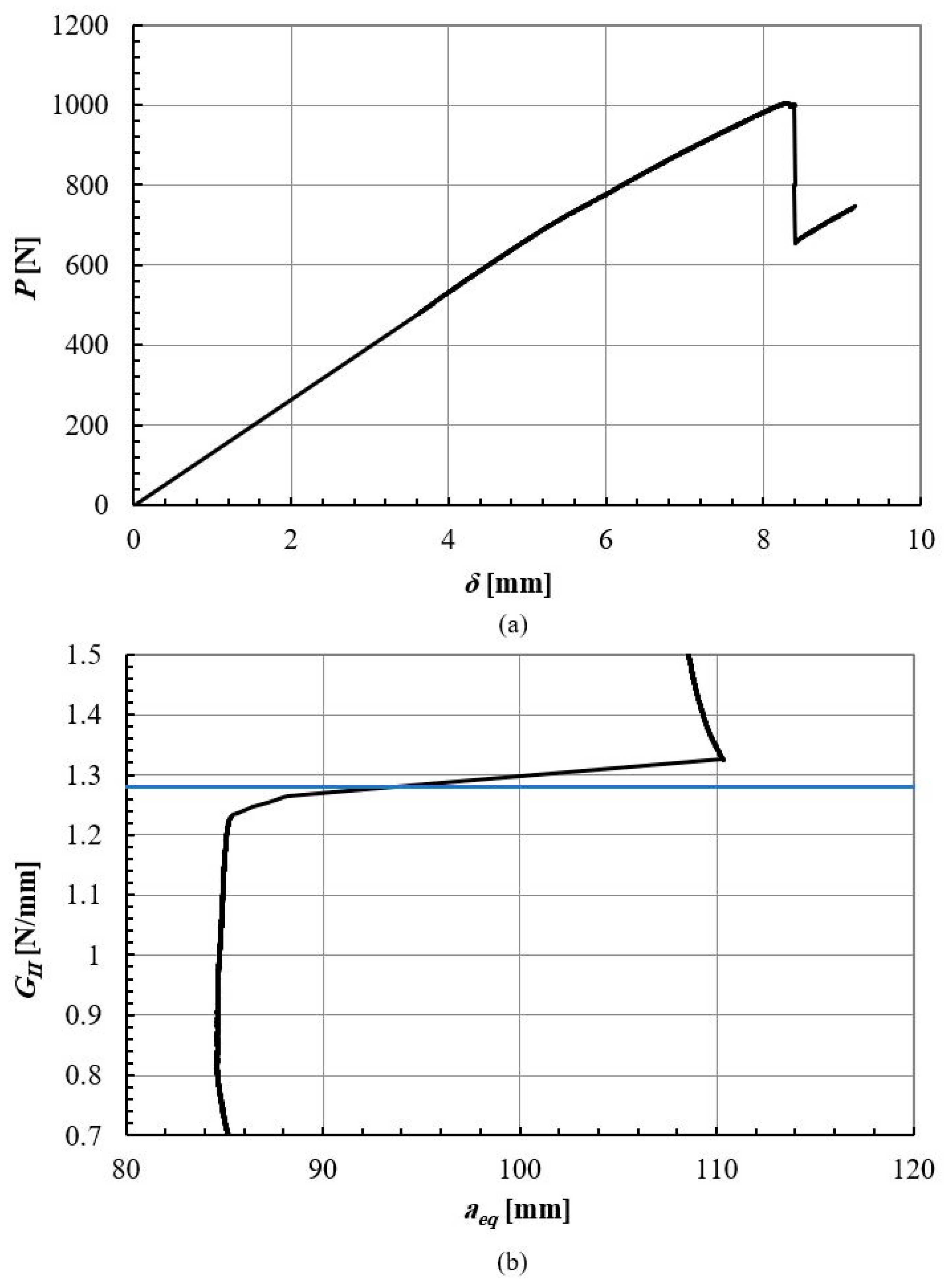

4.2.2. Fracture Tests

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C.Z.; Yaniger, S.I.; Jordan, V.C.; Klein, D.J.; Bittner, G.D. Most plastic products release estrogenic chemicals: A potential health problem that can be solved. Environ. Health Perspect. 2011, 119, 989–996. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Borges, C.S.P.; Akhavan-Safar, A.; Tsokanas, P.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. From fundamental concepts to recent developments in the adhesive bonding technology: A general view. Discov. Mech. Eng. 2023, 2, 8. [Google Scholar] [CrossRef]

- Venkatesan, R.; Surya, S.; Suganthi, S.; Muthuramamoorthy, M.; Pandiaraj, S.; Kim, S.-C. Biodegradable composites from poly(butylene adipate-co-terephthalate) with carbon nanoparticles: Preparation, characterization and performances. Polym. Adv. Technol. 2020, 31, 2267–2279. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N. ZnO/PBAT nanocomposite films: Investigation on the mechanical and biological activity for food packaging. Polym. Adv. Technol. 2016, 27, 1632–1640. [Google Scholar] [CrossRef]

- He, Z. (Ed.) Bio-Based Wood Adhesives: Preparation, Characterization, and Testing; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Gajula, S.; Antonyraj, C.A.; Odaneth, A.A.; Srinivasan, K. A consolidated road map for economically gainful efficient utilization of agro-wastes for eco-friendly products. Biofuels Bioprod. Biorefining 2019, 13, 899–911. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, C.; Bokka, S.K.; He, Z.; Ni, Y. Molded fiber and pulp products as green and sustainable alternatives to plastics: A mini review. J. Bioresour. Bioprod. 2022, 7, 14–25. [Google Scholar] [CrossRef]

- Jalali, S.; Ayatollahi, M.R.; Akhavan-Safar, A.; da Silva, L.F.M. Effects of impact fatigue on residual static strength of adhesively bonded joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1519–1523. [Google Scholar] [CrossRef]

- Oliveira, P.R.; May, M.; Panzera, T.H.; Scarpa, F.; Hiermaier, S. Reinforced biobased adhesive for eco-friendly sandwich panels. Int. J. Adhes. Adhes. 2020, 98, 102550. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; De Barros, S.; Da Silva, L.F.M. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Yildizhan, Ş.; Çalik, A.; Özcanli, M.; Serin, H. Bio-composite materials: A short review of recent trends, mechanical and chemical properties, and applications. Eur. Mech. Sci. 2018, 2, 83–91. [Google Scholar] [CrossRef]

- Gurr, J.; Barbu, M.C.; Frühwald, A.; Chaowana, P. The bond strength development of coconut wood in relation to its density variations. J. Adhes. 2022, 98, 1520–1533. [Google Scholar] [CrossRef]

- Souza, A.M.; Nascimento, M.F.; Almeida, D.H.; Silva, D.A.L.; Almeida, T.H.; Christoforo, A.L.; Lahr, F.A.R. Wood-based composite made of wood waste and epoxy based ink-waste as adhesive: A cleaner production alternative. J. Clean. Prod. 2018, 193, 549–562. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Dourado, N. Wood Fracture Characterisation; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Yang, H.; Gao, M.; Wang, J.; Mu, H.; Qi, D. Fast Preparation of high-performance wood materials assisted by ultrasonic and vacuum impregnation. Forests 2021, 12, 567. [Google Scholar] [CrossRef]

- Grunwald, C.; Fecht, S.; Vallée, T.; Tannert, T. Adhesively bonded timber joints–Do defects matter? Int. J. Adhes. Adhes. 2014, 55, 12–17. [Google Scholar] [CrossRef]

- Modenbach, A.A.; Nokes, S.E. Effects of sodium hydroxide pretreatment on structural components of biomass. Trans. ASABE 2014, 57, 1187–1198. [Google Scholar]

- Morsing, N. Densification of Wood. The Influence of Hygrothermal Treatment on Compression of Beech Perpendicular to Gain. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2000. [Google Scholar]

- Laine, K.; Belt, T.; Rautkari, L.; Ramsay, J.; Hill, C.A.S.; Hughes, M. Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J. Mater. Sci. 2013, 48, 8530–8538. [Google Scholar] [CrossRef]

- Schwarzkopf, M. Densified wood impregnated with phenol resin for reduced set-recovery. Wood Mater. Sci. Eng. 2021, 16, 35–41. [Google Scholar] [CrossRef]

- Sadatnezhad, S.H.; Khazaeian, A.; Sandberg, D.; Tabarsa, T. Continuous surface densification of wood: A new concept for large-scale industrial processing. BioResources 2017, 12, 3122–3132. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Follrich, J.; Höra, M.; Müller, U.; Teischinger, A.; Gindl, W. Adhesive bond strength of end grain joints in balsa wood with different density. Wood Res. 2010, 55, 21–32. [Google Scholar]

- Pizzi, A. Advanced Wood Adhesives Technology; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Pizzi, A.; Mittal, K.L. Wood Adhesives; VSP: Rancho Cordova, CA, USA, 2010. [Google Scholar]

- Sahoo, S.; Mohanty, S.; Nayak, S.K. Biobased polyurethane adhesive over petroleum based adhesive: Use of renewable resource. J. Macromol. Sci. Part A 2018, 55, 36–48. [Google Scholar] [CrossRef]

- Oliveira, J.M.Q.; De Moura, M.F.S.F.; Silva, M.A.L.; Morais, J.J.L. Numerical analysis of the MMB test for mixed-mode I/II wood fracture. Compos. Sci. Technol. 2007, 67, 1764–1771. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Corte-Real, L.M.; Jalali, S.; Borges, C.S.; Marques, E.A.; Carbas, R.J.; da Silva, L.F. Development and Characterisation of Joints with Novel Densified and Wood/Cork Composite Substrates. Materials 2022, 15, 7163. [Google Scholar] [CrossRef]

- De Moura, M.; Campilho, R.; Gonçalves, J.P.M. Pure mode II fracture characterization of composite bonded joints. Int. J. Solids Struct. 2009, 46, 1589–1595. [Google Scholar] [CrossRef]

- Hu, M.; Duan, Z.; Zhou, X.; Du, G.; Li, T. Effects of surface characteristics of wood on bonding performance of low-molar ratio urea–formaldehyde resin. J. Adhes. 2023, 99, 803–816. [Google Scholar] [CrossRef]

- Xu, G.; Liang, J.; Zhang, B.; Wu, Z.; Lei, H.; Du, G. Performance and structures of urea-formaldehyde resins prepared with different formaldehyde solutions. Wood Sci. Technol. 2021, 55, 1419–1437. [Google Scholar] [CrossRef]

| EL [GPa] | ER [GPa] | ET [GPa] | νLT | νLR | νTR | GLR [GPa] | GLT [GPa] | GTR [GPa] |

|---|---|---|---|---|---|---|---|---|

| 12.0 | 1.9 | 1.0 | 0.5 | 0.4 | 0.3 | 1.1 | 1.0 | 0.3 |

| EFiber direction [GPa] | σFiber direction [MPa] | ETransverse direction [MPa] | σTransverse direction [MPa] | |

|---|---|---|---|---|

| W | 12 ± 1 | 97.3 ± 8.3 | 155 ± 22 | 2.9 ± 0.2 |

| D | 31± 1 | 180.1 ±12.9 | 43 ± 3 | 2.1 ± 0.1 |

| WLR | DLR | WRL | DRL | |

|---|---|---|---|---|

| KIC [MPa/m] | 17.7 ± 0.3 | 39.4 ± 1.5 | 24.0 ± 4.1 | 128.1 ± 15.1 |

| GIC [N/mm] | 0.20 ± 0.01 | 0.76 ± 0.09 | 0.33 ± 0.04 | 0.75 ± 0.10 |

| E [MPa] | σ [MPa] | GIC [N/mm] | GIIC [N/mm] |

|---|---|---|---|

| 197.09 ± 9.76 | 3.27 ± 0.14 | 0.30 ± 0.03 | 1.27 ± 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jalali, S.; Borges, C.d.S.P.; Carbas, R.J.C.; Marques, E.A.d.S.; Bordado, J.C.M.; da Silva, L.F.M. Characterization of Densified Pine Wood and a Zero-Thickness Bio-Based Adhesive for Eco-Friendly Structural Applications. Materials 2023, 16, 7147. https://doi.org/10.3390/ma16227147

Jalali S, Borges CdSP, Carbas RJC, Marques EAdS, Bordado JCM, da Silva LFM. Characterization of Densified Pine Wood and a Zero-Thickness Bio-Based Adhesive for Eco-Friendly Structural Applications. Materials. 2023; 16(22):7147. https://doi.org/10.3390/ma16227147

Chicago/Turabian StyleJalali, Shahin, Catarina da Silva Pereira Borges, Ricardo João Camilo Carbas, Eduardo André de Sousa Marques, João Carlos Moura Bordado, and Lucas Filipe Martins da Silva. 2023. "Characterization of Densified Pine Wood and a Zero-Thickness Bio-Based Adhesive for Eco-Friendly Structural Applications" Materials 16, no. 22: 7147. https://doi.org/10.3390/ma16227147

APA StyleJalali, S., Borges, C. d. S. P., Carbas, R. J. C., Marques, E. A. d. S., Bordado, J. C. M., & da Silva, L. F. M. (2023). Characterization of Densified Pine Wood and a Zero-Thickness Bio-Based Adhesive for Eco-Friendly Structural Applications. Materials, 16(22), 7147. https://doi.org/10.3390/ma16227147