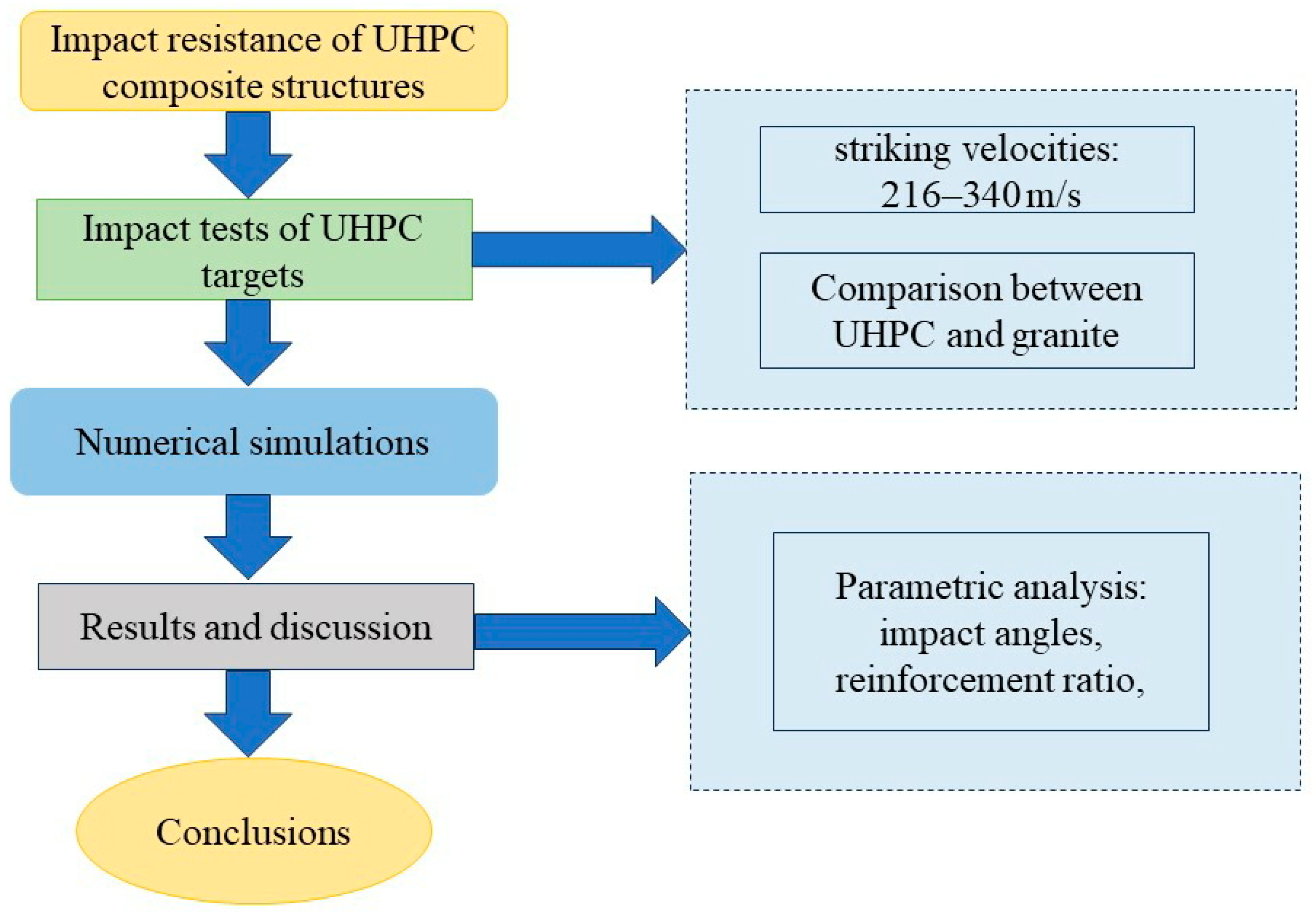

Impact Resistance of Ultra-High-Performance Concrete Composite Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

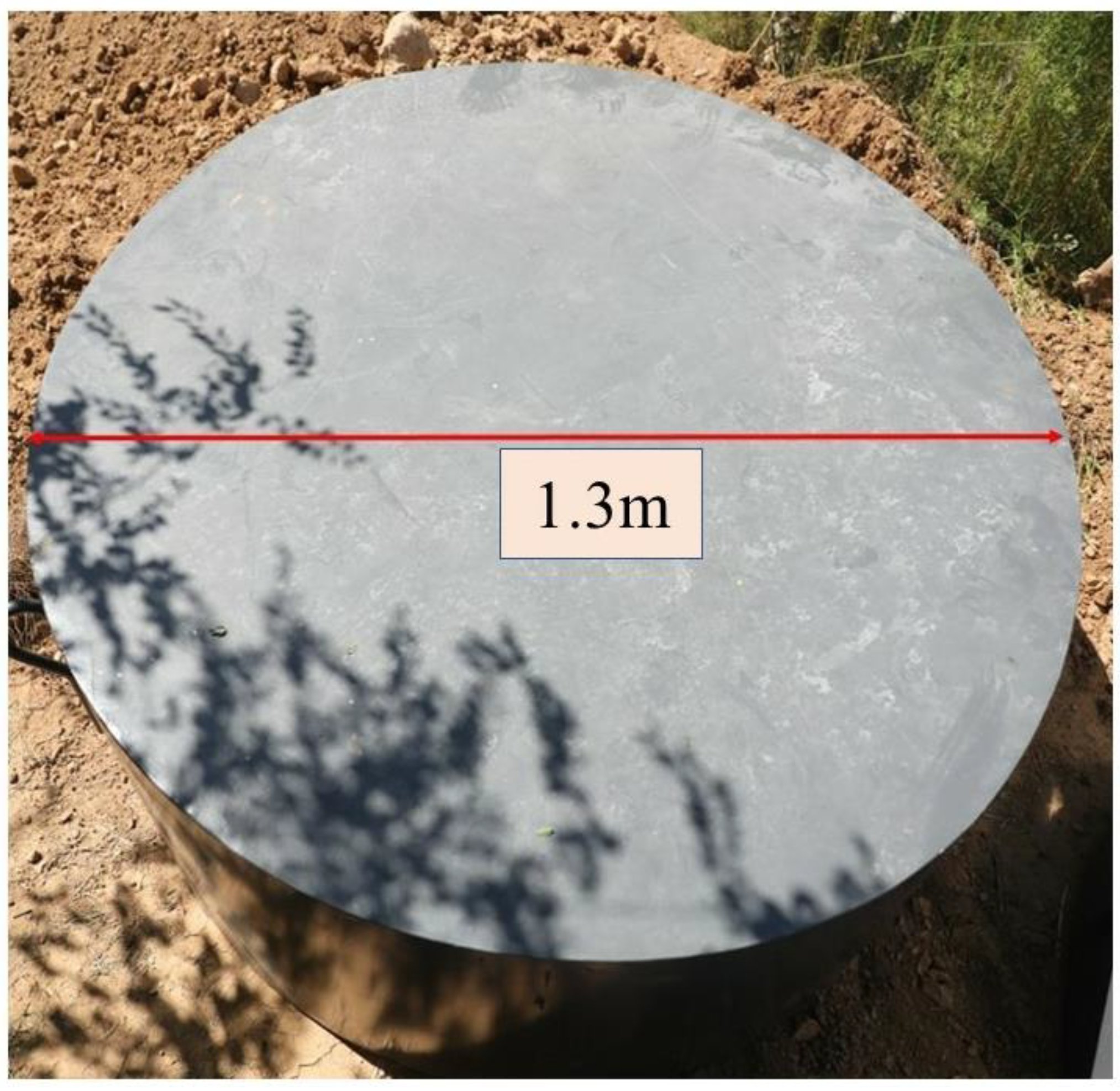

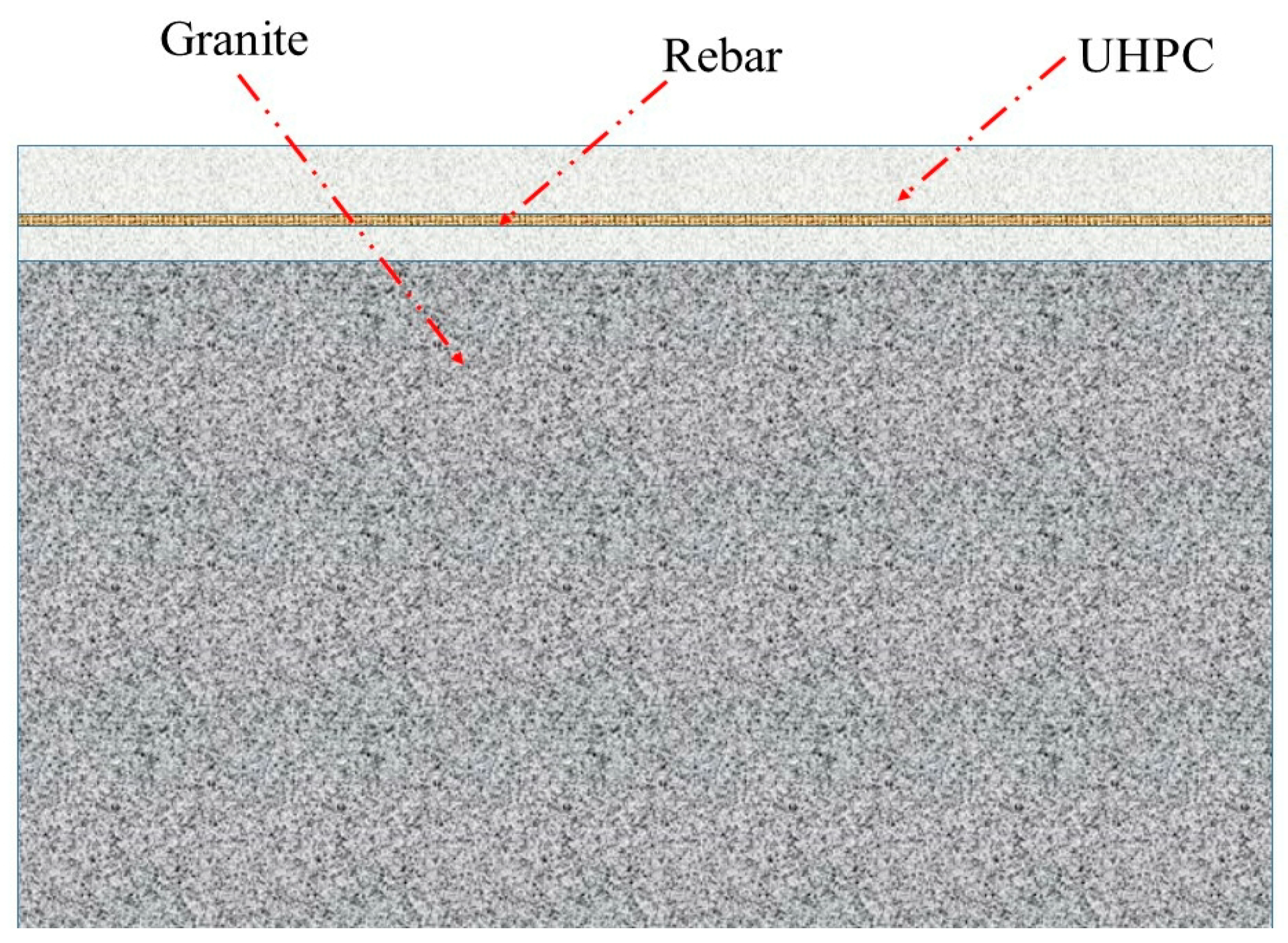

2.2. UHPC Targets

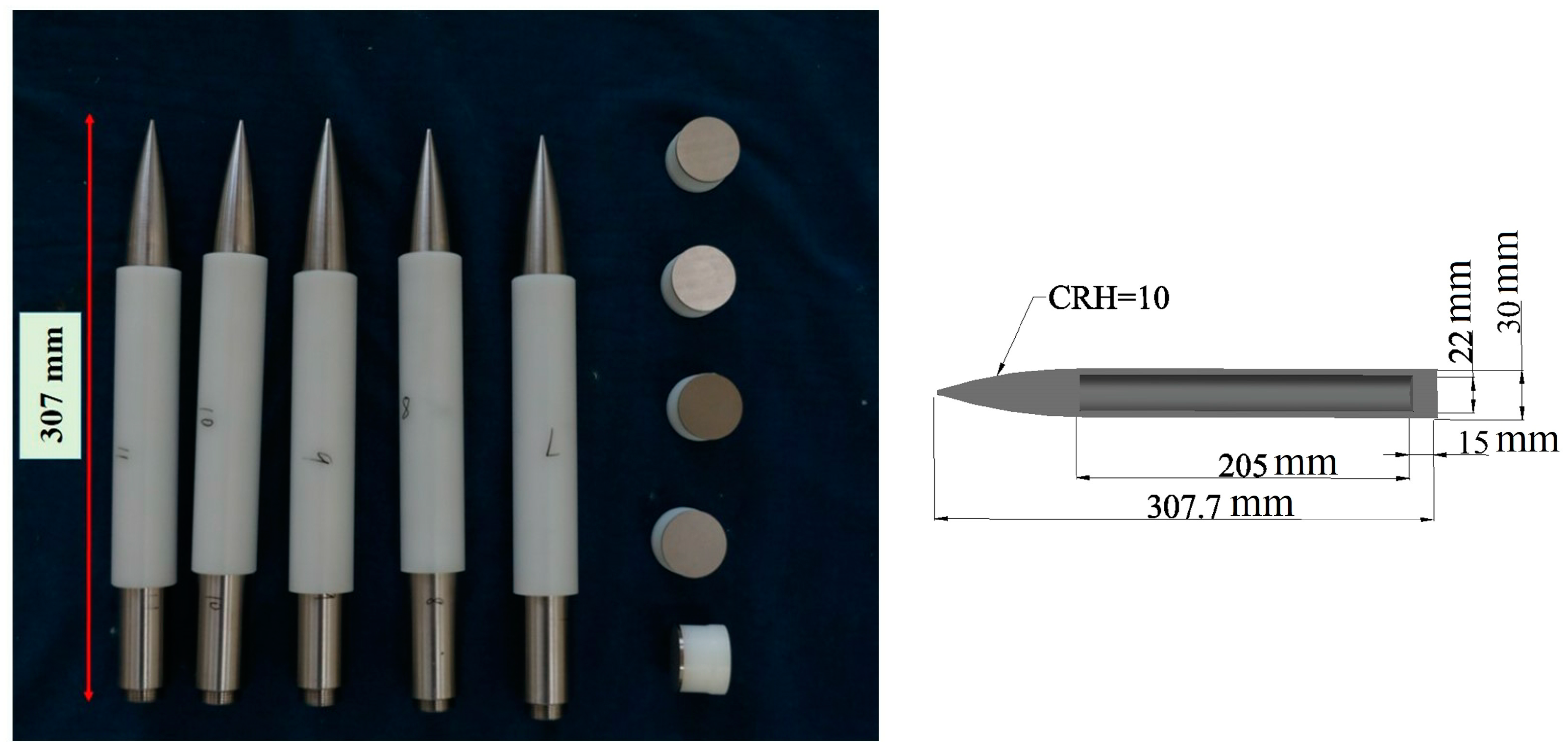

2.3. Projectile

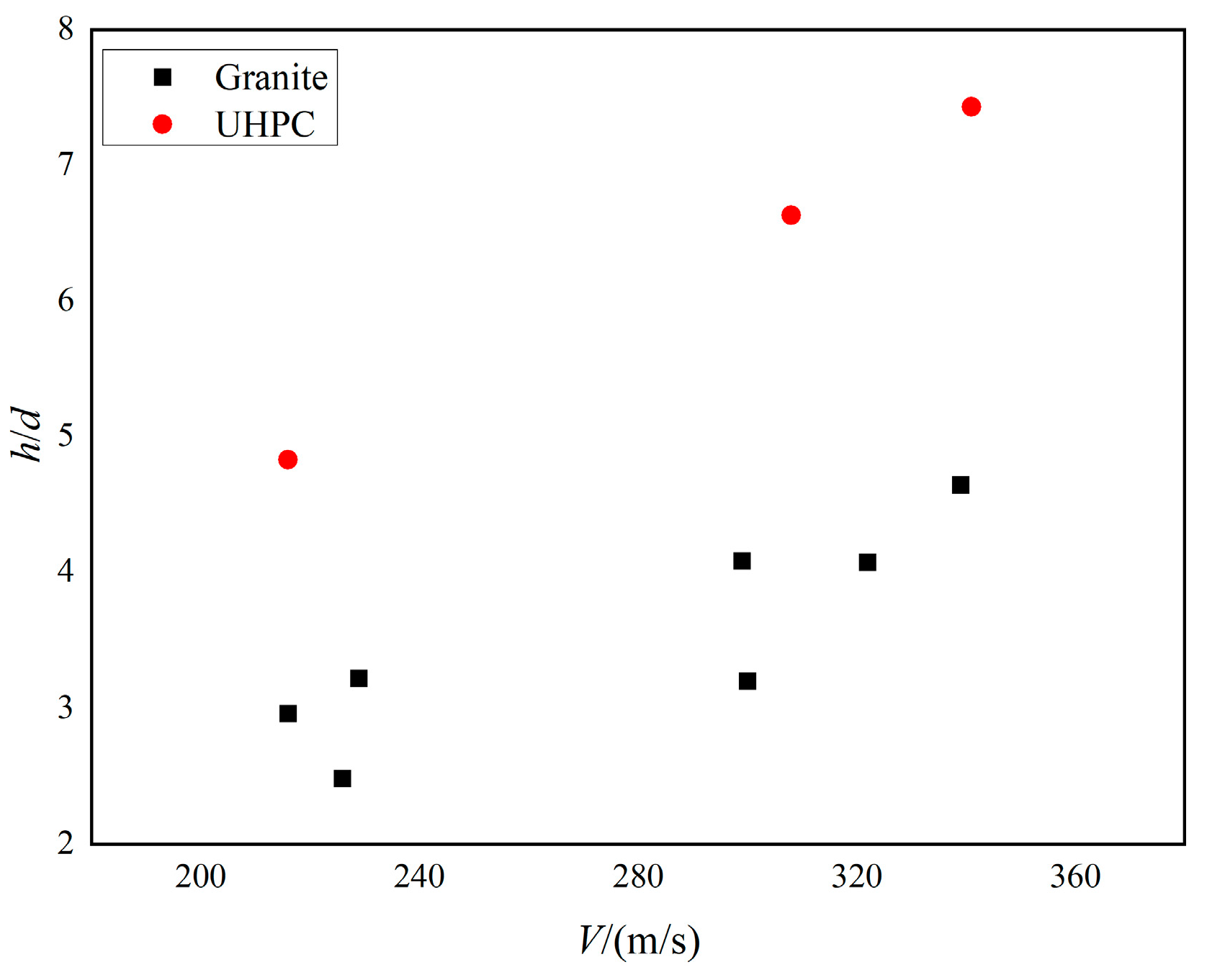

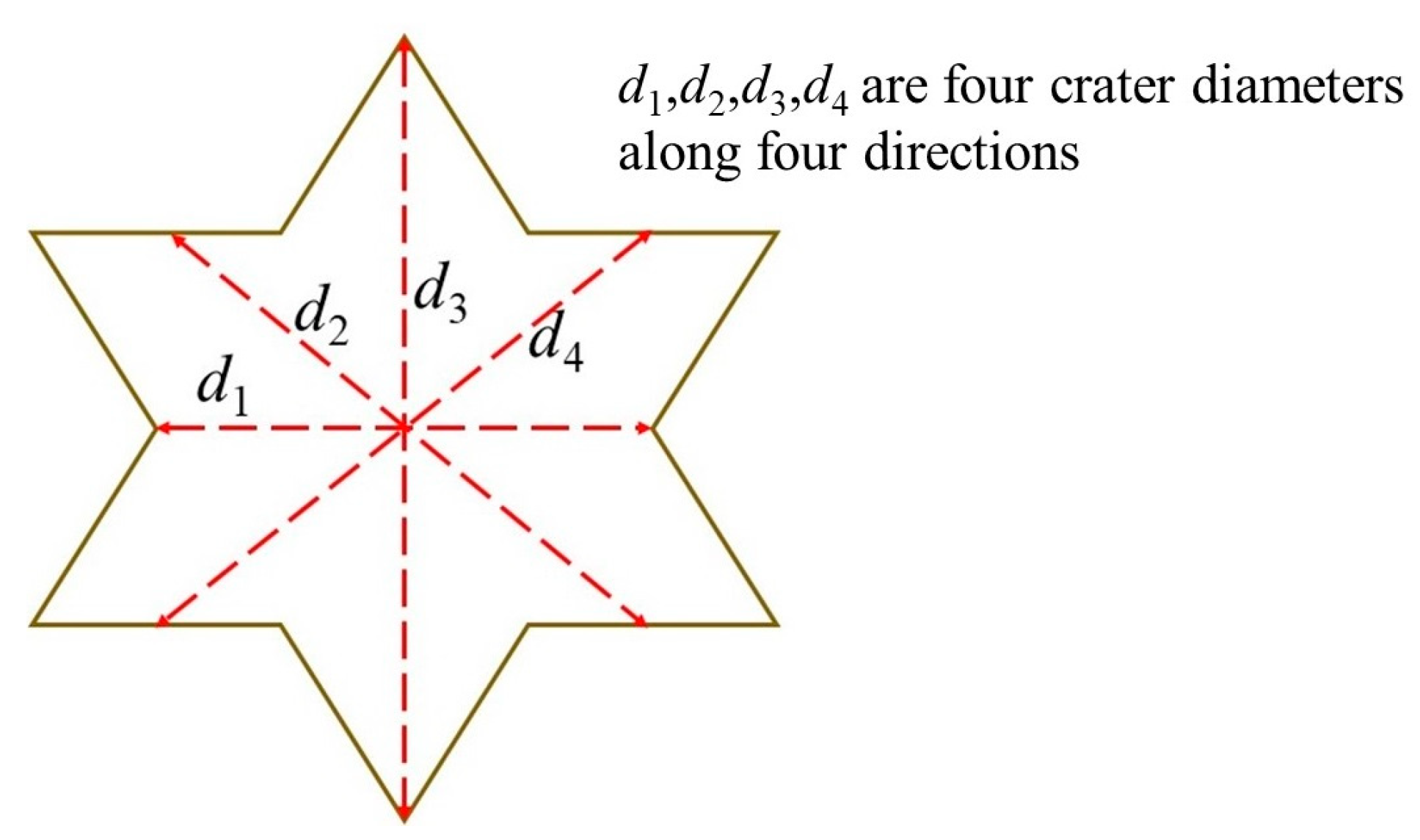

2.4. Results and Analysis

3. Numerical Simulation

3.1. Material Models

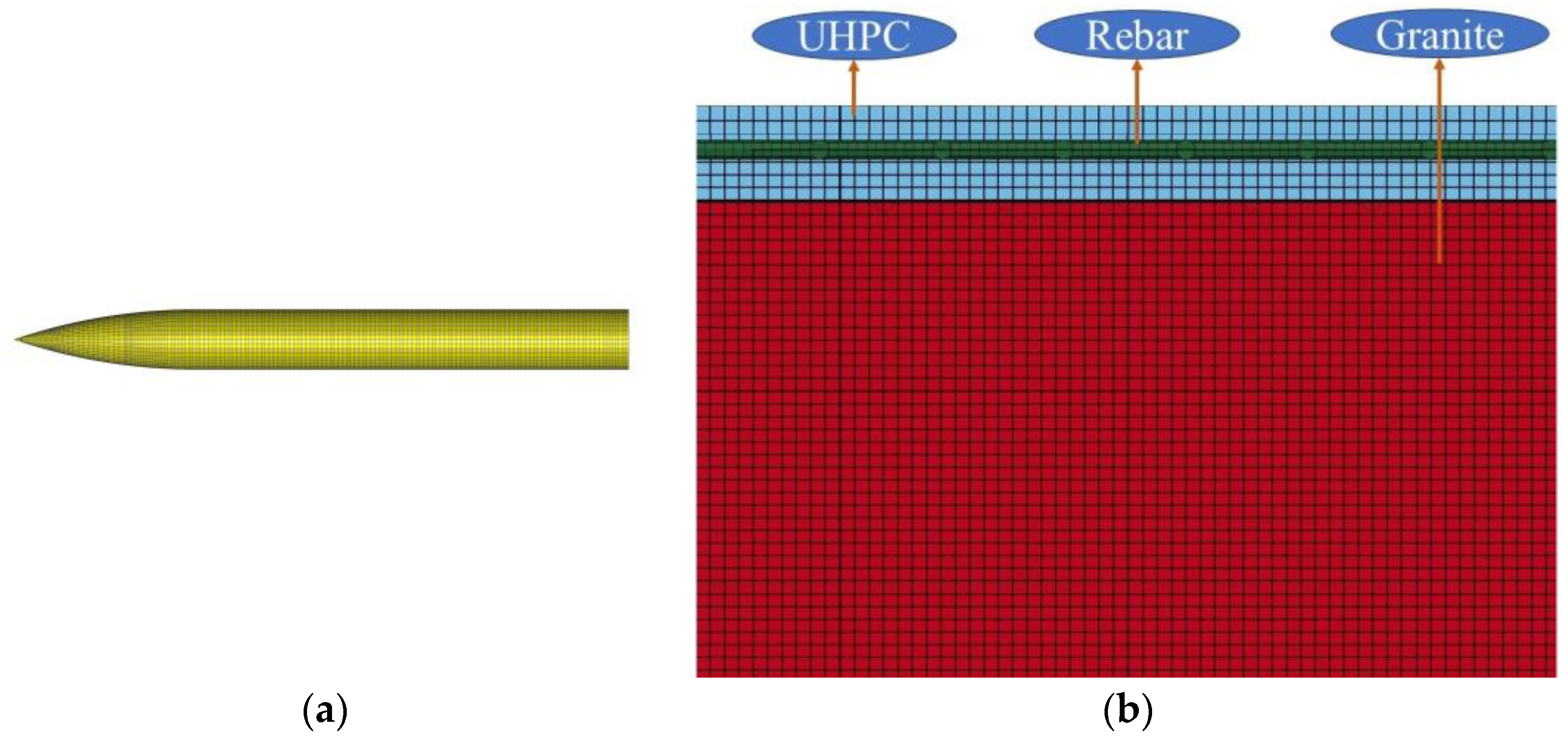

3.2. Numerical Models

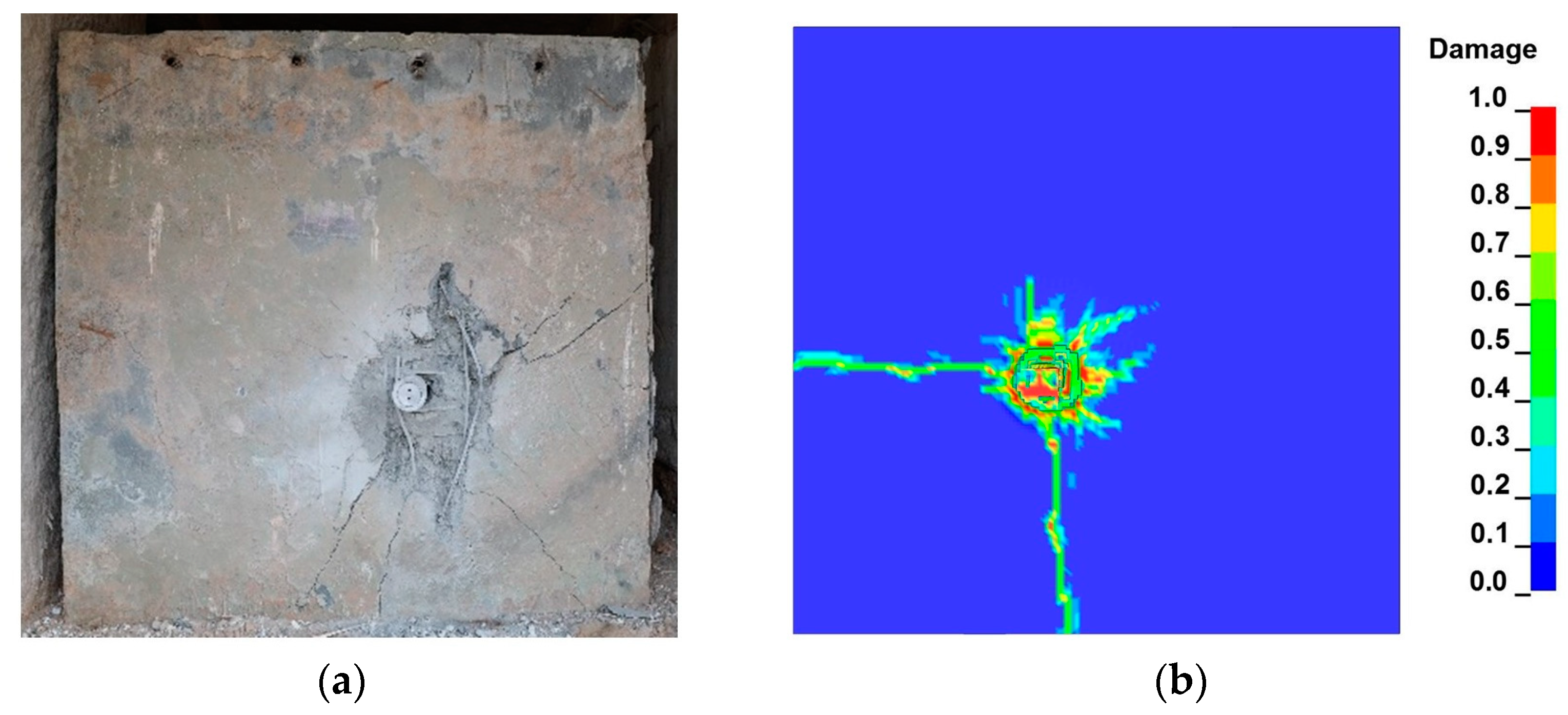

3.3. Validation of the Numerical Models

4. Results and Discussion

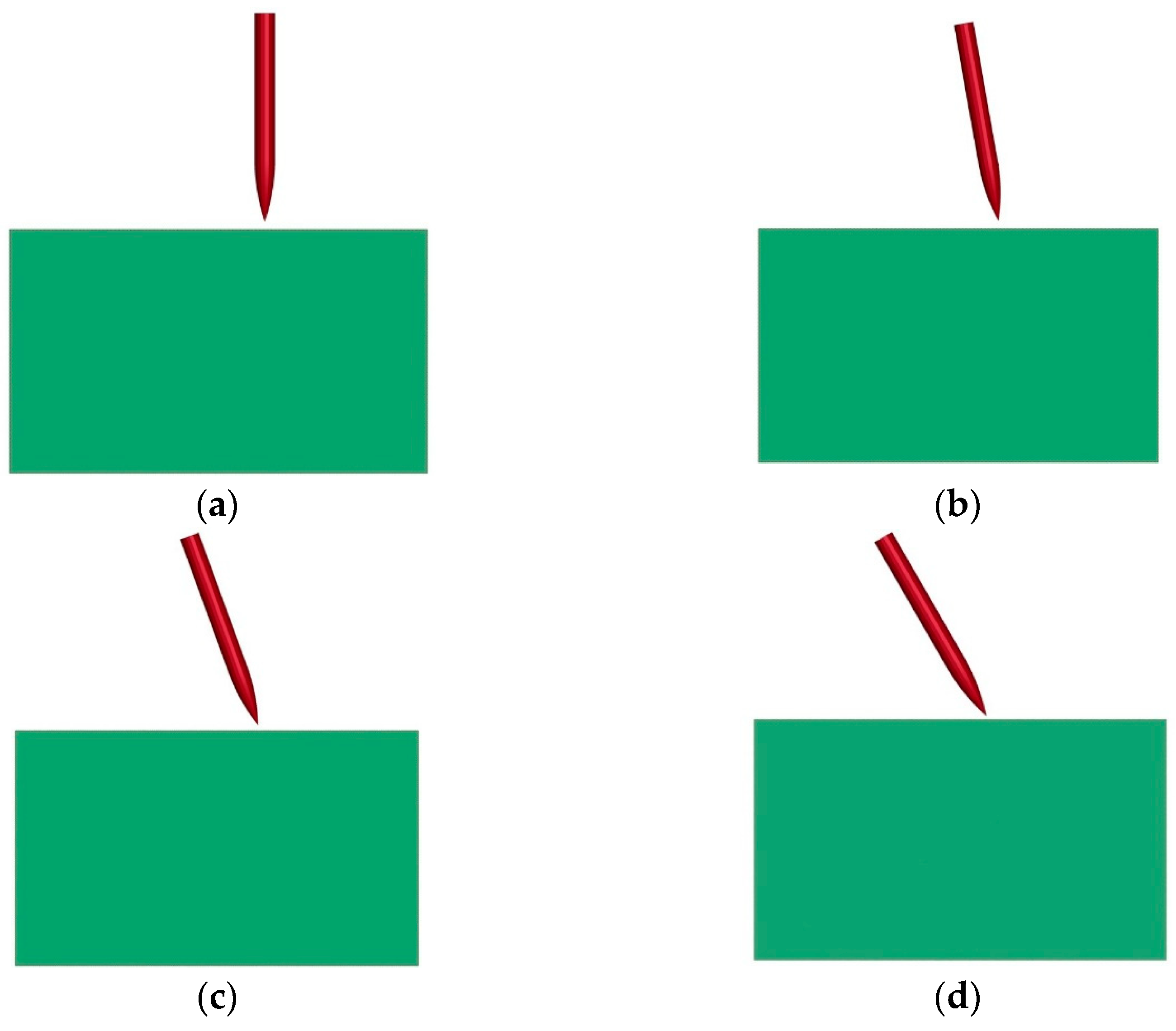

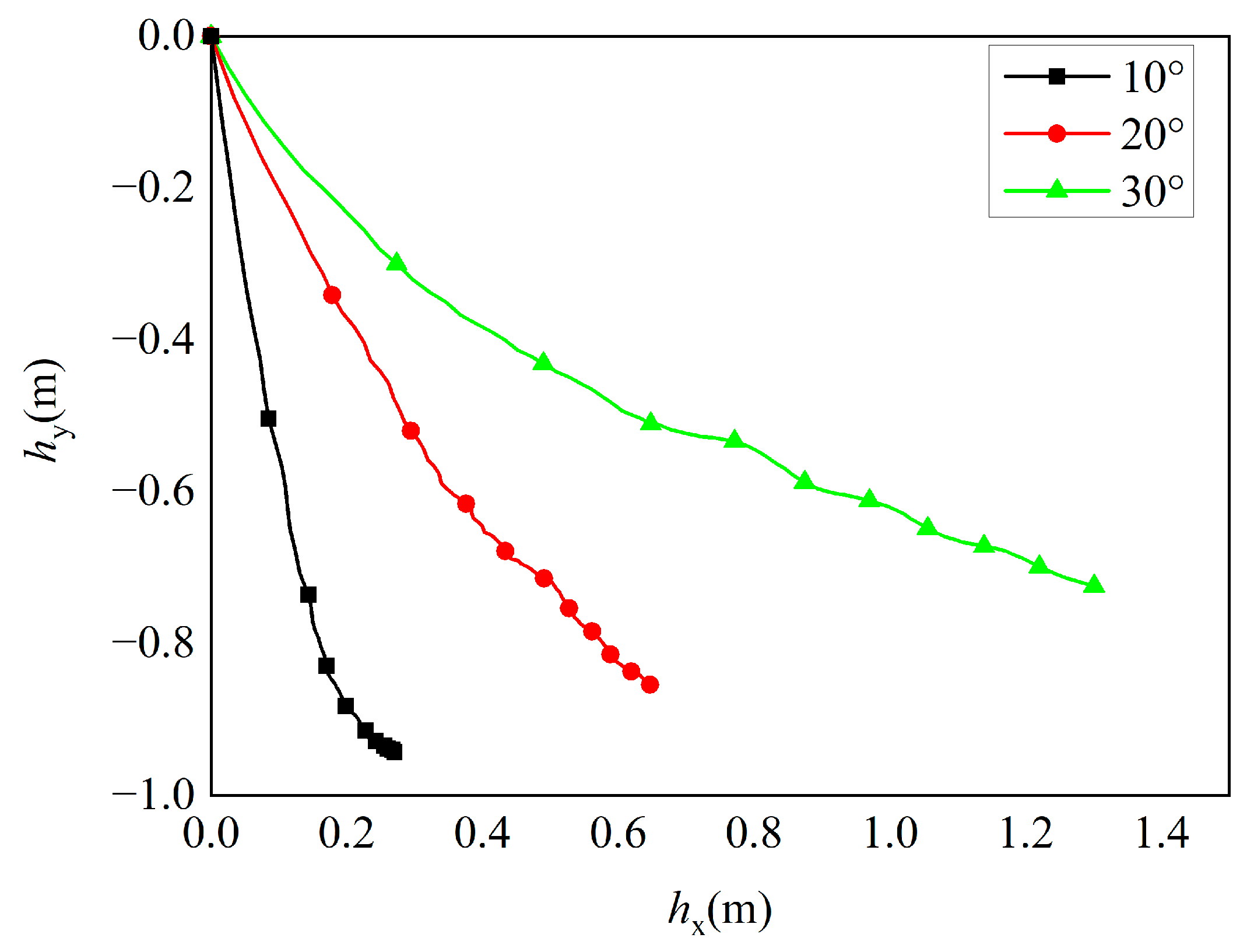

4.1. Effect of Impact Angle

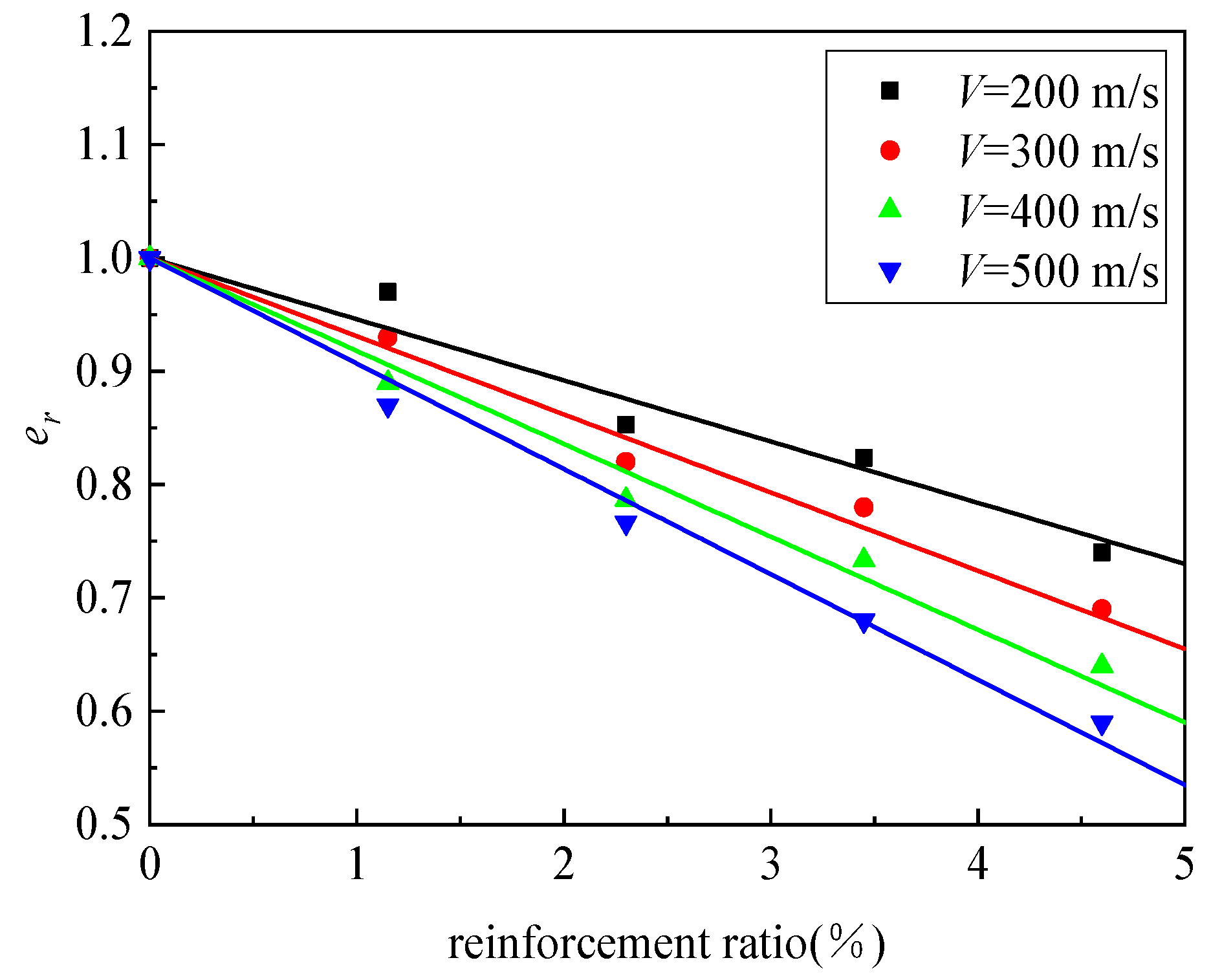

4.2. Effect of Reinforcement Ratio

5. Conclusions

- The impact tests were conducted on UHPC targets with velocities ranging from 216 to 340 m/s. Compared with granite targets, UHPC targets perform better in reducing crater diameter, while granite targets have a greater advantage in reducing penetration depth.

- The numerical models can effectively predict the penetration depth of projectiles into UHPC/granite composite structures. Meanwhile, compared with experimental results, the damage on the target surface obtained by the numerical model is consistent with the experimental observations.

- For the UHPC/granite composite structure, the penetration depth significantly decreases with the increase in the projectile incidence angle, and there is a linear relationship between penetration depth and impact angle.

- The greater the impact angle of the projectile, the more likely the trajectory of the projectile is to deflect during the penetration process. At the same time, the higher the velocity of the projectile, the less likely the trajectory is to deflect.

- For the UHPC/granite composite structure, there is a linear relationship between penetration depth and reinforcement ratio. Furthermore, the equivalent coefficient er of the reinforcement ratio is not only correlated with the reinforcement ratio but also related to the penetration velocity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbas, H.; Dabaan, M.; Siddiqui, N.; Almusallam, T.; Al-Salloum, Y. Performance of reinforced concrete composite wall systems under projectile impact. J. Mater. Res. Technol. 2023, 23, 3062–3090. [Google Scholar] [CrossRef]

- Abadel, A.A. Physical, Mechanical, and Microstructure Characteristics of Ultra-High-Performance Concrete Containing Lightweight Aggregates. Materials 2023, 16, 4883. [Google Scholar] [CrossRef]

- Ngoc, S.; Siga, S.; Thong, M.; Emad, P.; Shi, F.; Hao, H. Effect of grounded blast furnace slag and rice husk ash on performance of ultra-high-performance concrete (UHPC) subjected to impact loading. Constr. Build. Mater. 2022, 329, 127213. [Google Scholar]

- Darssni, R.; Prabhat, R.; Senthil, K.; Ambily, P. Influence of fibers on fresh and hardened properties of Ultra High Performance Concrete (UHPC)—A review. J. Build. Eng. 2022, 57, 104922. [Google Scholar]

- Tanarslan, H.M. Flexural strengthening of RC beams with prefabricated ultra-high performance fibre reinforced concrete laminates. Eng. Struct. 2017, 102, 337–348. [Google Scholar] [CrossRef]

- Doo, Y.Y.; Young, S.Y. Structural performance of ultrahigh-performance concrete beams with different steel fibers. Eng. Struct. 2015, 151, 409–423. [Google Scholar]

- Wang, H.; Shou, L.; Zhang, J.; Tian, Y.; Ou, Z.C.; Zhou, G. Experimental and numerical analysis of damage effects of granite target under impact of projectile. Chin. J. Rock Mech. Eng. 2014, 33, 366–375. [Google Scholar]

- Nabodyuti, D.; Prakash, N. State-of-the-art review on ultra-high performance concrete Ballistic and blast perspective. Cem. Concr. Compos. 2022, 127, 104383. [Google Scholar]

- Choi, J.; Park, S.; Nguyễn, H.; Lee, Y.; Lee, B. Resistance of hybrid layered composite panels composed of fiber-reinforced cementitious composites against high-velocity projectile impact. Compos. Struct. 2022, 281, 114993. [Google Scholar] [CrossRef]

- Máca, P.; Sovják, R.; Konvalinka, P. Mix design of UHPFRC and its response to projectile impact. Int. J. Impact Eng. 2014, 63, 158–163. [Google Scholar] [CrossRef]

- Anand, P.; Chandrakant, R.; Satish, S. Development of materials and structures for shielding applications against Blast and Ballistic impact: A Detailed Review. Thin-Walled Struct. 2022, 179, 109664. [Google Scholar]

- Beppu, M.; Kataoka, S.; Ichino, H.; Musha, H. Failure characteristics of UHPFRC panels subjected to projectile impact. Compos. Part B Eng. 2019, 182, 107505. [Google Scholar] [CrossRef]

- Kim, G.; Choi, J.; Park, S.; Kim, H.; Lee, Y.; Lee, B. Response of UHPFRC and HDFRC under static and high-velocity projectile impact loads. Constr. Build. Mater. 2018, 188, 399–408. [Google Scholar] [CrossRef]

- Park, G.; Lee, M.; Lee, N.; Park, G.; Kim, S. Dynamic structural responses of high-performance fiber-reinforced cement composites panels subjected to high-velocity projectile impact loadings. Compos. Struct. 2023, 306, 116581. [Google Scholar] [CrossRef]

- Kim, S.; Hwang, H.; Kang, T. Behavior of high-strength and ultra-high-performance concrete targets subjected to relatively rigid projectile impact. J. Struct. Eng. 2021, 147, 04021152. [Google Scholar] [CrossRef]

- Forrestal, M.J.; Altman, B.S.; Cargile, J.D.; Hanchak, S.J. An empirical equation for penetration depth of ogive-nose projectiles into concrete targets. Int. J. Impact Eng. 1994, 15, 395–405. [Google Scholar] [CrossRef]

- Forrestal, M.J.; Frew, D.J.; Hanchak, S.J.; Brar, N.S. Penetration of grout and concrete targets with ogive-nose steel projectiles. Int. J. Impact Eng. 1996, 18, 465–476. [Google Scholar] [CrossRef]

- Forrestal, M.J.; Frew, D.J.; Hickerson, J.P.; Rohwer, T.A. Penetration of concrete targets with deceleration-time measurements. Int. J. Impact Eng. 2003, 28, 479–497. [Google Scholar] [CrossRef]

- Wang, W.; Song, X.; Yang, J.; Liu, F.; Gao, W. Experimental and numerical research on the effect of ogive-nose projectile penetrating UR50 ultra-early-strength concrete. Cem. Concr. Compos. 2023, 136, 104902. [Google Scholar] [CrossRef]

- Sovjak, R.; Vavrinik, T.; Zatloukal, J.; Máca, P.; Mičunek, T.; Frydrýn, M. Resistance of slim UHPFRC targets to projectile impact using in-service bullets. Int. J. Impact Eng. 2015, 76, 166–177. [Google Scholar] [CrossRef]

- Almusallam, T.H.; Siddiqui, N.A.; Iqbal, R.A.; Abbas, H. Response of hybrid-fiber reinforced concrete slabs to hard projectile impact. Int. J. Impact Eng. 2013, 58, 17–30. [Google Scholar] [CrossRef]

- Lee, M.; Park, G.; Kim, S.; Kwak, H.-G. Damage Characteristics of High-Performance Fiber-Reinforced Cement Composites Panels Subjected to Projectile Impact. Int. J. Mech. Sci. 2022, 214, 106919. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Li, J.; Su, Y.; Shao, R.; Liu, Z.; Chen, G. Experimental and numerical study of reactive powder concrete reinforced with steel wire mesh against projectile penetration. Int. J. Solids Struct. 2017, 109, 131–149. [Google Scholar] [CrossRef]

- Shen, J.; Liu, R.; Yang, J. Experimental and theoretical studies of projectile penetrating rocks. Chin. J. Rock Mech. Eng. 2008, 27, 946–952. [Google Scholar]

- Zhang, D.; Zhang, X.; Lin, J. Experimental study of high strength steel projectile penetrating granite. Chin. J. Rock Mech. Eng. 2005, 24, 1612–1618. [Google Scholar]

- Huang, J.; Liu, K.; Jin, S. Numerical Simulation Study of High-strength Projectile Penetrating White Granite Target. Gold Sci. Technol. 2021, 29, 411–420. [Google Scholar]

- Yang, J.; Wu, B.; Jin, D. Experimental Study of Resistance Performance in Projectile Oblique Penetration/Impact for a Granite-reinforced Concrete Composite Structure. J. Exp. Mech. 2009, 24, 467–472. [Google Scholar]

- Sobhan, P.; Sonalisa, R.; Ki, Y. Dynamic behaviour of multi-layer composite against single and multiple projectile impact loading. Mechanics 2023, 129, 104189. [Google Scholar]

- Zhai, Y.; Wu, H.; Fang, Q. Impact resistance of armor steel/ceramic/UHPC layered composite targets against 30CrMnSiNi2A steel projectiles. Int. J. Impact Eng. 2021, 154, 103888. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Li, J.; Fang, J.; Su, Y.; Shao, R. Ceramic balls protected ultra-high performance concrete structure against projectile impact-A numerical study. Int. J. Impact Eng. 2019, 125, 143–162. [Google Scholar] [CrossRef]

- GB/T 31387-2015; Reactive Powder Concrete. Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- Nie, X.; Wu, X.; Yi, Z.; Long, Z.; Zhou, H.; Ji, N. Discussion on Static Resistance of Granite under Penetration. Materials 2023, 16, 3353. [Google Scholar] [CrossRef] [PubMed]

- Riedel, W.; Thoma, K.; Hiermaier, S. Penetration of Reinforced Concrete by BETA-B-500 Numerical Analysis using a Macroscopic Concrete Model for Hydrocode. In Proceedings of the 9th International Symposium Interaction of the Effect of Munitions with Structures, Berlin, Germany, 3–7 May 1999. [Google Scholar]

- Abdel-Kader, M. Modified settings of concrete parameters in RHT model for predicting the response of concrete panels to impact. Int. J. Impact Eng. 2019, 132, 103312. [Google Scholar] [CrossRef]

- Prakash, A.; Srinivasan, S.; Rao, A. Numerical investigation on steel fibre reinforced cementitious composite panels subjected to high velocity impact loading. Mater. Des. 2015, 83, 164–175. [Google Scholar] [CrossRef]

- Xue, J.; Shen, P.; Wang, X. Anti-penetration behavior of concrete and reinforced concrete and its equivalent relationship. J. Build. Mater. 2017, 20, 174–179. [Google Scholar]

| Cement | Quartz Sand | Quartz Powder | Silica Fume | Fly Ash | Steel Fibers | Water | Superplasticizer |

|---|---|---|---|---|---|---|---|

| 666 | 1065 | 160 | 160 | 80 | 157 | 135 | 6.7 |

| Diameter (mm) | Length (mm) | Strength (MPa) | Young’s Modulus (GPa) | Density (kg/m3) |

|---|---|---|---|---|

| 0.2 | 13 | 2000 | 200 | 7800 |

| Types of Target | d 1 (mm) | m 2 (kg) | V 3 (m/s) | Depth of Penetration | Crater Diameter | ||

|---|---|---|---|---|---|---|---|

| h 4 (mm) | h/d | dc (mm) | dc/d | ||||

| UHPC | 30 | 1.001 | 216 | 145 | 4.83 | 200 | 6.67 |

| 30 | 1.003 | 308 | 199 | 6.63 | 300 | 10 | |

| 30 | 1.003 | 341 | 223 | 7.43 | 320 | 10.67 | |

| Granite [32] | 30 | 0.999 | 216 | 89 | 2.97 | 253 | 8.43 |

| 30 | 1.002 | 226 | 74 | 2.47 | 370 | 12.33 | |

| 30 | 1.003 | 229 | 97 | 3.23 | 305 | 10.17 | |

| 30 | 0.999 | 300 | 122 | 4.07 | 363 | 12.1 | |

| 30 | 1.004 | 300 | 96 | 3.2 | 365 | 12.17 | |

| 30 | 1.005 | 322 | 122 | 4.07 | 513 | 17.1 | |

| 30 | 1.003 | 340 | 139 | 4.6 | 363 | 12.1 | |

(kg·m−3) | E (GPa) | (MPa) | (MPa) | C | P | |||

|---|---|---|---|---|---|---|---|---|

| 7800 | 210 | 280 | 0.3 | 600 | 1 | 40 | 5 | 0.2 |

(kg·m−3) | G (GPa) | (MPa) | (GPa) | A | (s−1) | (s−1) | (s−1) | (s−1) | |||

| 2450 | 18.5 | 160 | 1.22 | 1.22 | 44 | 0 | 1.6 | 3.0 × 1025 | 3.0 × 1025 | 3.0 × 10−5 | 3.0 × 10−6 |

(MPa) | (GPa) | (GPa) | (GPa) | ||||||||

| 53.3 | 0.53 | 0.7 | 0.67 | 0.04 | 0.008 | 1.75 | 0.52 | 44 | 49.38 | 11.28 | 0.0125 |

| B | N | n | (GPa) | ||||||||

| 0.0143 | 0.0105 | 4.0 | 1 | 0.681 | 0.61 | 0.0613 | 0.267 | 6 | 1.18 |

| Test No | Diameter of the Projectile (mm) | Velocities V (m/s) | Reinforcement Ratio (%) | Experiments (m) | Simulation (m) | Error |

|---|---|---|---|---|---|---|

| 1 | 117 | 300 | 2.3 | 0.58 | 0.54 | 6.9% |

| 1 (°) | d 2 (mm) | V 3 (m/s) | Depth of Penetration | |

|---|---|---|---|---|

| h 4 (m) | h/d | |||

| 0 | 117 | 200 | 0.4 | 3.4 |

| 0 | 300 | 0.64 | 5.5 | |

| 0 | 400 | 0.88 | 7.5 | |

| 0 | 500 | 1.05 | 9.0 | |

| 10 | 200 | 0.36 | 3.1 | |

| 10 | 300 | 0.55 | 4.7 | |

| 10 | 400 | 0.73 | 6.2 | |

| 10 | 500 | 0.95 | 8.1 | |

| 20 | 200 | 0.32 | 2.7 | |

| 20 | 300 | 0.46 | 3.9 | |

| 20 | 400 | 0.64 | 5.5 | |

| 20 | 500 | 0.85 | 7.3 | |

| 30 | 200 | 0.27 | 2.3 | |

| 30 | 300 | 0.41 | 3.5 | |

| 30 | 400 | 0.62 | 5.3 | |

| 30 | 500 | 0.72 | 6.2 | |

| Reinforcement Ratio (%) | d (mm) | V (m/s) | Depth of Penetration | |

|---|---|---|---|---|

| h (m) | h/d | |||

| 0 | 117 | 200 | 0.4 | 3.4 |

| 0 | 300 | 0.64 | 5.5 | |

| 0 | 400 | 0.88 | 7.5 | |

| 0 | 500 | 1.05 | 9.0 | |

| 1.15 | 200 | 0.35 | 3.0 | |

| 1.15 | 300 | 0.56 | 4.8 | |

| 1.15 | 400 | 0.75 | 6.4 | |

| 1.15 | 500 | 0.90 | 7.6 | |

| 2.3 | 200 | 0.34 | 2.9 | |

| 2.3 | 300 | 0.54 | 4.6 | |

| 2.3 | 400 | 0.69 | 5.9 | |

| 2.3 | 500 | 0.81 | 6.9 | |

| 3.45 | 200 | 0.33 | 2.8 | |

| 3.45 | 300 | 0.50 | 4.3 | |

| 3.45 | 400 | 0.64 | 5.5 | |

| 3.45 | 500 | 0.75 | 6.4 | |

| 4.6 | 200 | 0.30 | 2.6 | |

| 4.6 | 300 | 0.42 | 3.6 | |

| 4.6 | 400 | 0.53 | 4.5 | |

| 4.6 | 500 | 0.61 | 5.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, H.; Ren, H.; Wang, W.; Nie, X. Impact Resistance of Ultra-High-Performance Concrete Composite Structures. Materials 2023, 16, 7456. https://doi.org/10.3390/ma16237456

Ning H, Ren H, Wang W, Nie X. Impact Resistance of Ultra-High-Performance Concrete Composite Structures. Materials. 2023; 16(23):7456. https://doi.org/10.3390/ma16237456

Chicago/Turabian StyleNing, Huijun, Huiqi Ren, Wei Wang, and Xiaodong Nie. 2023. "Impact Resistance of Ultra-High-Performance Concrete Composite Structures" Materials 16, no. 23: 7456. https://doi.org/10.3390/ma16237456

APA StyleNing, H., Ren, H., Wang, W., & Nie, X. (2023). Impact Resistance of Ultra-High-Performance Concrete Composite Structures. Materials, 16(23), 7456. https://doi.org/10.3390/ma16237456