Evaluation of Durability Performance for Chloride Ingress Considering Long-Term Aged GGBFS and FA Concrete and Analysis of the Relationship between Concrete Mixture Characteristic and Passed Charge Using Machine Learning Algorithm

Abstract

:1. Introduction

2. Fabrication of OPC, GGBFS, and FA Concretes and Evaluation of Mechanical and Durability Performances

2.1. Used Materials and Mix Design

2.2. Method of Evaluating the Passed Charge

2.3. Method of Evaluating the Compressive Strength

3. Results of Time-Dependent Mechanical and Durability Performance Evaluations for OPC, GGBFS, and FA Concretes

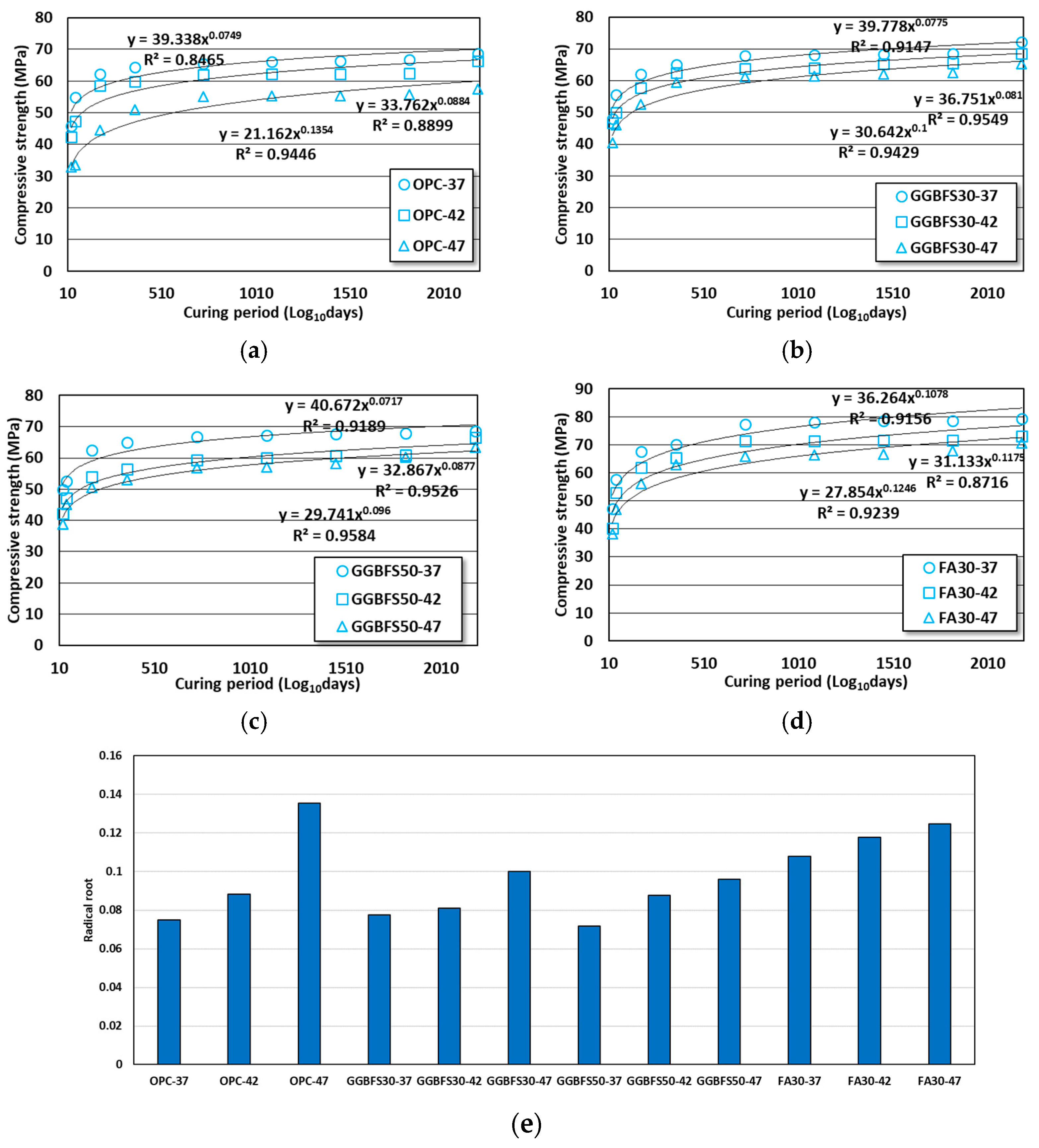

3.1. Results of Time-Dependent Compressive Strength Evaluation

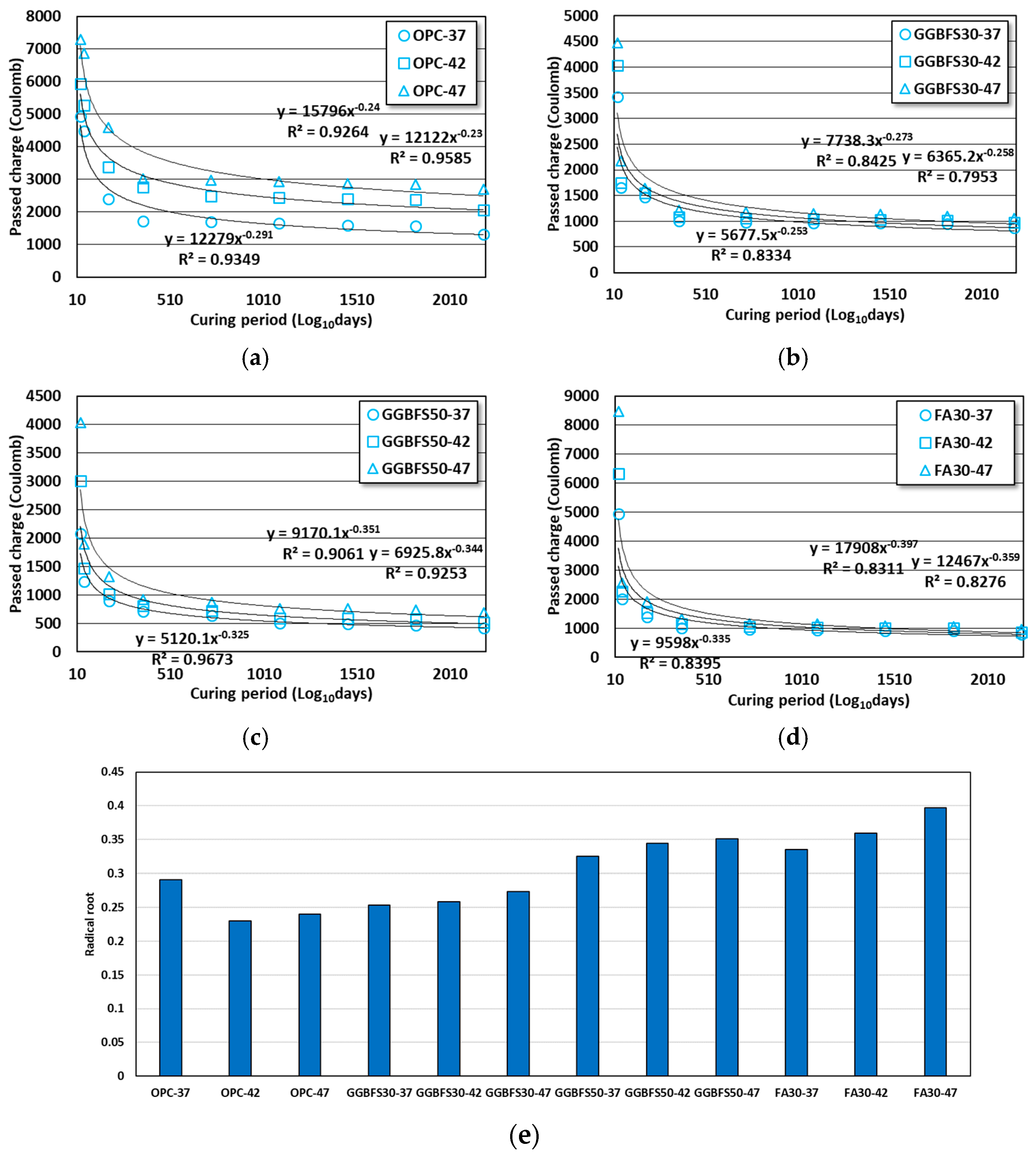

3.2. Results of Time-Dependent Passed Charge Evaluation

4. Correlation Analysis of Concrete Mix Properties with Mechanical and Durability Performances Using Machine Learning Algorithm

4.1. Machine Learning Algorithm for Regression Analysis

4.2. Building a Dataset for Predicting Concrete Performance Based on Machine Learning Algorithm

4.3. Result of Correlation Analysis between Mix Properties and Concrete Performance Using a Machine Learning Model

5. Conclusions

- Compressive strength analysis with increasing aged days showed that the strength increase was insignificant in every mix after 2 years of age. A regression analysis in a radical root form was performed on aged days and compressive strength to analyze the effect of aged days on compressive strength behavior. The effect of aged days on compressive strength increased with higher W/B ratios, and mixes with replaced admixtures were less affected by aged days than the OPC mix.

- When the decrease in passed charge at 6 years of age was analyzed in comparison to 3 years of age, the last evaluation date of previous studies, the OPC mix showed a larger decrease than other mixes due to the fact that in other mixes, a significant decrease had already occurred before 3 years of age. The variability of passed charge due to W/B ratio decreased with increase in age when admixtures such as GGBFS and FA were added. A regression analysis with aged days as the x-axis and passed charge as the y-axis was performed to analyze the effect of aged days on passed charge behavior. For GGBFS and FA concretes, the effect of age increased as the W/B ratio increased. In the case of GGBFS and FA concretes, although the W/B ratio was relatively high, the material properties of latent hydraulic and pozzolanic reactions significantly improved the long-term chloride ingress durability performance.

- When the correlation between mix properties and chloride ingress durability performance was analyzed by a multiple regression model in three cases, the best performance was observed when mix properties (unit quantity, unit cement quantity, FA quantity, GGBFS quantity, fine aggregate quantity, coarse aggregate quantity), aged days, and compressive strength were set as independent variables, while passed charge was the dependent variable. Thus, considering compressive strength in addition to mix properties and age can better explain the correlation between passed charge and mix properties. In the future, further analysis of the correlation between mix properties and chloride ingress durability performance through DL algorithms based on the time series characteristics of the data will be conducted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Metha, P.K.; Monteiro, P.M. Concrete-Structure, Properties, and Materials, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2009; pp. 113–171. [Google Scholar]

- Zheng, Y.; Wen, Y.; Pan, T.; Liu, Y.; Zhou, Y.; Li, R.; Zhou, Y. Fractal characteristics and damage evaluation of corroded beams under four-point bending tests based on acoustic emission techniques. Measurement 2022, 202, 111792. [Google Scholar] [CrossRef]

- Yu, Z.; Ni, C.; Tang, M.; Shen, X. Relationship between water permeability and pore structure of Portland cement paste blended with fly ash. Constr. Build. Mater. 2018, 175, 458–466. [Google Scholar] [CrossRef]

- Maekawa, K.; Ishida, T.; Kishi, T. Multi-Scale Modeling of Structural Performance; Taylor Francis: London, UK, 2009; pp. 322–325. [Google Scholar]

- Al-amoudi, O.S.B.; Maslehuddin, M. The effect of chloride and sulfate ions on reinforcement corrosion. Cem. Concr. Res. 1993, 23, 139–146. [Google Scholar] [CrossRef]

- Amey, S.L.; Johnson, D.A.; Miltenberger, M.A.; Farzam, H. Predicting the service life of concrete marine structures: An environmental methodology. ACI Struct. J. 1998, 95, 205–214. [Google Scholar]

- Kouloumbi, N.; Batis, G.; Malami, C.H. The anticorrosive effect of fly ash, slag and a Greek pozzolan in reinforced concrete. Cem. Concr. Compos. 1994, 16, 253–260. [Google Scholar] [CrossRef]

- Kim, H.J.; Yoon, Y.S.; Yang, K.H.; Kwon, S.J. Durability and purification performance of concrete impregnated with silicate and sprayed with photocatalytic TiO2. Constr. Build. Mater. 2019, 199, 106–114. [Google Scholar] [CrossRef]

- Qu, F.; Li, W.; Guo, Y.; Zhang, S.; Zhou, J.L. Chloride-binding capacity of cement-GGBFS-nanosilica composites under seawater chloride-rich environment. Constr. Build. Mater. 2022, 342, 1278901. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Illikainen, M. Improved strength development and frost resistance of Portland cement ground-granulated blast furnace slag binary binder cured at 0 C with the addition of calcium silicate hydrate seeds. J. Build. Eng. 2022, 48, 103904. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Yap, S.P. Feasibility Study of High Volume Slag as Cement Replacement for Sustainable Structural Lightweight Oil Palm Shell Concrete. J. Clean Prod. 2015, 91, 297–304. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Rath, S.; Attachaiyawuth, A. Enhancement in self-compactability and stability in volume of entrained air in self-compacting concrete with high volume fly ash. Constr. Build. Mater. 2016, 128, 349–360. [Google Scholar] [CrossRef]

- KCI. KDS 14 20 40-Standard for Durability Design of Concrete Structures; Korea Concrete Institute: Seoul, Republic of Korea, 2021; pp. 652–653. [Google Scholar]

- JSCE. Standard Specification for Concrete Structures—Design, JSCE-Guidelines for Concrete 15; Japan Society of Civil Engineering: Tokyo, Japan, 2007. [Google Scholar]

- ACI Committee 365. ACI 365.1R-17-Report on Service Life Prediction; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- Yang, K.H.; Mun, J.H.; Yoon, Y.S.; Kwon, S.J. Effects of loading conditions and cold joint on service life against chloride ingress. Comput. Concr. 2018, 22, 319–326. [Google Scholar]

- ASTM C 1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2005.

- NT Build 492; Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments. Nordtest: Espoo, Finland, 1999.

- Fan, Z.; Su, D.; Zhang, Z.; Zhong, M.; Zhang, X.; Xiong, J.; Li, P. Transfer Parameter Analysis of Chloride Ingress into Concrete Based on Long-Term Exposure Tests in China’s Coastal Region. Materials 2022, 15, 8517. [Google Scholar] [CrossRef] [PubMed]

- Yoon, Y.S.; Jeong, G.C.; Kwon, S.J. The Comparison of Apparent Chloride Diffusion Coefficients in GGBFS Concrete Considering Sea Water Exposure Conditions. J. Korea Inst. Struct. Maint. Inspect. 2022, 26, 18–27. [Google Scholar]

- Thomas, M.D.A.; Bentz, E.C. Computer Program for Predicting the Service Life and Life-Cycle Costs of Reinforced Concrete Exposed to Chlorides (Life365 Manual); SFA: Lovettsville, VA, USA, 2002. [Google Scholar]

- Chithra, S.; Kumar, S.S.; Chinnaraju, K.; Ashmita, F.A. A comparative study on the compressive strength prediction models for High Performance Concrete containing nano silica and copper slag using regression analysis and Artificial Neural Networks. Constr. Build. Mater. 2016, 114, 528–535. [Google Scholar] [CrossRef]

- Kim, I.S.; Lee, J.H.; Yang, D.S.; Park, S.K. Prediction on Mix Proportion Factor and Strength of Concrete Using Neural Network. J. Korean Concr. Inst. 2002, 14, 457–466. [Google Scholar]

- Lee, S.C. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Yeh, I.C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Liu, K.H.; Zheng, J.K.; Pacheco-Torgal, F.; Zhao, X.Y. Innovative modeling framework of chloride resistance of recycled aggregate concrete using ensemble-machine-learning methods. Constr. Build. Mater. 2022, 337, 127613. [Google Scholar] [CrossRef]

- Hafez, H.; Teirelbar, A.; Kurda, R.; Tošić, N.; de la Fuente, A. Pre-bcc: A novel integrated machine learning framework for predicting mechanical and durability properties of blended cement concrete. Constr. Build. Mater. 2022, 352, 129019. [Google Scholar] [CrossRef]

- Ziolkowski, P. Computational complexity and its influence on predictive capabilities of machine learning models for concrete mix design. Materials 2023, 16, 5956. [Google Scholar] [CrossRef]

- Najafabadi, M.M.; Villanustre, F.; Khoshgoftaar, T.M.; Seliya, N.; Wald, R.; Muharemagic, E. Deep learning applications and challenges in big data analytics. J. Big Data 2015, 2, 1. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; Beskopylny, N. Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials 2022, 15, 6740. [Google Scholar] [CrossRef] [PubMed]

- Maulud, D.; Abdulazeez, A.M. A review on linear regression comprehensive in machine learning. J. Appl. Sci. Technol. Trends 2020, 1, 140–147. [Google Scholar] [CrossRef]

- Cunningham, P.; Cord, M.; Delany, S.J. Supervised Learning, Machine Learning Techniques for Multimedia: Case Studies on Organization and Retrieval; Springer: Berlin, Germany, 2008; pp. 21–49. [Google Scholar]

- Janiesch, C.; Zschech, P.; Heinrich, K. Machine learning and deep learning. Electron. Mar. 2021, 31, 685–695. [Google Scholar] [CrossRef]

- Jeong, D.H. A Study on Prediction of Concrete Carbonation Using Deep Learning. Master’s Thesis, Hanyang University, Ansan, Republic of Korea, 2020. [Google Scholar]

- Zhou, Y.; Li, W.; Peng, Y.; Tang, S.; Wang, L.; Shi, Y.; Li, Y.; Wang, Y.; Geng, Z.; Wu, K. Hydration and Fractal Analysis on Low-Heat Portland Cement Pastes Using Thermodynamics-Based Methods. Fractal Fract. 2023, 7, 606. [Google Scholar] [CrossRef]

- Liao, Y.; Yao, J.; Deng, F.; Li, H.; Wang, K.; Tang, S. Hydration behavior and strength development of supersulfated cement prepared by calcined phosphogypsum and slaked lime. J. Build. Eng. 2023, 80, 108075. [Google Scholar] [CrossRef]

- Yang, K.H.; Kwon, S.J.; Hwang, J.W.; Yoon, Y.S. Temperature effect on strength and chloride migration in nuclear power plant concrete. Constr. Build. Mater. 2023, 405, 133345. [Google Scholar] [CrossRef]

- Yoon, Y.S.; Kwon, S.J. Evaluation of Chloride Behavior and Service Life in Long-Term Aged FA Concrete through Probabilistic Analysis. J. Korean Rec. Constr. Resour. Inst. 2020, 8, 276–285. [Google Scholar]

- Yoon, Y.S.; Kim, T.H.; Kwon, S.J. Evaluation of Chloride Diffusion Behavior and Analysis of Probabilistic Service Life in Long Term Aged GGBFS Concrete. J. Korea Inst. Struct. Maint. Inspect. 2020, 24, 47–56. [Google Scholar]

- Berke, N.S.; Hicks, M.C. Predicting Chloride Profiles in Concrete. Corrosion 1994, 50, 234–239. [Google Scholar] [CrossRef]

- KS F 2405; Standard Test Method for Compressive Strength of Concrete. KSSN: Seoul, Republic of Korea, 2015.

- Wang, X.Y. Effect of fly ash on properties evolution of cement based materials. Constr. Build. Mater. 2014, 69, 32–40. [Google Scholar] [CrossRef]

- Kelley, K.; Bolin, J.H.H. Multiple Regression, Handbook of Quantitative Methods for Educational Research; Brill: Leiden, The Netherlands, 2013; pp. 69–101. [Google Scholar]

- Tibshirani, R. Regression shrinkage and selection via the lasso. J. R. Stat. Soc. Ser. B-Stat. Methodol. 1996, 58, 267–288. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Miles, J. R-squared, adjusted R-squared. In Encyclopedia of Statistics in Behavioral Science; Wiley Online Library: Hoboken, NJ, USA, 2005. [Google Scholar]

| Chemical Composition (Mass %) | Physical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Items | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Ig.loss | Specific Gravity (g cm−3) | Blaine (cm2 g−1) | |

| Types | ||||||||||

| OPC | 21.96 | 5.27 | 3.44 | 63.41 | 2.13 | 1.96 | 0.79 | 3.16 | 3214 | |

| GGBFS | 32.74 | 13.23 | 0.41 | 44.14 | 5.62 | 1.84 | 0.20 | 2.89 | 4340 | |

| FA | 55.66 | 27.76 | 7.04 | 2.70 | 1.14 | 0.49 | 4.3 | 2.19 | 3621 | |

| Items | Gmax (mm) | Specific Gravity (g cm−3) | Absorption (%) | F.M. | |

|---|---|---|---|---|---|

| Types | |||||

| Fine aggregate | - | 2.58 | 1.01 | 2.90 | |

| Coarse aggregate | 25 | 2.64 | 0.82 | 6.87 | |

| W/B (%) | Unit Weight (kg m−3) | S.P (wt%) | ||||||

|---|---|---|---|---|---|---|---|---|

| W | C | GGBFS | FA | Fine Agg. | Coarse Agg. | |||

| OPC | 37 | 168 | 454 | 0 | 0 | 767 | 952 | 1.10 |

| 42 | 168 | 400 | 0 | 0 | 787 | 976 | 1.00 | |

| 47 | 168 | 357 | 0 | 0 | 838 | 960 | 0.95 | |

| GGBFS30 | 37 | 168 | 318 | 136 | 0 | 762 | 946 | 1.30 |

| 42 | 168 | 280 | 120 | 0 | 783 | 972 | 1.10 | |

| 47 | 168 | 250 | 107 | 0 | 835 | 956 | 1.00 | |

| GGBFS50 | 37 | 168 | 227 | 227 | 0 | 760 | 943 | 1.40 |

| 42 | 168 | 200 | 200 | 0 | 780 | 969 | 1.20 | |

| 47 | 168 | 179 | 179 | 0 | 832 | 853 | 1.10 | |

| FA30 | 37 | 168 | 318 | 0 | 136 | 745 | 952 | 1.40 |

| 42 | 168 | 280 | 0 | 120 | 768 | 953 | 1.20 | |

| 47 | 168 | 250 | 0 | 107 | 820 | 939 | 1.00 | |

| Total Passed Charge (C) | Chloride Ion Permeability |

|---|---|

| >4000 | High |

| 2000–4000 | Moderate |

| 1000–2000 | Low |

| 100–1000 | Very low |

| <100 | Negligible |

| Independent Variables | Dependent Variables | |

|---|---|---|

| Case 1 | Water, Cement, FA, GGBFS, Sand, Gravel | Passed Charge |

| Case 2 | Water, Cement, FA, GGBFS, Sand, Gravel | Compressive Strength |

| Case 3 | Water, Cement, FA, GGBFS, Sand, Gravel, Compressive Strength | Passed Charge |

| Analysis Method | Regression Equation | R2-Train Dataset | R2-Test Dataset |

|---|---|---|---|

| Linear analysis | 0.512 | 0.407 | |

| 0.700 | 0.611 | ||

| 0.877 | 0.789 | ||

| Ridge analysis | 0.512 | 0.407 | |

| 0.700 | 0.611 | ||

| 0.877 | 0.789 | ||

| Lasso analysis | 0.512 | 0.408 | |

| 0.699 | 0.601 | ||

| 0.877 | 0.789 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, Y.-S.; Kwon, S.-J.; Kim, K.-C.; Kim, Y.; Koh, K.-T.; Choi, W.-Y.; Lim, K.-M. Evaluation of Durability Performance for Chloride Ingress Considering Long-Term Aged GGBFS and FA Concrete and Analysis of the Relationship between Concrete Mixture Characteristic and Passed Charge Using Machine Learning Algorithm. Materials 2023, 16, 7459. https://doi.org/10.3390/ma16237459

Yoon Y-S, Kwon S-J, Kim K-C, Kim Y, Koh K-T, Choi W-Y, Lim K-M. Evaluation of Durability Performance for Chloride Ingress Considering Long-Term Aged GGBFS and FA Concrete and Analysis of the Relationship between Concrete Mixture Characteristic and Passed Charge Using Machine Learning Algorithm. Materials. 2023; 16(23):7459. https://doi.org/10.3390/ma16237459

Chicago/Turabian StyleYoon, Yong-Sik, Seung-Jun Kwon, Kyong-Chul Kim, YoungSeok Kim, Kyung-Taek Koh, Won-Young Choi, and Kwang-Mo Lim. 2023. "Evaluation of Durability Performance for Chloride Ingress Considering Long-Term Aged GGBFS and FA Concrete and Analysis of the Relationship between Concrete Mixture Characteristic and Passed Charge Using Machine Learning Algorithm" Materials 16, no. 23: 7459. https://doi.org/10.3390/ma16237459