A Method of Producing Low-Density, High-Strength Thin Cement Sheets: Pilot Run for a Glass-Free Solar Panel

Abstract

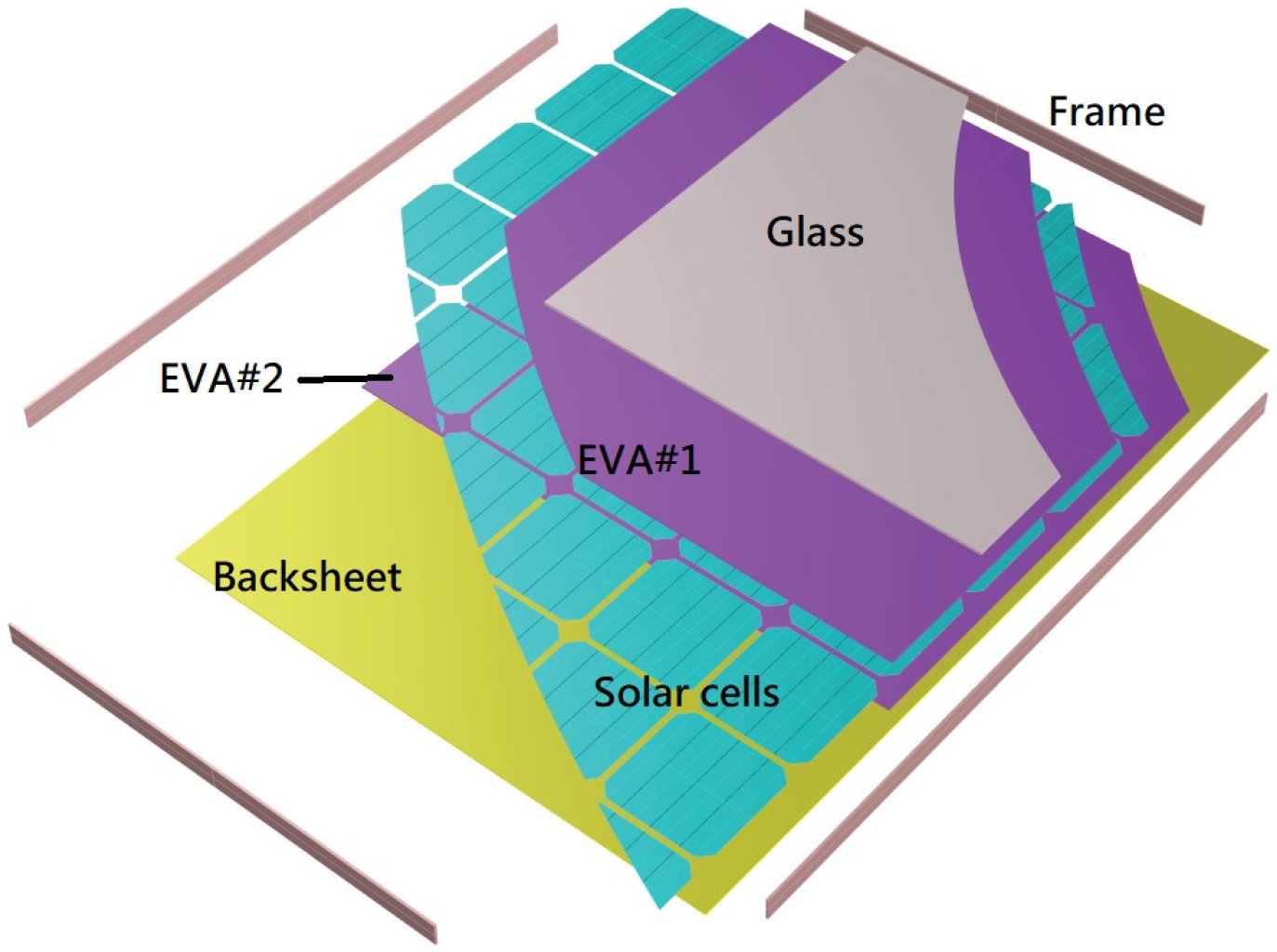

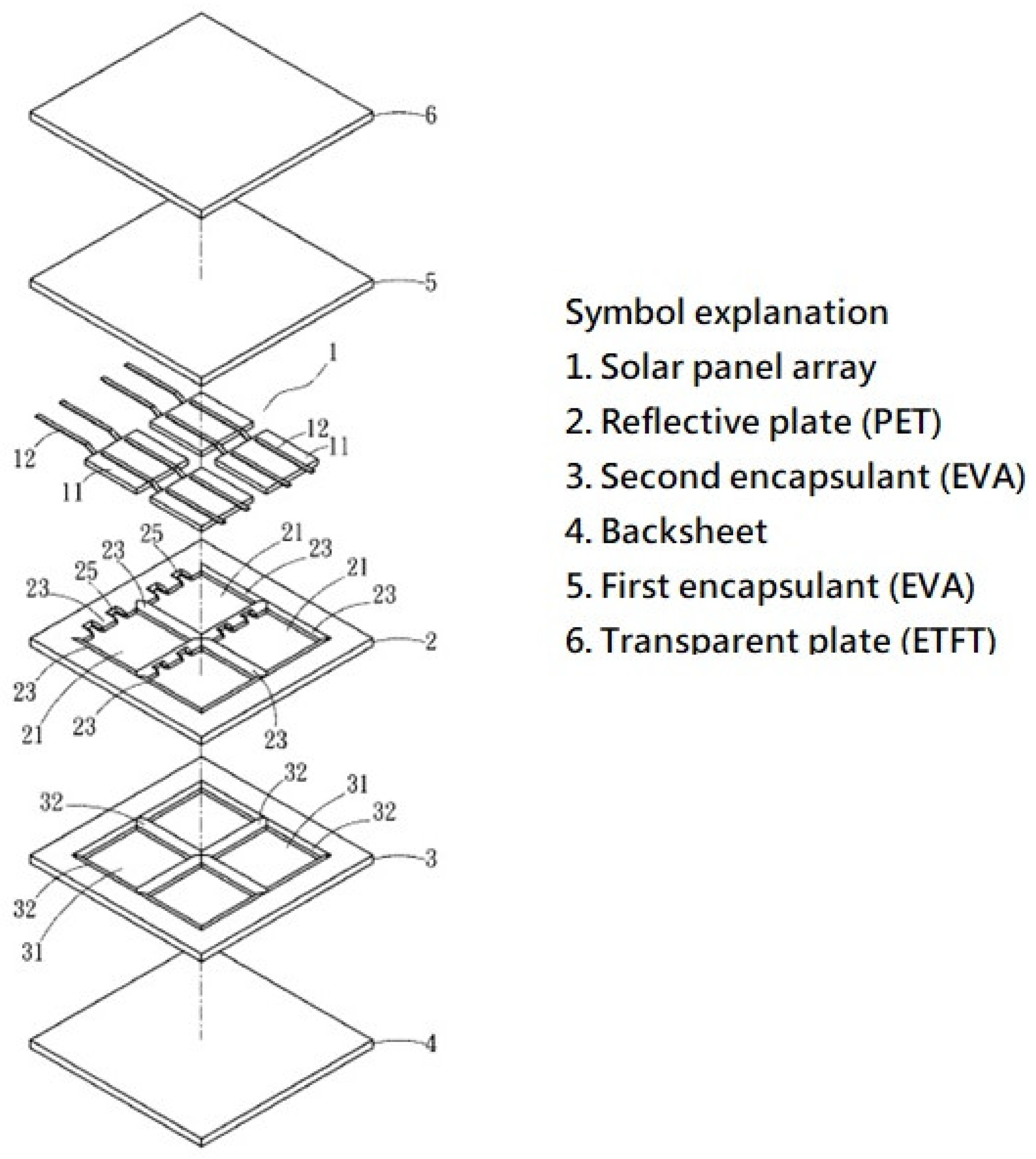

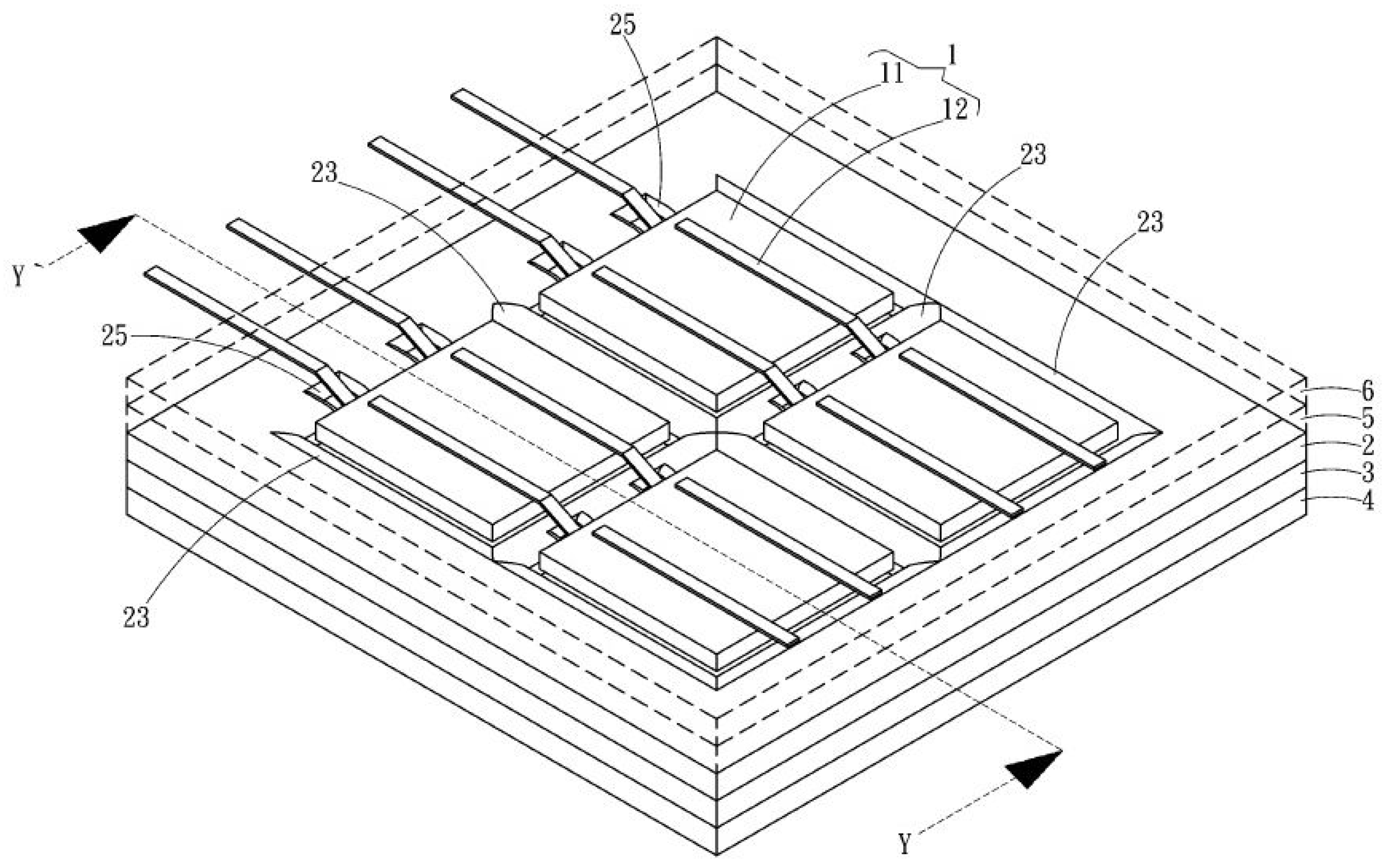

:1. Introduction

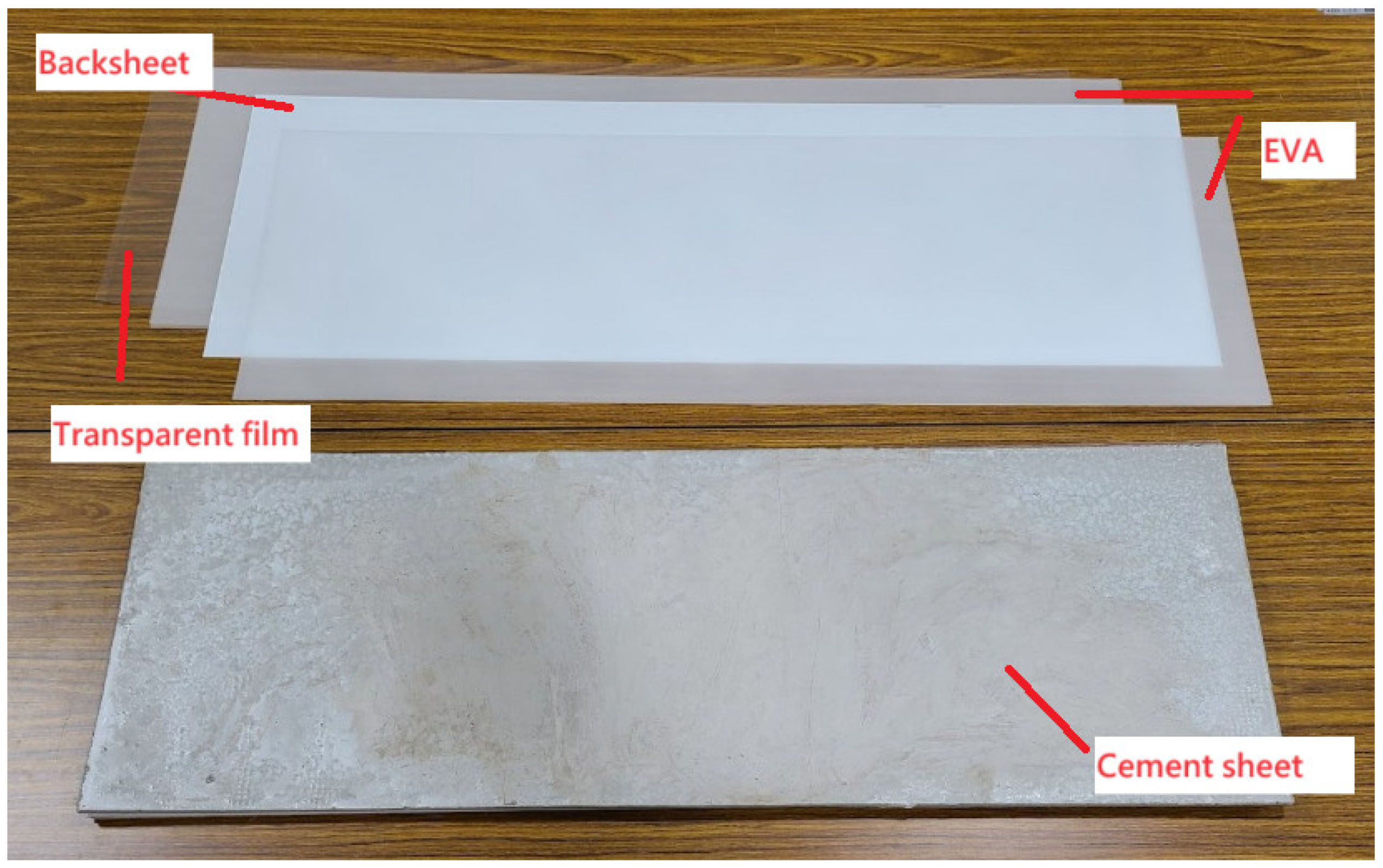

2. Literature Review

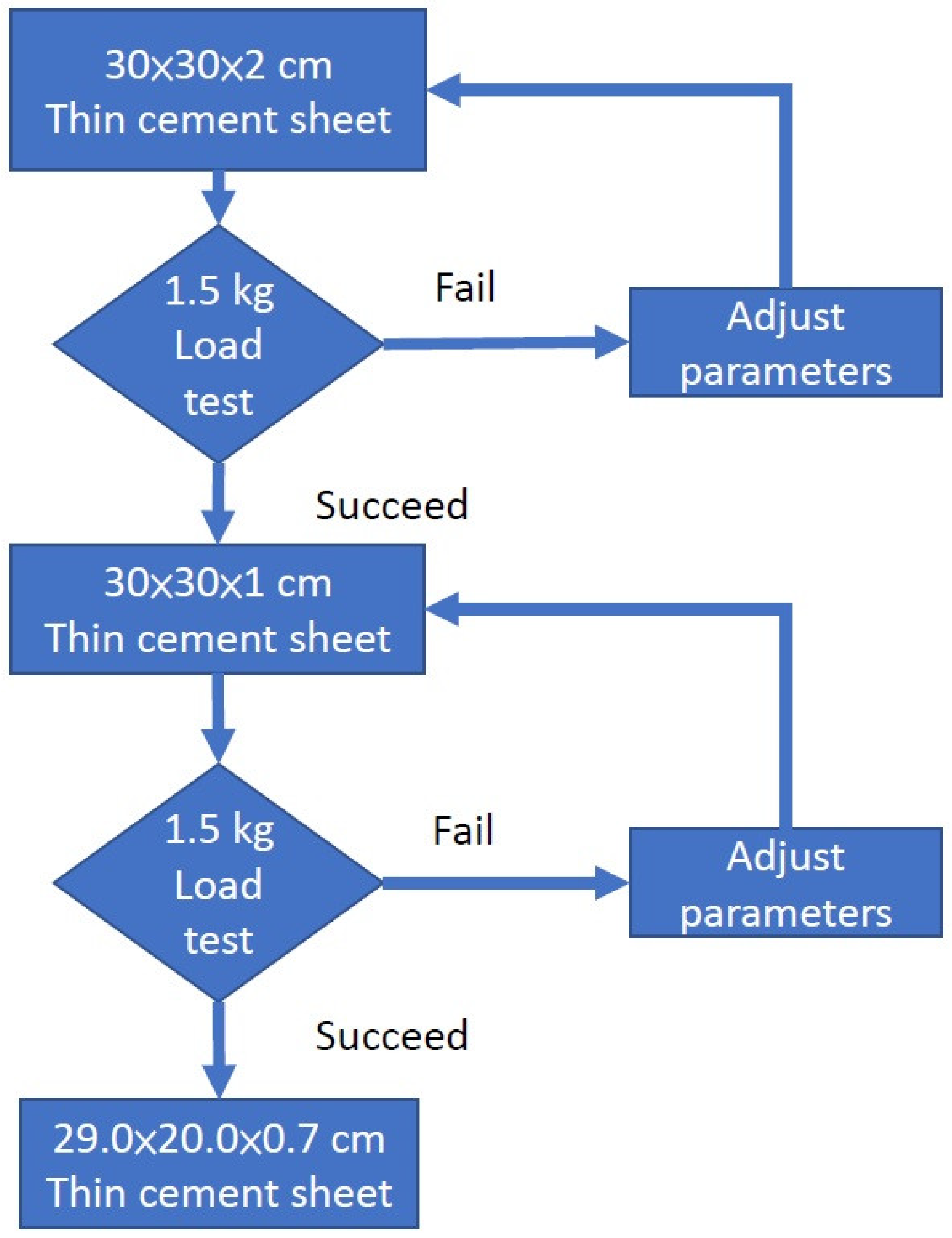

3. Materials, Methods, and Results

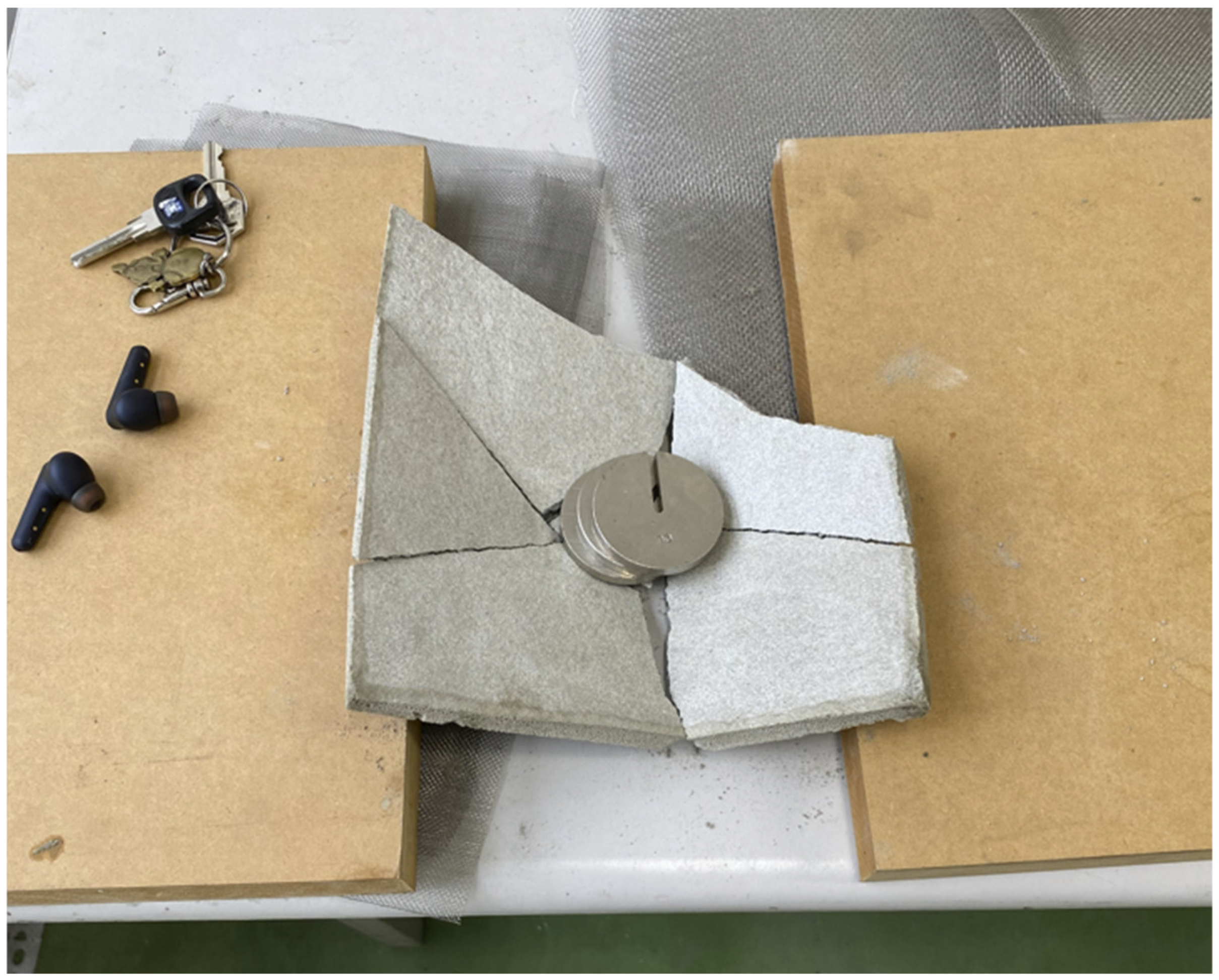

3.1. Initial Attempt

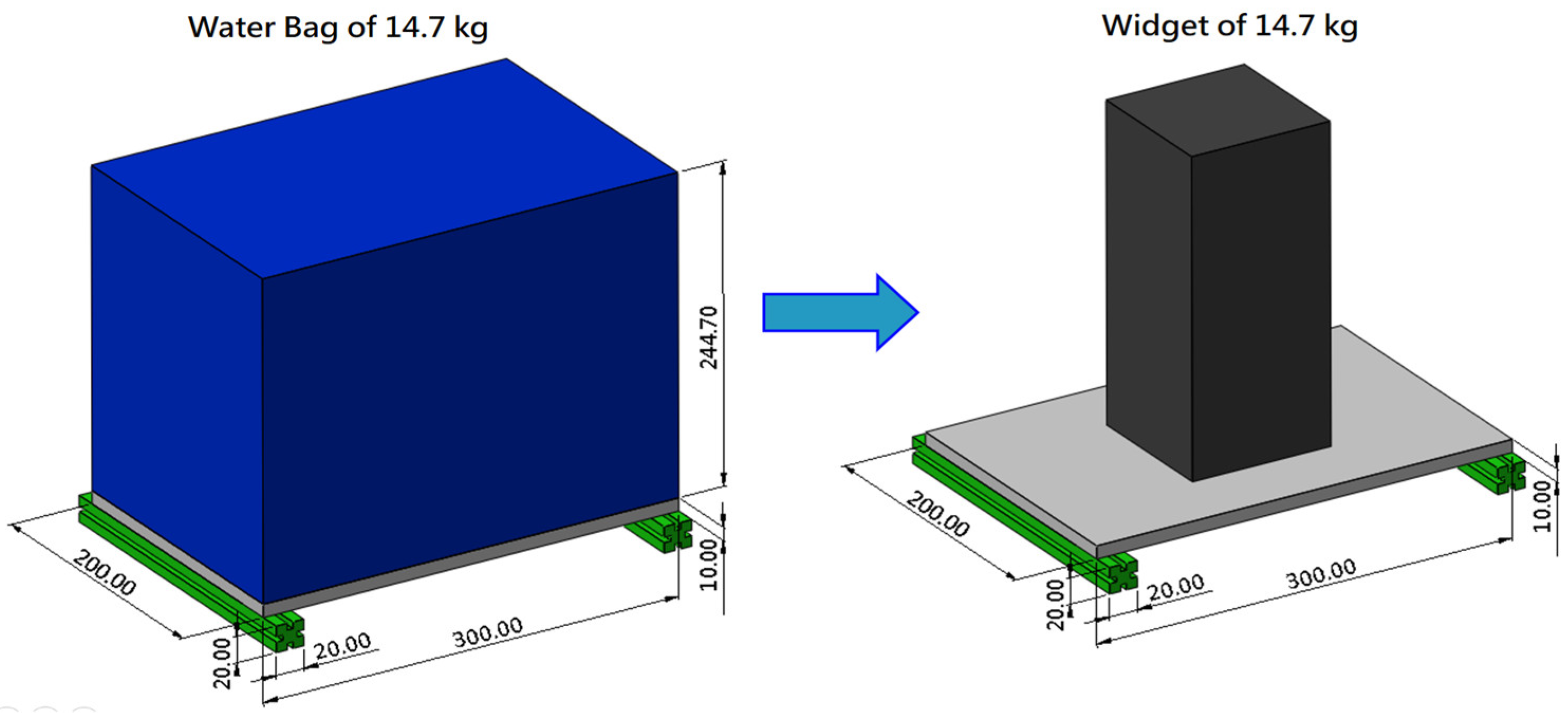

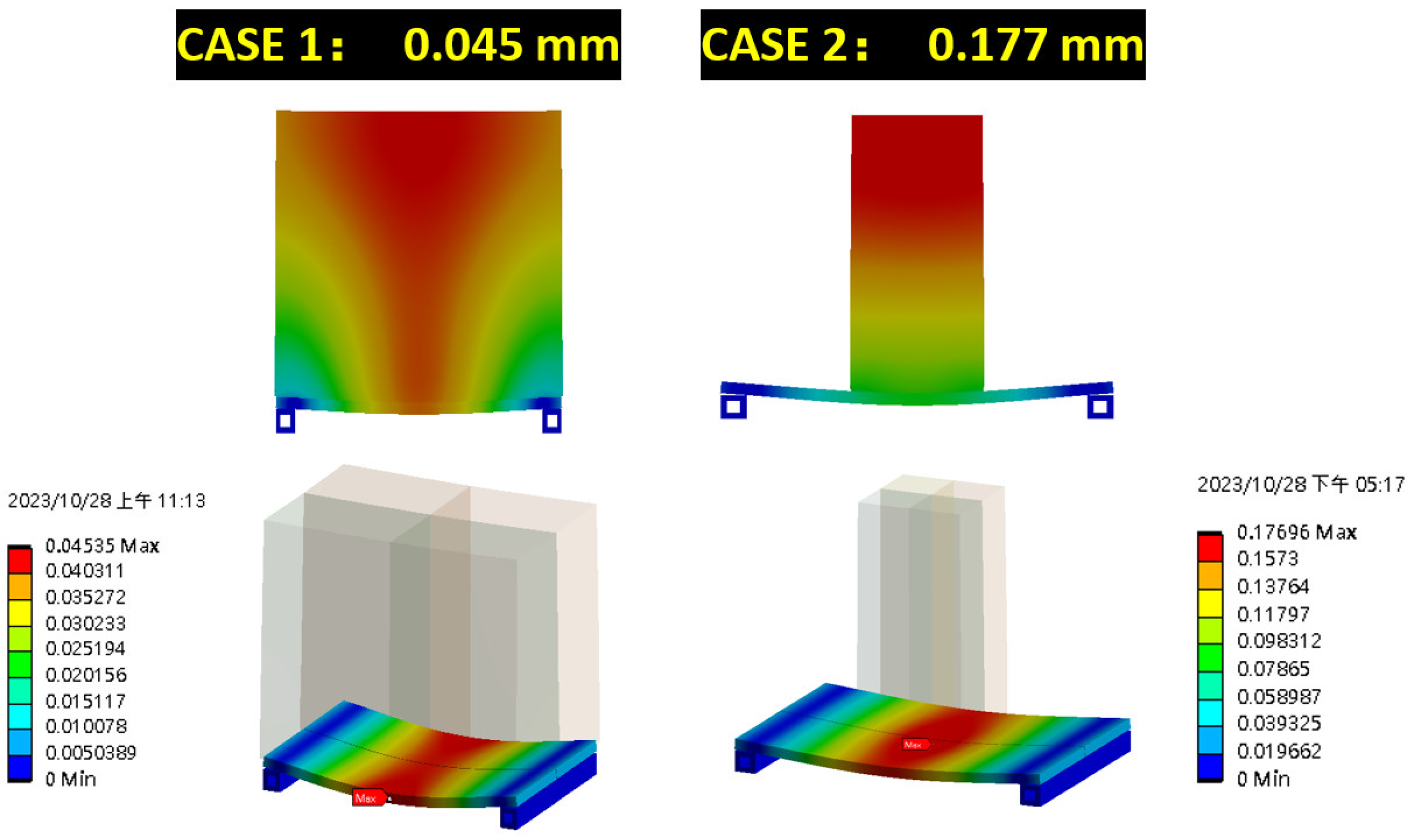

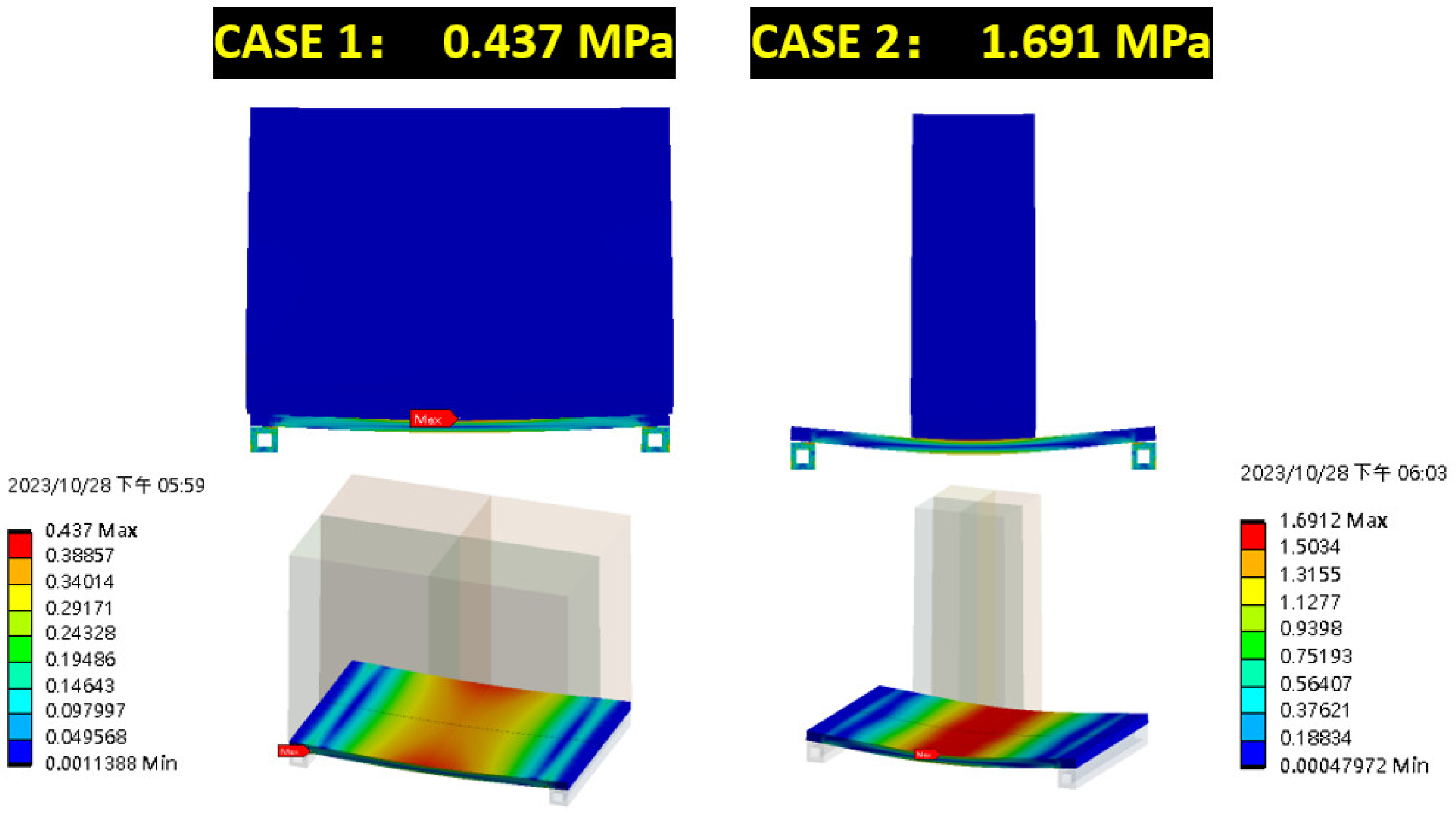

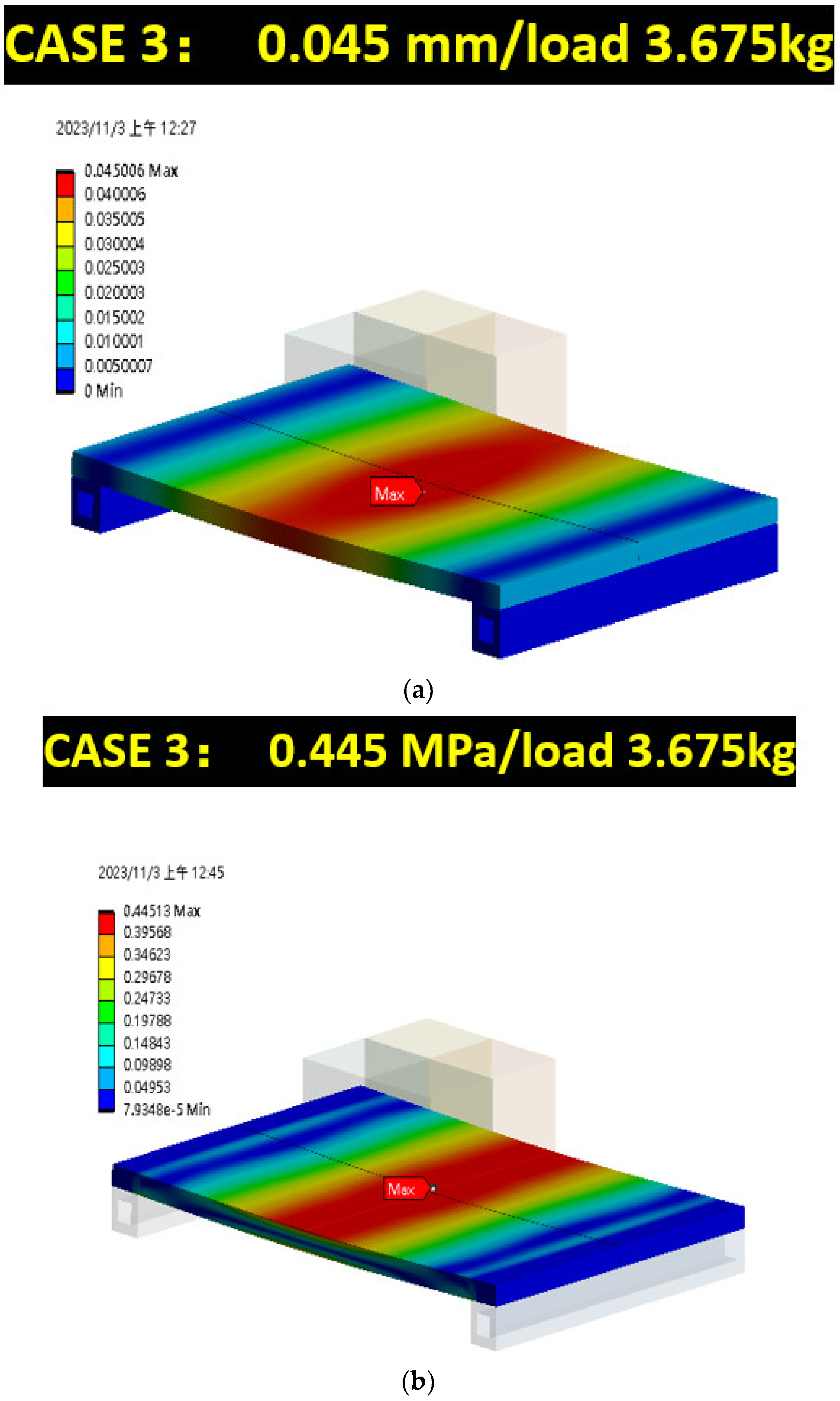

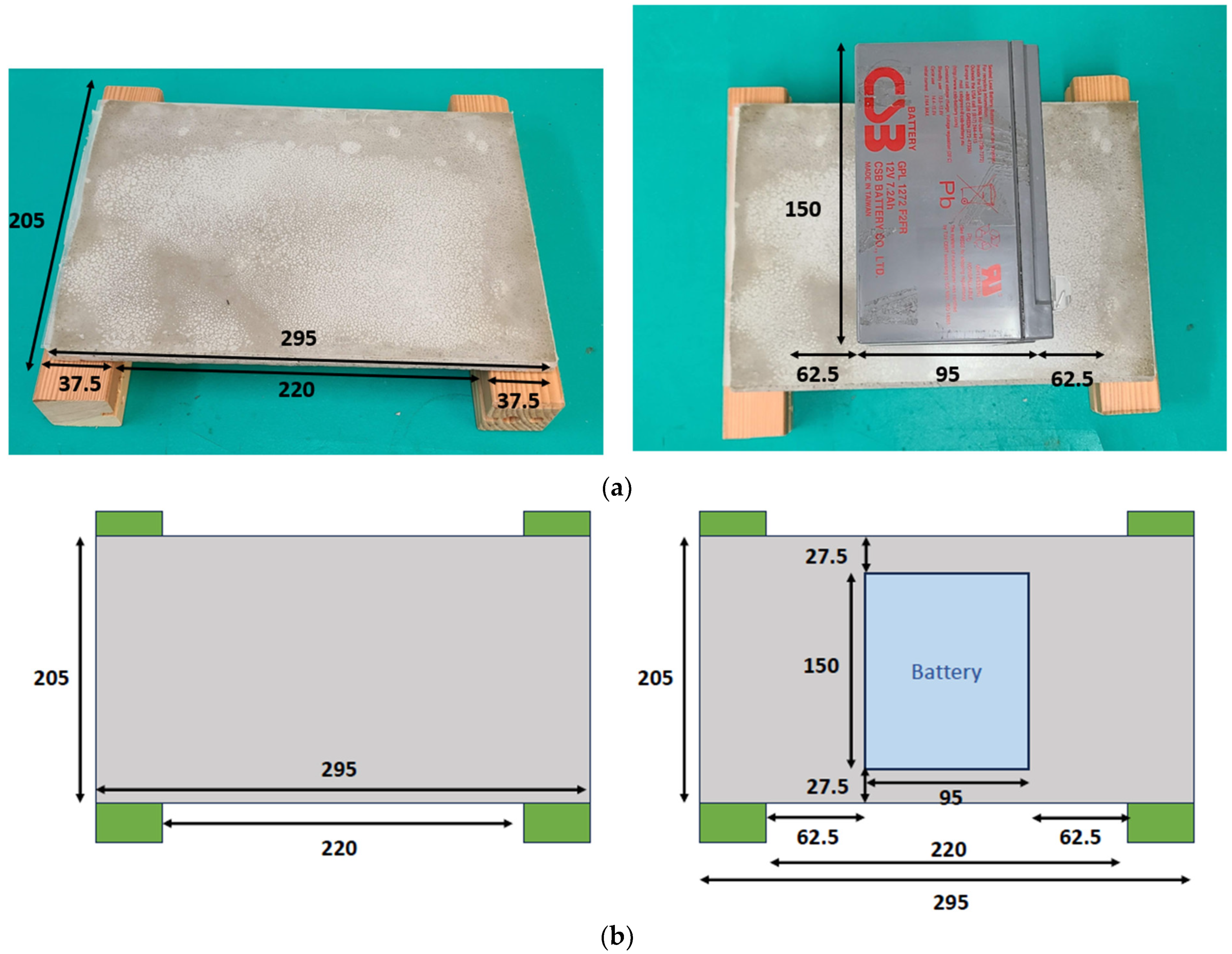

3.2. Molds for Cement Sheet

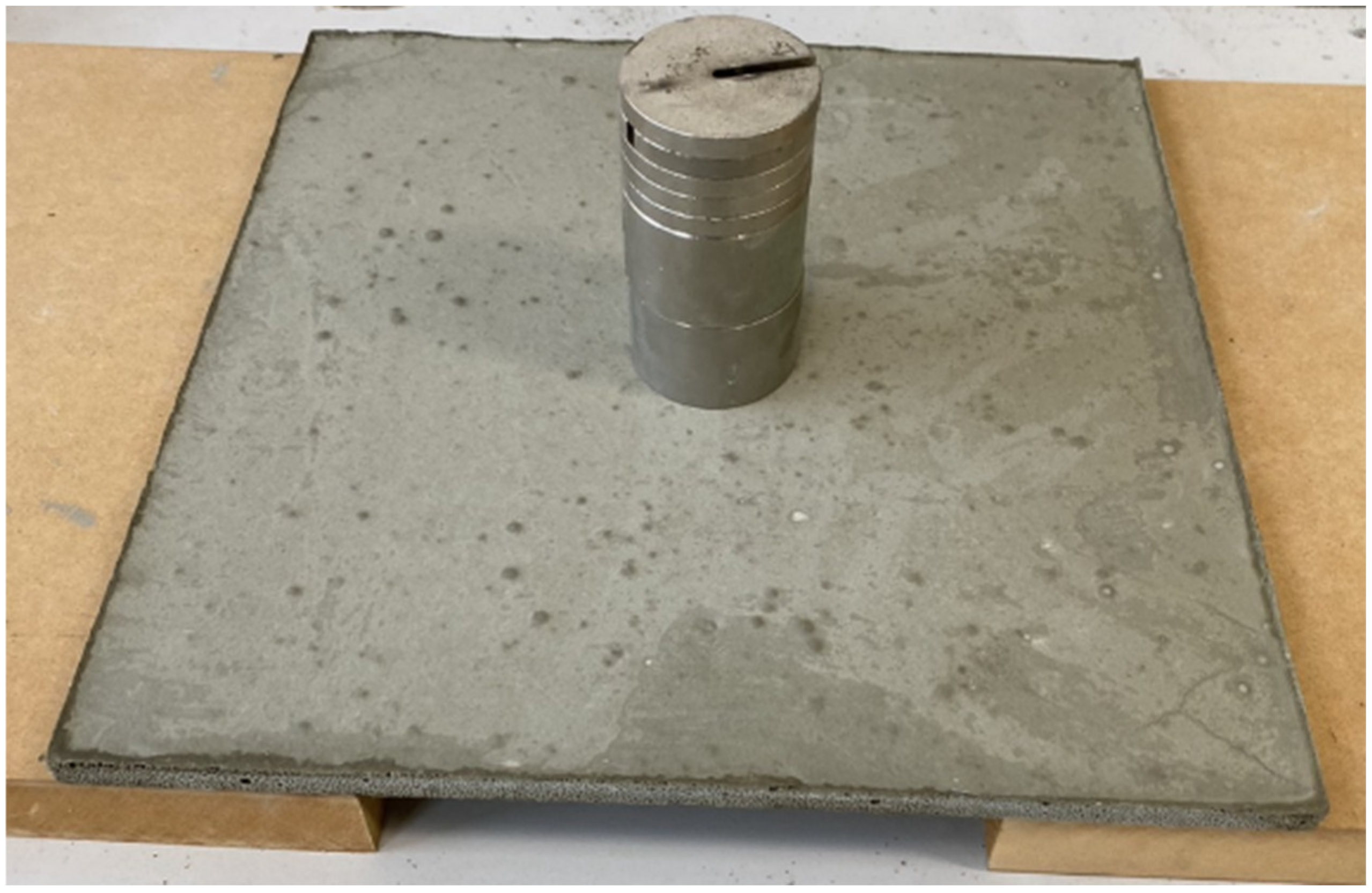

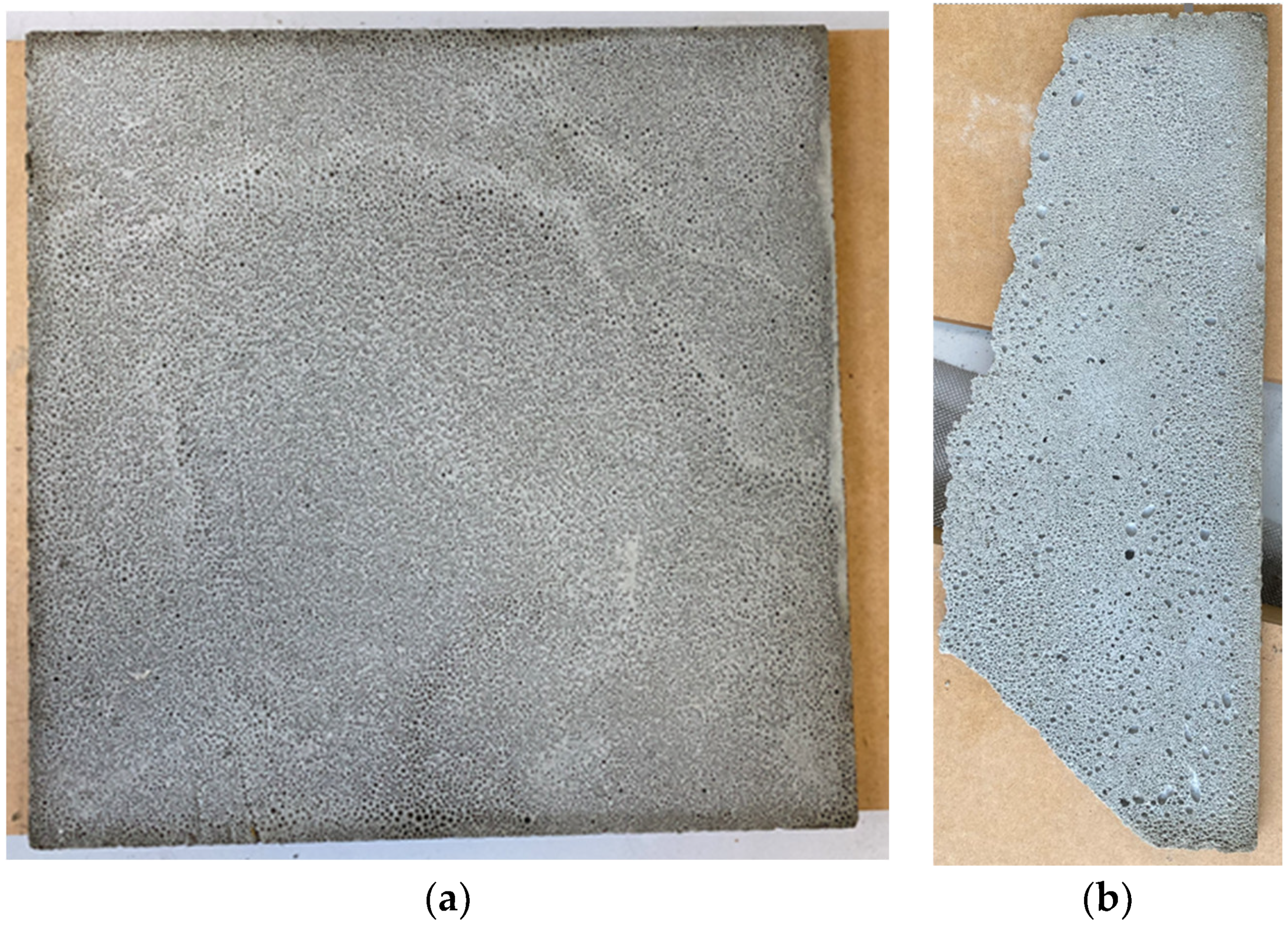

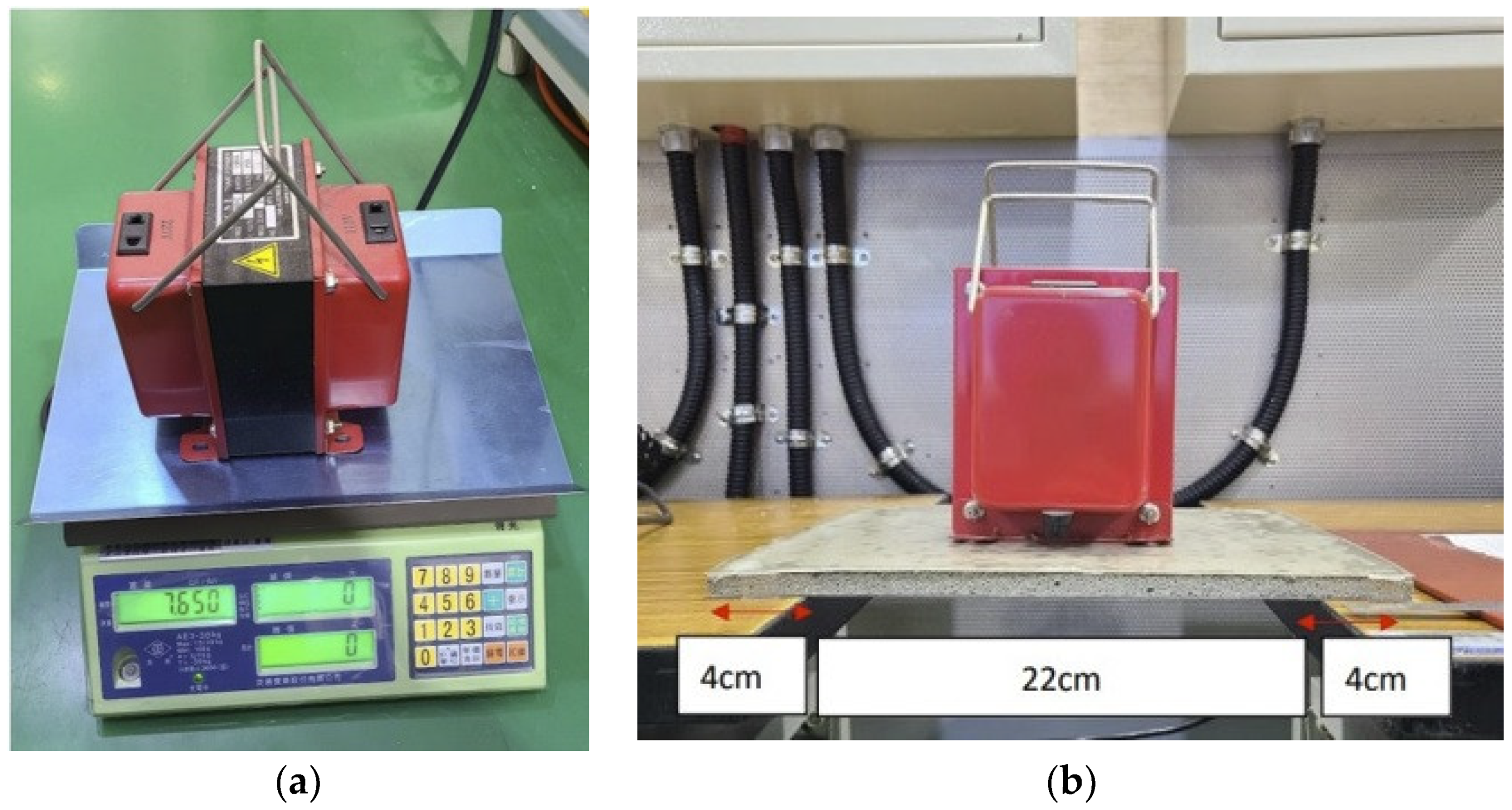

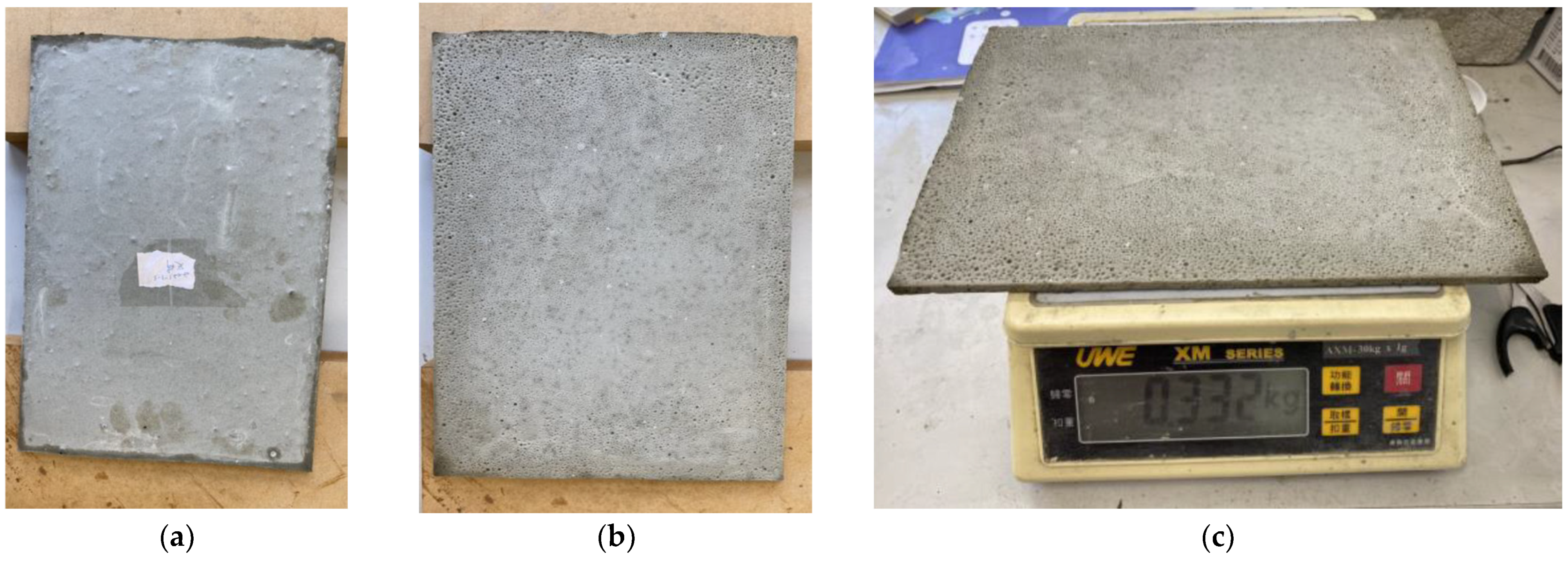

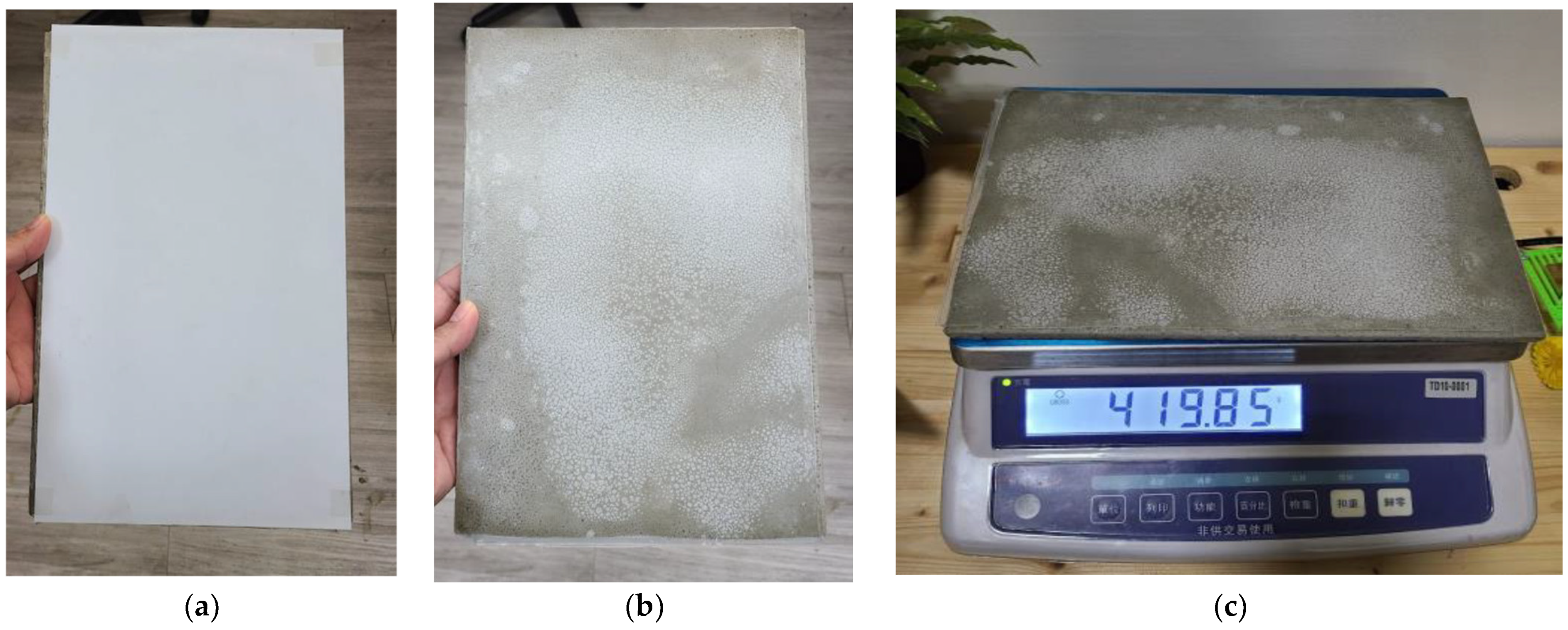

3.3. First Formula for Thin Cement Sheet with Seaweed Powder

3.4. Second Formula for Thin Cement Sheet with Seaweed Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Belançon, M.P.; Sandrini, M.; Tonholi, F.; Herculano, L.S.; Dias, G.S. Towards long term sustainability of c-Si solar panels: The environmental benefits of glass sheet recovery. Renew. Energy Focus 2022, 42, 206–210. [Google Scholar] [CrossRef]

- Lim, H.; Cho, S.H.; Moon, J.; Jun, D.Y.; Kim, S.H. Effects of reflectance of backsheets and spacing between cells on photovoltaic modules. Appl. Sci. 2022, 12, 443. [Google Scholar] [CrossRef]

- Hsiao, Y.C.; Chiang, Y.W.; Lin, C.H.; Huang, K.H. Solar Photovoltaic Panel Package Structure. Taiwan Patent TW I769951 B, 1 July 2022. [Google Scholar]

- Huang, T.H.; Chou, C.N. Solar Panel Module and Method for Fabricating the Same. Taiwan Patent TW I612684 B, 21 January 2018. [Google Scholar]

- Lin, T.H.; Deng, J.; Chen, Y.C. Using response surface for searching the nearly optimal parameters combination of the foam concrete muffler. Materials 2022, 15, 8128. [Google Scholar] [CrossRef] [PubMed]

- Weckend, S.; Wade, A.; Heath, G.A. End of Life Management: Solar Photovoltaic Panels (No. NREL/TP-6A20-73852); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2016.

- Krishnamoorthy, S. Lightweight Solar Panels with Solar Cell Structural Protection. U.S. Patent 2018/0309003 A1, 25 October 2018. [Google Scholar]

- Brouwer, J.; Philippe, R.; Wijnard, T. Solar Cell Laminate Comprising a Semiconductor Layer. U.S. Patent 2010/0243033 A1, 30 September 2010. [Google Scholar]

- Martins, A.C.; Chapuis, V.; Sculati-Meillaud, F.; Virtuani, A.; Ballif, C. Light and durable: Composite structures for building-integrated photovoltaic modules. Prog. Photovolt. Res. Appl. 2018, 26, 718–729. [Google Scholar] [CrossRef]

- Martins, A.C.; Virtuani, A.; Chapuis, V. Lightweight Solar Photovoltaic Module. WIPO Patent WO 2019/037837 A1, 28 February 2019. [Google Scholar]

- Wu, H.C.; Sun, P.; Teng, J. Development of fiber-reinforced cement-based composite sheets for structural retrofit. J. Mater. Civ. Eng. 2010, 22, 572–579. [Google Scholar] [CrossRef]

- Kawabe, S.; Miwa, M.; Harada, S. Manufacture of Woven Fabric-Reinforced Large-Scale Cement Thin Sheet. Japanese Patent JP S63-315206, 22 December 1988. [Google Scholar]

- Chen, Z.; Li, J.; Yang, E.H. Development of ultra-lightweight and high strength engineered cementitious composites. J. Compos. Sci. 2021, 5, 113. [Google Scholar] [CrossRef]

- BS EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Management Centre: Brussels, Belgium, 2009.

- IEC 61215-2:2016; Terrestrial Photovoltaic (PV) Modules–Design Qualification and Type Approval–Part 2: Test Procedures. IEC: Geneva, Switzerland, 2016.

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Ballif, C. Robust glass-free lightweight photovoltaic modules with improved resistance to mechanical loads and impact. IEEE J. Photovolt. 2018, 9, 245–251. [Google Scholar] [CrossRef]

- Gabor, A.M.; Janoch, R.; Anselmo, A.; Lincoln, J.L.; Seigneur, H.; Honeker, C. Mechanical load testing of solar panels—Beyond certification testing. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; IEEE: Piscataway, NJ, USA; pp. 3574–3579. [Google Scholar]

- IEC-DTS-62782; Photovoltaic (PV) Modules—Cyclic (Dynamic) Mechanical Load Testing. International Electrotechnical Commission: Genève, Switzerland, 2016.

- Ansys Academic Product. Available online: https://www.ansys.com/academic (accessed on 10 September 2023).

- Mydin, M.A.O.; Wang, Y.C. Structural performance of lightweight steel-foamed concrete-steel composite walling system under compression. Thin-Walled Struct. 2011, 49, 66–76. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Reilly, A.; West, R.; Kinnane, O. Thermal investigation of thin precast concrete sandwich panels. J. Build. Eng. 2020, 27, 100937. [Google Scholar] [CrossRef]

- Kannan Rajkumar, P.R.; Mathangi, D.P.; Sudha, C.; Neelamegam, M. Experimental investigation of reactive powder concrete exposed to elevated temperatures. Constr. Build. Mater. 2020, 261, 119593. [Google Scholar]

- Baghel, R.S.; Reddy, C.R.K.; Singh, R.P. Seaweed-based cellulose: Applications, and future perspectives. Carbohydr. Polym. 2021, 267, 118241. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.R.; Ozlutas, K.; Zheng, L. High-volume, ultra-low-density fly ash foamed concrete. Mag. Concr. Res. 2017, 69, 1146–1156. [Google Scholar] [CrossRef]

- Chahbi, M.; Mortadi, A.; El Moznine, R.; Monkade, M.; Zaim, S.; Nmila, R.; Rchid, H. A new approach to investigate the hydration process and the effect of algae powder on the strength properties of cement paste. Aust. J. Mech. Eng. 2022, 2066855. [Google Scholar] [CrossRef]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C78-09; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2010.

| Production Procedure | Material | Weight (g) | Mix Time (min) |

|---|---|---|---|

| 1. Seaweed glue | Seaweed powder | 6 | 5 |

| Water 1 | 200 | ||

| 2. Cement slurry | Portland cement | 1080 | 5 |

| Calcium sulfoaluminate (CSA) | 120 | ||

| Seaweed glue (step 1) | 206 | ||

| Water 2 | 600 | ||

| 3. Foam | Foaming agent | 13 | 7 |

| Water 3 | 225 | ||

| 4. Calcium chloride anhydrous solution | Calcium chloride anhydrous | 30 | 6 |

| Water 4 | 26 | ||

| 5. Foam cement | Cement slurry (step 2) | 2006 | 15 |

| Foam (step 3) | 238 | ||

| Calcium chloride anhydrous solution (step 4) | 56 |

| Production Procedure | Material | Weight (g) | Mix Time (min) |

|---|---|---|---|

| 1. Seaweed glue | Seaweed powder | 6 | 5 |

| Water 1 | 200 | ||

| 2. Cement slurry | Portland cement | 1080 | 5 |

| Calcium sulfoaluminate (CSA) | 120 | ||

| Seaweed glue | 206 | ||

| Water 2 | 360 | ||

| 3. Foam | Foaming agent | 13 | 7 |

| Water 3 | 225 | ||

| 4. Calcium chloride anhydrous solution | Calcium chloride anhydrous | 30 | 6 |

| Water 4 | 26 | ||

| 5. Foam cement | Cement slurry (step 2) | 1766 | 15 |

| Foam (step 3) | 238 | ||

| Calcium chloride anhydrous solution (step 4) | 56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.-J.; Lin, T.-H.; Wang, J.-S.; Hsiao, Y.-C.; Tu, G.-Y.; Huang, Q.-H. A Method of Producing Low-Density, High-Strength Thin Cement Sheets: Pilot Run for a Glass-Free Solar Panel. Materials 2023, 16, 7500. https://doi.org/10.3390/ma16237500

Deng J-J, Lin T-H, Wang J-S, Hsiao Y-C, Tu G-Y, Huang Q-H. A Method of Producing Low-Density, High-Strength Thin Cement Sheets: Pilot Run for a Glass-Free Solar Panel. Materials. 2023; 16(23):7500. https://doi.org/10.3390/ma16237500

Chicago/Turabian StyleDeng, Jyh-Jeng, Teng-Hsuan Lin, Jean-Shyan Wang, Yao-Chung Hsiao, Grung-Yi Tu, and Qi-Hung Huang. 2023. "A Method of Producing Low-Density, High-Strength Thin Cement Sheets: Pilot Run for a Glass-Free Solar Panel" Materials 16, no. 23: 7500. https://doi.org/10.3390/ma16237500